Welding device used for pipeline and using method of welding device

A technology for welding devices and pipes, which is applied to other manufacturing equipment/tools, manufacturing tools, etc., and can solve problems such as inconvenient portability and large limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

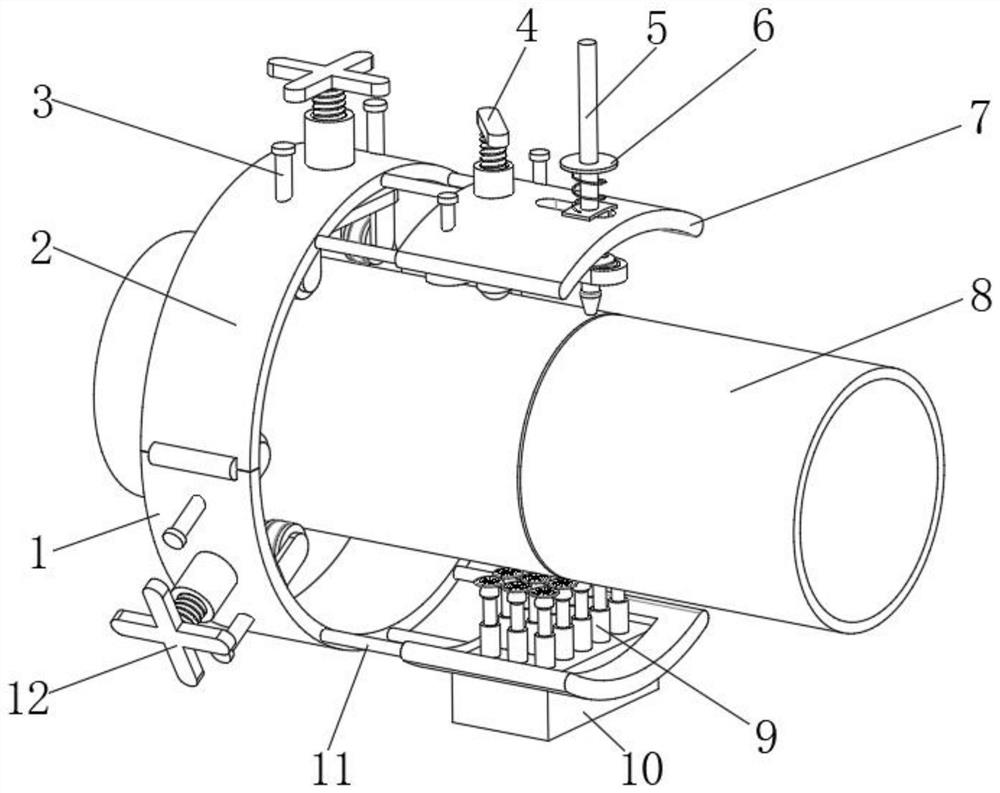

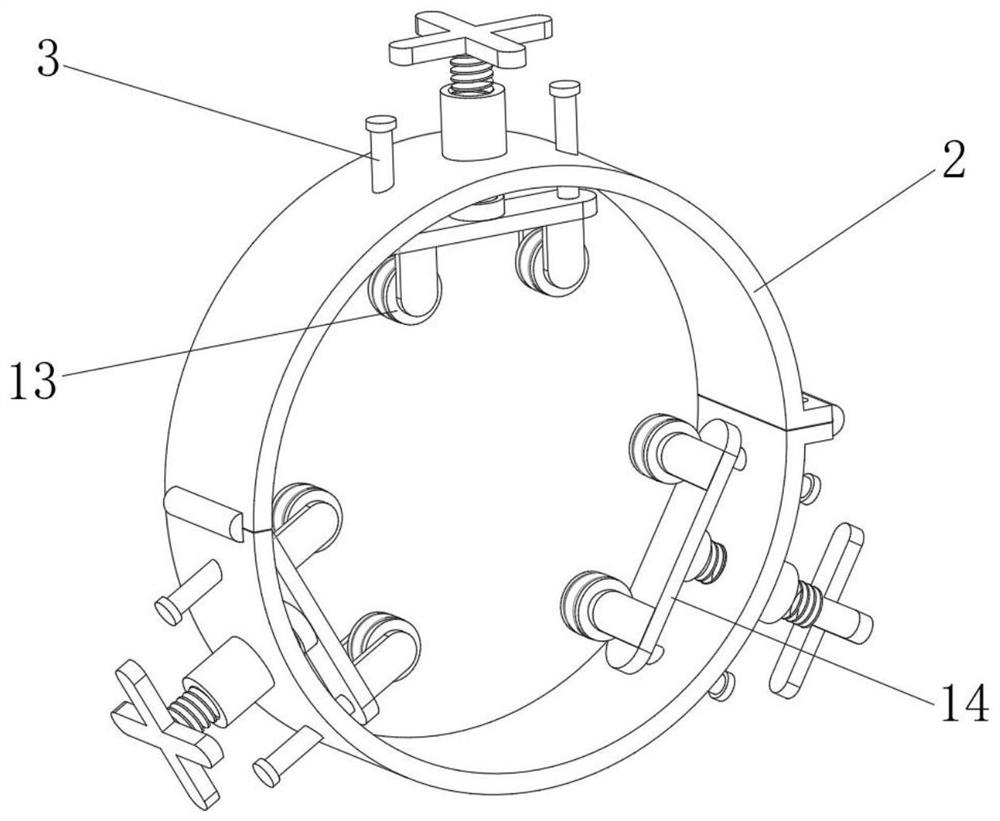

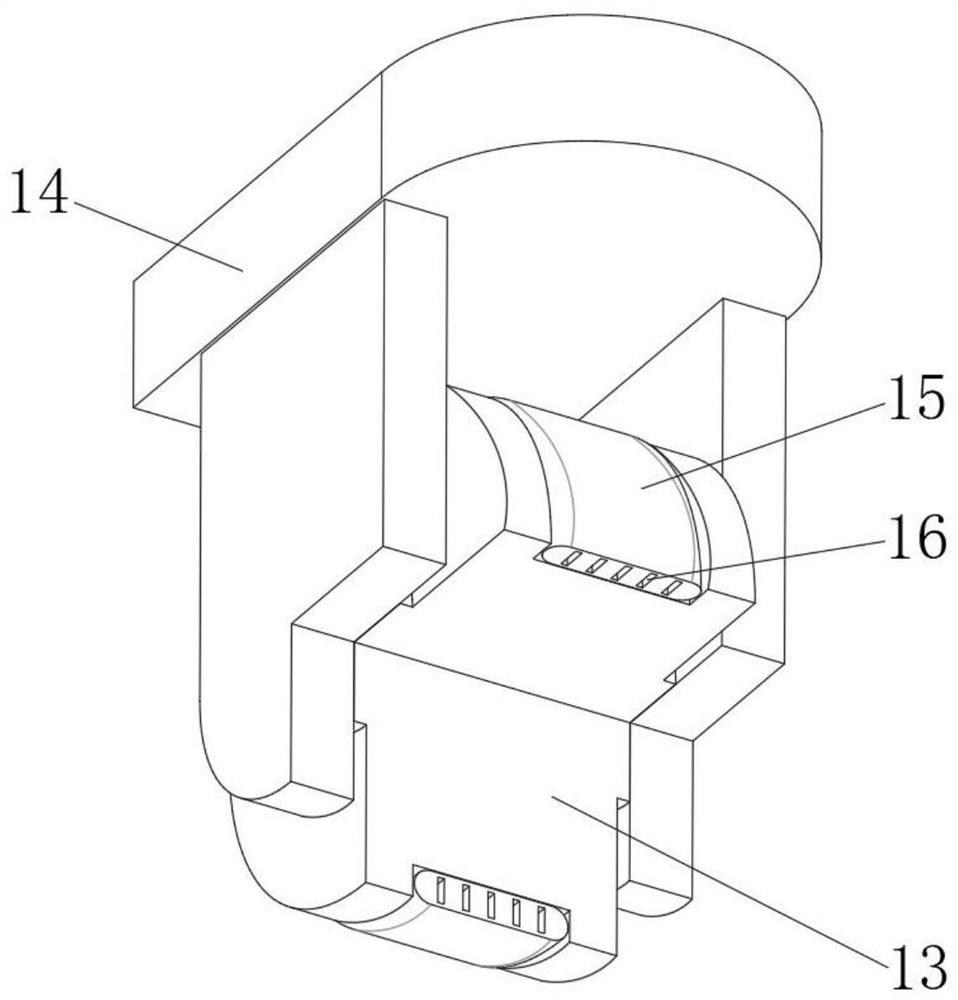

[0039] A welding device for pipes such as Figure 1-5As shown, it includes a lower fixing base 1 and an upper fixing base 2 installed on the pipeline 8, the lower fixing base 1 is fixed on the outer walls of the upper fixing base 2 through hinges and buckles, the lower fixing base 1 and the upper fixing base The seat 2 is a matching semi-circular structure; the inner wall of the lower fixed seat 1 and the upper fixed seat 2 is threadedly connected with more than three fixed knobs 12 equidistantly distributed, and one end of the fixed knob 12 is rotatably connected with a mounting Frame 14, described mounting frame 14 near the side outer wall of pipeline 8 is equipped with roller 13 by axle, and roller 13 peripheral walls are tangent to the peripheral wall of pipeline 8; Two first guide columns 3, the first guide column 3 is slidingly connected to the inner wall of the lower fixing base 1 or the upper fixing base 2; Seat 7 and lower mounting base 31, described upper mounting b...

Embodiment 2

[0048] A method for using a welding device for pipelines, comprising the steps of:

[0049] S1: Install the lower fixing seat 1 and the upper fixing seat 2 on the pipe 8 through buckles;

[0050] S2: adjust the position of the mounting bracket 14 through the fixing knob 12, so that the rollers 13 are attached to the outer wall of the pipe 8;

[0051] S3: Install the grinding seat 10 on the lower mounting seat 31, and adjust the position of the lower mounting seat 31, so that the grinding head 29 fits with the outer wall of the pipeline 8;

[0052] S4: Rotate the lower fixing seat 1 and the upper fixing seat 2, and use the grinding head 29 to grind the welded part of the pipe 8;

[0053] S5: After finishing the grinding, remove the grinding mechanism, and control the welding torch assembly 5 to work;

[0054] S6: Continue to rotate the lower fixing seat 1 and the upper fixing seat 2, and control the welding torch assembly 5 to move back and forth in the waist-shaped mouth 21,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com