Patents

Literature

598results about How to "Reliable welding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

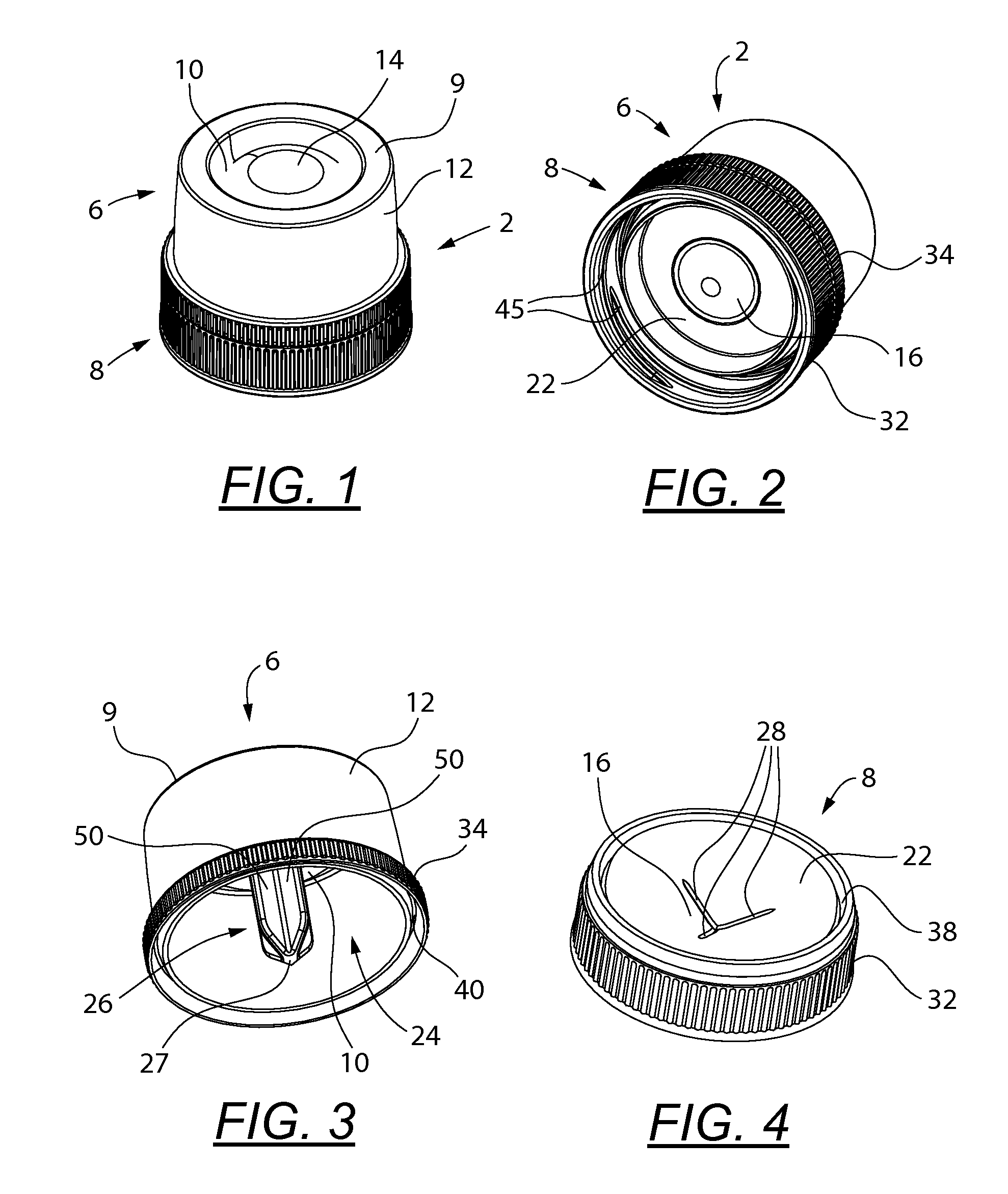

Dispensing capsule

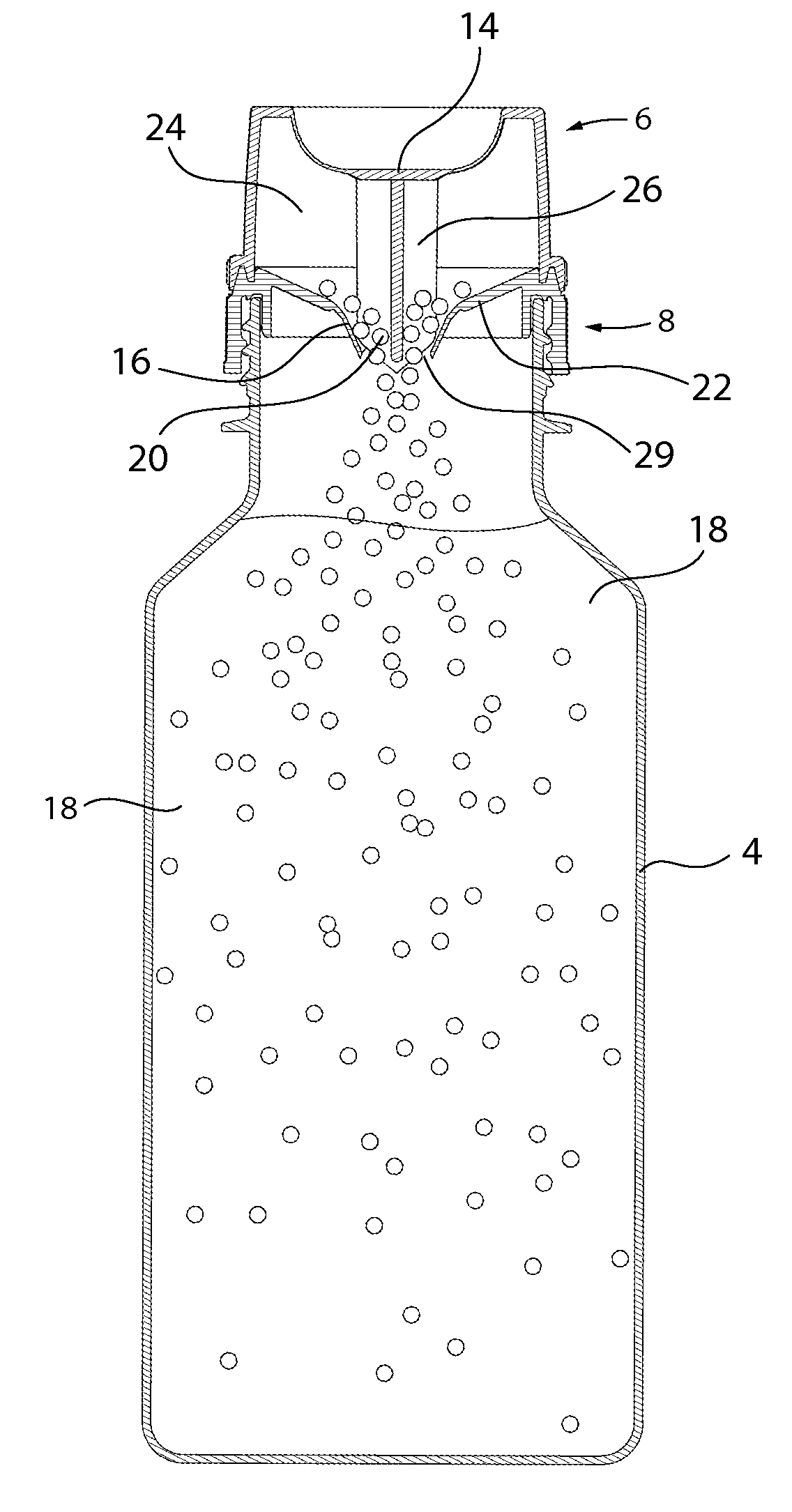

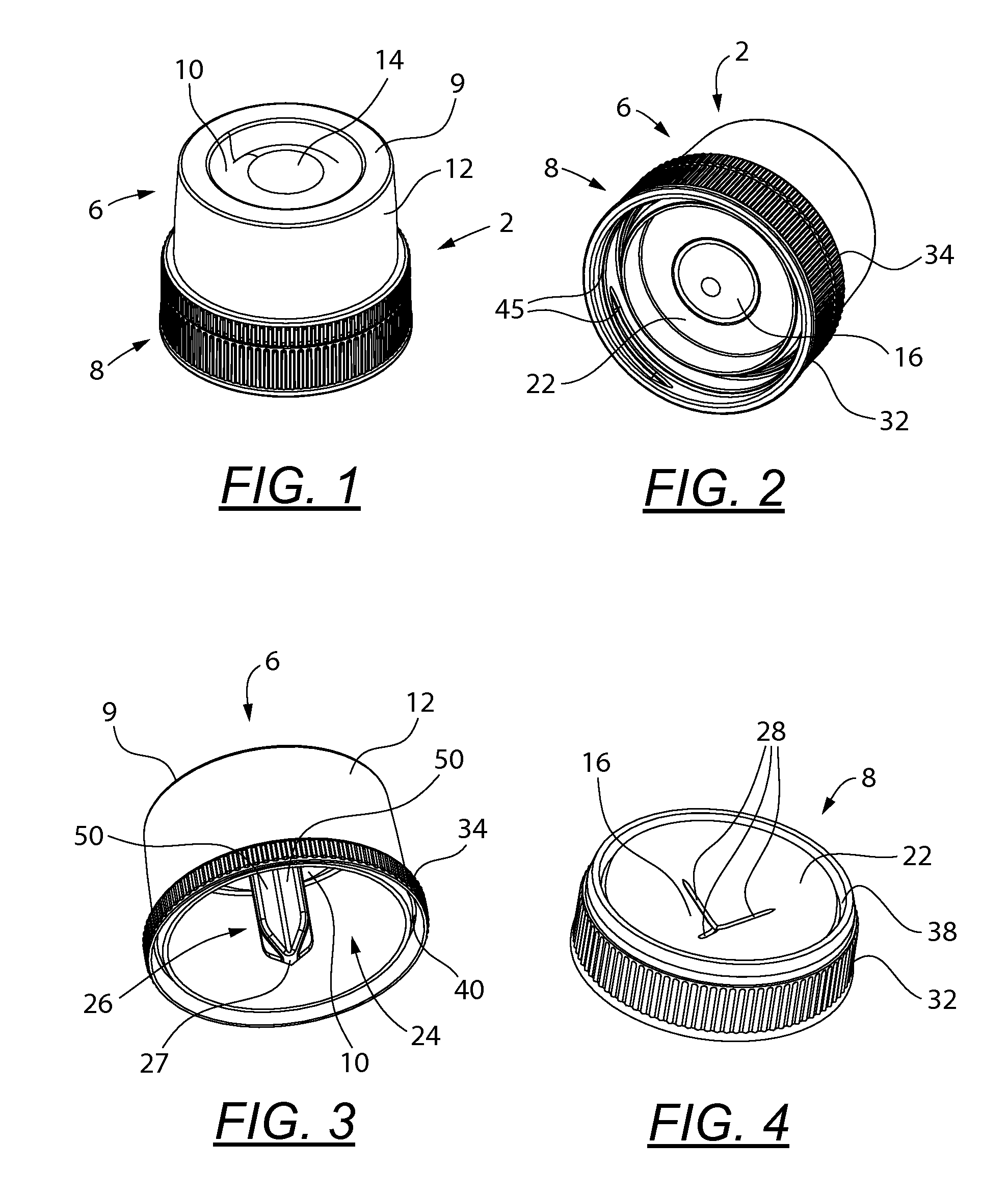

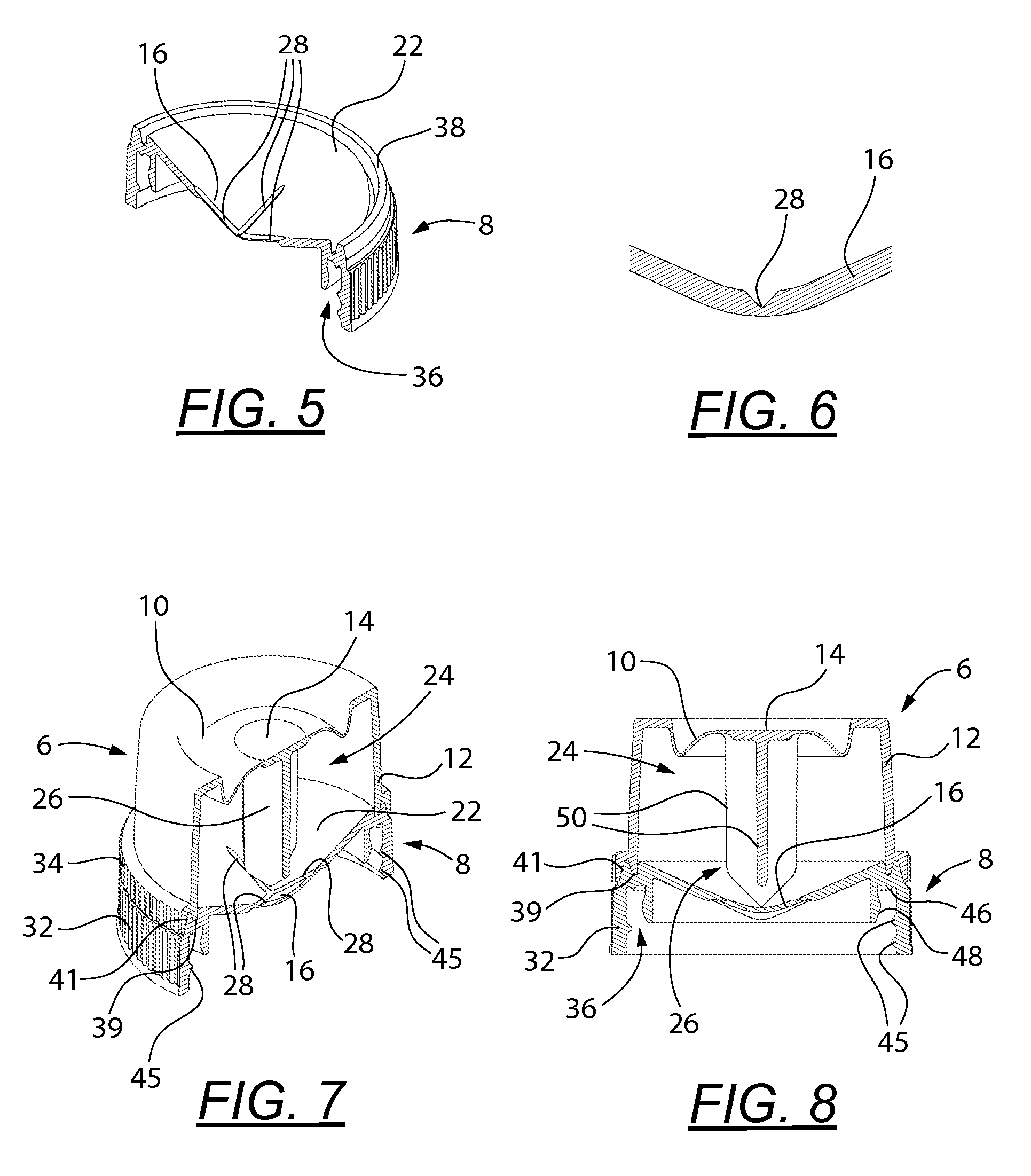

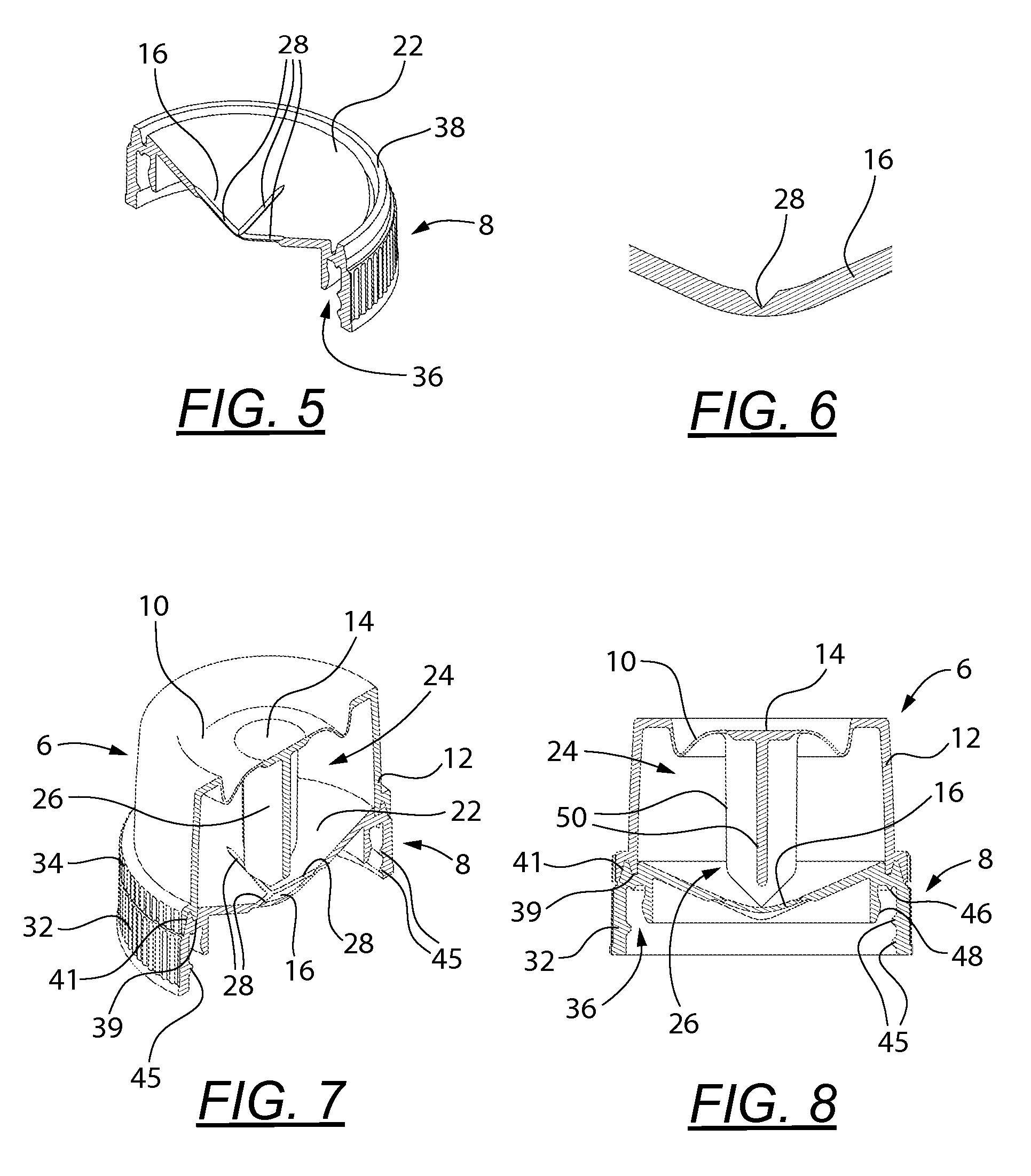

ActiveUS20110174642A1Easy to moveIncrease the differential pressureCapsClosure using stoppersBottleSharp point

A dispensing capsule has a diaphragm button, stake and frangible membrane for a system for selectively dispersing the contents of a cup into an attached bottle. A frangible membraned cup has a diaphragm button operably attached to a stake with the stake's sharp point at one end and the diaphragm button on the opposing end. A cavity is disposed in the cup for consumable product defined by side walls and a base plate. Preloaded ingredients contained within the hermetically sealed cup are discharged from the dispensing capsule into a bottle by simply depressing a button disposed on the diaphragm of the cup, thereby actuating the stake to thrust forward and apply concentrated pressure abaxially to the frangible membrane. This concentrated pressure pierces substantially the center of the frangible membrane, causing it to rupture and progressively opening it. The diaphragm button locks in this downward position, holding the stake into the opened frangible membrane to maintain the opening, permitting the contents to flow through the frangible membrane and exit the cavity of the cup.

Owner:GENESEE REGIONAL BANK

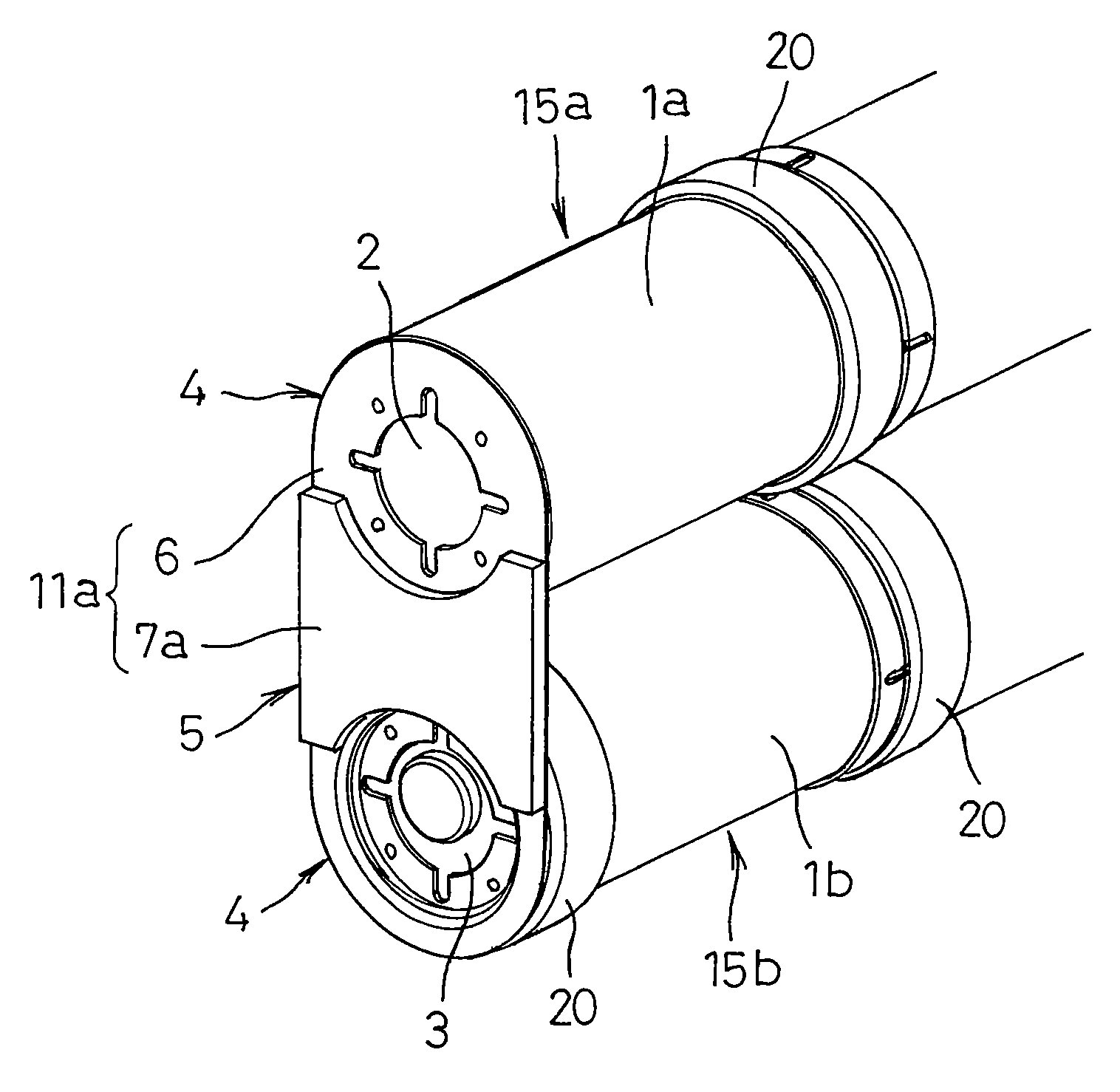

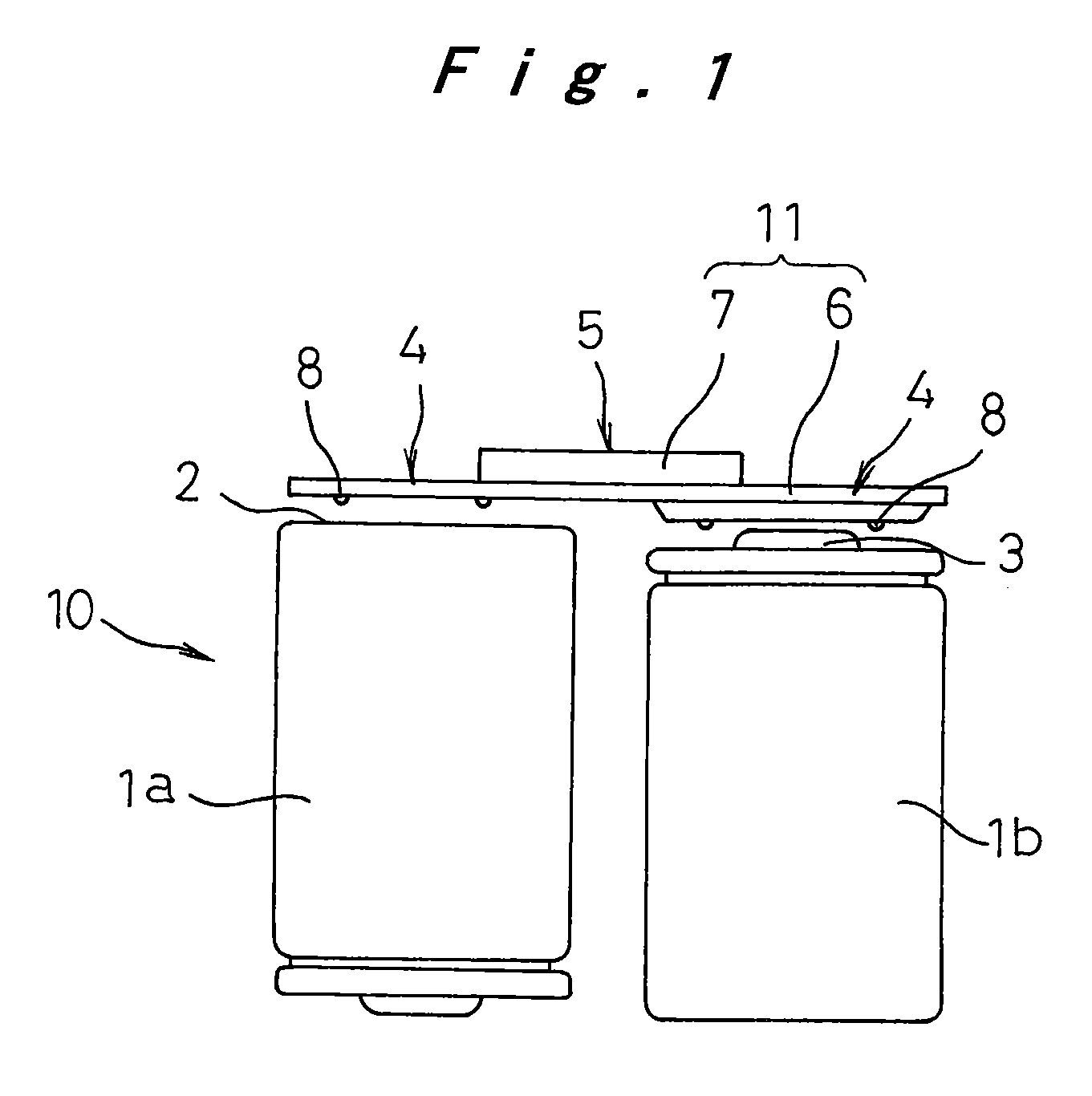

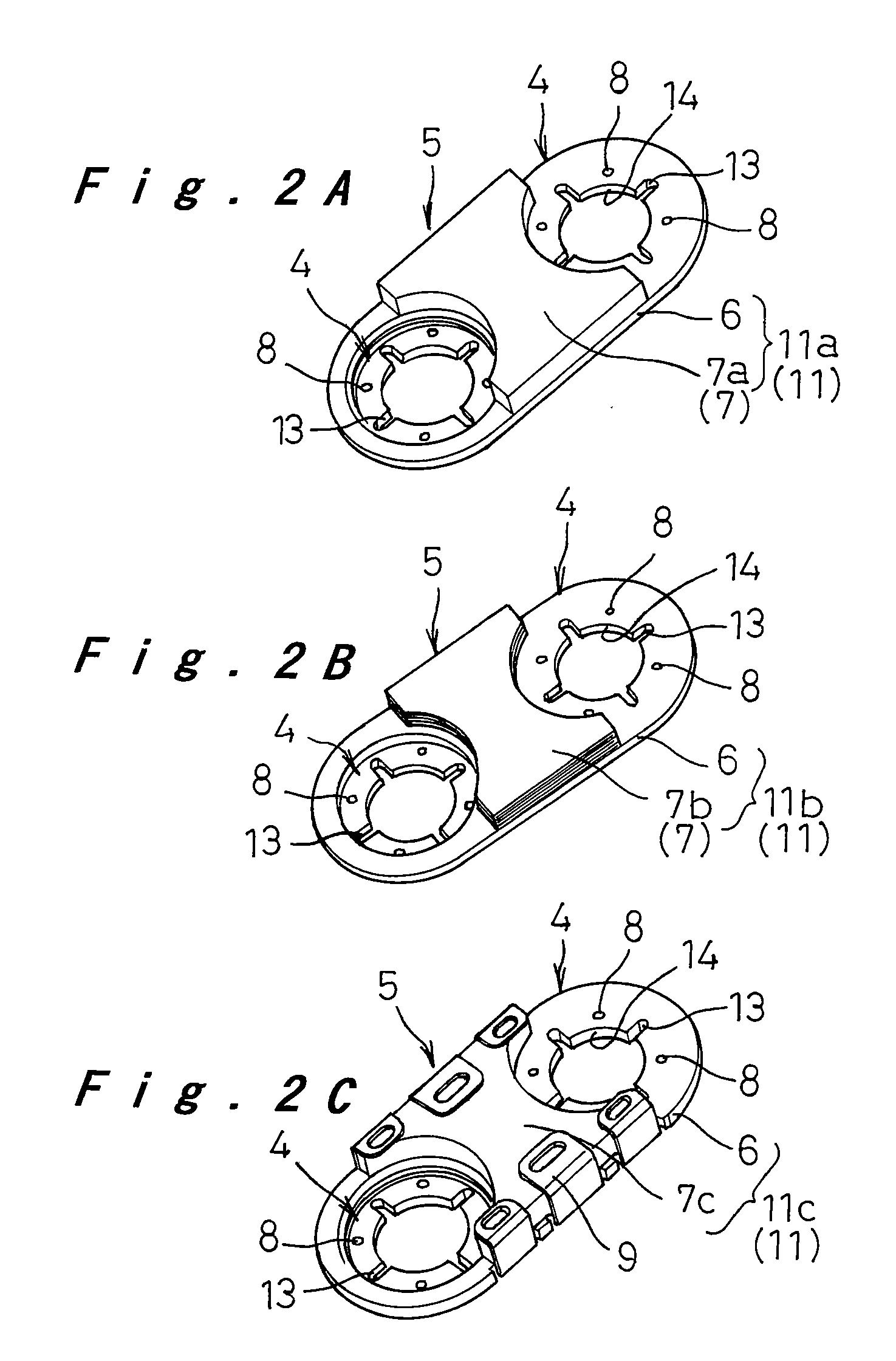

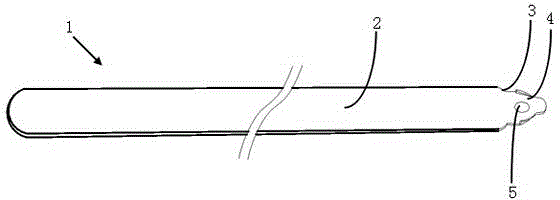

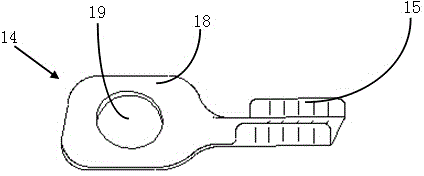

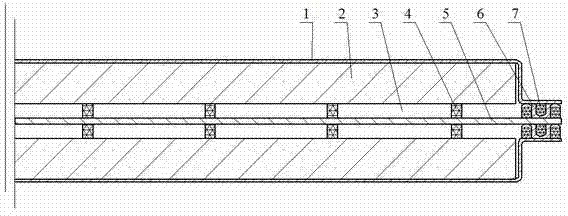

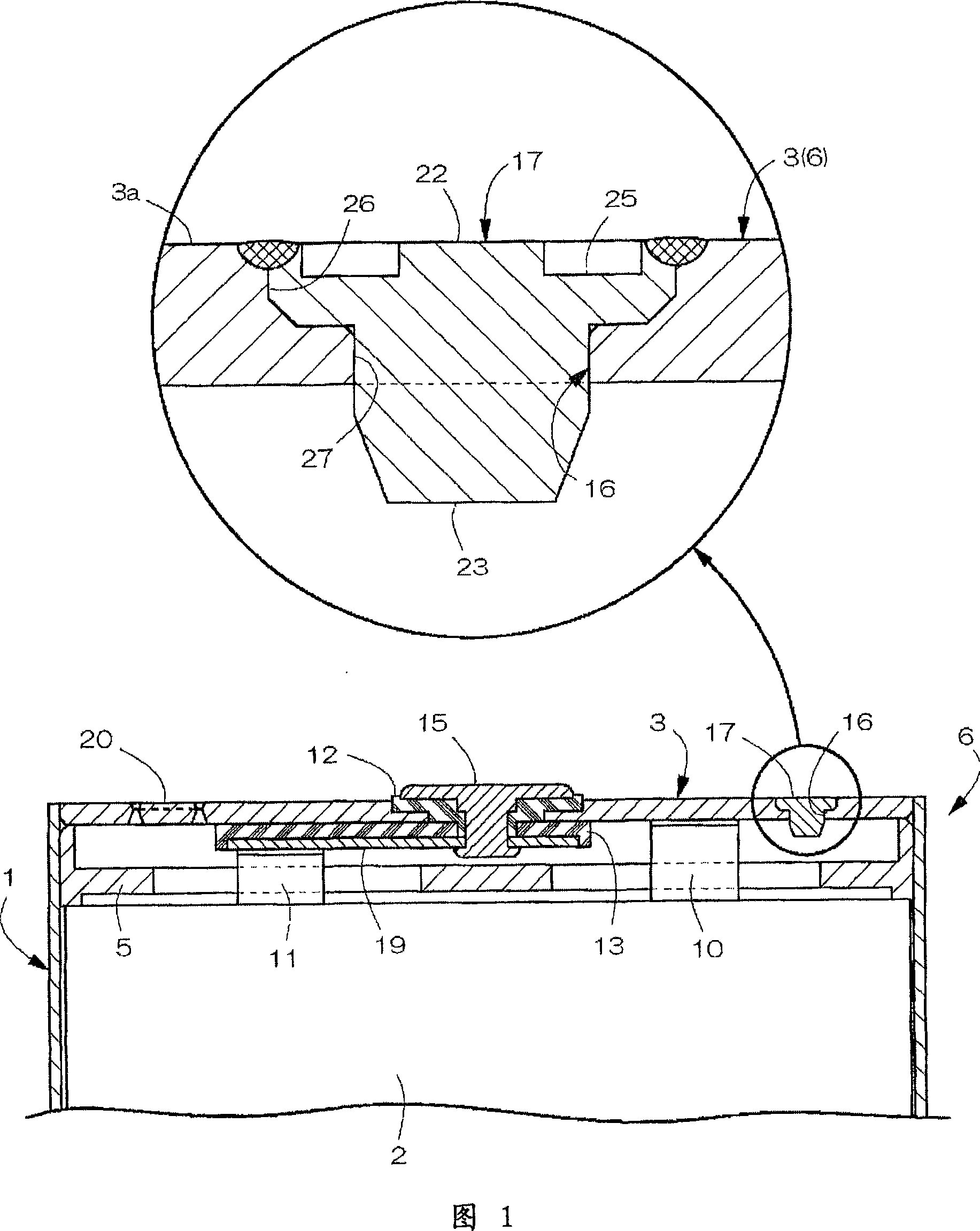

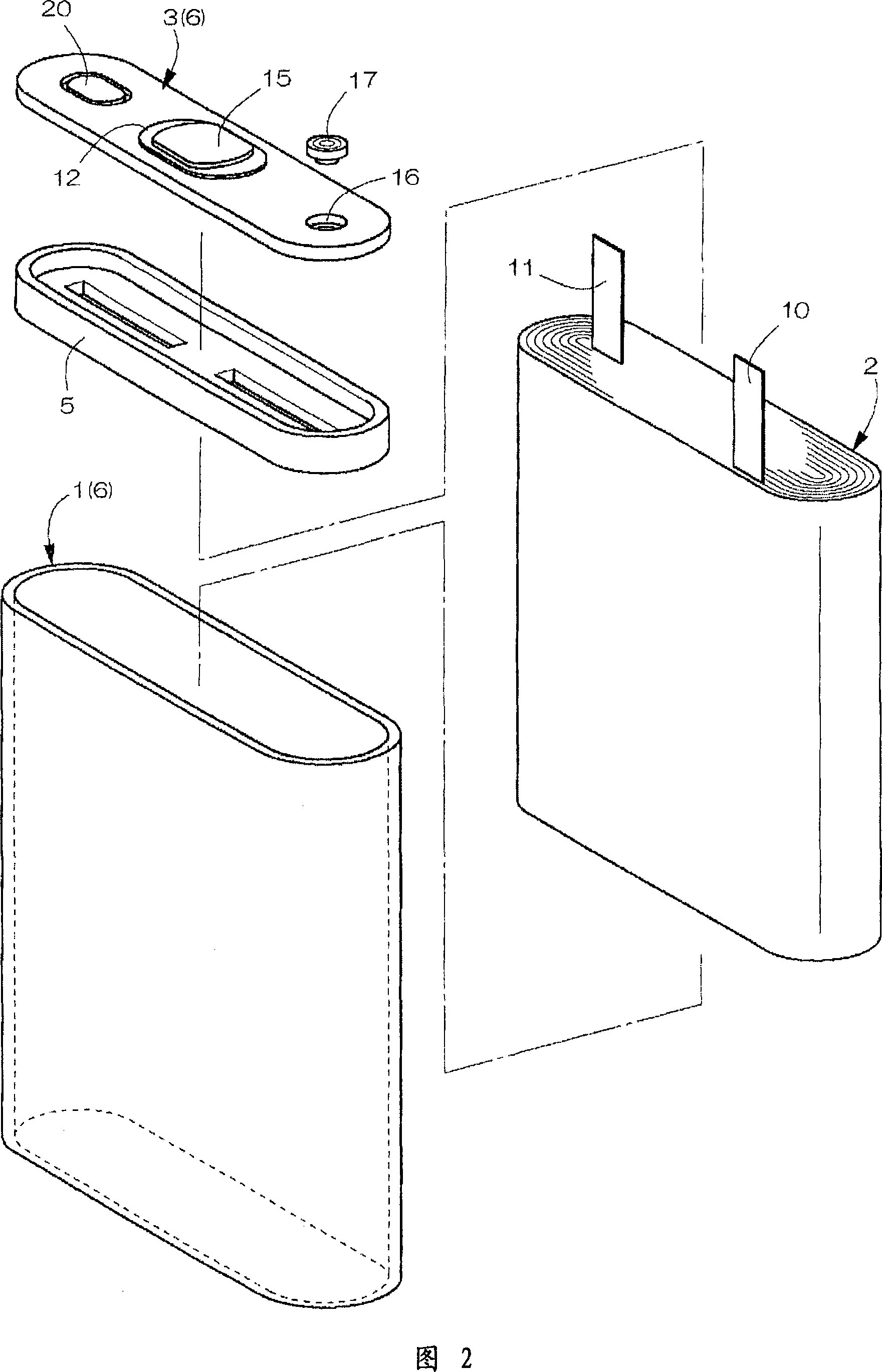

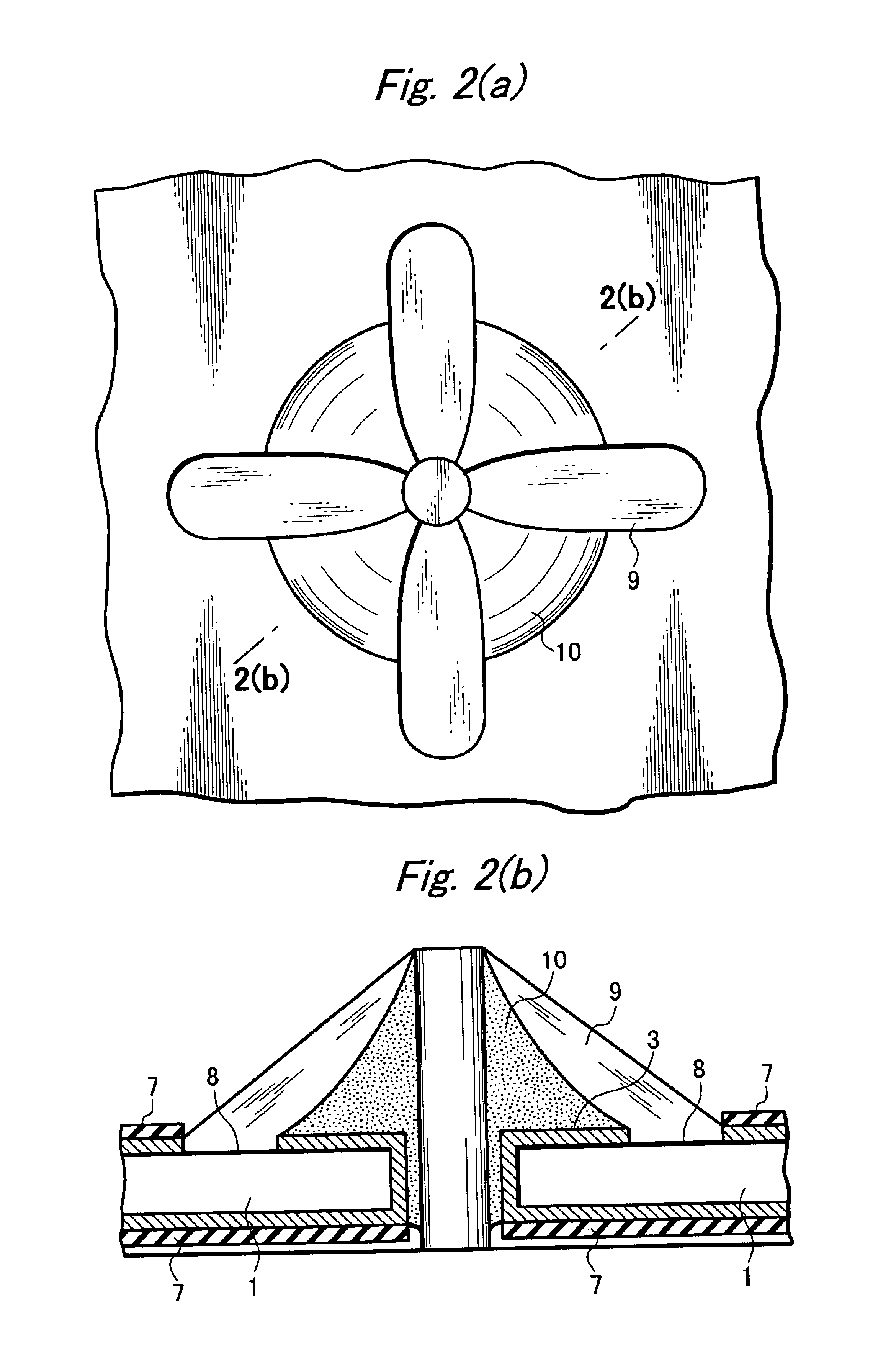

Inter-battery connection device

InactiveUS20090123830A1Avoid problemsReliable weldingPrimary cell to battery groupingNon-aqueous electrolyte accumulatorsElectrical batteryEngineering

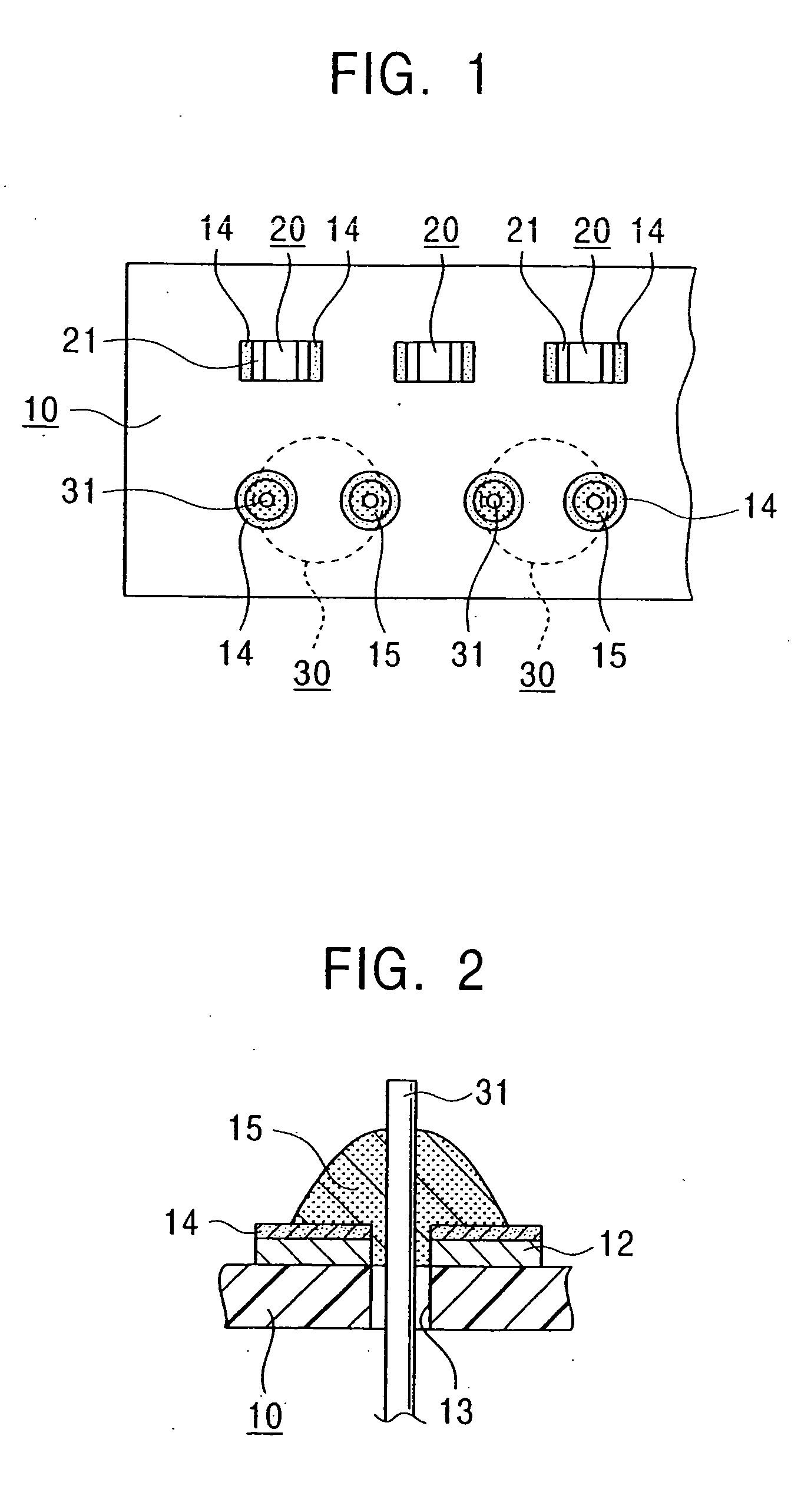

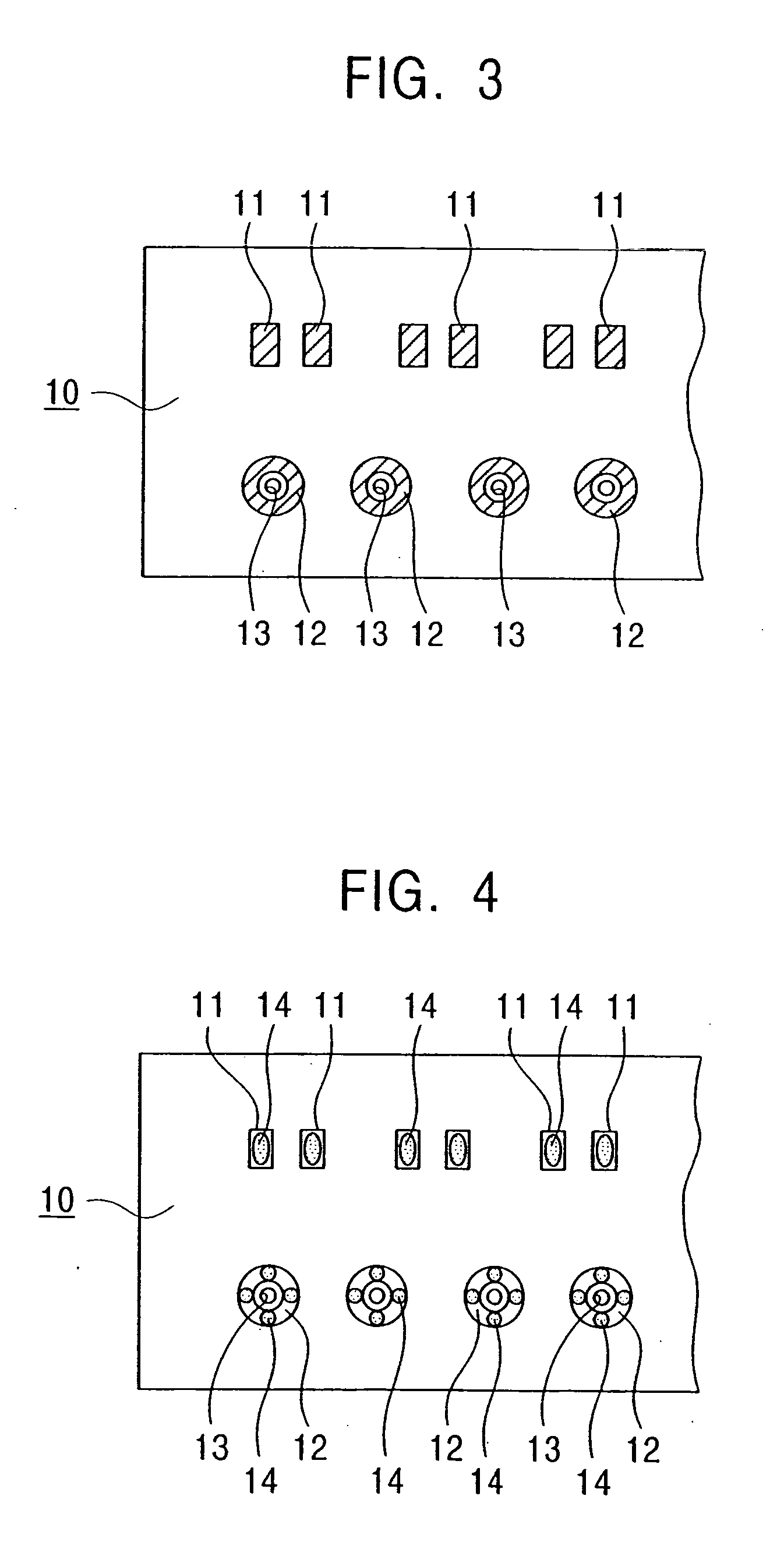

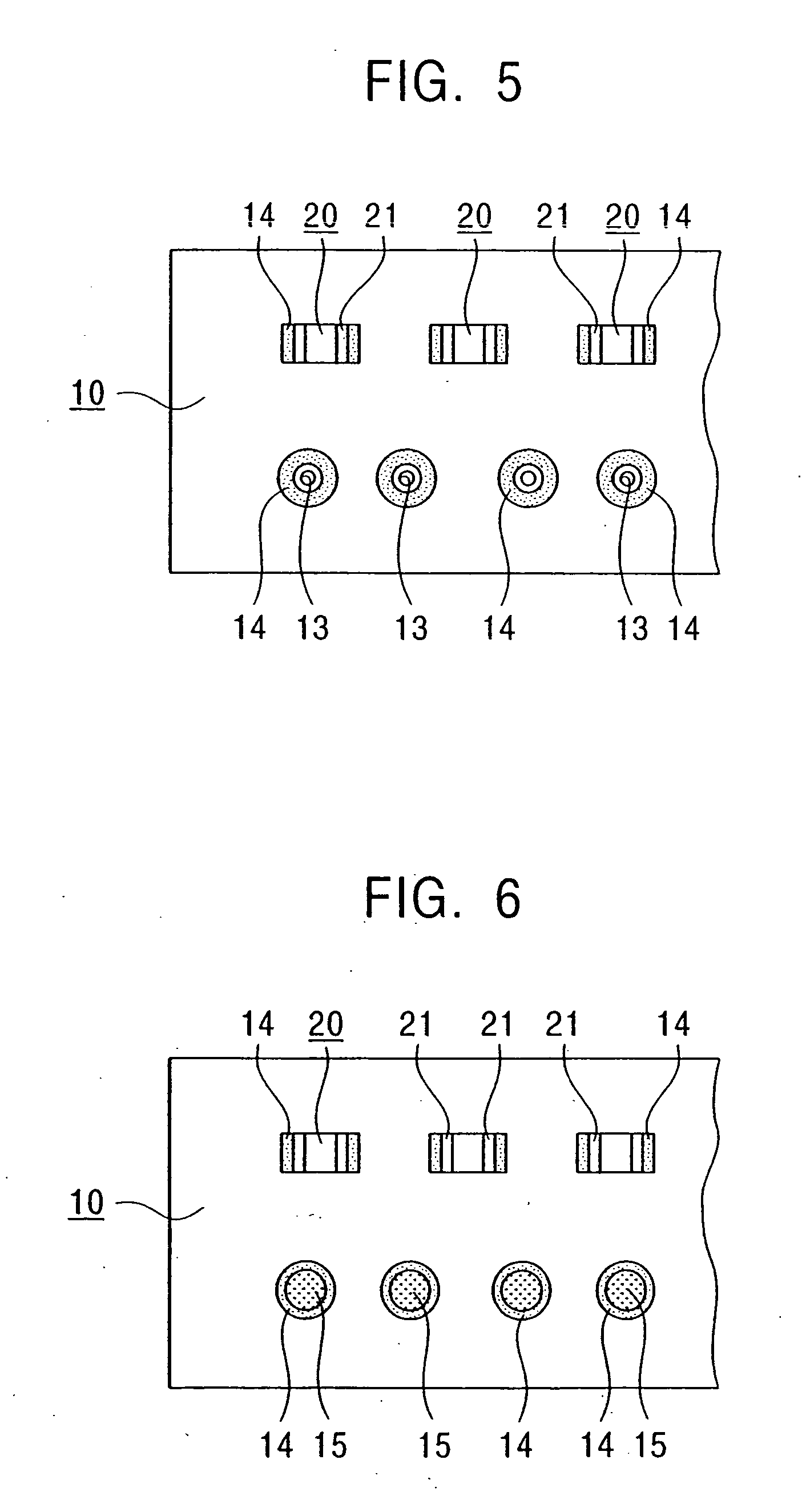

An inter-battery connection device for connecting terminals of two batteries (1a, 1b) arranged with their axes parallel to each other. The inter-battery connection device includes an inter-battery connection plate (11) that connects the battery case bottom (2) and the sealing plate (3) of the two batteries. The inter-battery connection plate (11) includes welding portions (4) at the ends of its base plate (6) for welding to the case bottom (2) and the sealing plate (3), respectively. An intermediate metal plate (7) is joined to the middle part of the base plate (6) between the welding portions (4, 4) to form an intermediate portion (5) having a greater thickness than each welding portion (4). The inter-battery connection device has reduced electric resistance while achieving improved weldability.

Owner:PANASONIC CORP

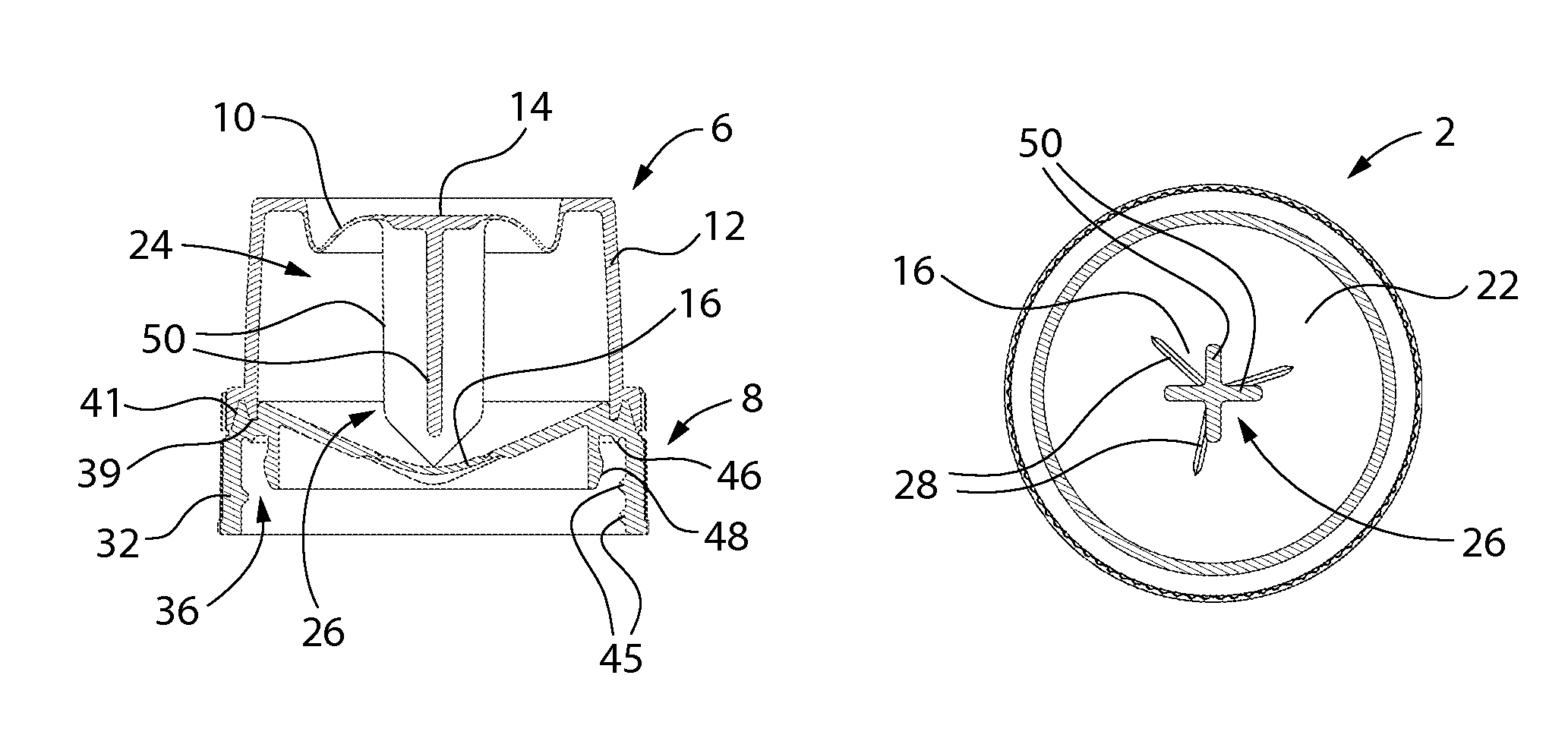

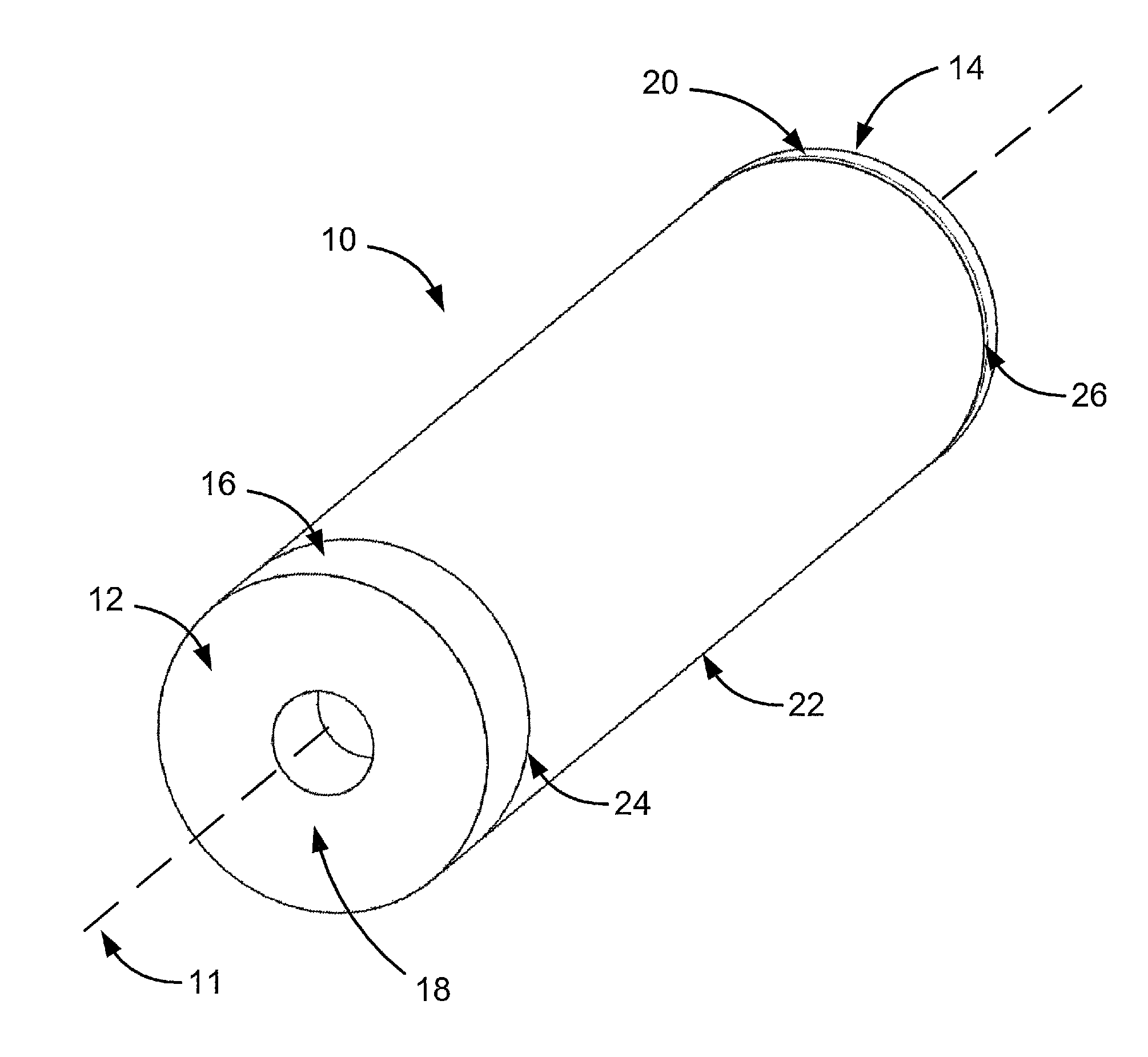

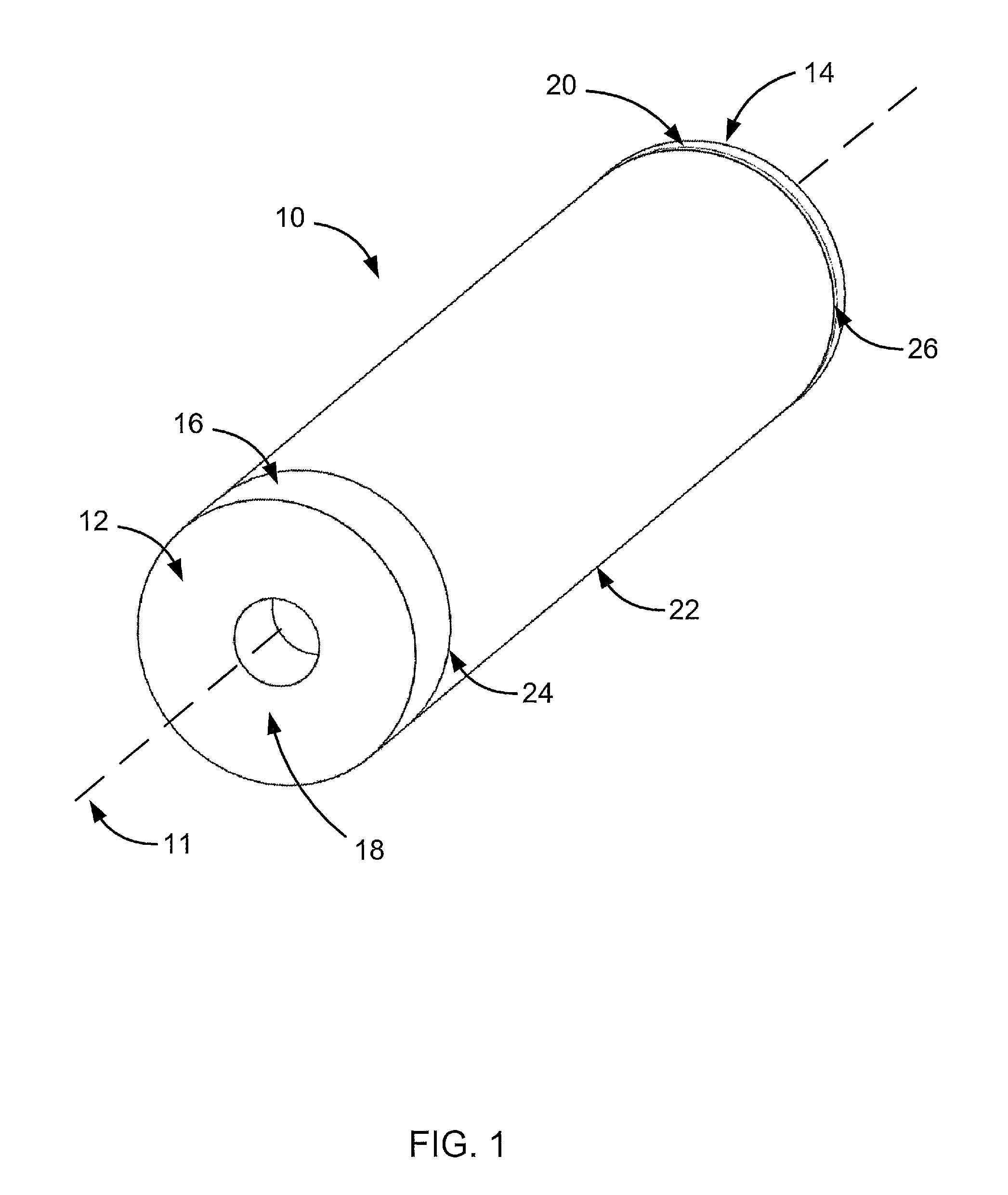

Dispensing capsule

ActiveUS8443970B2Easy to moveIncrease the differential pressureCapsClosure using stoppersEngineeringBottle

A dispensing capsule has a diaphragm button, stake and frangible membrane for a system for selectively dispersing the contents of a cup into an attached bottle. A frangible membraned cup has a diaphragm button operably attached to a stake with the stake's sharp point at one end and the diaphragm button on the opposing end. A cavity is disposed in the cup for consumable product defined by side walls and a base plate. Preloaded ingredients contained within the hermetically sealed cup are discharged from the dispensing capsule into a bottle by simply depressing a button disposed on the diaphragm of the cup, thereby actuating the stake to thrust forward and apply concentrated pressure abaxially to the frangible membrane. This concentrated pressure pierces substantially the center of the frangible membrane, causing it to rupture and progressively opening it. The diaphragm button locks in this downward position, holding the stake into the opened frangible membrane to maintain the opening, permitting the contents to flow through the frangible membrane and exit the cavity of the cup.

Owner:GENESEE REGIONAL BANK

Thermal sensitive ceramic heater and heating body and heating core applied to thermal sensitive ceramic heater

ActiveCN104797015AImprove insulation performanceIncrease productivityOhmic-resistance electrodesHeater elementsHeat conductingHeat sensitive

The invention discloses a thermal sensitive camera heater. The thermal sensitive camera heater comprises a heating portion, a connection wire harness and a mounting frame, the heating portion is formed by a heating body and a radiator, the heating body comprises a heat conducting tube and a heating core, the heating core comprises a heating slice, an electrode slice and insulation paper, and the connection wire harness comprises a connection slice. Not fewer than two semi-circular grooves are formed in the outer lateral side of the heat conducting tube. A heat conducting face of the heat conducting tube is 0-15mm wider than the radiator. The thermal sensitive camera heater has the advantages that by the aid of the connection slice added on the electrode slice, reliable connection point contact and stable connection between the heater and the wire harness and convenience in manufacturing are achieved; by the aid of the heat conducting tube and the radiator which are different in width, the radiator can be combined with the heat conducting tube more stably and more uniform in radiation; by the aid of the semi-circular grooves in the lateral side of the heat conducting tube, the inner wall of the heat conducting tube causes less damage to a heating core insulation film, combination of the heating core in the heat conducting tube is tighter, and safety and heat efficiency are improved greatly.

Owner:SUZHOU GUOWEI CERAMIC ELECTRICAL APPLIANCE CO LTD

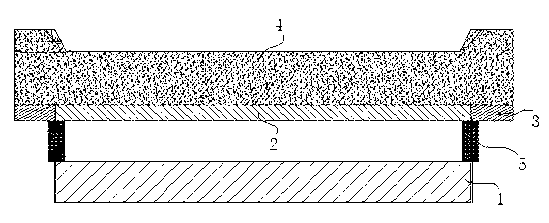

Battery and method of manufacturing the battery

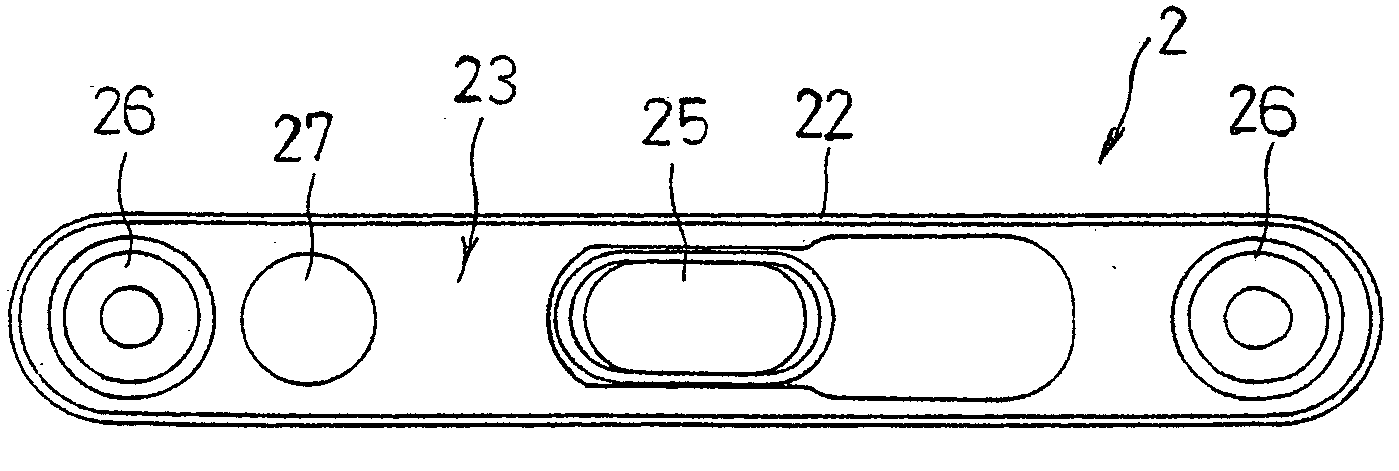

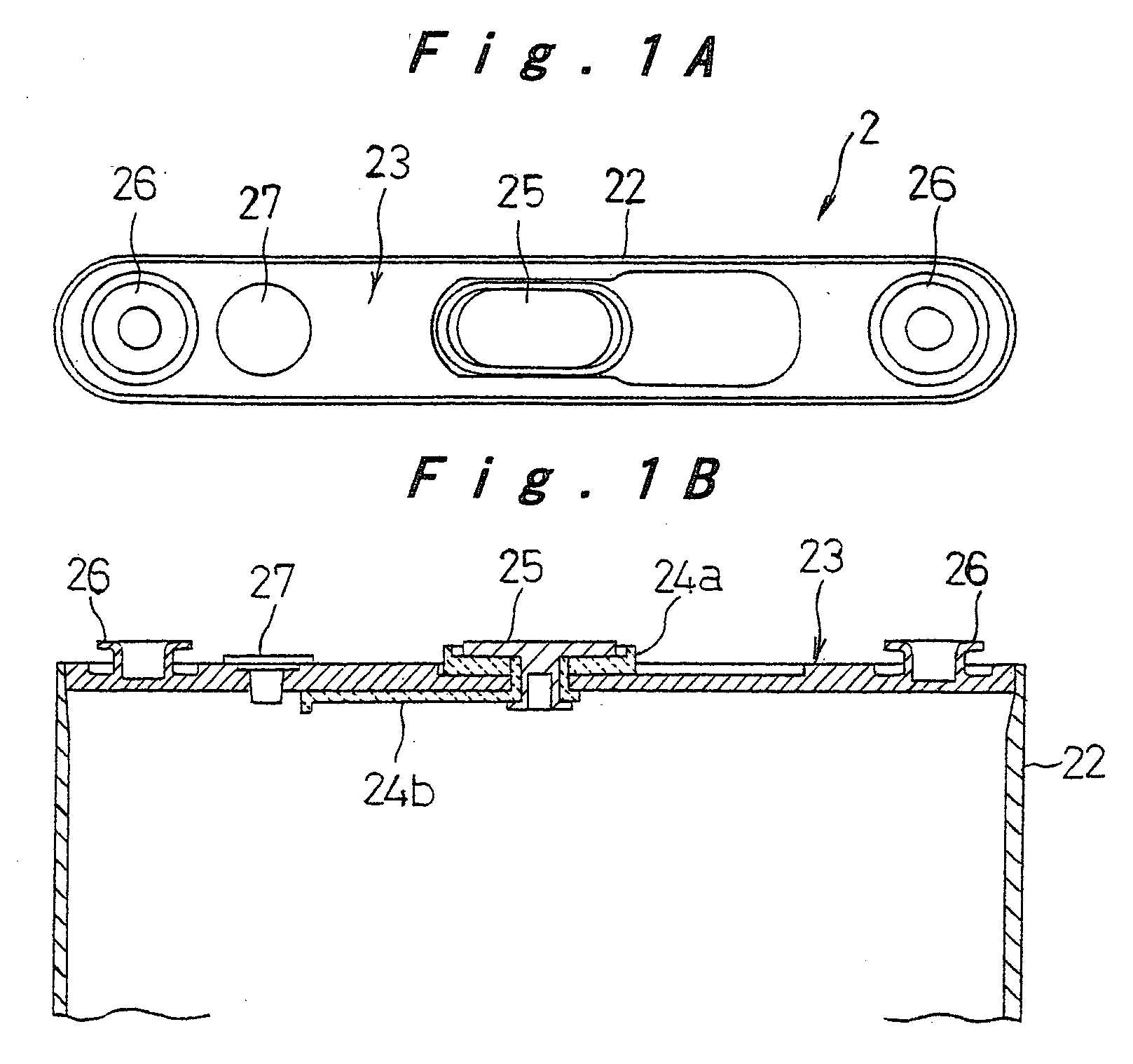

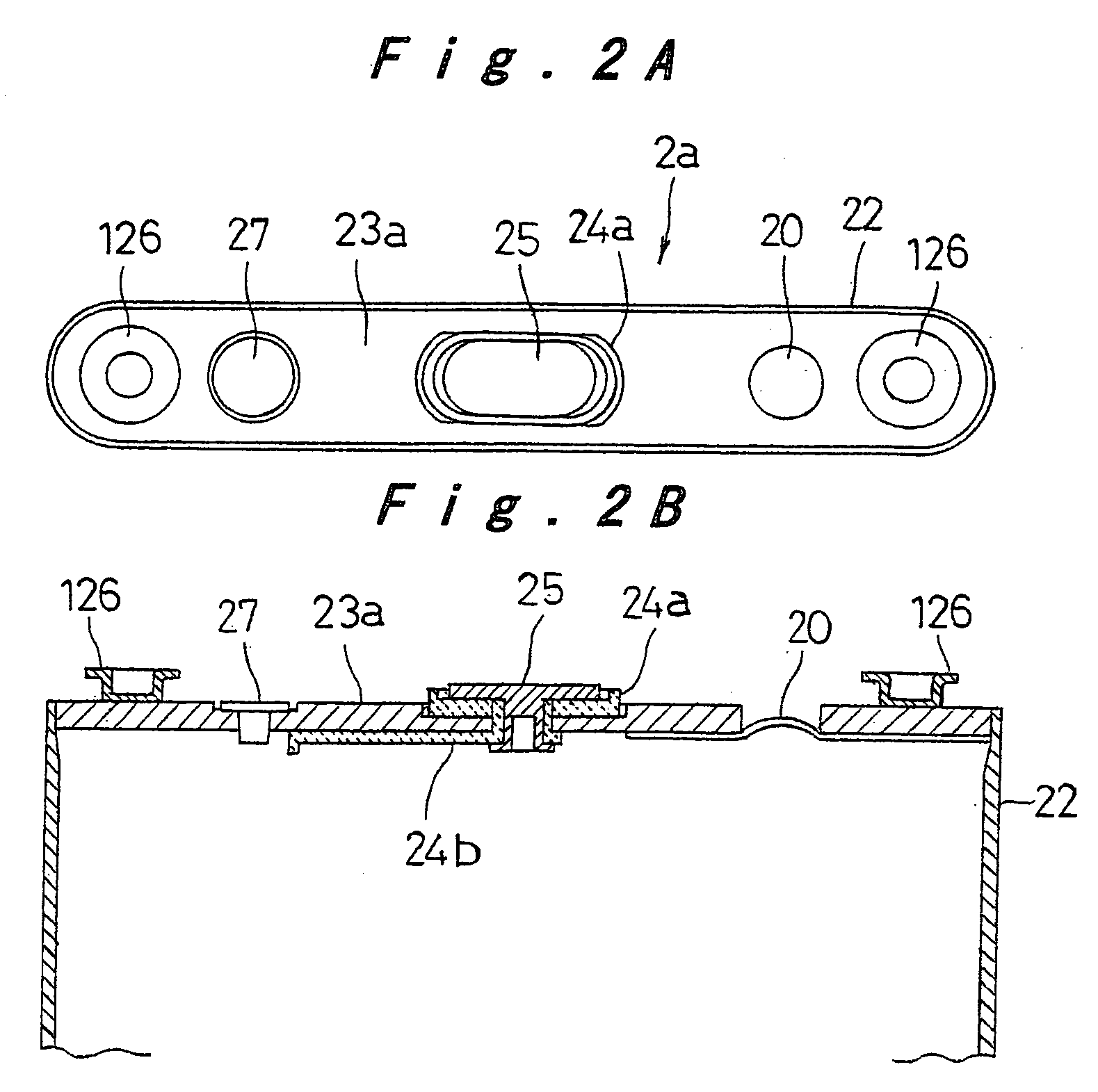

InactiveUS20050106454A1Less variationReliable weldingFinal product manufactureSmall-sized cells cases/jacketsElectrical and Electronics engineering

A circuit substrate (3) being electrically connected to a rechargeable battery (2) is arranged upon a sealing plate (23) with a gap therebetween and united with the rechargeable battery (2) by filling resin in the gap. A primary mold (11) formed by the resin is firmly retained by undercut portions formed in engaging protrusions (26). The engaging protrusions (26) may be formed by welding separate engaging members (126, 126a, 126b, 126c, 66, 68).

Owner:PANASONIC CORP

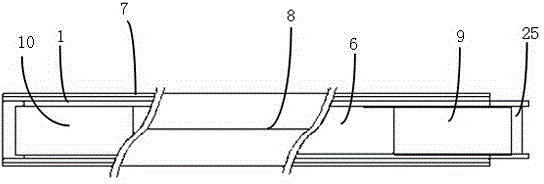

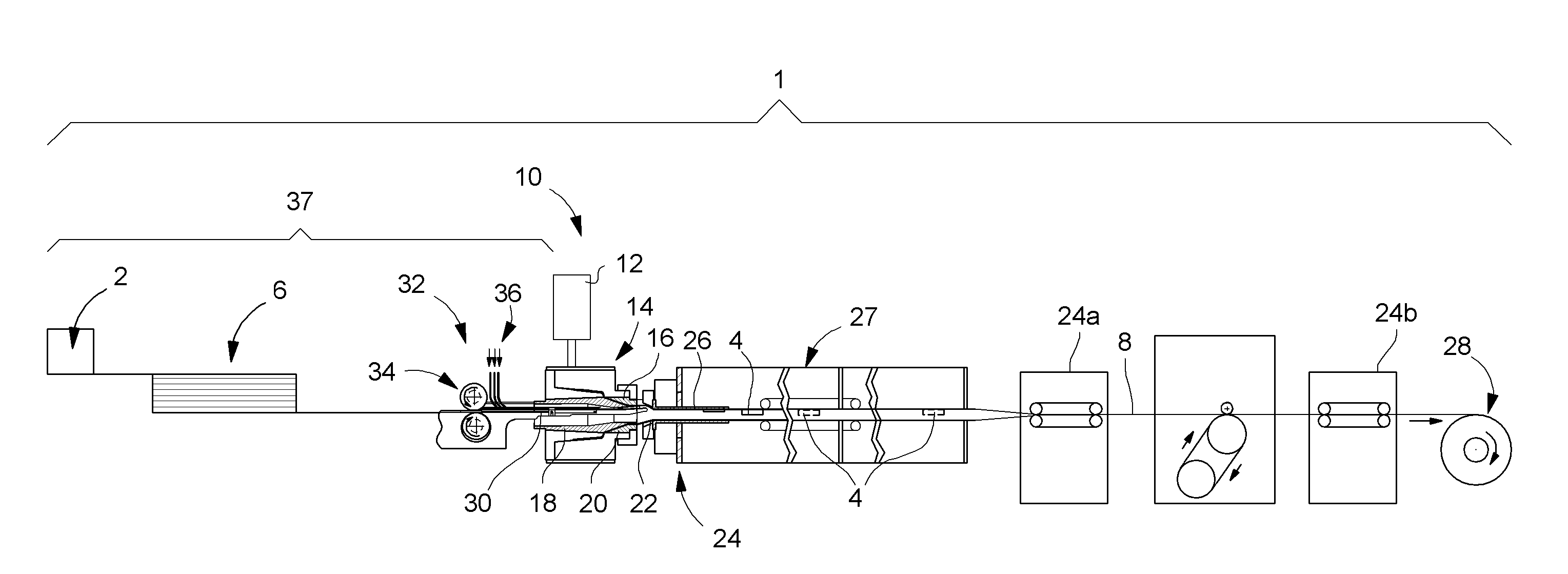

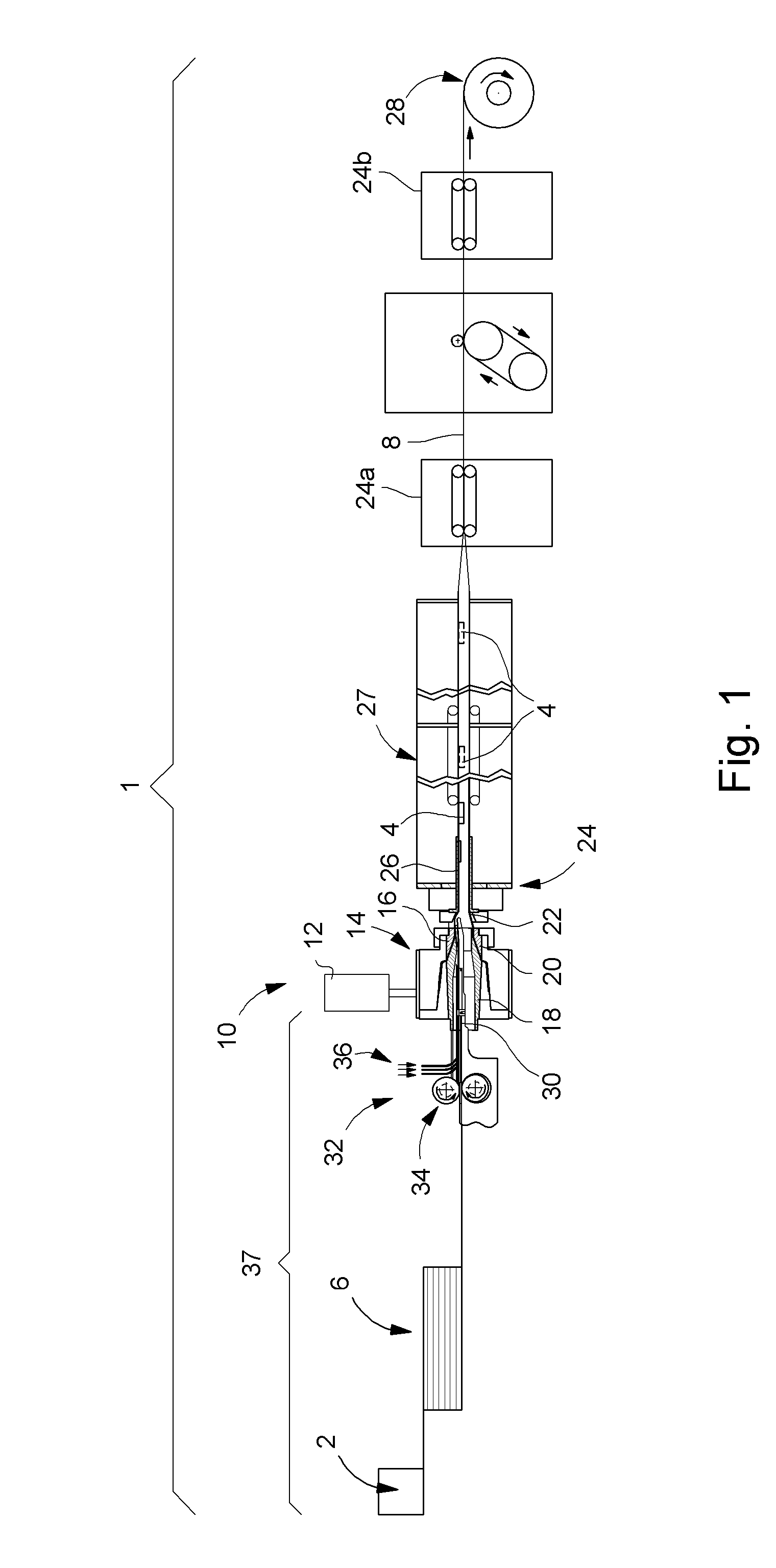

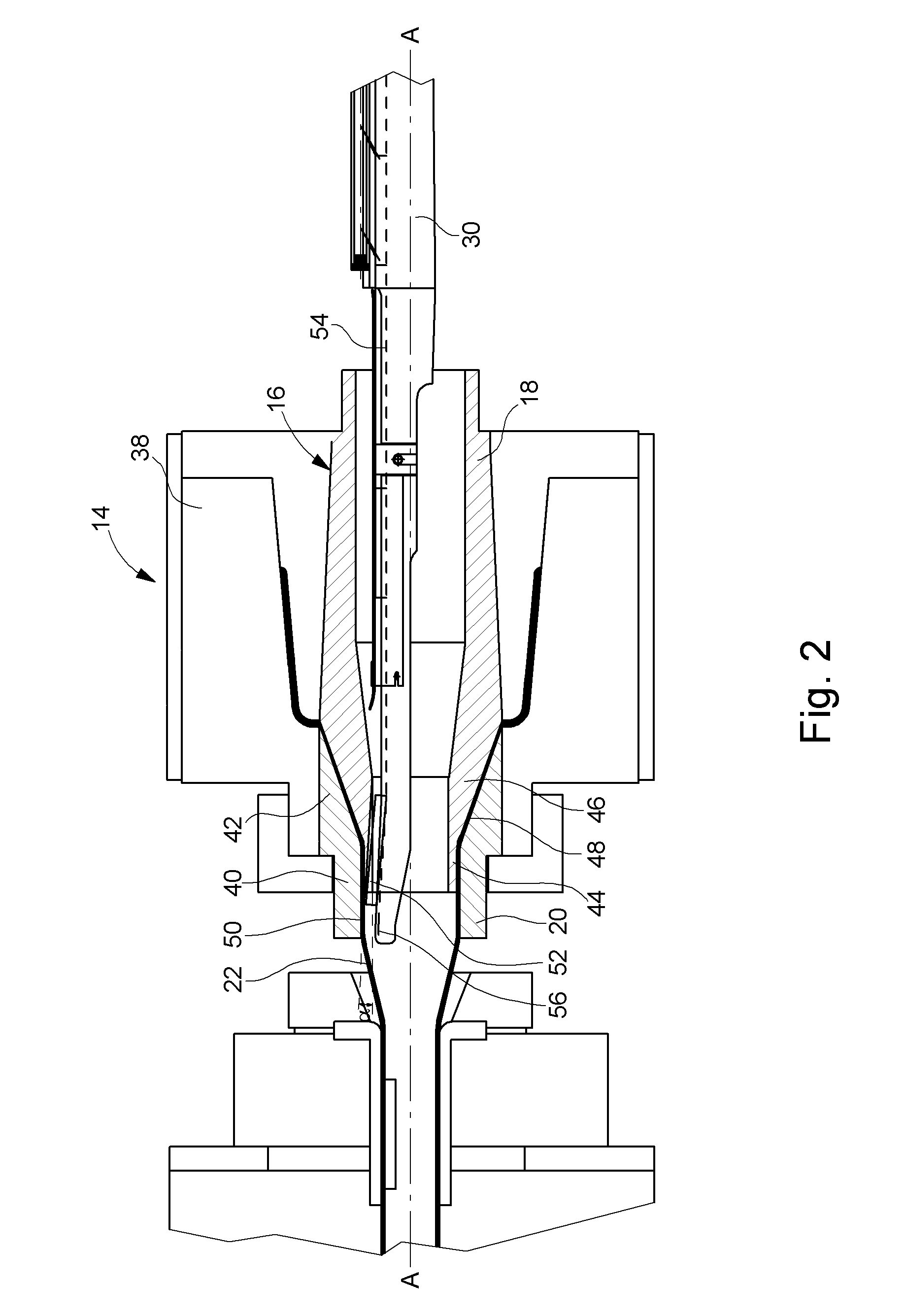

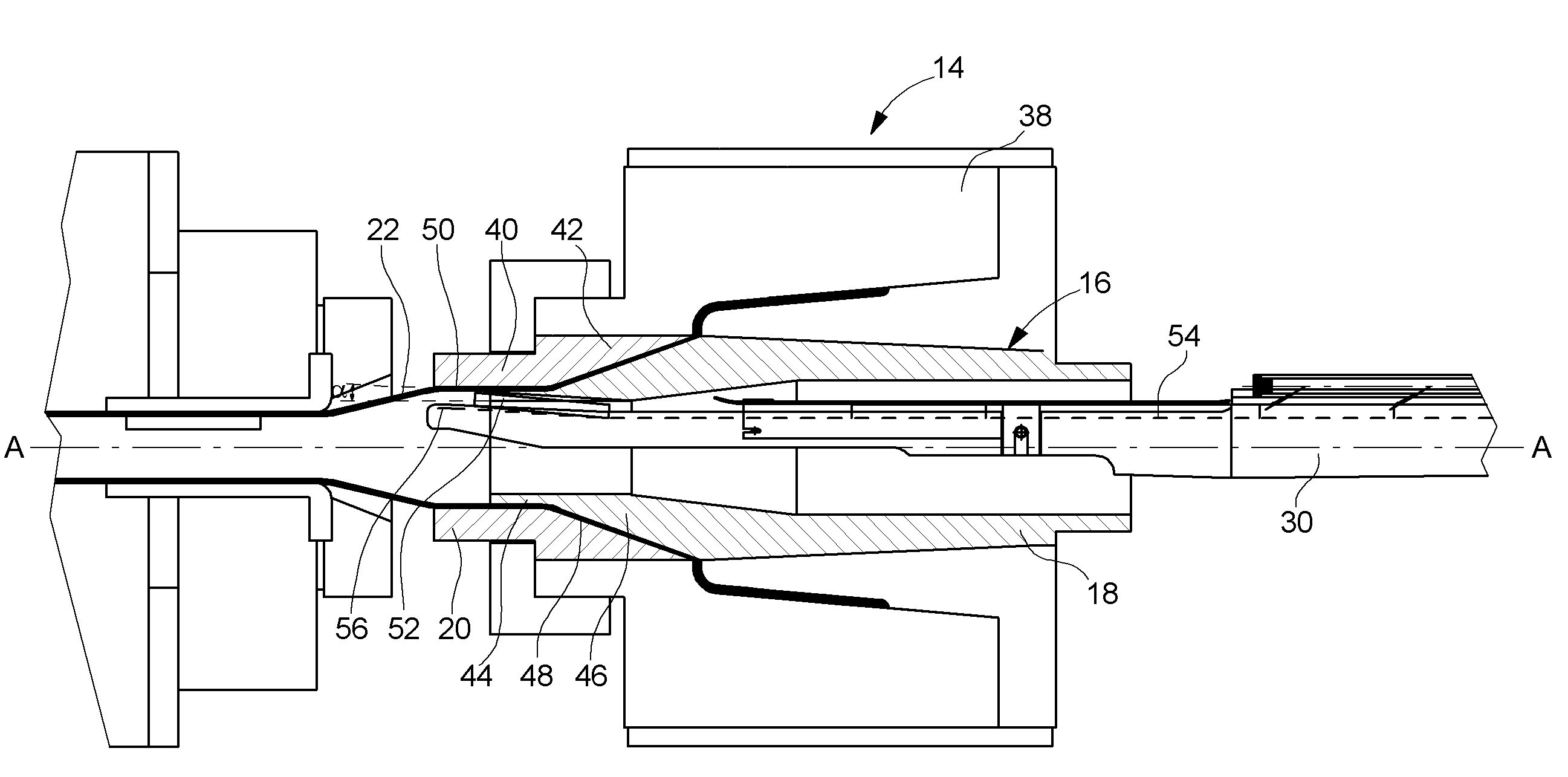

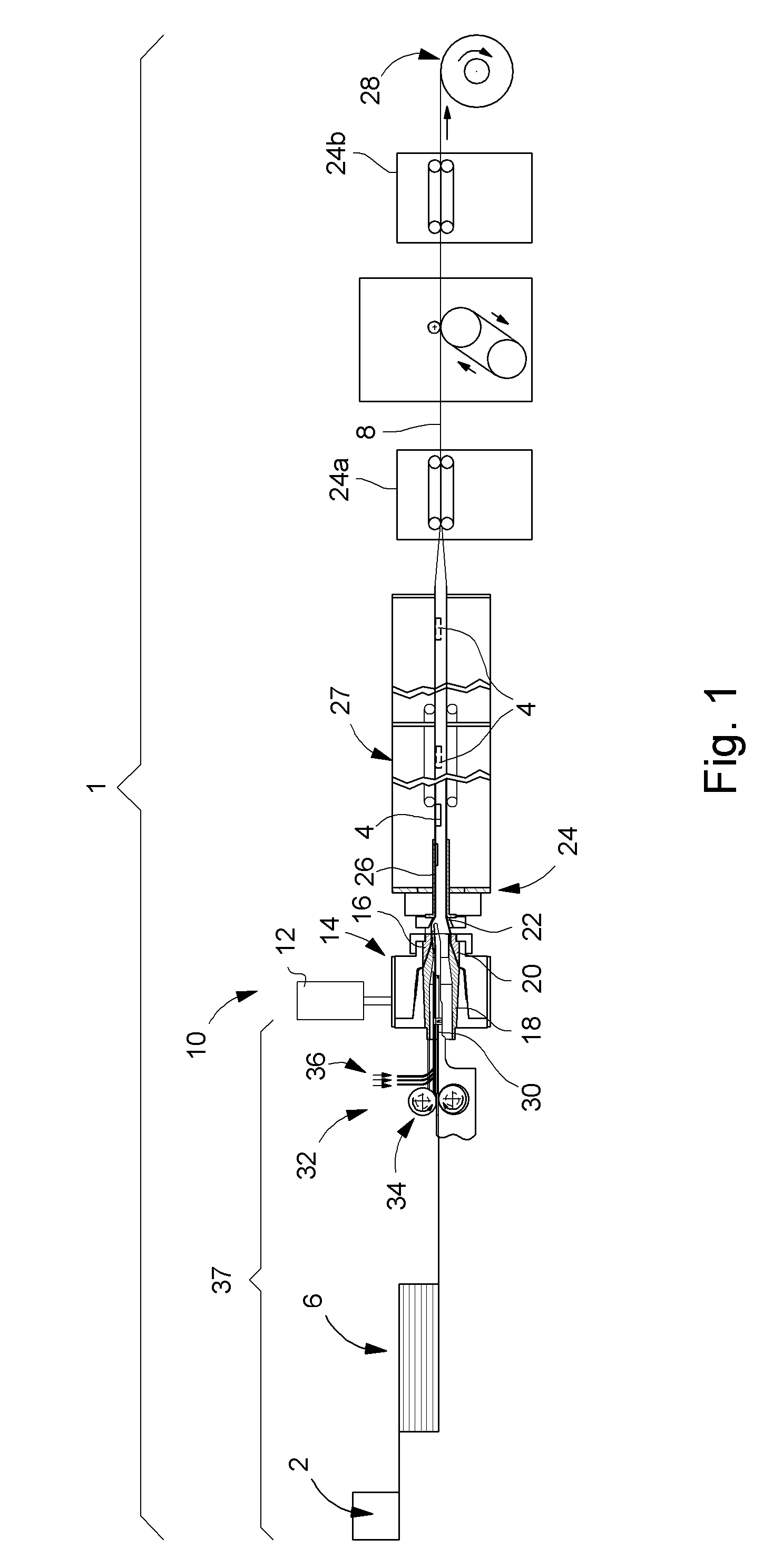

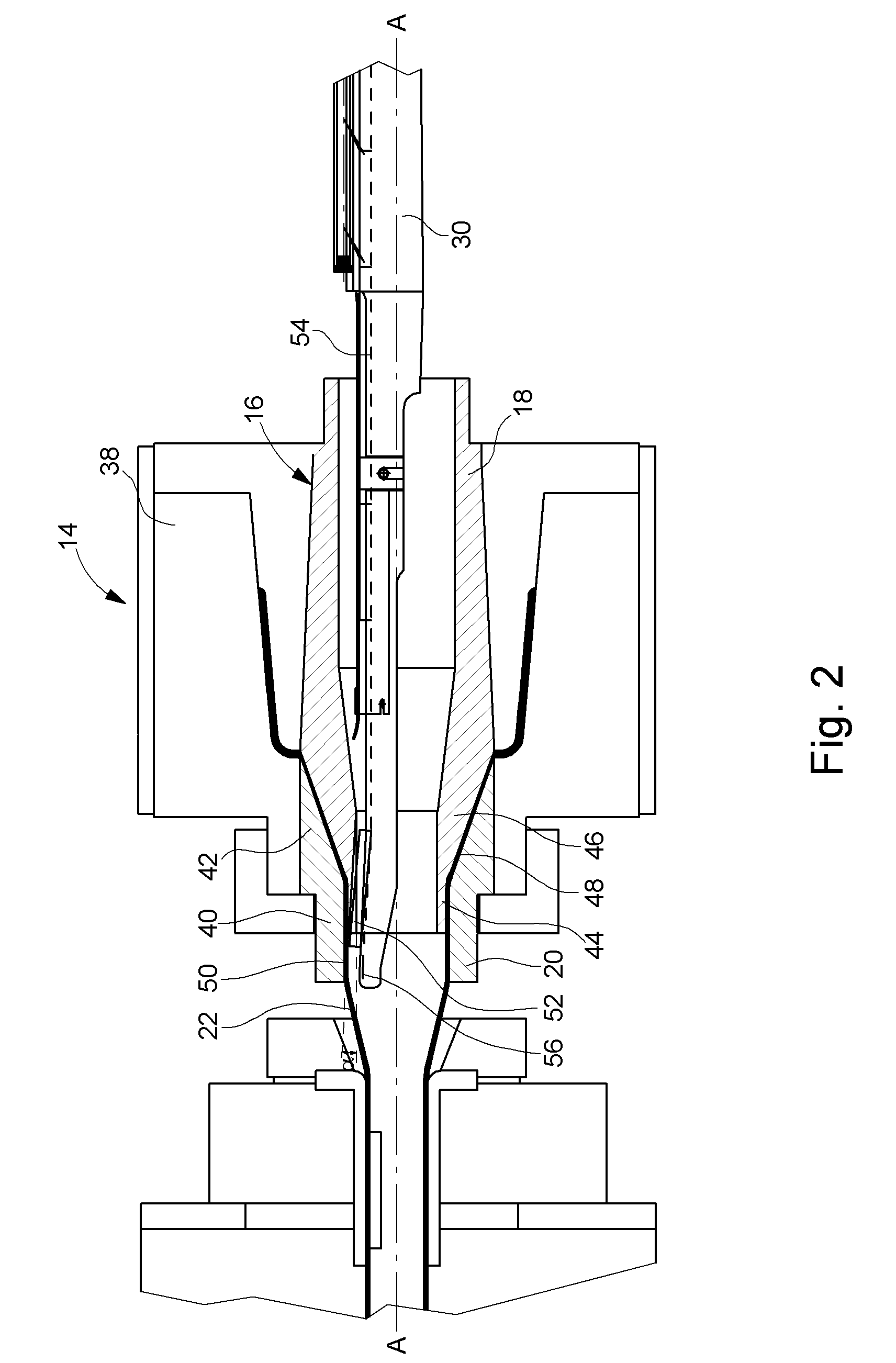

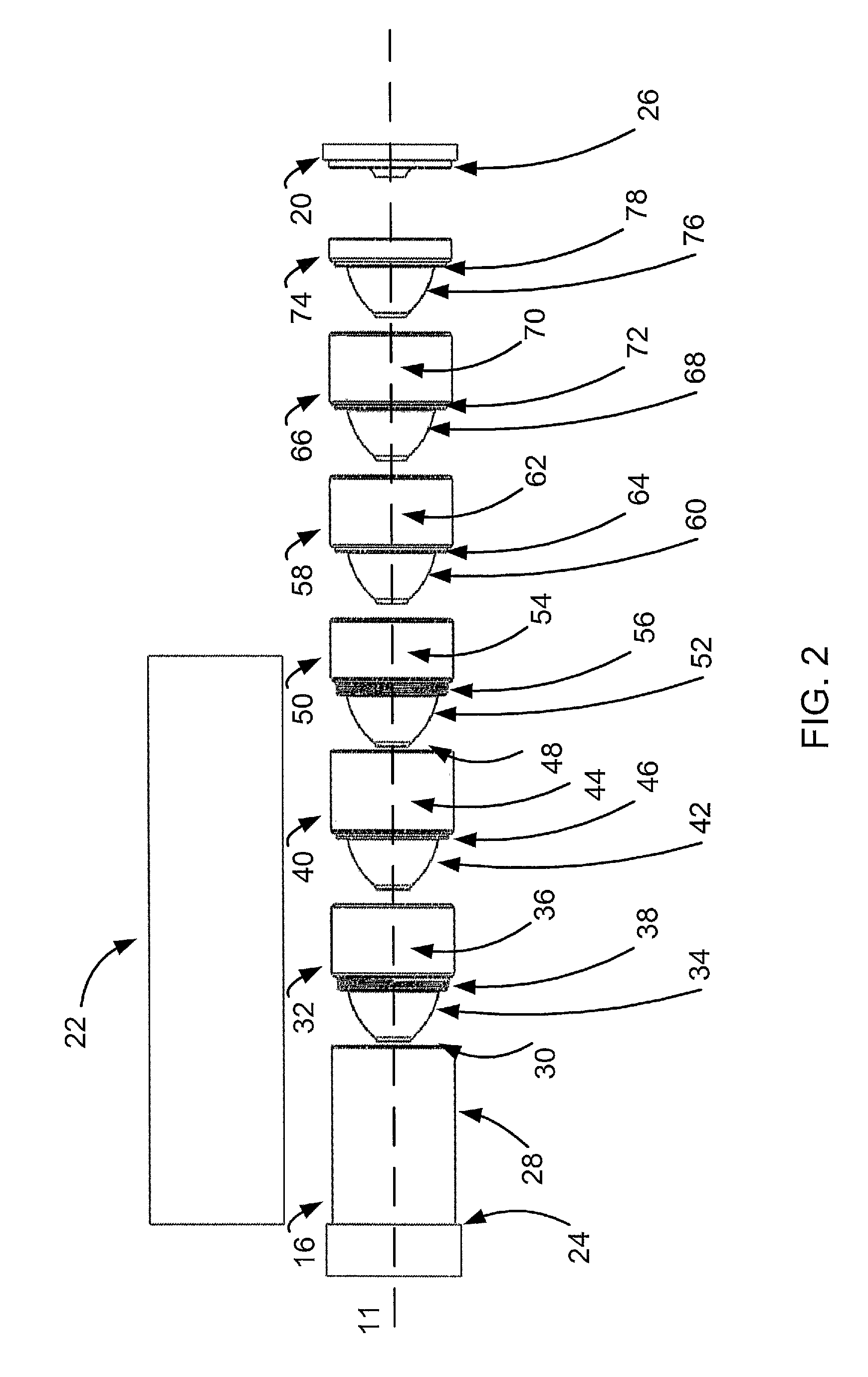

Installation and method for manufacturing drip irrigation pipes

InactiveUS20070187031A1Easy to weldImprove approachClimate change adaptationWatering devicesExtrusionWelding

The invention concerns an installation for manufacturing a drip irrigation pipe (8) formed of a pipe (8) provided with drippers (4), including a dripper feed station (37), followed by an extrusion station (10), including an extrusion head (14) producing a tubular blank (22) and means for welding the drippers (4) to the inner wall of said blank (22), characterized in that the dripper welding means (4) include a support surface (50) and a counter-support surface (56) between which the drippers (4) are pressed against said tubular blank (22) so as to be welded thereto, said support (50) and counter-support (56) surfaces being arranged upstream of the calibrating means (24).

Owner:THE MACHINES YVONAND

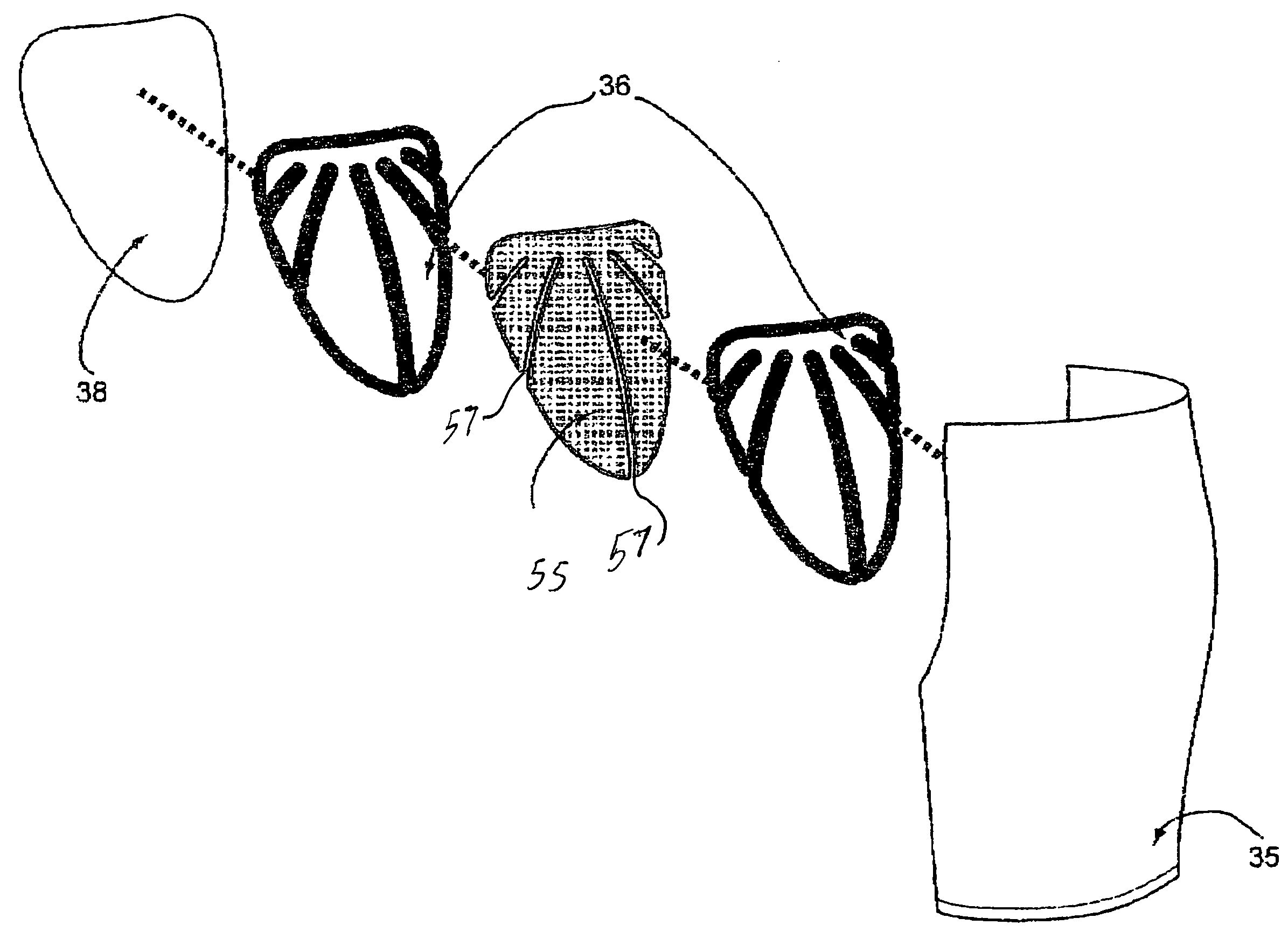

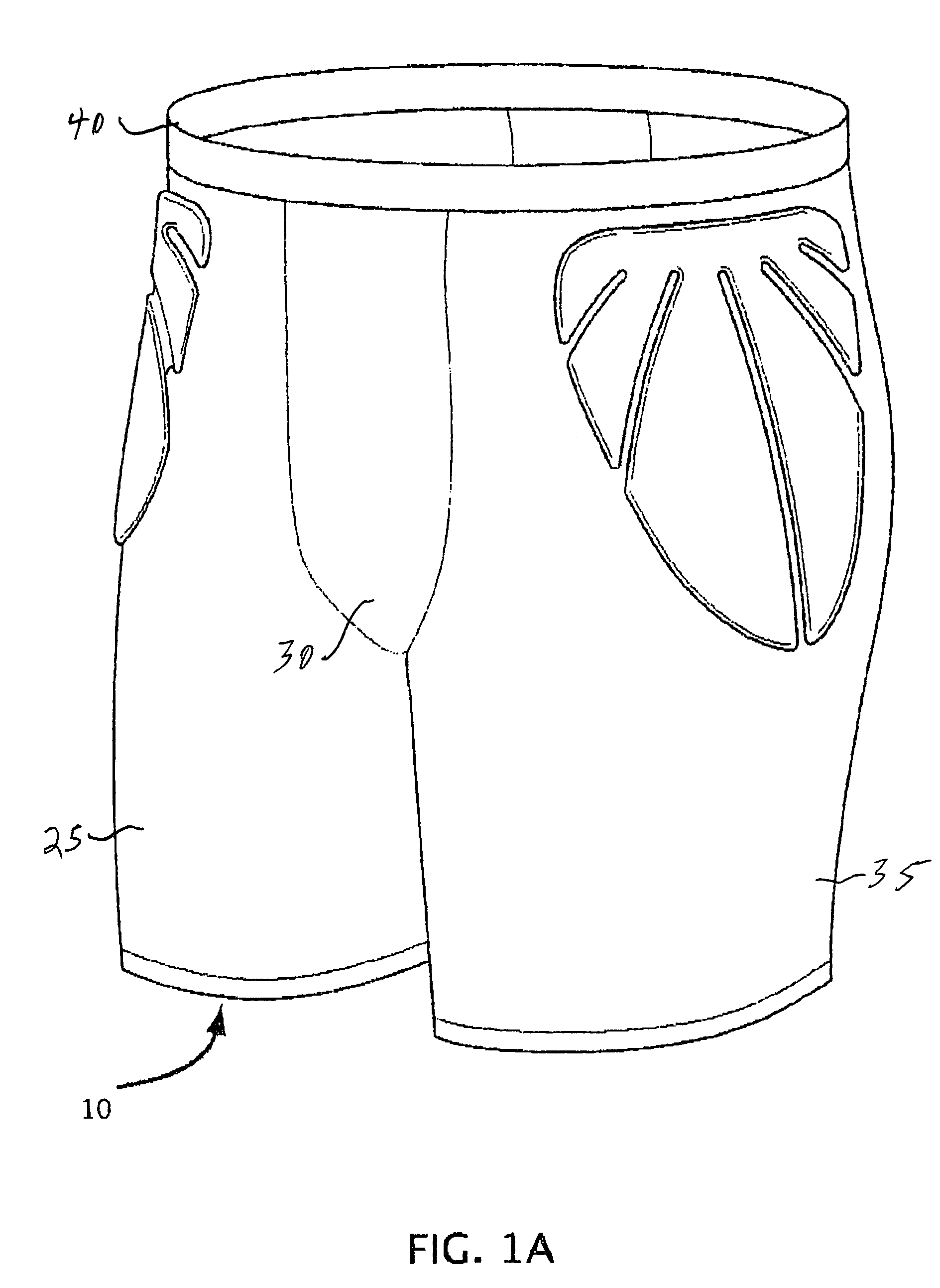

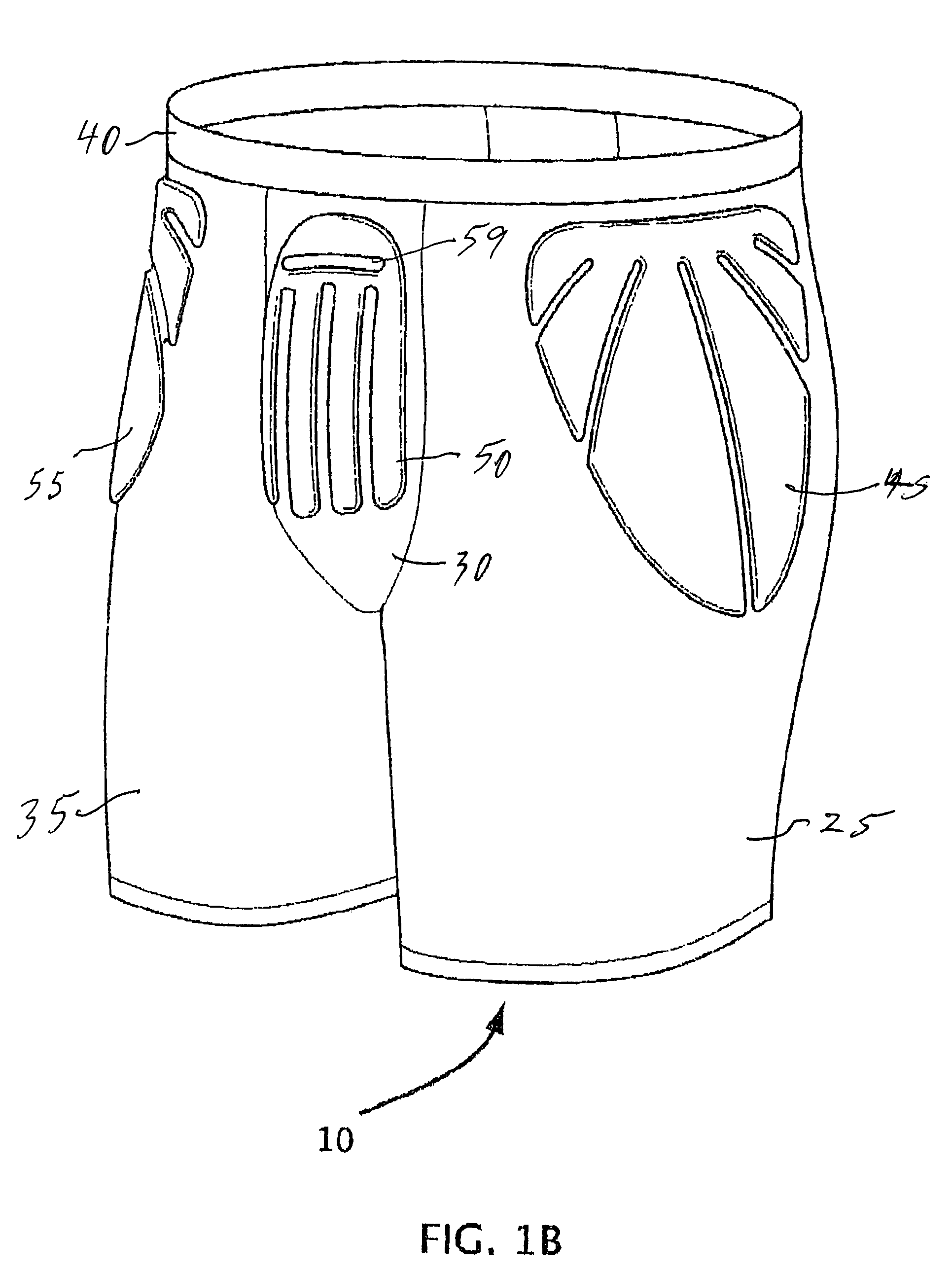

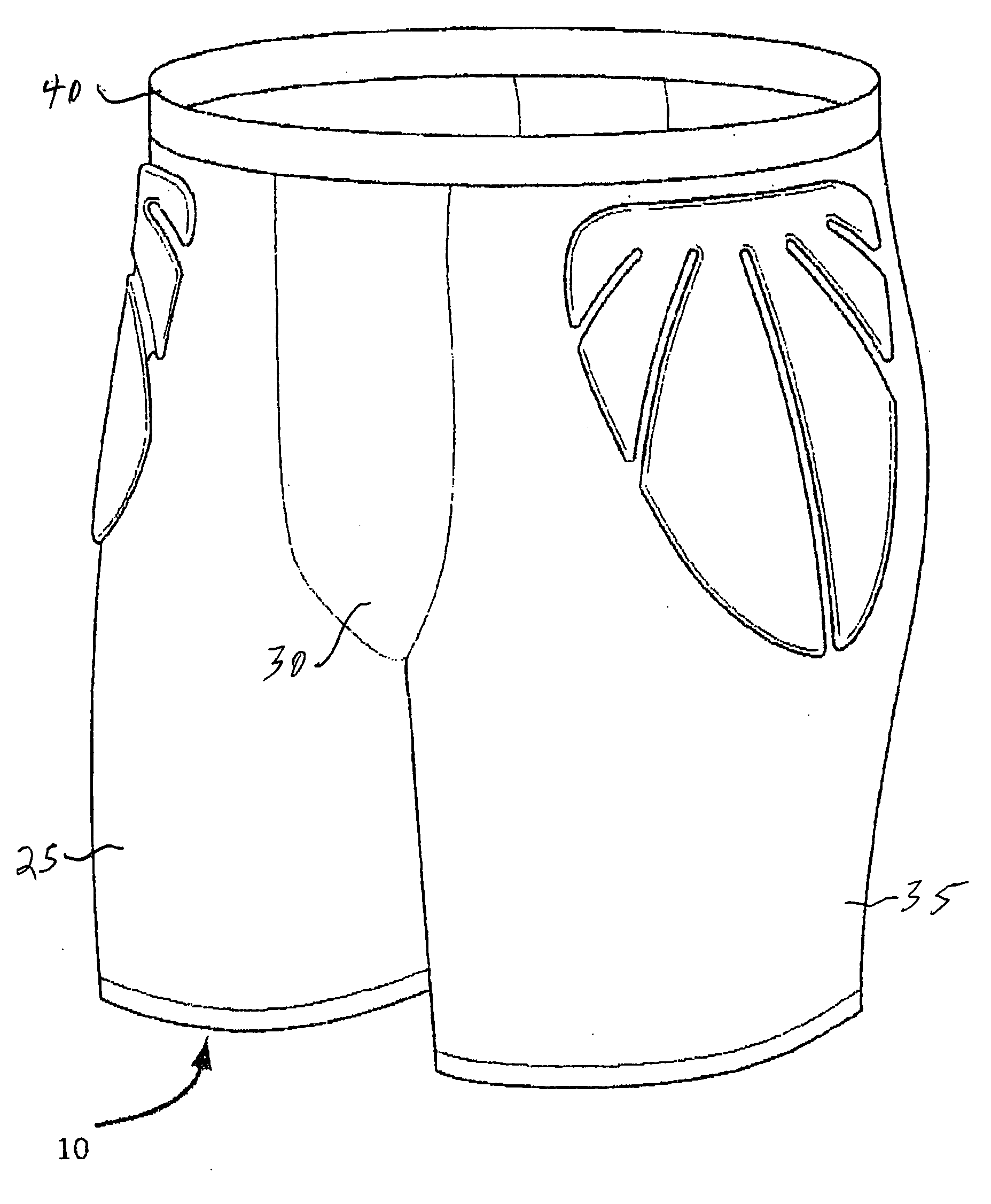

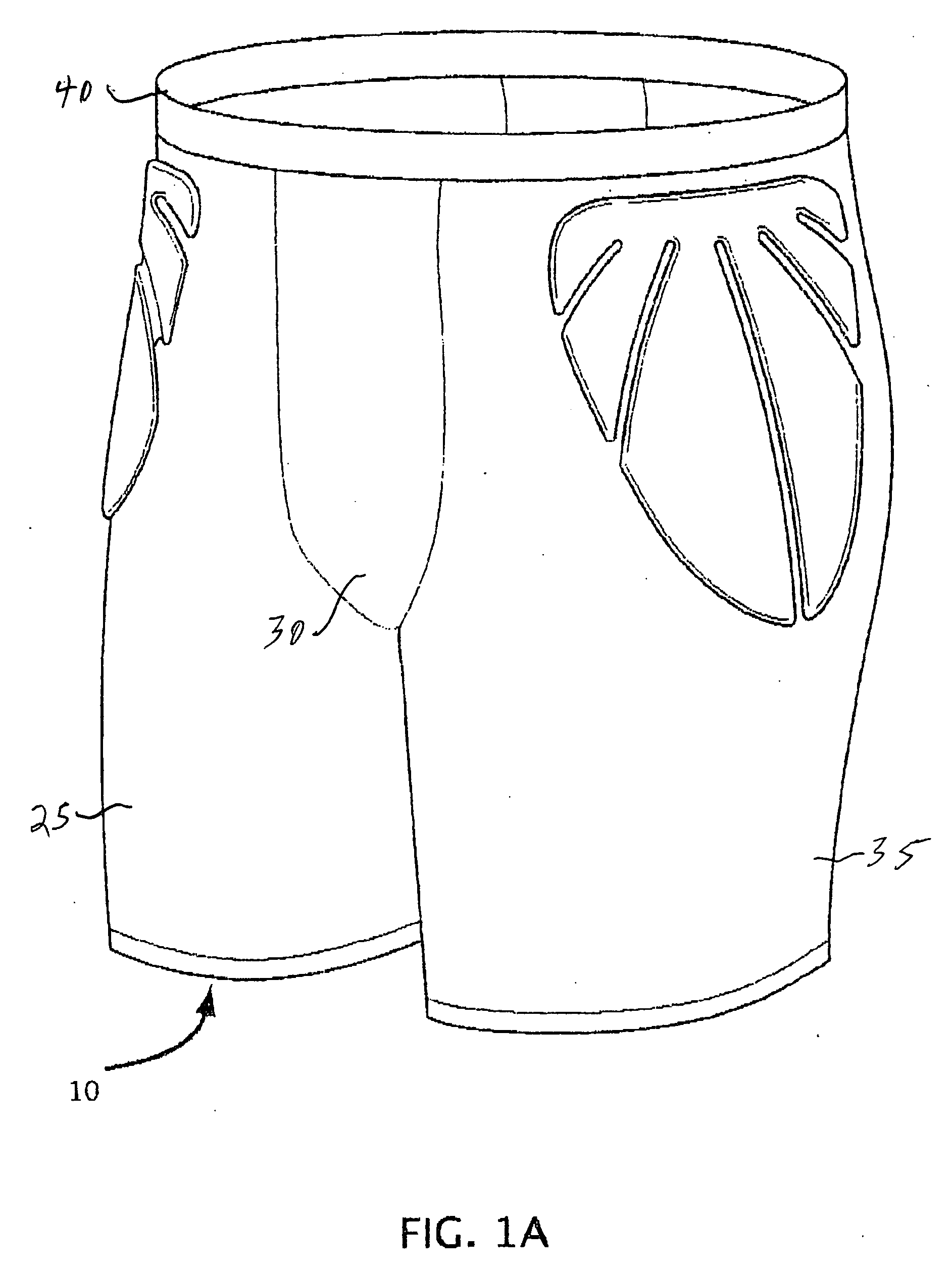

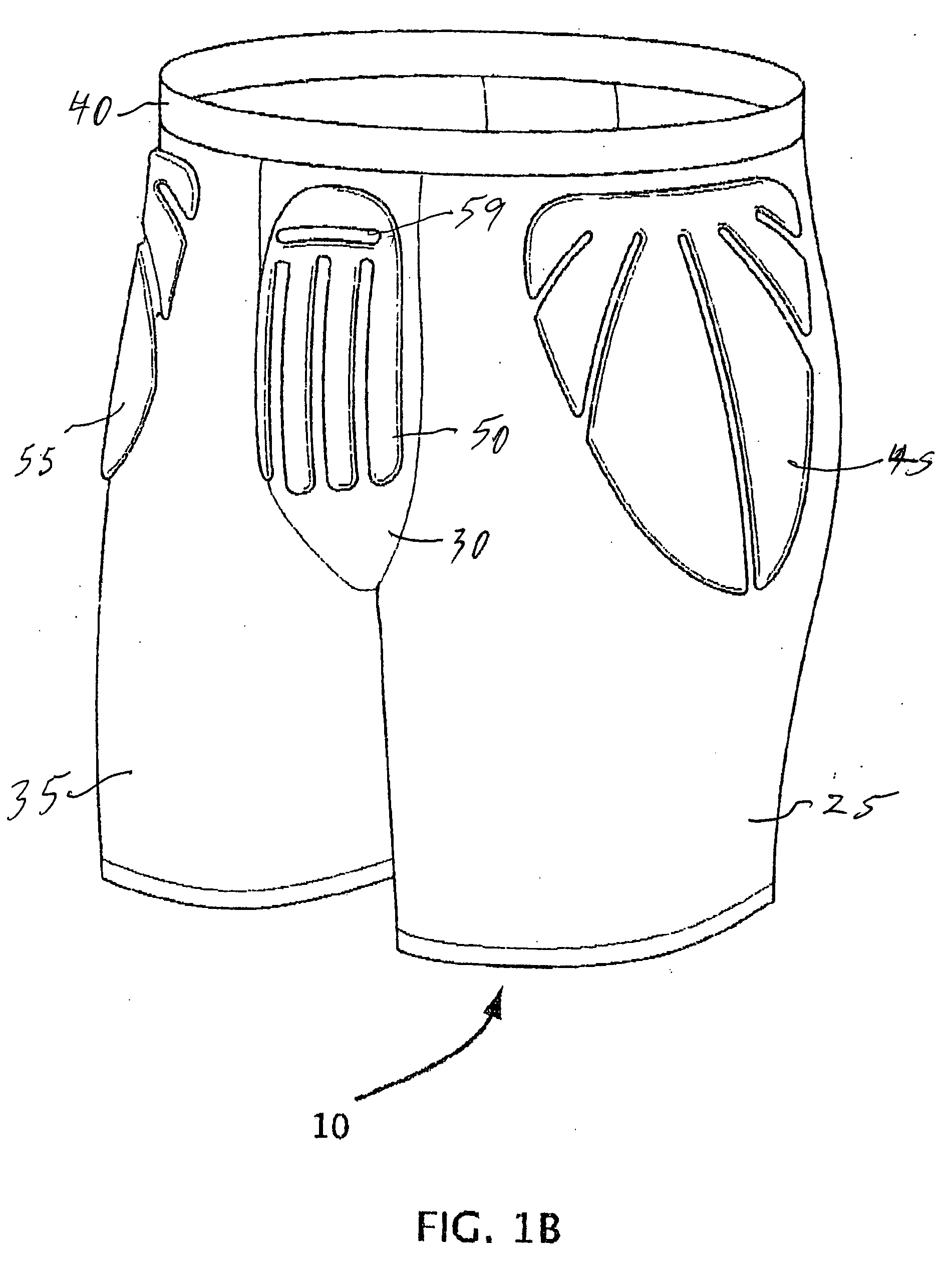

Athletic protective undergarment

ActiveUS7412731B1Avoid of propertiesInhibition strengthChemical protectionHeat protectionWelding processElectrical and Electronics engineering

A protective undergarment, such as trousers or a shirt intended for use under other clothing, employs seamless welding to permanently affix one or more protective pad segments to the main body of material. An ultra-sonic welding process may be employed. Thus, a welding material, such as a suitable polymeric film, may be used to fuse a small-area fabric member to the main body material of the undergarment, so as to form a pocket for a pad segment. To ensure that the pad segment does not fold or otherwise move within the pocket, at least one channel may be formed within the pad segment to allow welding within the interior of the pad segment.

Owner:SHOCK DOCTOR

Installation and method for manufacturing drip irrigation pipes

InactiveUS7695587B2Easy to weldWeld the drippers more reliablyMechanical working/deformationWatering devicesDrip irrigationSupport surface

The invention concerns an installation for manufacturing a drip irrigation pipe (8) formed of a pipe (8) provided with drippers (4), including a dripper feed station (37), followed by an extrusion station (10), including an extrusion head (14) producing a tubular blank (22) and means for welding the drippers (4) to the inner wall of said blank (22), characterized in that the dripper welding means (4) include a support surface (50) and a counter-support surface (56) between which the drippers (4) are pressed against said tubular blank (22) so as to be welded thereto, said support (50) and counter-support (56) surfaces being arranged upstream of the calibrating means (24).

Owner:THE MACHINES YVONAND

Double-vacuum-layer metal vacuum composite plate with edge sealed by seal strip and manufacturing method thereof

InactiveCN104746690AImprove air tightnessImprove sound insulationCovering/liningsHeat proofingThermal dilatationComposite plate

A double-vacuum-layer metal vacuum composite plate with the edge sealed by a seal strip comprises a housing, at least two core plates and a vacuum cavity and is characterized in that the housing is a low-carbon steel plate or a low-carbon steel composite plate, the core plates are located in the vacuum cavity formed through seal welding of the housing, the core plates provide additional strength for the housing and ensure the smoothness of the housing under atmospheric pressure, the vacuum cavity is welded and sealed by utilizing a glass solder in a vacuum furnace under high vacuum and high temperature, the seal strip is arranged at the welding position of the edge portion of the low-carbon steel plate, the coefficient of thermal expansion of the low-carbon steel plate is matched with that of the glass solder, a partition plate is arranged in the vacuum cavity and divides the vacuum cavity into two to form double vacuum layers, and supports are arranged in the vacuum layers and are independently manufactured or are directly formed on the core plate or the partition plate. A manufacturing method of the double-vacuum-layer metal vacuum composite plate is simple in process, and strength, heat-insulation, sound-insulation and fireproof performance and a decorative function can be improved.

Owner:戴长虹

Athletic protective undergarment

ActiveUS20080184467A1Reliable weldingGood flexibilityChemical protectionHeat protectionUltrasonic weldingEngineering

A protective undergarment, such as trousers or a shirt intended for use under other clothing, employs seamless welding to permanently affix one or more protective pad segments to the main body of material. An ultrasonic welding process may be employed. Thus, a welding material, such as a suitable polymeric film, may be used to fuse a small-area fabric member to the main body material of the undergarment, so as to form a pocket for a pad segment. To ensure that the pad segment does not fold or otherwise move within the pocket, at least one channel may be formed within the pad segment to allow welding within the interior of the pad segment.

Owner:SHOCK DOCTOR

Full self-control non-woven fabrics thermal compression welding device and method

ActiveCN101508186AReliable weldingGuaranteed pressureMechanical working/deformationSeaming textilesEngineeringNonwoven fabric

The invention relates to rapid, convenient, intellectually-controlled full autocontrol nonwoven fabric hot-press welding equipment and a welding method. The full autocontrol nonwoven fabric hot-press welding equipment comprises a PLC controller, a stand, a lower electric heating welding wheel axle, an upper electric heating welding wheel axle, a step motor, an oil cylinder, wherein the upper part of the stand has a groove structure; the lower part of the stand is provided with a hole; the lower electric heating welding wheel axle is positioned in the hole of the lower part of the stand by a lower slide block; the lower end face of the lower slide block is pressed on a pressure sensor; the upper electric heating welding wheel axle is positioned in a groove of the upper part of the stand; the lower end face of an upper slide block is positioned on an adjustable oblique wedge block of a screw rod; the adjustable oblique wedge block of the screw rod passes through a transmission mechanism and is driven by the step motor; the power end of the step motor is controlled by the PLC controller; the oil hydraulic cylinder is positioned on the upper end of the stand; a piston of the oil hydraulic cylinder is connected with the upper slide block by a connecting rod and a connecting plate; and the operation of the oil hydraulic cylinder is controlled by the PLC controller. The equipment has the advantages of: 1, realizing the reliable welding of more than four layers of nonwoven fabric on a production line at an online speed of more than 120 meters per minutes; and 2, according to predetermined welding pressure and welding temperature, freely and automatically carrying out free micro-adjustment by online construction and the change of welding temperature and ambient temperature and ensuring pressure and temperature needed for high-efficient welding.

Owner:杭州珂瑞特新机械制造有限公司

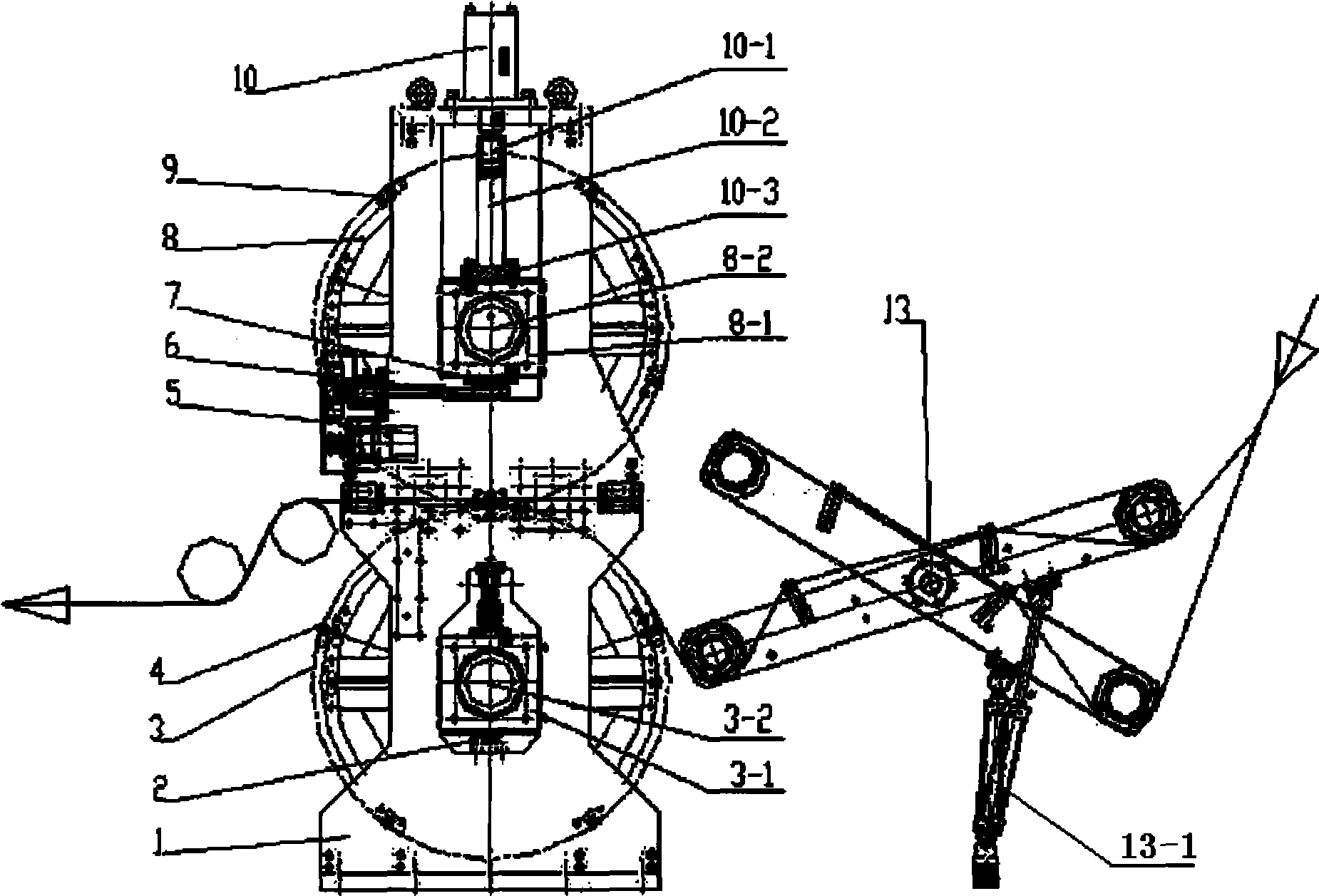

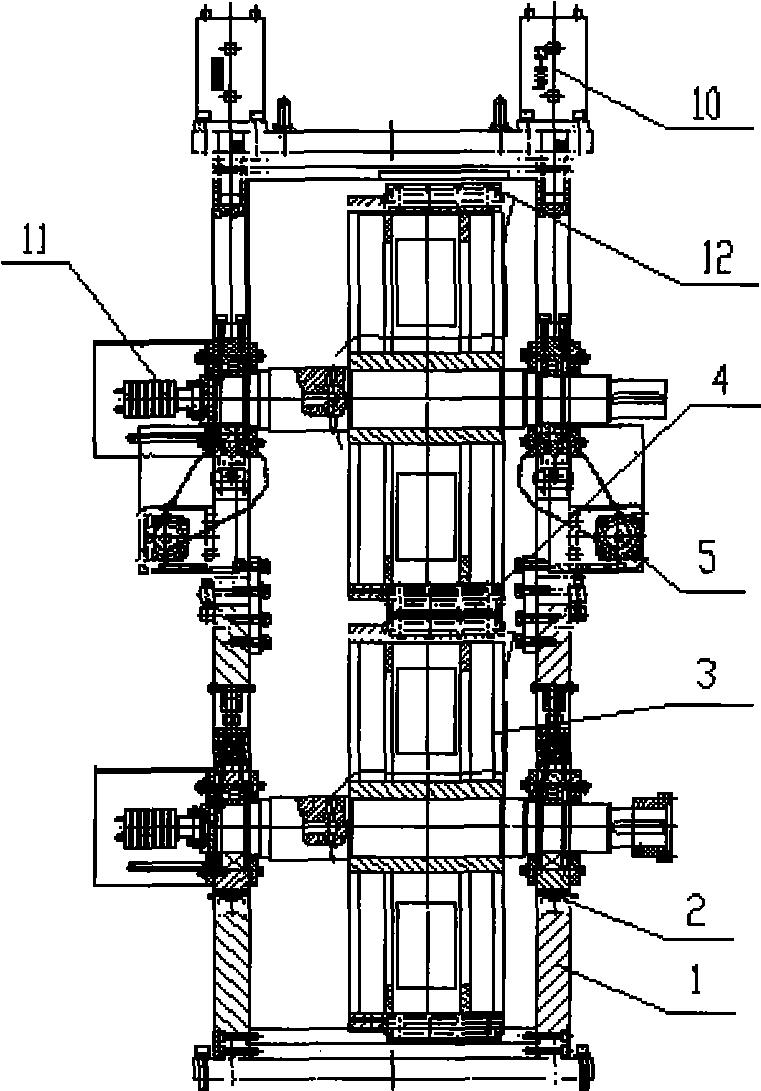

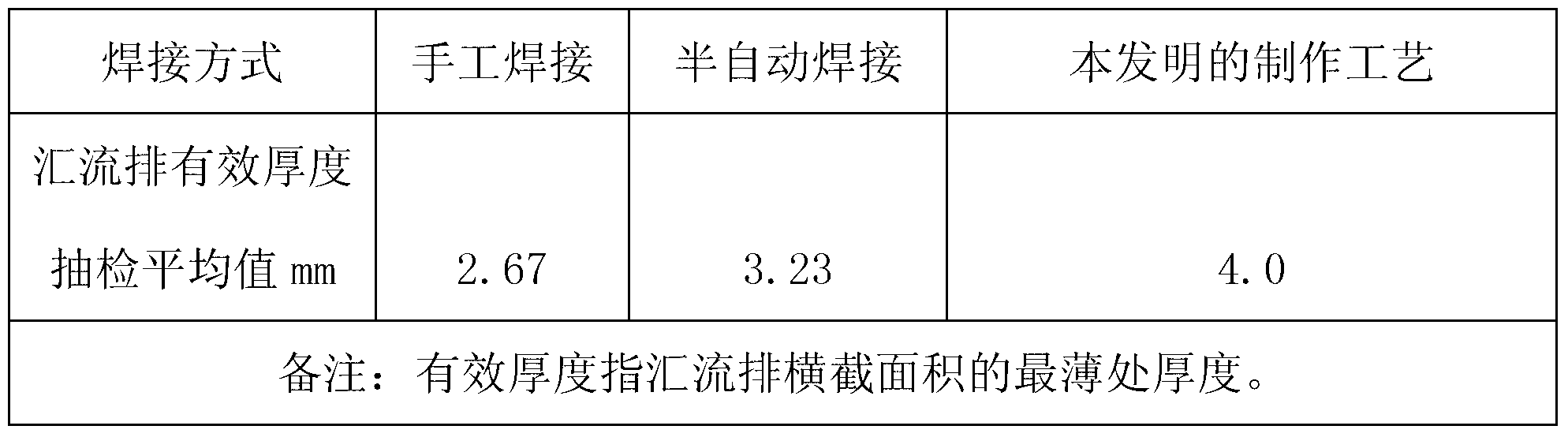

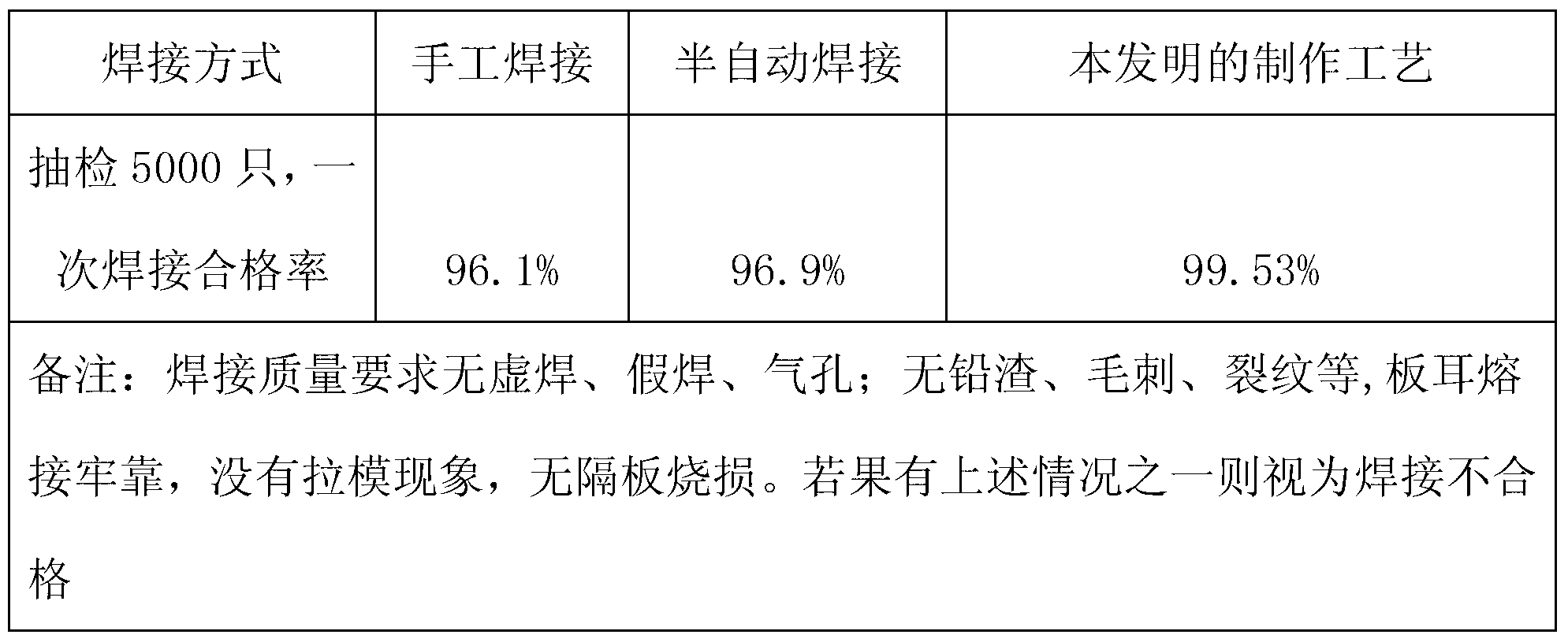

Production process of inner formation storage battery

ActiveCN103268963AGood corrosion resistanceNo burning lossFinal product manufactureCell component detailsGrid alloyL&D process

The invention discloses a production process of an inner formation storage battery, and belongs to the field of a lead-acid storage battery, and solves the easily occurring welding quality problem of a bus-bar and a lug. The process comprises the following steps of loading a plate group into an assembling box, arranging a lug, cutting and brushing the lug, dipping soldering flux, cast welding, inspecting and qualification and down-conversion, wherein the cast welding flow is carried out by adopting a cast welding machine. The cast welding flow comprises the following steps of (1) heating a lead pot; (2) loading a mold and preheating the mold; (3) scraping the lead liquid; (4) cast welding the plate group; (5) cooling the plate group through water; (6) cooling the plate group collectively through water and air; (7) cooling the plate group through the air; (8) loading the mold and preheating the mold again; and (9) loading the plate group into a tank. The production process is suitable for the cast welding of the inner formation storage battery with positive grid alloy being lead calcium tin aluminum or lead calcium alloy series grid.

Owner:CHAOWEI POWER CO LTD

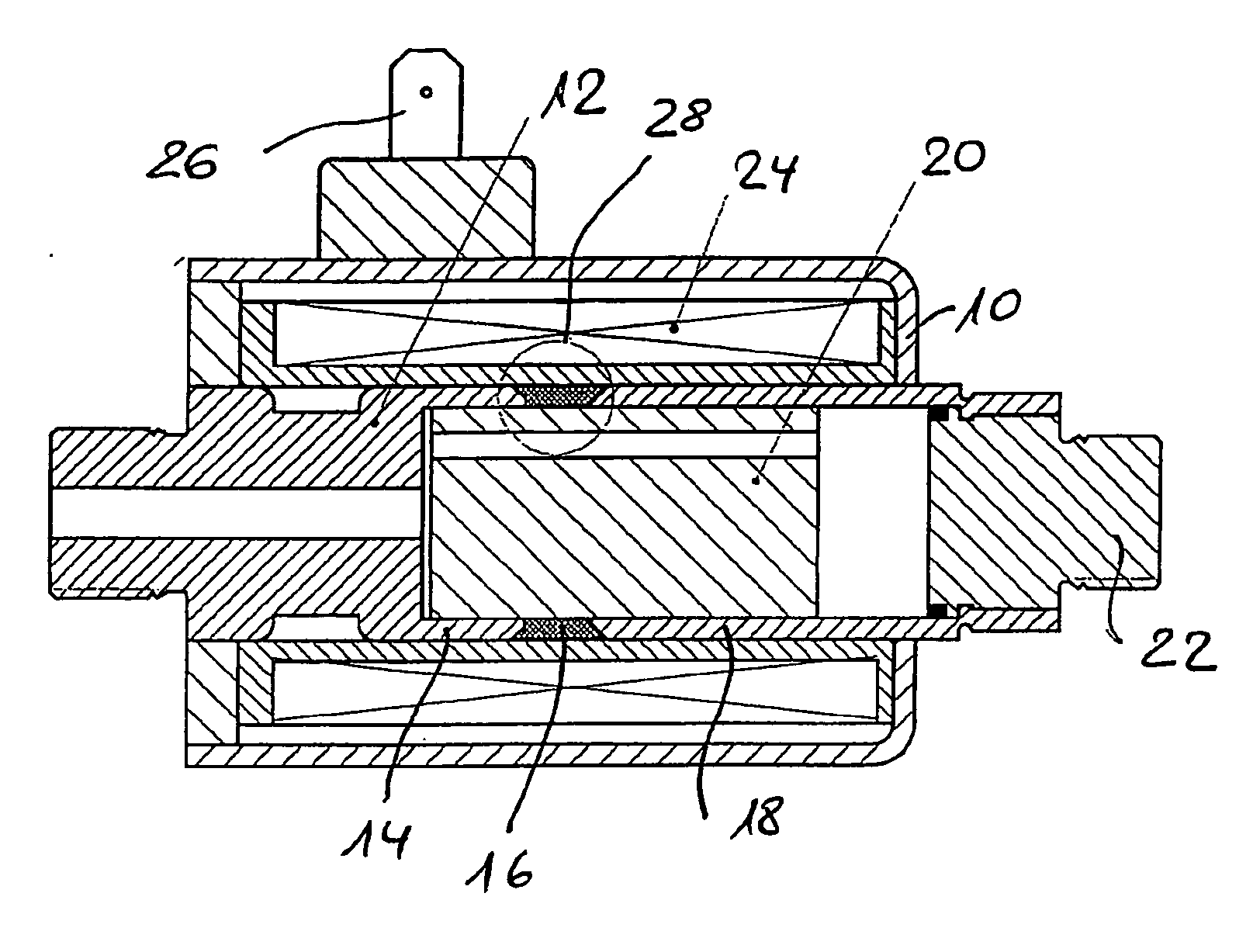

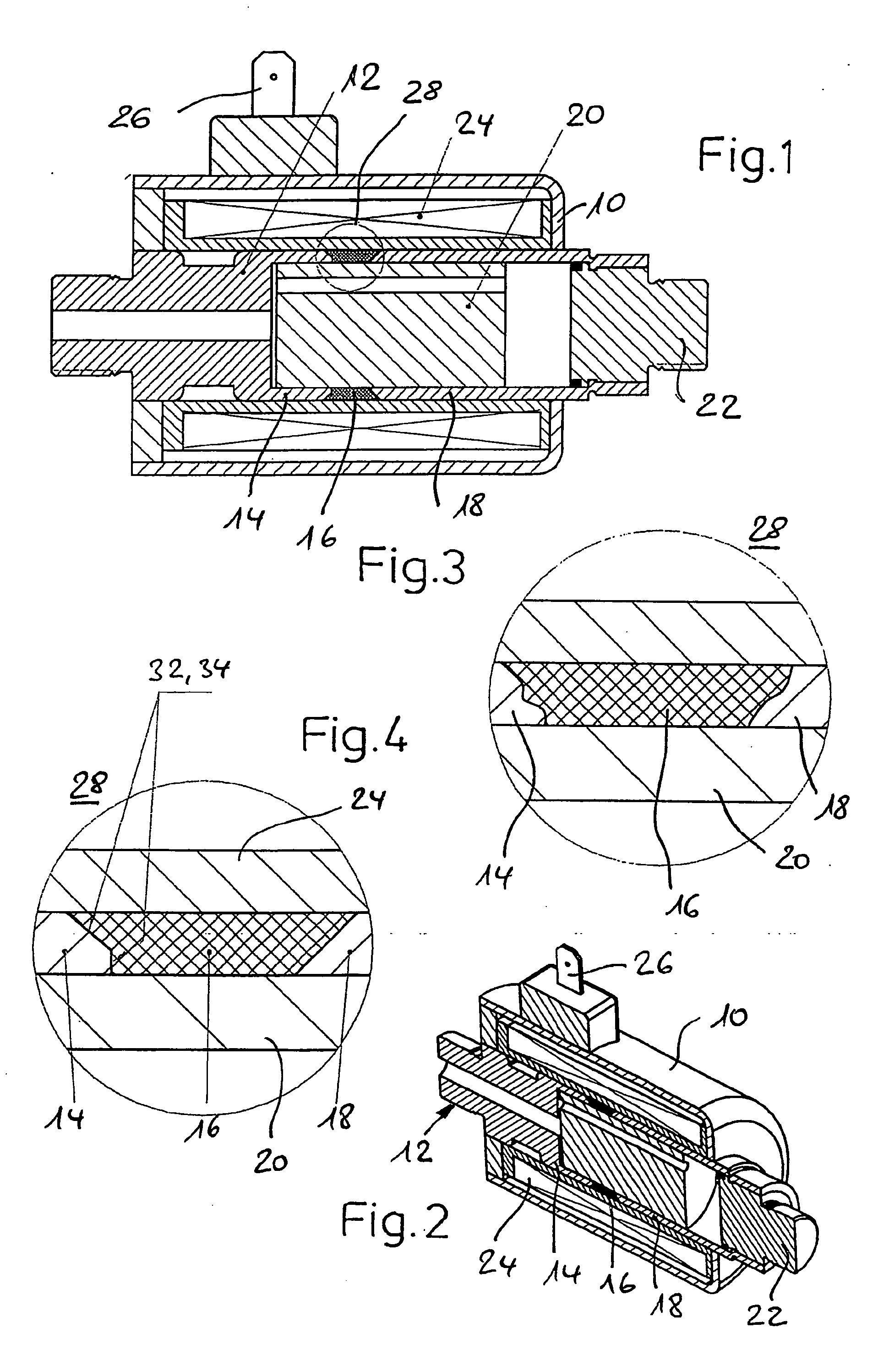

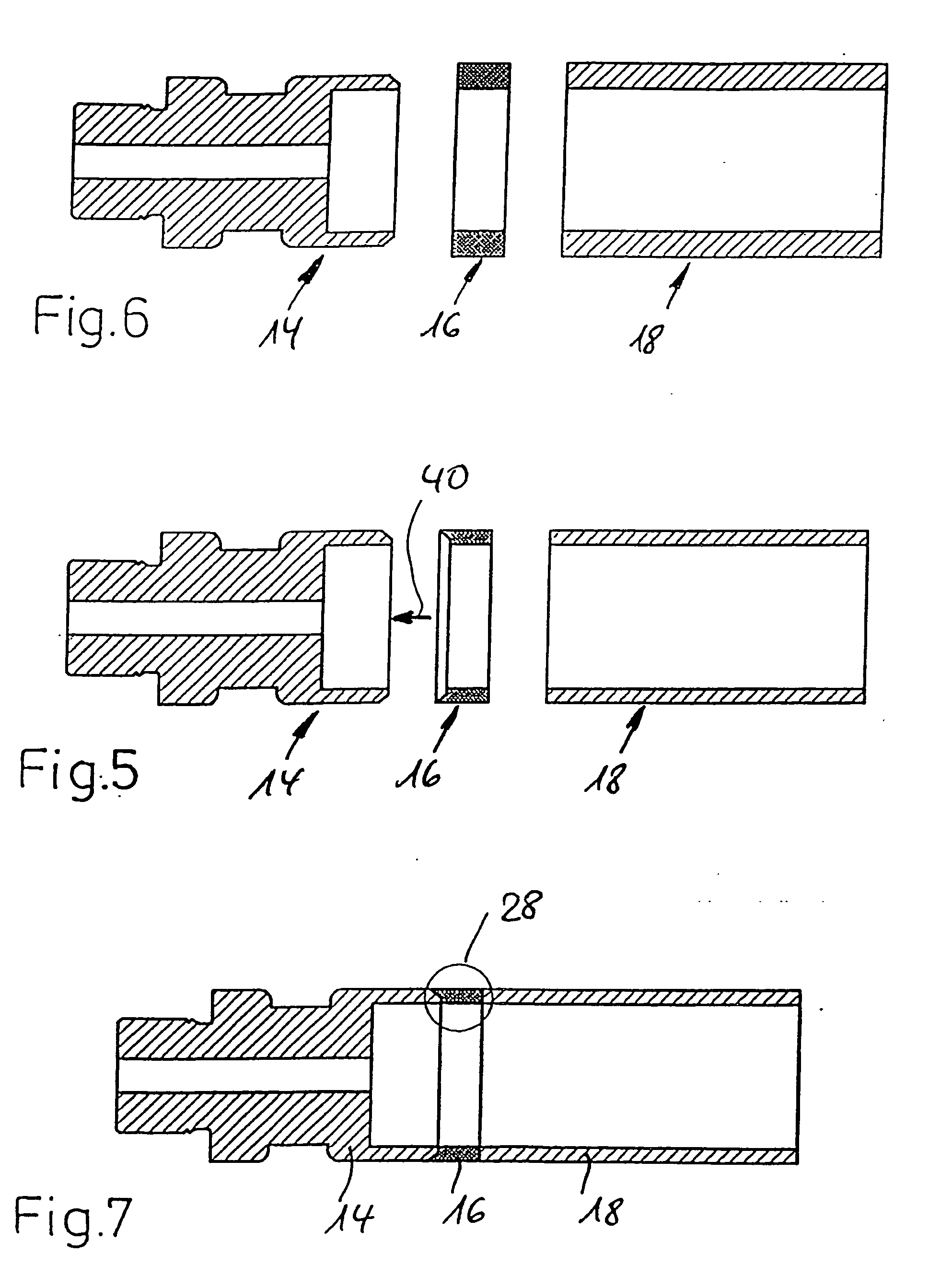

Electromagnetic actuating device

InactiveUS20060028311A1Low costImprove electromagnetic performanceElectromagnets with armaturesNon-electric welding apparatusFriction weldingEngineering

The invention relates to an electromagnetic actuating device, comprising an armature (20) which is provided in a housing (10) in such a way that it can be moved in an axial direction relative to a magnet frame (12) consisting of a core section (14) and a yoke section (18), and a coil device (24) which can be subjected to an electrical current in order to generate the movement, wherein the magnet frame is designed in a hollow-cylindrical manner in such a way that it at least partially surrounds the armature and comprises an intermediate section (16) consisting of non-magnetic material between the core section and the yoke section, wherein a permanent material connection is established in at least one of the cross-over areas (28) between the yoke section and the intermediate section and between the intermediate section and the core section by means of a friction welding method.

Owner:ETO MAGNETIC GMBH

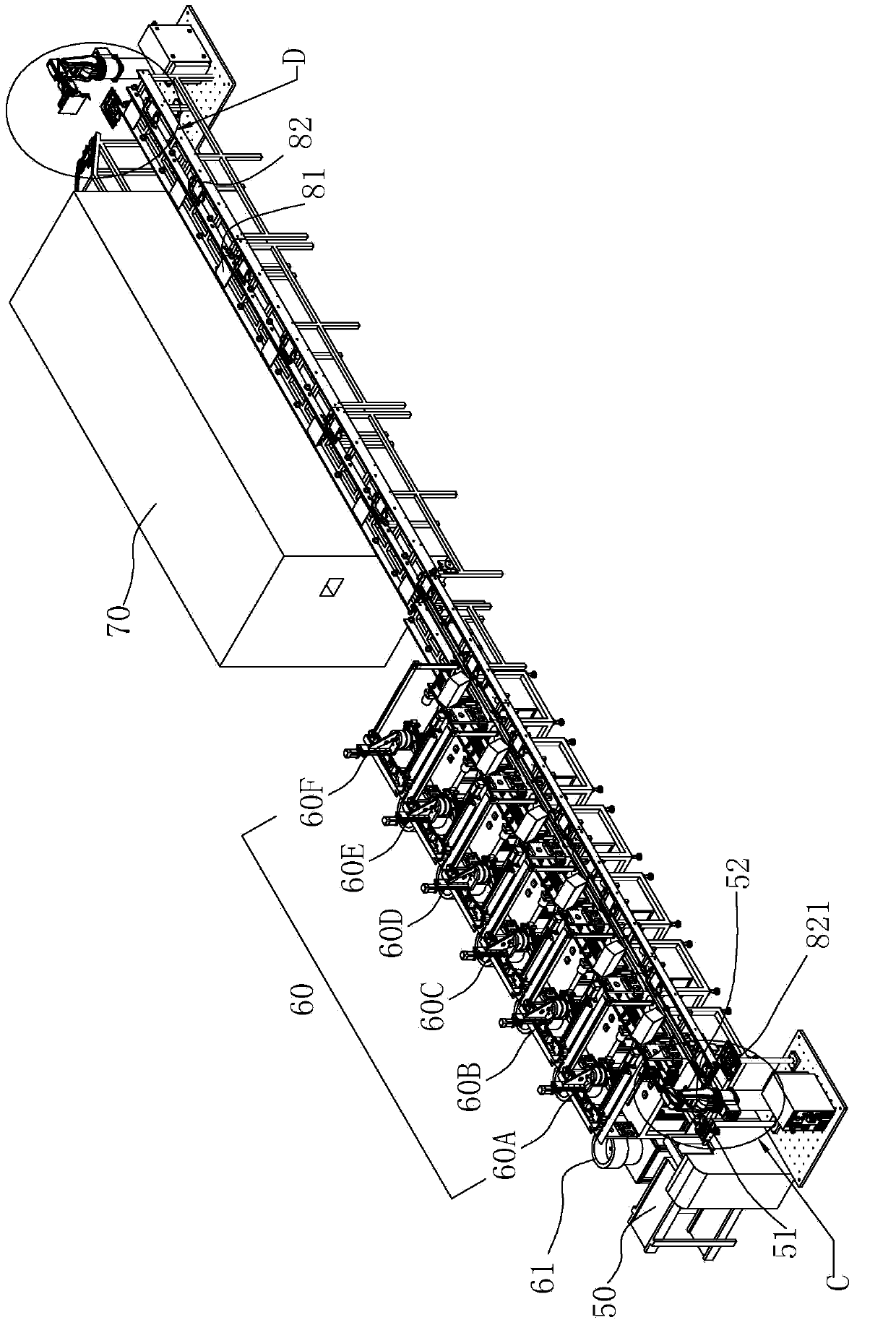

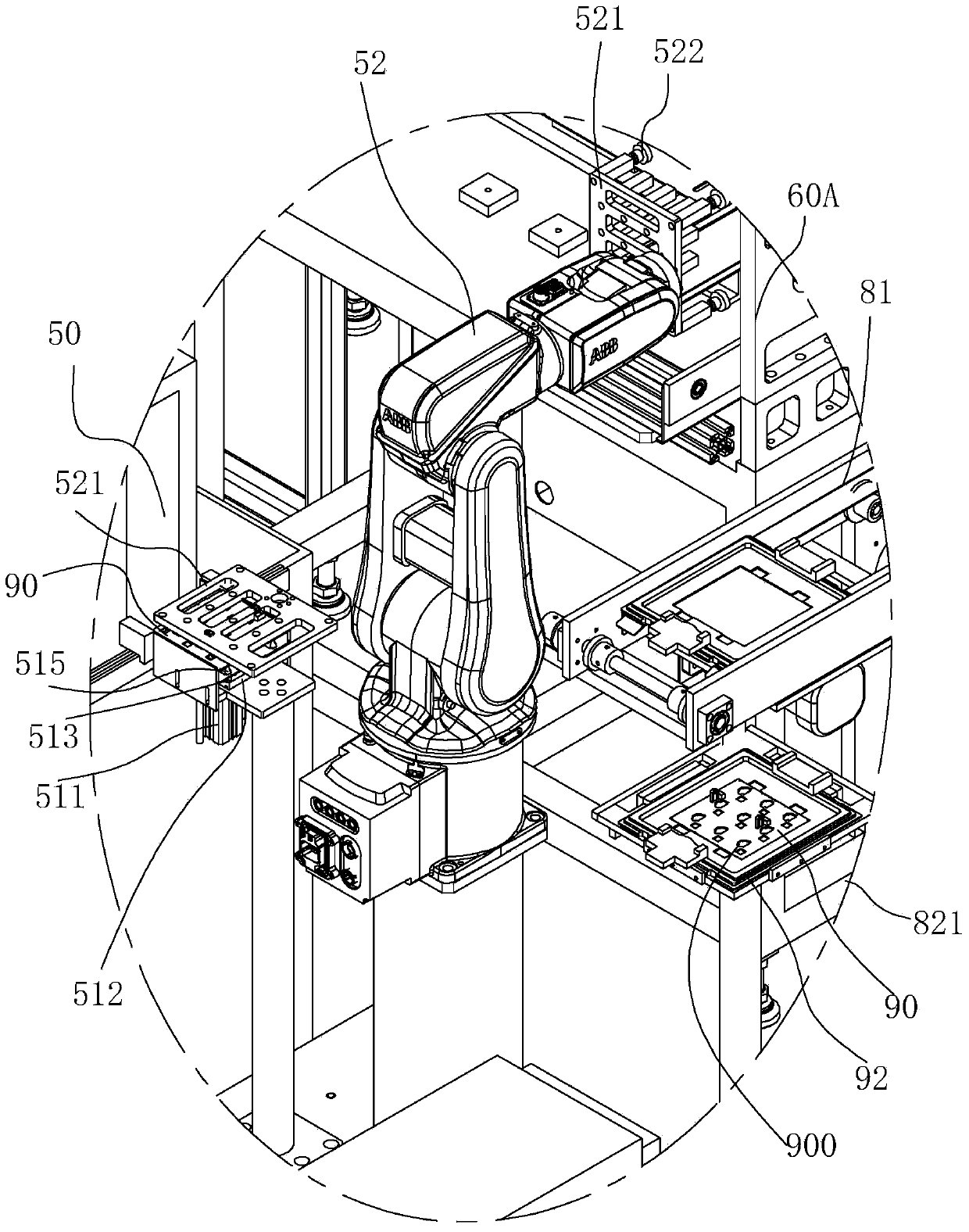

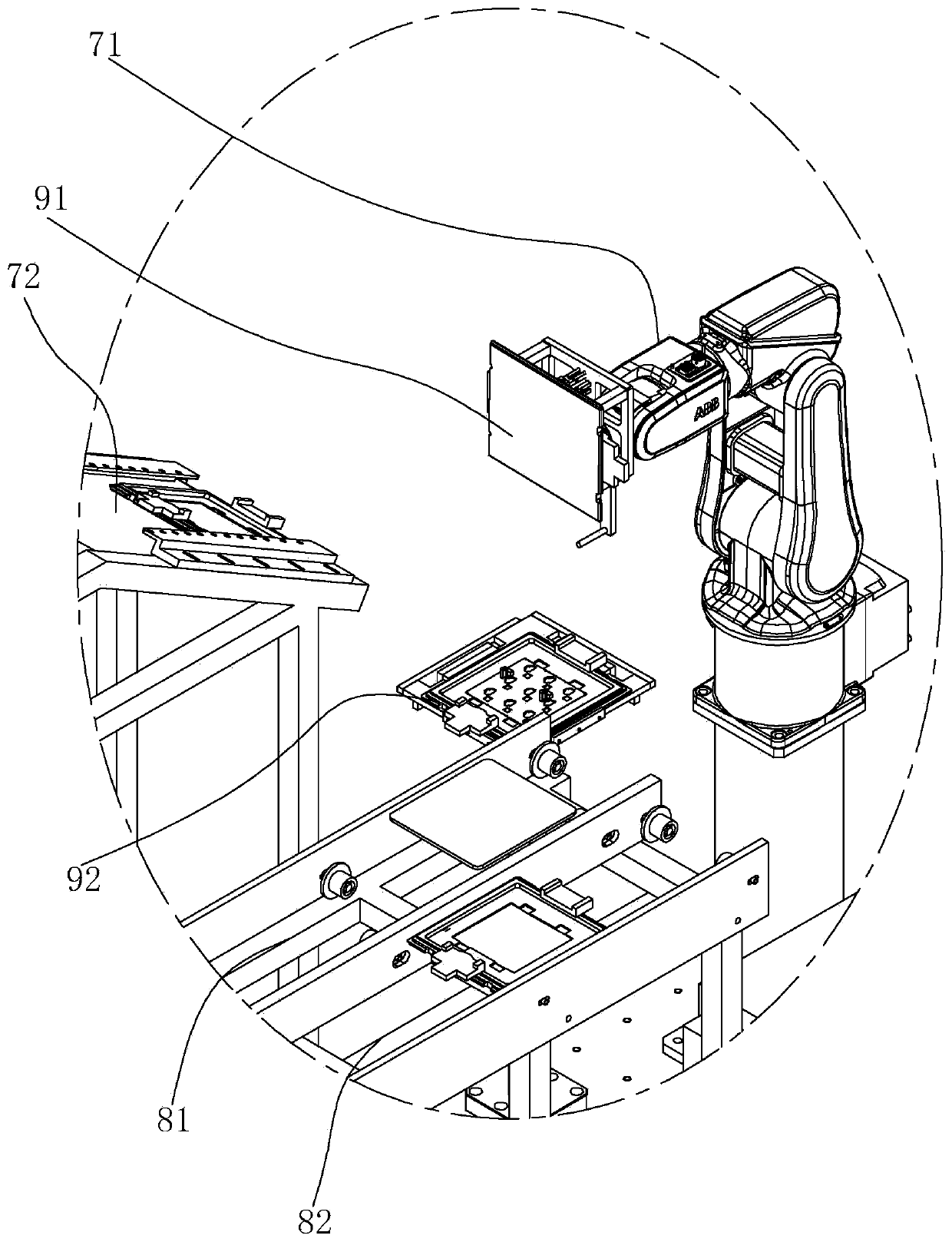

Multi-station plug-in mounting production line and automatic mouse PCB (printed circuit board) production line

ActiveCN103747665AImprove reliabilityImprove stabilityPrinted circuit assemblingElectrical componentsProduction linePrinted circuit board

The invention discloses a multi-station plug-in mounting production line and an automatic mouse PCB (printed circuit board) production line. The multi-station plug-in mounting production line comprises a PCB loading device, a plurality of sets of sequentially butted plug-in mounting equipment, a reflow welding machine arranged at the outer end of the last plug-in mounting equipment, an unloading device arranged at the material discharging end of the reflow welding machine, an upper cover conveying device which is arranged from the material discharging end of the reflow welding machine to the outer end of the last plug-in mounting equipment, and a bottom cover conveying device arranged from the material discharging end of the reflow welding machine to the PCB loading device, wherein the first plug-in mounting equipment is butted with the PCB loading device. According to the multi-station plug-in mounting production line, a bottom cover is used as a lower part of a plug-in mounting jig; after a PCB is subjected to plug-in mounting at multiple stations, an upper cover is used as an upper part of the jig; the upper cover is fixedly connected with the bottom cover, so that an electronic element can be reliably fixed on the PCB, and the electronic element which is plugged into the PCB but is not completely fixed can be reliably welded in a process of the reflow welding machine; therefore the reliability and the stability of a PCB product can be improved.

Owner:SHENZHEN RAPOO TECH

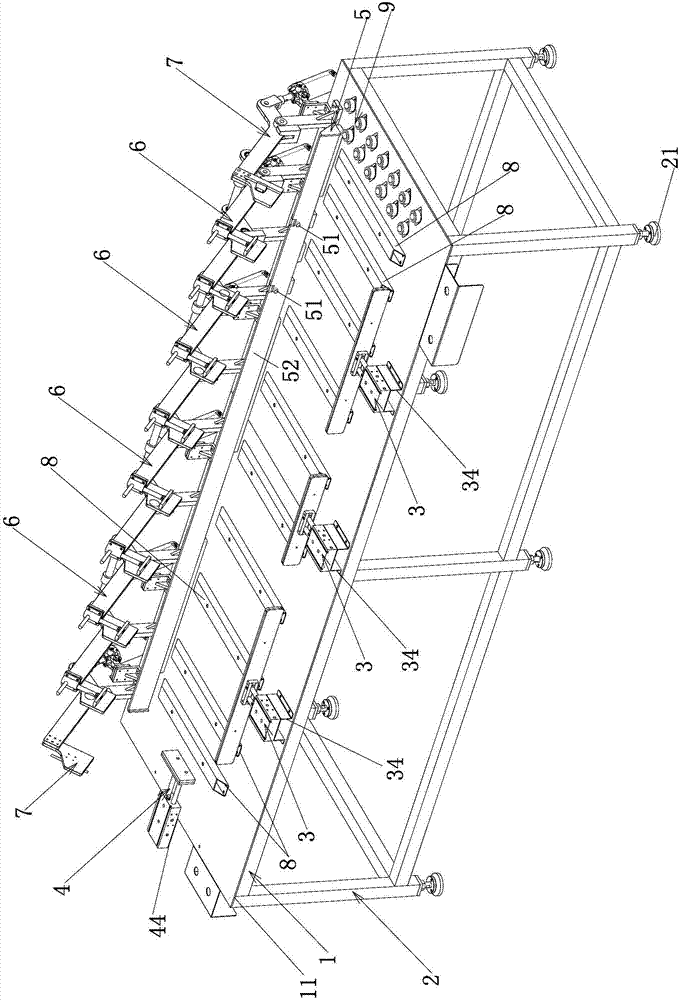

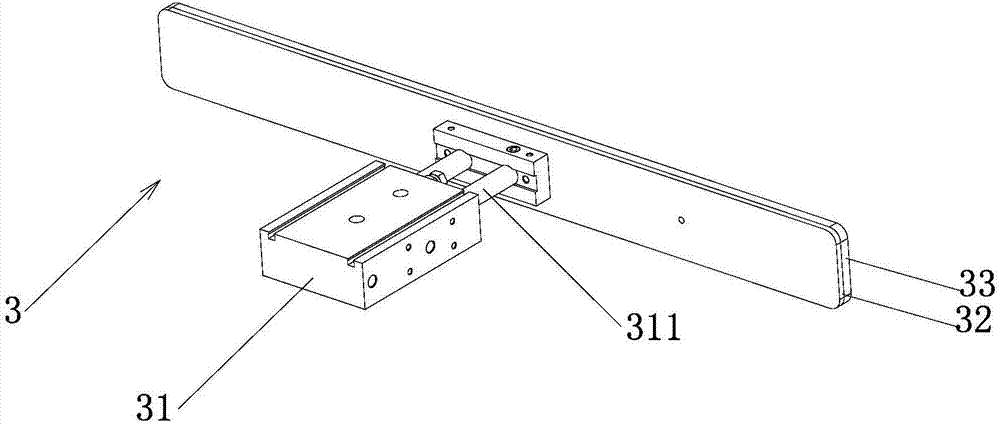

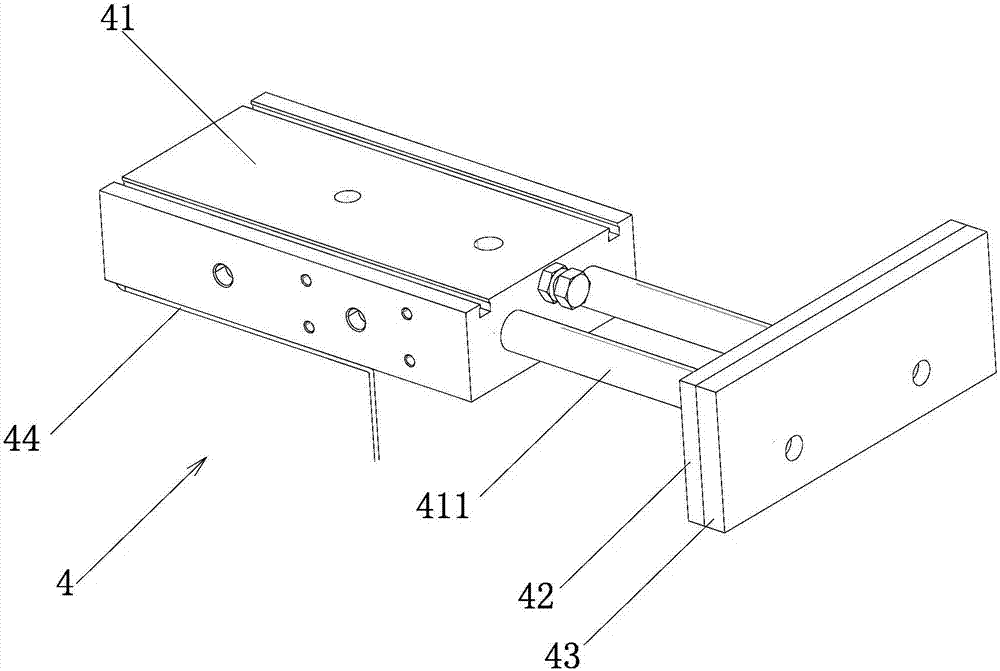

Welding and positioning tool platform for aluminium alloy template

PendingCN107138899AReduce labor intensitySimple and fast operationWelding/cutting auxillary devicesAuxillary welding devicesMetallurgyEngineering

A welding and positioning tool platform for an aluminium alloy template comprises a working platform supported on a frame body, at least one lateral positioning and pressing device arranged on the platform surface of the working platform, a longitudinal positioning and pressing device arranged at one end of the platform surface in the length direction, a positioning backing plate arranged in the length direction of the platform surface and located on one side of the platform surface, duplex overturning mechanisms close to the positioning backing plate as well as two single overturning mechanisms located at two ends of the platform surface in the length direction separately; multiple transverse supporting ribs are arranged on the platform surface at intervals in parallel; the positioning backing plate is used for positioning a to-be-welded aluminium alloy template main body; the at least one lateral positioning and pressing device presses the to-be-welded aluminium alloy template main body transversely; the longitudinal positioning and pressing device presses the to-be-welded aluminium alloy template main body in the length direction; the duplex overturning mechanisms are used for positioning and pressing to-be-welded transverse ribs; and the two single overturning mechanisms are used for positioning and pressing two to-be-welded gland plates separately. The platform is accurate in positioning, simple to operate and convenient in welding.

Owner:SHANDONG XINHUOXIN MATERIAL TECH CO LTD

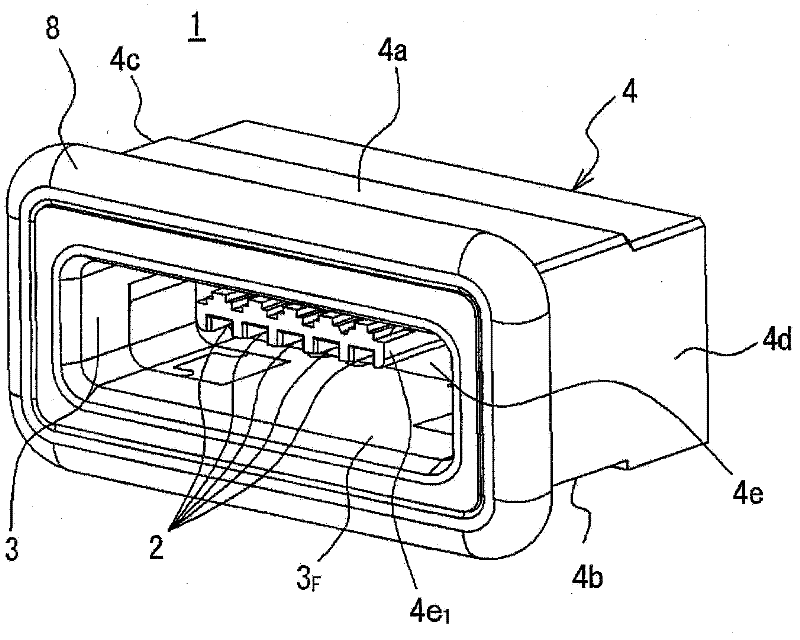

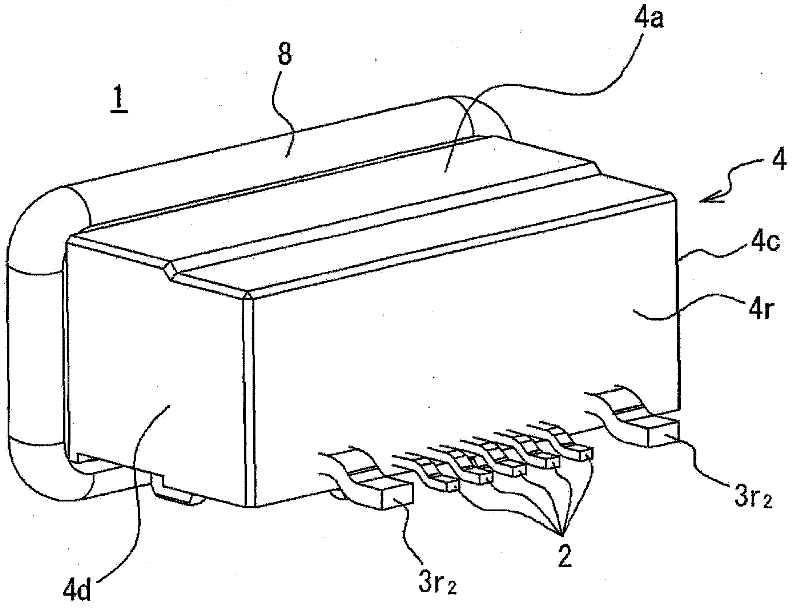

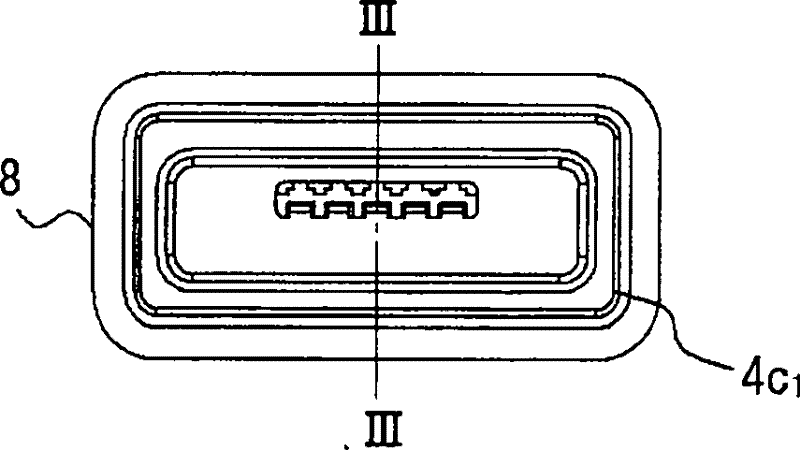

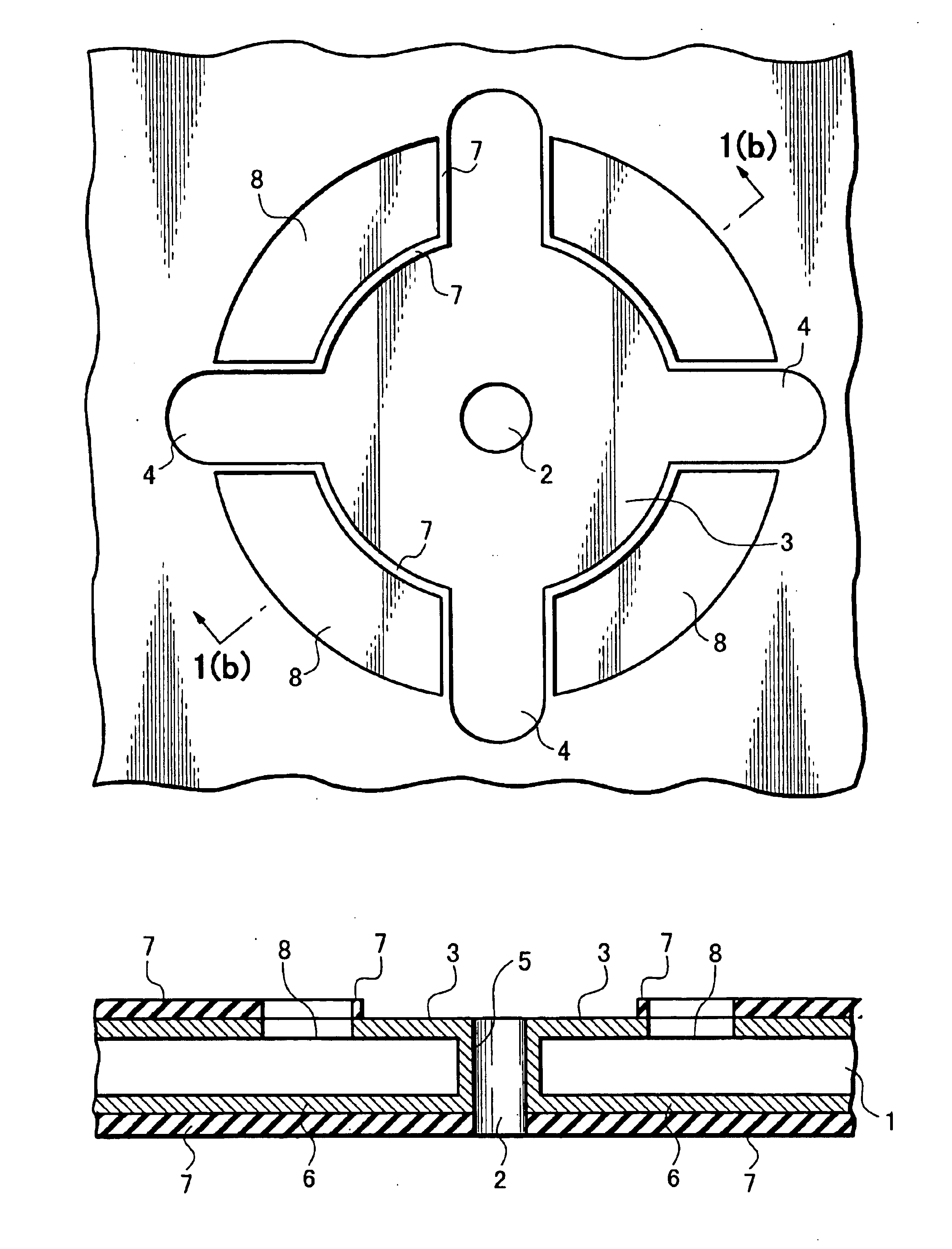

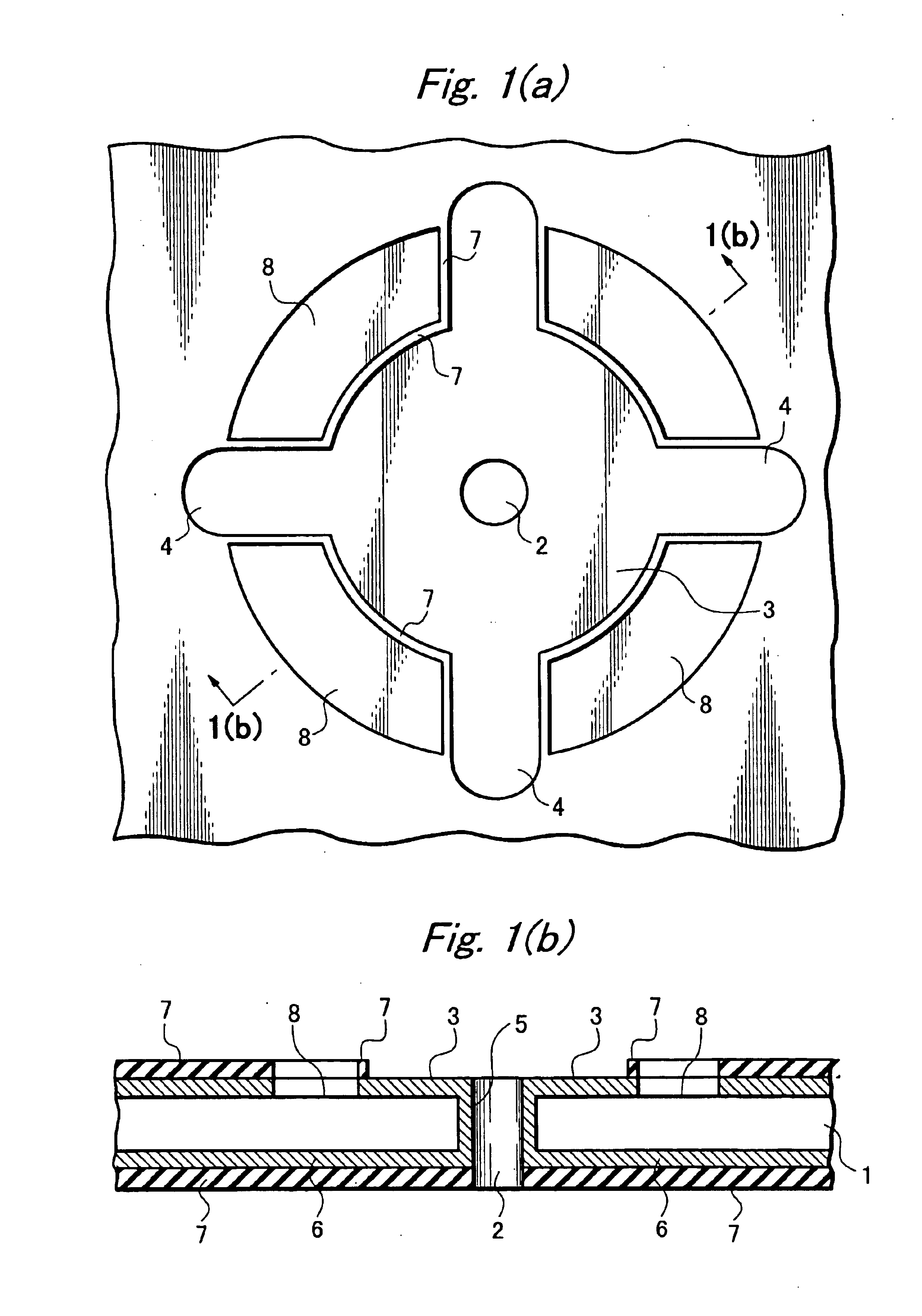

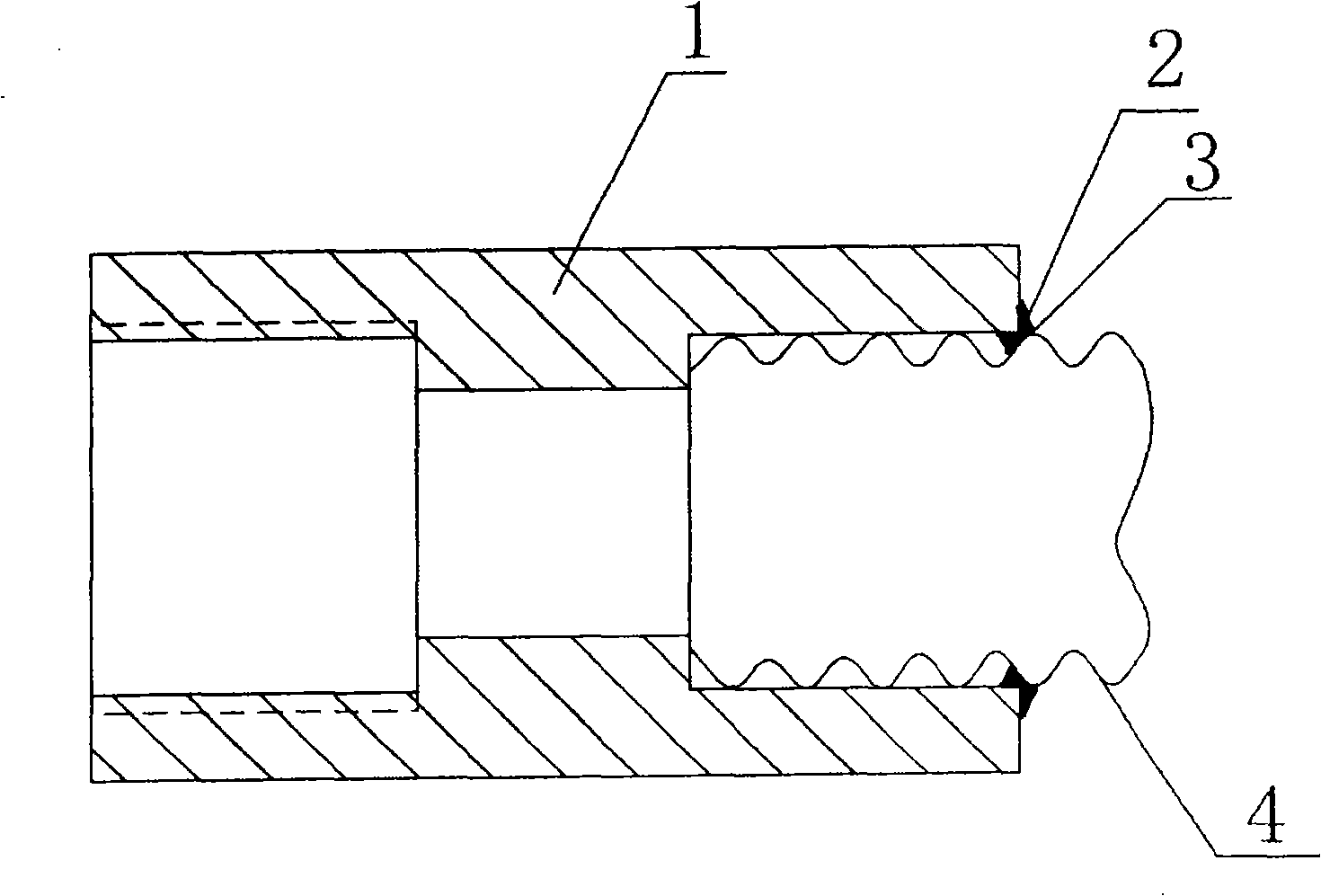

Water-proof connector and producing method thereof

InactiveCN102544888AImprove waterproof performancePrevent intrusionContact member cases/bases manufactureCouplings bases/casesEngineeringSealant

The invention provides a water-proof connector and a producing method thereof. The water-proof connector improves the waterproofness of a molded connector formed by inserting a metallic connector component in electrically insulating resin. The water-proof connector (1) is composed of a molded connector which is obtained in a manner that the metallic connector components forming the connector are inserted in the electrically insulating resin, enabling the electrically insulating resin to be a connector housing. The metallic connector components are a contact point (2) and a metallic cover (3), wherein the contact point (2) enables one end to electrically contact with the contact point of the connector; the metallic cover (3) is composed of metallic tube-shaped body which has an opening at at least one end and has a cavity hole communicated with the opening. The internal part of the opening is an insertion part for other connectors to insert. Water-proof sealants (Li1) for water resistance and sealing are filled in the contact point (2) and between the metallic cover (3) and the connector housing (4).

Owner:JST MFG CO LTD

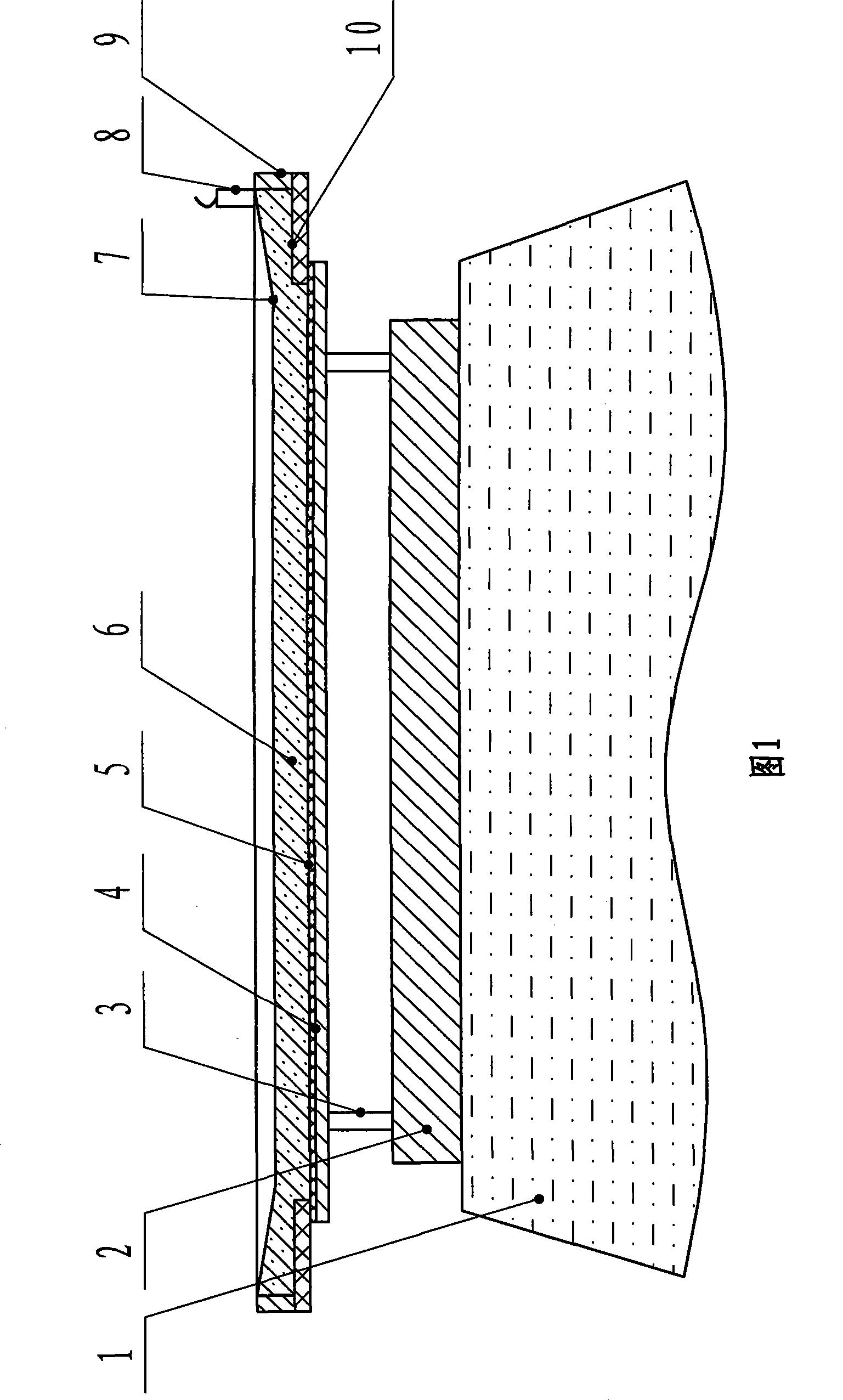

Method for producing copper alloy plate composite steel plate

InactiveCN101372065AGuaranteed stiffnessReliable weldingWelding/soldering/cutting articlesNon-electric welding apparatusSheet steelHardness

The invention provides a method used for manufacturing a copper alloy composite steel plate; the substrate material is carbon steel plate and the composite plate is copper alloy plate; the manufacture method comprises the manufacture steps as follows: I matching: copper alloy composite plate and normal carbon steel plate which comply with the national standard and usage technical requirement according to the detection are combined in pairs according to the requirement of final products; II: stress troughs of 8-10mm deep and 10-12mm wide are arranged at the circumference of the copper alloy composite plate; III: grinding the surface: oxides and sundries on the explosive combination surface of the substrate and the composite plate are removed; subsequently, a protection layer is uniformly coated on the contact surface of composite plate and dynamite; IV explosive welding: the composite plate and the substrate are supported by copper fulcrum or aluminium fulcrum and welded together by virtue of explosive welding. The combination rate of the manufacture method of the copper alloy plate and the composite steel is more than 99%, with the hardness of HB130-150, thus completely meeting the requirement of copper motor plate on the hardness.

Owner:太原钢铁(集团)有限公司

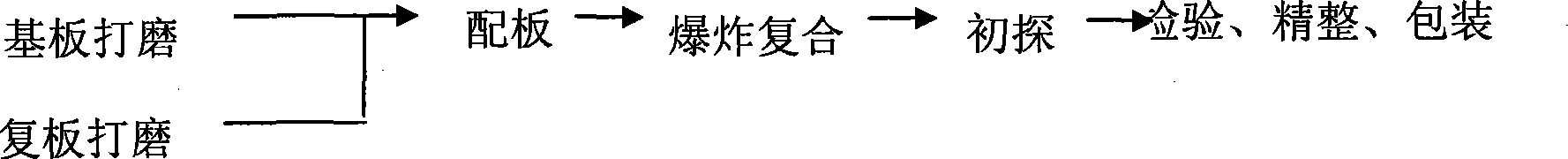

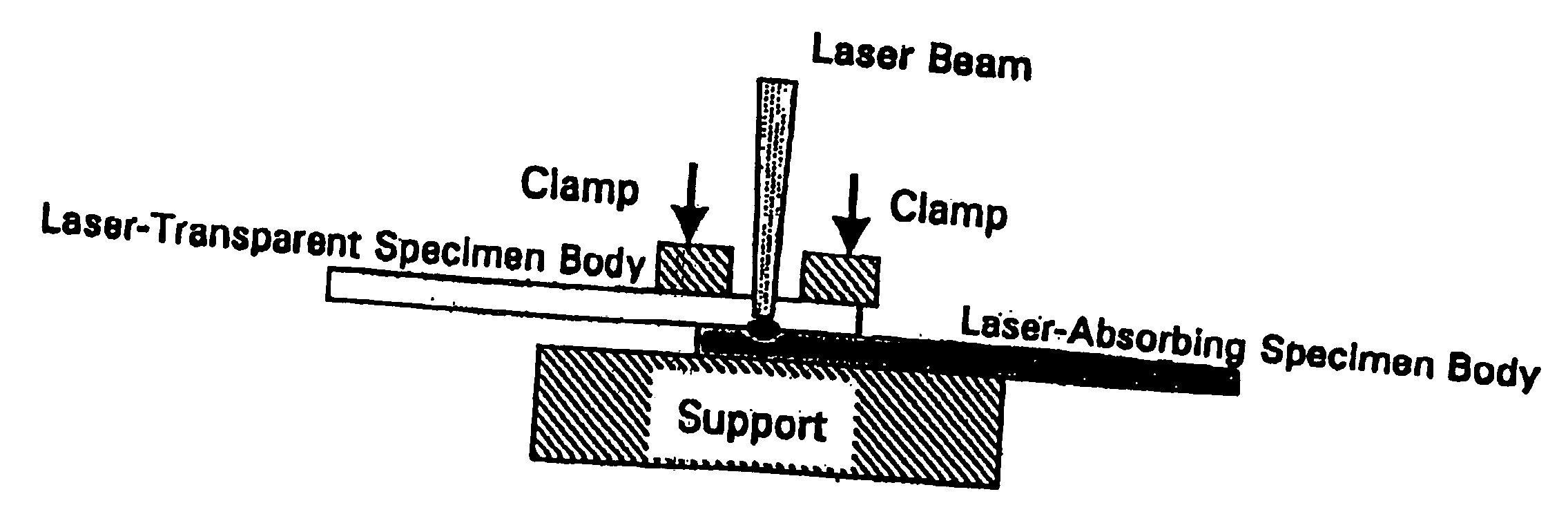

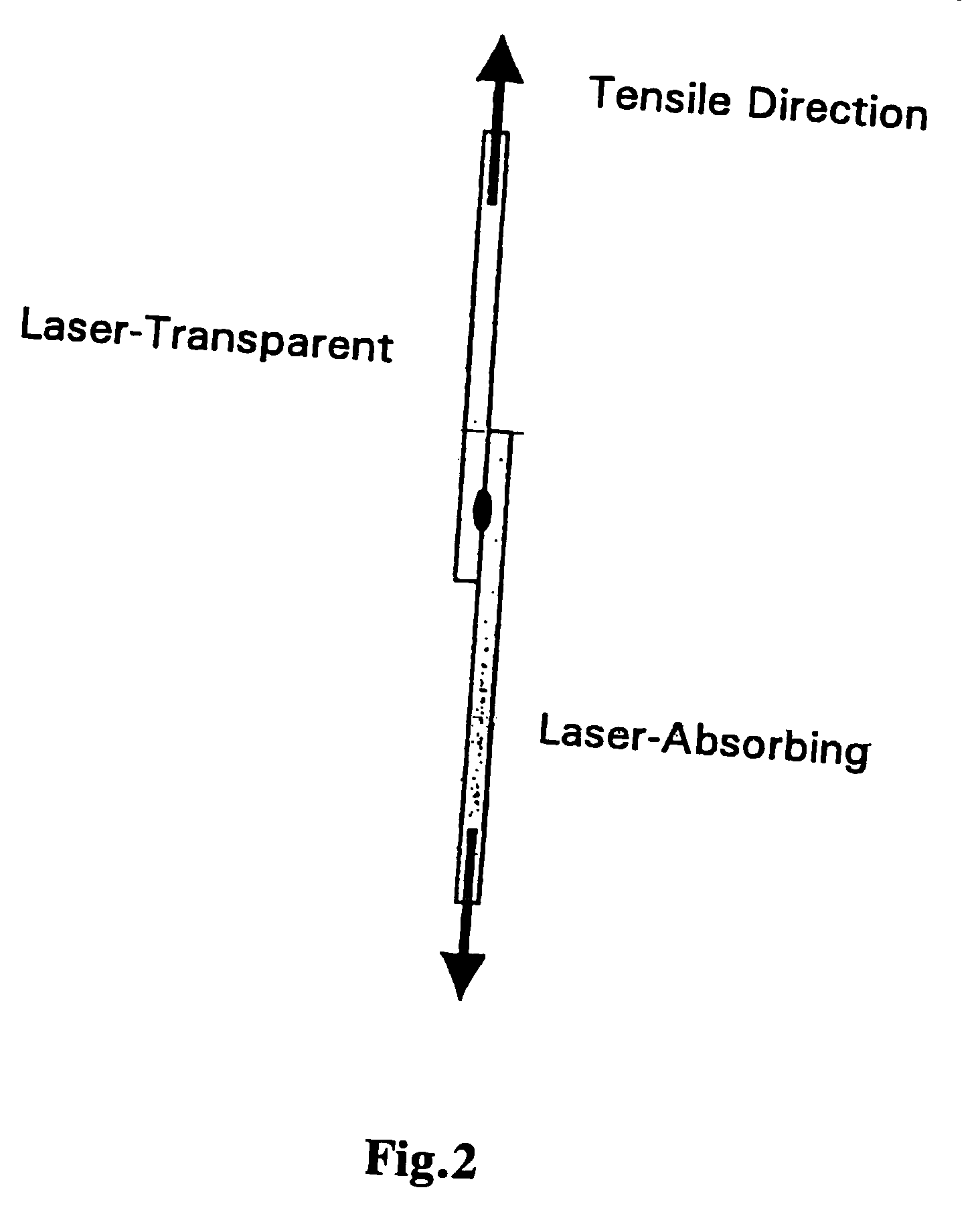

Laser-absorbing molding compositions with low carbon black contents

InactiveUS20050217790A1Improve surface qualitySimilar optical appearanceLamination ancillary operationsLaminationOptoelectronicsLaser light

The present invention relates to natural-colored and pigmented thermoplastic molding compositions and molded parts fabricated therefrom that are laser-absorbing at least in partial spectral regions of the wavelength range from 700 to 1200 nm and that can be welded by laser beam welding and to molded parts that are transparent or translucent to laser light.

Owner:JOACHIMI DETLEV +4

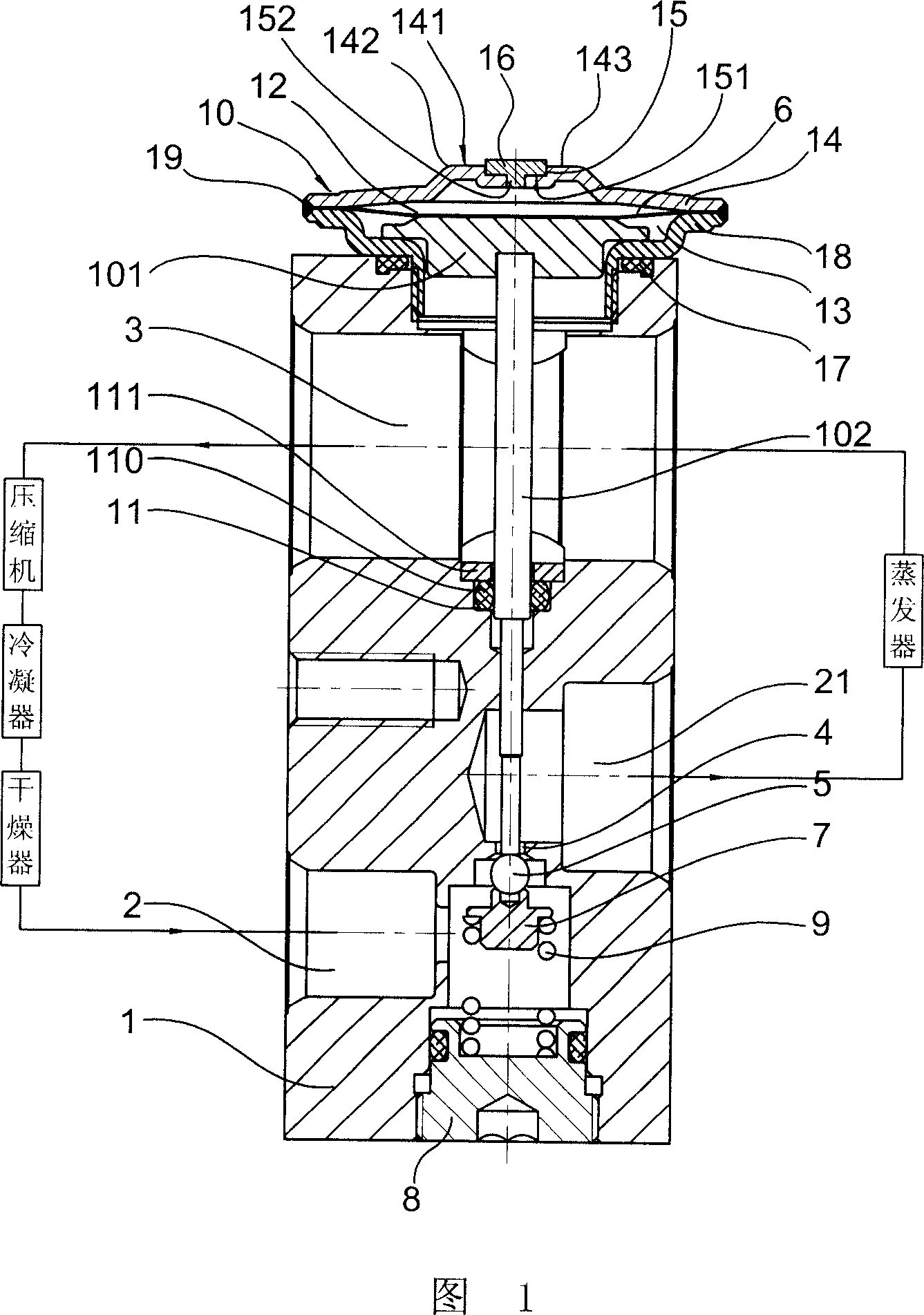

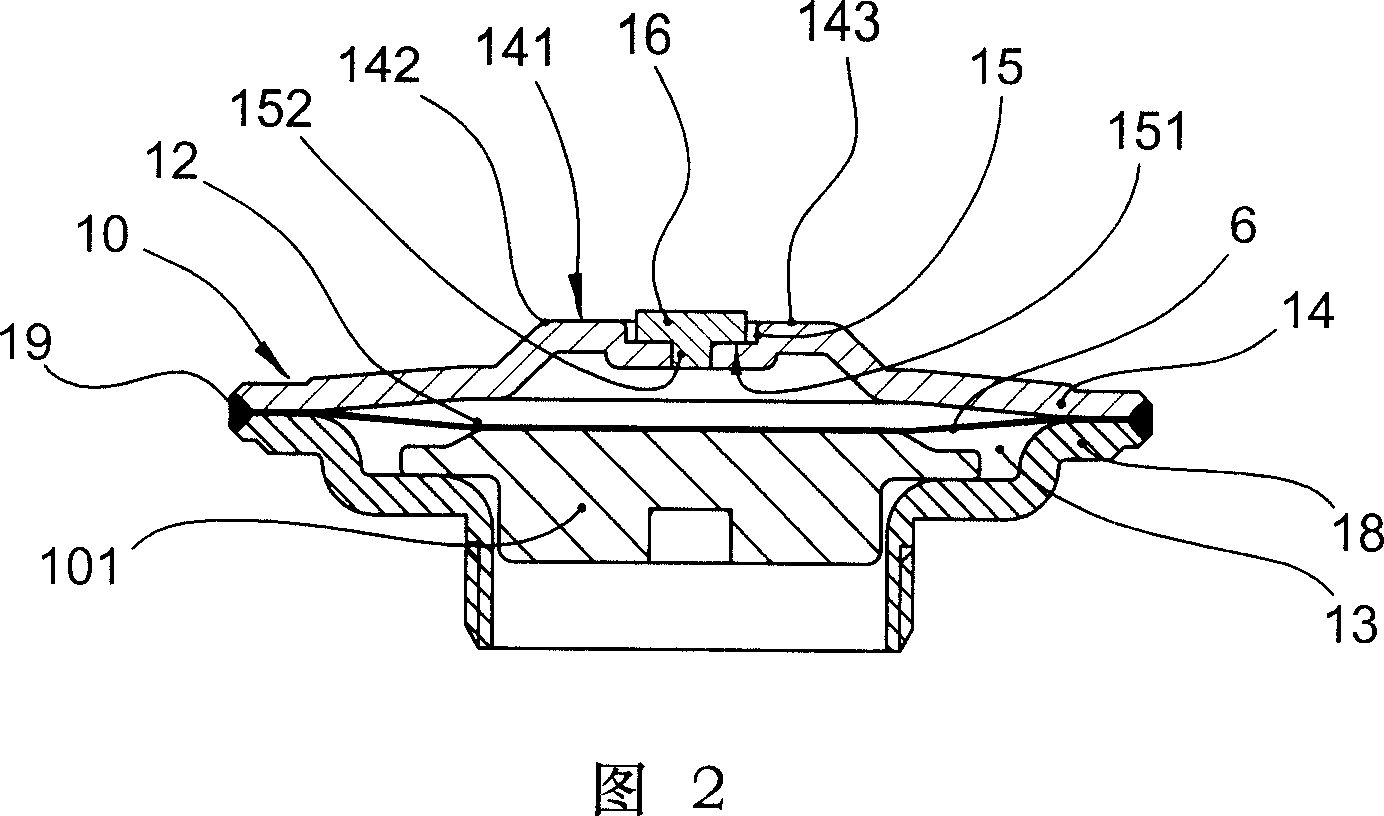

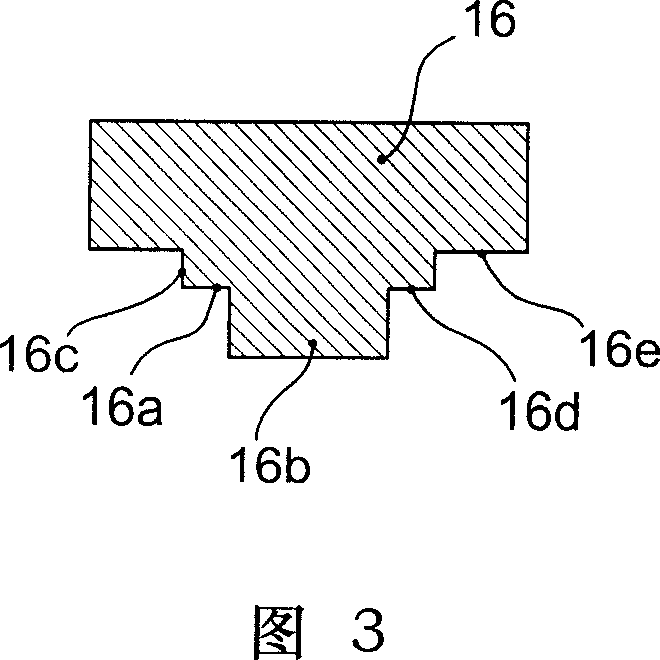

Thermal expansion valve

ActiveCN1932344AReliable weldingRealize energy savingOperating means/releasing devices for valvesFluid circulation arrangementElectrical resistance and conductanceStructural engineering

The present invention relates to a thermal expansion valve. It includes the following several main portions: valve core, diaphragm, air tight chamber and seal head. Said invention also provides the concrete structure of the above-mentioned every portion and the connection mode of all the above-mentioned portions. Besides, said also provides the concrete working principle of said thermal expansion valve and its concrete application method.

Owner:ZHEJIANG SANHUA AUTOMOTIVE COMPONENTS CO LTD

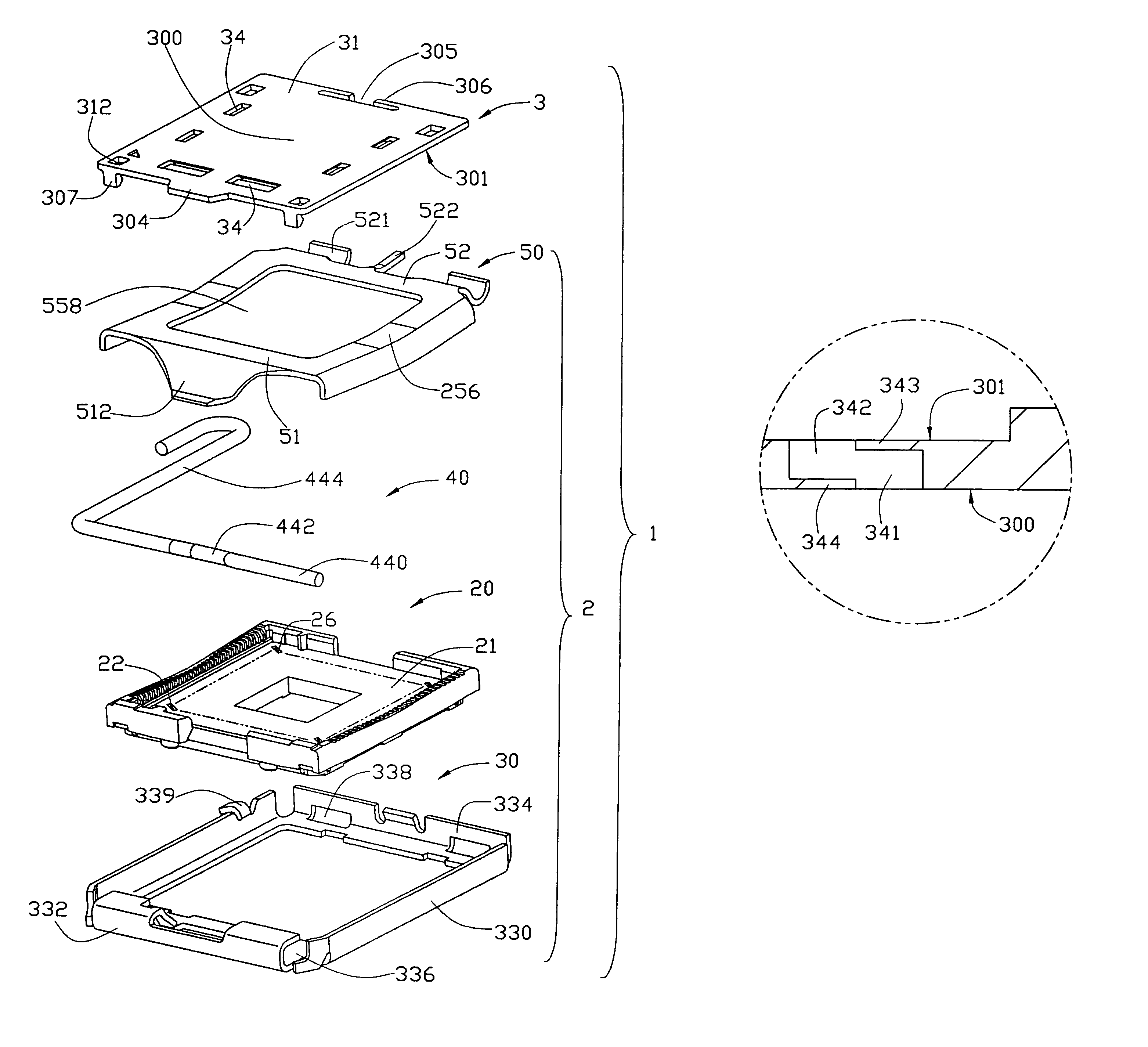

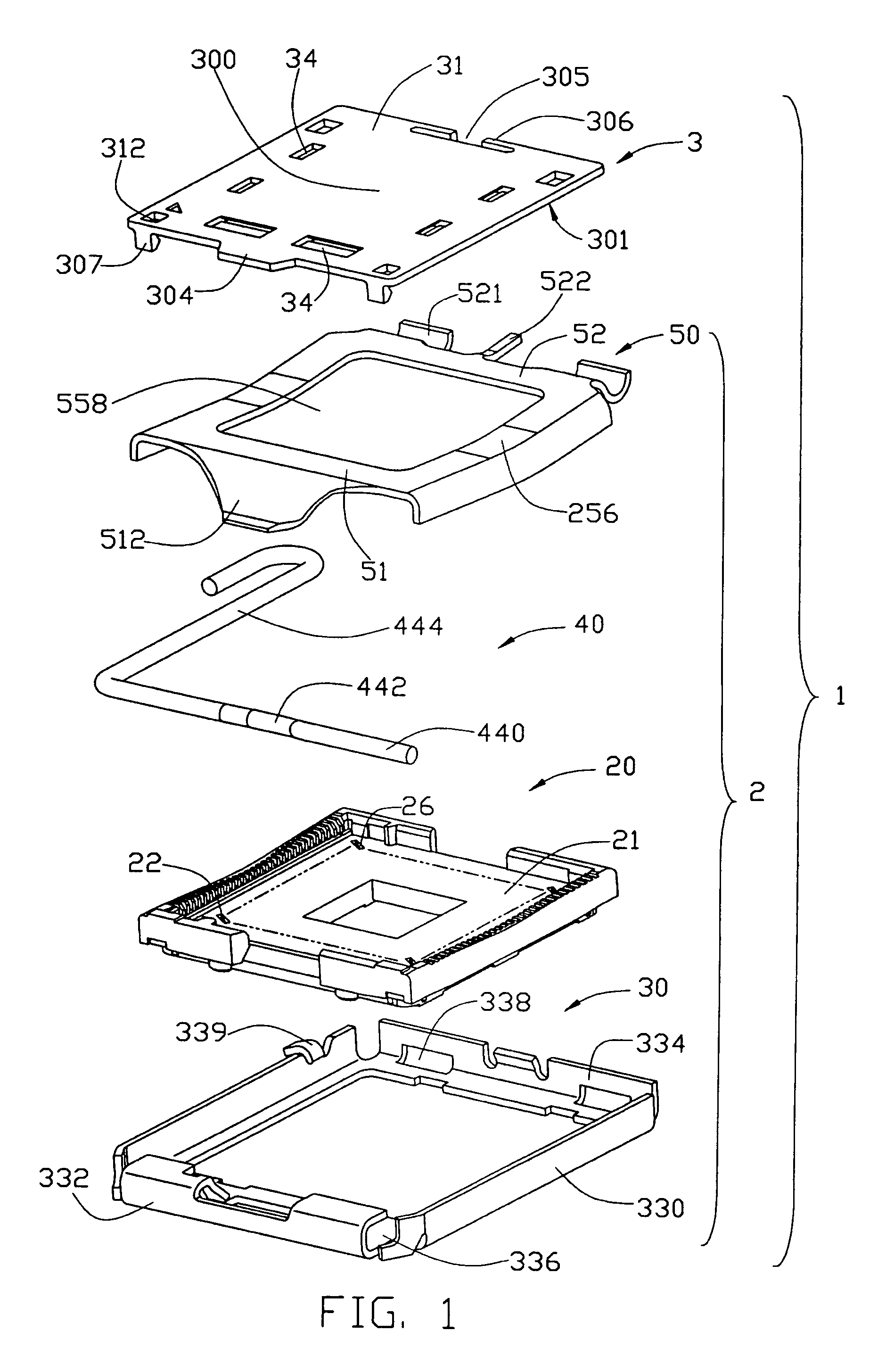

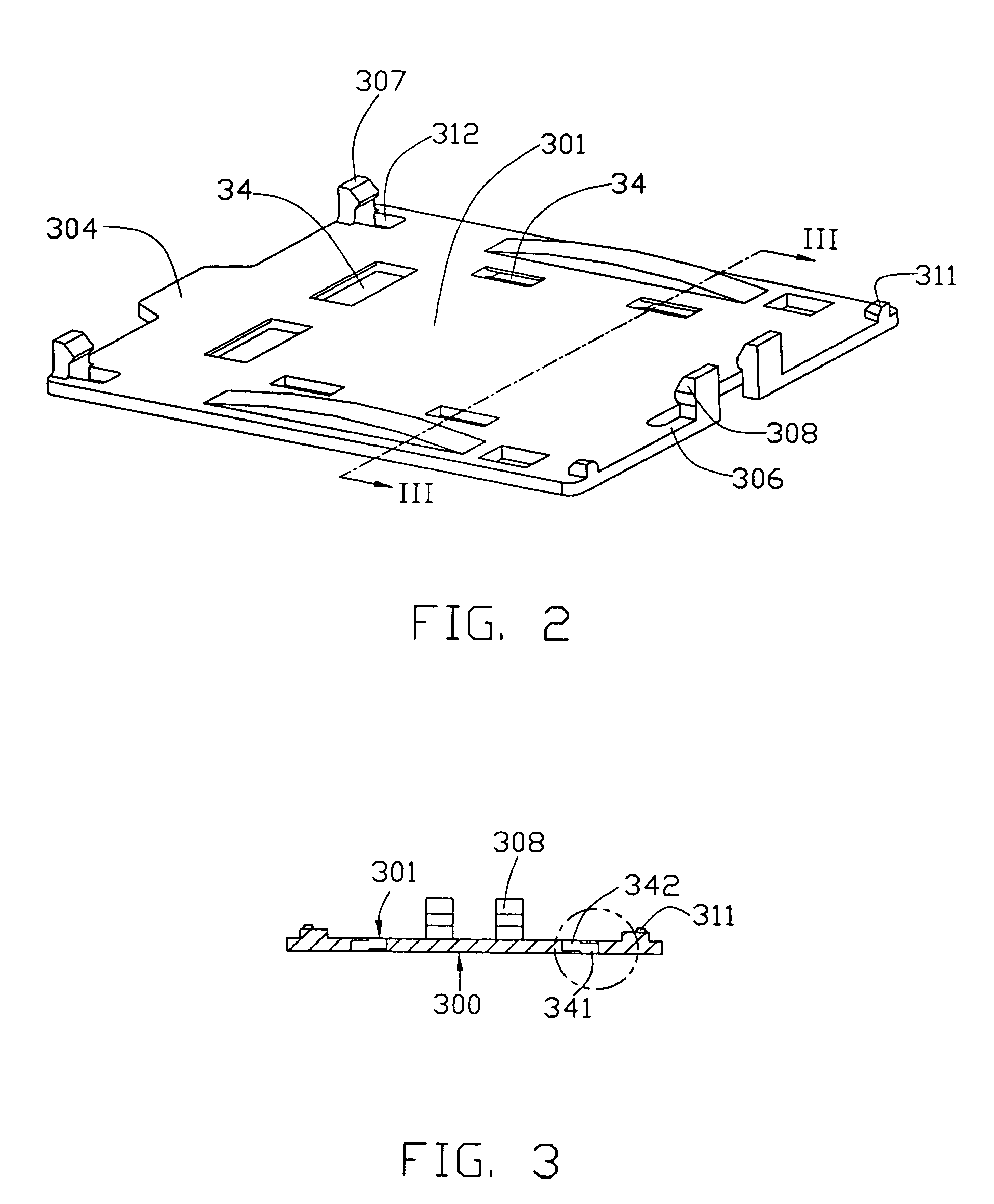

Electrical connector assembly with pick up cap

InactiveUS7070427B2Facilitates soldering the connectorReliablyPrinted circuit assemblingLine/current collector detailsElectrical connectorMechanical engineering

An electrical connector assembly (1) includes an LGA connector (2) and a pick up cap (3) mounted onto the connector. The connector defines a number of cells (26) for receiving a corresponding number of contacts (22). The pick up cap has a planar body (31) forming a plane top surface (300) and a bottom surface (301) opposite to the top surface. Several vents (34) each extend zigzag from the top surface to the bottom surface. Each vent forms an upper chamber (341) and a lower chamber (342) communicating and displacing with each other in a manner, such that the upper and lower chambers do not overlap in a direction perpendicular to the top surface. The vents can prevent the contacts from any dirty material and heated air can flow quickly through the vents and the cells to a bottom portion of the connector during curing adhesive film at high temperature.

Owner:HON HAI PRECISION IND CO LTD

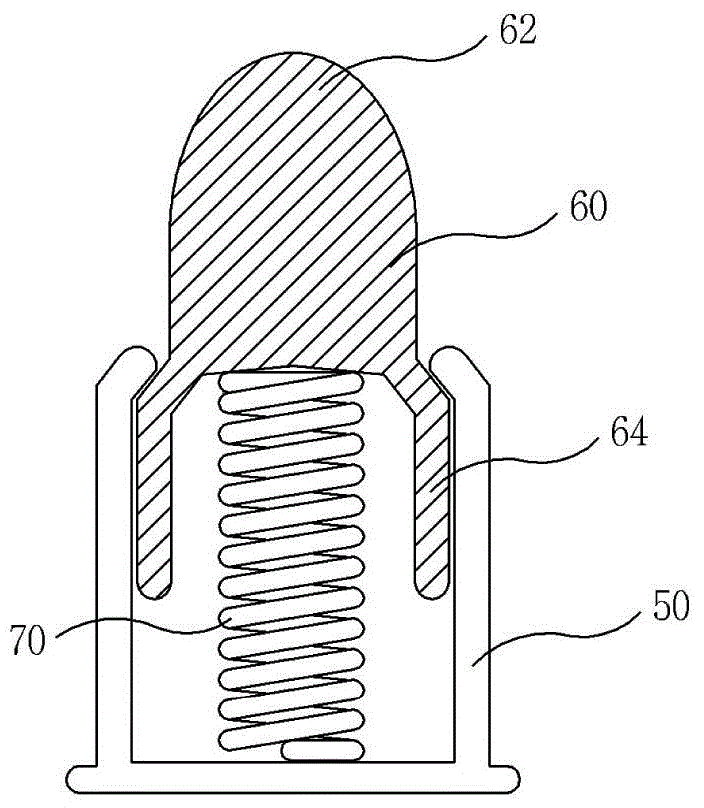

Sealed battery

ActiveCN101083310AReduce areaReliable leak tightnessNon-aqueous electrolyte accumulatorsCell component detailsEngineeringBearing surface

The present invention provides a sealing battery, which prevents electrolyte from remaining in the injecting hole and joints a sealing bolt and injecting hole. After injecting electrolyte into the battery box through the injecting hole, to joint the sealing bolt on the injecting hole to seal the injecting hole. The sealing bolt is arranged with a head and a axis extending from the lower surface of the head. The injecting hole is arranged with a chimeric concave part to table the head of the sealing bolt and a chimeric part of the axis part which is pressed into the sealing bolt. The chimeric part of the injecting hole includes: vertical inner surface part; taper inner surface part with taper surface shaped which turns narrow downwards; and bearing surface part to support the lower surfaceof the head of the sealing bolt. The head of the sealing bolt includes: lower surface; vertical outer surface part which is opposite to the vertical inner surface part of the injecting hole; and taper outer surface part with taper surface shaped which is opposite to the taper inner surface part of the injecting hole and turns narrow downwards.

Owner:MAXELL HLDG LTD

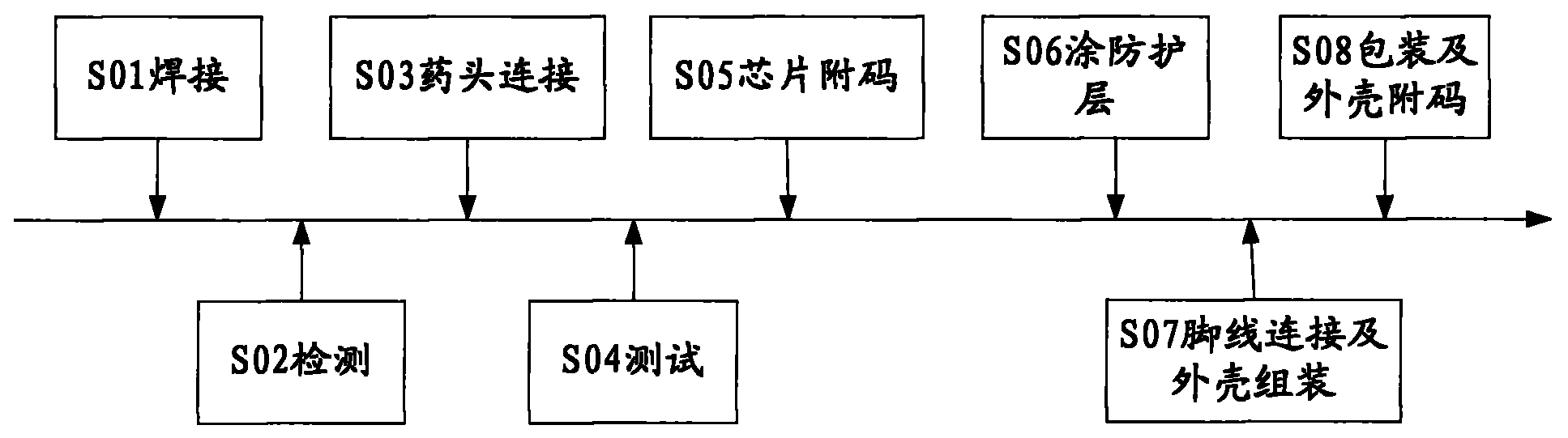

Method for assembling digital electronic detonator

The invention provides a method for assembling a digital electronic detonator, which comprises the process steps of welding, detection, medicament head connection, testing, chip encoding, protective layer coating, leg wire connection, outer shell assembly, packaging, shell encoding and the like. The method has the characteristics of high productivity, low production cost, high automation degree, safety, reliability and the like.

Owner:北京维深数码科技有限公司

Noise suppressor for firearm

Novel durable, lightweight, and accurate noise suppressors to attach to firearms comprised of components made of dissimilar materials, as well as methods to create the same. Disclosed embodiments include using a threaded interface between components made of dissimilar materials to increase the strength of the interface between such components in order to improve the durable of the noise suppressor and the accuracy of the firearm.

Owner:THUNDER BEAST ARMS

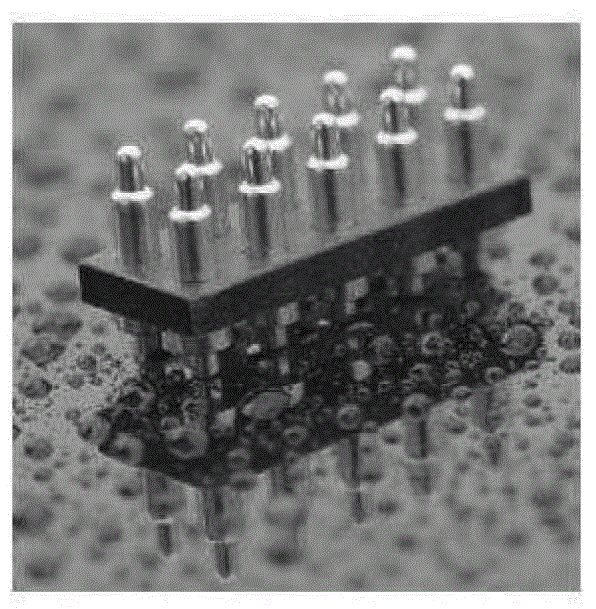

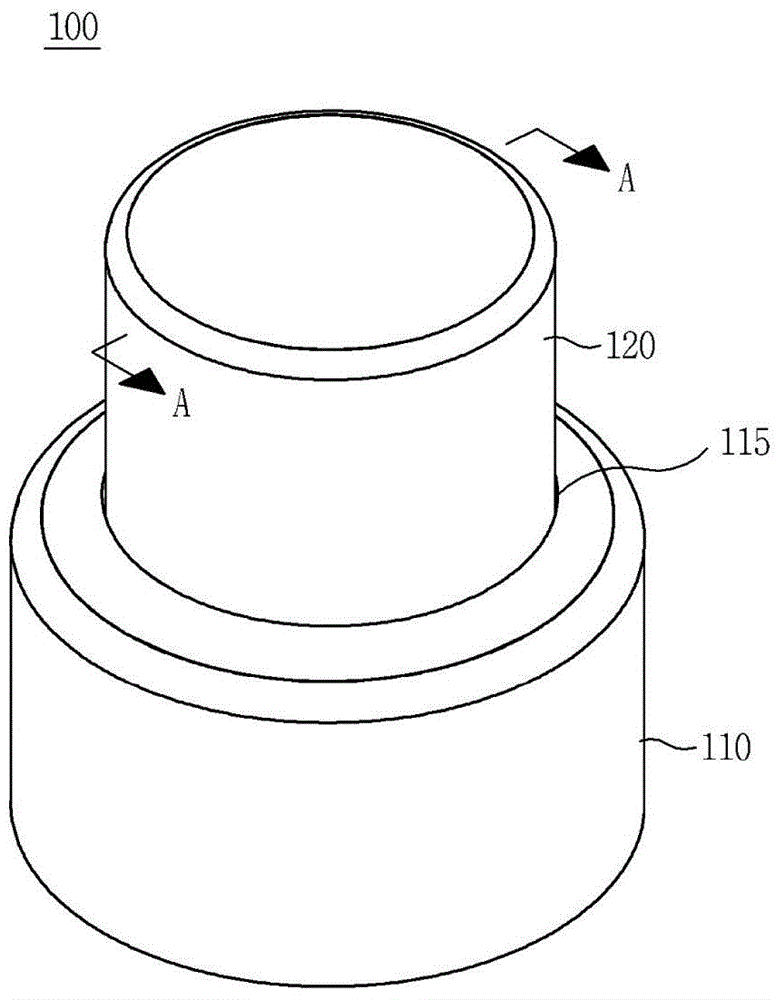

Surface-mount type electric connecting terminal, electronic module unit and circuit board using the same

ActiveCN104638413AIncrease travel distanceReduce the overall heightElectrically conductive connectionsFinal product manufactureSurface mountingMetallic materials

Provided is a surface-mount type electric connecting terminal which is disposed between opposing conductive objects (including for example a conductive pattern 12 on a PCB 10) and is configured to electrically connect the objects while easily adjusting pressing force and recovery force. The electric connecting terminal includes a cylindrical fixed member 410 which is made from a metallic material; a cylindrical movable member 420 which is slidably inserted in the fixed member and is made from a metallic material; and an electrical conductive spring 430 which is accommodated in the fixed member and whose one end contacts with the bottom of the fixed member and the other end contacts with the bottom of the movable member for thereby allowing the movable member to elastically slide against the fixed member. The fixed member comprises a hook portion to prevent the movable member from being disengaged from the fixed member when elastic recovery force is transferred from the spring. A flat surface is formed in an upper end surface of the movable member for the sake of vacuum pickup, and a lower end surface of the fixed member is configured to be reflow-soldered using solder cream 14.

Owner:JOINSET +1

Printed circuit board and soldering structure for electronic parts thereto

InactiveUS6853091B2Prevent leakageReliable weldingPrinted circuit assemblingSemiconductor/solid-state device detailsThermal energyCopper foil

A printed circuit board having circuit patterns printed thereon has a plurality of composite lands each including a first land having a terminal hole formed at its center for inserting the terminal of a selected electric or electronic part or device, and a plurality of second lands each being contiguous to and extending outwards from the first land. The areas contiguous to the contours of the first and second lands have no conductive foils, such as copper foils, thereon such that the substrate surface of the printed circuit board is exposed in these areas. The exposed areas are effective to confine the thermal energy in the limited areas for soldering. And the composite land shape defines a ridged cone-like solder lump, which can fixedly grip the terminal of the part or device.

Owner:ORION ELECTRIC CO LTD

Explosive welding method for bimetal composite boards with special quality requirements

InactiveCN103056508AReliable weldingMeet welding quality requirementsNon-electric welding apparatusBond interfaceCharged body

The invention discloses an explosive welding method for bimetal composite boards with special quality requirements. The explosive welding method includes preprocessing blanks; charging powder; and performing explosive welding. In a powder charging procedure, 'basin'-shaped powder charge bodies are arranged on shroud plates and extension plates, upper and lower surfaces of the powder charge bodies are parallel to the shroud plates and the extension plates, and powder charging quantities are acquired by computing according to a formula. The welded rate of the composite boards welded by the explosive welding method reaches 100%, the bonding strength of welded surfaces of the bimetal composite boards meet a bimetal solid-phase metallurgical bonding strength law, bonding interfaces of the bimetal composite boards are finely wavy and are excellent in quality, and accordingly the quality requirements of critical equipment of thermonuclear fusion power generation test reactors on the composite boards are met.

Owner:中国人民解放军理工大学野战工程学院 +2

Method for welding thin wall stainless steel tube and copper pipe piece

InactiveCN101279394AMeet the use requirementsThe welding is firm and tightSoldering apparatusWelding/soldering/cutting articlesSolder pasteThermal water

The invention discloses a welding method of a thin-walled stainless steel tube and a copper tube part, which can lead the thin-walled stainless steel tube and the copper tube part to form a permanent fastening and sealing connecting structure at the connecting part. The welding method has simple process, the steps of the process thereof are that: (1) the connecting part of the thin-walled stainless steel tube and the copper tube part is cleaned, silver welding paste is coated at the connecting part of the thin-walled stainless steel tube and the copper tube part which is clean; (2) the connecting part of the thin-walled stainless steel tube is inserted in the connecting part of the copper tube part, the outer wall of the copper tube part is heated; (3) when the connecting part of the copper tube part and the thin-walled stainless steel tube is indirectly heated to the temperature range of 750 DEG C to 860 DEG C, a silver welding strip is arranged along the exposed position of the connecting part of the thin-walled stainless steel tube and the copper tube part, the silver welding strip is melted by utilizing the heat stored in the copper tube part, and the welding connection of the thin-walled stainless steel tube and the copper tube part can be completed after the cooling. The welding method can be widely applied in cold and hot water supply pipelines of various tap water supply pipelines and water heaters.

Owner:陈雪辉 +1

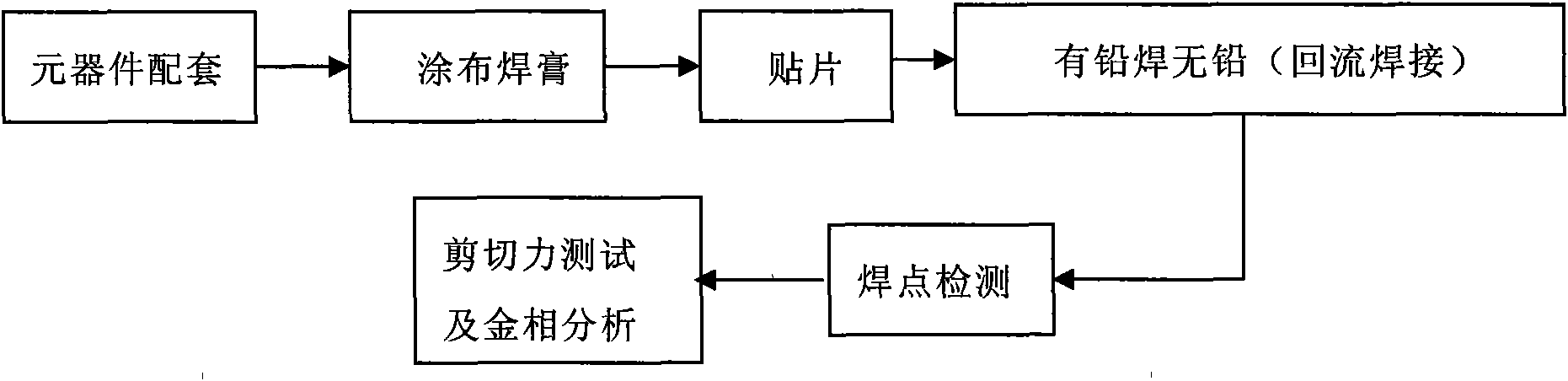

Method of welding printed circuit board containing mixed lead components and leadless components

ActiveCN101553092AIncrease soldering temperatureReliable weldingPrinted circuit assemblingWelding/cutting media/materialsTemperature curveEngineering

The present invention relates to a method of welding printed circuit board containing mixed lead components and leadless components, using lead solder and controlling welding temperature curve to improve welding peak temperature and prolong solder liquid phase time properly on the base of conventional lead welding technics to implement reliable welding of leadless components. Applying the invention provided technical scheme can implement solder paste coating, patching and welding in one time of most lead components and leadless components, of which the production efficiency is far higher than separate welding technics of lead components and leadless components. The invention provided method improves production efficiency and reduces materials control difficulty of production field while shorts production period of mixed products and reduces production cost.

Owner:BEIJING RES INST OF TELEMETRY +1

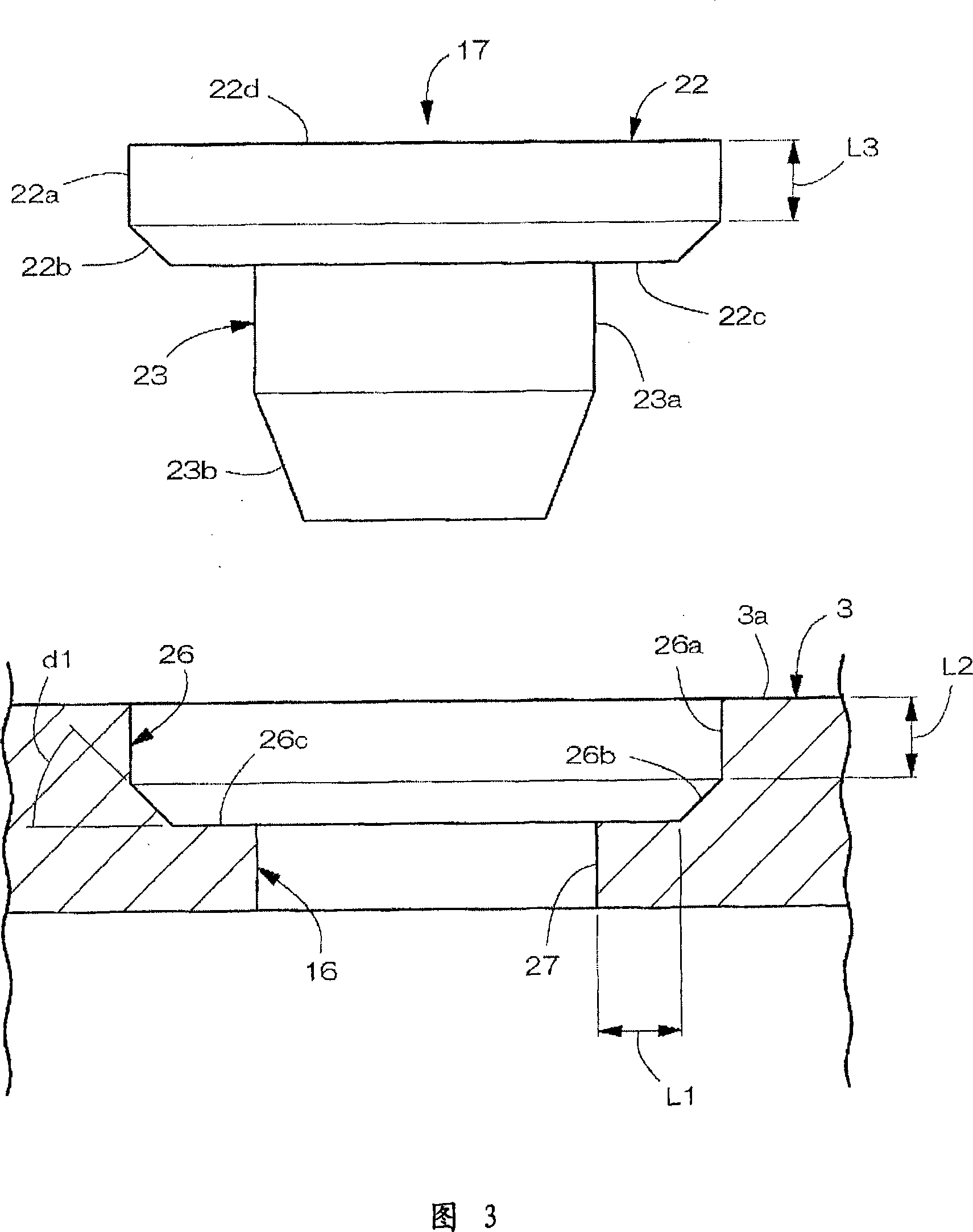

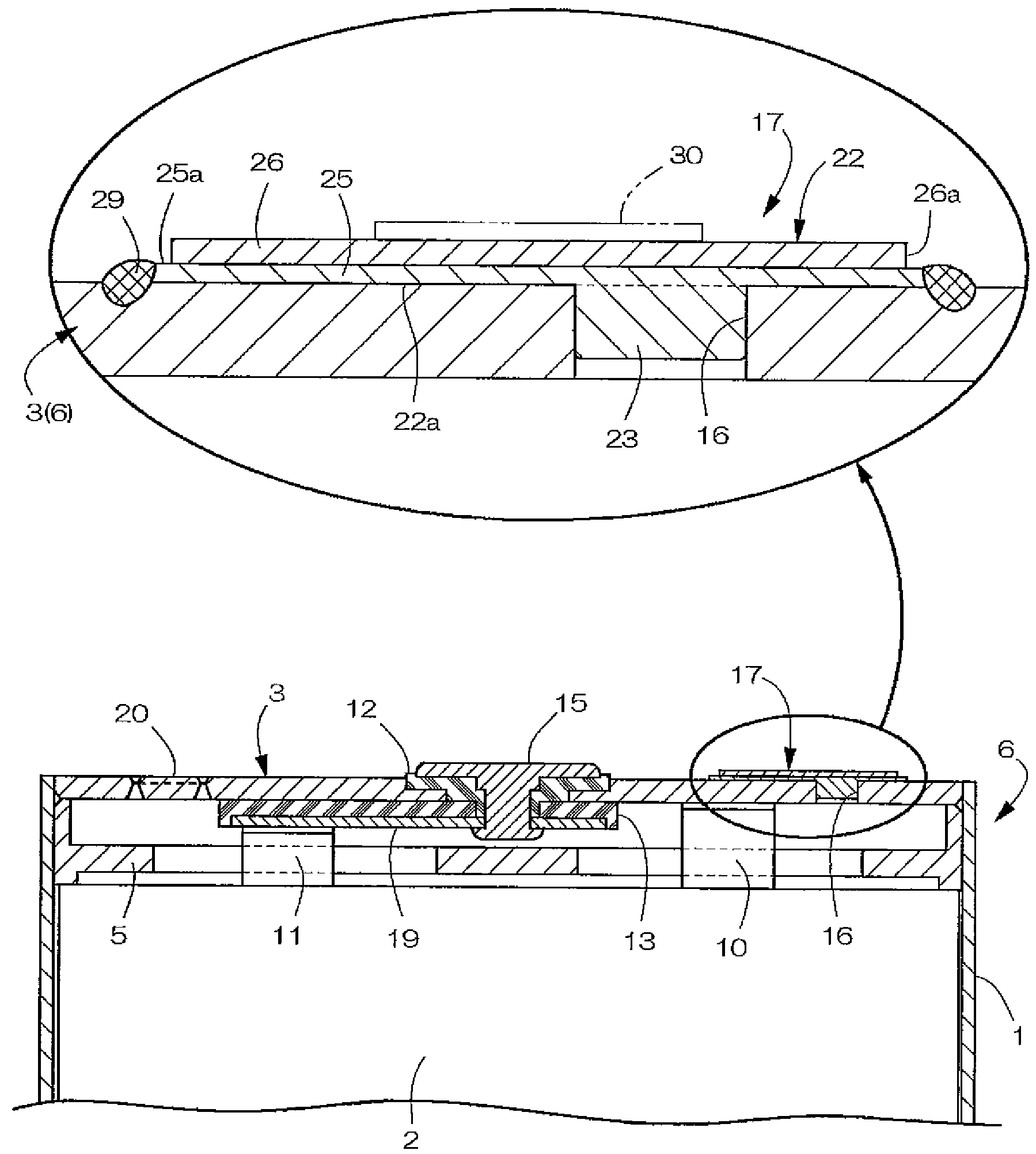

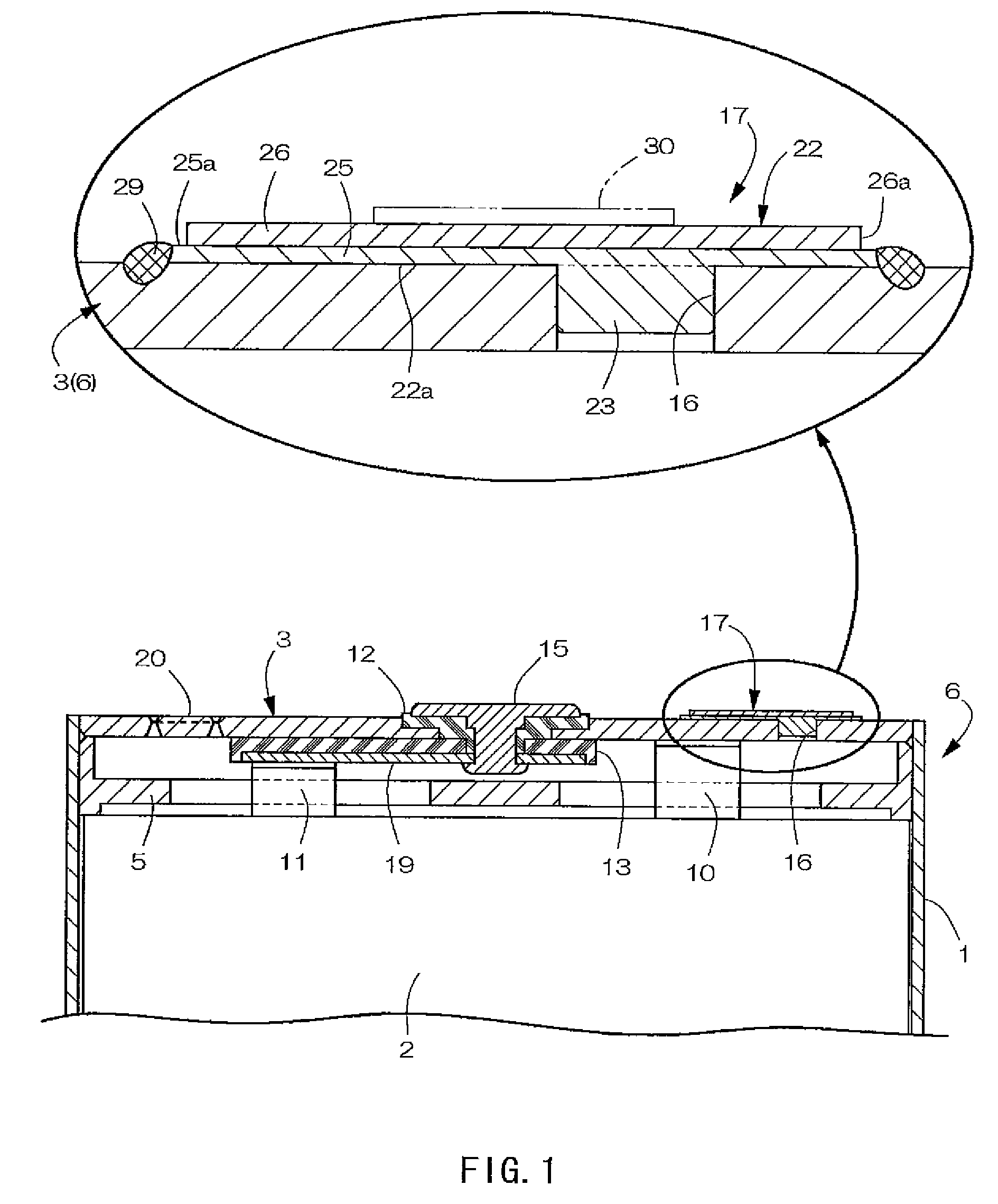

Hermetically sealed battery

InactiveUS20090136841A1Good welding strengthImprove welding strengthNon-aqueous electrolyte accumulatorsOrganic electrolyte cellsThermal conductivityAluminium

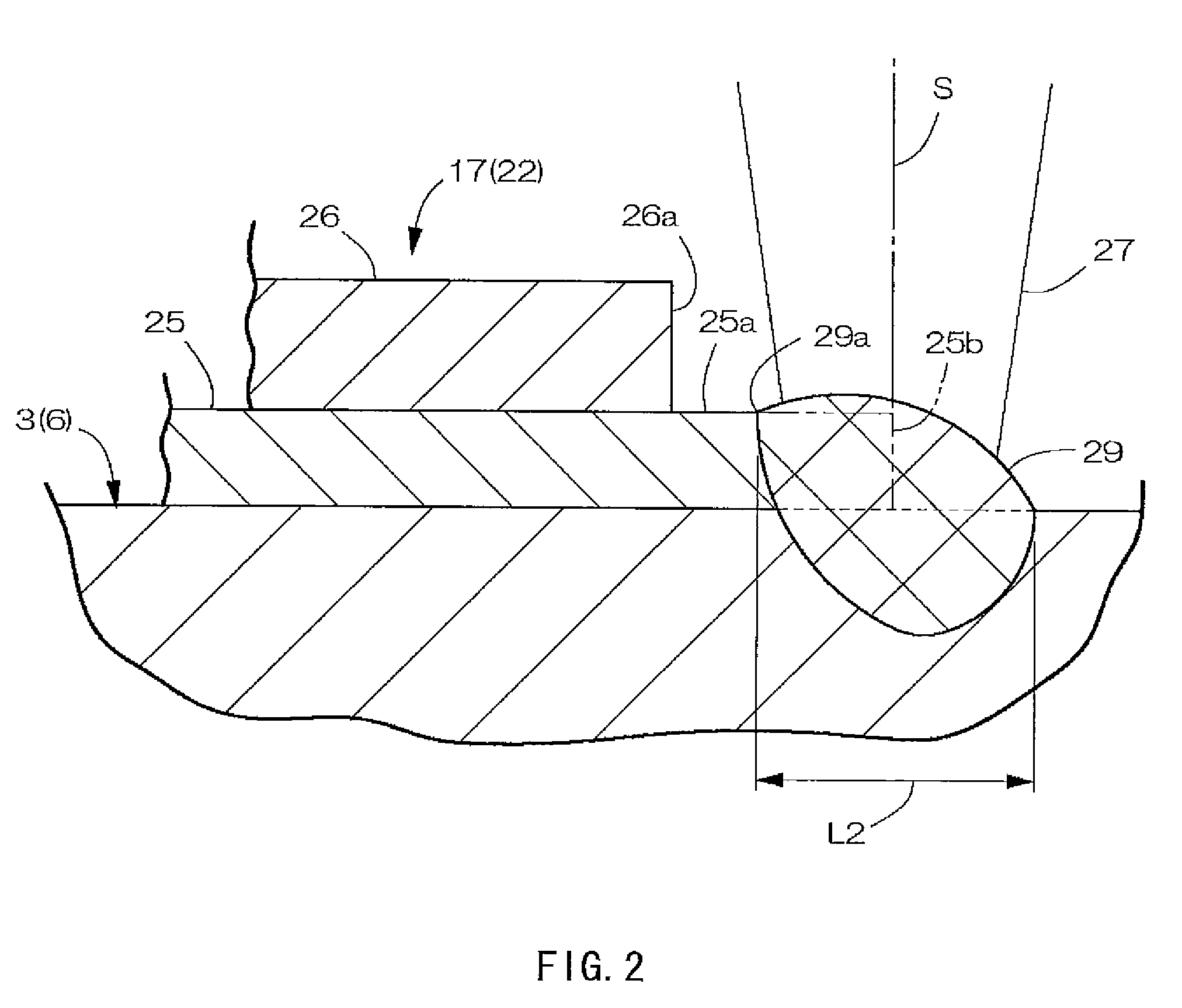

To provide a hermetically sealed battery having a seal that also serves as a terminal plate, in which the seal can be reliably welded to a battery case without causing spatters and the like while ensuring good weld strength of a lead to the seal.A seal 17 is constituted by an aluminum layer 25 that is made of aluminum or the like and is disposed on a battery case 6 side and a dissimilar metal layer 26 having less thermal conductivity than the aluminum layer 25 and is formed on the aluminum layer 25. The aluminum layer 25 has a larger size than the dissimilar metal layer 26, and an outer peripheral edge portion 25a of the aluminum layer 25 protrudes outward beyond an outer peripheral edge 26a of the dissimilar metal layer 26. The seal 17 is welded to the battery case 6 in a state where the central axis S of a laser beam 27 moves along an outer peripheral edge 25b of the aluminum layer 25 and an edge 29a of a welding mark 29 due to irradiation with the laser beam 27 on the dissimilar metal layer 26 side is positioned outside the outer peripheral edge 26a of the dissimilar metal layer 26.

Owner:HITACHI MAXELL ENERGY LTD

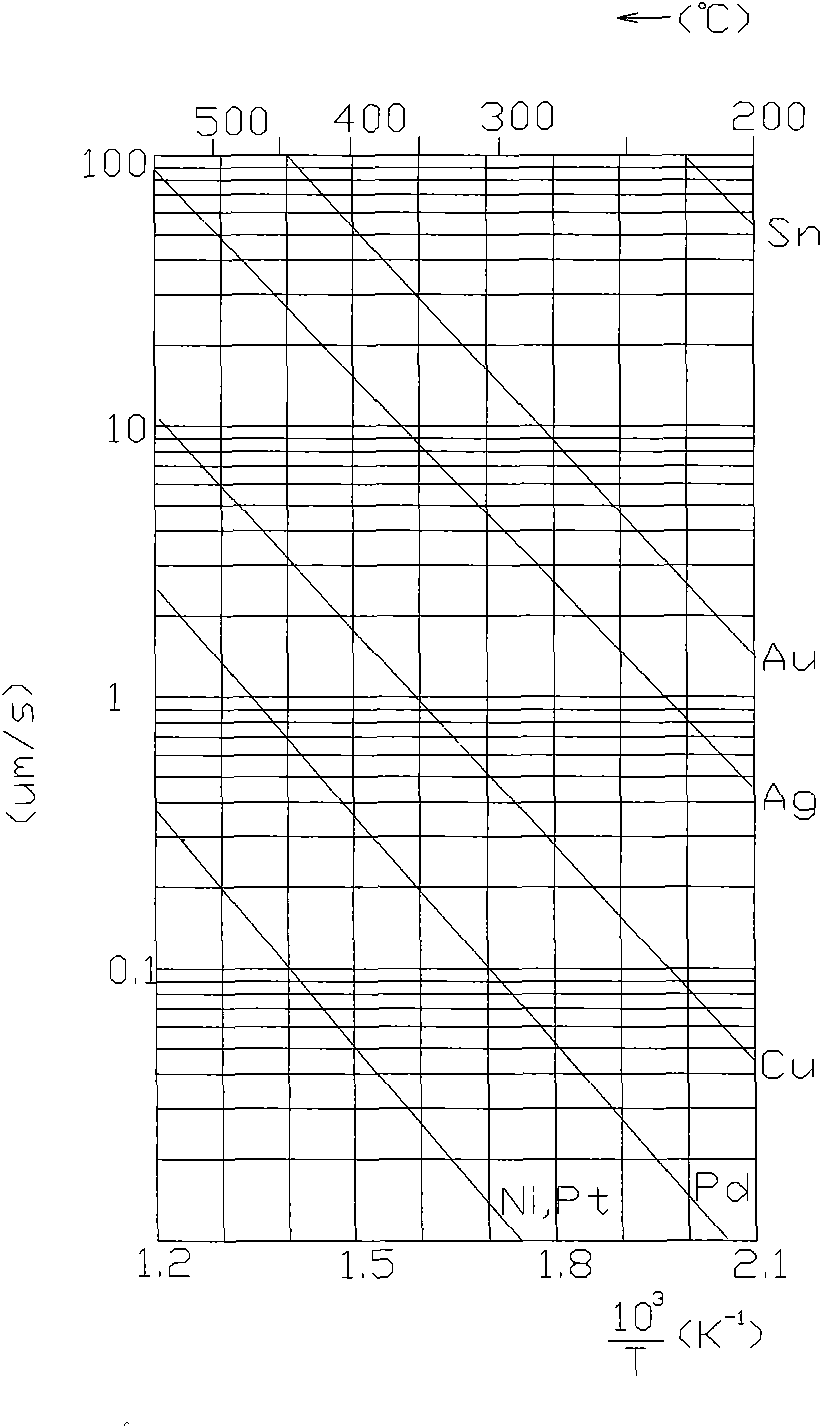

Solder joint structure and method for soldering electronic components

InactiveUS20050127143A1Highly reliable lead-free solderingLow melting pointPrinted circuit assemblingPrinted circuit aspectsCopperElectronic component

A method for soldering an electronic component is provided. A first solder land containing copper and a second solder land are formed on a surface of a circuit board. A first solder section composed of a Sn—Ag—Cu solder material is formed on each of the first and the second solder lands, and a terminal of an electronic component chip is mounted on the first solder land. The first solder land and the terminal are fusion-bonded. A second solder section composed of a Sn—Zn solder material is formed on the first solder section disposed on the second solder land. A lead terminal of another electronic component is inserted into a terminal hole formed near the second solder land; and the second solder section and the lead terminal are heated at a temperature lower than the temperature in step (d) to connect the lead terminal to the second solder section by fusion bonding.

Owner:ALPS ALPINE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com