Adhesive Thread System

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

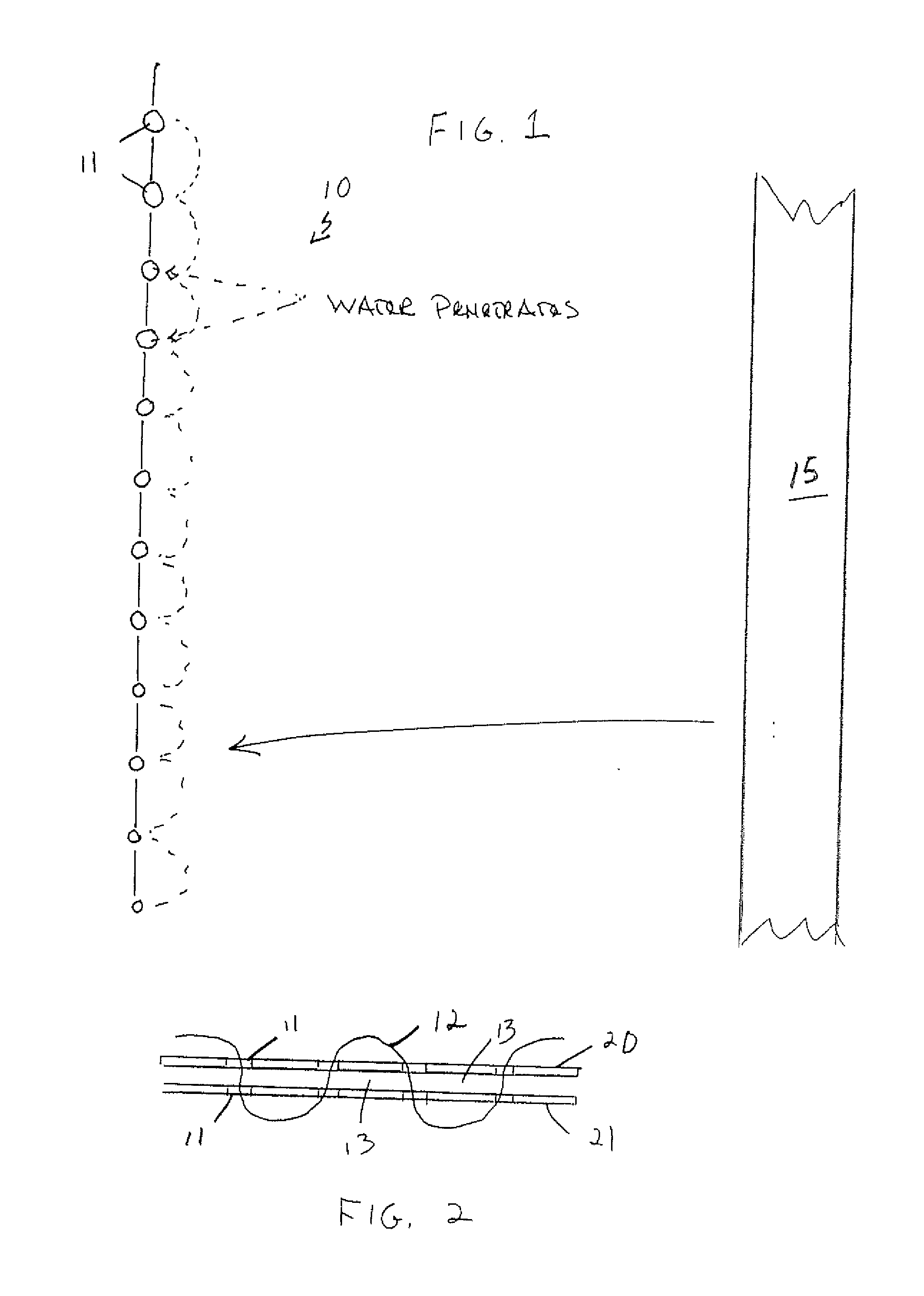

[0026]Referring to the drawings in detail wherein like elements are indicated by like numerals, there is shown an FIGS. 1 and 2, an example of a prior art waterproof seam 10. The prior art seam 10 has a series of needle punctures 11 through which thread 12 is passed. In the example shown, two pieces of material 20, 21 are being joined along the seam 10. Water / moisture can pass through the punctures 11 along side the thread 12 and also between the joined material pieces 20, 21 in the areas 13 between puncture holes 11. A separate sealing tape 15 having an adhesive coating is placed over the seam 10 and adhered to the seam with heat and pressure. This second step provides a waterproof seam.

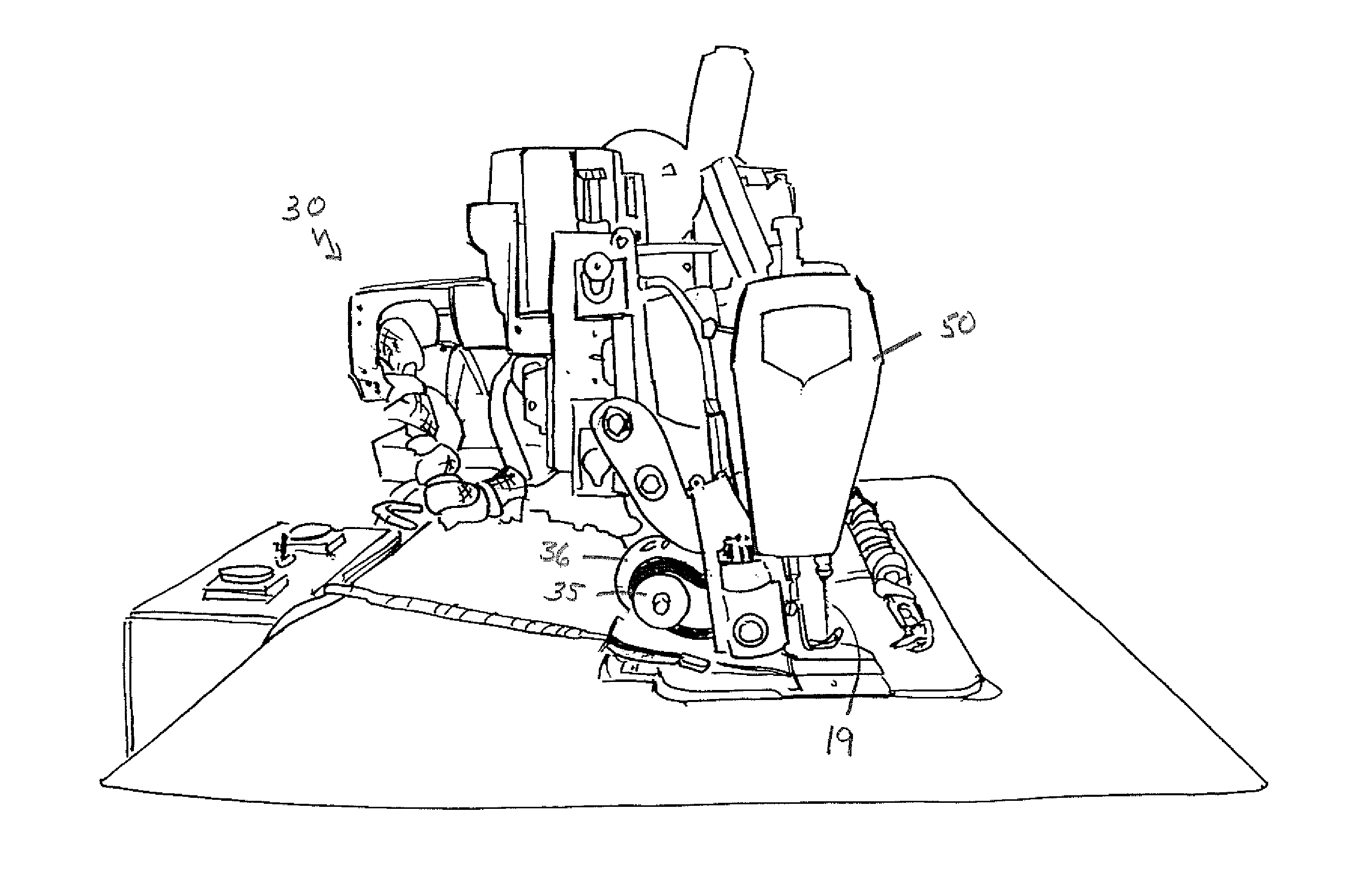

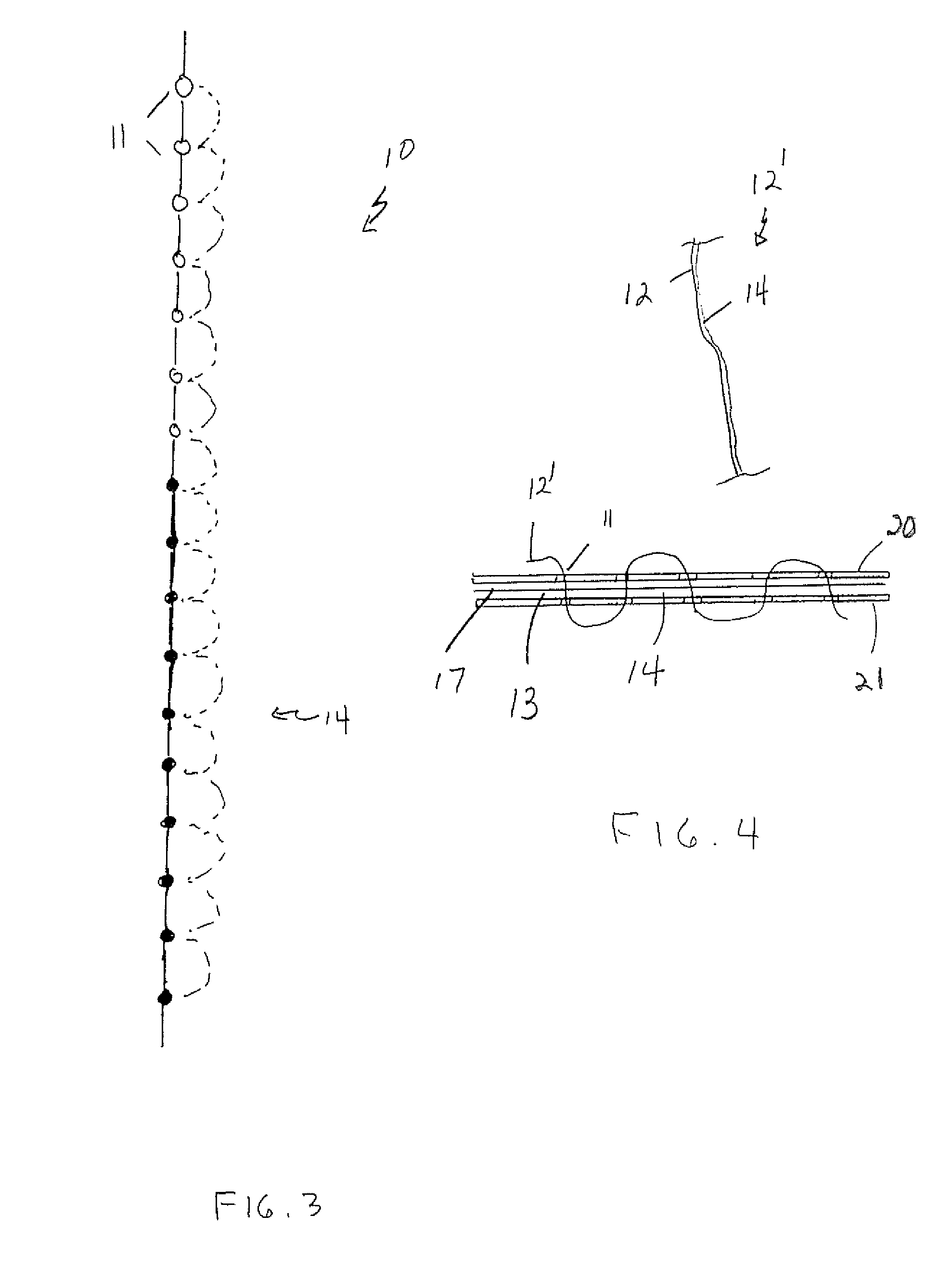

[0027]Referring to FIGS. 3 and 4, the present invention seam 10 is formed using an adhesive coated thread 12′. The coated thread 12′ is comprised of a thread 12 with an adhesive coating 14. As the coated thread 12′ is applied, heat and pressure are simultaneously applied, melting the adhesive coatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Flow rate | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com