Thermal sensitive ceramic heater and heating body and heating core applied to thermal sensitive ceramic heater

A technology of heat-sensitive ceramics and heating cores, applied in the direction of electric heating devices, heating elements, ohmic resistance heating, etc., can solve the problems of disconnection of connection points, damage of insulating paper, low thermal efficiency, etc., to eliminate potential safety hazards, eliminate contact resistance, reduce The effect of cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

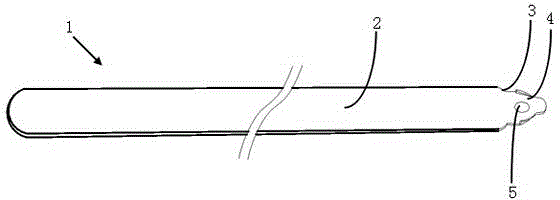

[0063] as attached figure 1 As shown, an electrode sheet of a heat-generating core of a heat-sensitive ceramic heating element, the length direction of the electrode sheet 1 is a heat-conducting surface 2, and the lead-out end 3 of the heat-conducting surface 2 of the electrode sheet 1 has a lead-out surface 4. There is a first through hole 5 on the lead-out surface 4, the width of the lead-out surface 4 is 10mm smaller than the width of the heat-conducting surface 2 of the electrode sheet 1, and the thickness of the electrode sheet 1 is 0.8mm.

Embodiment 2

[0065] as attached figure 1 As shown, an electrode sheet of a heat-generating core of a heat-sensitive ceramic heating element, the length direction of the electrode sheet 1 is a heat-conducting surface 2, and the lead-out end 3 of the heat-conducting surface 2 of the electrode sheet 1 has a lead-out surface 4. There is a first through hole 5 on the lead-out surface 4 , the width of the lead-out surface 4 is the same as the width of the heat-conducting surface 2 of the electrode sheet 1 , and the thickness of the electrode sheet 1 is 0.1 mm.

Embodiment 3

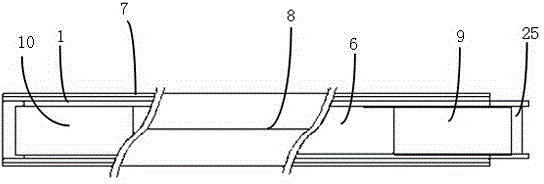

[0067] as attached image 3 As shown, a heating core of a heat-sensitive ceramic heating element, the heating core includes a heat-sensitive ceramic heating sheet 6, an electrode sheet 1 and an insulating paper 7, the length direction of the heating sheet 6 is a heating surface, and the insulating paper 7. Tightly cover the electrode sheet 1 and the heating sheet 6 clamped in the middle, the heating surface of the heating sheet 6 is closely attached to the heat conducting surface 2 of the electrode sheet 1, and the thickness of a single layer of the insulating paper 7 is 0.05mm and a width of 28mm.

[0068] One side of the surface of the insulating paper 7 is coated with a composite adhesive layer that softens at 200-350°C and solidifies at room temperature, and the outer surface of the electrode sheet 1 sandwiching the heating sheet 6 is covered with two layers of insulating paper 7. The joint part 8 of the insulating paper 7 is located on the non-heat-conducting sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com