Multi-station plug-in mounting production line and automatic mouse PCB (printed circuit board) production line

An automatic production line and PCB board technology, which is applied in the direction of assembling printed circuits, electrical components, electrical components, etc., can solve the problem that the product design of the circuit board does not fully consider the characteristics of the plug-in process, low efficiency, and the structure of the plug-in equipment Technology upgrades and other issues to achieve the effect of achieving reliable qualitative, improving production efficiency, improving reliability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific examples, but not limited thereto.

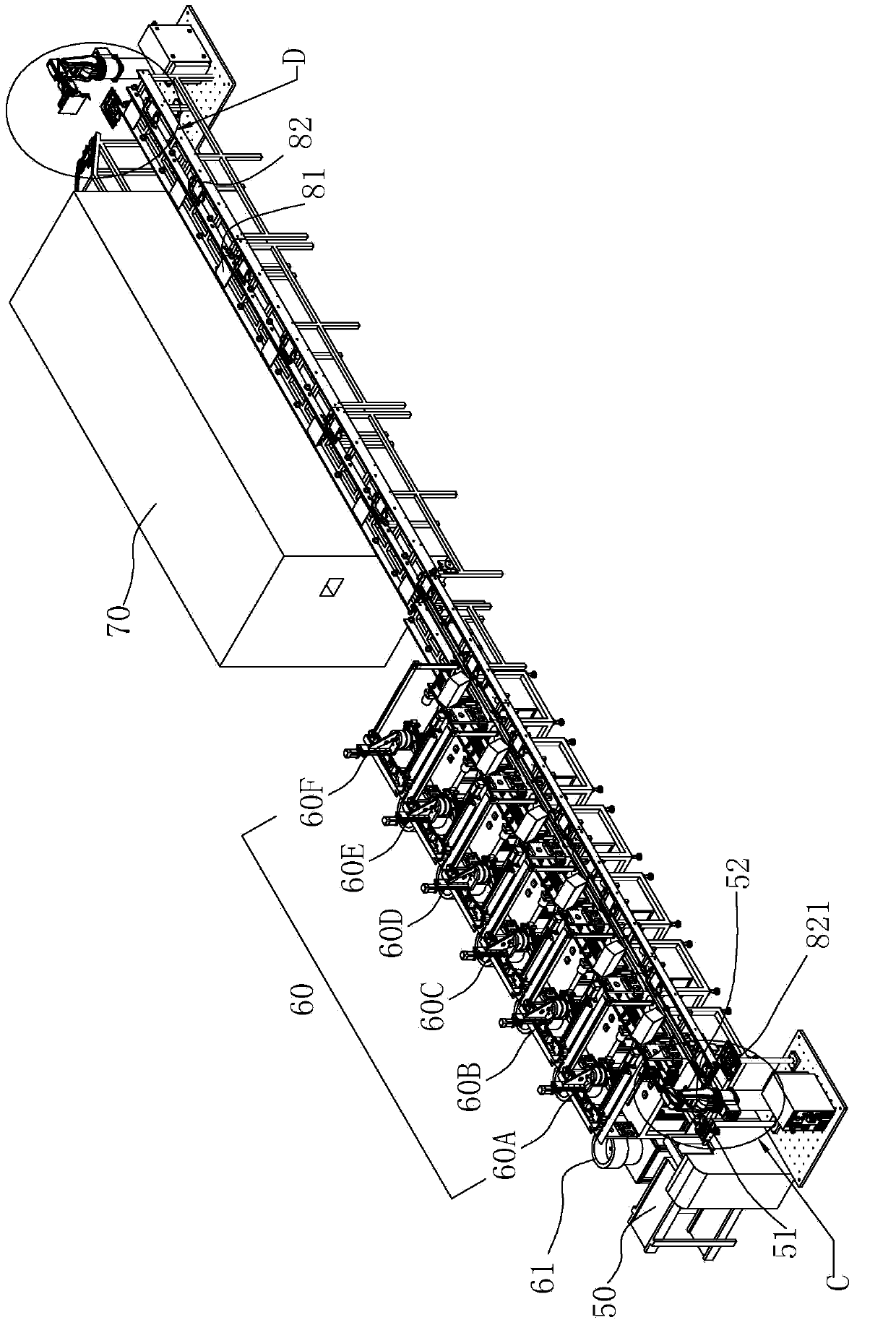

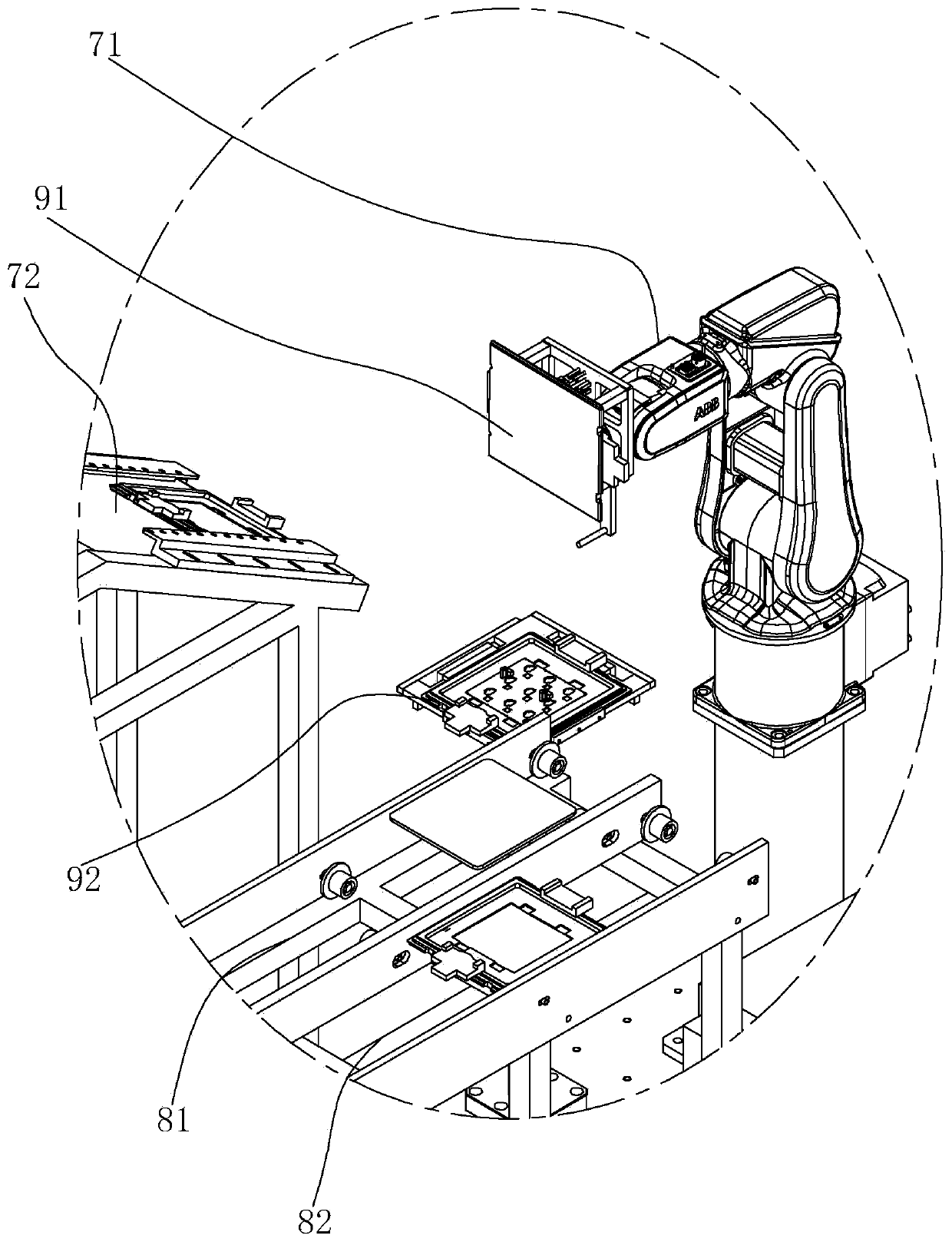

[0069] Such as Figure 1 to Figure 3 Shown, the structure of the multi-station plug-in production line of the present invention is illustrated with the mouse PCB automatic production line. The automatic production line includes the following components:

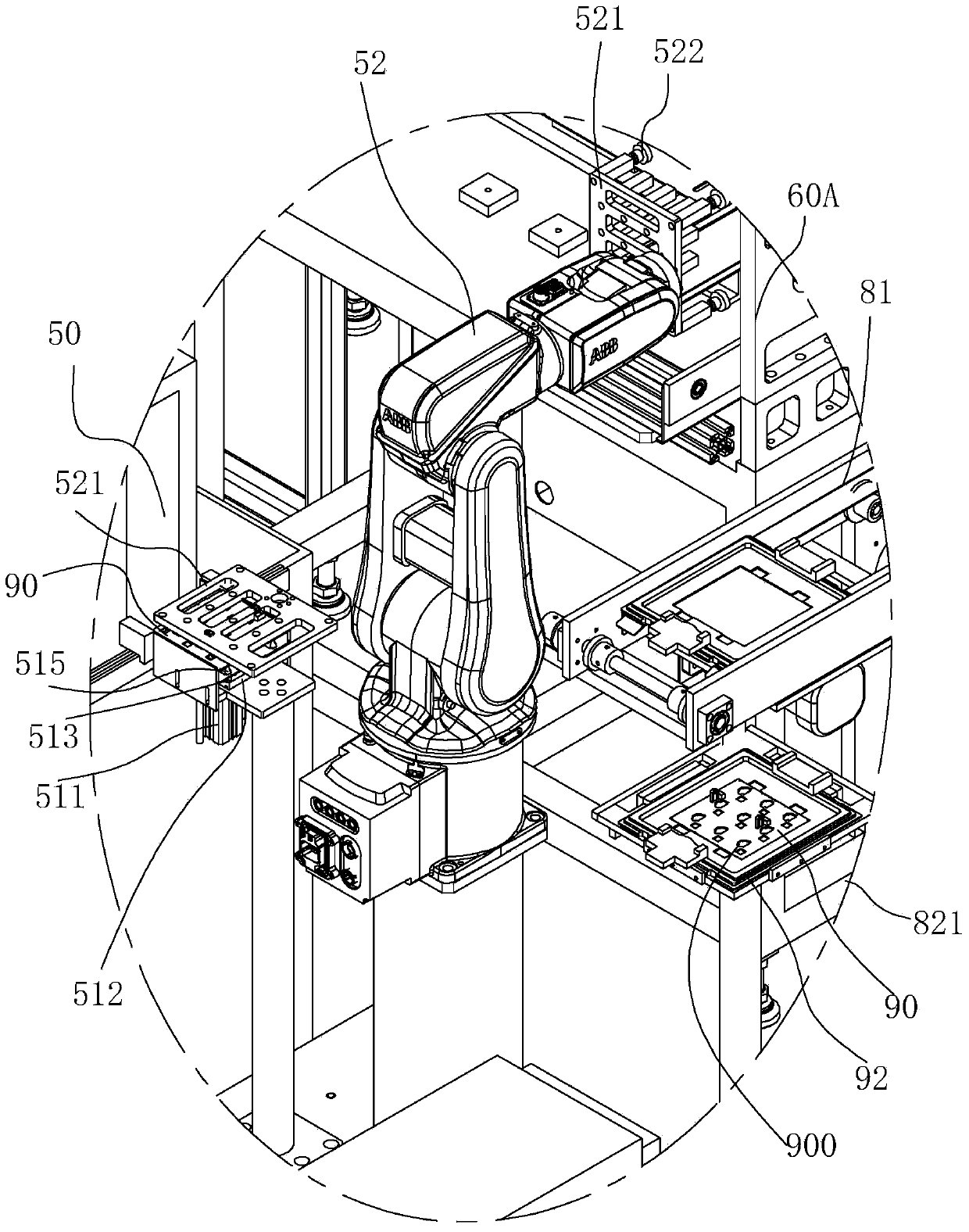

[0070] The PCB board feeding device 50 adopts a lifting mechanism and a pushing mechanism to send the PCB boards with 9 mouse circuit boards (that is, 3x3 matrix distribution) from the discharge guide rail to the PCB board secondary positioning device 51 one by one for feeding Robot 52 takes material.

[0071] 6 sets of plug-in devices 60 connected in sequence, respectively IC plug-in device 60A, left-key component plug-in device 60B, right-click component plug-in device 60C, roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com