Patents

Literature

338results about "Seaming textiles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

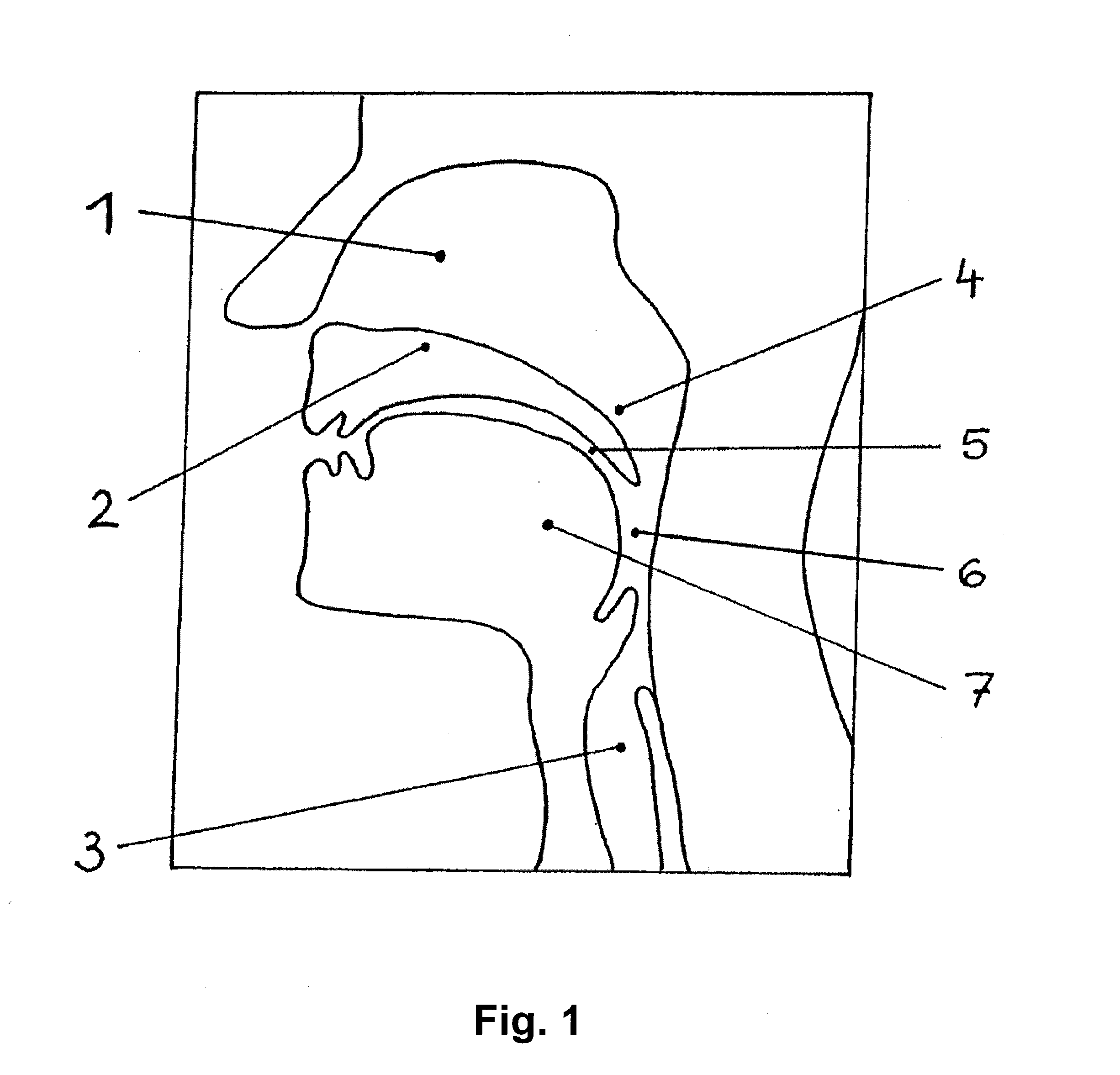

Device for splinting a cavity, organ duct and/or vessel

ActiveUS20130090720A1Easy to disassembleEasy to insertMechanical cleaningPressure cleaningSurgeryAnimal body

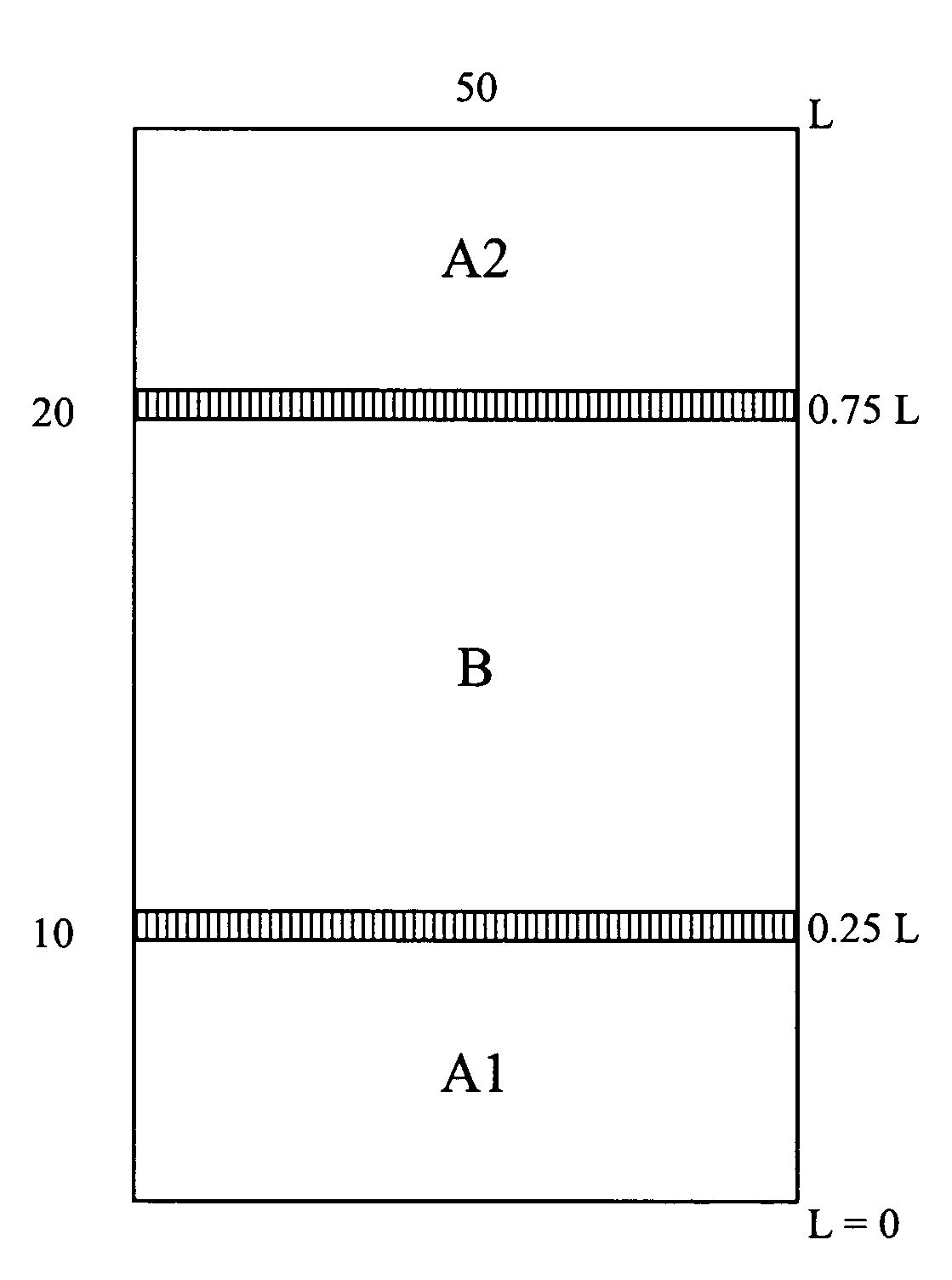

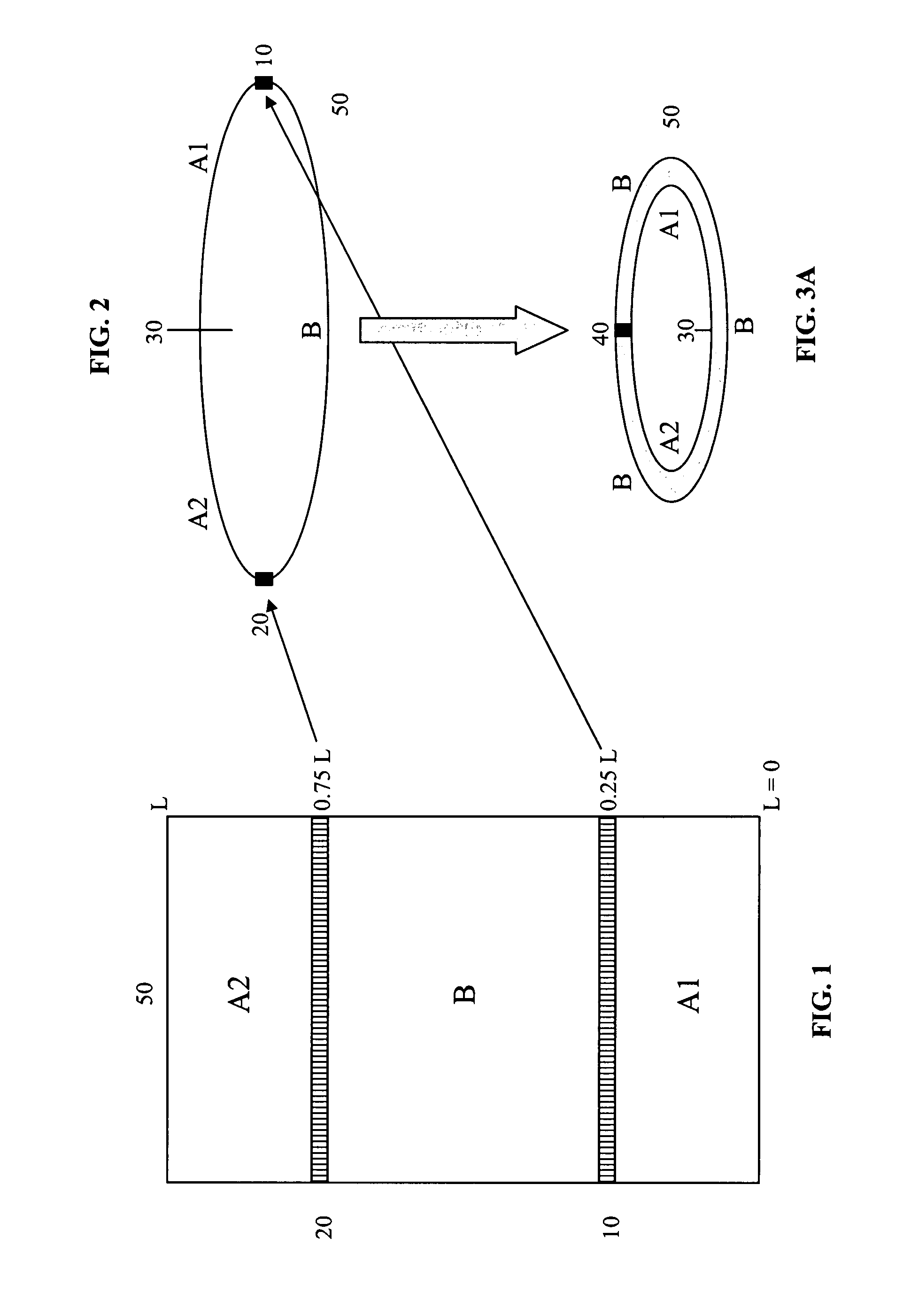

The invention relates to a device for splinting and / or maintaining a cavity, an organ duct and or a vessel in a human or animal body, said device including at least one compressible and self-expanding stent that is composed of at least three phases.

Owner:DURING KLAUS

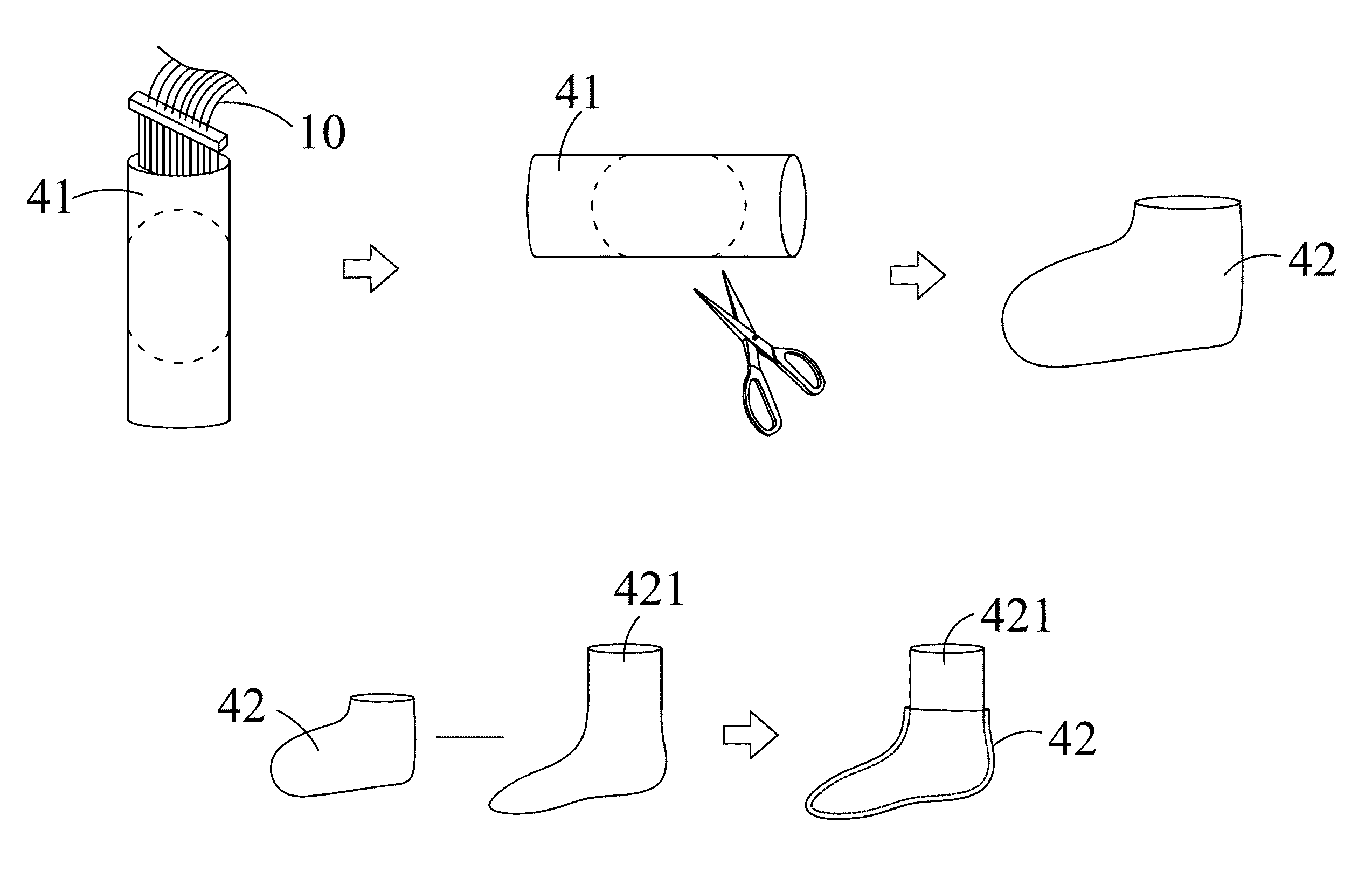

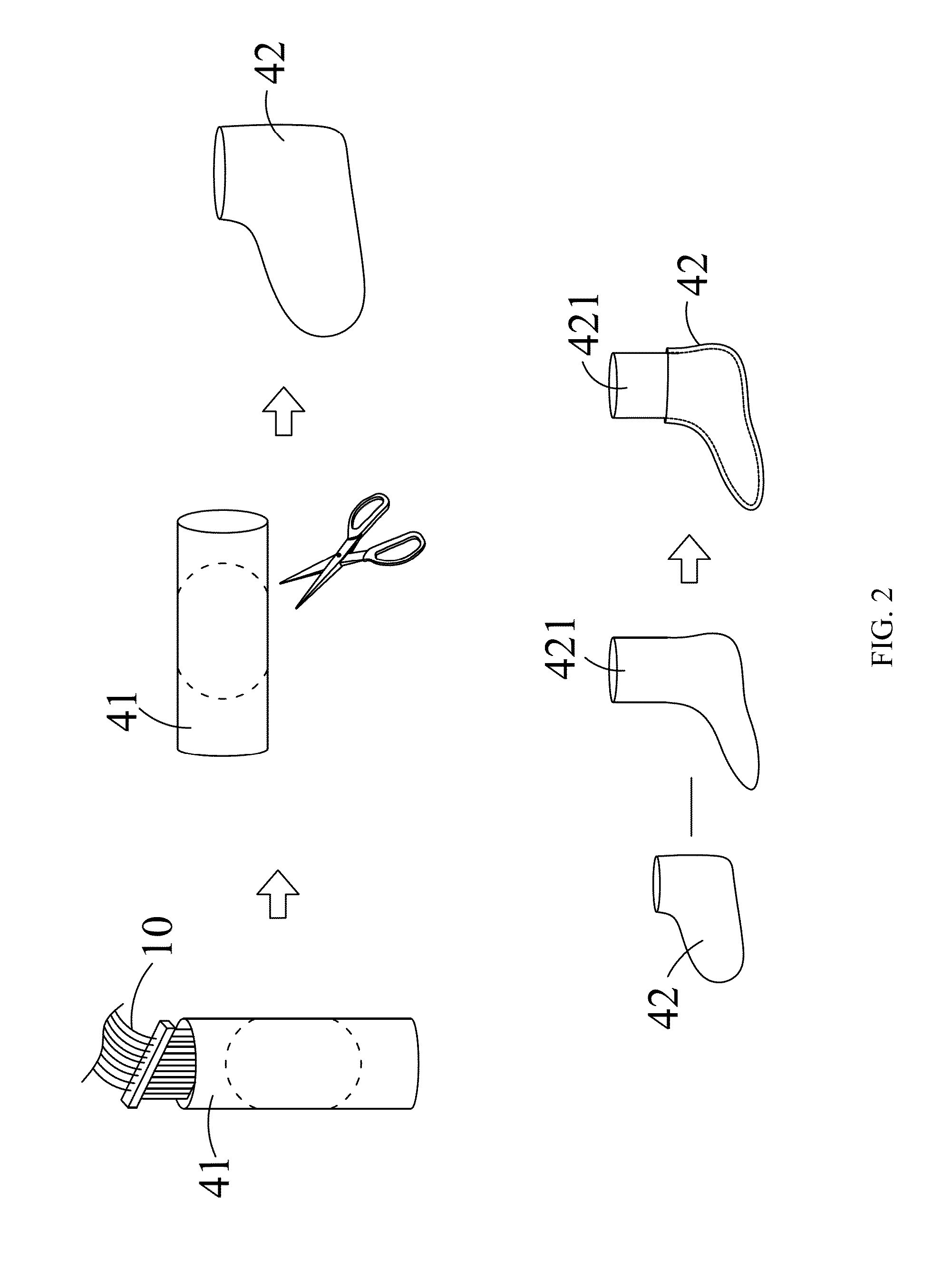

Weaving Method of Three-Dimensional Vamp

ActiveUS20140082905A1Increase labor costEliminate needMechanical cleaningPressure cleaningEngineeringHot melt

A weaving method of a three-dimensional vamp includes the steps of: weaving yarn by a warp-knitting machine to form a top vamp by a first part needle bar of the warp-knitting machine which is interactively woven with a bottom vamp formed by a second part needle bar of the warp-knitting machine so as to form a tube-shaped fabric; cutting the tube-shaped fabric to form a sock-shaped fabric; disposing the sock-shaped fabric on a shoe last; and heating the sock-shaped fabric to tighten the sock-shaped fabric in order to seal the shoe last and consequently obtain the three-dimensional vamp. The heat shrinkable and irreversible properties of a high shrinkage yarn or hot melt yarn are used to seal the sock-shaped fabric with the shoe last, thereby achieving the substantial physical properties. The turner cost and the fabric flotsam can be reduced by the process of manufacturing the integrally formed vamp.

Owner:LONG JOHN TSUNG RIGHT IND

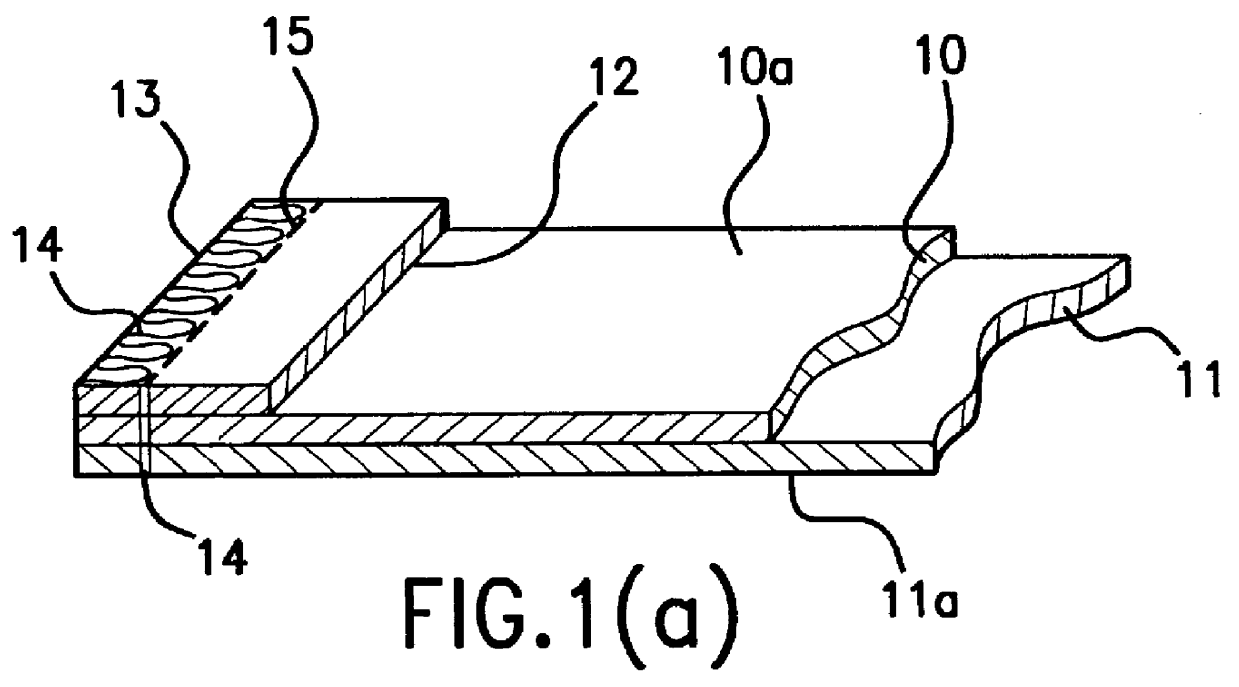

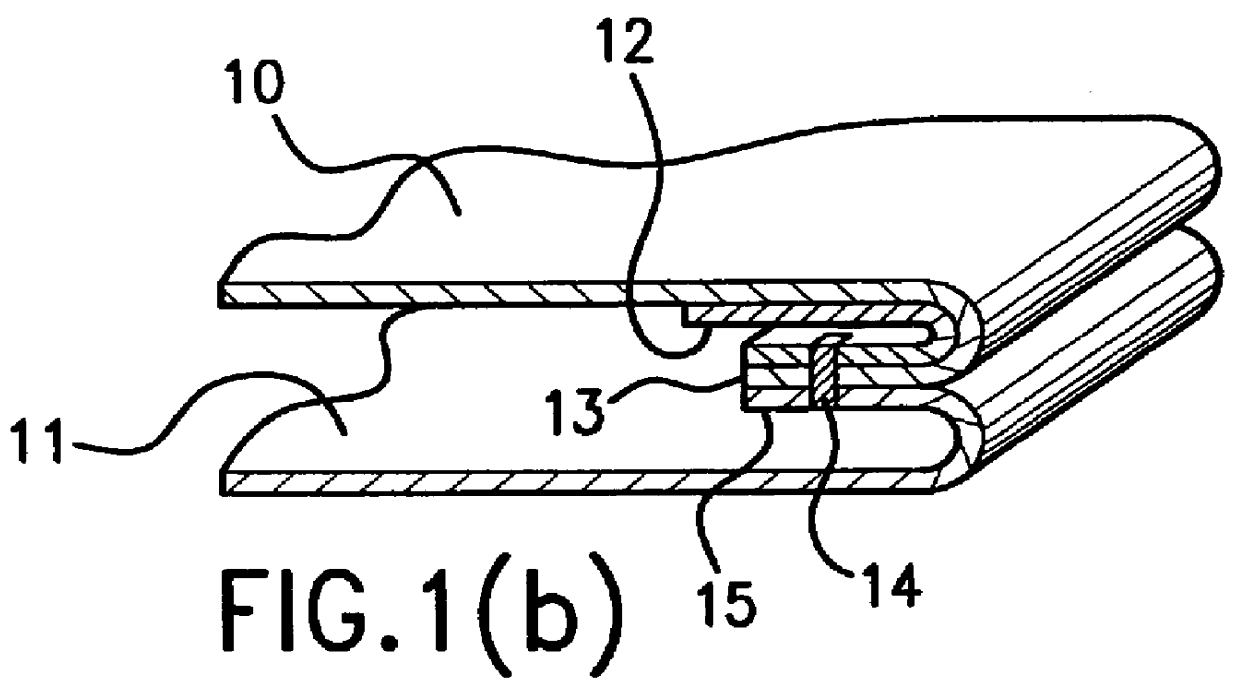

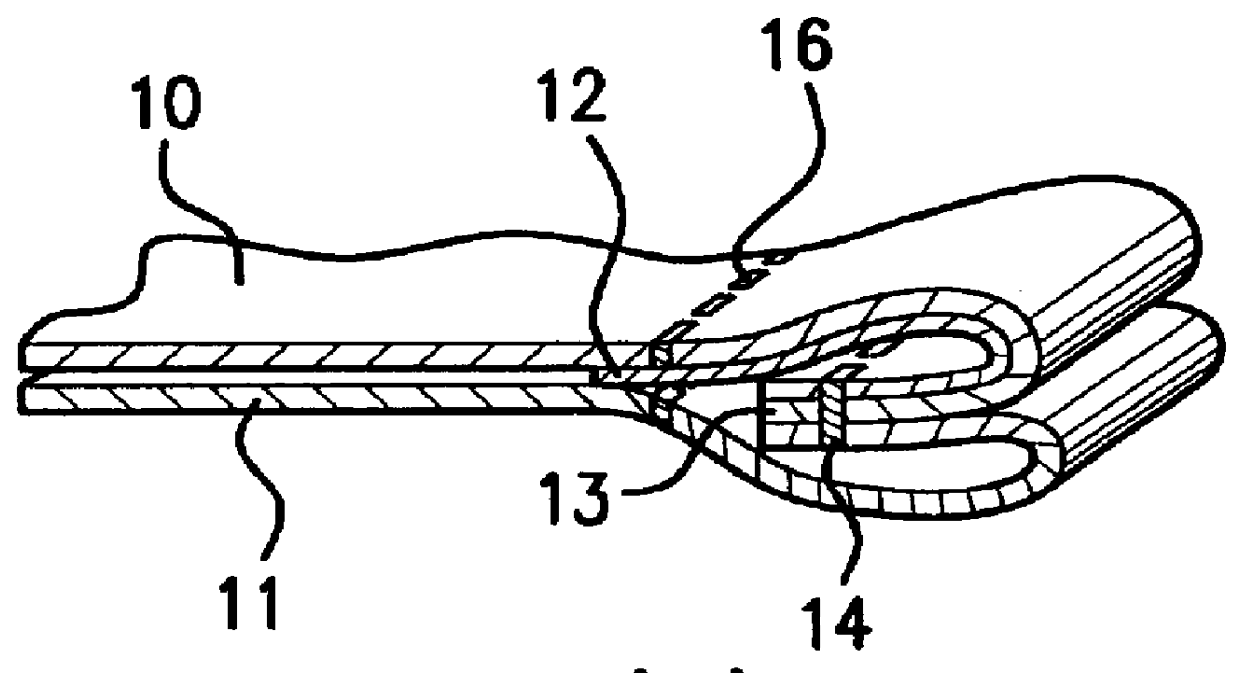

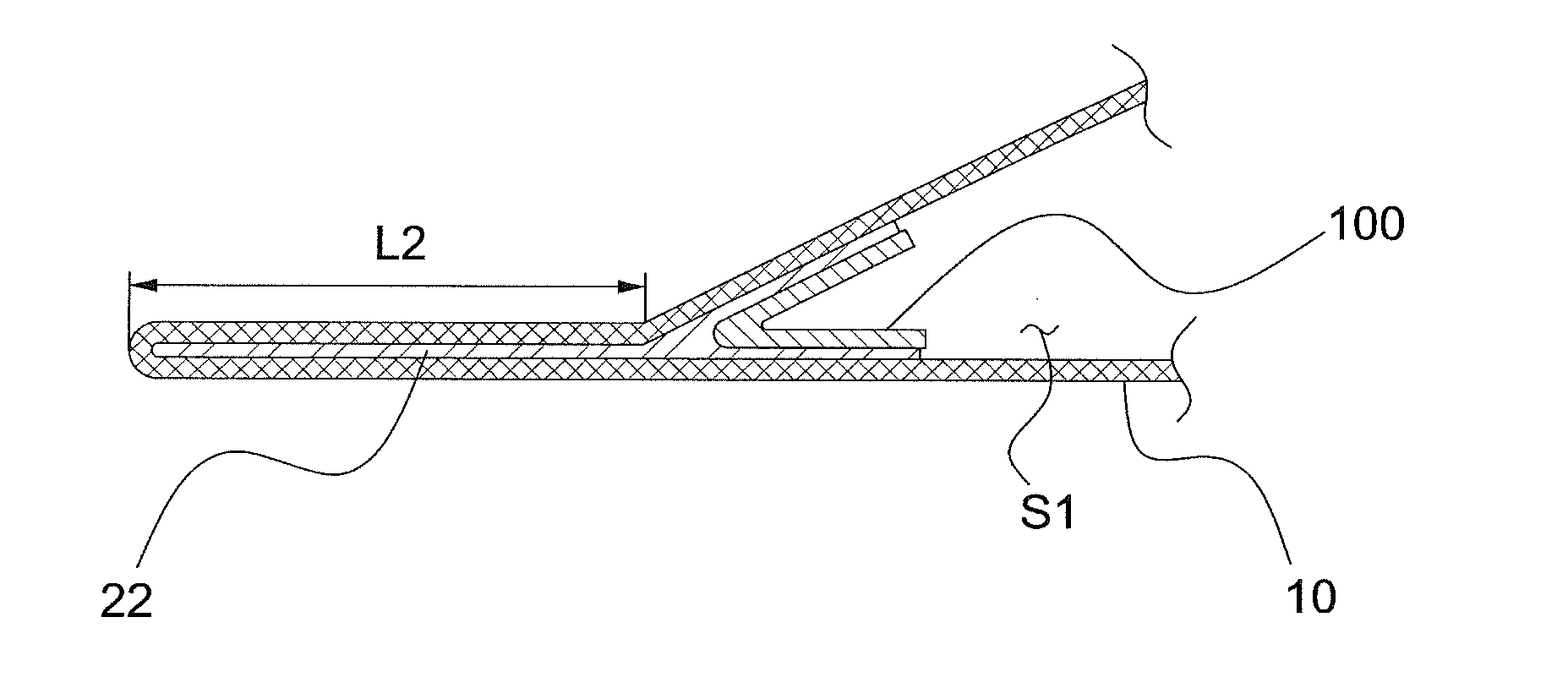

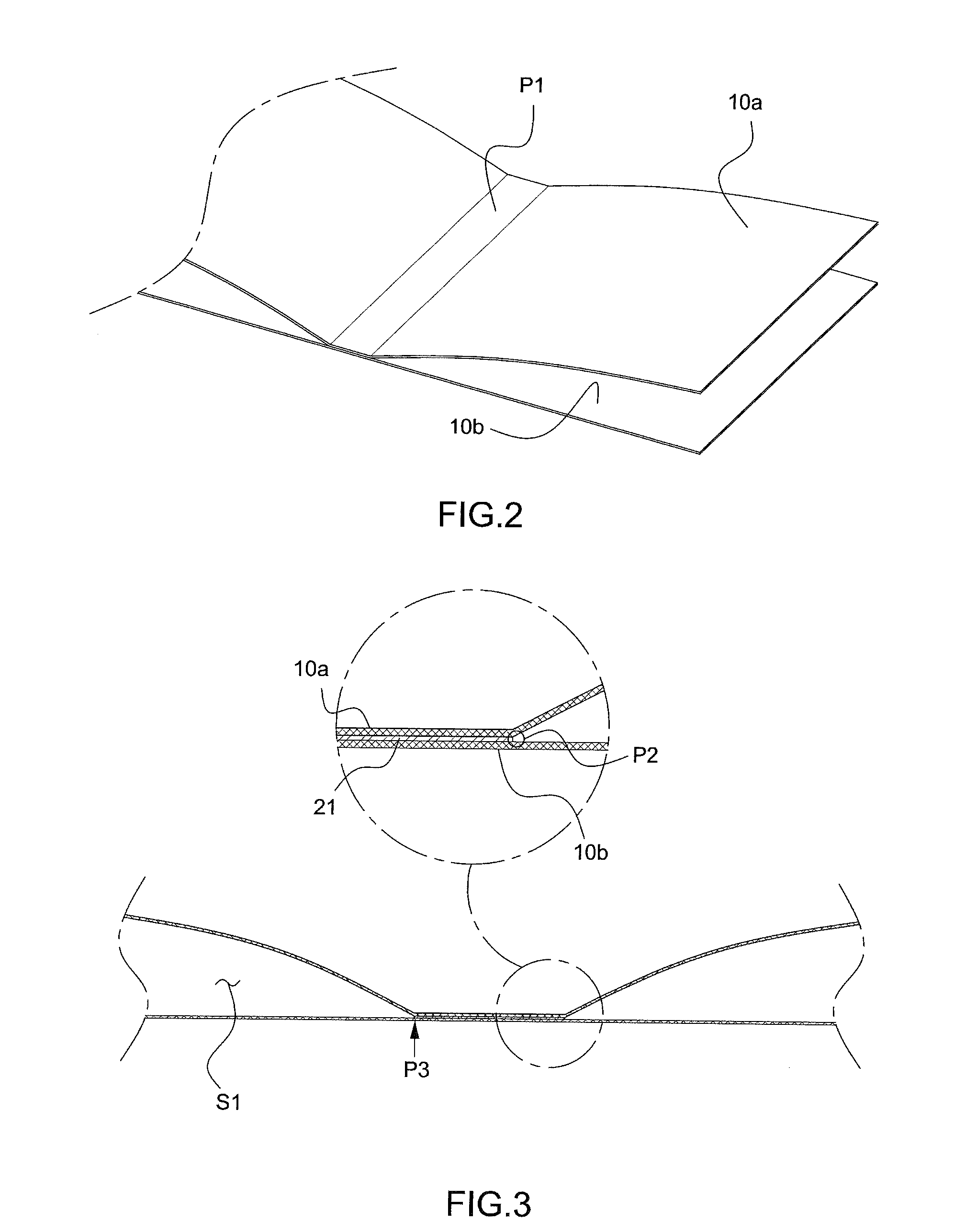

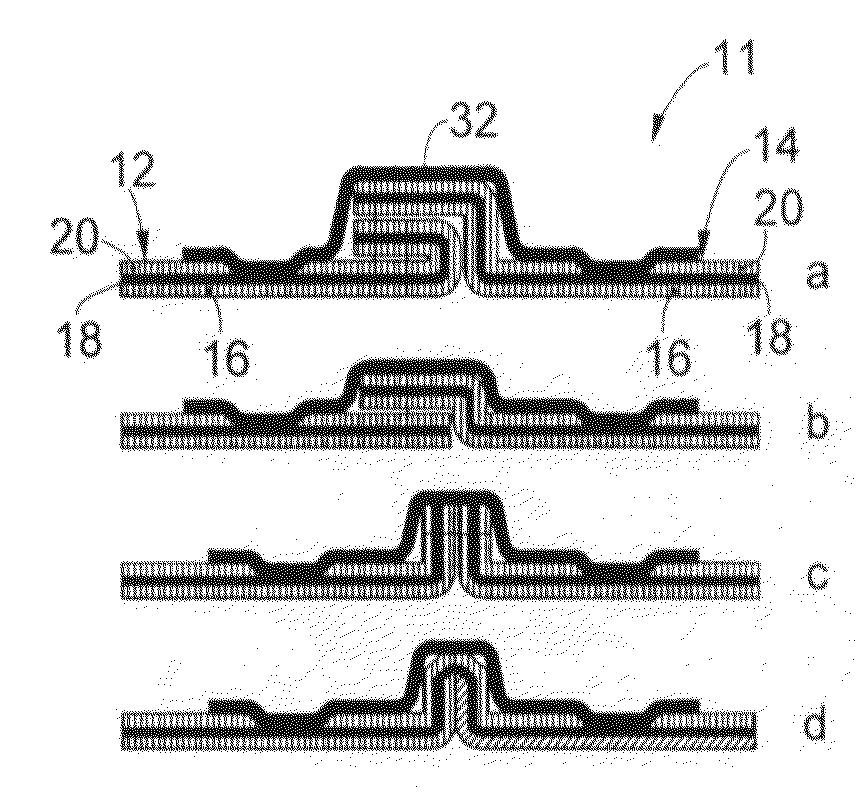

A composite seam system

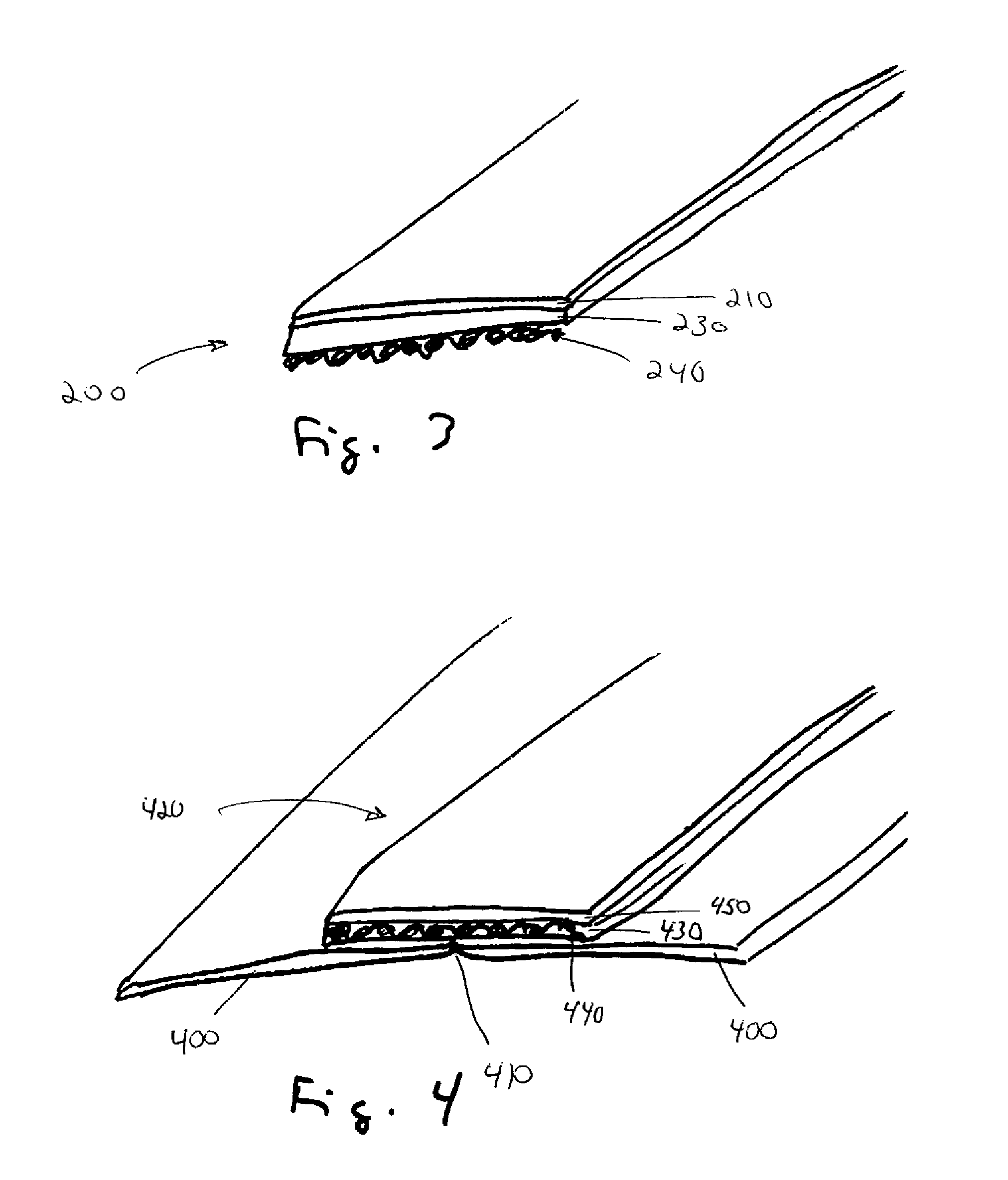

ActiveUS20050114989A1Small volumeReduce decreaseGarmentsSynthetic resin layered productsPolyesterAdhesive belt

A composite seam system including a narrow weld bead joining two panels of fabric and a seam tape applied thereon. The applied seam tape comprises a top layer, a reinforcing layer and an adhesive layer melted through the reinforcing layer and connecting the top layer to the fabric panels over the weld bead. The narrow weld bead and the small seam allowance of the fabric panels it joins allows the seam tape to be secured over the weld bead to the fabric panels while lying in a flat plane. The use of a narrow reinforcing layer of woven polyester, nylon or non-woven ultra-fine fibrous material in the seam tape allows the seam tape to be flexible enough to move with the fabric it joins, reducing the incidence of tape edge abrasion.

Owner:PATAGONIA

Method for sewing stretchable cloths

Owner:ITO MITSURU

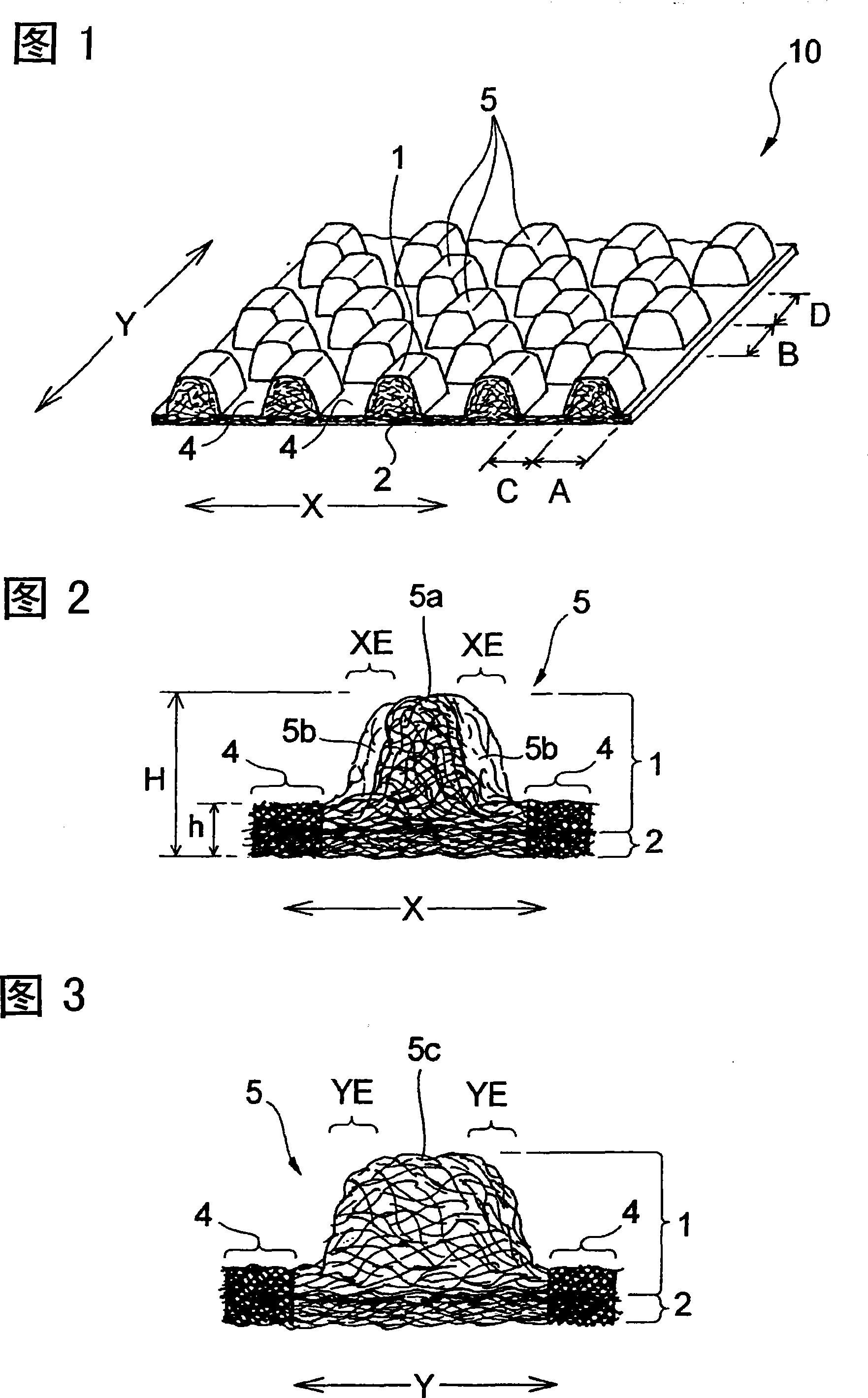

Yoga Towel

ActiveUS20130153081A1Good sweat absorptionPrevent slippingLayered productsSeaming textilesFiberEngineering

A yoga towel comprising a first layer for standing poses made of woven nylon threads and fibers made from skin-polishing cloth, and an opposite second layer for sitting, kneeling and lying poses made of waffle-woven microfiber fabric. The yoga towel has an edge made of sailcloth. The yoga towel is constructed to prevent a participant from slipping during standing yoga poses, and the exterior remains dry to the touch during use.

Owner:SILVER PLUME

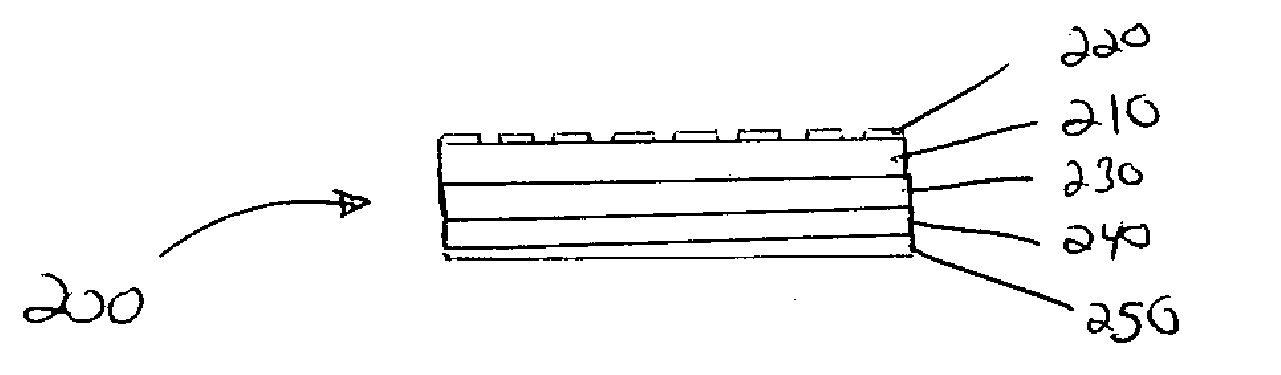

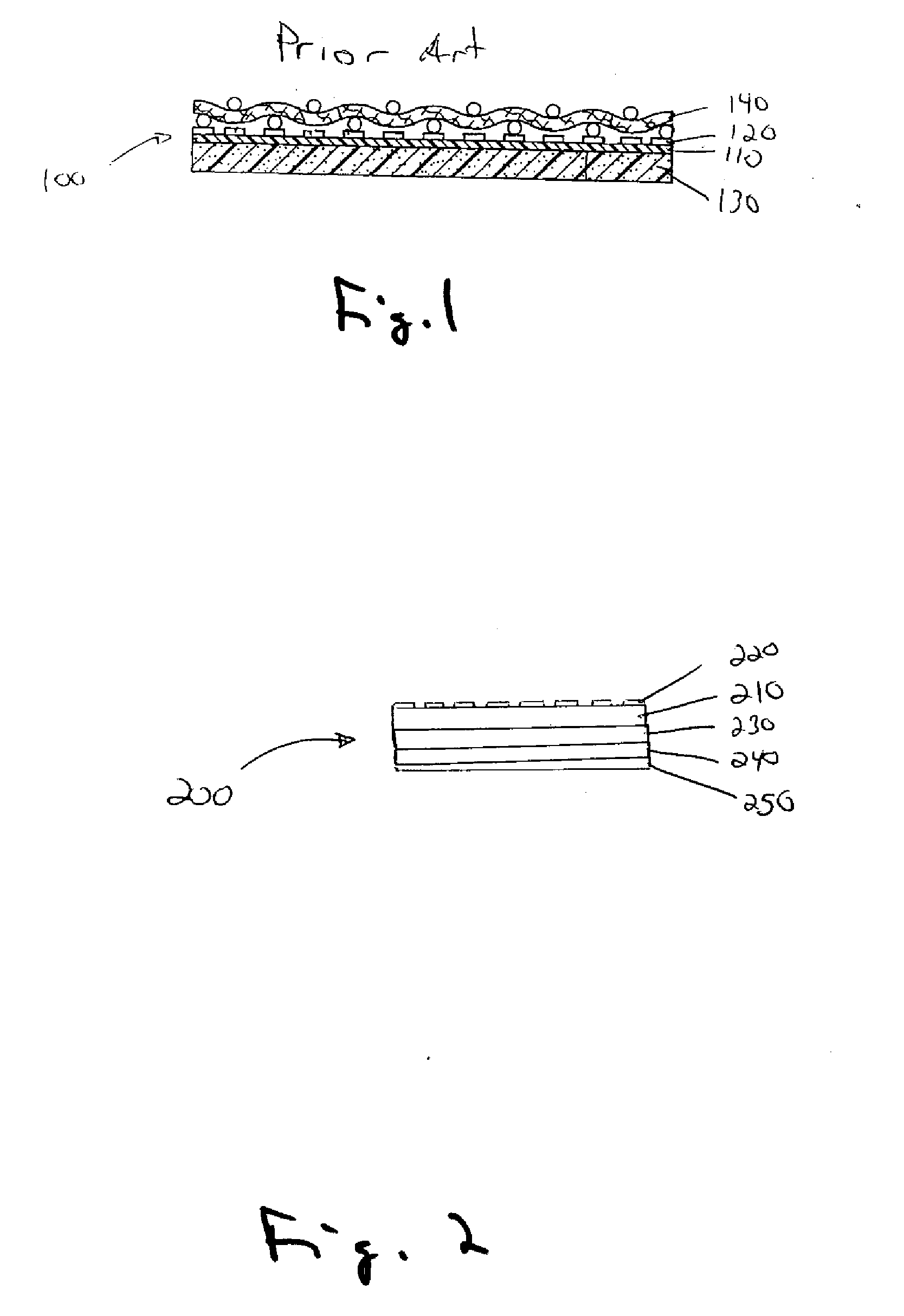

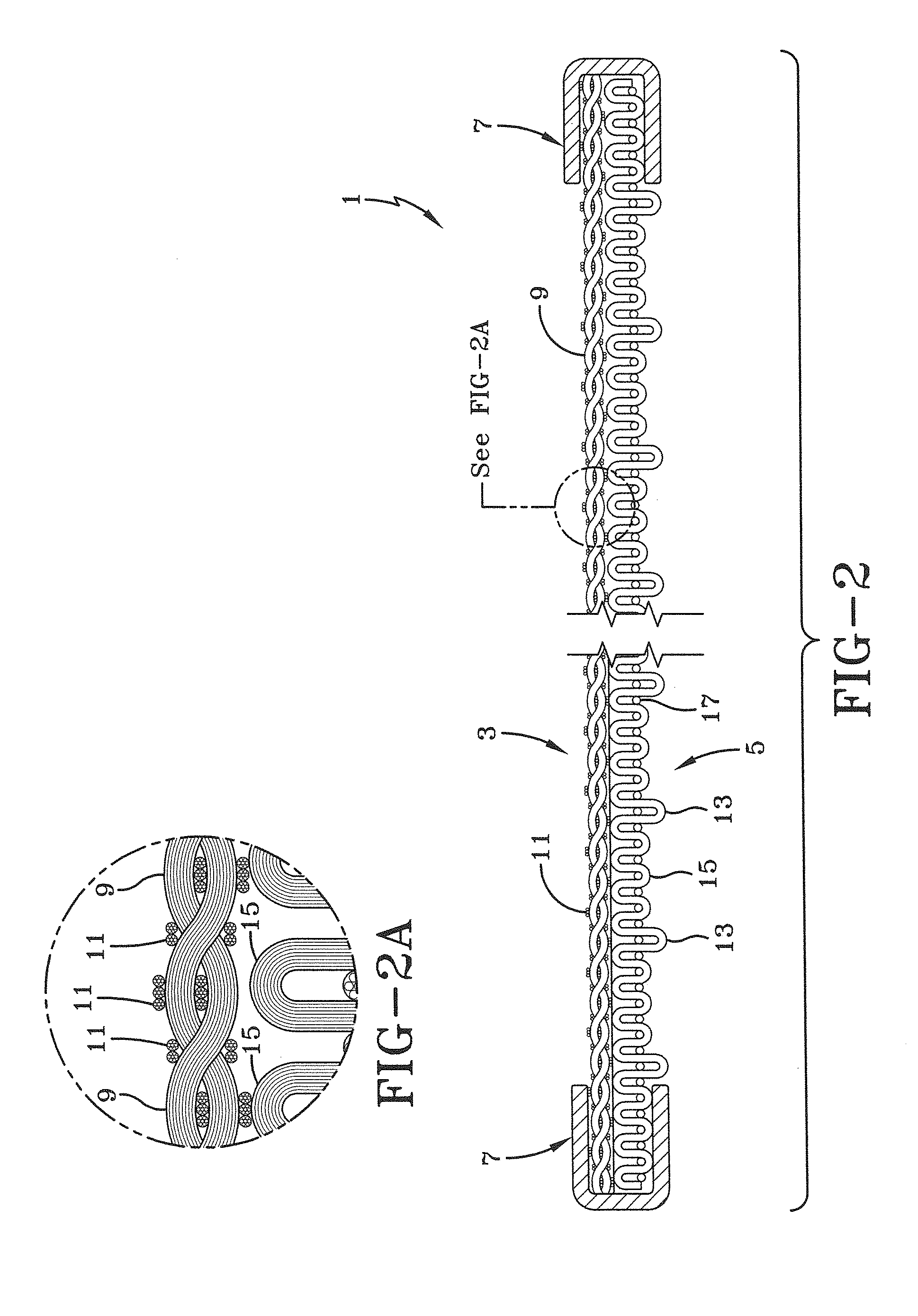

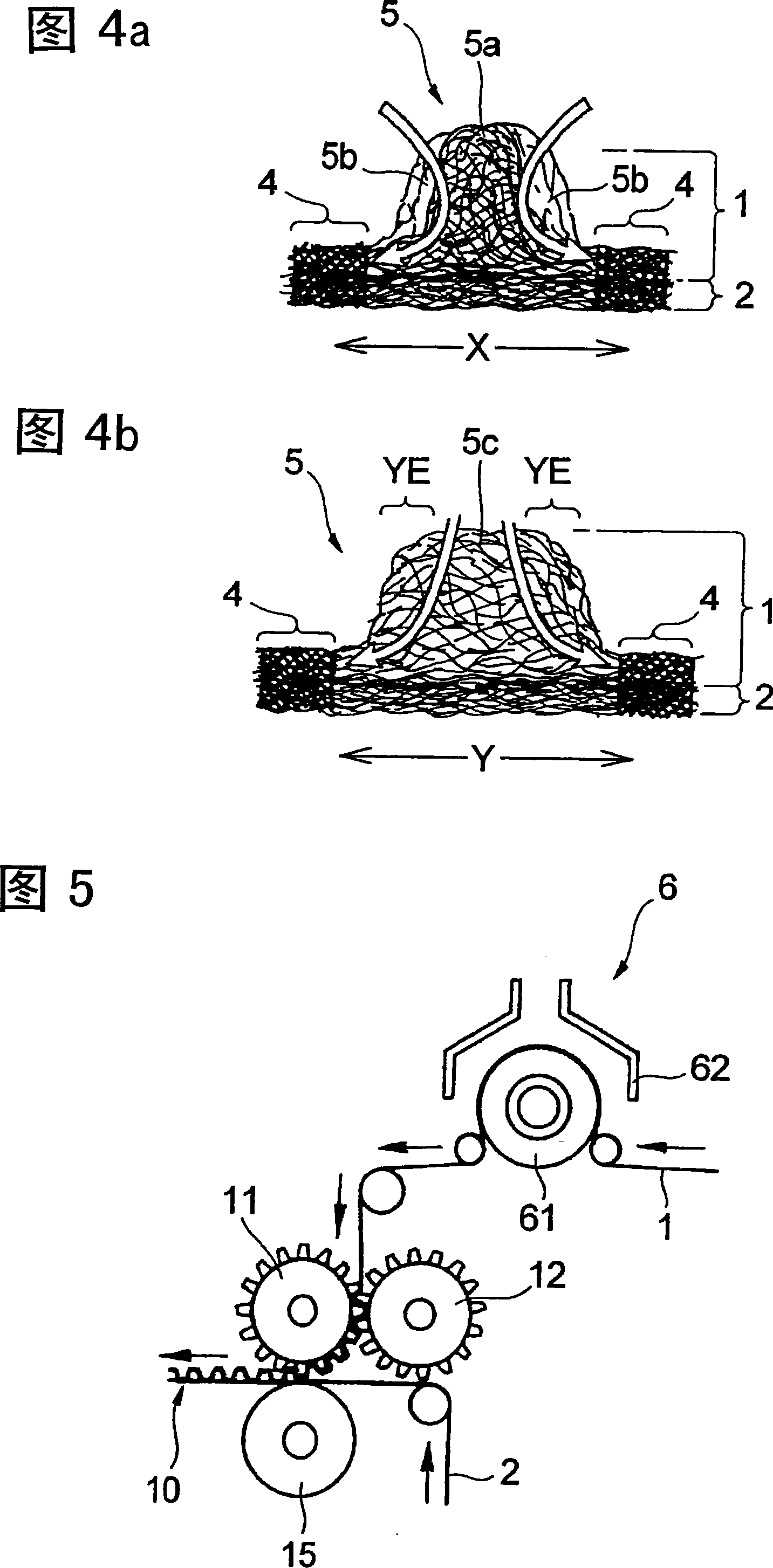

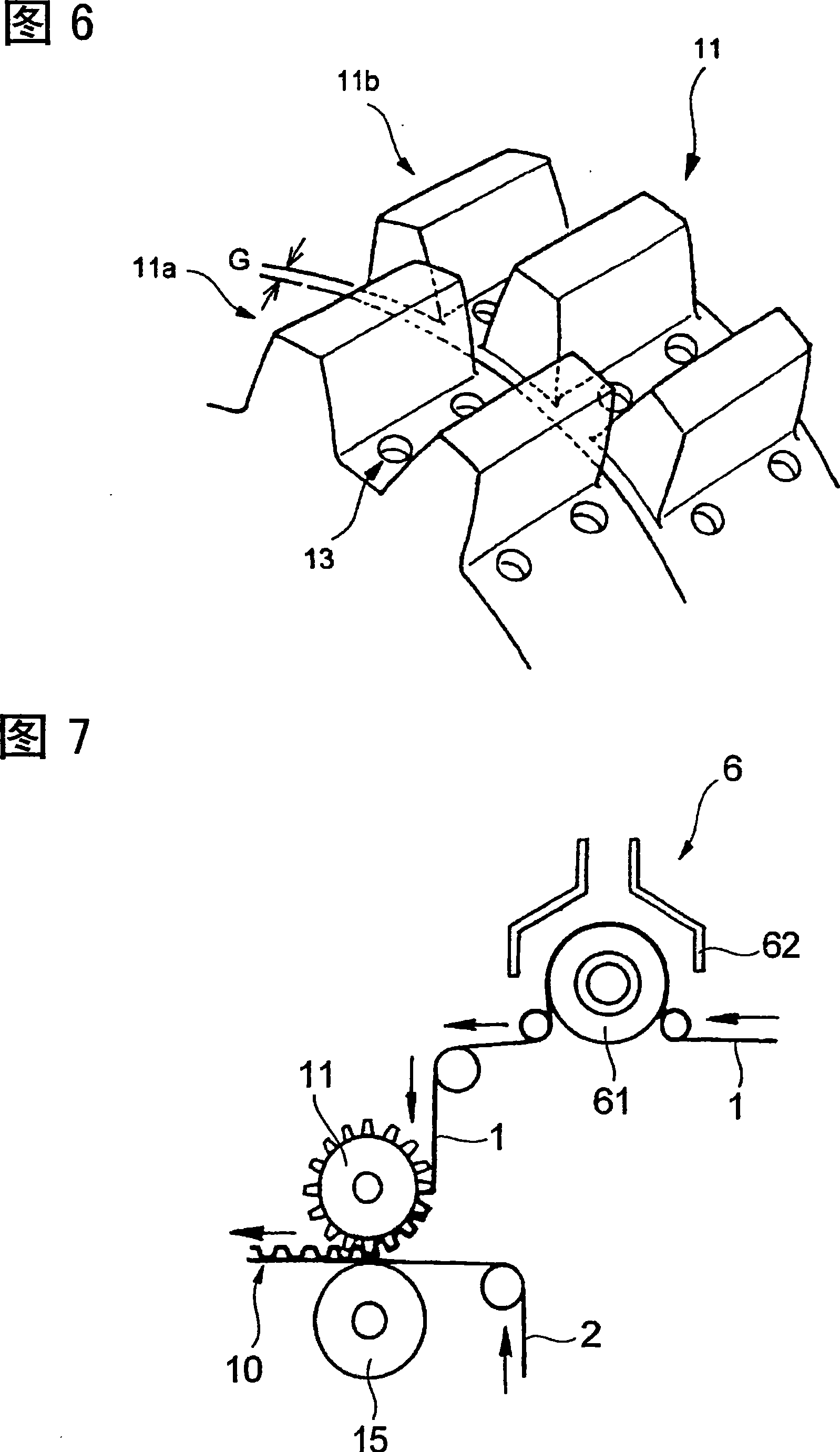

Face sheet for absorption article and method for producing the same

A face sheeting is used as a skin contact surface for an absorbency object, and stacked first non-woven fabrics and second non-woven fabrics are partially melted and cohered to form a melted cohere part. Other parts of the first non-woven fabrics except the melted cohere part protrudes to the skin of the wearer to form a plurality of bulges. The bulge and the melted cohere part are disposed alternately to form an array arrangement with a plurality of arrays. At least part of bulges in a fiber orientation direction of the first non-woven fabrics have a fiber sparse part with a lower fibre density than that at a center part in the fiber orientation direction at one end or two ends.

Owner:KAO CORP

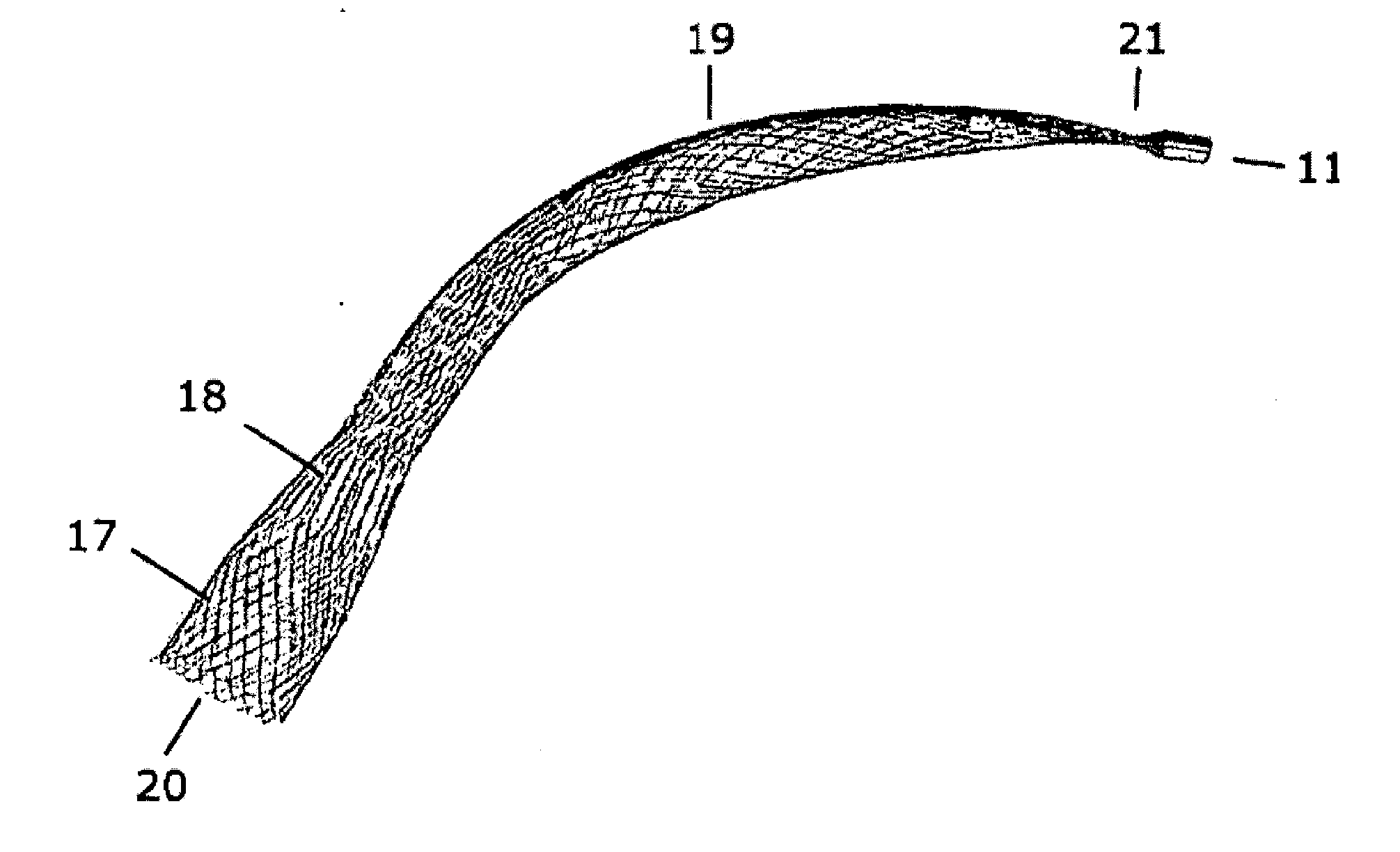

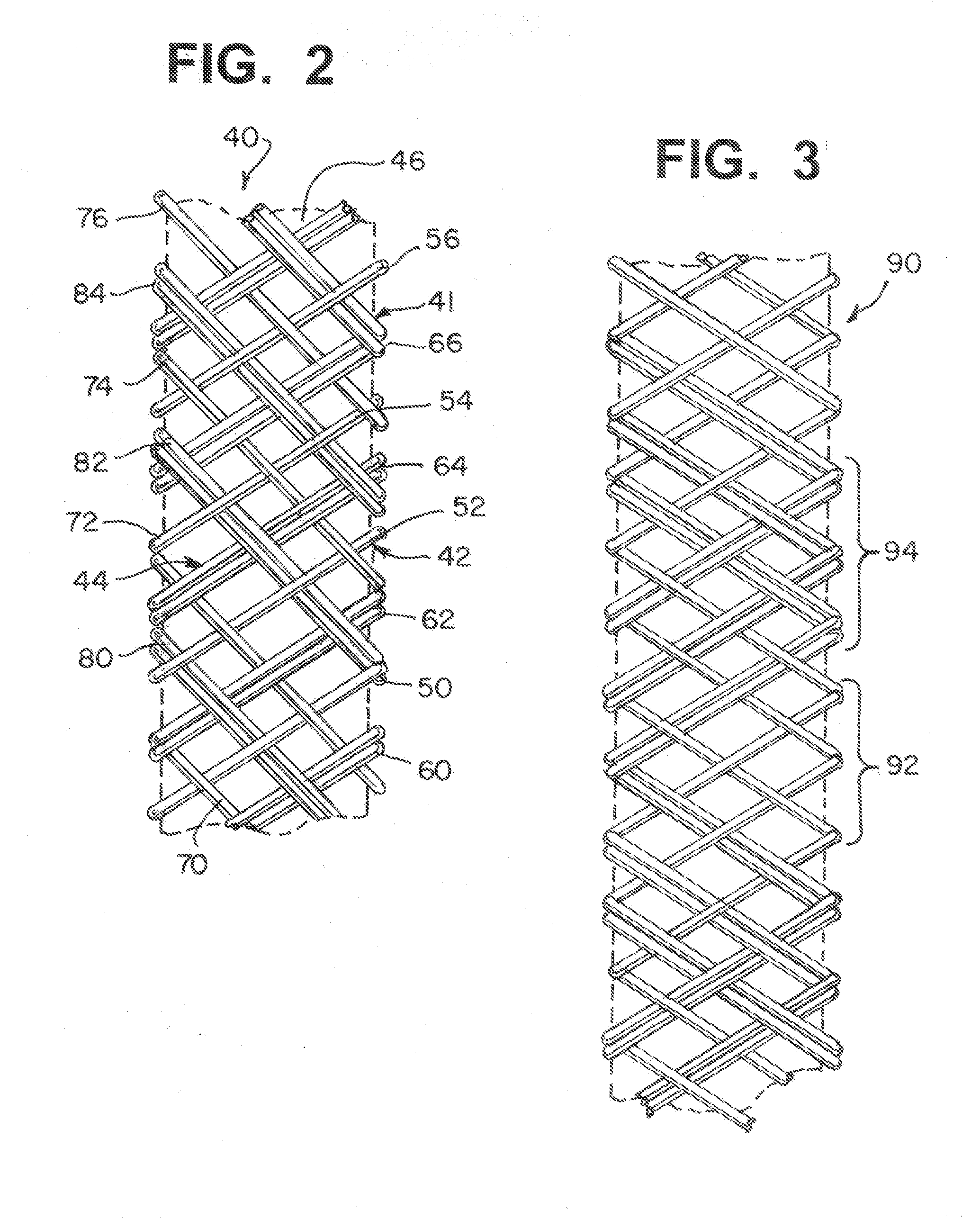

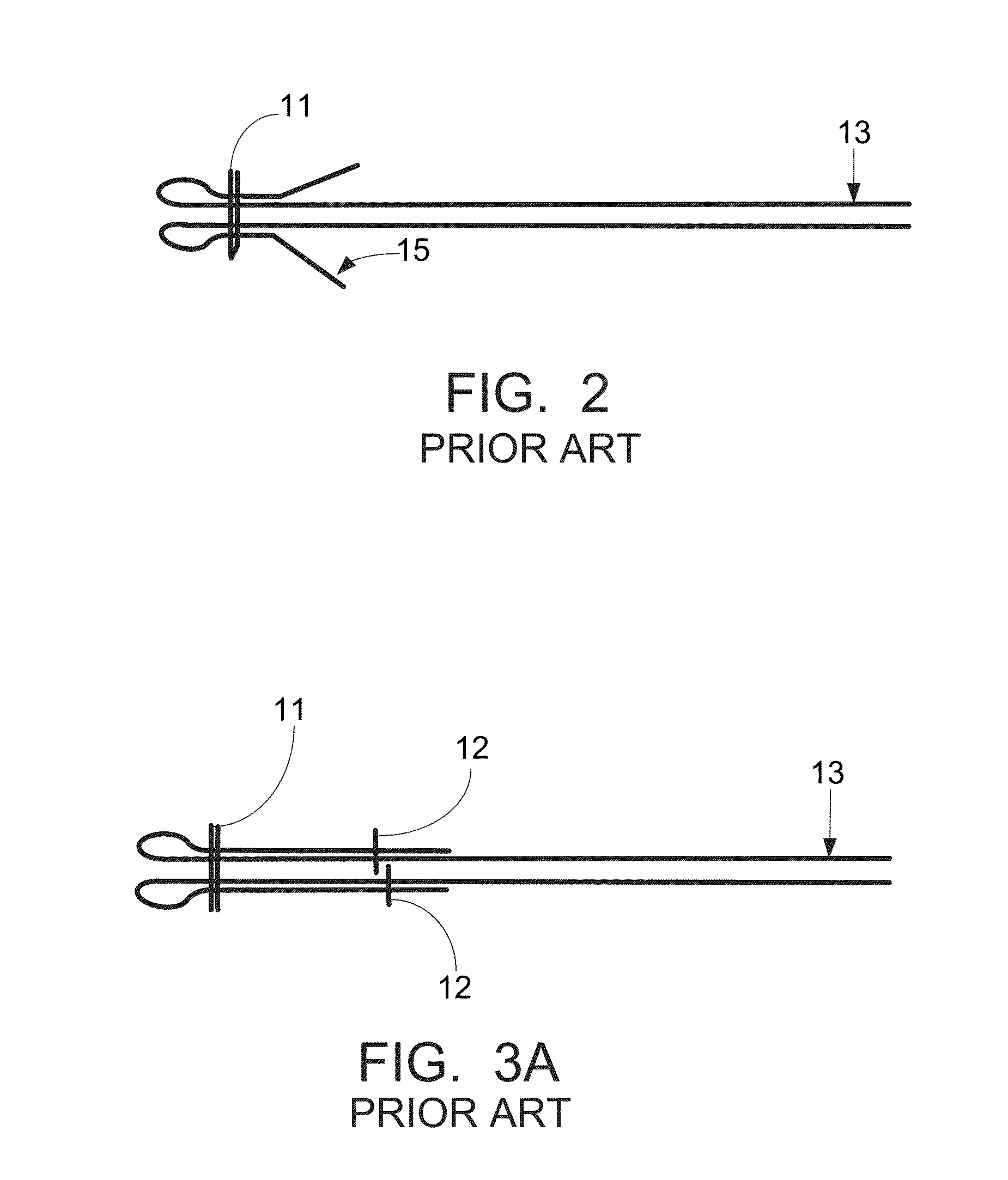

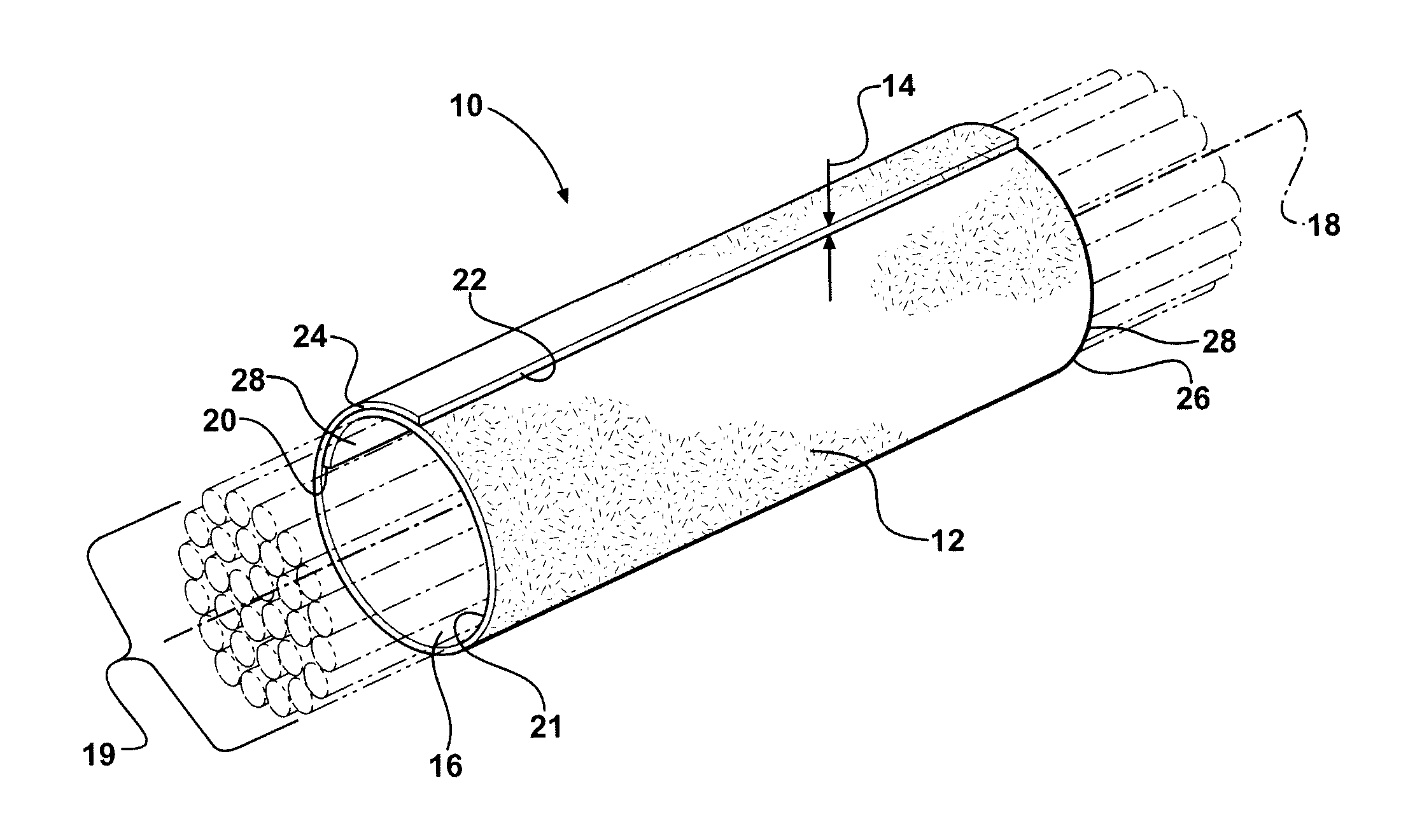

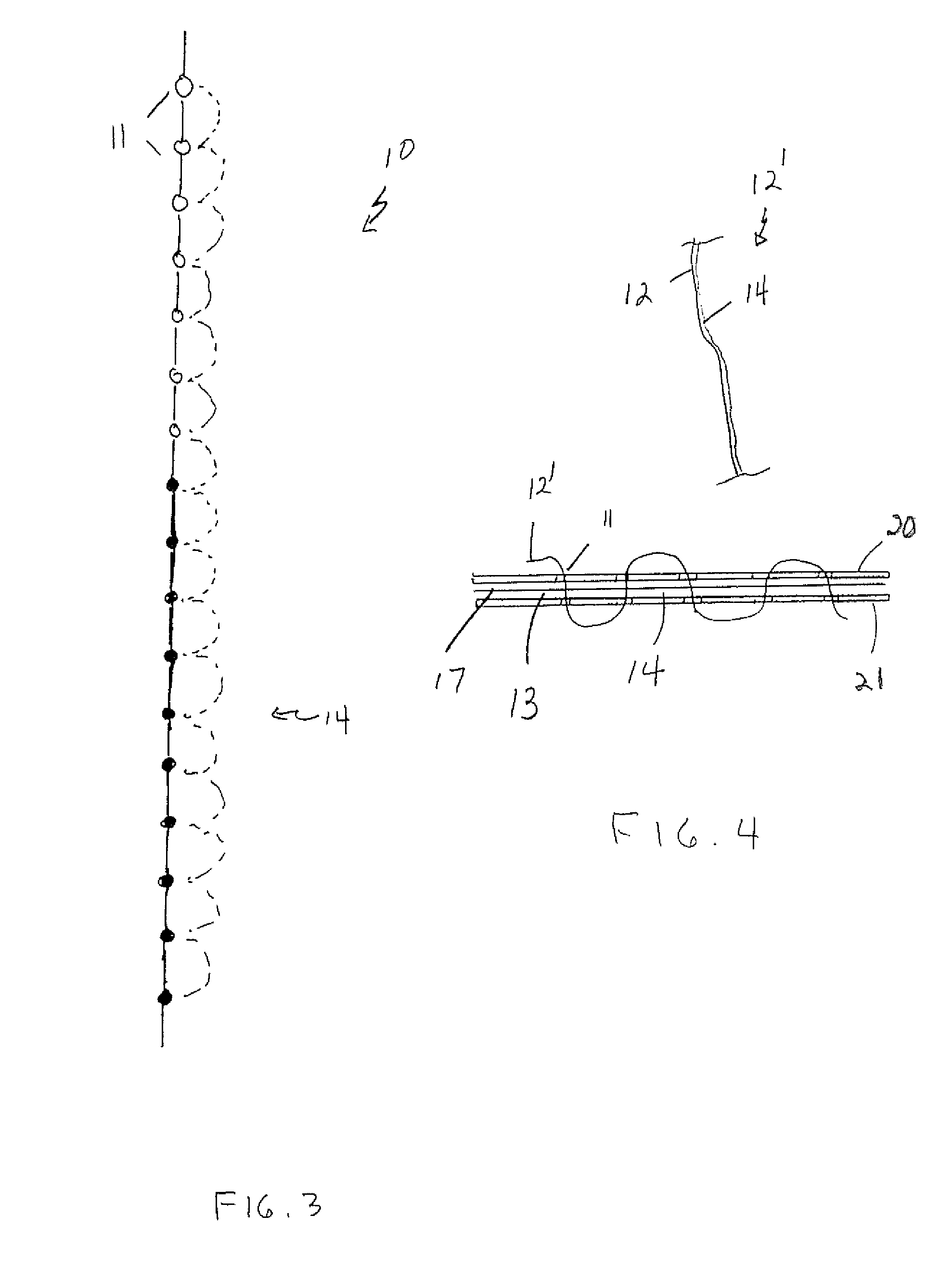

Multi-strand implant with enhanced radiopacity

ActiveUS20160058524A1Improve radiopacityMinimize changesMechanical cleaningPressure cleaningSingle strandBiomedical engineering

An implant for medical use, and methods of making same, having a body formed of a plurality of single strands of a first material. The body further includes at least one multi-strand of radiopaque material incorporated among the single strands, the multi-strand having at least two side-by-side filaments of radiopaque material that lie substantially contiguous to each other over substantially the entire length of the multi-strand.

Owner:DEPUY SYNTHES PROD INC

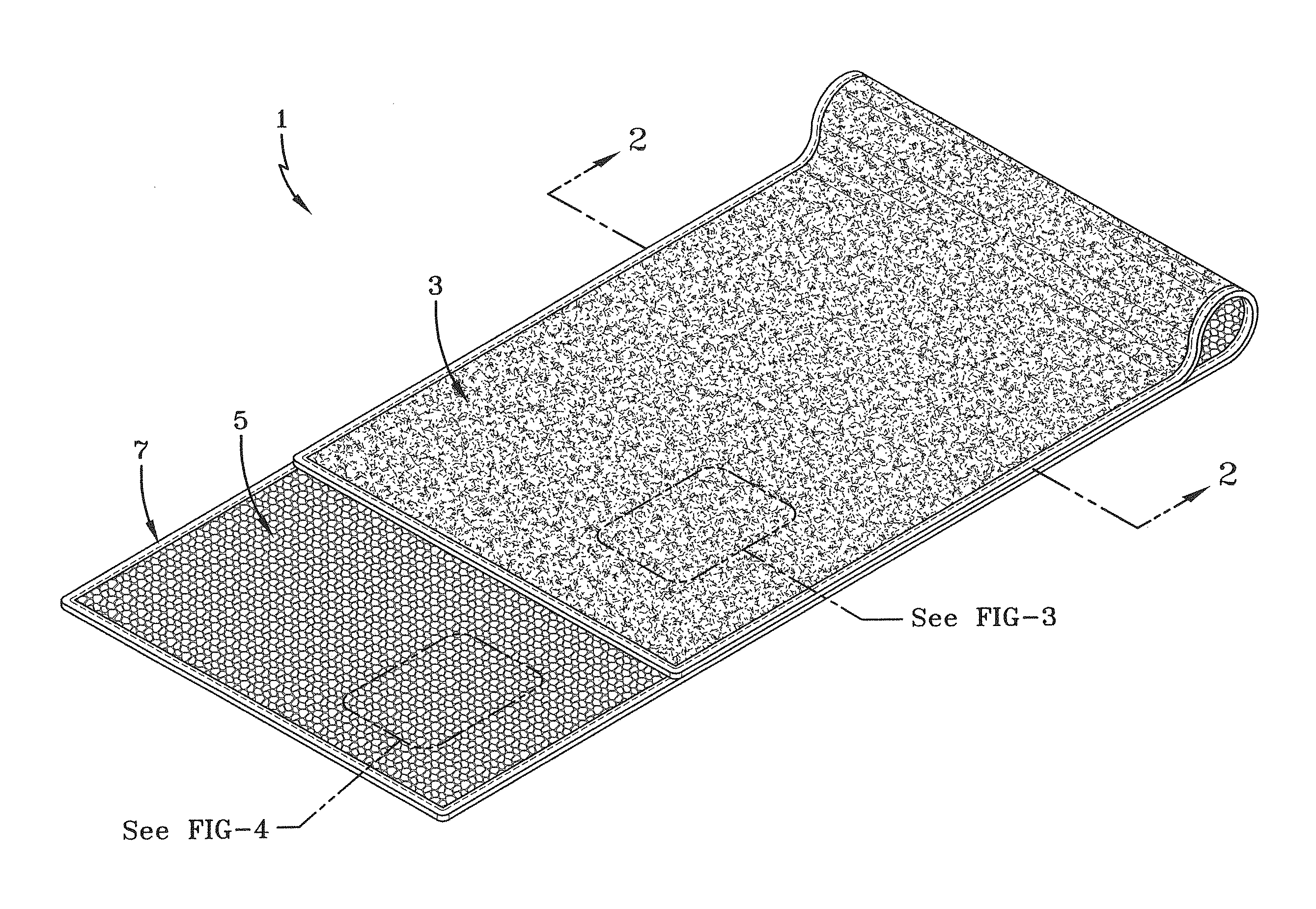

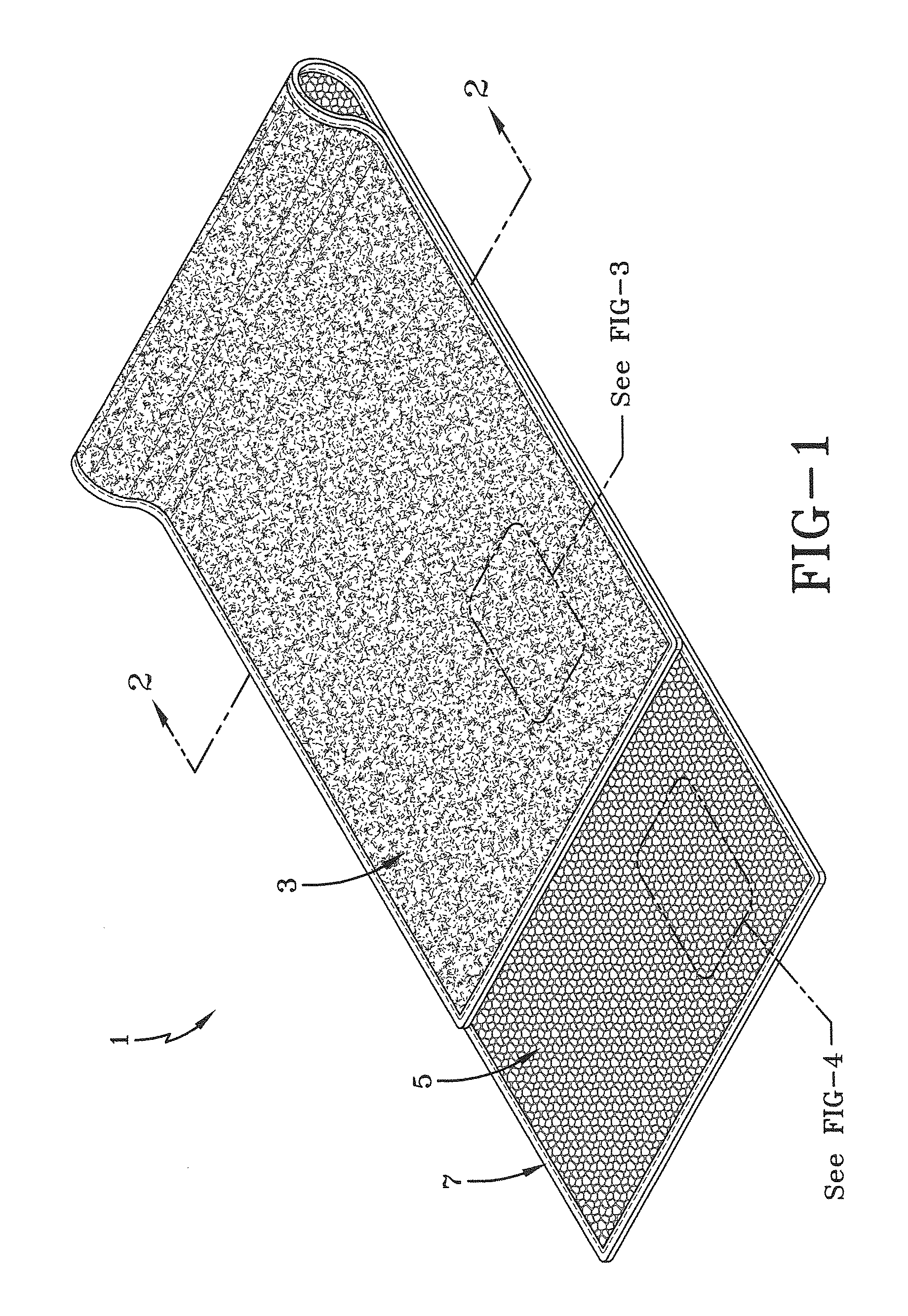

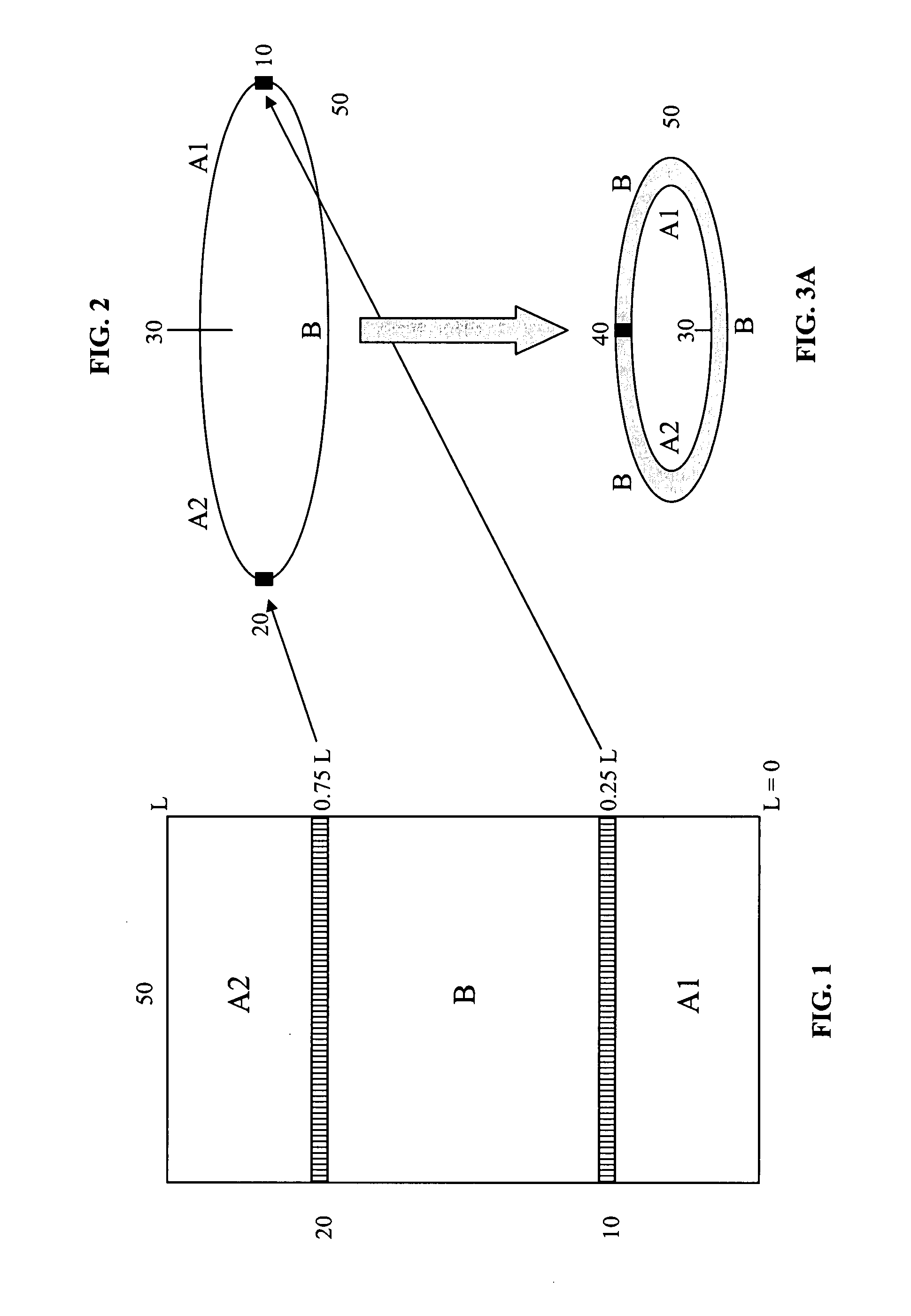

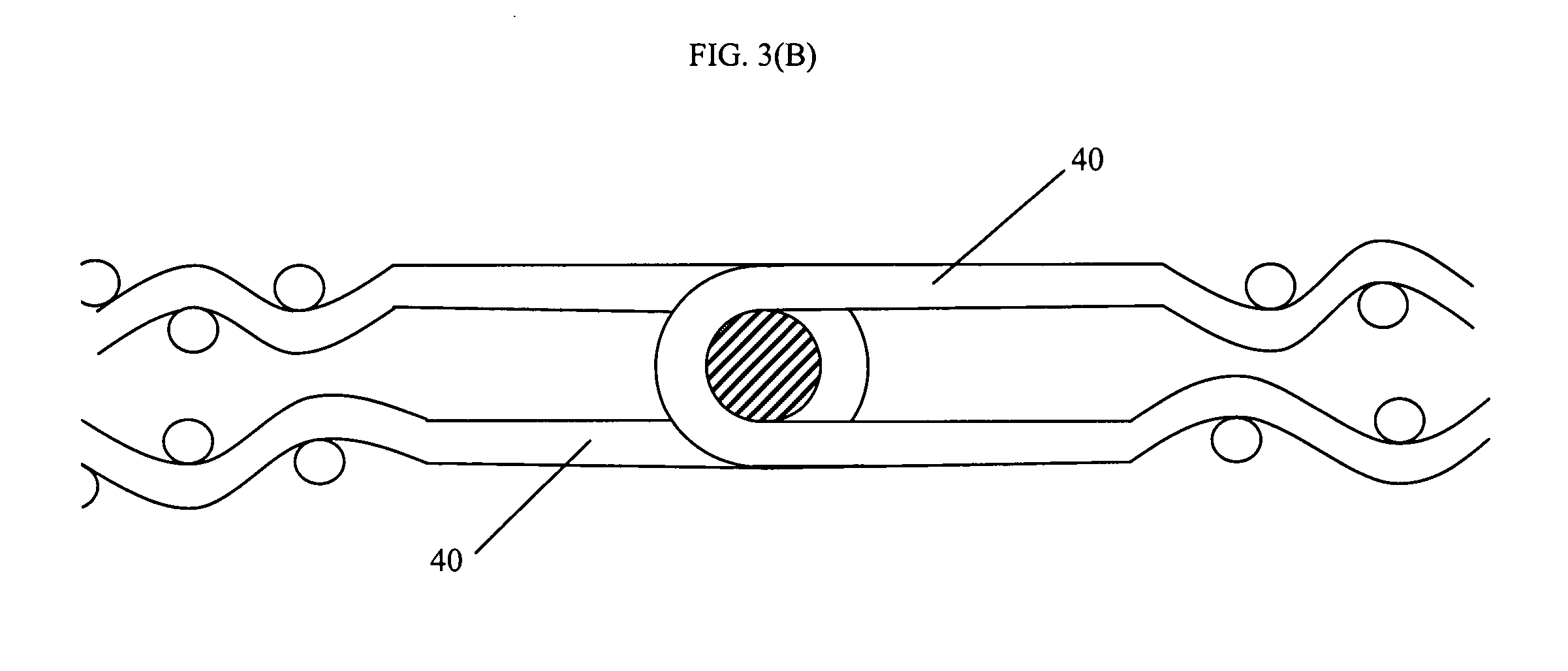

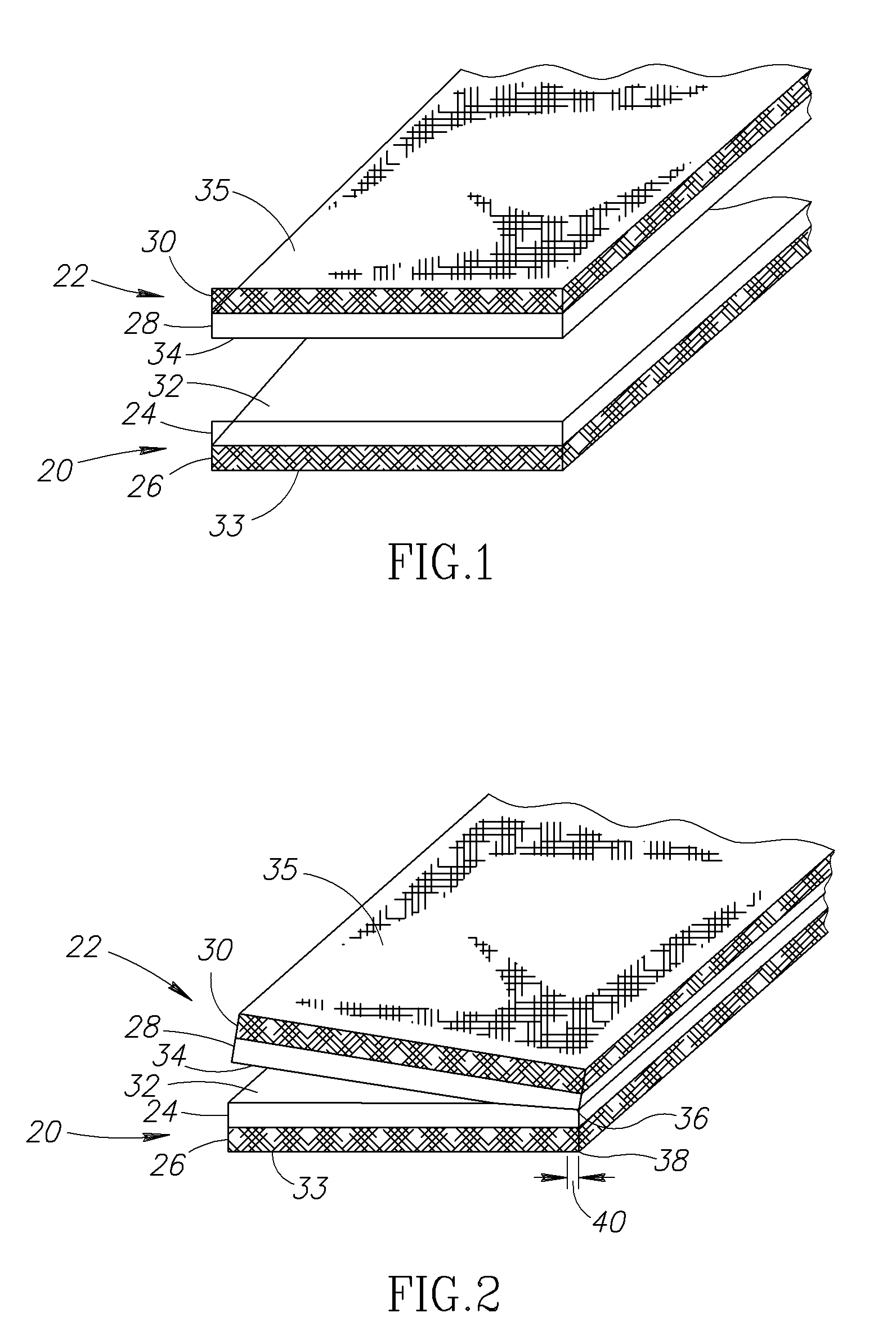

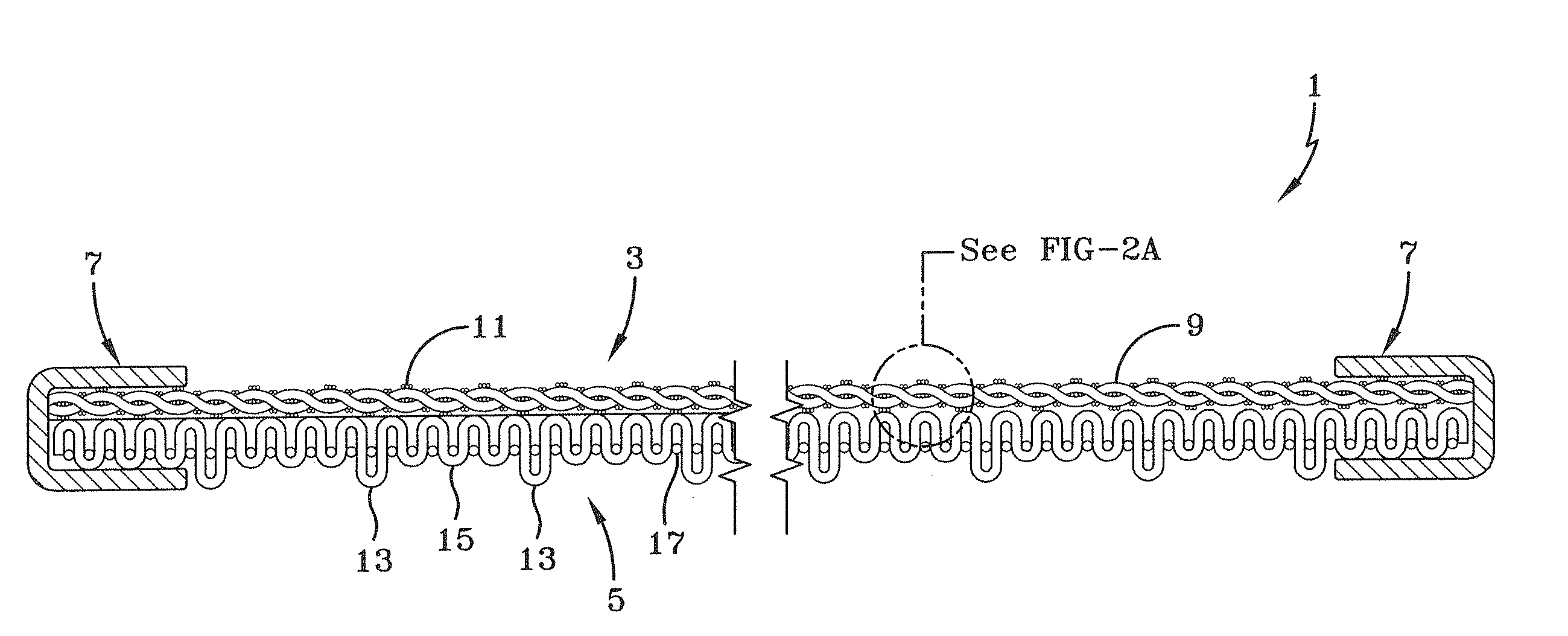

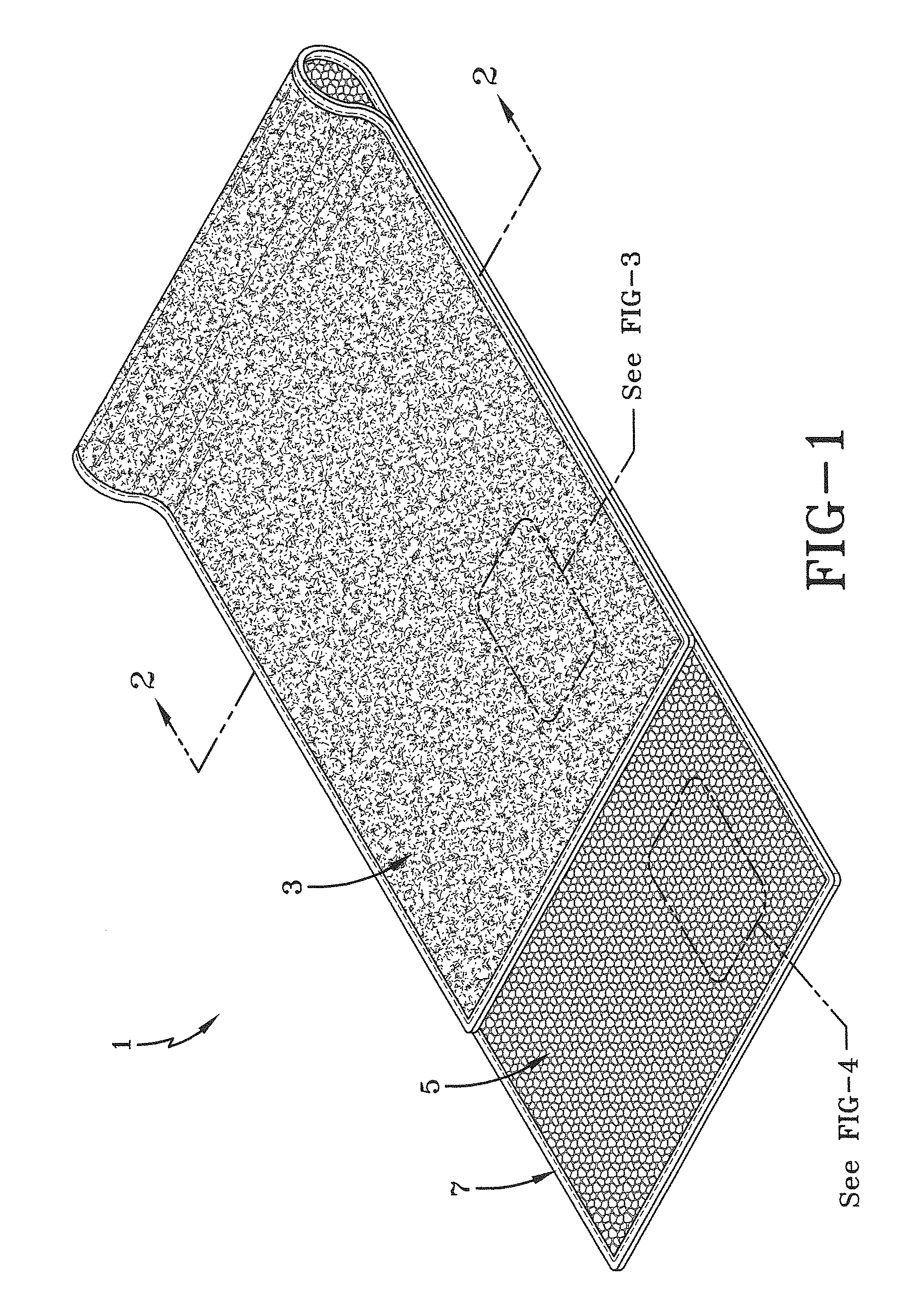

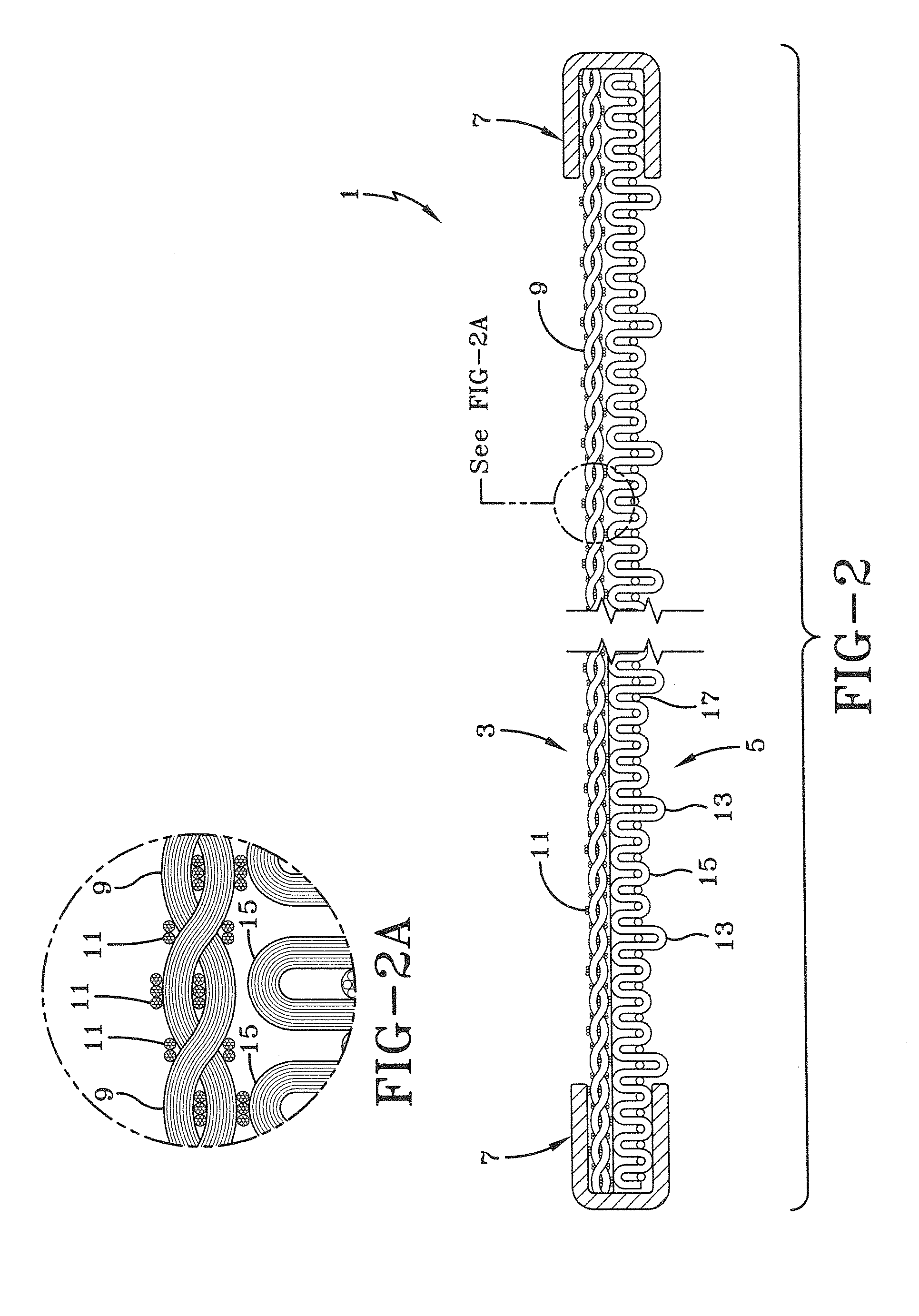

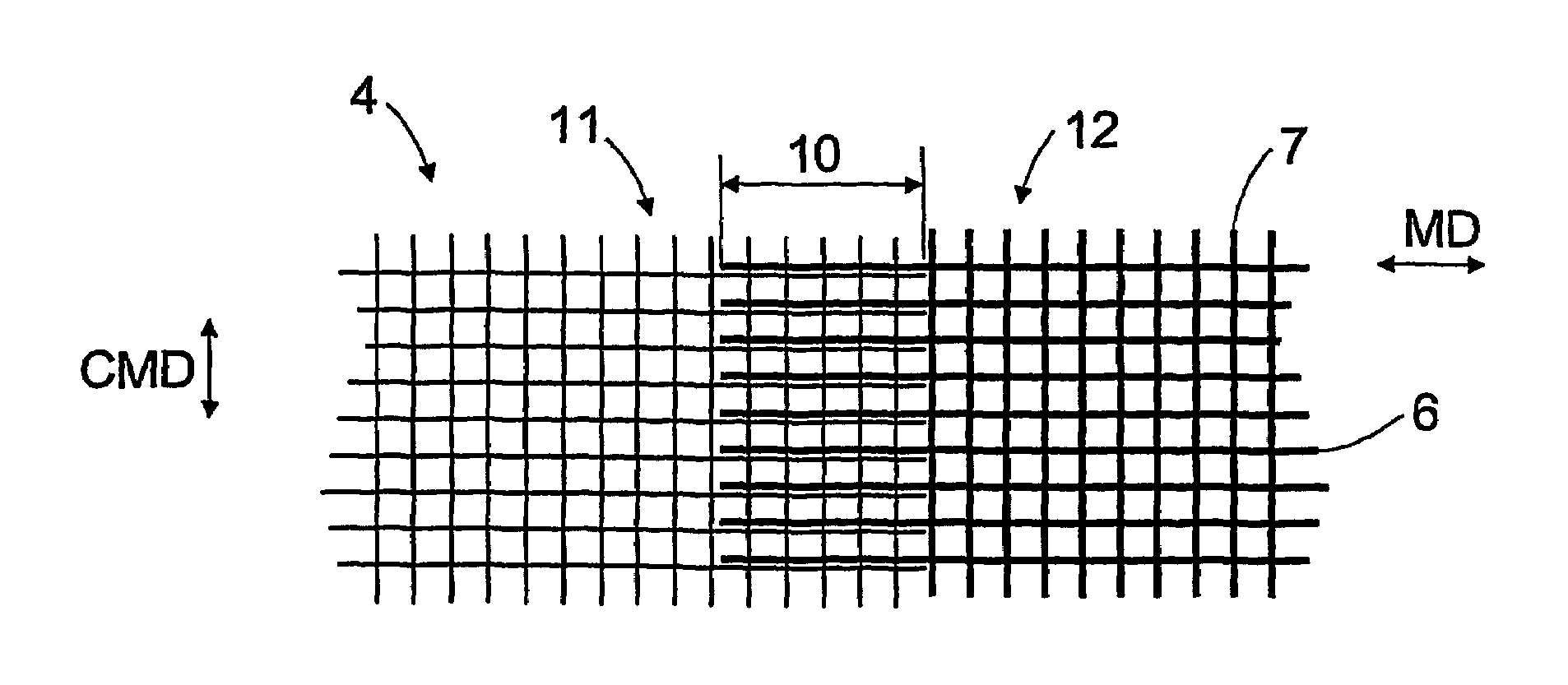

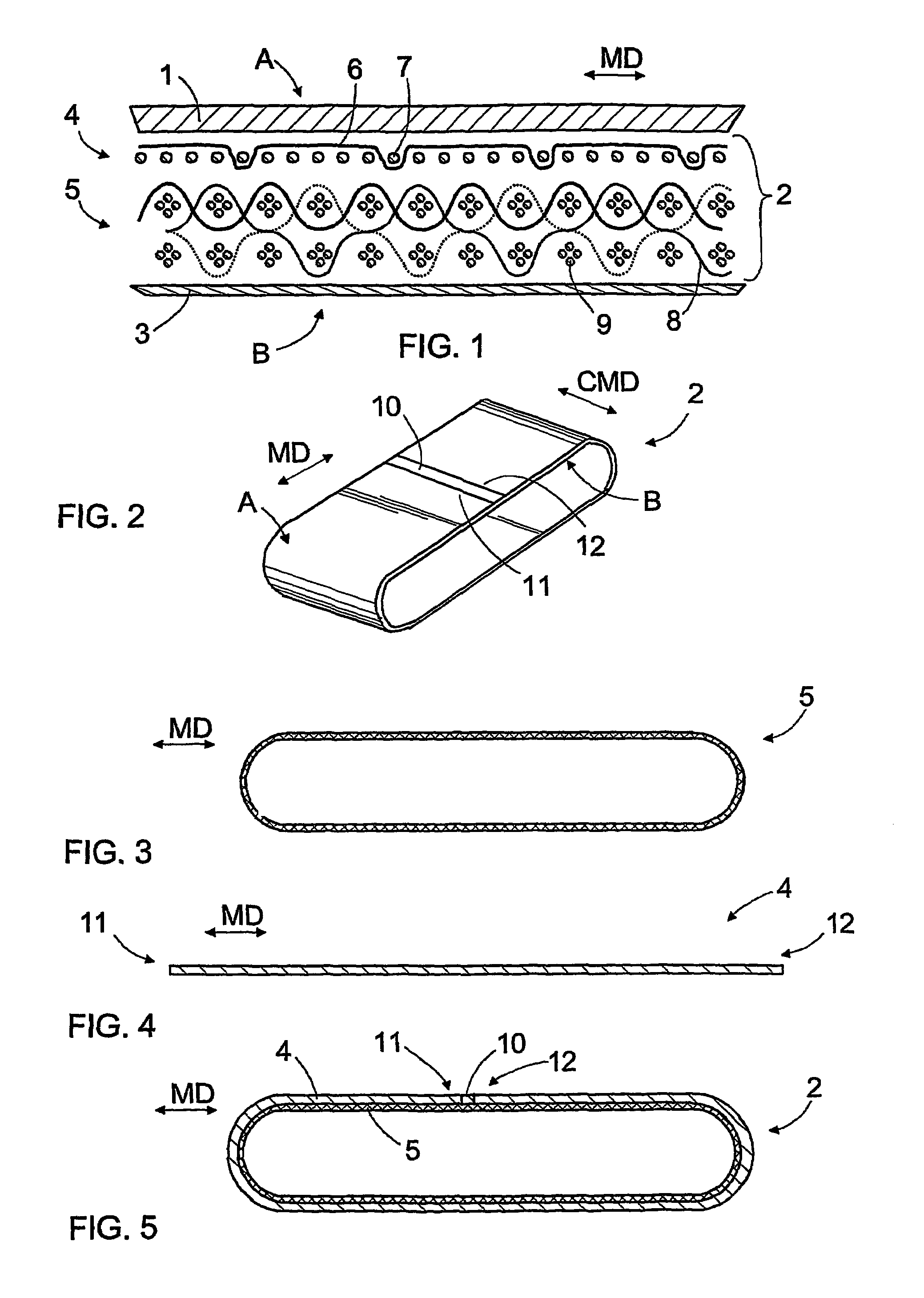

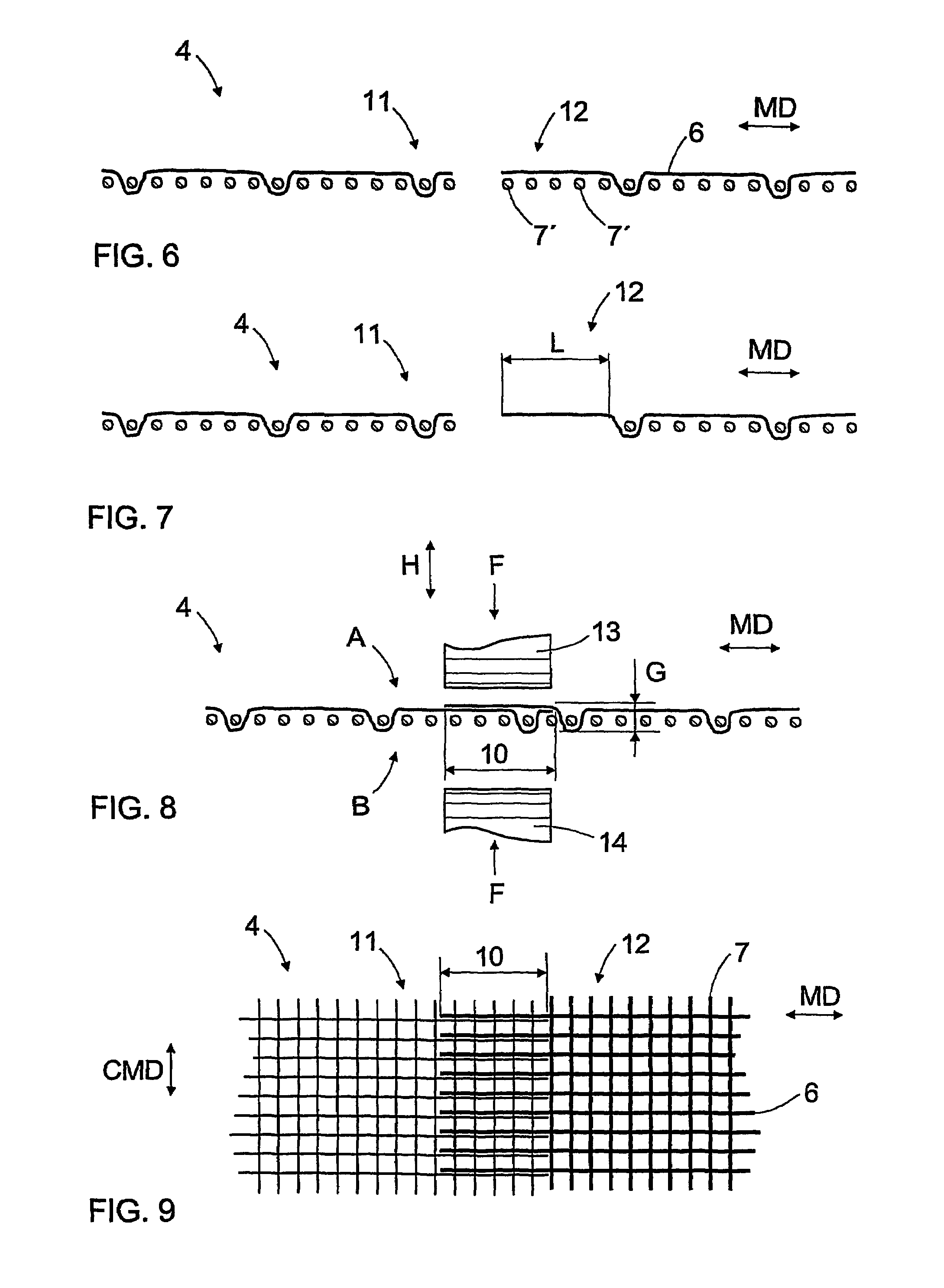

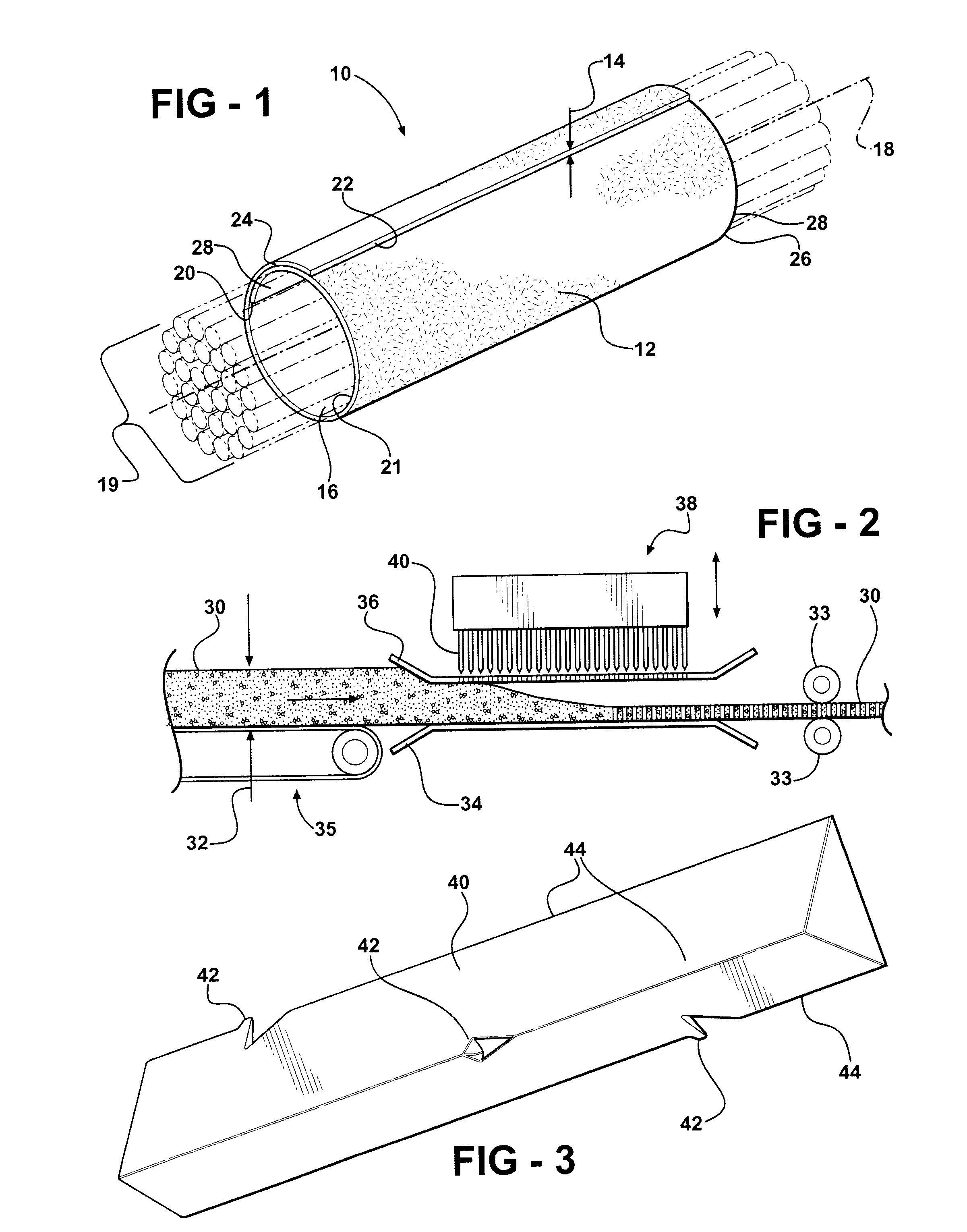

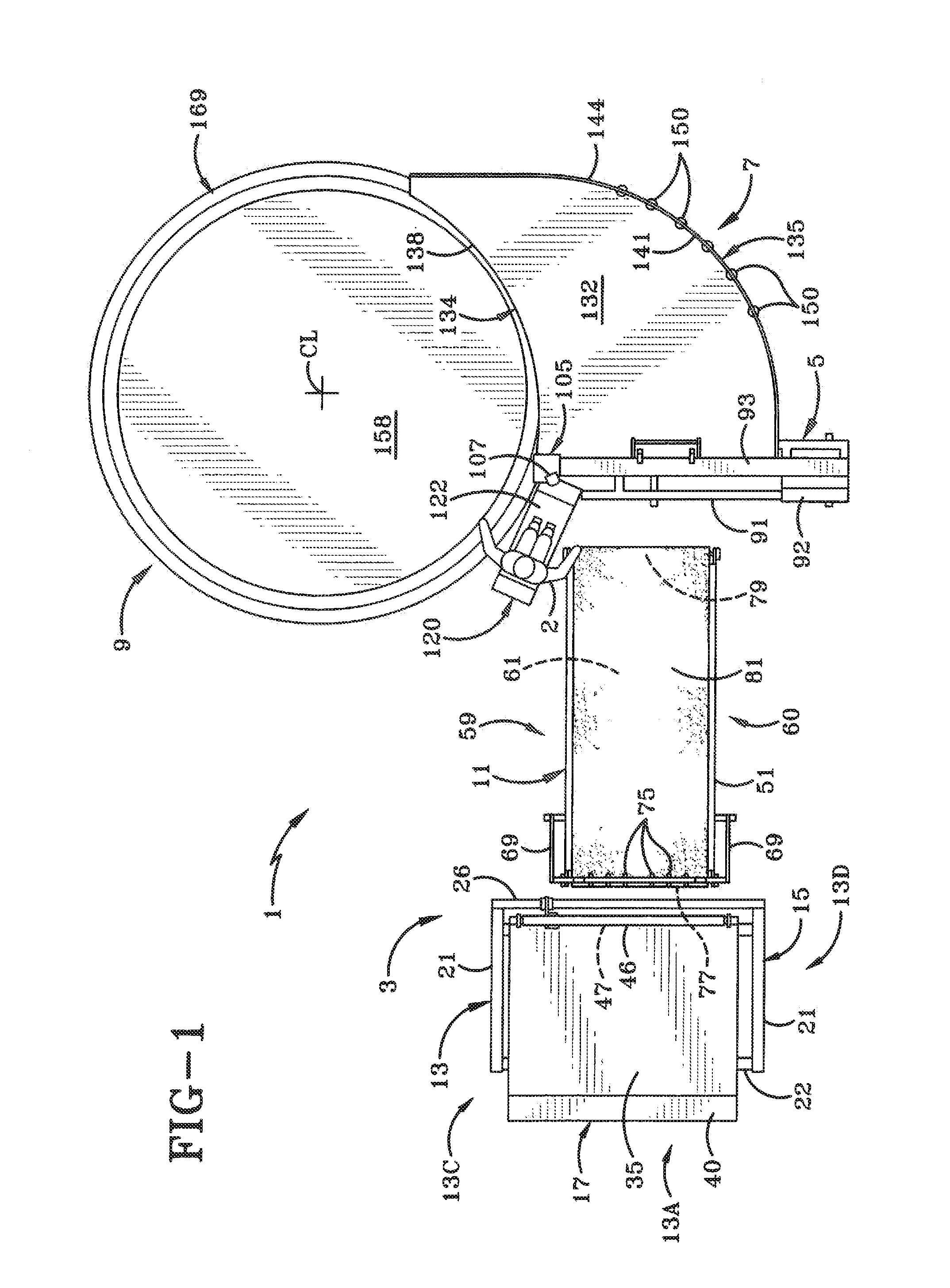

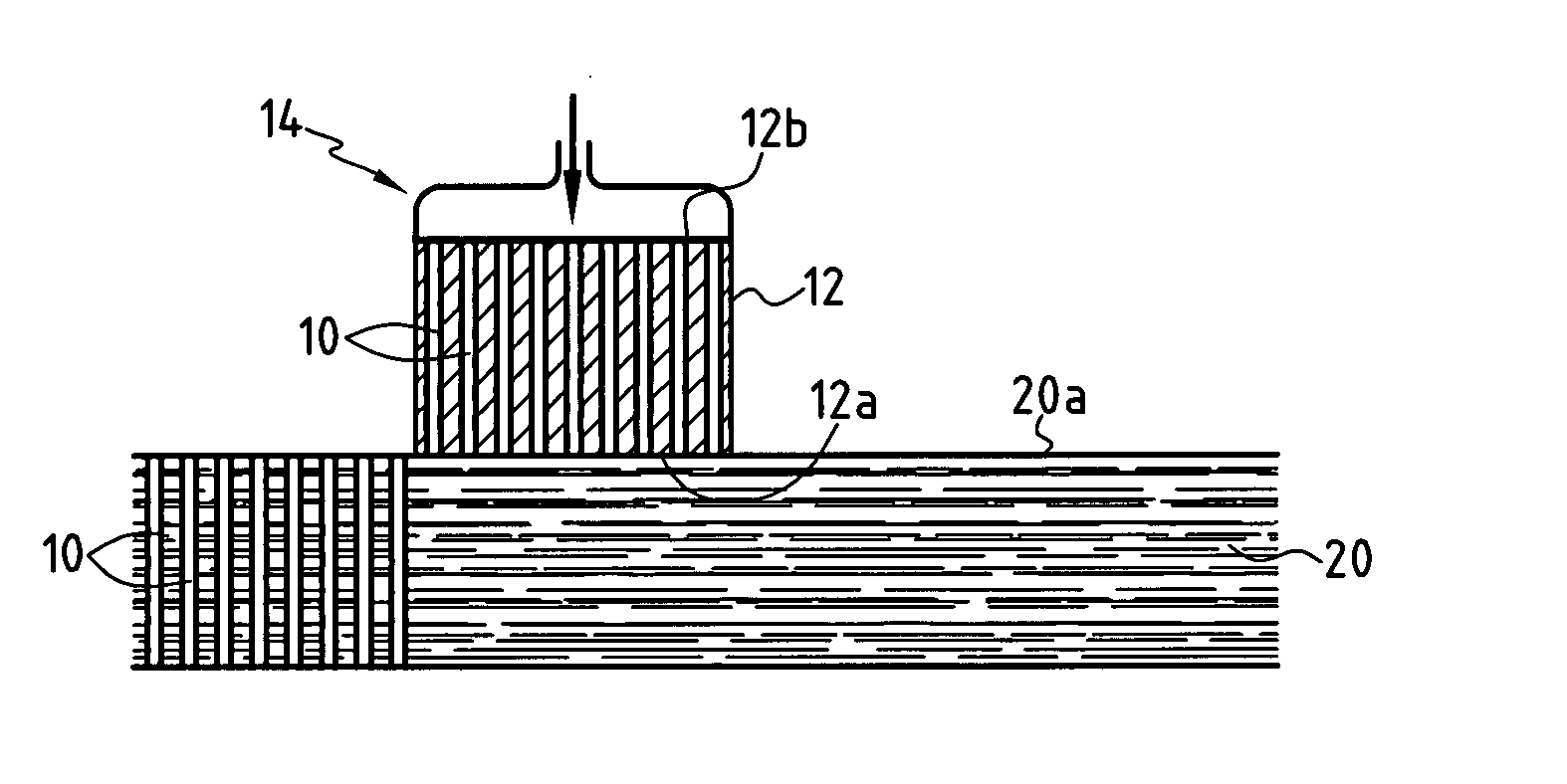

Flat woven full width on-machine-seamable fabric

ActiveUS7892402B2Strong and reliable fabricMethod of manufactureSeaming textilesMachine wet endEngineering

A laminated on-machine-seamable industrial fabric made from a flat woven full width base fabric layer wherein the base fabric layer is folded inwardly and flattened to produce a fabric with seaming loops disposed at the two widthwise edges.

Owner:ALBANY INT CORP

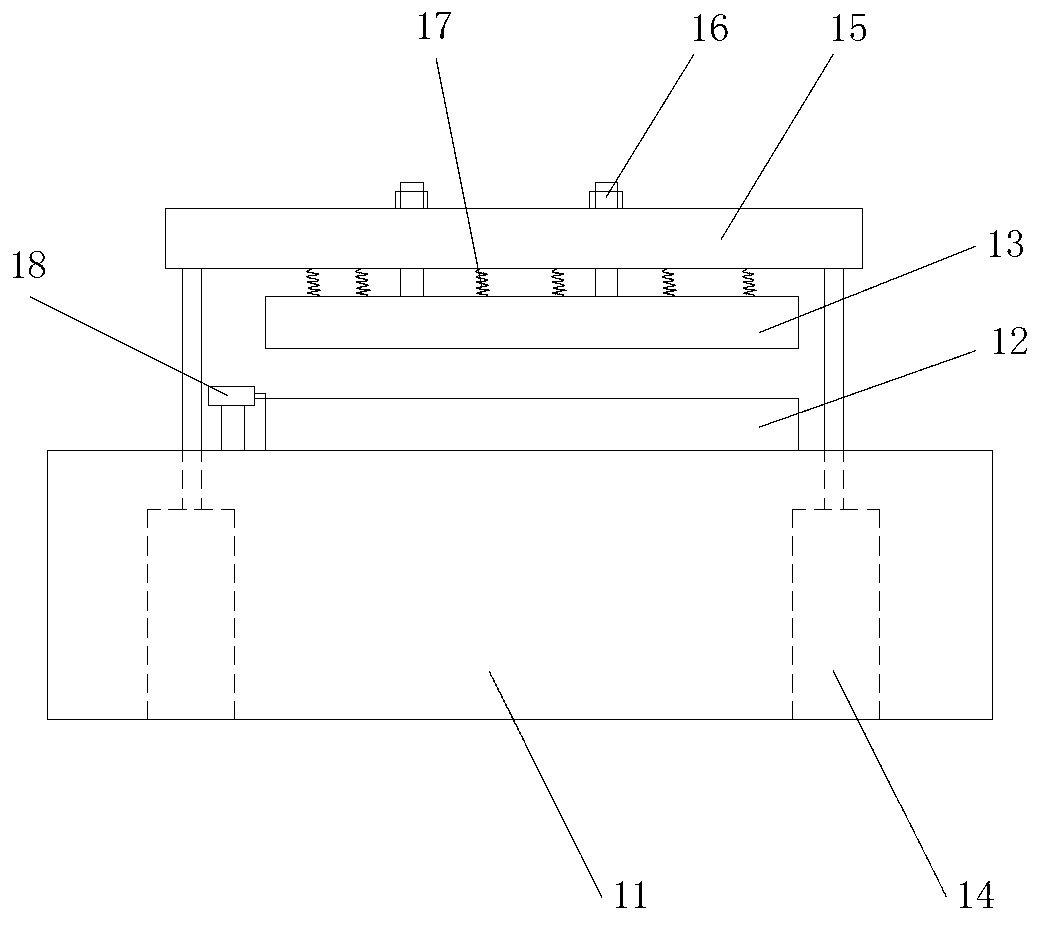

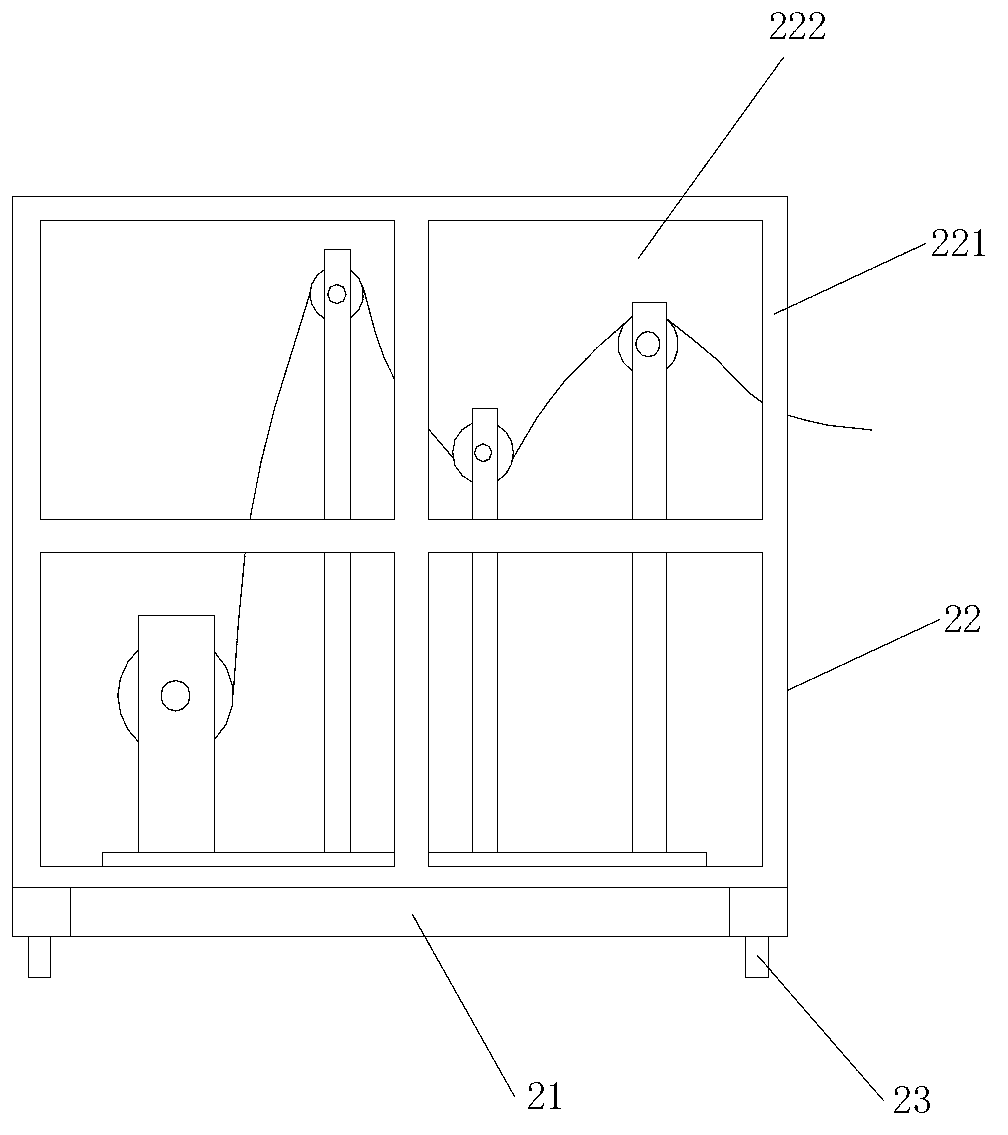

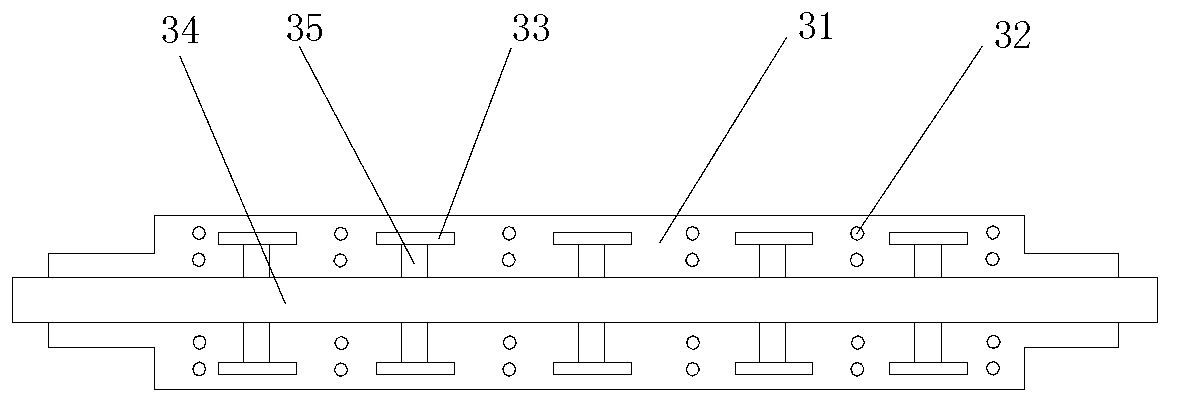

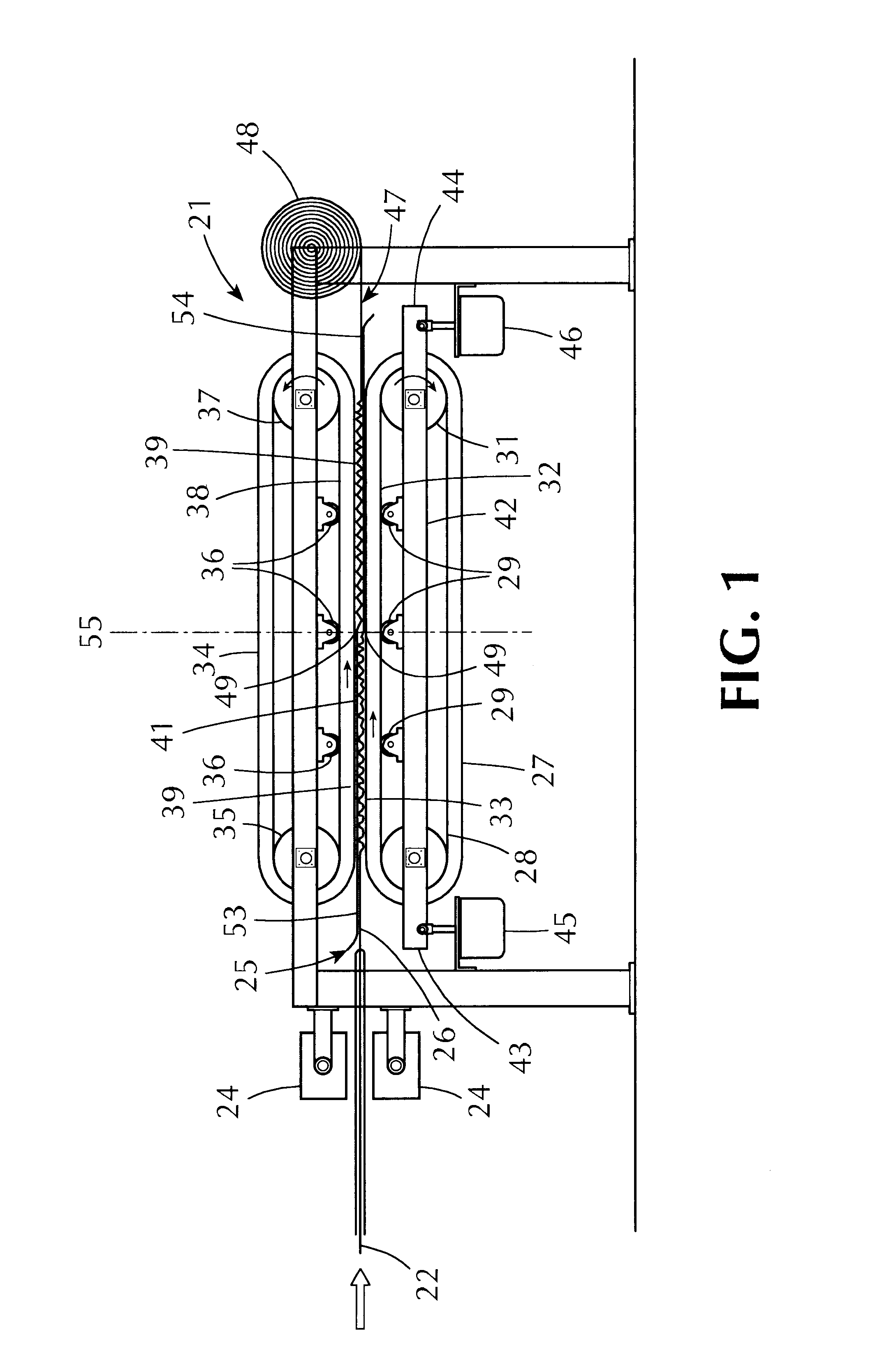

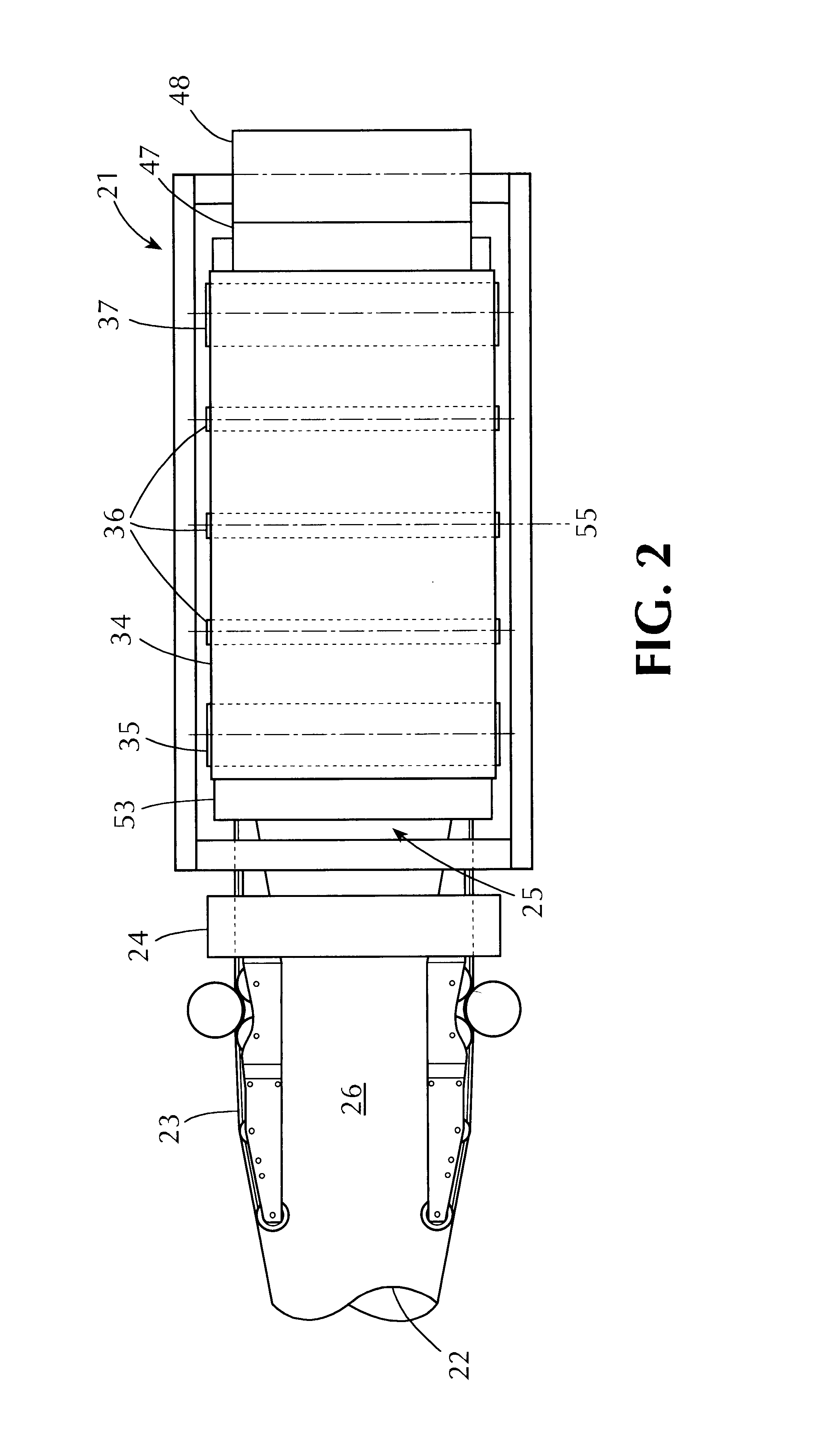

Double-point coating production line for hot-melt adhesive padding cloth

InactiveCN102697213APrevent flutteringAvoid wrinklesInspecting textilesGarmentsProduction linePulp and paper industry

The invention provides a double-point coating production line for hot-melt adhesive padding cloth, and the double-point coating production line comprises a cloth reception device, a wind shielding screen, a size discharging roller, a holt-melt rubber powder blowing / sucking device, a drying oven, a cooling device, an ultraviolet lamp perching device and a rolling device which are arranged in sequence from front to back, wherein the cloth reception device comprises a cloth reception underframe, a lower pressing mould which is arranged on the cloth reception underframe and an upper pressing mould which is arranged on the cloth reception underframe and matched with the lower pressing mould in a lifting manner to crimp padding cloth; the wind shielding screen comprises a screen underframe and a screen plate which is arranged on the screen underframe; the size discharging roller comprises a discharging roller main body and a discharging hole which is formed in the discharging roller main body; and a scraper is arranged in the discharging roller main body. According to the double-point coating production line for hot-melt adhesive padding cloth, the unrolling speed of the padding cloth is increased, the continuous production is realized, the work efficiency is improved, the production cost is reduced and the quality of the padding cloth is improved.

Owner:HANGZHOU AOKE GARMENT ACCESSORIES

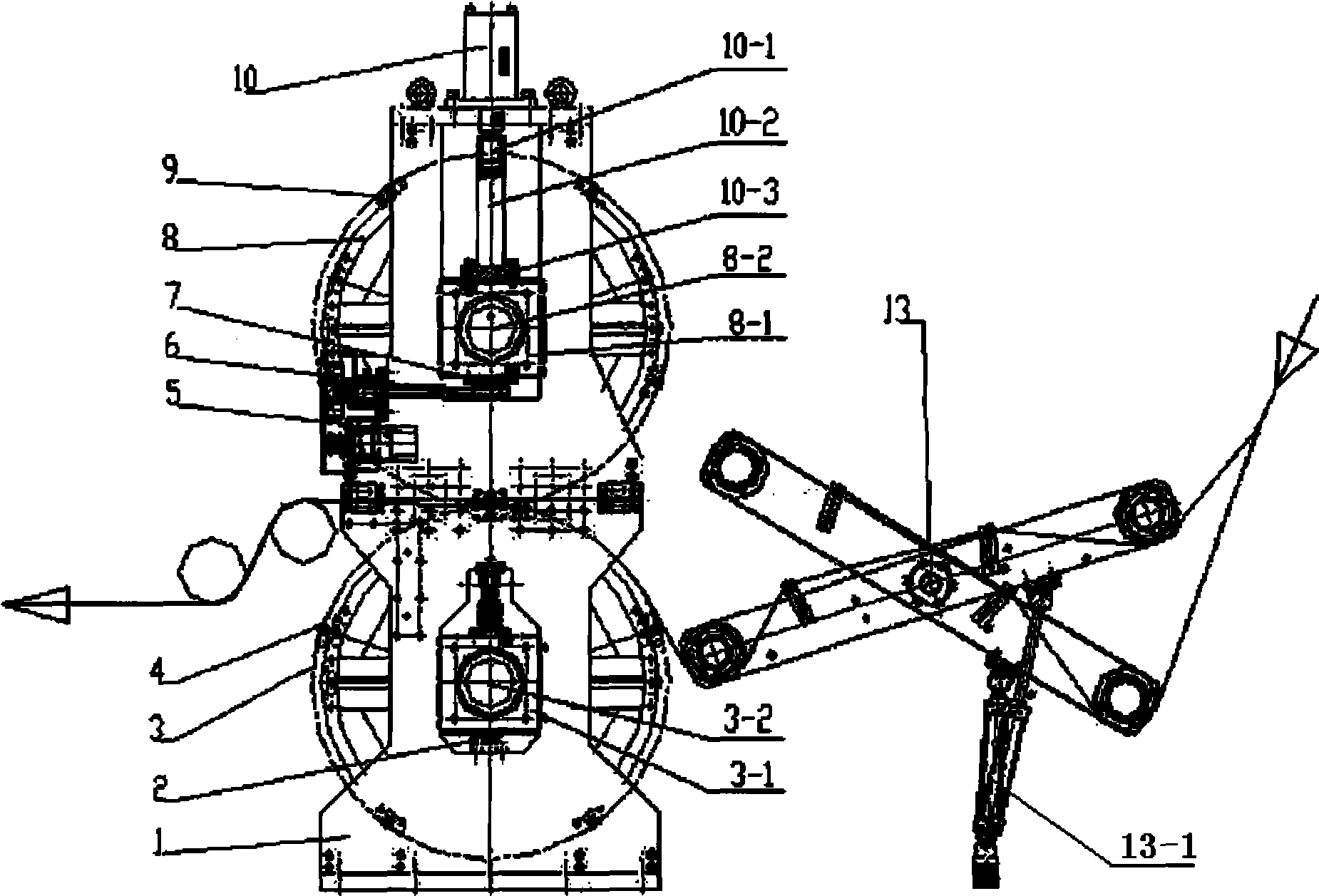

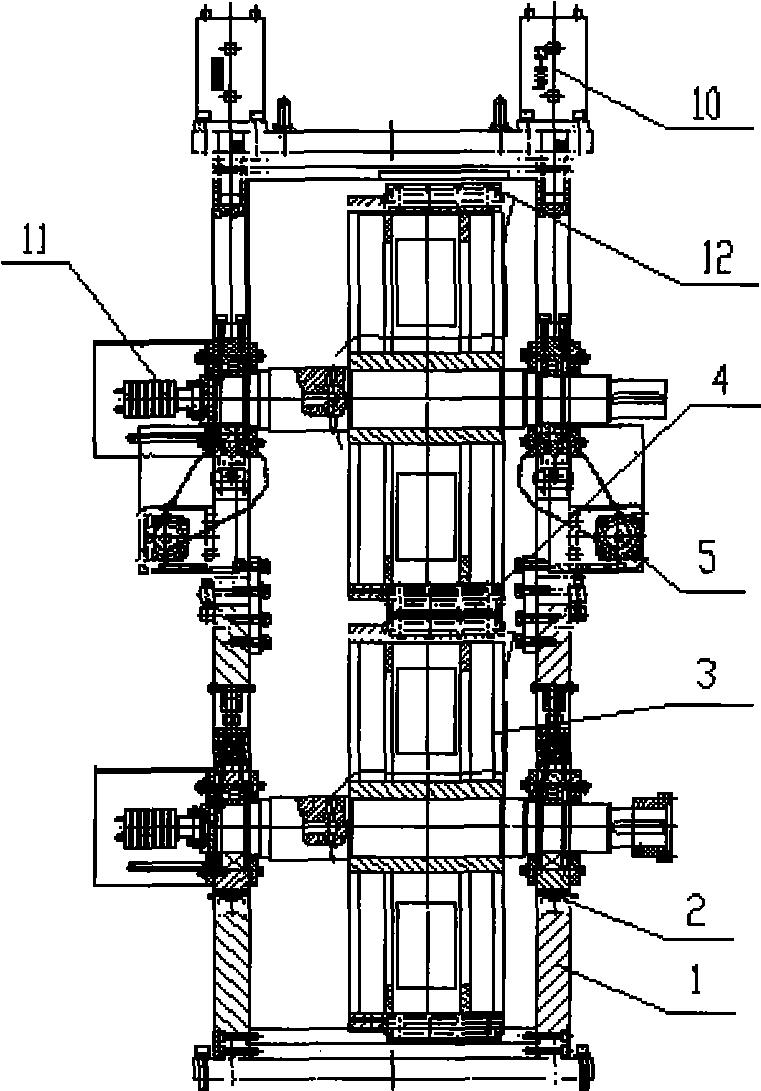

Full self-control non-woven fabrics thermal compression welding device and method

ActiveCN101508186AReliable weldingGuaranteed pressureMechanical working/deformationSeaming textilesEngineeringNonwoven fabric

The invention relates to rapid, convenient, intellectually-controlled full autocontrol nonwoven fabric hot-press welding equipment and a welding method. The full autocontrol nonwoven fabric hot-press welding equipment comprises a PLC controller, a stand, a lower electric heating welding wheel axle, an upper electric heating welding wheel axle, a step motor, an oil cylinder, wherein the upper part of the stand has a groove structure; the lower part of the stand is provided with a hole; the lower electric heating welding wheel axle is positioned in the hole of the lower part of the stand by a lower slide block; the lower end face of the lower slide block is pressed on a pressure sensor; the upper electric heating welding wheel axle is positioned in a groove of the upper part of the stand; the lower end face of an upper slide block is positioned on an adjustable oblique wedge block of a screw rod; the adjustable oblique wedge block of the screw rod passes through a transmission mechanism and is driven by the step motor; the power end of the step motor is controlled by the PLC controller; the oil hydraulic cylinder is positioned on the upper end of the stand; a piston of the oil hydraulic cylinder is connected with the upper slide block by a connecting rod and a connecting plate; and the operation of the oil hydraulic cylinder is controlled by the PLC controller. The equipment has the advantages of: 1, realizing the reliable welding of more than four layers of nonwoven fabric on a production line at an online speed of more than 120 meters per minutes; and 2, according to predetermined welding pressure and welding temperature, freely and automatically carrying out free micro-adjustment by online construction and the change of welding temperature and ambient temperature and ensuring pressure and temperature needed for high-efficient welding.

Owner:杭州珂瑞特新机械制造有限公司

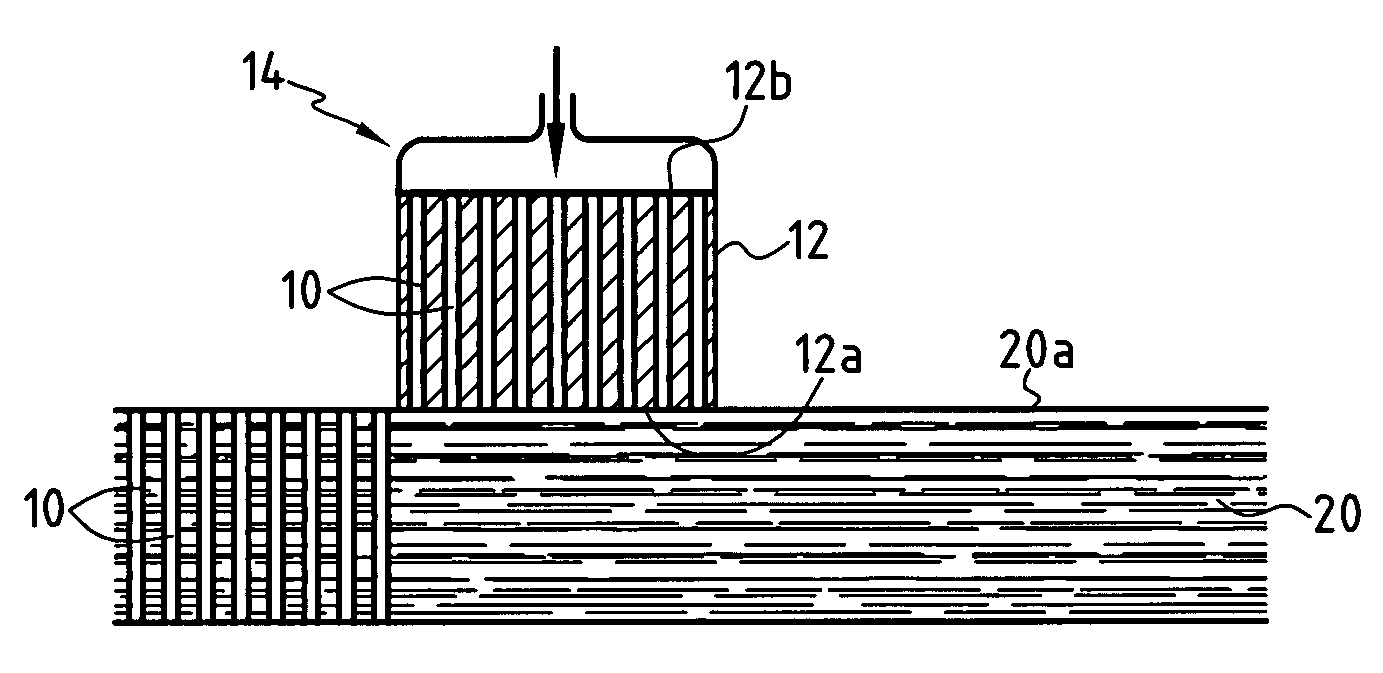

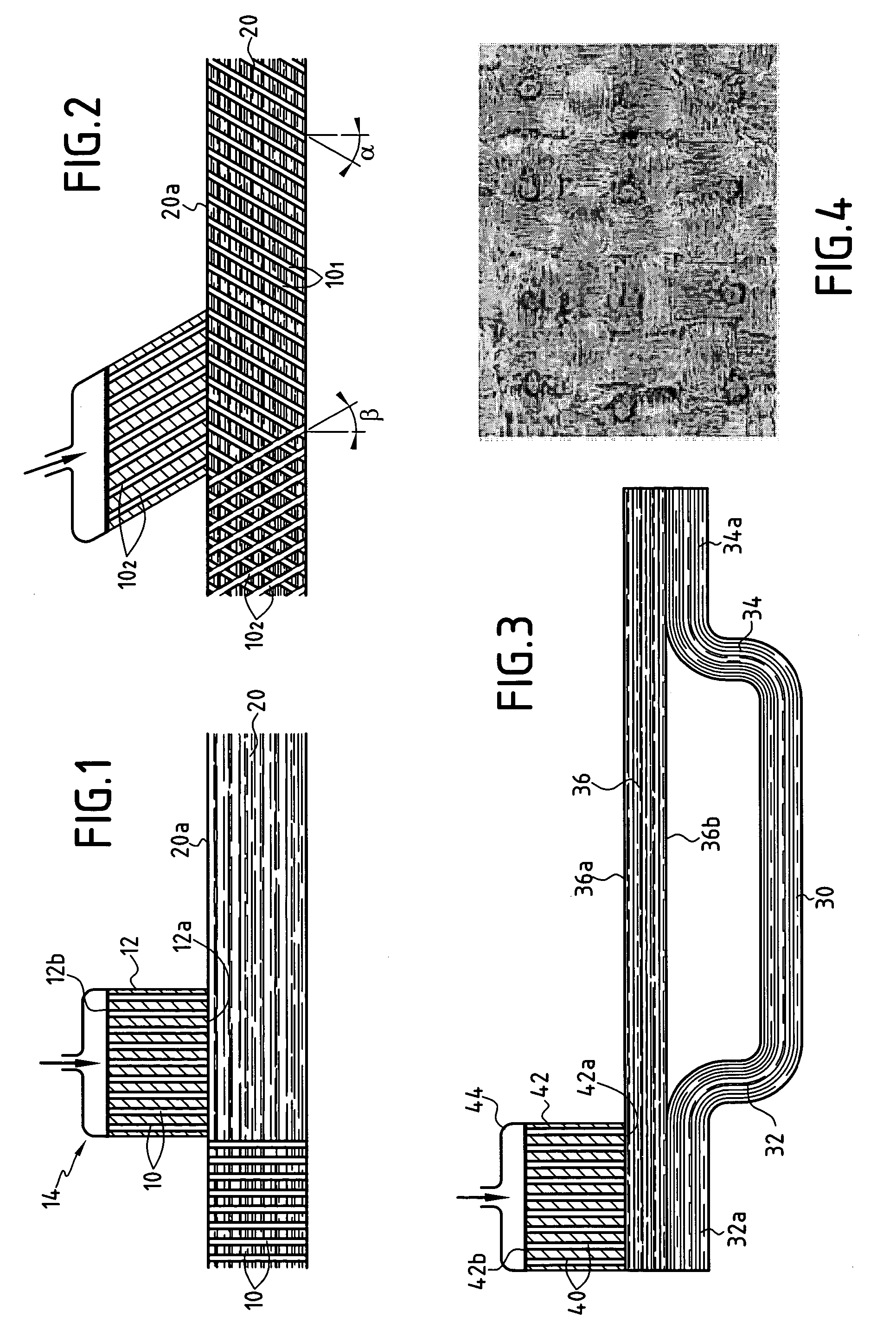

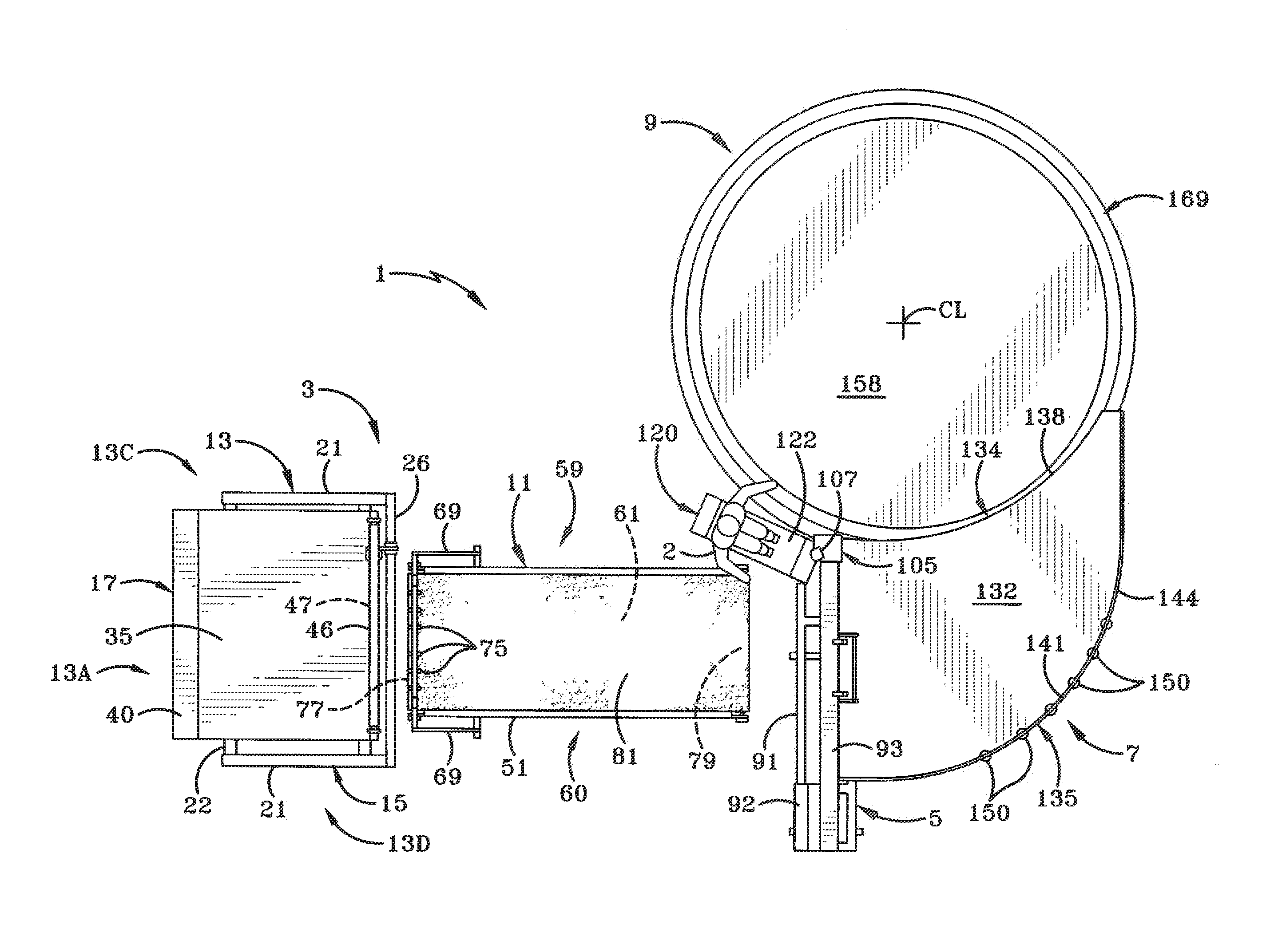

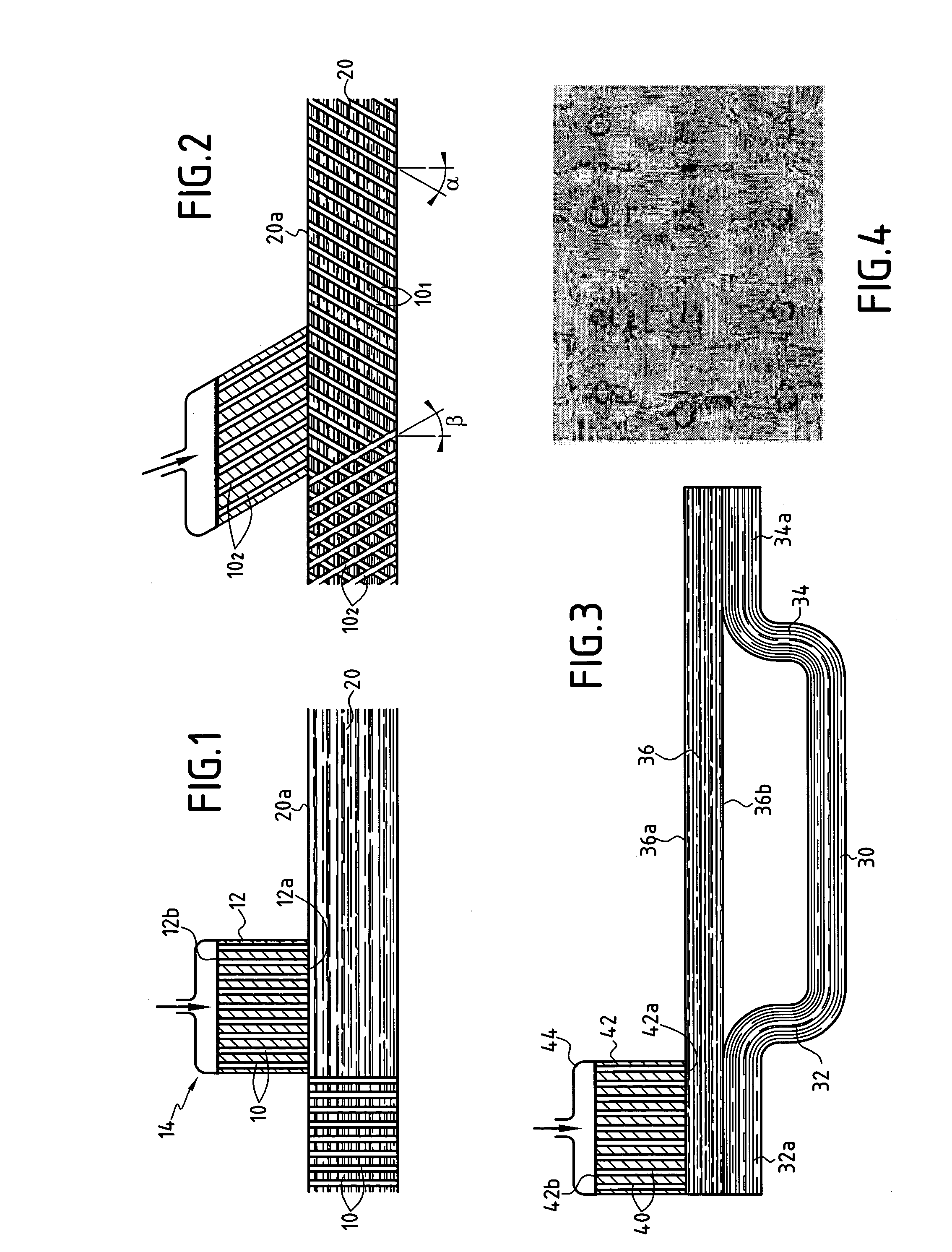

Making composite material parts from blanks made by reinforcing a fiber structure and/or bonding fiber structures together

ActiveUS7200912B2High densityEasy to shapeAutomatic/semiautomatic turning machinesSeaming textilesRefractoryOptoelectronics

A porous fiber structure is consolidated by forming within a deposit of a refractory material by partially densifying the fiber structure in such a manner as to bond together the fibers of the fiber structure so as to enable the fiber structure to be handled without being deformed, while leaving empty the major fraction of the initial pore volume of the fiber structure, and rigid pins are implanted through the consolidated porous structure. A blank is obtained by reinforcing a fiber structure by implanting pins or by bonding together consolidated fiber structures, the bonding being performed by implanting pins. A composite material part is obtained by densifying the blank.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

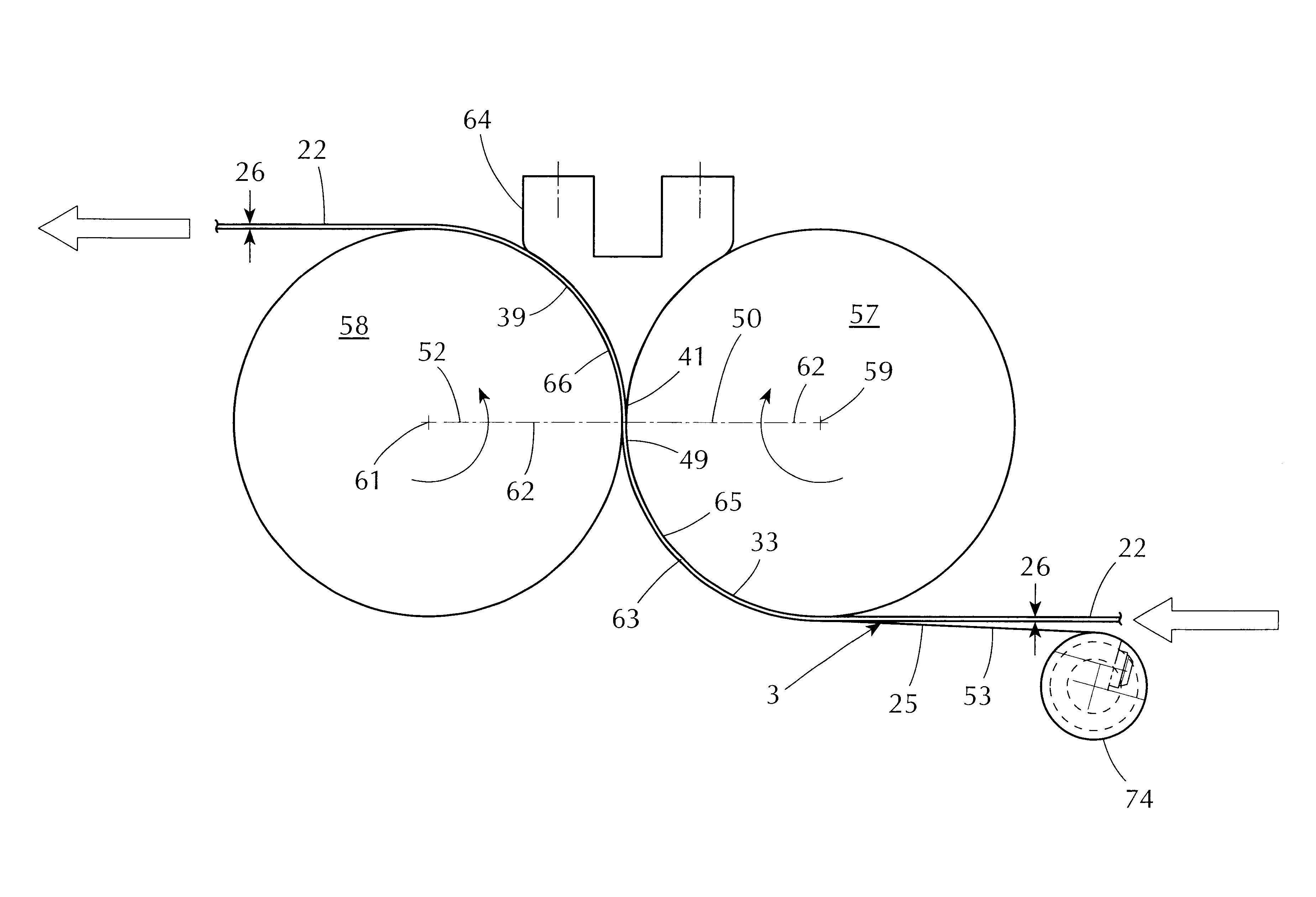

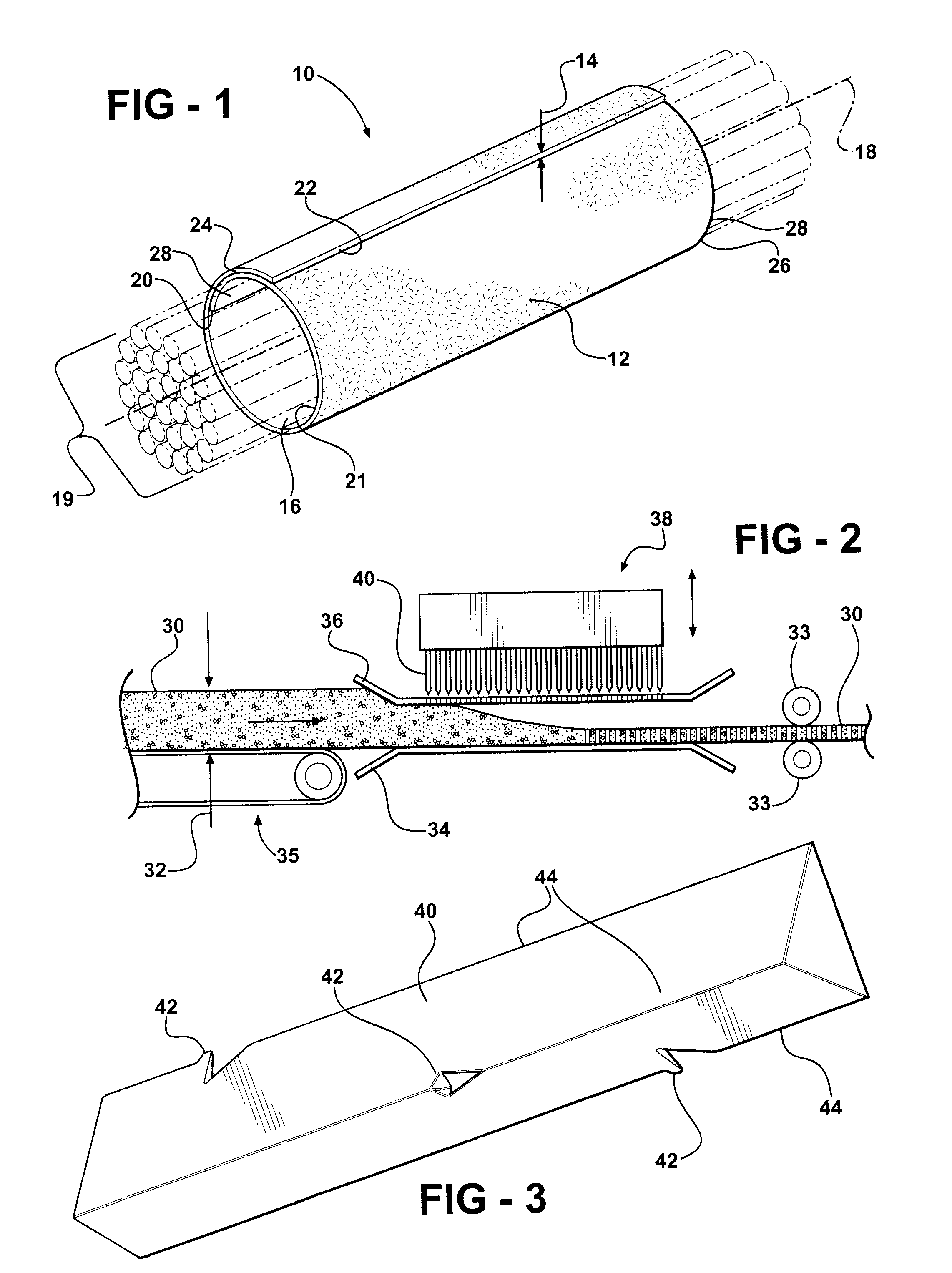

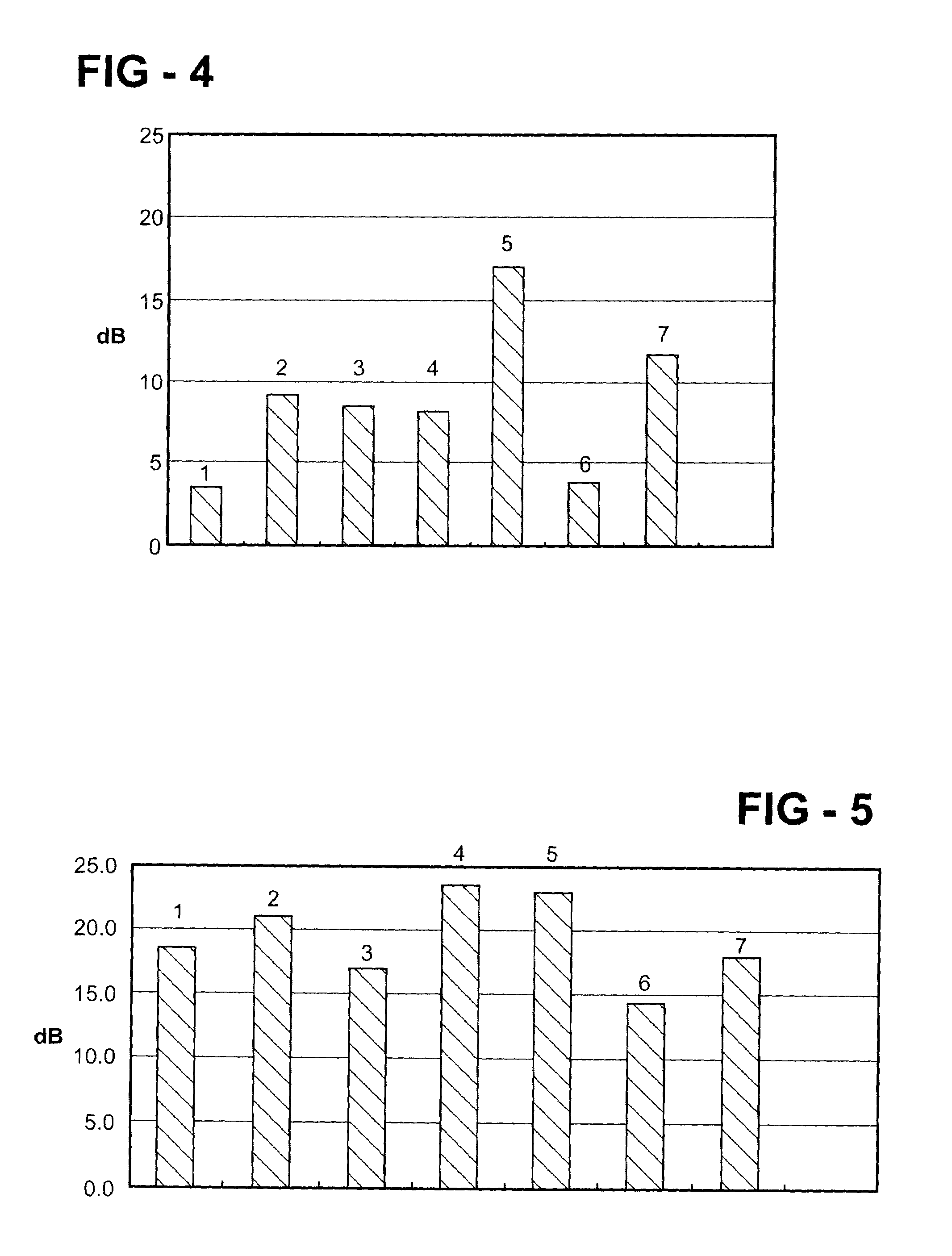

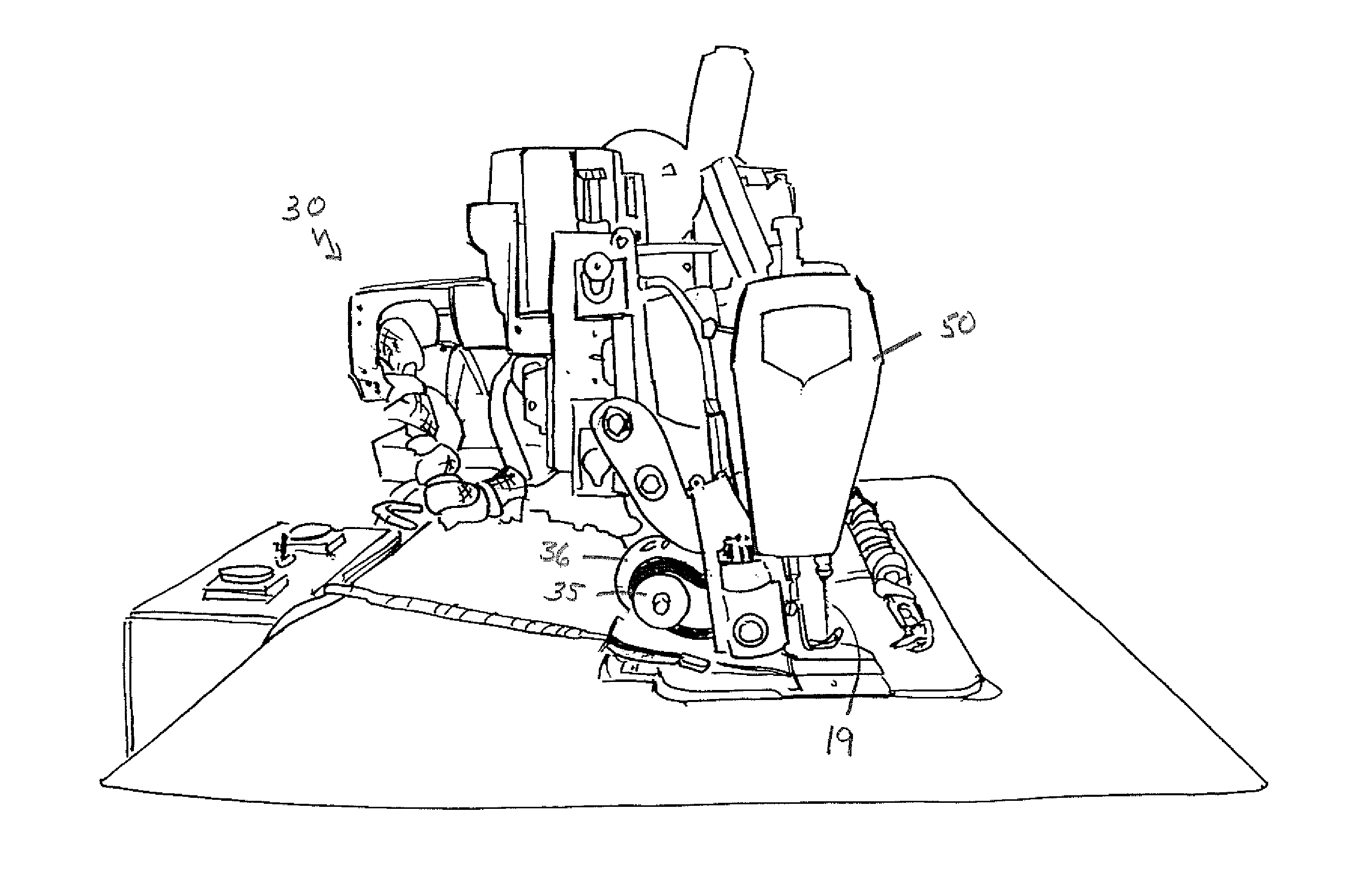

Dual-slip compressive shrink-proofing apparatus for fabric and related method

InactiveUS6681461B1Superior-quality controlled permanent compactionReduced Power RequirementsShrinkingMechanical cleaningFiberYarn

A method and related apparatus for shrink-proofing a fabric, typically a knitted textile composed of interlocked loops of yarn made of natural and / or man-made fibers. The loops interlock along stitch rows that may become skewed. According to the invention the fabric is confined from expanding as it is delivered to and discharged from an in-line compression zone free of obstructions such as crimps, bends or kinks. The fabric is confined, preferably resiliently, coming to, passing through and leaving the compression zone so as to accommodate variation of thickness and irregularities of the fabric being compacted in the compression zone. The interlocked loops are organized whereby they are allowed to move toward each other orthogonally along their related stitch row so as to reduce volume of the fabric. Non-woven textiles, papers, papers with additives and the like are shrink-proofed in the same manner.

Owner:CATALLO FRANK

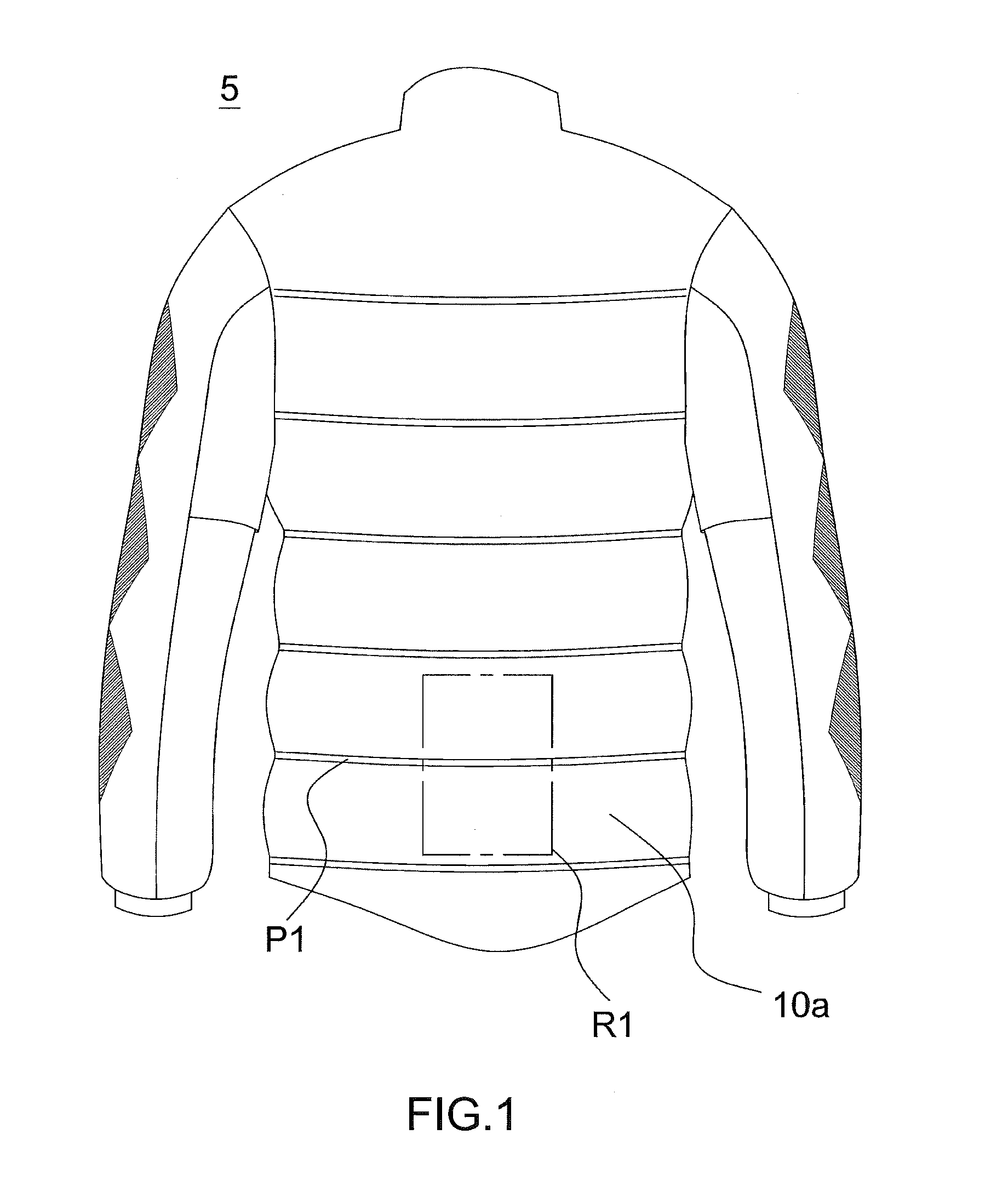

Fabric bonding structure and processed fabric goods having the same

Disclosed are a fabric bonding structure and processed fabric goods having the same. The fabric bonding structure includes: a first fabric; a second fabric provided so as to be in contact with the first fabric; and a bonding member having a first surface and a second surface at the other side of a side of the first surface, and being folded so that two points of the first surface meet, and the second surface being bonded to each of the first fabric and the second fabric, and the fabric bonding structure is applicable to processed fabric goods, such as clothes and bedclothes. According to the fabric bonding structure and the processed fabric goods having the same, it is possible to isolate fillings filled inside a fabric from the outside even without forming a sewing line, and bonding force at a bonding portion is excellent compared to a method of forming a sewing line or a bonding method using an adhesive in the related art.

Owner:YOUNGWON

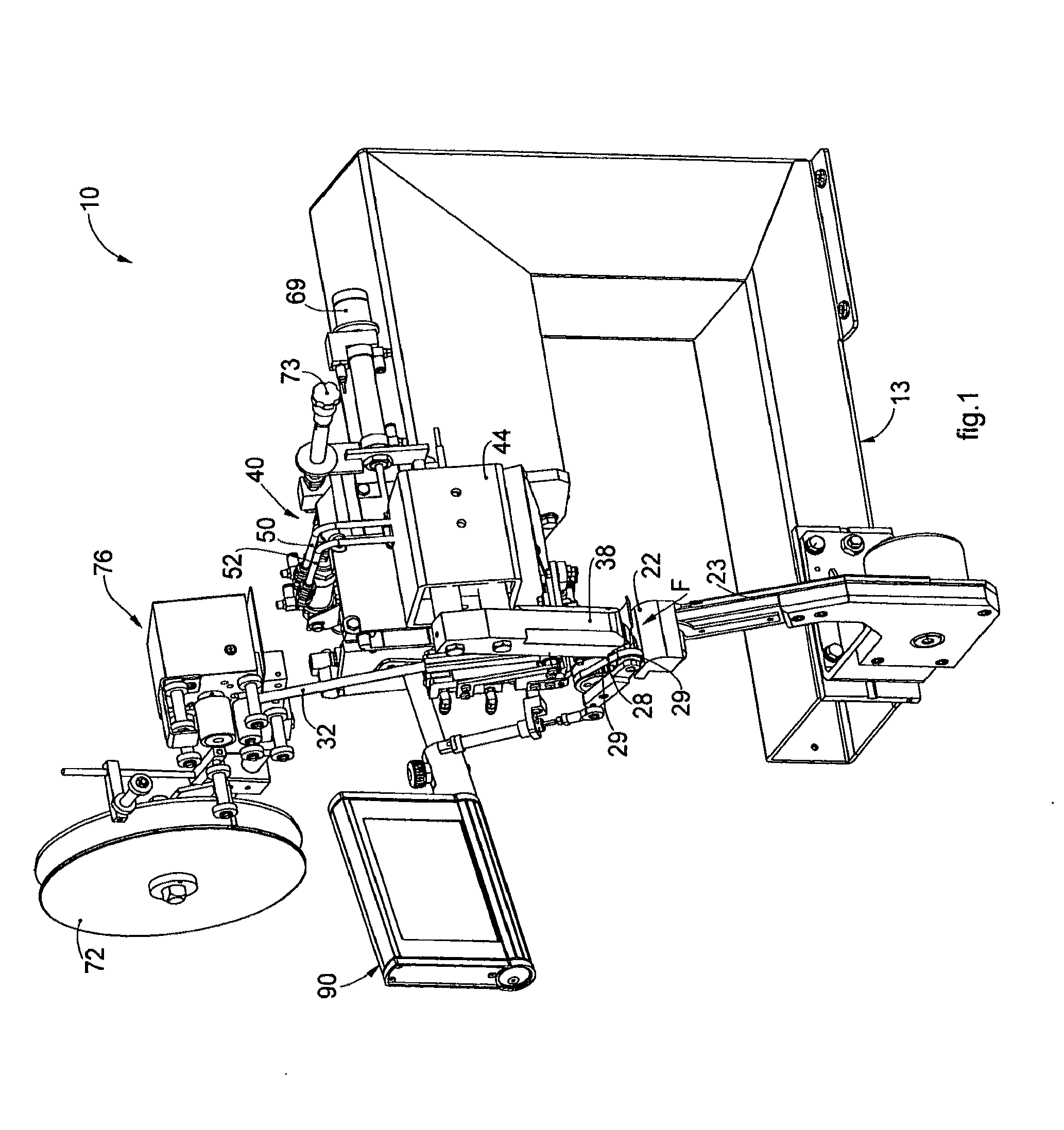

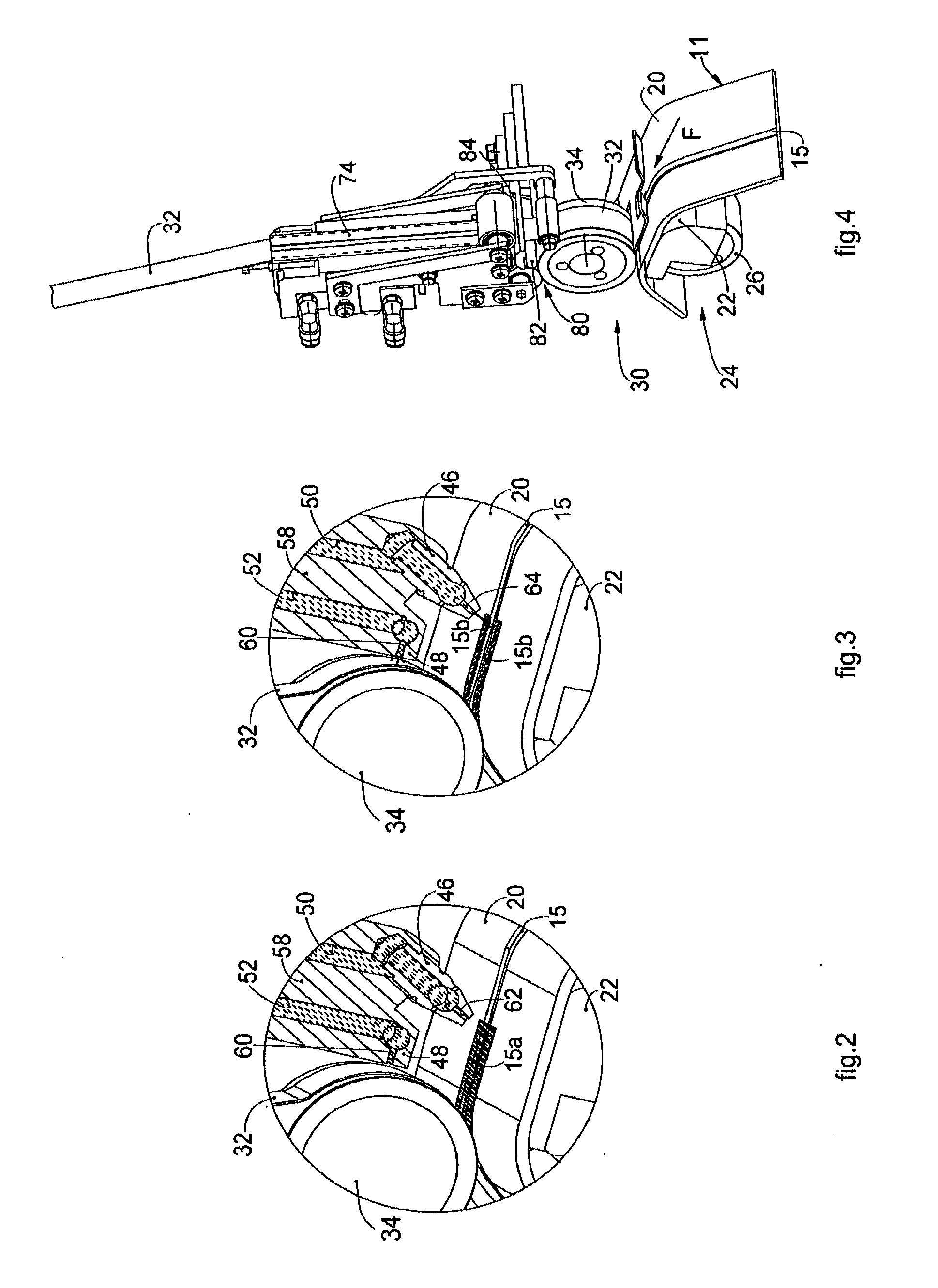

Machine for making an impermeable join on impermeable three-layer or two-layer fabrics

ActiveUS20120328824A1Process knownSimple processMechanical working/deformationDecorative surface effectsAdhesiveInternal layer

A machine for making an impermeable join between two panels made of three-layer or two-layer textile material including at least an internal layer, already joined along a joining line by way of a stitching operation, simple or complex, or by ultrasound joining or other, includes first movement element able to move the textile material in a direction of feed and impermeabilization element able to achieve the impermeabilization along said joining line and including second movement element able to move an impermeable tape for hot taping with adhesive, in order to determine the hot application and welding on the internal layer along the joining line. The impermeabilization element also comprise heating element suitable to effect a cauterization of the material of the internal layer and positionable directly upstream of the second movement element in the direction of feed, so that the hot taping can be effected immediately after the cauterization.

Owner:MACPI PRESSING DIV SPA

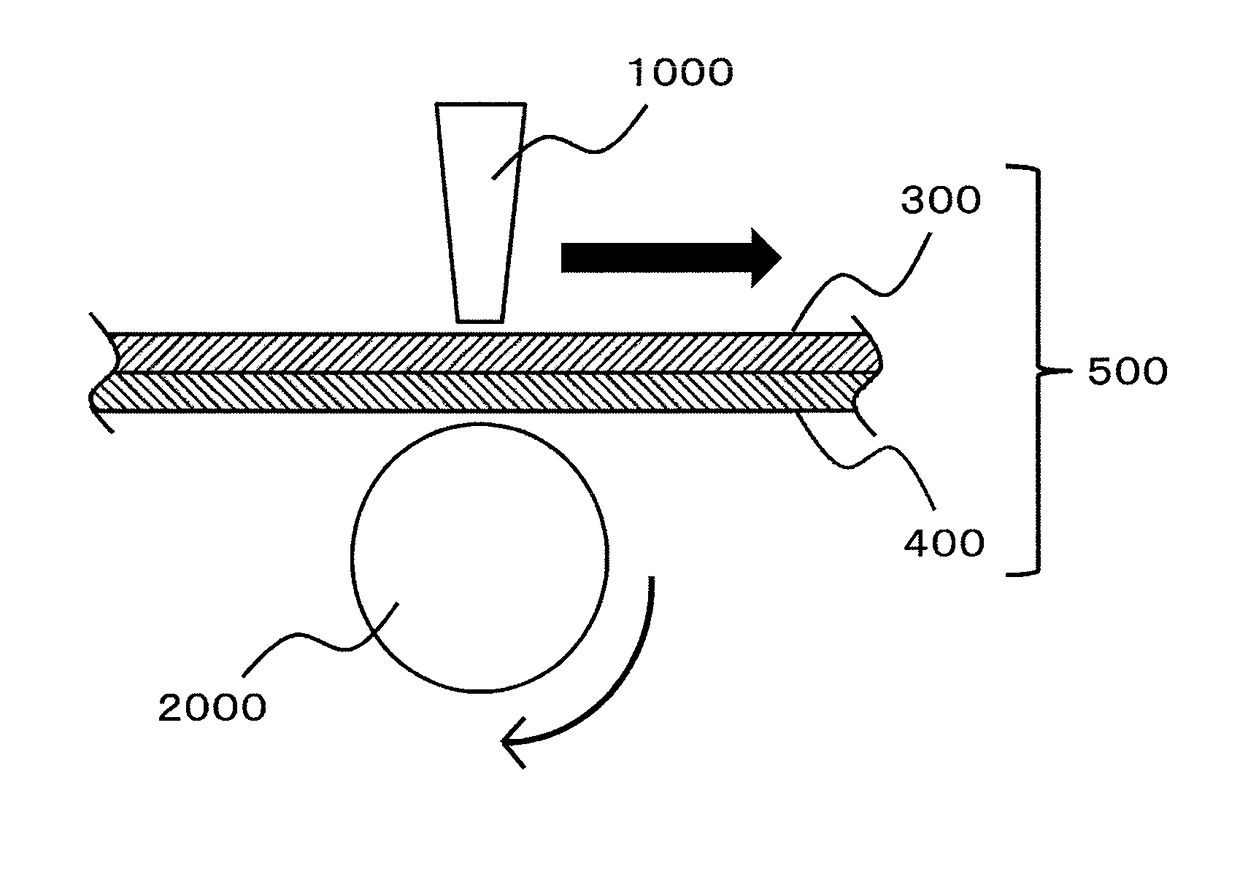

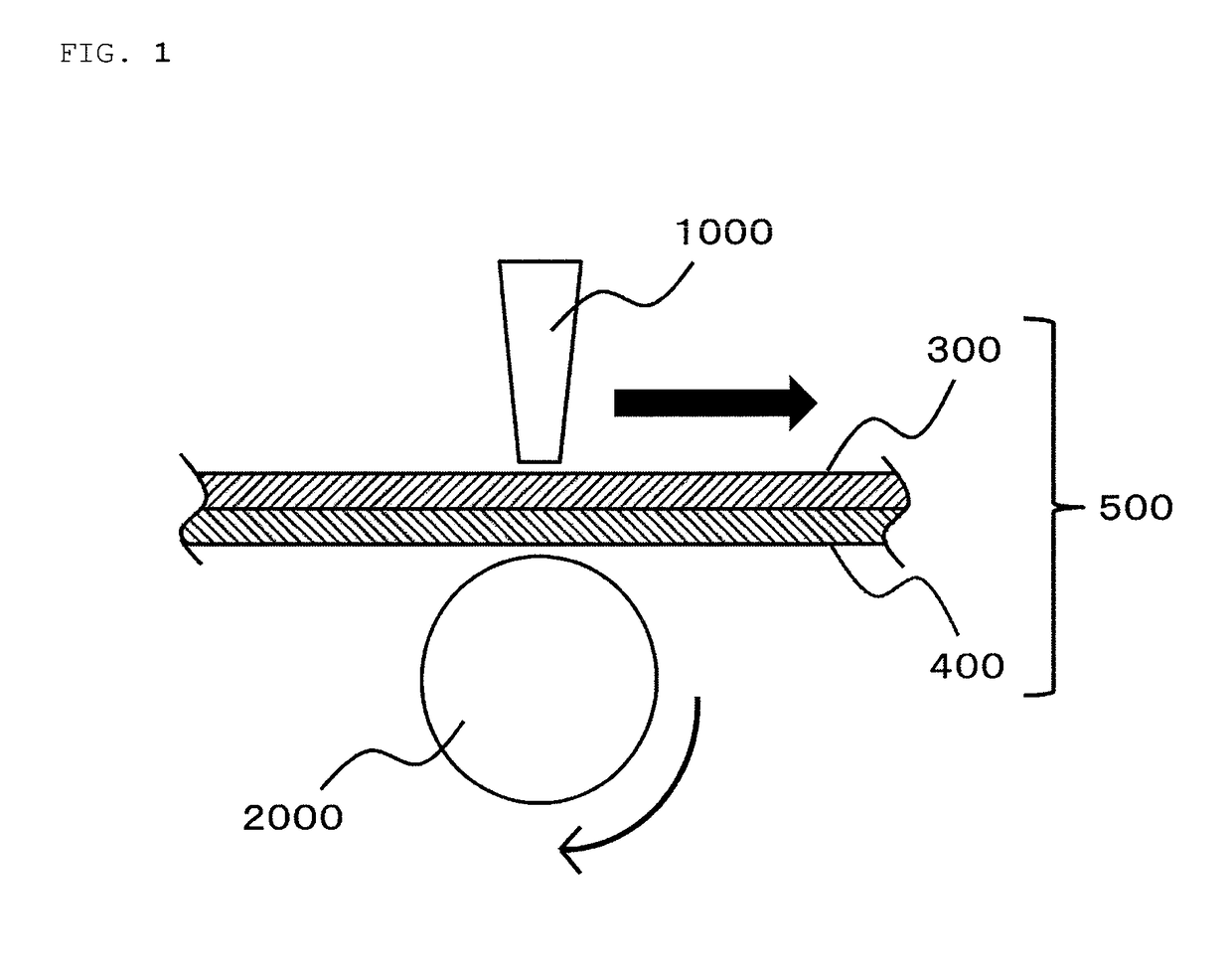

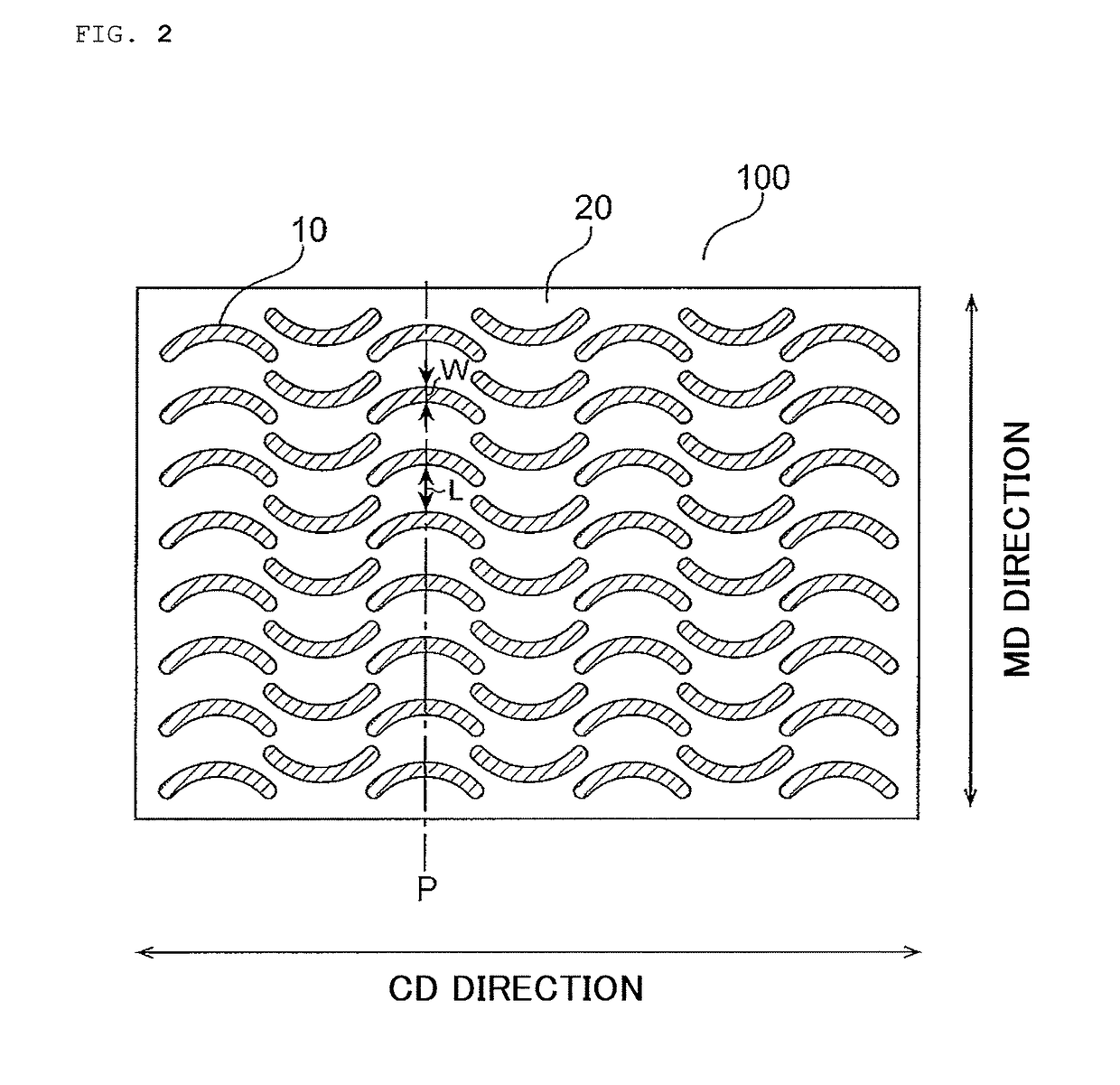

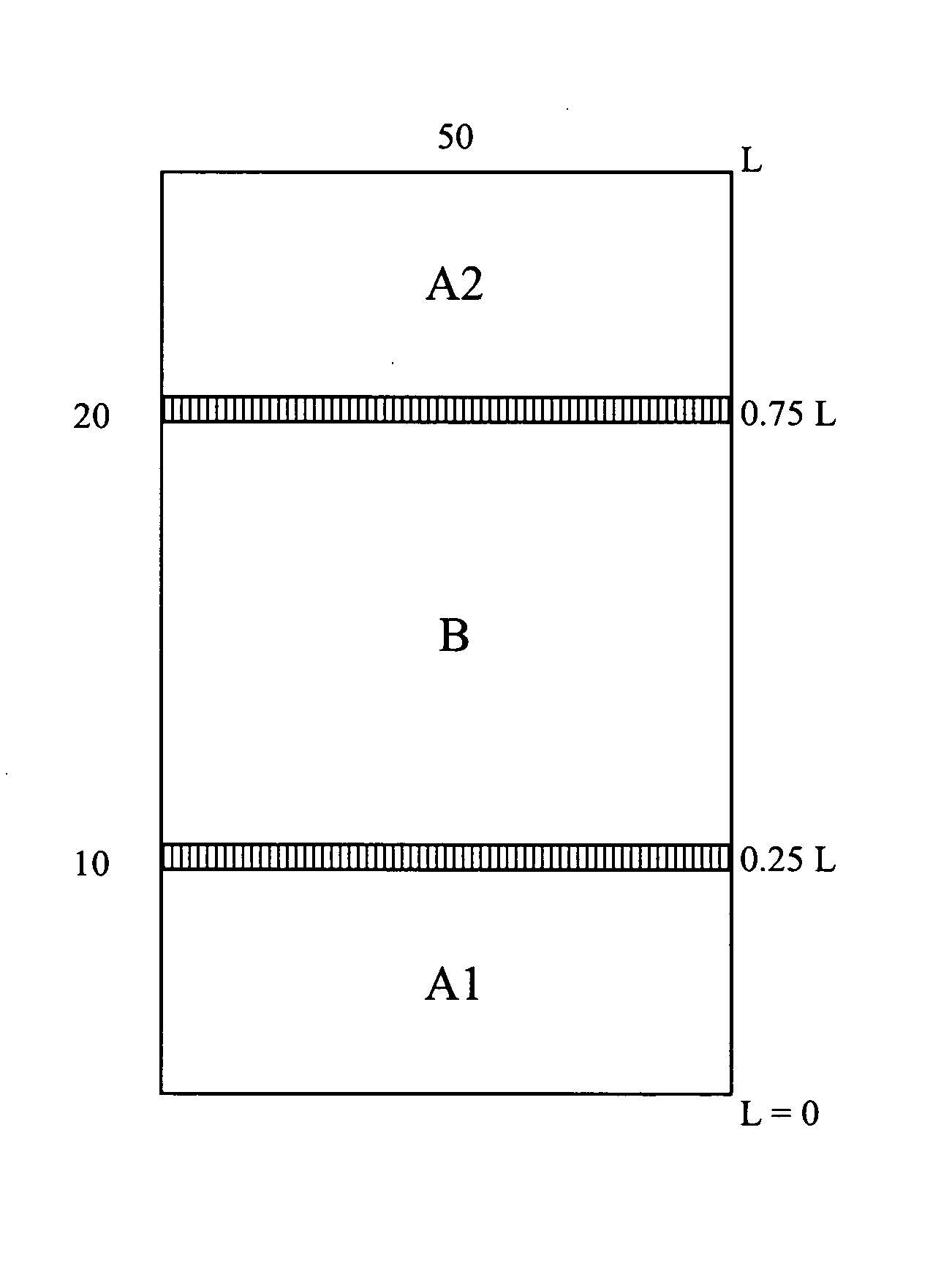

Method for producing layered article

ActiveUS20180281296A1Sufficient production speedVariation in fusion strength can be suppressedPersonal careSeaming textilesFiberUltrasonic welding

Provided is a method of producing a layered article by which a sufficient production speed can be achieved, and preferably, a variation in fusion strength can be suppressed and hence a variation in product quality can be reduced. The method of producing a layered article of the present invention includes fusing at least part of a single-layer body or a laminate including at least one layer including a non-woven fabric of fiber having a fiber diameter of 100 μm or less through ultrasonic welding.

Owner:NITTO DENKO CORP

Flat woven full width on-machine-seamable fabric

ActiveUS20090090425A1Stable and reliableMethod of manufactureSeaming textilesMachine wet endEngineeringFull width

A laminated on-machine-seamable industrial fabric made from a flat woven full width base fabric layer wherein the base fabric layer is folded inwardly and flattened to produce a fabric with seaming loops disposed at the two widthwise edges.

Owner:ALBANY INT CORP

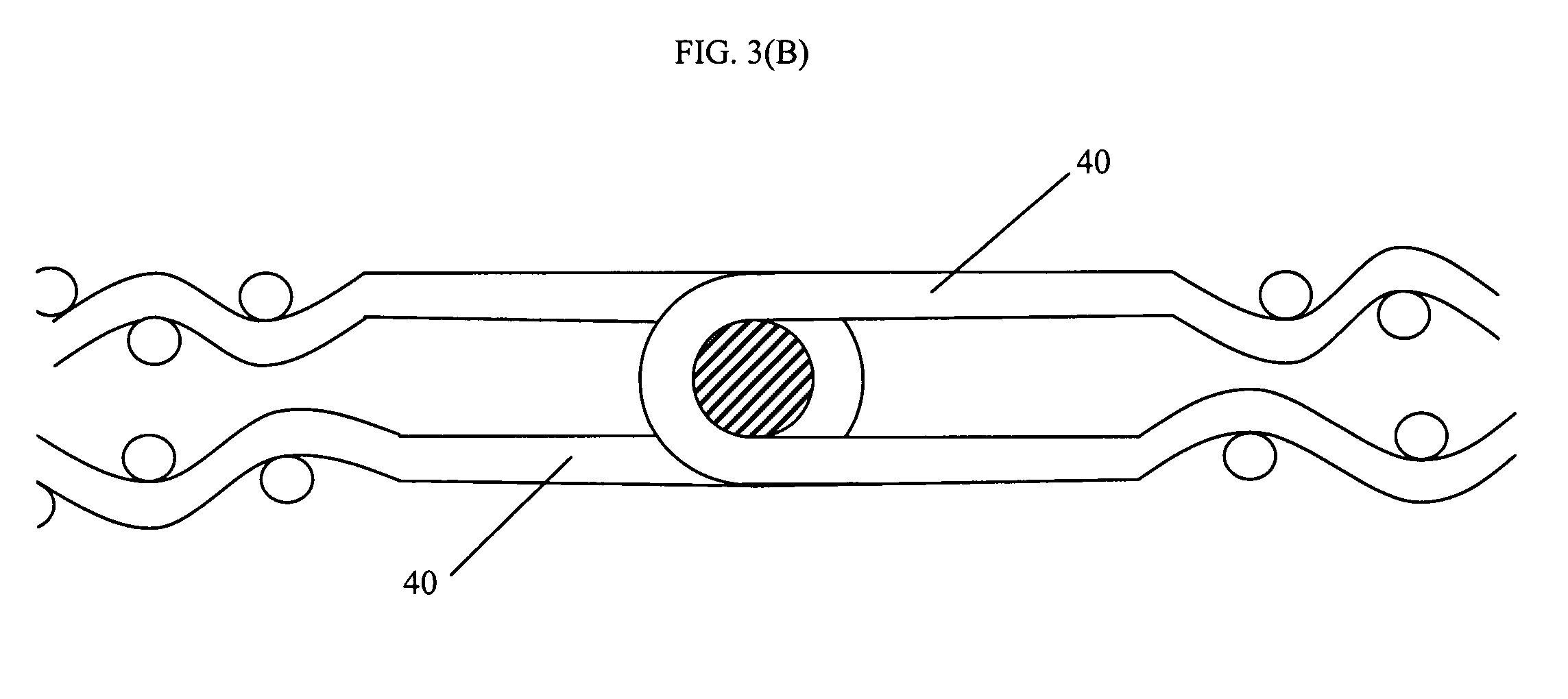

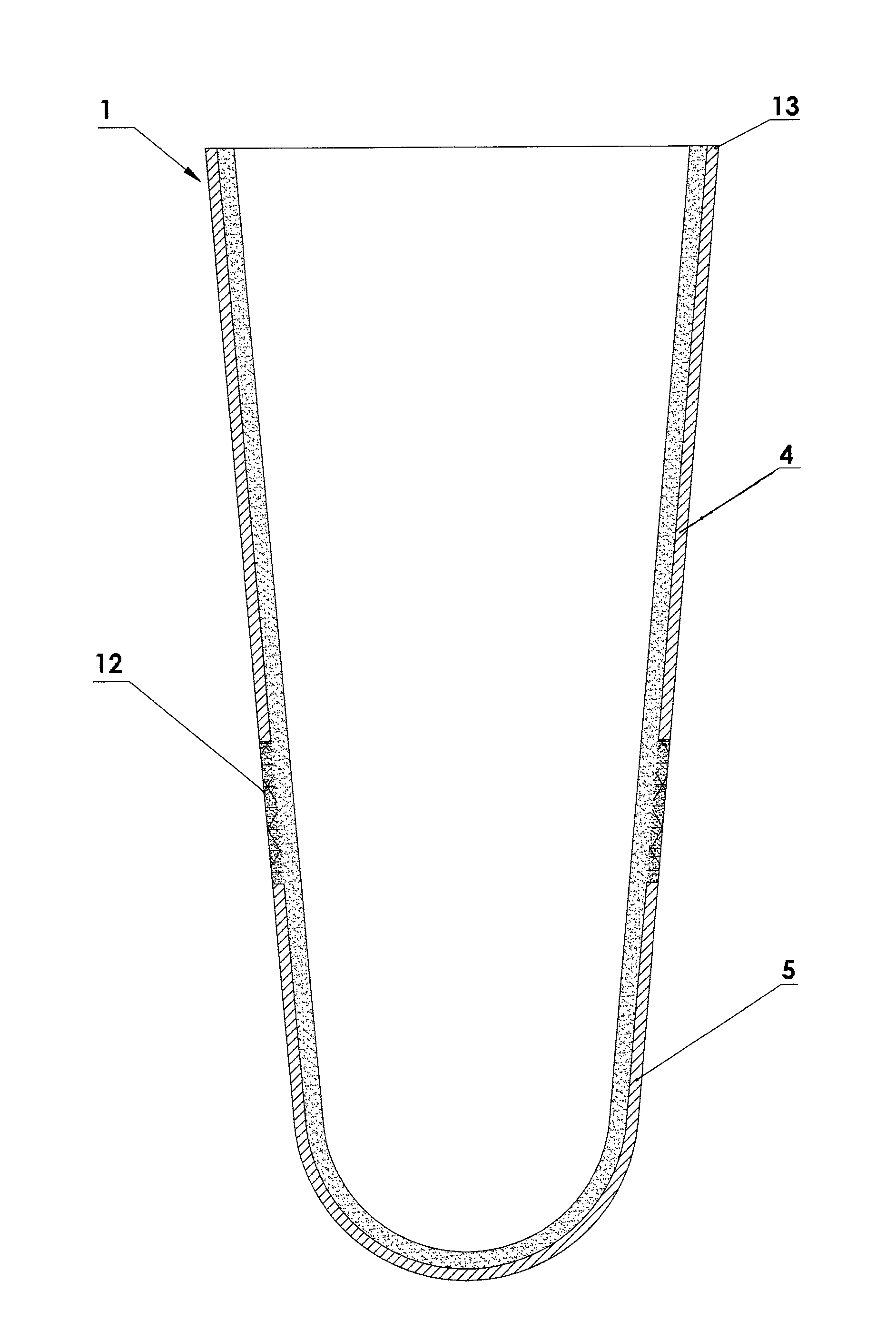

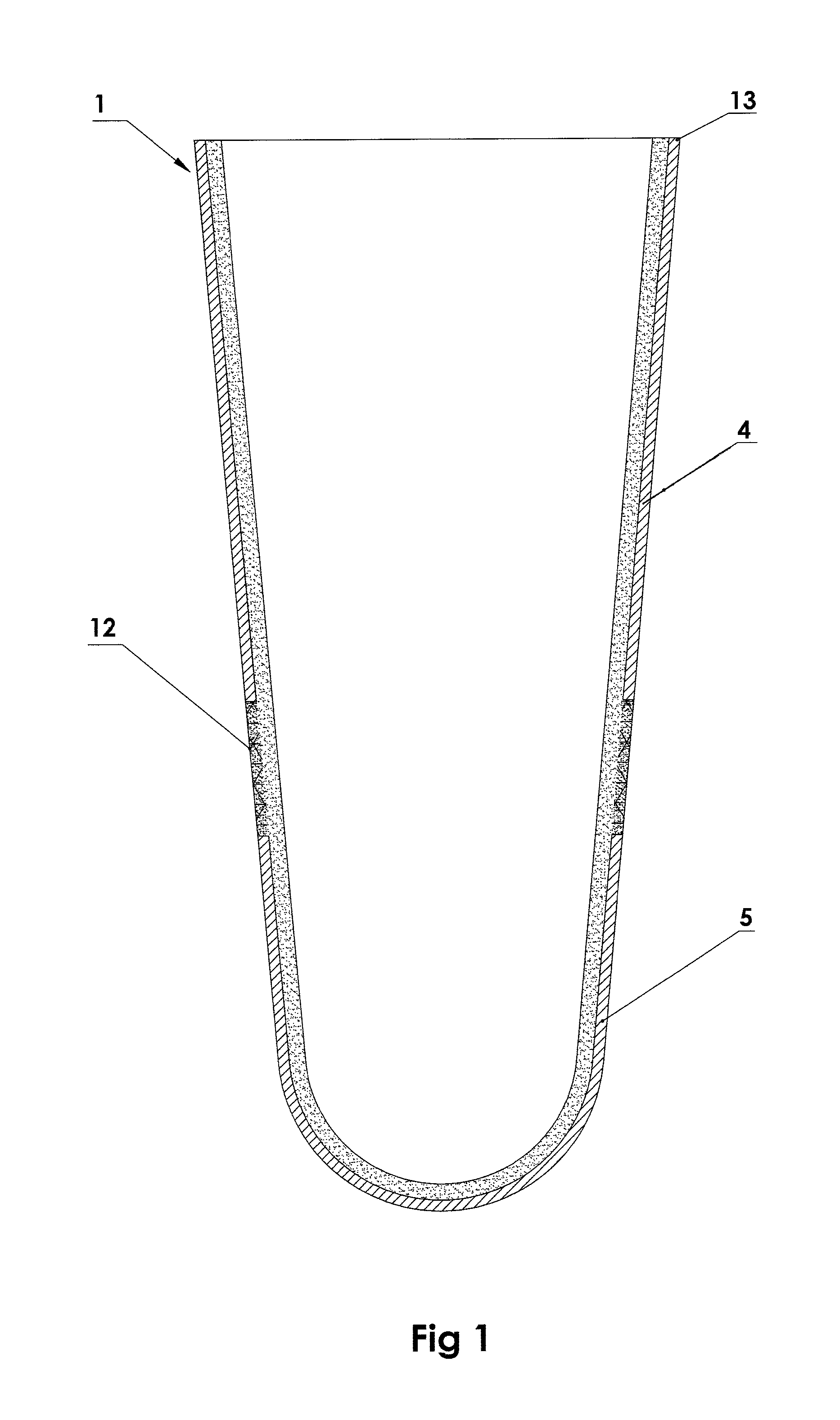

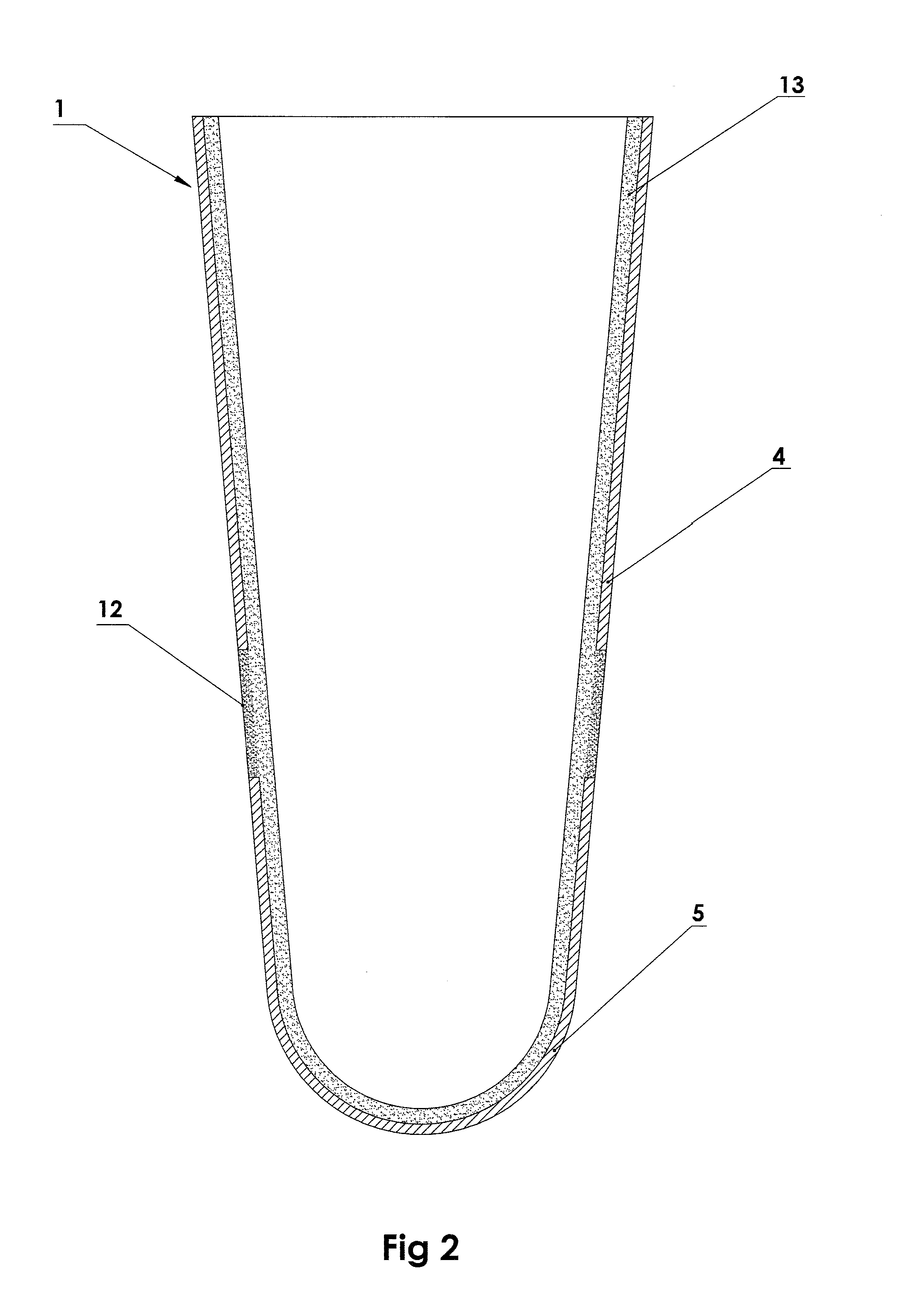

Method and apparatus of an integrated gel sealing liner

ActiveUS20140249650A1Sacrificing levelLess discomfortMechanical cleaningPressure cleaningYarnEngineering

A gel liner made by starting initially with a one-piece knitted tubular sock-shaped fabric having a closed distal end section of gel impermeable knitted fabric and an open proximal end section of gel impermeable knitted fabric and being a gel permeable loosely knitted fabric. Molding the liner to have a gel cushion layer on its interior surface with the gel passing through and partially embedding the yarns of the proximal fabric section with the outermost portions of the yarns free of gel to form at least one annular seal whereby the proximal end section forming a seal not inhibited in deformation and / or elongation by the fabric when the liner is worn thereby reducing or eliminating any twisting or discomfort of the liner during ambulation caused by the annular seal.

Owner:ALPS SOUTH EURO

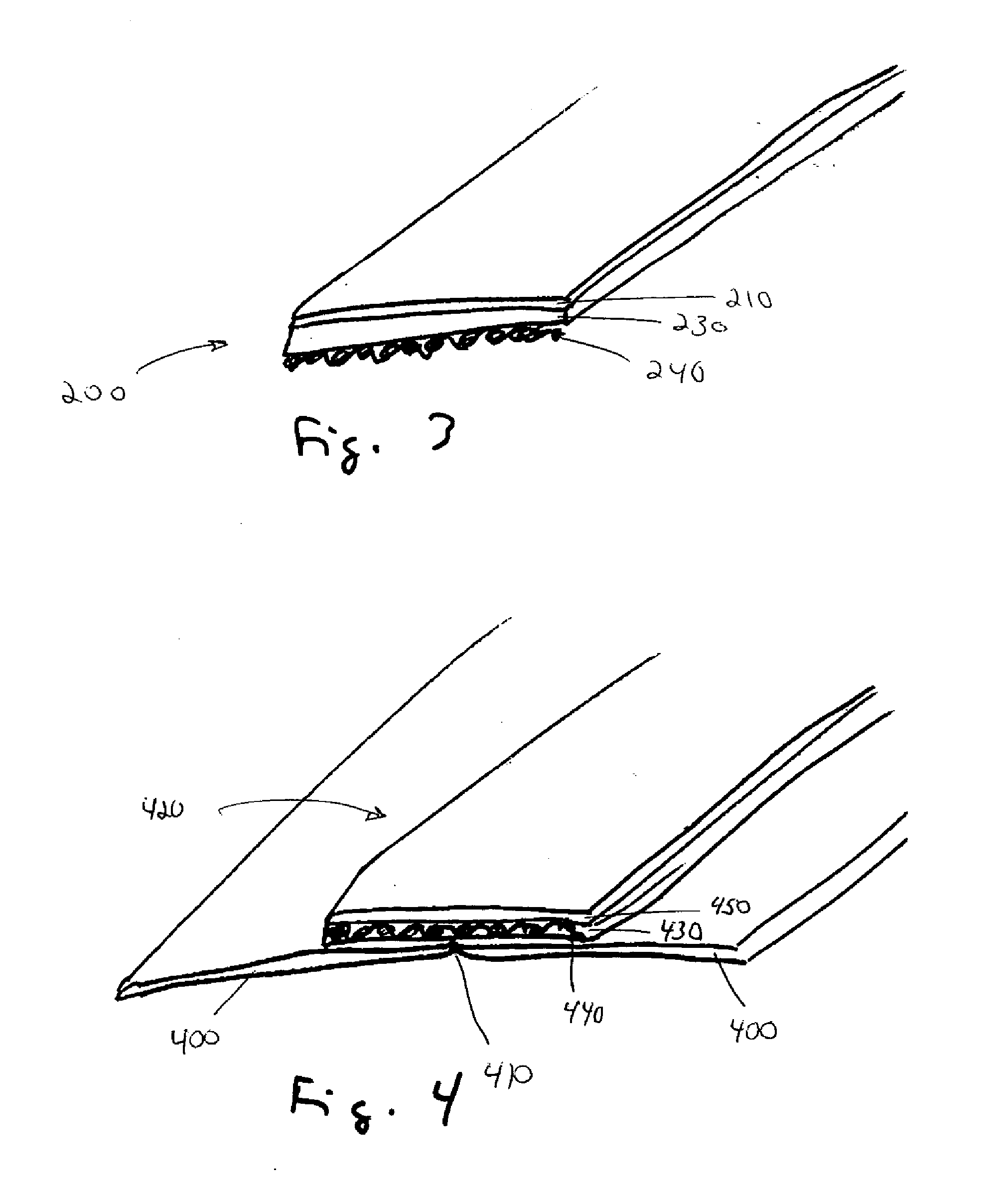

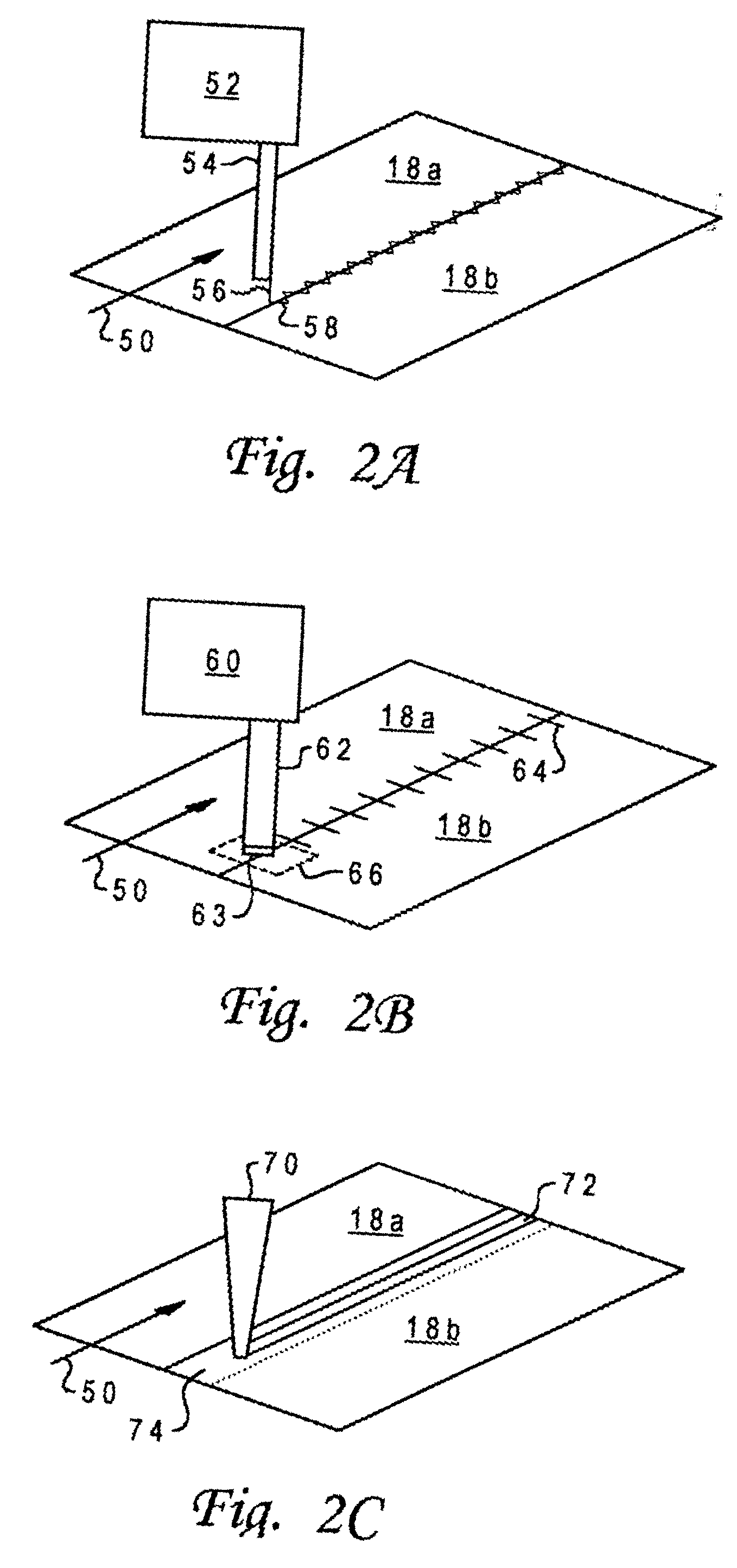

Fabric seam formation by radiation welding process

A method for forming a radiation, such as laser, welded point of attachment between at least two fabric pieces, such as ends, is provided. The method comprises the steps of lapping the fabric pieces to be attached; applying to the lapped fabric pieces in a region where the fabric pieces are to be attached a radiation, preferably an infrared energy, absorbing ink; and exposing the ink applied region of lapped fabric pieces to a source of radiation in the wave length absorbed by the radiation absorbing ink. In the case of an infrared absorbing ink, a laser light power has been applied in the range of 200 to 1000 Watts while scanning laser light along the ink applied region at a rate of one to twenty-five meters per minute. The method provides a fabric construction useful as an air bag, a gas inflatable safety cushion or curtain or in other applications, such as articles of apparel.

Owner:INVISTA NORTH AMERICA R L

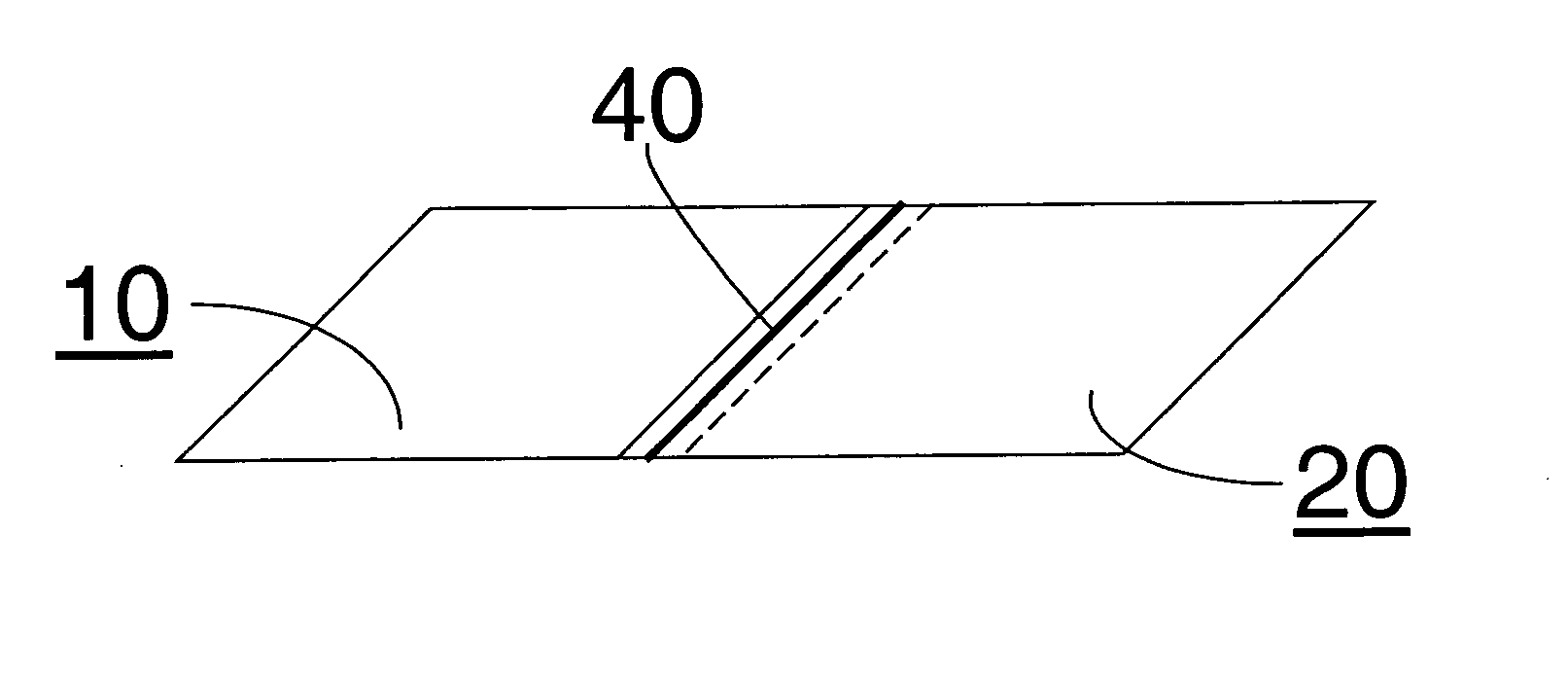

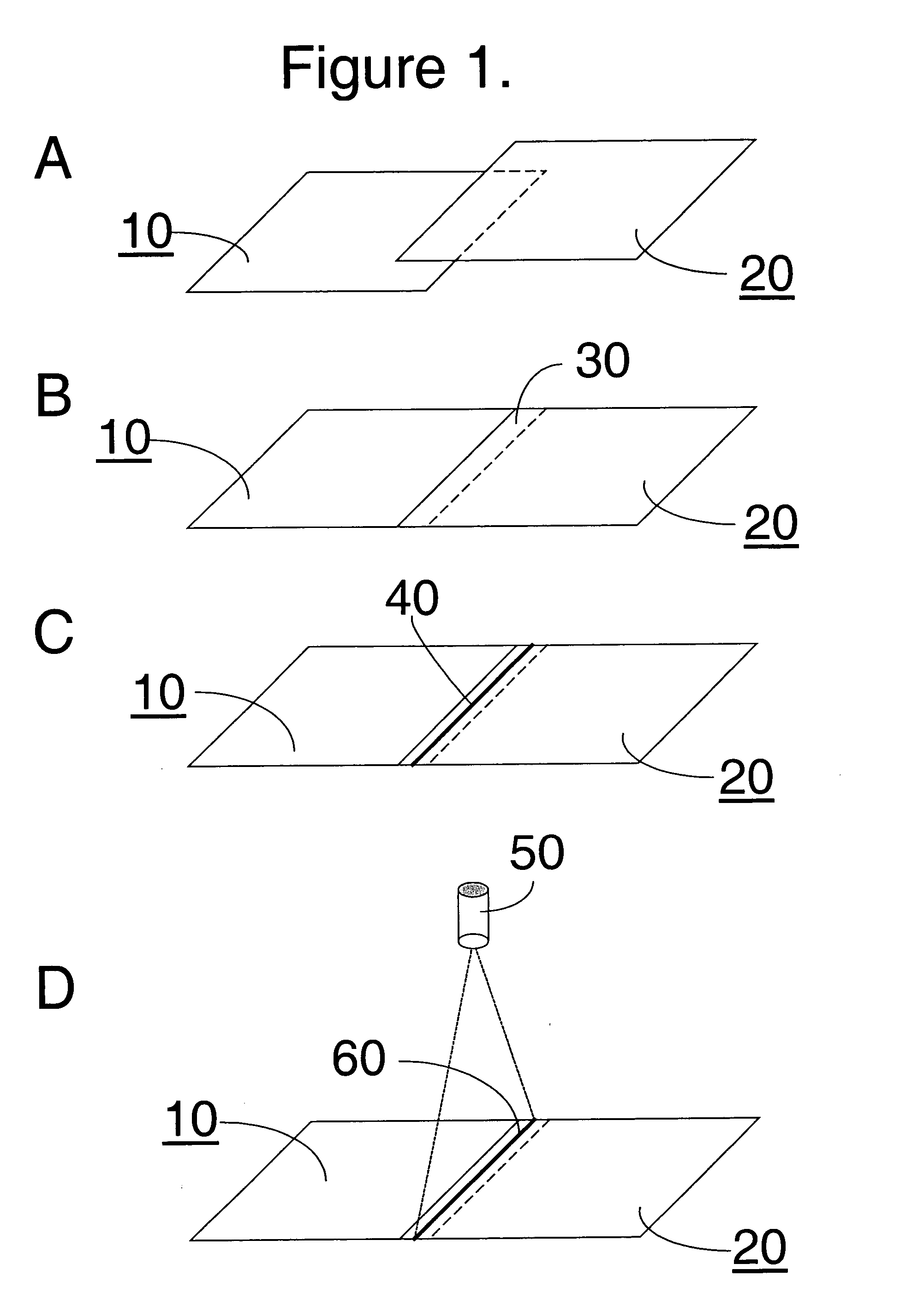

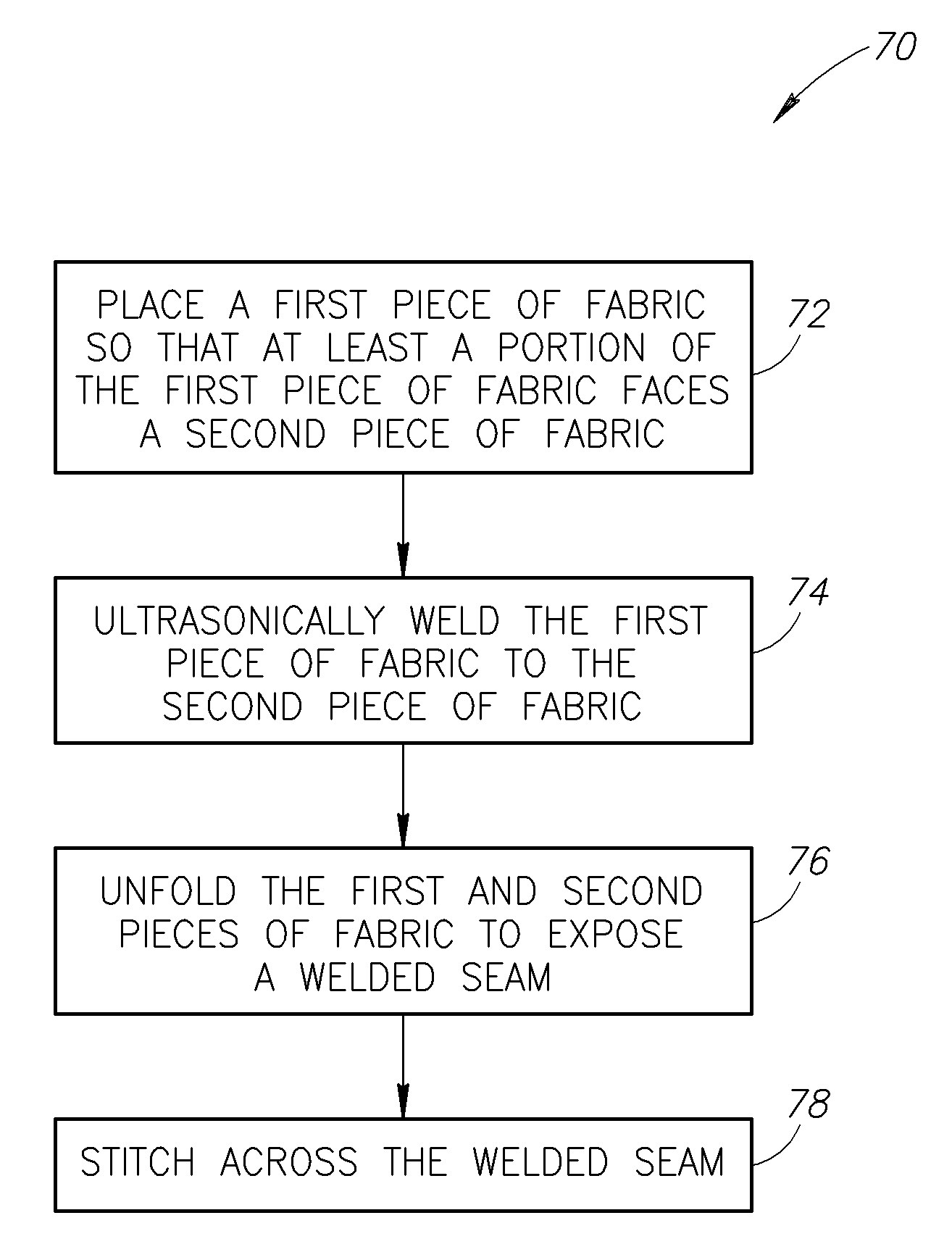

Fabric joining method and system

A fabric joining method and system for attaching a first piece of fabric having synthetic content to a second piece of fabric having synthetic content. The method includes welding the first piece of fabric to the second piece of fabric at a seam and sewing the first piece of fabric to the second piece of fabric using a stitch that crosses the welded seam. An example method includes ultrasonically welding a first piece of fleece fabric to a second piece of fleece fabric followed by stitching along and across the welded seam completely through the fabric layers using a zig-zag stitch. The system includes a first piece of fabric, a second piece of fabric fused to the first piece of fabric at a welded seam, and a thread stitched across the welded seam.

Owner:PATAGONIA INC

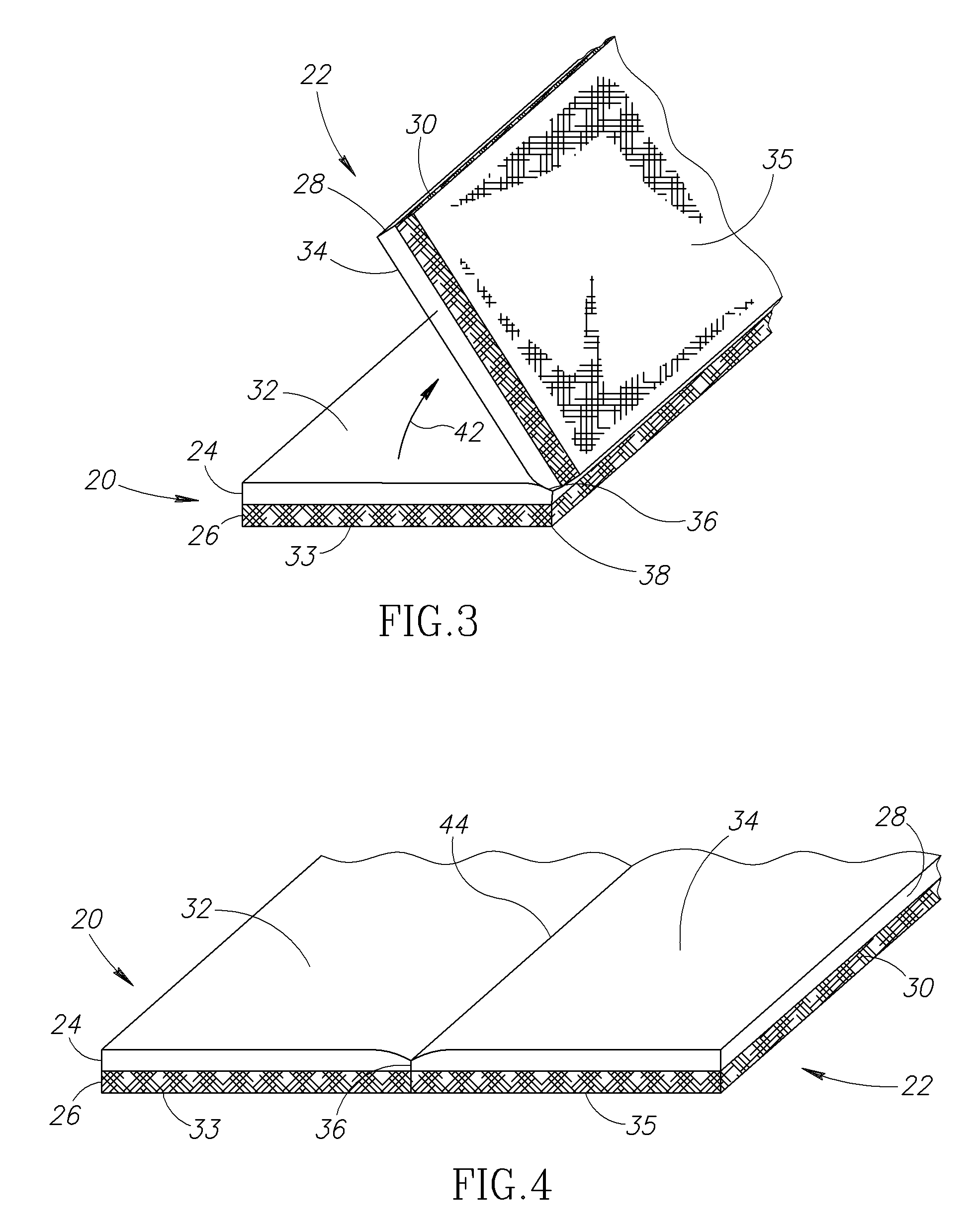

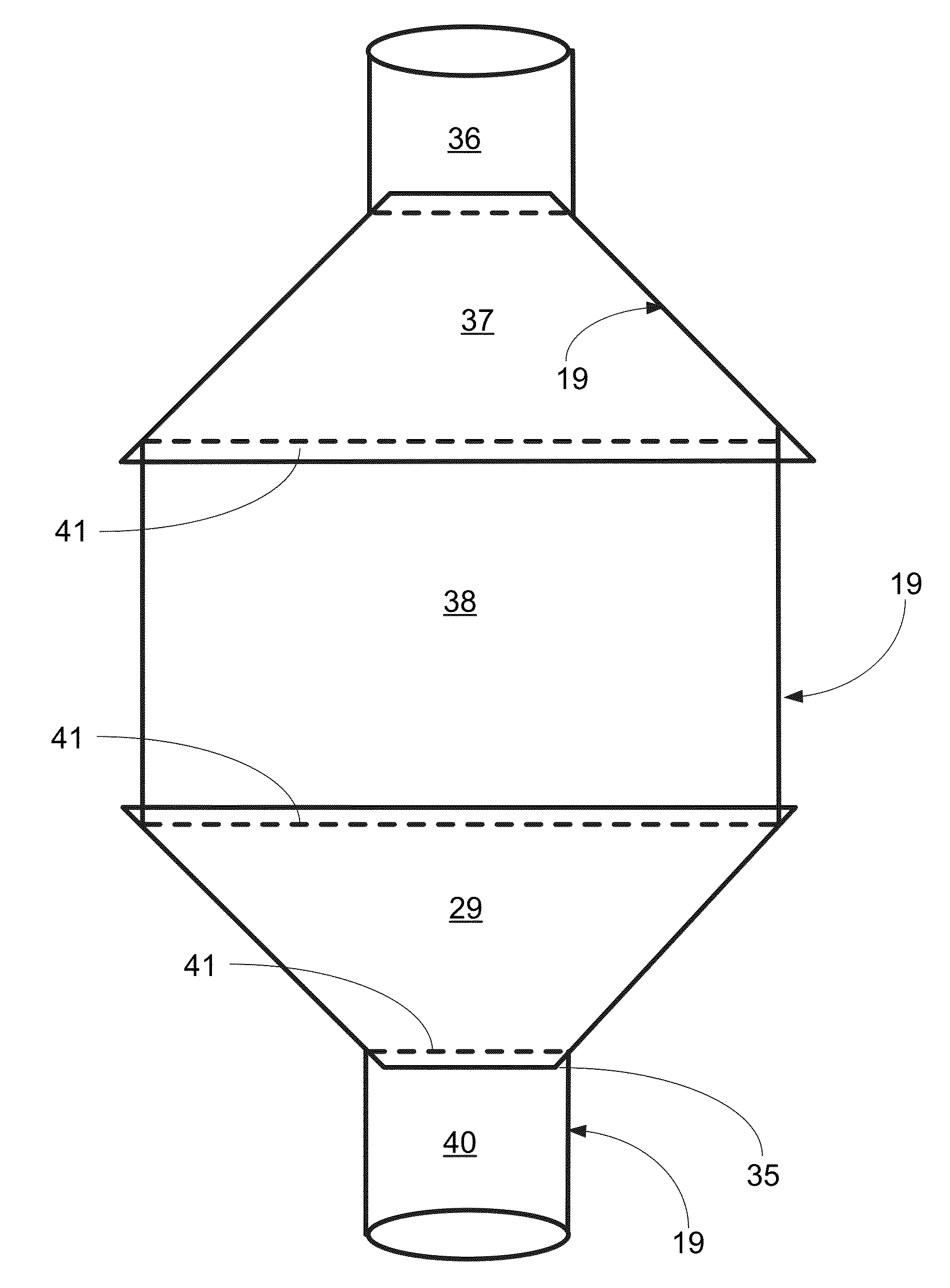

Method of production of fabric bags or containers using heat fused seams

ActiveUS20140363106A1Reduce laborSolve the real problemBag making operationsBox making operationsEngineeringPolypropylene

A method of producing flexible polypropylene fabric bags with heat fused seams comprising providing fabric pieces, wherein each fabric piece has a coated side and an uncoated side; positioning fabric pieces so that a coated side of one fabric piece faces a coated side of another fabric piece; selecting an area of fabric to be joined for forming a seam or joint; applying heat to the area to be joined that is less than the melting point of the fabrics, for forming one or more seams or joints and wherein the heat fused seams or joints of a resulting polypropylene bag retains at least 85% of the fabric strength without using sewing machines.

Owner:DOW GLOBAL TECH LLC +1

Yoga towel

ActiveUS8631833B2Good sweat absorptionPrevent slippingLayered productsSeaming textilesFiberEngineering

A yoga towel comprising a first layer for standing poses made of woven nylon threads and fibers made from skin-polishing cloth, and an opposite second layer for sitting, kneeling and lying poses made of waffle-woven microfiber fabric. The yoga towel has an edge made of sailcloth. The yoga towel is constructed to prevent a participant from slipping during standing yoga poses, and the exterior remains dry to the touch during use.

Owner:SILVER PLUME

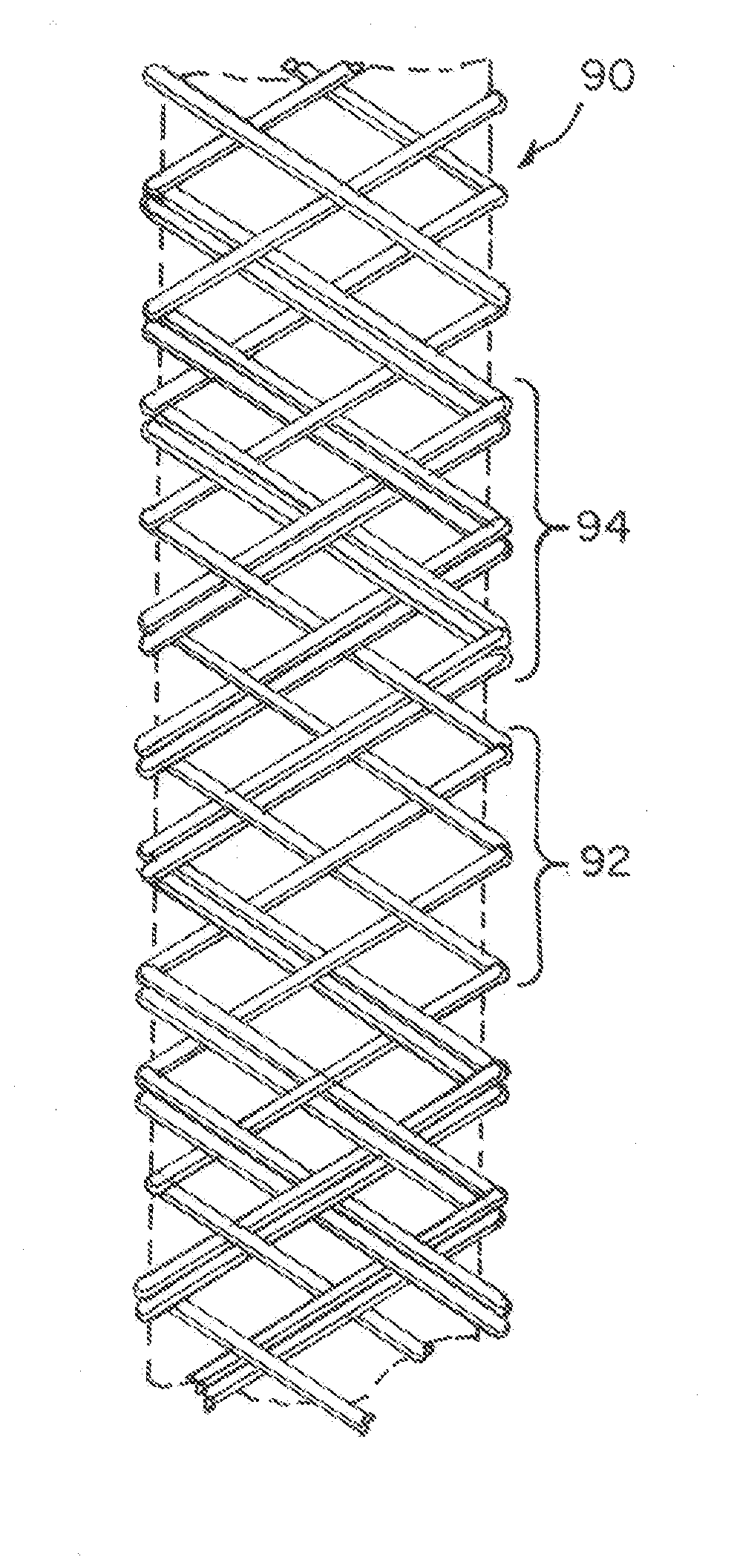

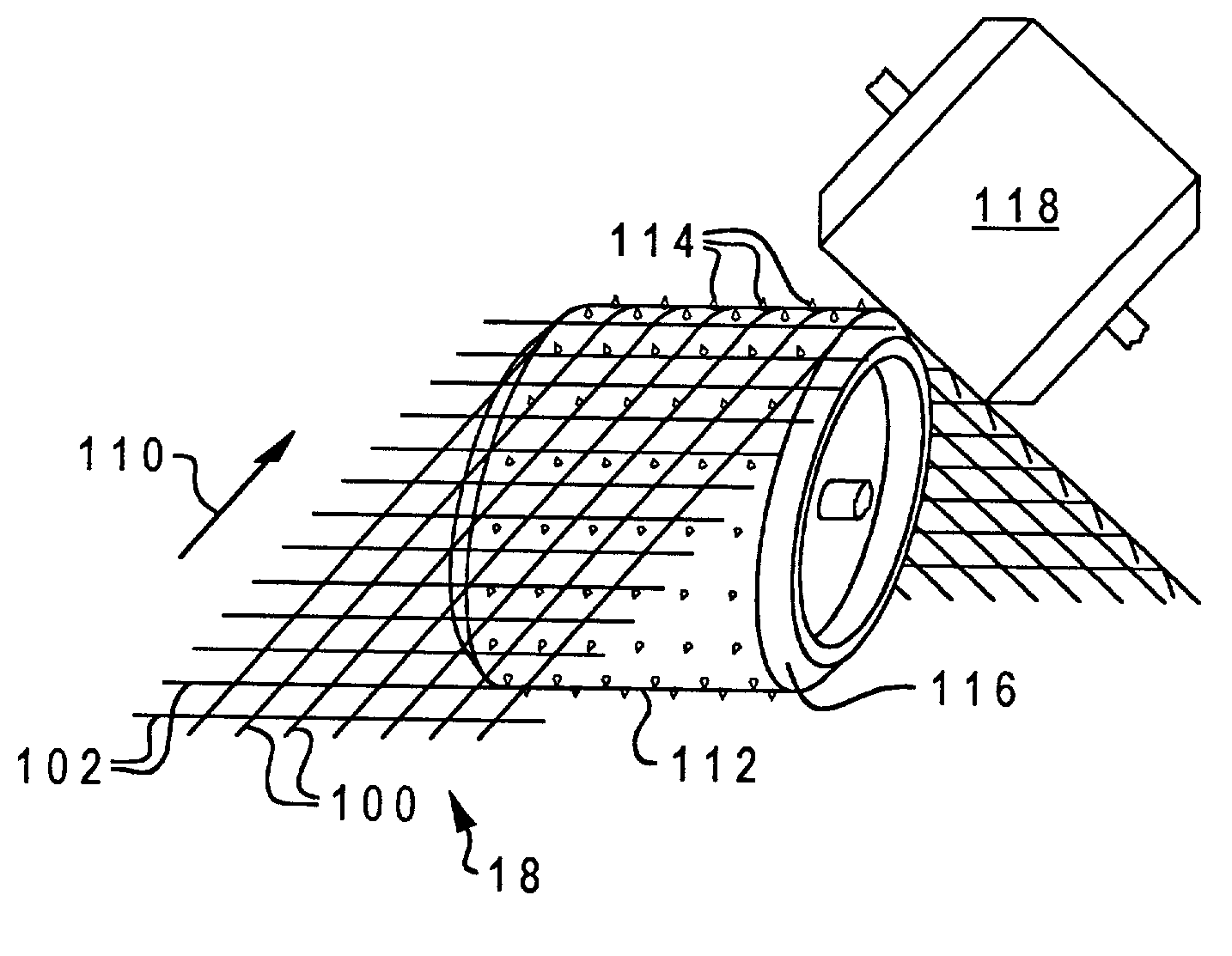

Method of manufacturing a press felt, and a press felt, with the shape of a closed loop

ActiveUS7381307B2Easy to manufactureFast preparationMechanical cleaningPressure cleaningClosed loopMechanical engineering

Owner:TAMFELT PMC OY

Apparatus and method for joining sheets of woven material

Disclosed herein are an apparatus and method for joining sheets of woven material such as wire cloth in side-by-side relation to form a unitary sheet of material having a greater width. In accordance with one preferred embodiment, the apparatus includes a joining mechanism for joining the multiple sheets to form a unitary sheet, and optionally, either or both of a planarizing mechanism for reducing (or eliminating) differences in the thickness of the joint(s) from the bulk of the unitary sheet and a coating mechanism for coating at least areas of the unitary sheet near a joint. Following processing, the unitary sheet can be wound on a spindle to form a roll of woven material having greater than standard width.

Owner:FAIR ROBERT WOOD

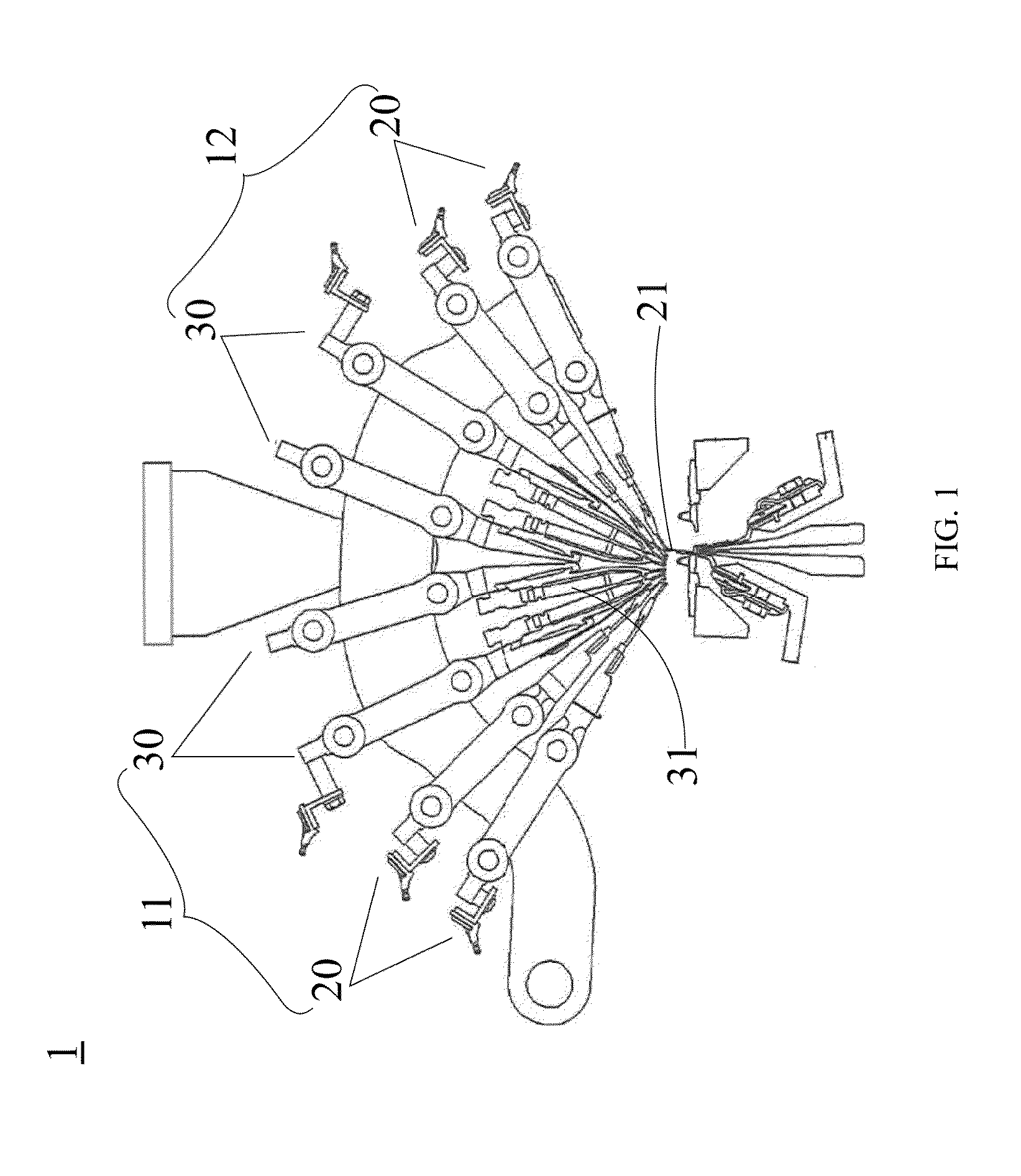

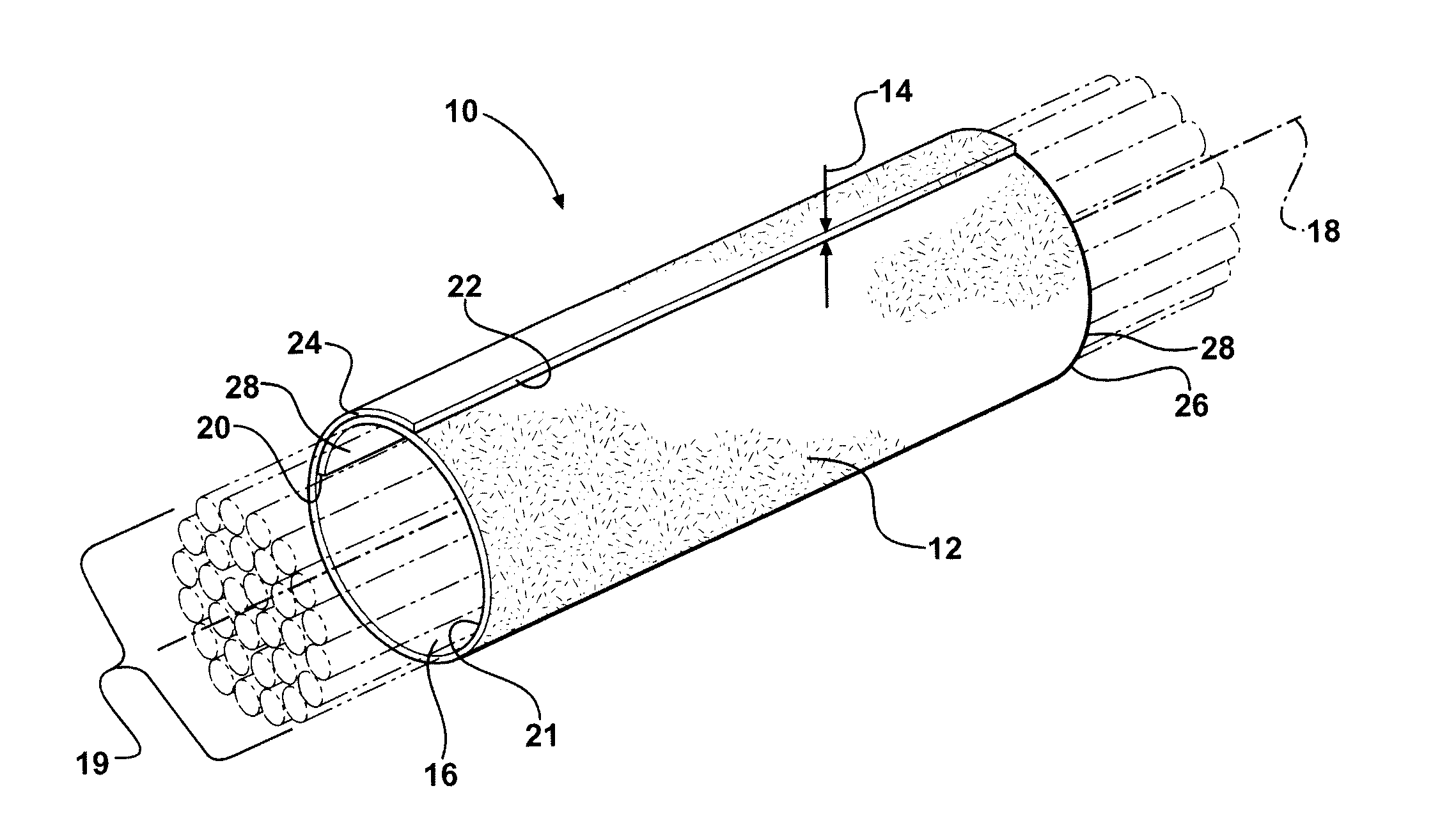

Non-woven self-wrapping acoustic sleeve and method of construction thereof

ActiveUS20080006432A1Avoid spreadingAffecting protective strengthMechanical cleaningPressure cleaningNoise generationArchitectural engineering

A non-woven acoustic sleeve and method of construction thereof provides routing and protection for elongate members and suppression of noise generation from the elongate members while in the sleeve. The sleeve has an elongate wall with opposite sides that are self-wrapping about a longitudinal axis to define a generally tubular cavity. The opposite sides are extendable away from one another under an externally applied force to allow the elongate members to be disposed radially into or removed from the cavity. When the external force is released, the opposite sides of the wall to return to their self wrapped configuration to enclose the elongate members and suppress noise therefrom.

Owner:FEDERAL MOGUL WORLD WIDE LLC

Reinforced fabric seam

ActiveUS8518511B2Small volumeReduce decreaseGarmentsSynthetic resin layered productsPolyesterEngineering

A composite seam system including a narrow weld bead joining two panels of fabric and a seam tape applied thereon. The applied seam tape comprises a top layer, a reinforcing layer and an adhesive layer melted through the reinforcing layer and connecting the top layer to the fabric panels over the weld bead. The narrow weld bead and the small seam allowance of the fabric panels it joins allows the seam tape to be secured over the weld bead to the fabric panels while lying in a flat plane. The use of a narrow reinforcing layer of woven polyester, nylon or non-woven ultra-fine fibrous material in the seam tape allows the seam tape to be flexible enough to move with the fabric it joins, reducing the incidence of tape edge abrasion.

Owner:PATAGONIA INC

Non-woven self-wrapping acoustic sleeve and method of construction thereof

ActiveUS7523532B2Suppresses noise generationMaximize dampening potentialMechanical cleaningPressure cleaningNoise generationArchitectural engineering

Owner:FEDERAL MOGUL WORLD WIDE LLC

Method and apparatus for welding a curved seam

ActiveUS20140374020A1Lamination ancillary operationsControlling laminationControl signalMechanical engineering

A system and method for welding flexible fabric is presented. A welding system for flexible fabric includes a welding machine with a roller and a user interface. The welding machine is adapted to weld a first fabric to a second fabric using a first heat. The roller on the welding machine can be used to roll at a first speed the first fabric and / and or the second fabric through the welding machine. Later, an operator of the welding machine through the user interface sends a single speed control signal to the welding machine. Response of the single speed control signal, the welding machine changes from the first heat to a second heat and also changes the speed of the roller from the first speed to a second speed.

Owner:MILLER WELDMASTER CORP

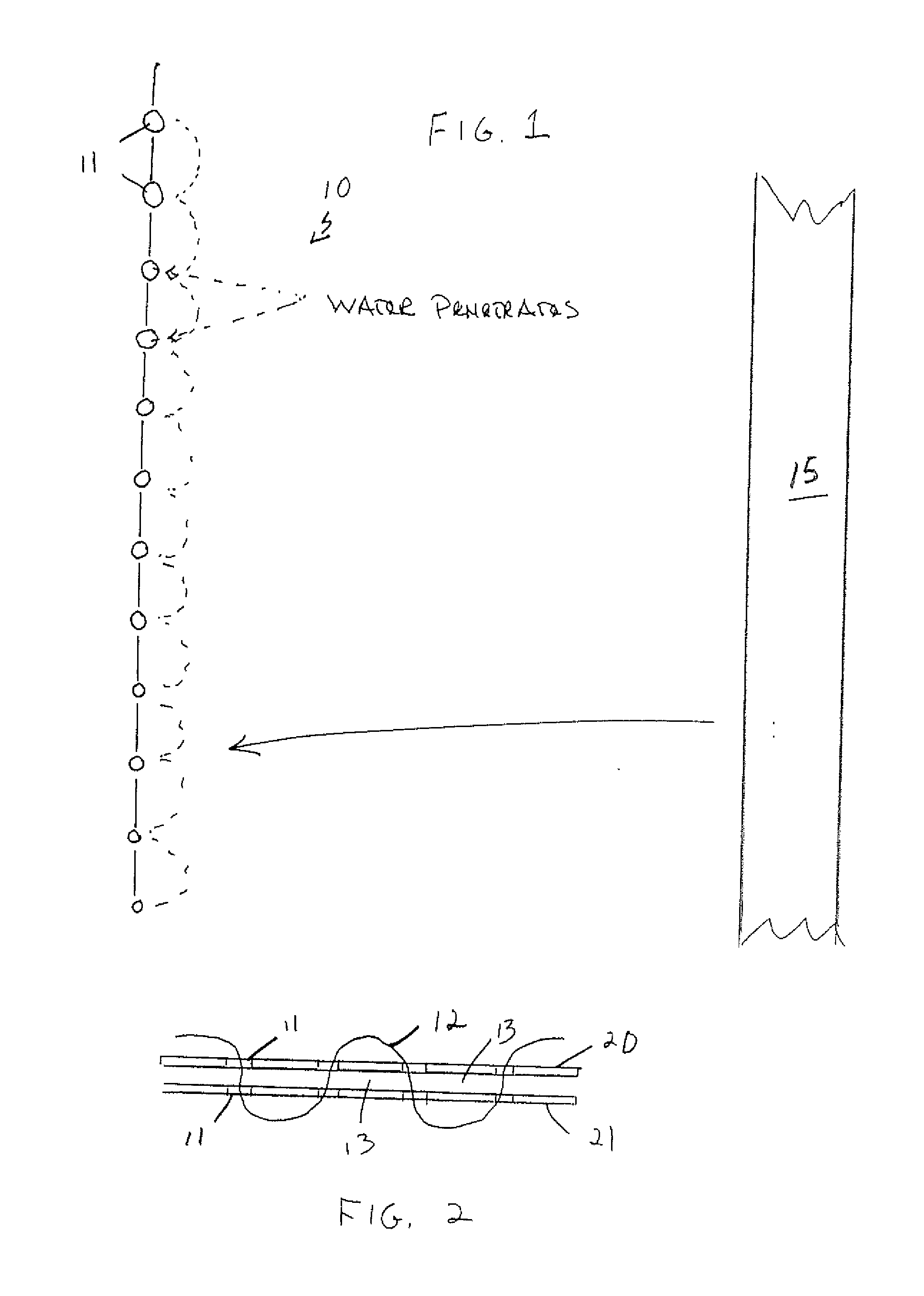

Adhesive Thread System

InactiveUS20130048219A1Improve waterproof performanceEliminate needLamination ancillary operationsGarmentsNeedle punctureGlue line

A system for forming a waterproof seam between to sewn materials. The seam is formed using an adhesive coated thread. A thin strip of adhesive is placed between the two materials at the seam line. As the coated thread is sewn into the seam heat and pressure are simultaneously applied, melting the adhesive coating thereby filling the needle punctures. The melted adhesive coating will also flow into the areas between the needles punctures and between the materials. The heat and pressure applied to the coated thread will also melt the adhesive strip, causing additional adhesive to flow into the needle punctures and the areas between needle punctures.

Owner:FERREIRO ROXANNE

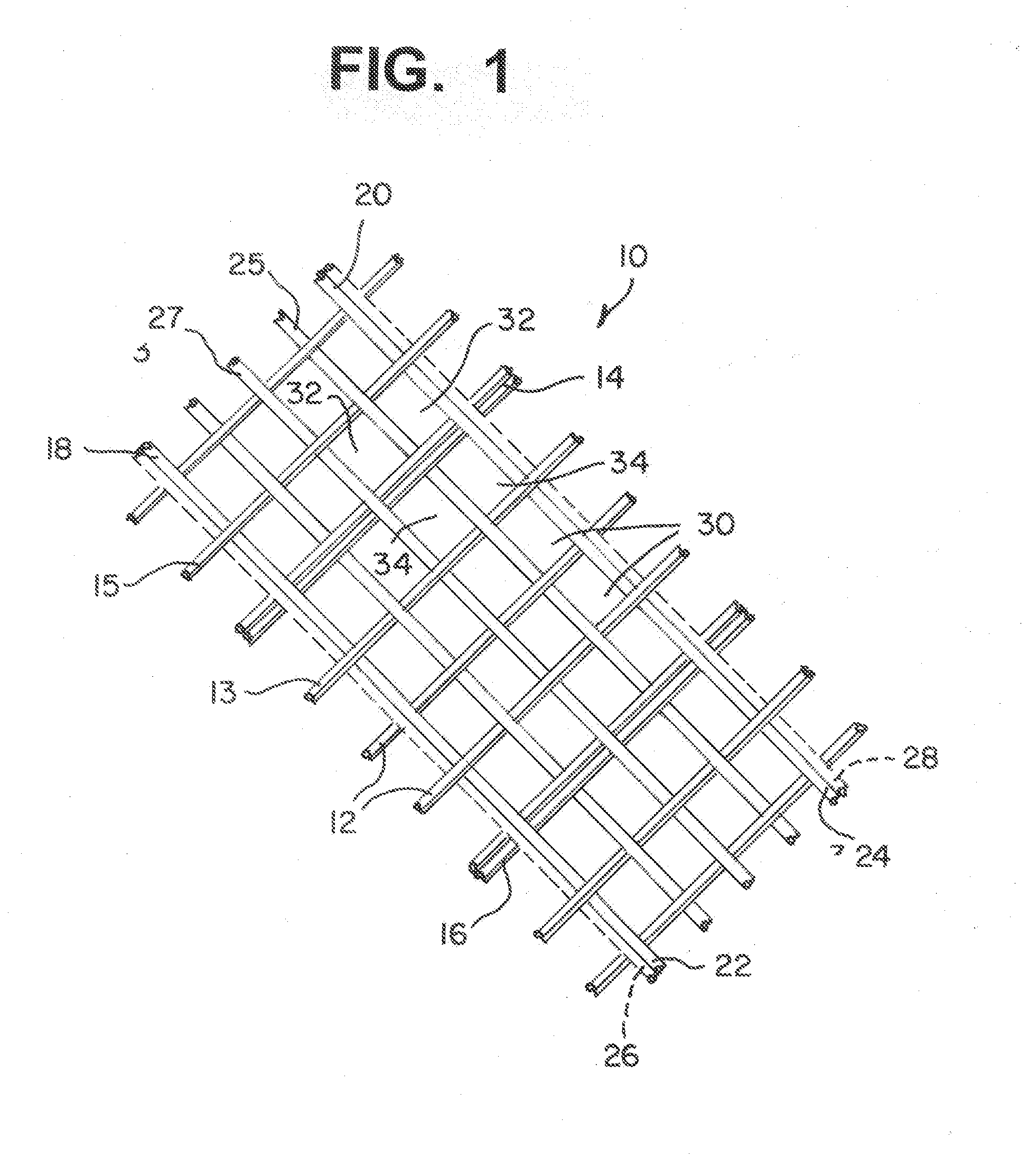

Making a blank by reinforcing a fiber structure and/or bonding fiber structures together, and use in making composite material parts

ActiveUS20040175553A1Density of pin can be highHigh densitySeaming textilesCeramic layered productsRefractoryOptoelectronics

A porous fiber structure is consolidated by forming within a deposit of a refractory material by partially densifying the fiber structure in such a manner as to bond together the fibers of the fiber structure so as to enable the fiber structure to be handled without being deformed, while leaving empty the major fraction of the initial pore volume of the fiber structure, and rigid pins are implanted through the consolidated porous structure. A blank is obtained by reinforcing a fiber structure by implanting pins or by bonding together consolidated fiber structures, the bonding being performed by implanting pins.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

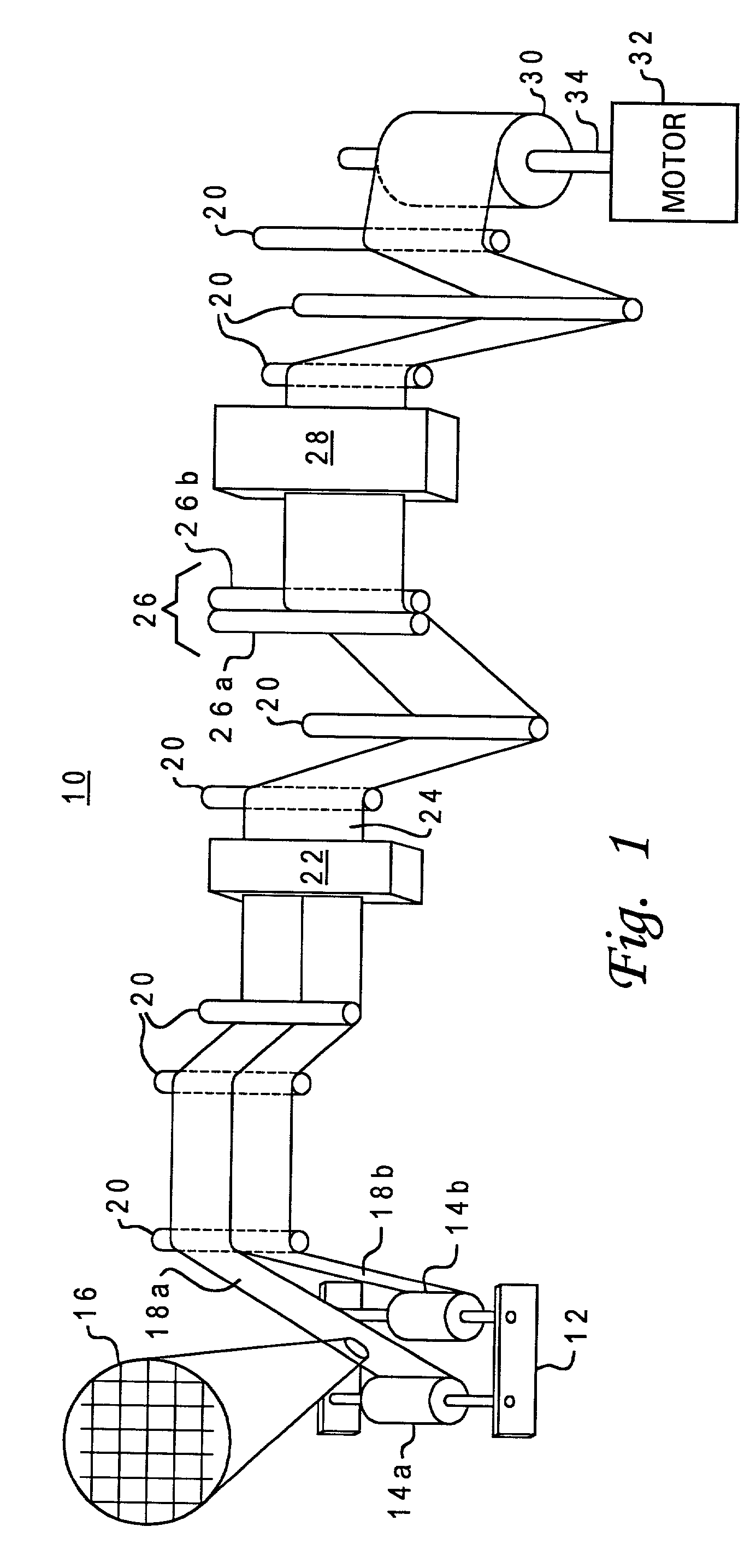

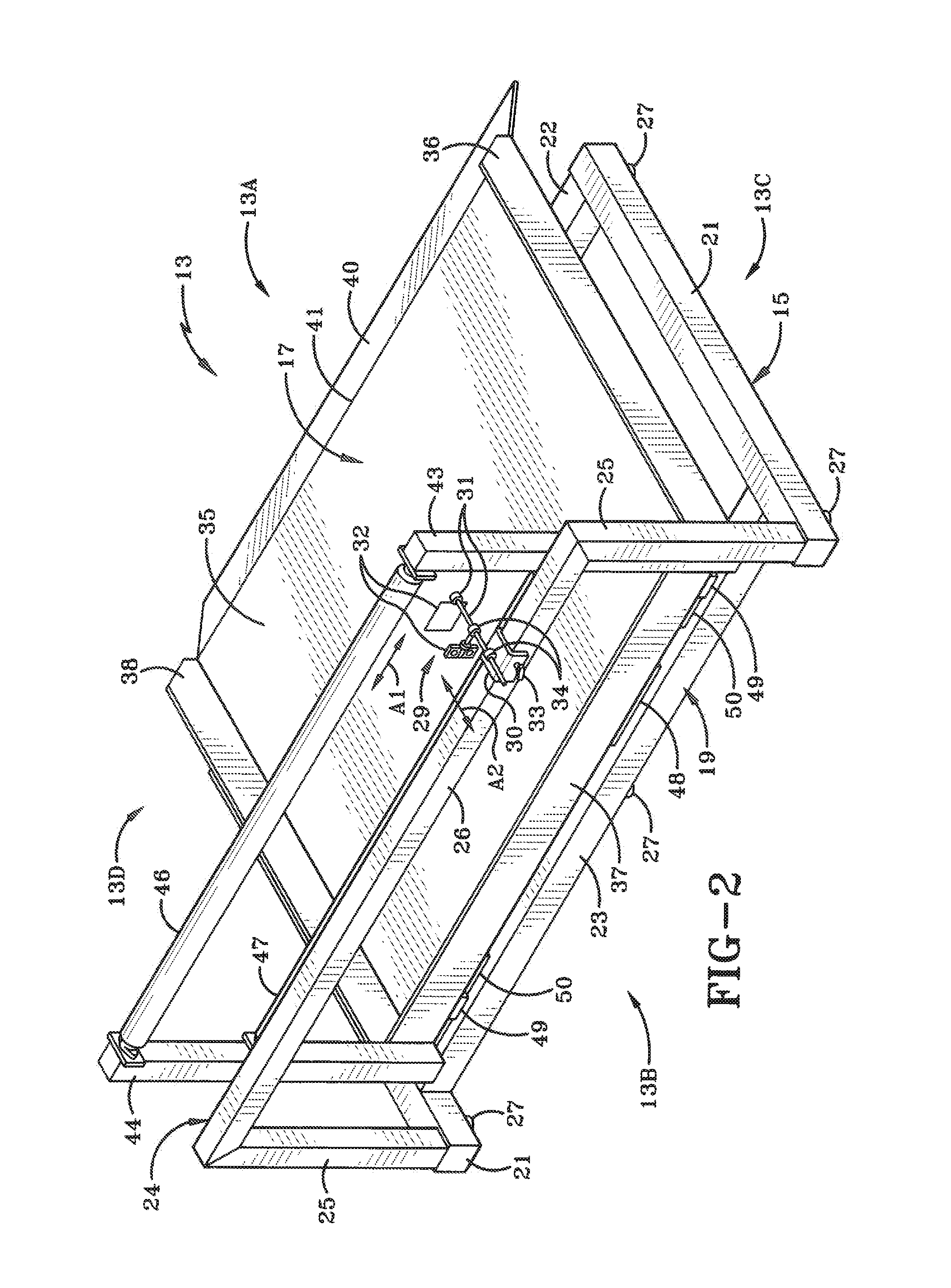

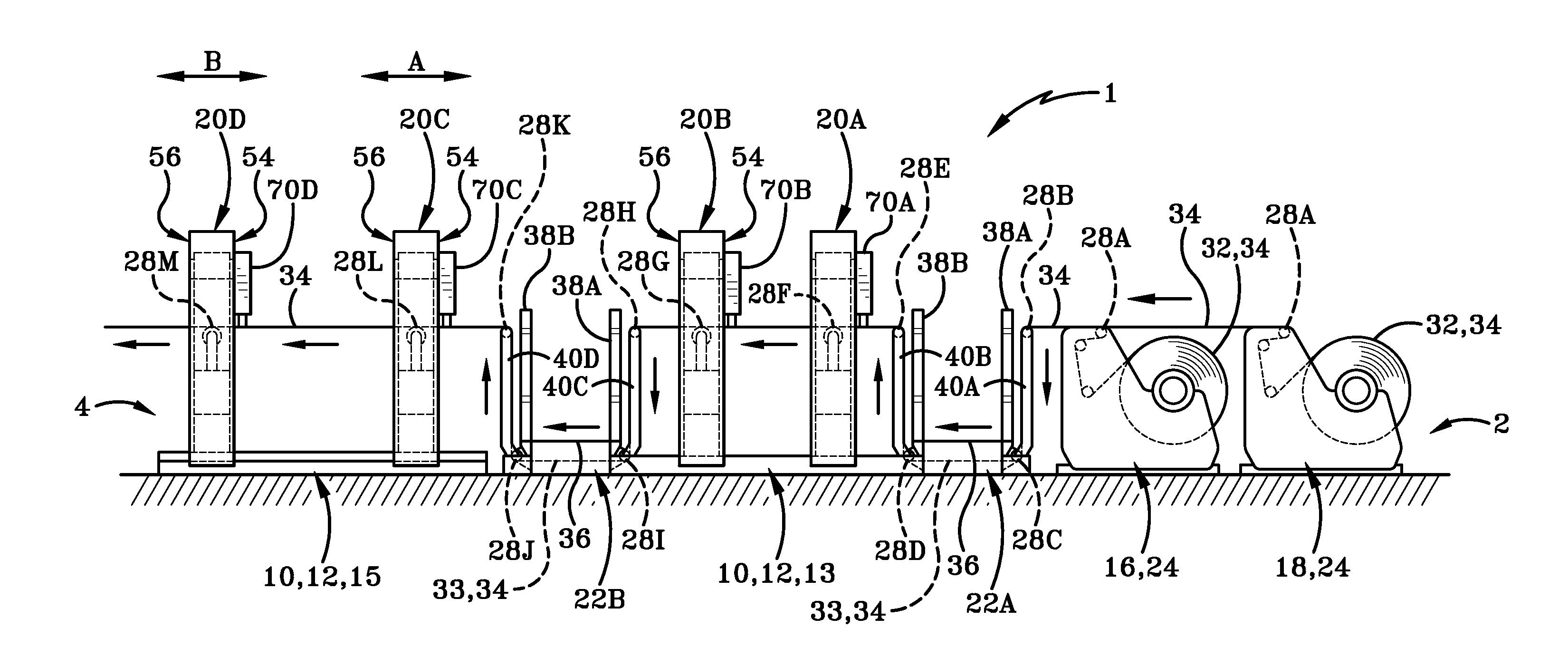

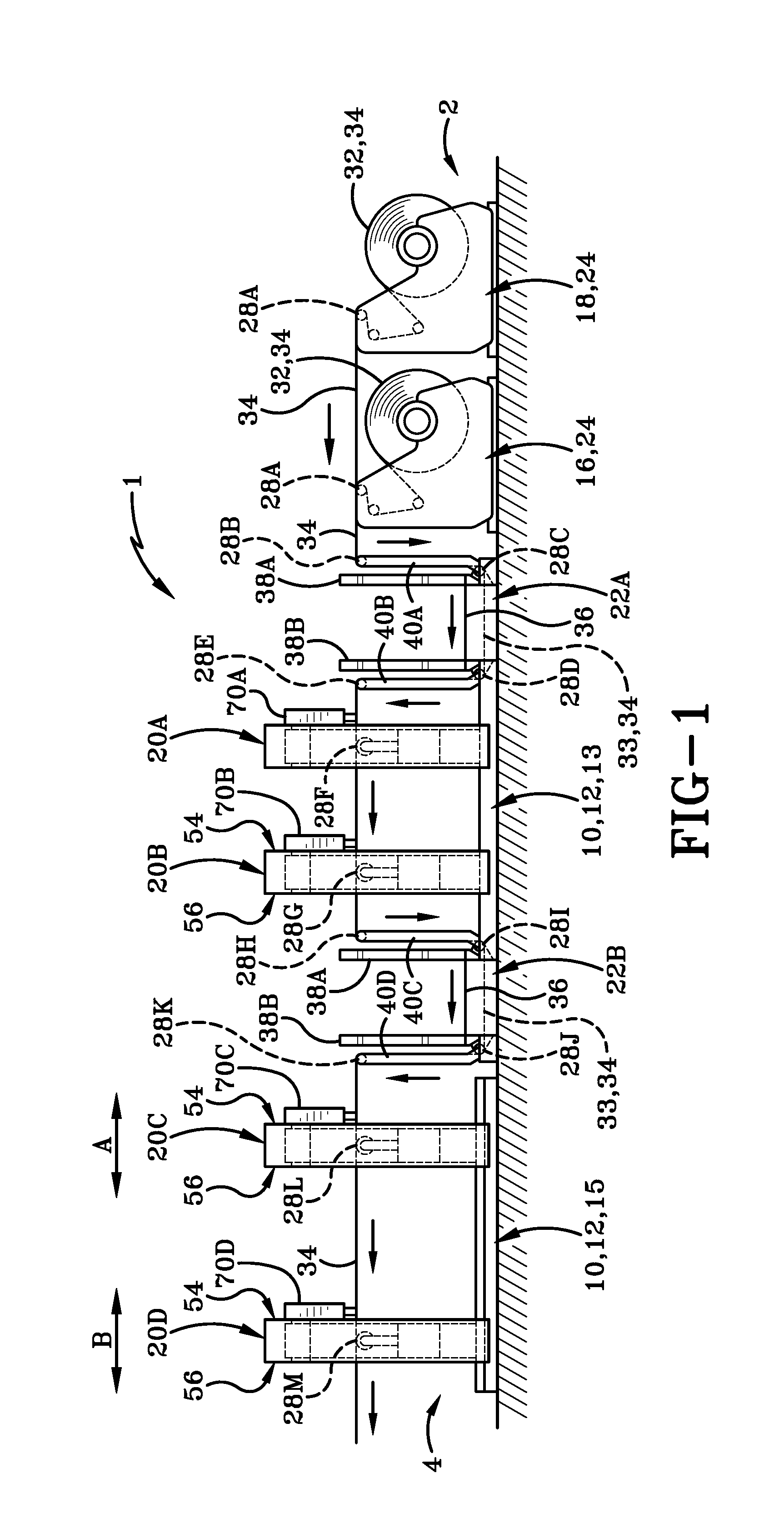

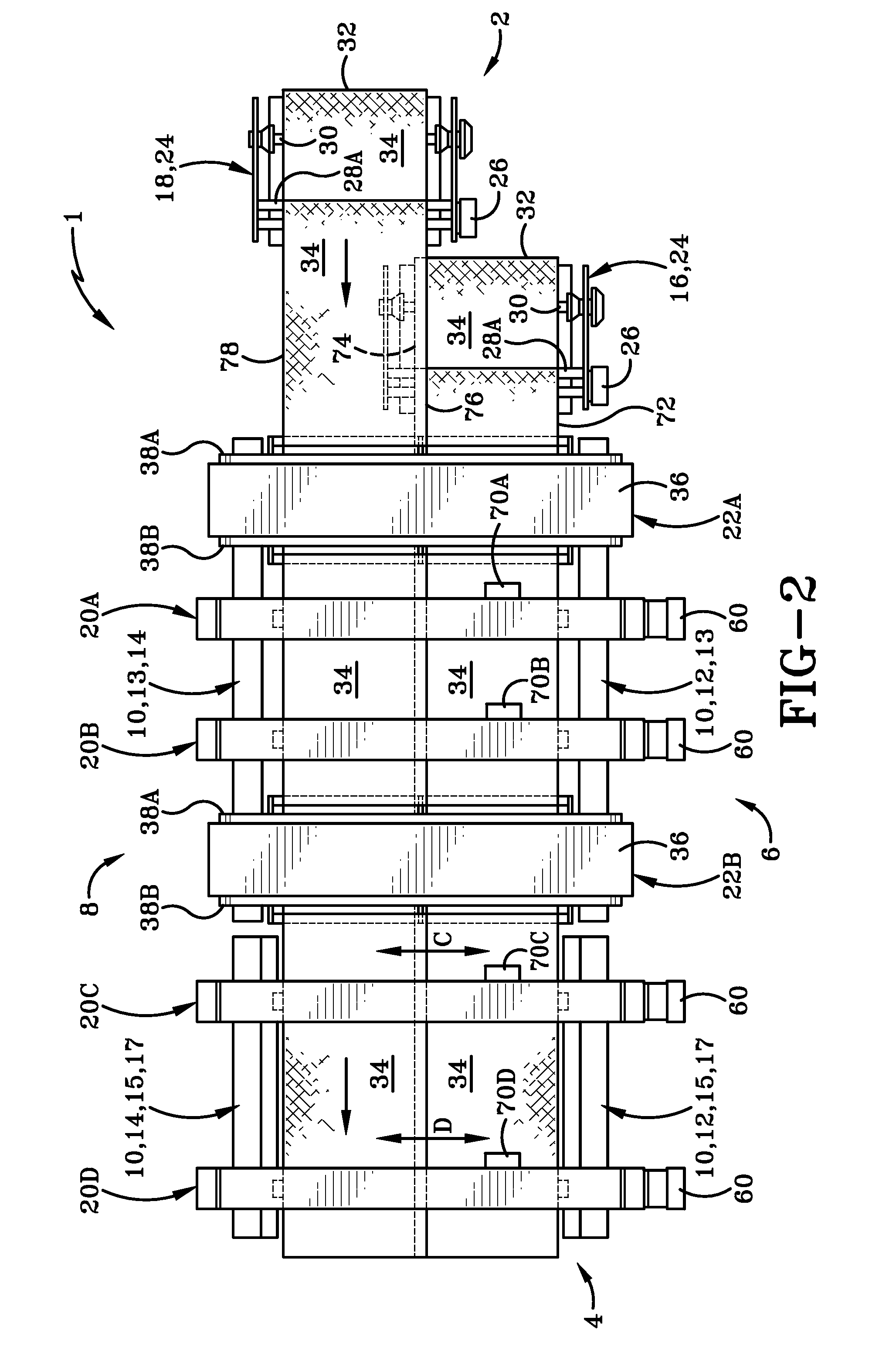

Dual roll fabric welding machine and method of operation

A dual roll fabric welding or seaming machine is configured to seam pieces of sheet material to one another as the pieces move downstream. The machine includes modular gantries and various actor devices which may be readily mounted on any of the gantries to interact with the moving sheet material to achieve various functions, such as seaming pieces of sheet material together, forming hems, applying grommets to the sheet material, printing on the sheet material, connecting reinforcement strips or ropes to the sheet material and cutting the sheet material.

Owner:MILLER WELDMASTER CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com