Apparatus and method for joining sheets of woven material

a technology of woven materials and apparatuses, applied in the direction of layered products, chemistry apparatus and processes, synthetic resin layered products, etc., can solve the problem that the production of bulk rolls of wire cloth having greater than standard widths is not generally employed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

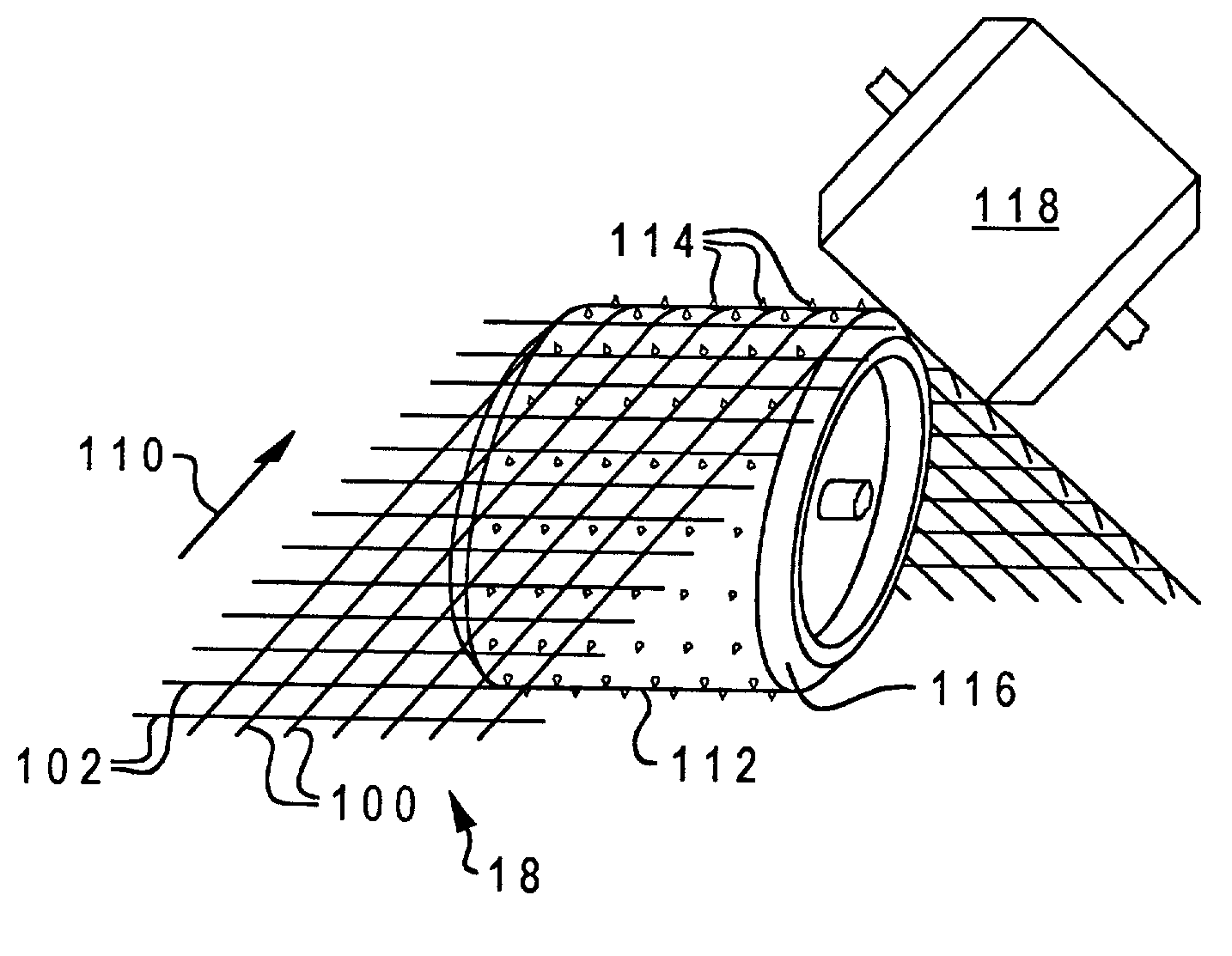

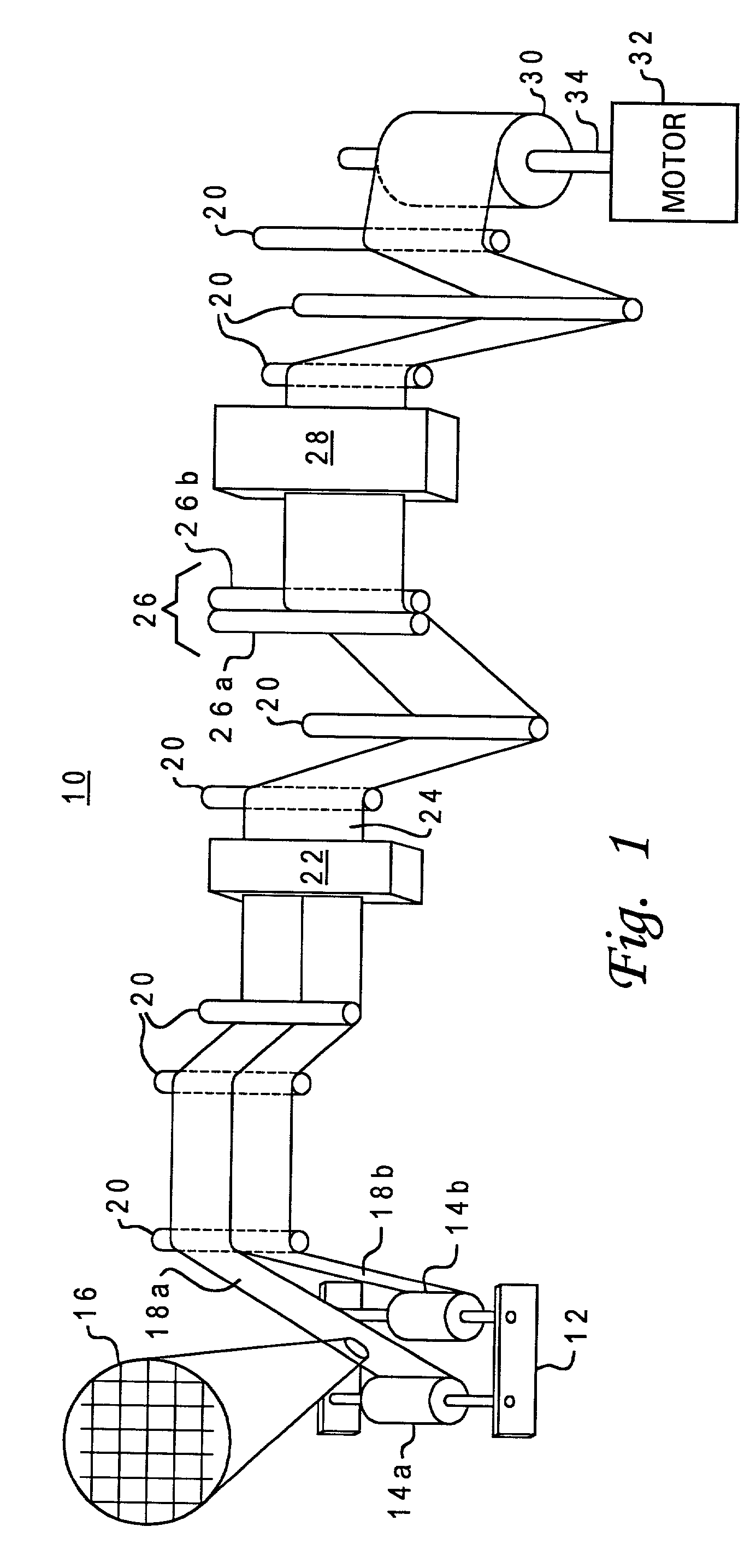

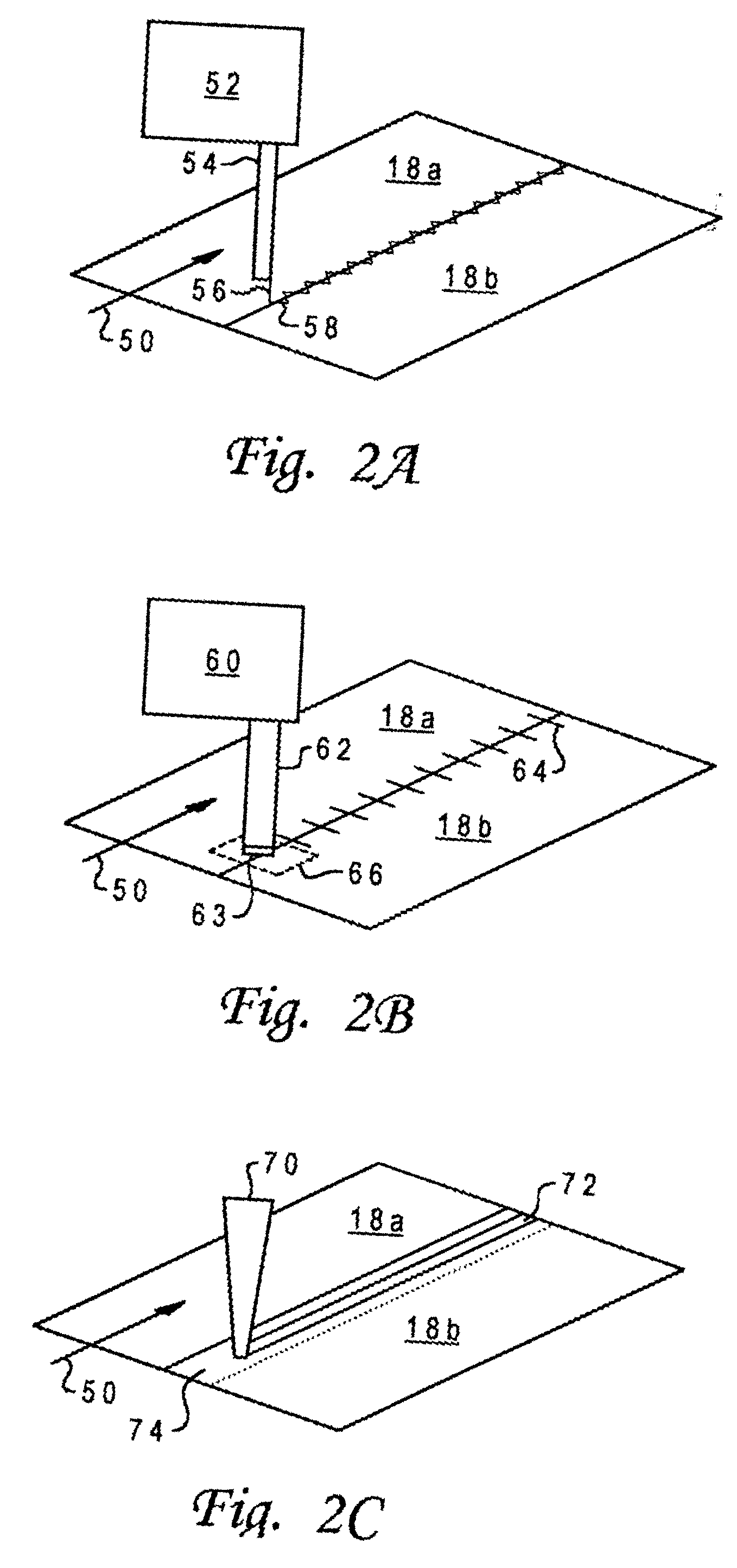

[0019] With reference now to the figures and in particular with reference to FIG. 1, there is illustrated a high-level perspective view of an apparatus for joining widths of wire cloth in accordance with a preferred embodiment of the present invention. As depicted, apparatus 10 includes a support rack 12 that supports two or more supply rolls 14 of convolute wire cloth, as shown in detail at reference numeral 16. Each supply roll 14 may have any width, but widths of standard rolls typically range between 24 and 72 inches, as noted above. Support rack 12 preferably supports at least some supply rolls 14 at differing axial alignments so that the raw edges of multiple sheets 18a, 18b of wire cloth will not snag or interfere as they are payed out. In an alternative embodiment of the present invention (not illustrated), support rack 12 can be eliminated, and sheets 18 can be received directly from looms for weaving wire cloth.

[0020] The multiple wire cloth sheets 18 are unwound from supp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com