Welding and positioning tool platform for aluminium alloy template

An aluminum alloy template, welding positioning technology, applied in welding equipment, auxiliary welding equipment, metal processing equipment and other directions, can solve the problems of no positioning structure, inaccurate positioning, uneven strength distribution of aluminum alloy templates, etc., to achieve simple operation, reduce The effect of labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

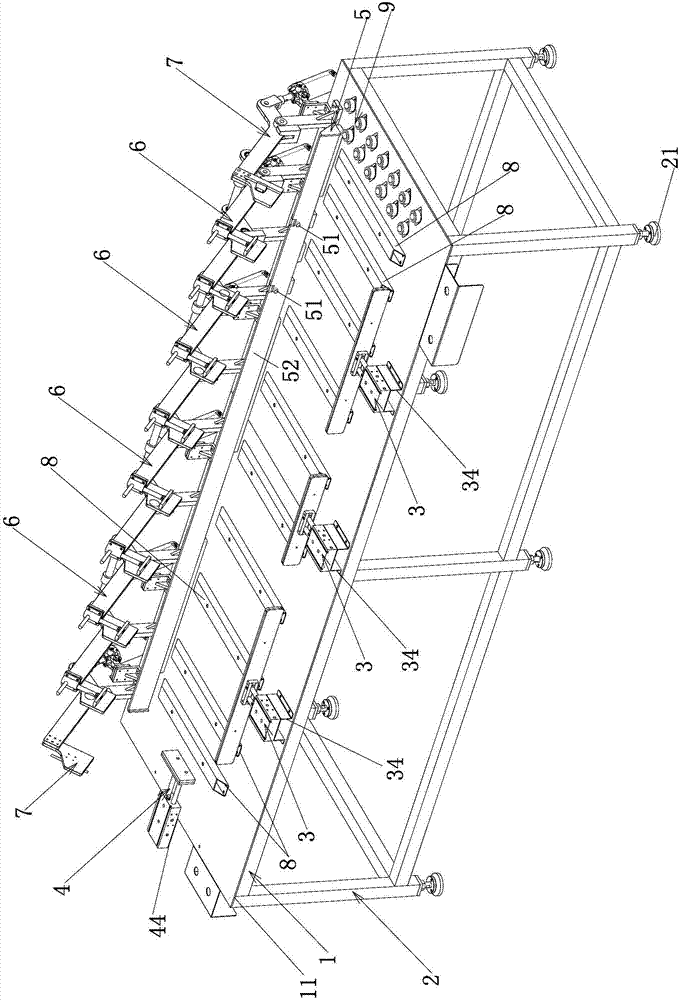

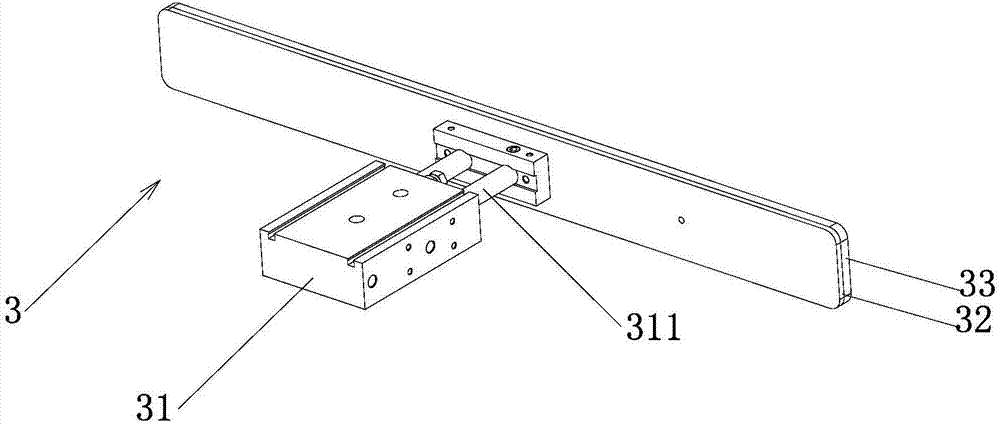

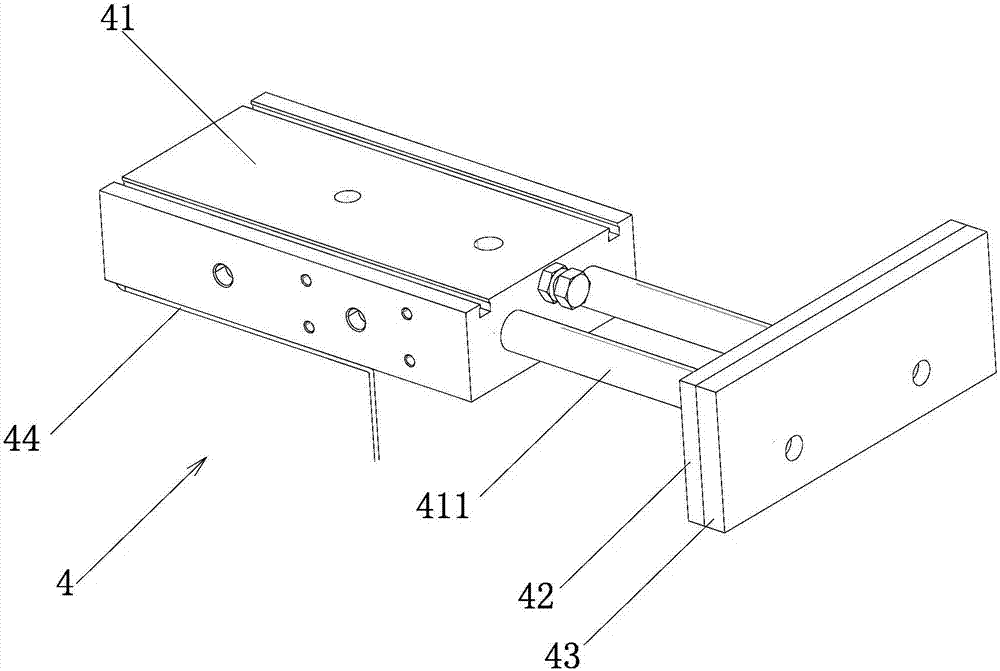

[0024] to combine figure 1 and Figure 6 As shown, the aluminum alloy formwork welding positioning tooling platform of the present invention includes a workbench 1 supported on the frame body 2, at least one set of lateral positioning and pressing devices 3 arranged on the tabletop 11 of the workbench 1, and a set of lateral positioning and pressing devices 3 arranged on the tabletop 11 The longitudinal positioning and pressing device 4 at one end of the length direction, the positioning backing plate 5 arranged along the length direction of the table top 11 and positioned at one side of the table top 11, the double-link turning mechanism 6 arranged near the positioning backing plate 5, and the two sides of the table top 11 in the length direction There are two single turning mechanisms 7 at the end, and a plurality of horizontal support ribs 8 are arranged at intervals and in parallel on the table 11. The positioning support plate 5 is used to position the main body 10' of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com