Full self-control non-woven fabrics thermal compression welding device and method

A technology of hot-press welding and welding method, which is applied to the seams of textile materials, textiles and papermaking, mechanical processing/deformation, etc. The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

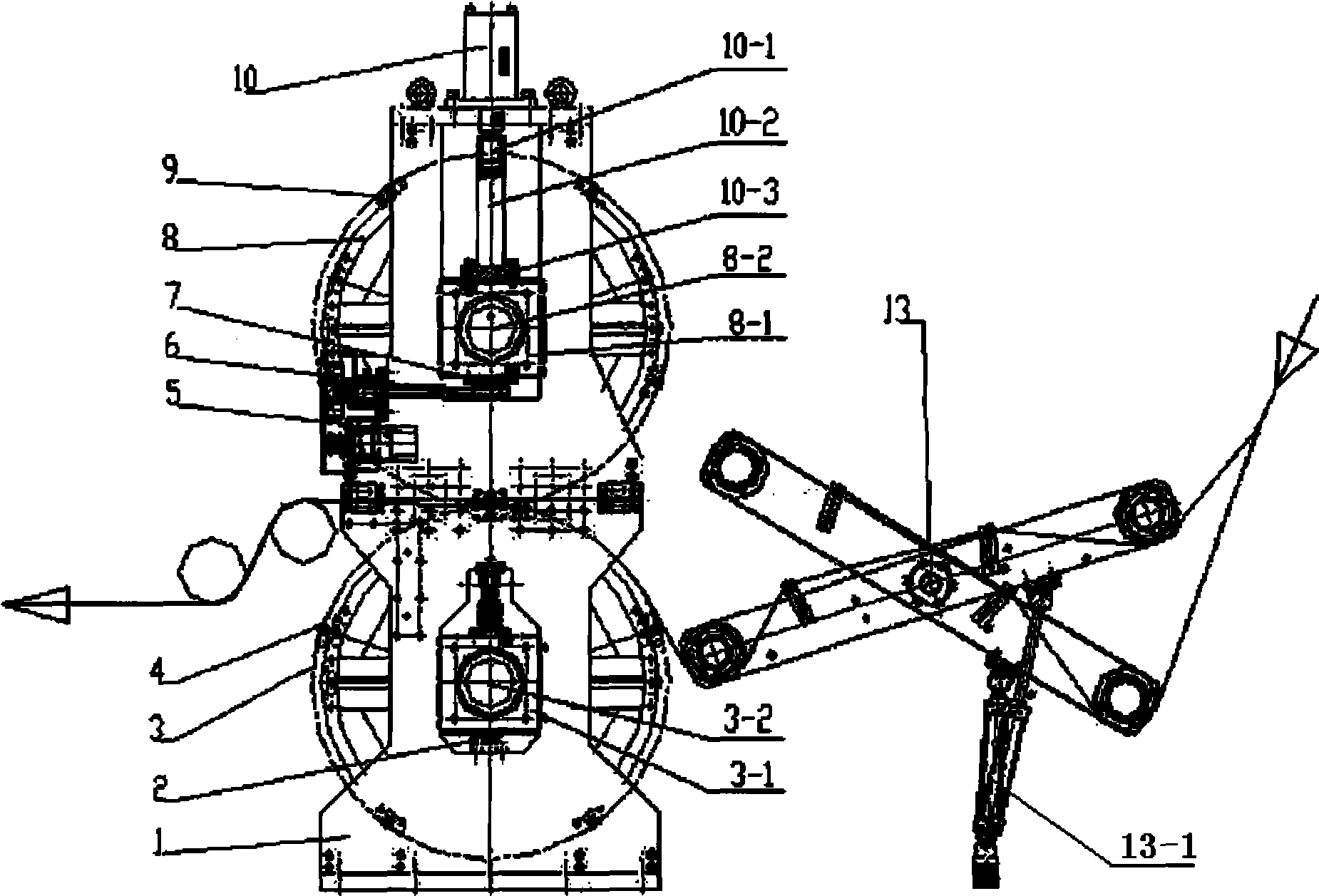

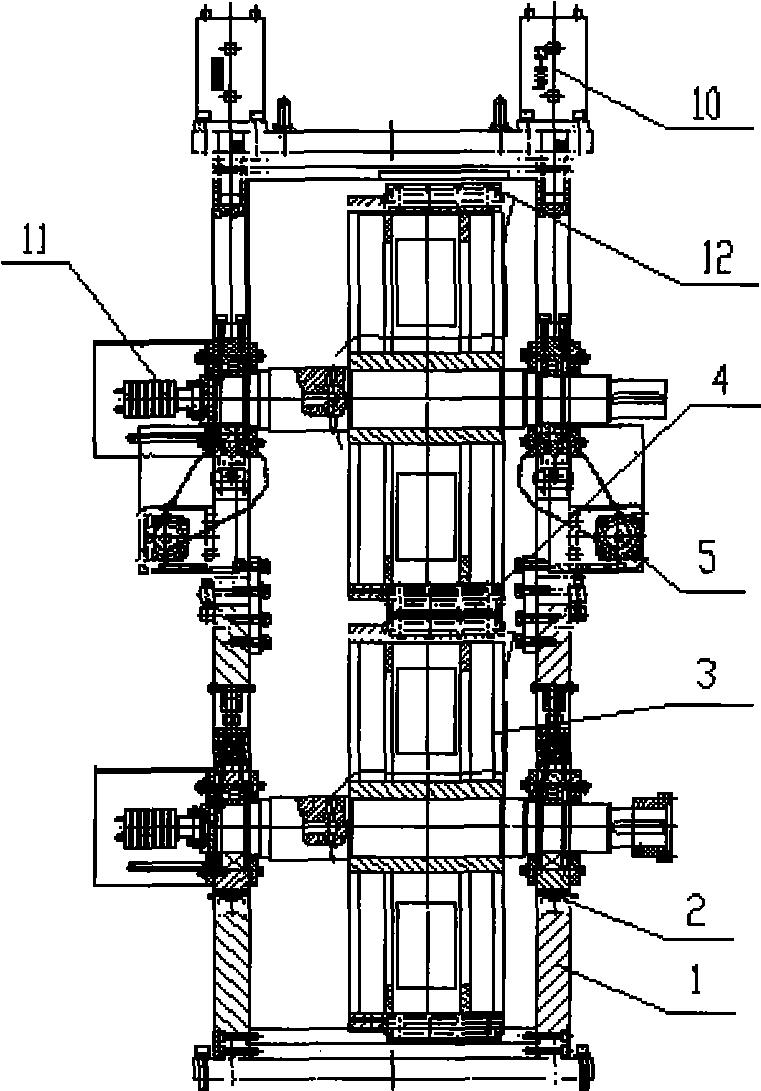

[0010] Embodiment 1: with reference to attached Figure 1~2 . Fully automatic non-woven hot-press welding device, which includes a PLC controller, a groove structure on the upper part of the frame 1, and a hole in the lower part, and the lower electric heating welding wheel 3 Axle 3-2 passes through the lower slider 3-1 and is located on the frame 1 In the lower hole and the lower end surface of the lower slider 3-1 is pressed on the pressure sensor 2, the upper electric heating welding wheel 8 axle 8-2 is located in the upper groove of the frame 1 through the upper slider 8-1 and the upper slider 8 -1 The lower end surface is located on the screw adjustment wedge 7 and the screw adjustment wedge 7 is driven by the stepper motor 5 through the transmission mechanism, the power supply end of the stepper motor 5 is controlled by the PLC controller, and the hydraulic cylinder 10 is located on the machine On the upper end of the frame 1, the piston 10-1 of the hydraulic cylinder 1...

Embodiment 2

[0011] Embodiment 2: On the basis of Embodiment 1, the welding method of the fully automatic non-woven fabric hot-press welding equipment, the welding pressure and welding temperature required for welding products are input into the PLC controller, and the welding program built in the PLC controller According to the pressure and welding temperature required for product welding, calculate the welding pressure of the product and the gap between the welding dies, and then according to the pressure value detected by the pressure sensor 2, under the rated working pressure set by the hydraulic cylinder 10, command the stepping motor 5 Adjust the screw rod adjustment wedge block 7 so that the welding gap between the welding dies reaches the gap required by the pressure setting value, and then welding can be carried out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com