Silicon-based pressure sensor and manufacturing method thereof

A pressure sensor and sensor technology, applied in the field of sensors, can solve the problems of oil leakage at the welding joint of the package structure, low production yield, restrictions and other problems, and achieve the effect of simplifying the process, avoiding the problem of undercutting, and improving the reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

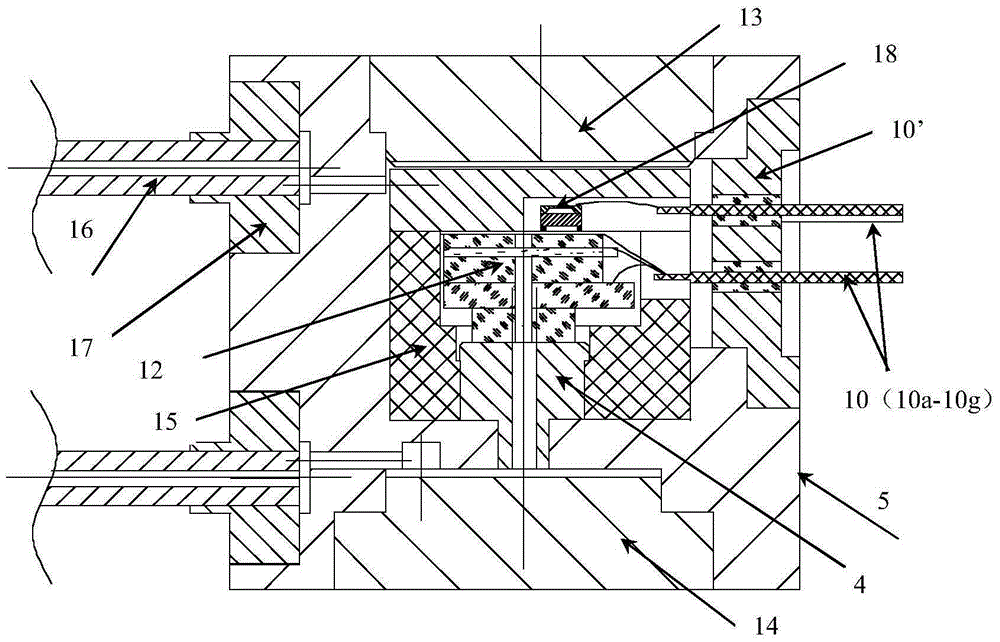

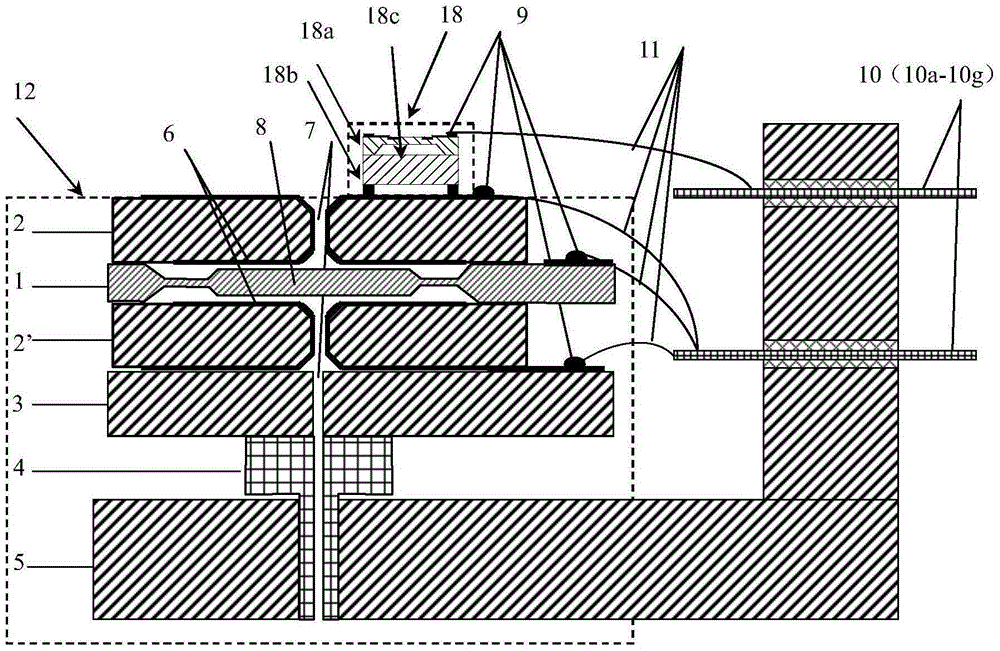

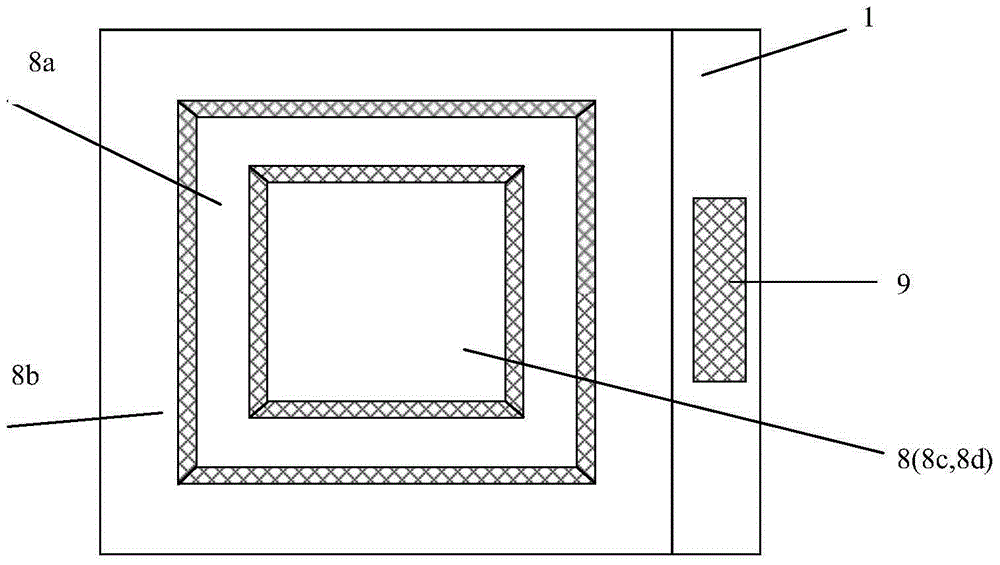

[0039] Such as figure 1 As shown, the silicon-based pressure sensor of the present invention is characterized in that the structure of the silicon-based pressure sensor consists of three parts: a differential pressure sensitive device 12, a static pressure compensation unit 18 and a package structure. Such as figure 2 As shown, the differential pressure sensitive device 12 is characterized in that it consists of an upper glass fixed plate 2, a silicon sensitive chip movable plate 1, a lower glass fixed plate 2', a glass bottom plate 3, and a pressure guiding plate from top to bottom. The tube 4 is packaged to form a differential capacitor structure for collecting differential pressure signals. The static pressure compensation unit is vacuum electrostatically sealed by a silicon piezoresistive chip 18a and a non-porous glass 18b to form an absolute pressure element with a vacuum sealed cavity 18c for measuring the static pressure value on site. The static pressure compensati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com