Face sheet for absorption article and method for producing the same

An absorbent, sheet technology, applied in absorbent pads, textiles and papermaking, applications, etc., can solve problems such as stickiness, poor liquid absorption, and deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

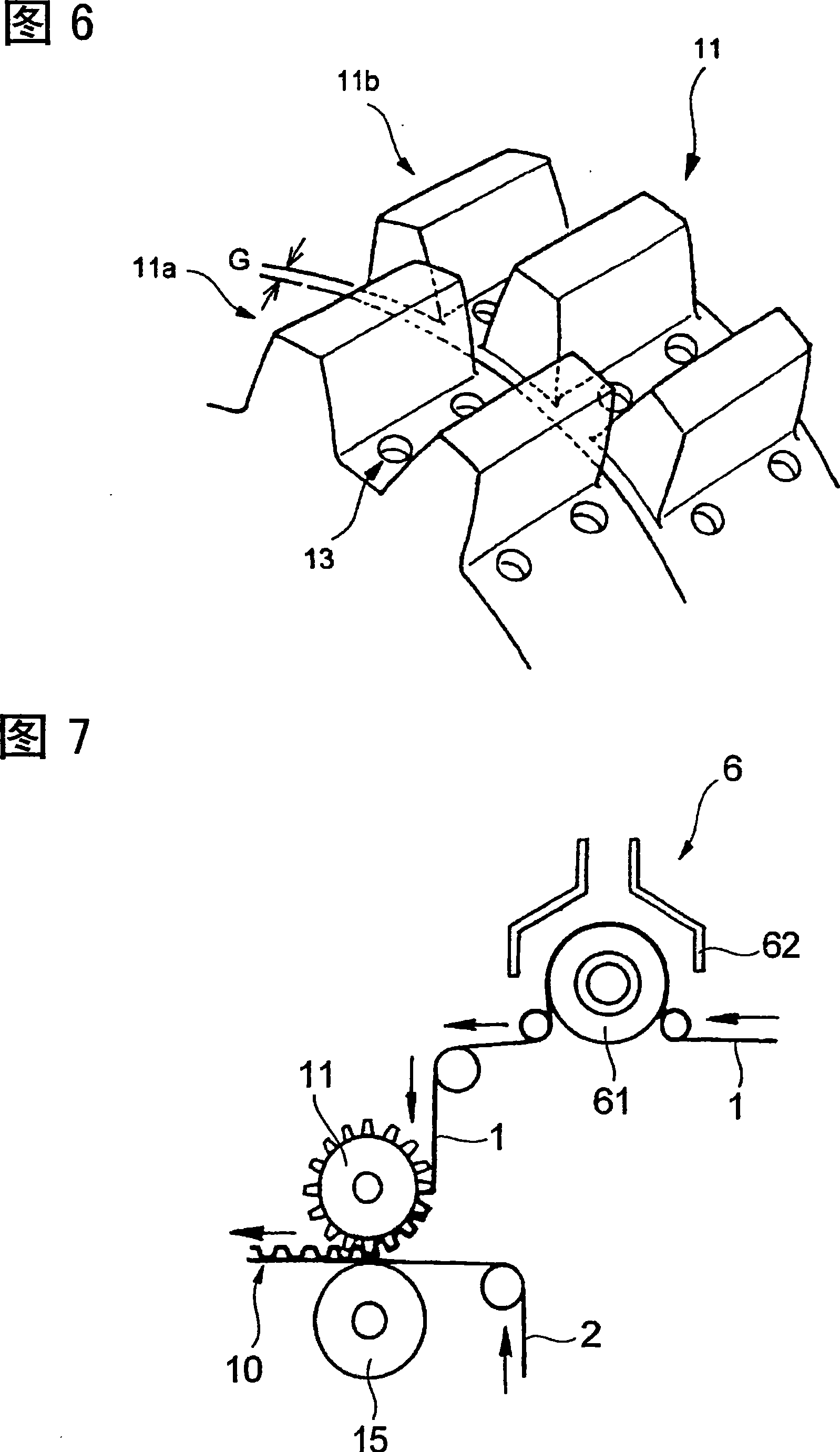

[0036] Hereinafter, the present invention will be described based on preferred embodiments of the present invention with reference to the accompanying drawings.

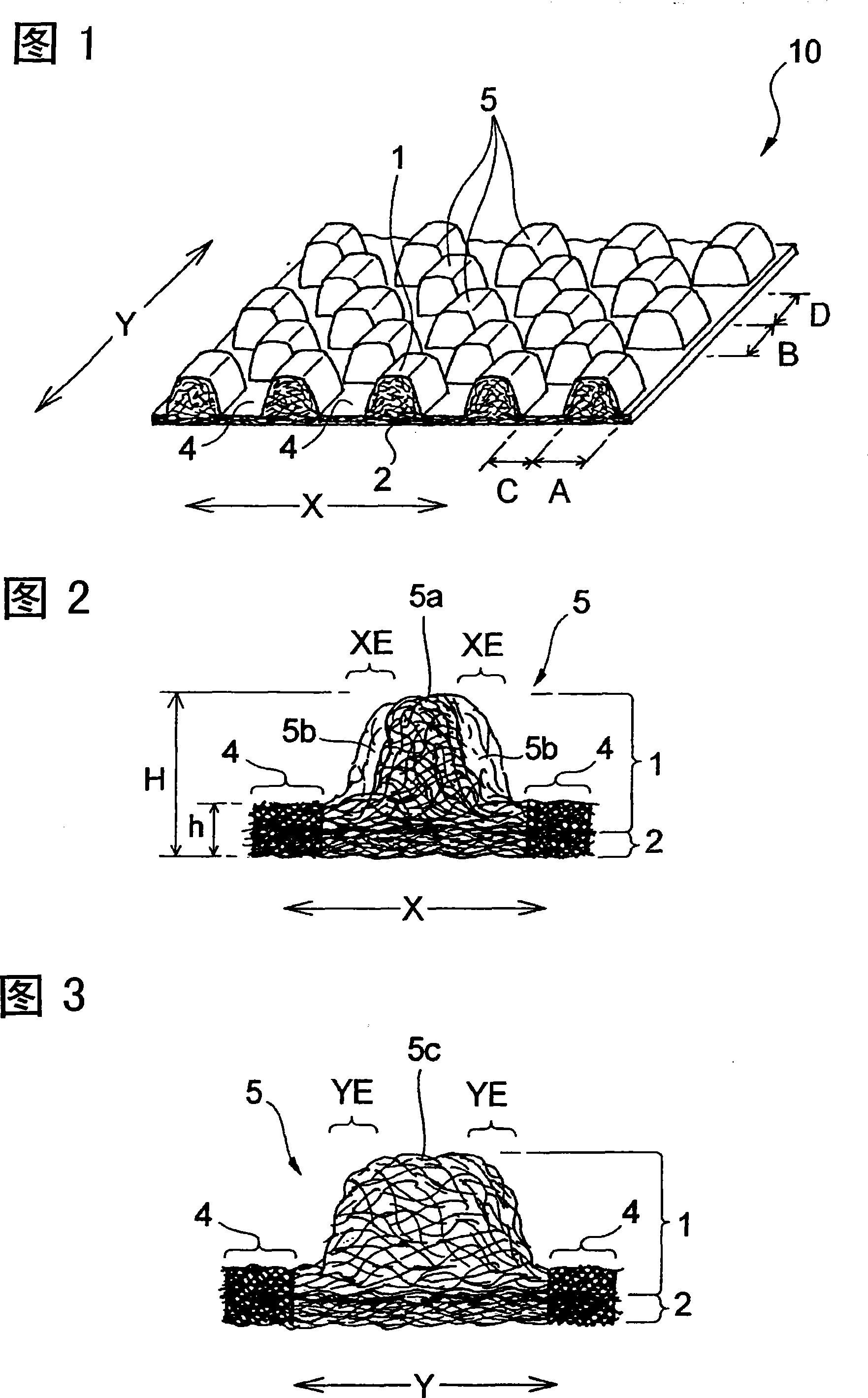

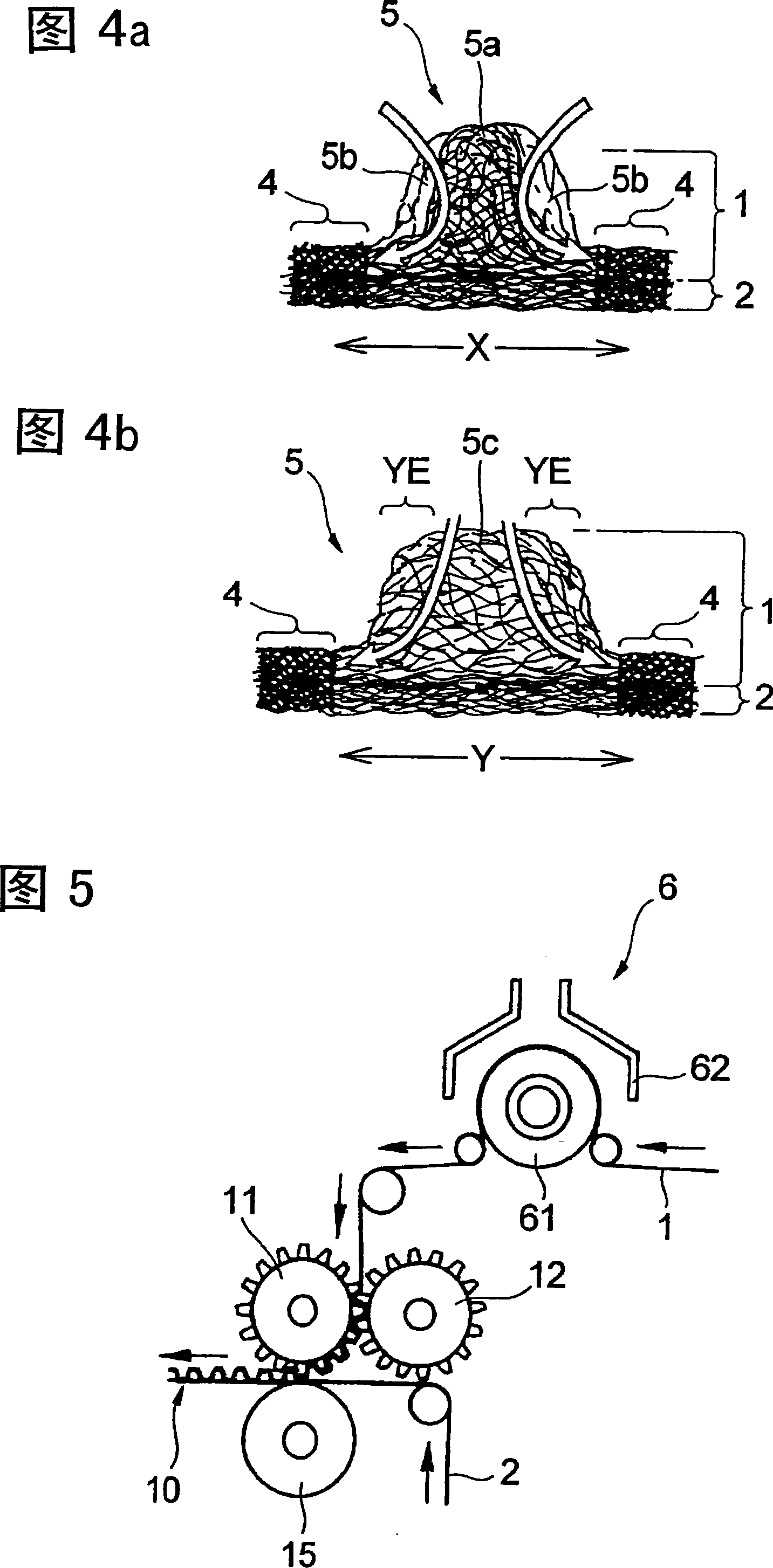

[0037] Fig. 1 is a perspective view showing one embodiment of the topsheet for absorbent articles of the present invention.

[0038] The topsheet 10 shown in FIG. 1 is used for the skin-contacting surface of absorbent articles such as disposable diapers, sanitary napkins, panty liners (panty liners), and incontinence pads.

[0039] The surface sheet 10 is comprised from the 1st nonwoven fabric 1 and the 2nd nonwoven fabric 2 laminated|stacked mutually. The first nonwoven fabric 1 forms the surface of the topsheet 10 facing the wearer's skin (skin contacting surface), and the second nonwoven fabric 2 forms the surface of the topsheet 10 facing the absorber side (non-skin contacting surface).

[0040] The first nonwoven fabric 1 and the second nonwoven fabric 2 are thermally fused locally, whereby many thermally fused...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Orientation degree | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com