Method for assembling digital electronic detonator

A technology of a digital electronic detonator and an assembling method, applied in the field of pyrotechnics manufacturing, can solve the problems of low production efficiency and low quality, and achieve the effects of improving production efficiency, firm welding and safe product circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

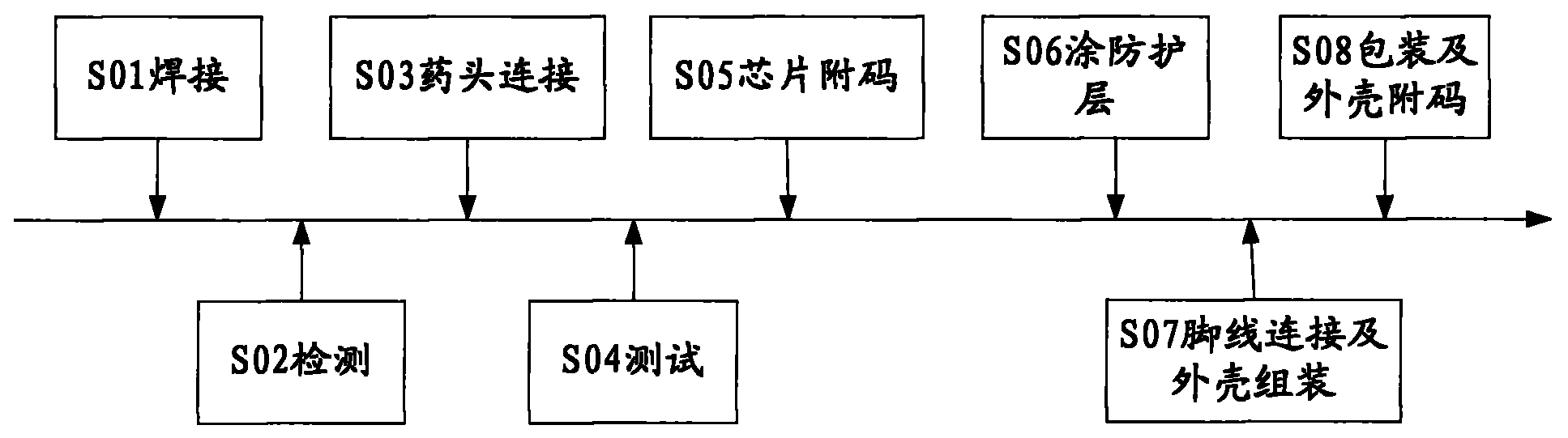

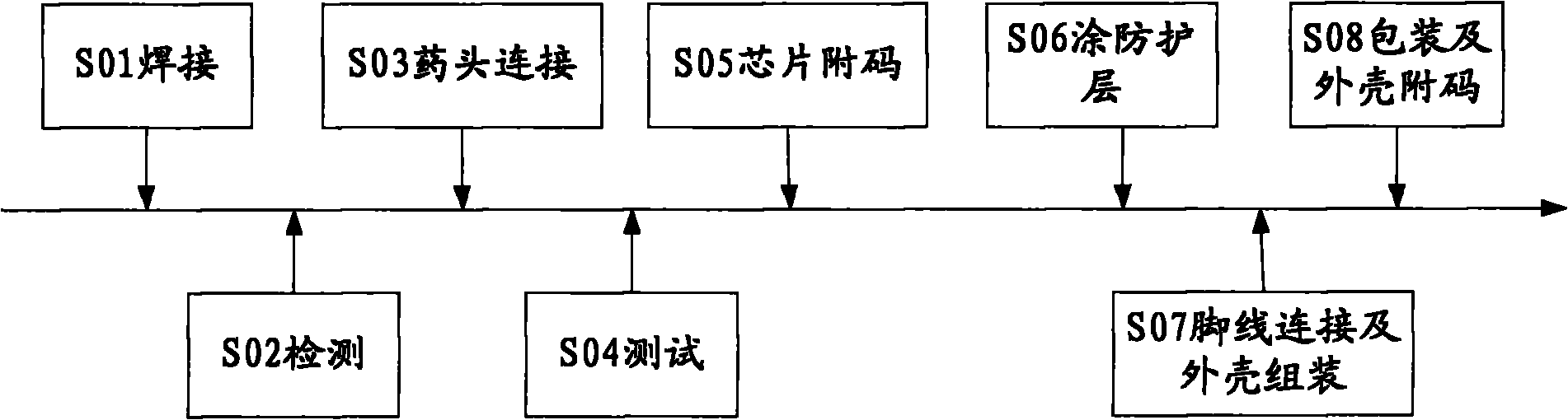

[0021] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

[0022] With reference to Fig. 1, the embodiment of the present invention provides a kind of assembly method of digital electronic detonator, and described method comprises the following steps:

[0023] S01, welding, welding the digital electronic detonator chip and peripheral components to the circuit board;

[0024] S02, detecting, detecting the connection reliability of the circuit board after the above welding steps;

[0025] S03, connecting the drug head, connecting one end of the circuit board through the above detection steps with the digital electronic detonator drug head;

[0026] S04, testing, that is, testing the overall connection reliability and compatibility of the circuit board and the digital electronic detonator drug head after the above steps of connecting the drug head;

[0027] S05, coding the chip, that is, writing an electronic prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com