Method for solving grinding track of front tool face of arc edge of arc head end mill

A circular arc edge and rake face technology, which is applied in the field of numerical control grinding trajectory solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

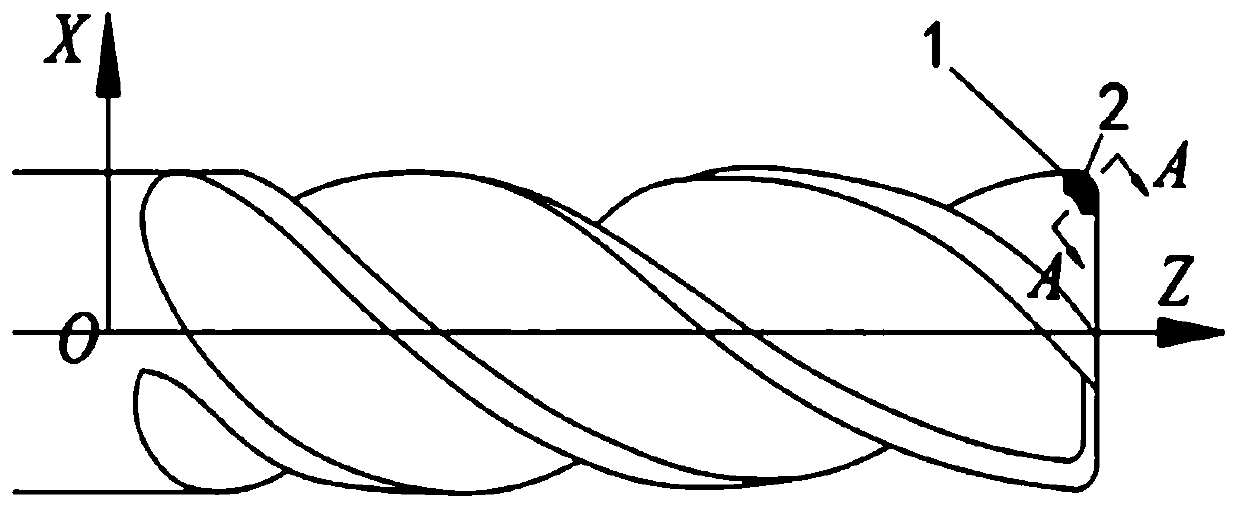

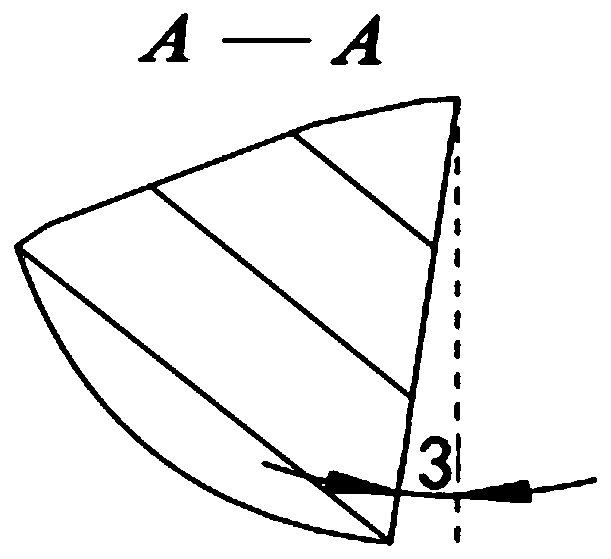

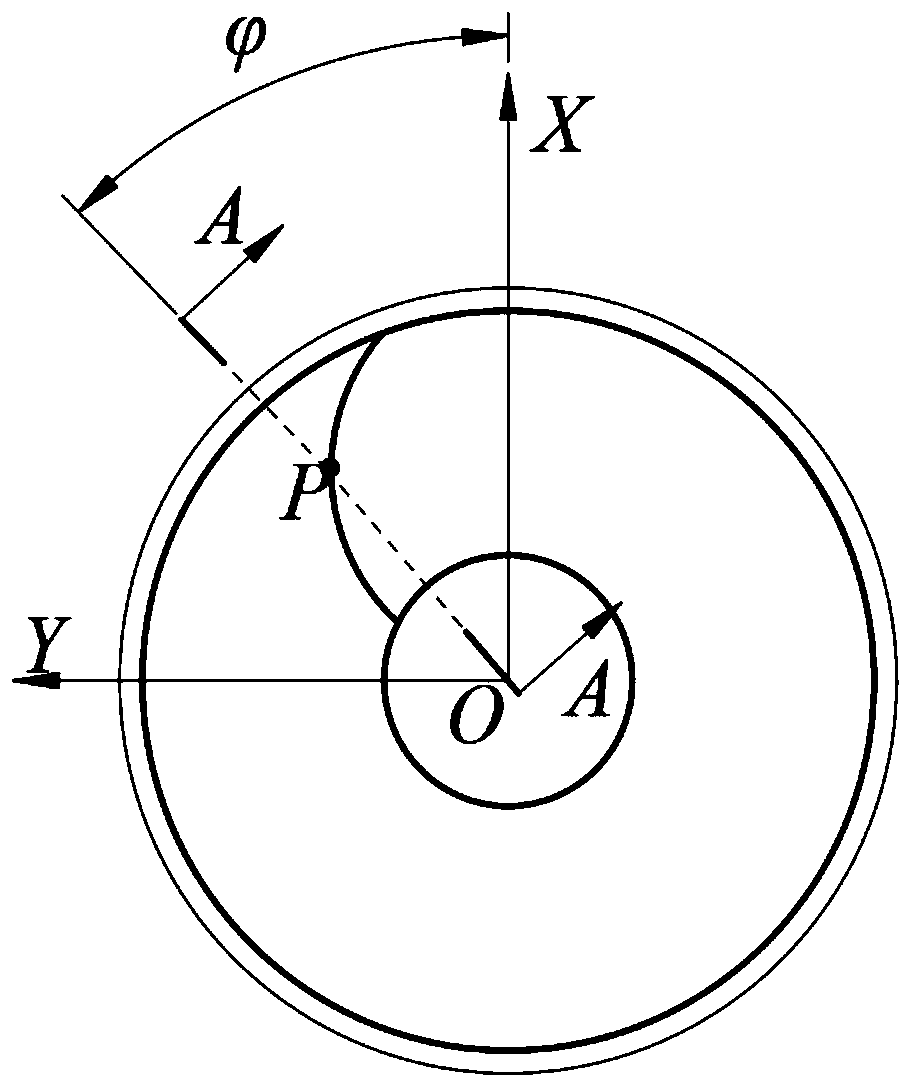

[0092] The technical solution is as follows:

[0093] 1. Definition of technological features of rake face of arc edge

[0094] In the grinding process of the rake face of the arc edge, a conical grinding wheel is used for grinding. Establish Figure 1a The workpiece coordinate system shown is O-XYZ, and the Z axis coincides with the tool axis. In the case of determining the cutting edge curve, the rake face is constrained by width and rake angle. In this algorithm, given the edge line formula of any arc edge curve, the corresponding grinding trajectory posture of the grinding wheel can be calculated, so the edge line of the arc edge is regarded as a known curve. During the grinding process, there is a spatial relationship between the grinding wheel and the cutter body, and it is difficult to directly determine the attitude of the grinding wheel. This algorithm projects the grinding process to the instantaneous rake face of the arc edge for calculation, and constrains the gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com