Boiler thermodynamic system for conducting automatic control based on steam fuel consumption

A thermal system and fuel consumption technology, applied in the field of boilers, can solve the problems of no monitoring and application, so as to achieve the effect of maintaining high efficiency of boilers and avoiding energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0040] In this article, if there is no special explanation, when involving formulas, " / " means division, and "×" and "*" mean multiplication.

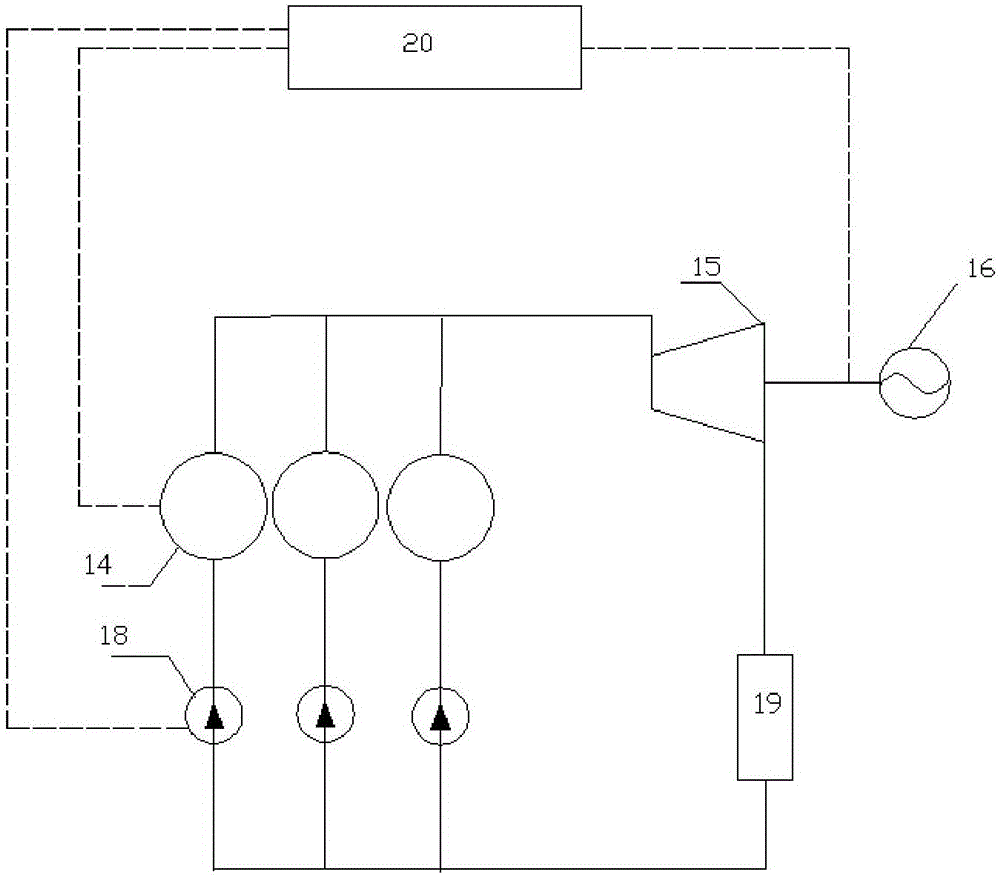

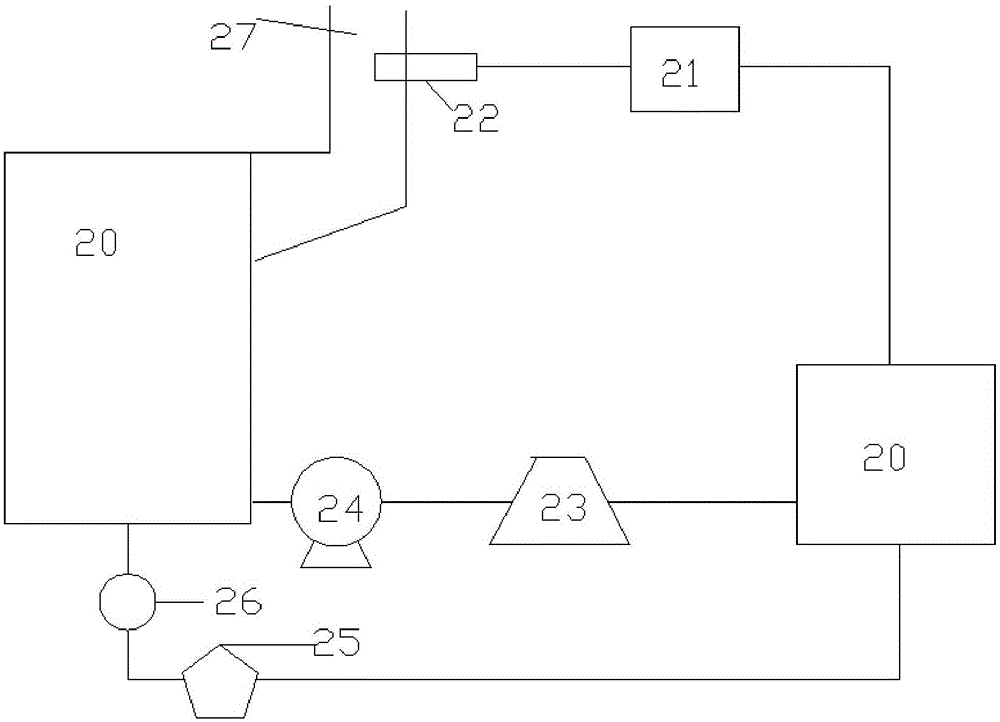

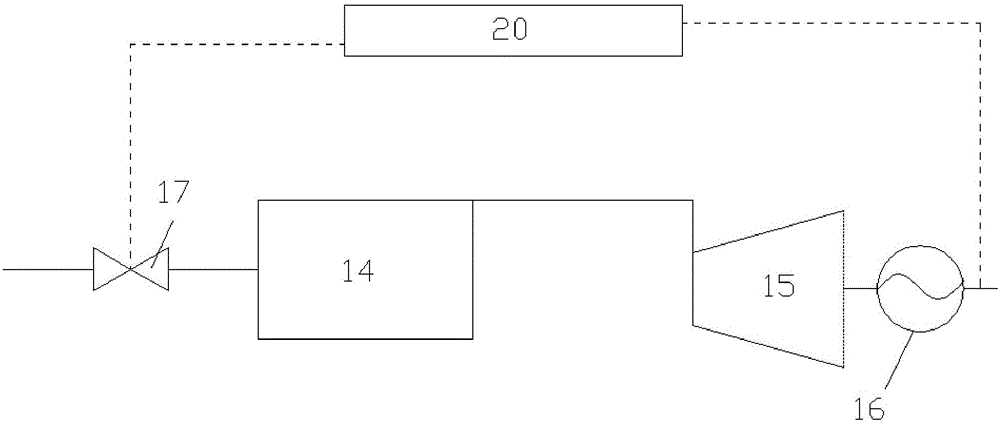

[0041] A boiler thermal system. The boiler thermal system includes multiple boilers 14 for generating steam. The multiple boilers 14 are respectively connected to a central monitoring and diagnosis system 20 for monitoring the operation of the boilers.

[0042] By integrating the operation monitoring automation system of all boilers into a centralized monitoring automation monitoring platform, that is, the central monitoring and diagnosis system 20, this platform can realize automatic online monitoring of various parameters of all boilers, and solve the automation island existing in the existing boiler operation question.

[0043] Further, such as figure 1 As shown, the boiler thermal system incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com