Patents

Literature

549 results about "Steam turbine rotor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

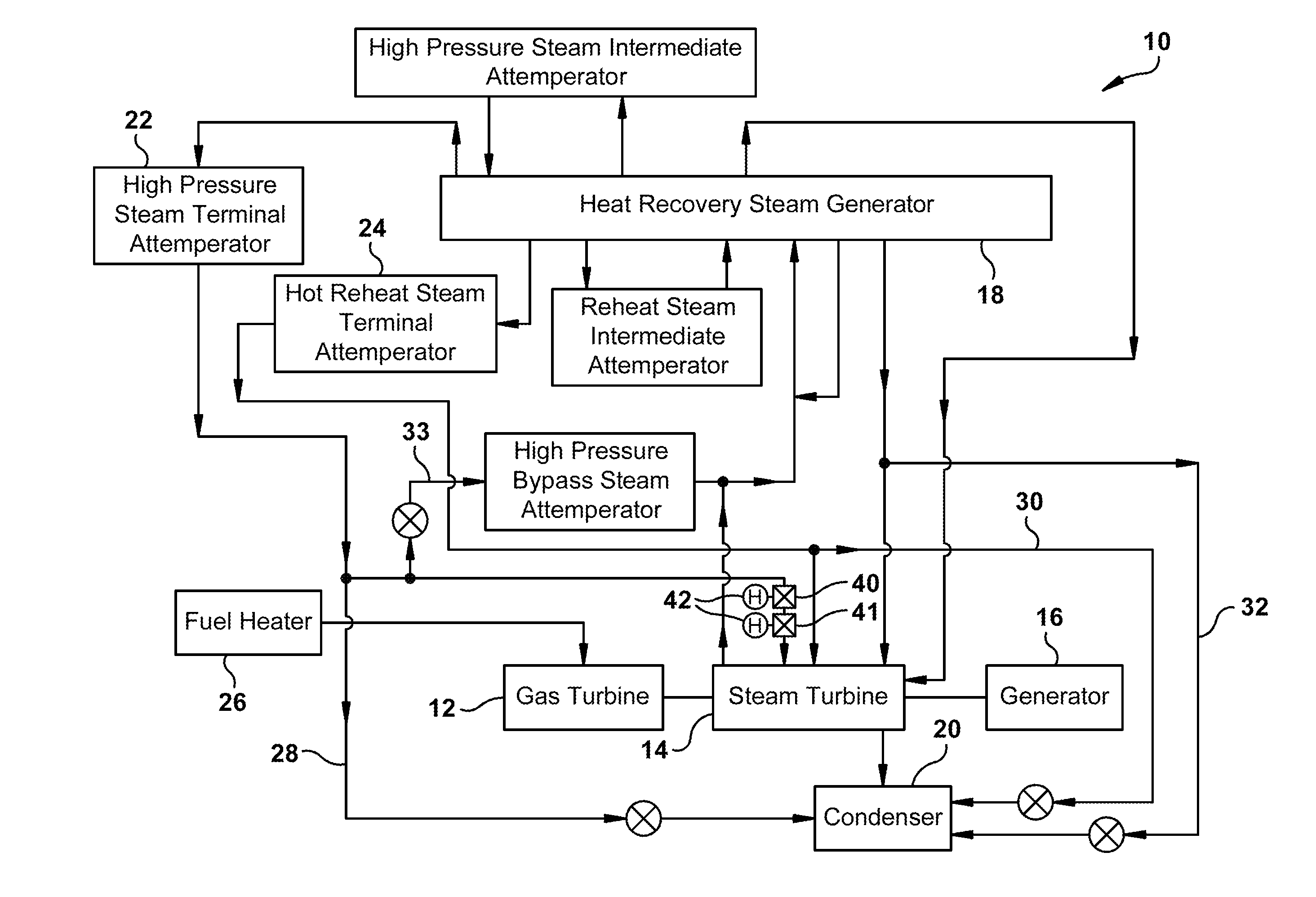

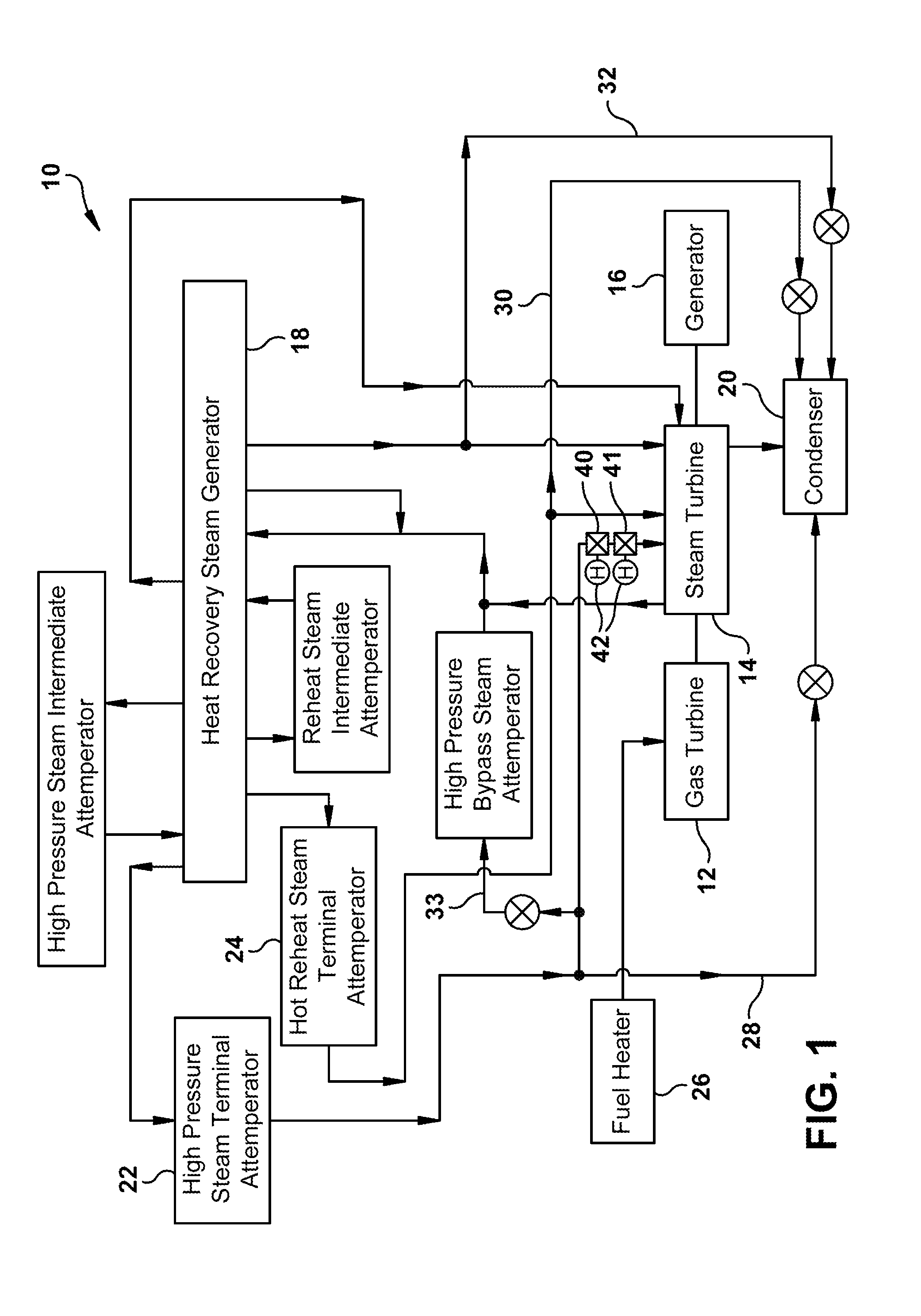

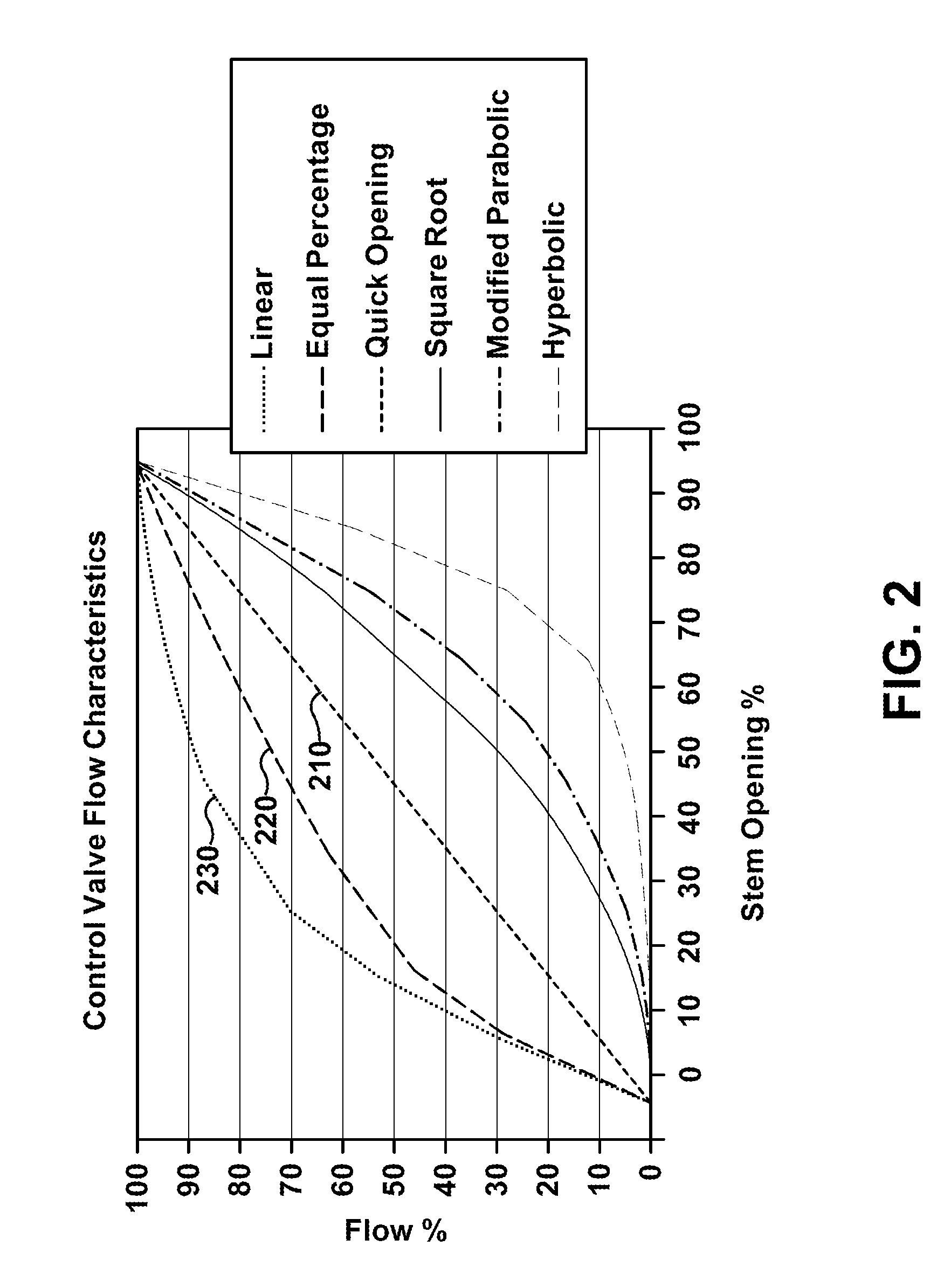

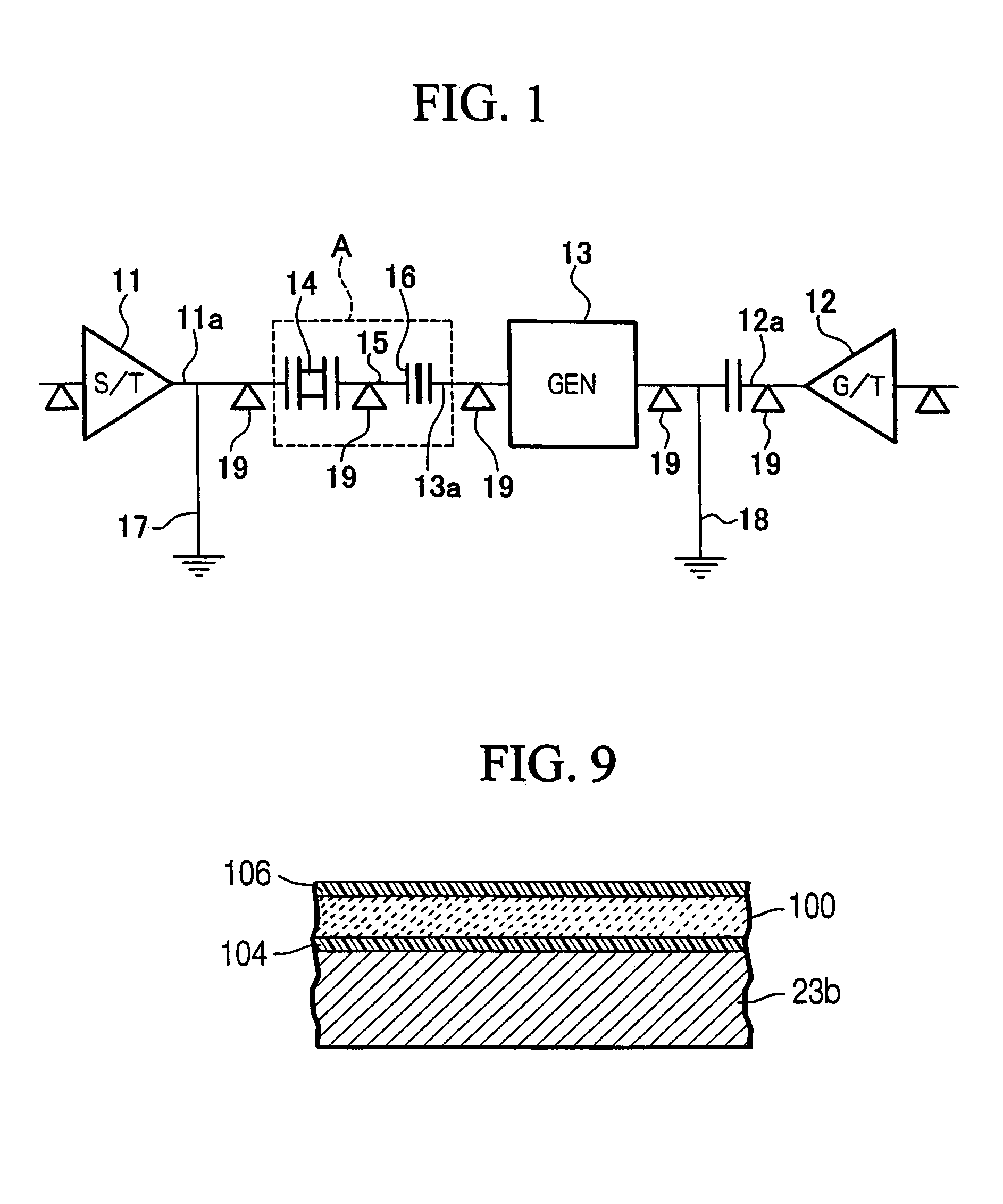

Apparatus for starting a steam turbine against rated pressure

ActiveUS20100162721A1Start fastTurbine/propulsion fuel supply systemsEngine fuctionsControl valvesControllability

An external steam turbine main steam startup control valve bypass loop is provided to facilitate a full pressure combined cycle rapid response / fast start powerplant. The main steam startup bypass control loop particularly includes a main steam startup bypass control valve, which allows for the implementation of high efficiency, low pressure drop main steam control valve that otherwise would not be able to handle the severe throttling duty during a full pressure steam turbine startup and enhances the controllability of the steam turbine allowing for the high fidelity controls necessary to minimize steam turbine rotor stresses.

Owner:GENERAL ELECTRIC CO

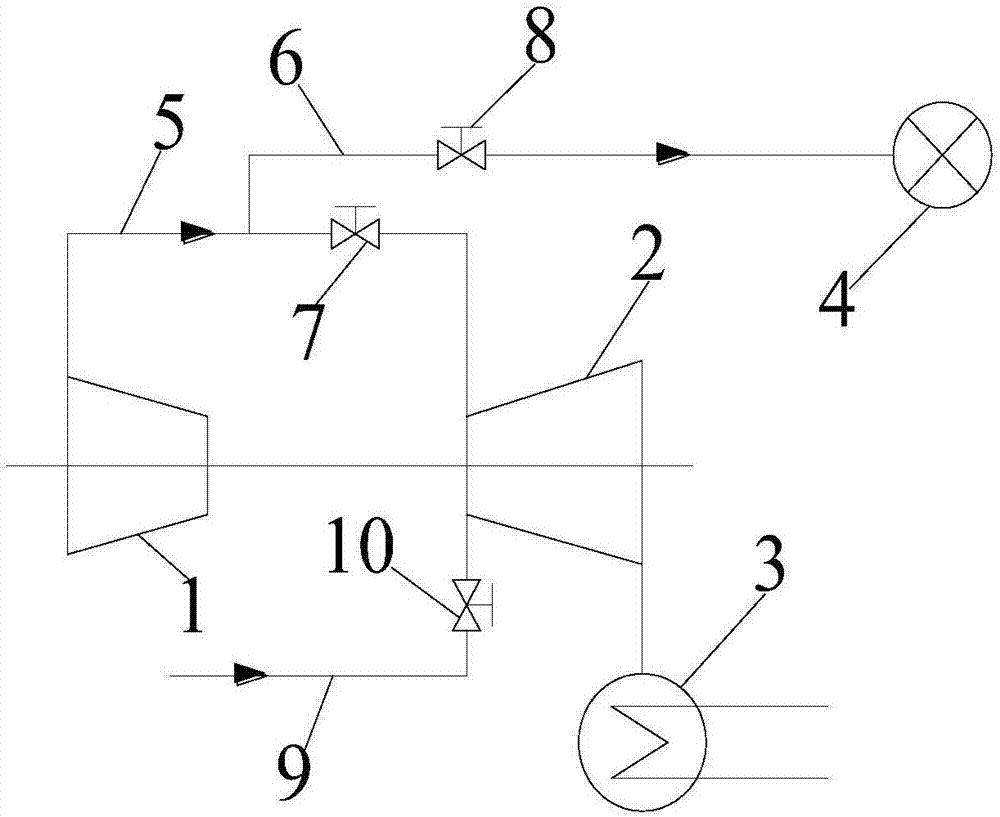

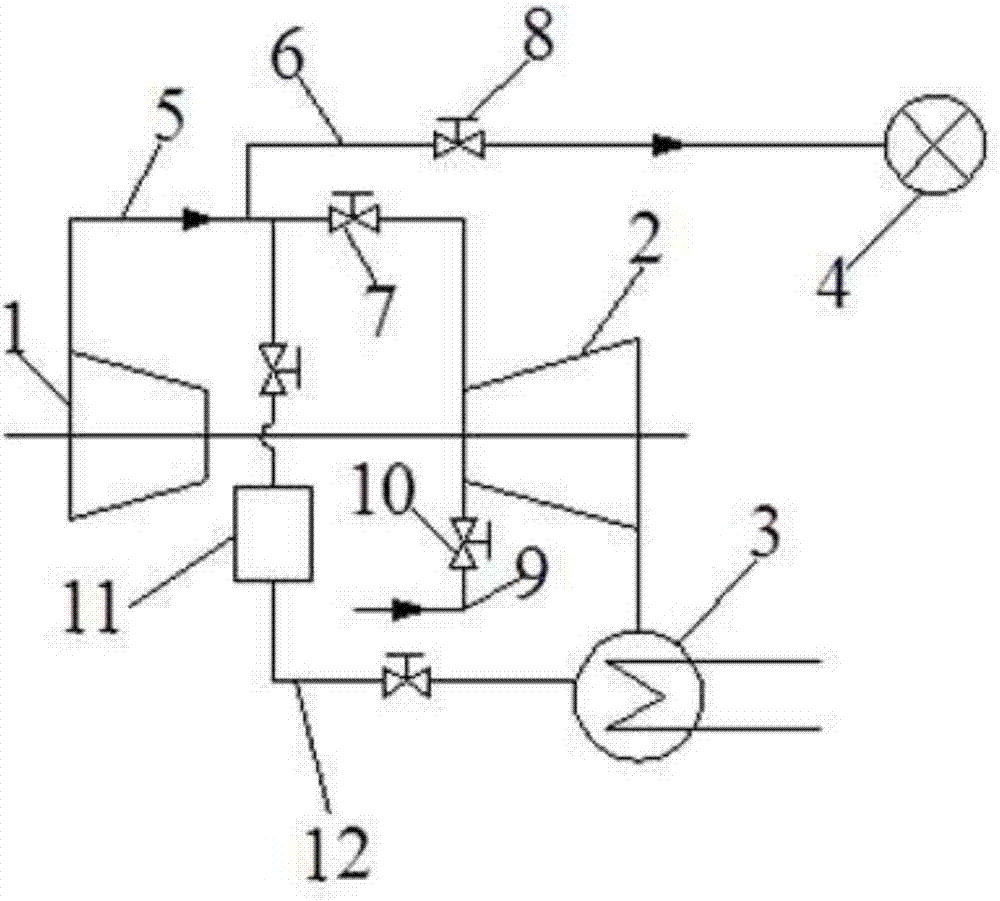

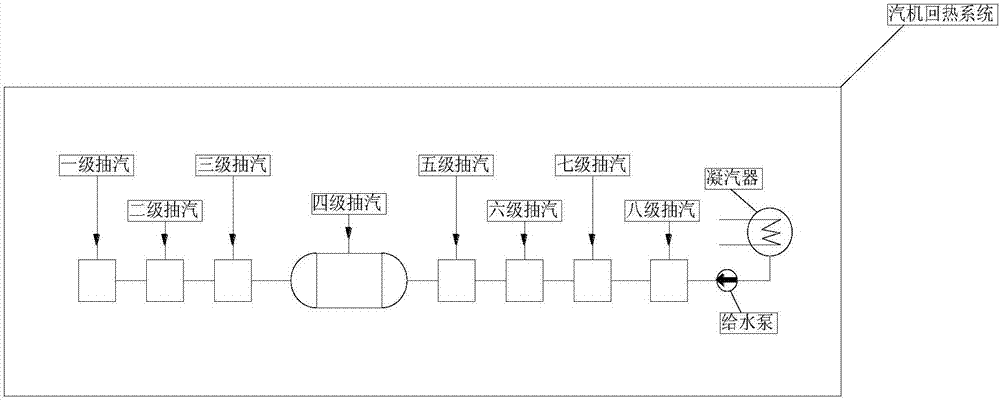

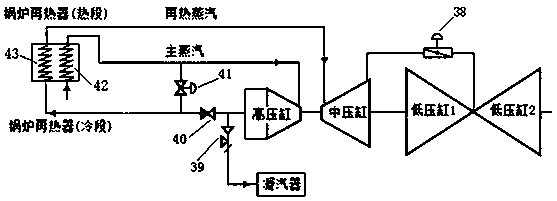

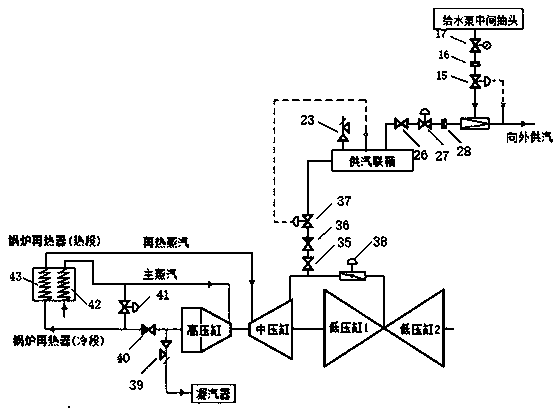

Extracting, condensing and backpressure system for steam turbine and adjusting method of system

ActiveCN107023337AReasonable designSimple structureSteam useCombined combustion mitigationEngineeringHeating system

The invention relates to a steam turbine pumping and condensing system and an adjustment method thereof. The steam turbine pumping and condensing system includes a steam turbine medium-pressure cylinder, a steam turbine low-pressure cylinder, a condenser and a heat supply system. The steam turbine medium-pressure cylinder and the steam turbine low-pressure cylinder are coaxial. connection, the exhaust steam of the medium-pressure cylinder of the steam turbine is connected with the low-pressure cylinder of the steam turbine through a communication pipe, and the first valve is installed on the communication pipe, and the heating extraction steam of the heating system comes from the exhaust steam of the medium-pressure cylinder of the steam turbine; the medium-pressure cylinder of the steam turbine is connected with the first A heat supply system is also connected between the valves through a heat supply and extraction pipe, and a second valve is arranged on the heat supply and extraction pipe; the condenser is connected with the low-pressure cylinder of the steam turbine; Function. The system can realize the switching operation of the steam turbine among the pure condensing working condition, steam extraction working condition and back pressure working condition without replacing the steam turbine rotor or blades.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

Electric power generator, steam turbine rotor spindle repaired by laser and repairing method thereof

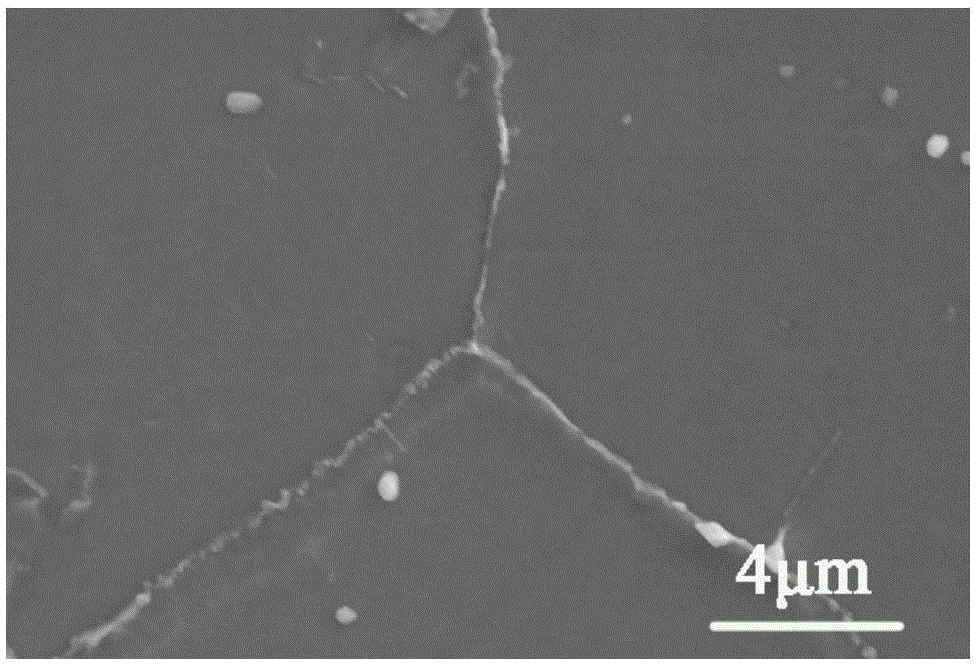

InactiveCN1674408AMeet working conditionsHigh creep limitMagnetic circuit rotating partsPump componentsOptoelectronicsCobalt

The present invention provides a laser repaired power generator and turbine rotor shaft, on its matrix surface on alloy covering layer which can be mutually merged with matrix surface and is different from matrix completely in components is formed, and on the surface where the matrix and alloy layer are connected a micromolten layer whose thickness is 0.05-0.1 mm is formed, and said alloy covering layer is nickel base, cobalt base or iron base alloy. Said invention also provides a laser repairing method of the described power generator and turbine rotor shaft. It adopts a pre-set laser melt-covering mode, and its technological parameters are: laser power 1200-2000 W, spot diameter 2-6 mm and spot moving speed 2-20 mm / s.

Owner:SHENYANG DALU LASER TECH

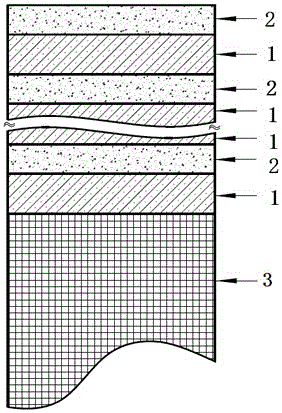

Preparation process of TiCN multilayer composite coating layer on slotting cutter surface of steam turbine rotor

ActiveCN105154880AImprove performanceExtend your lifeVacuum evaporation coatingSputtering coatingMilling cutterHardness

The invention relates to a preparation process of a TiCN multilayer composite coating layer on a slotting cutter surface of a steam turbine rotor; and the preparation process comprises surface pretreatment of a cutter basal body, cleaning, cutter clamping and loading, preparation of the multilayer composite coating layer, cooling and discharge, and aftertreatment. The multilayer structure formed by the coating layer preparation process uses TiN and TiCN as alternating coating layers to prepare 50 TiN and TiCN alternating coating layers on the slotting cutter surface; TiN is the backing layer; and TiCN is the outermost layer. The coating layer prepared by the method relieves the residual stress of the coating layer and the cutter basal body, so that the bonding force of the basal body and the coating layer is larger, the bonding degree of the coating layer is higher, and the coating layer is not easy to be stripped off. In addition, C atoms are introduced based on TiN to cause the lattice distortion and the solid solution strengthening effect, so that the surface hardness of the cutter basal body can reach HV3500, the cutter wear resistance is improved, the cutter service life is prolonged, the machining quality of the steam turbine rotor is guaranteed, and the production cost is reduced.

Owner:SHANGHAI INST OF TECH +1

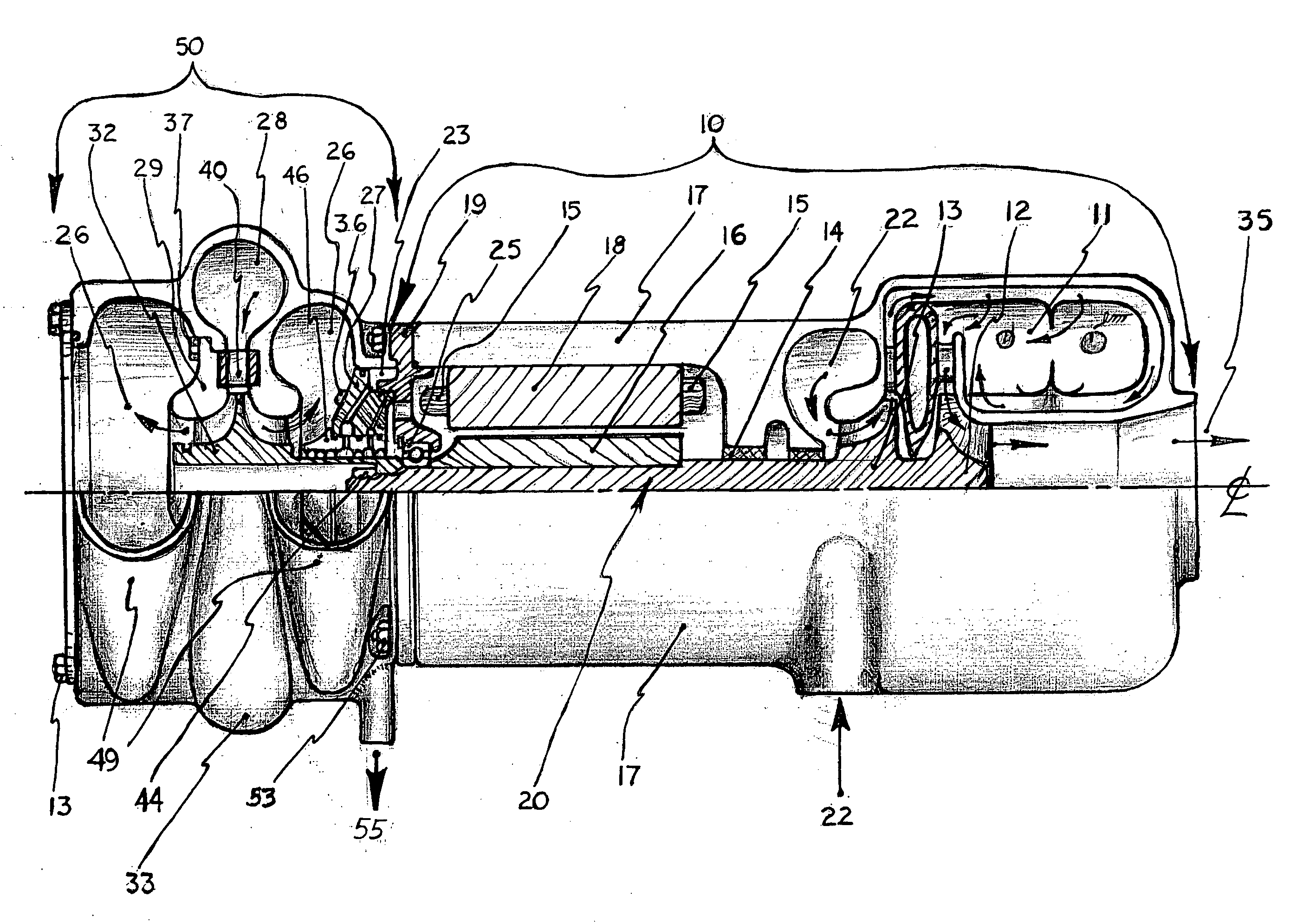

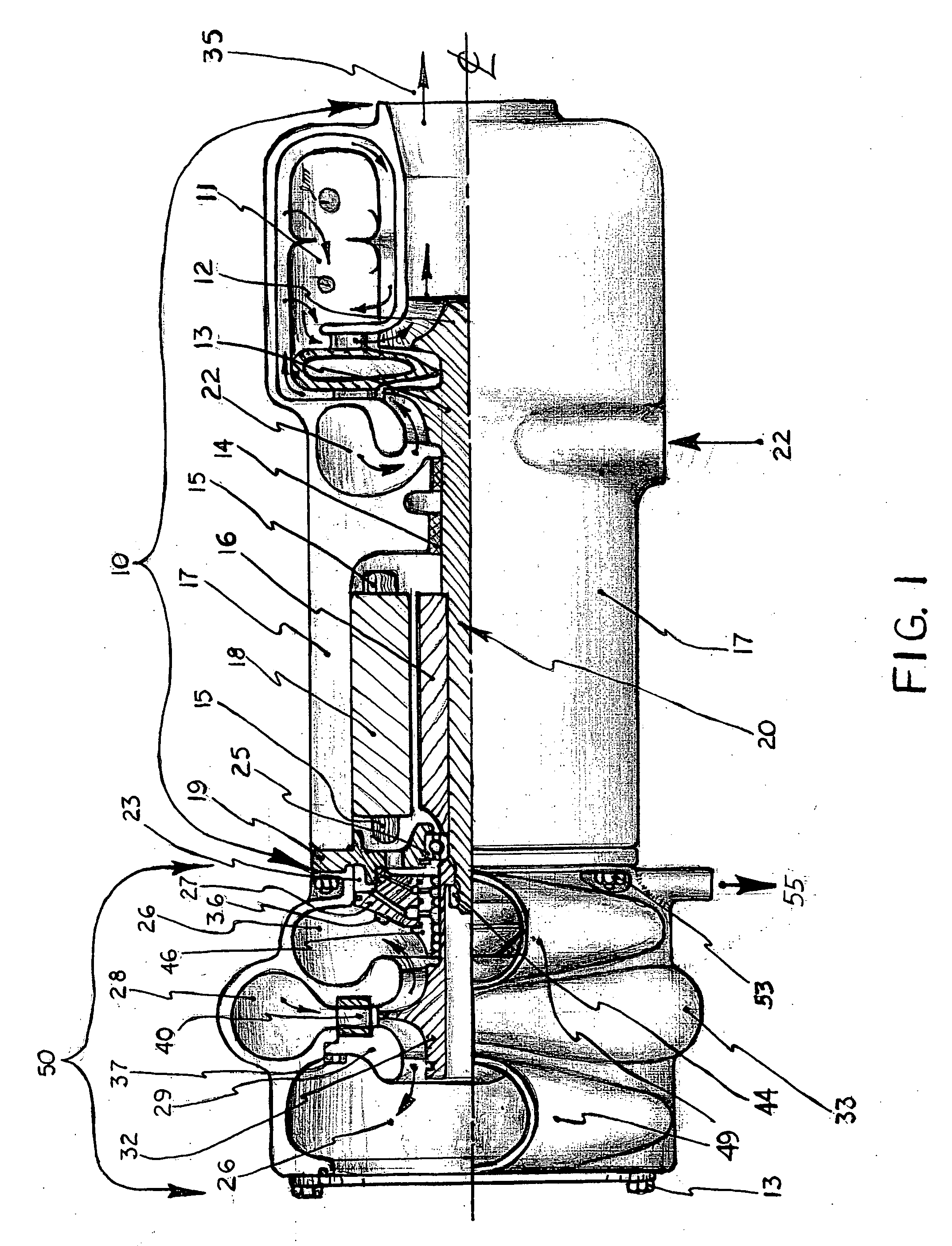

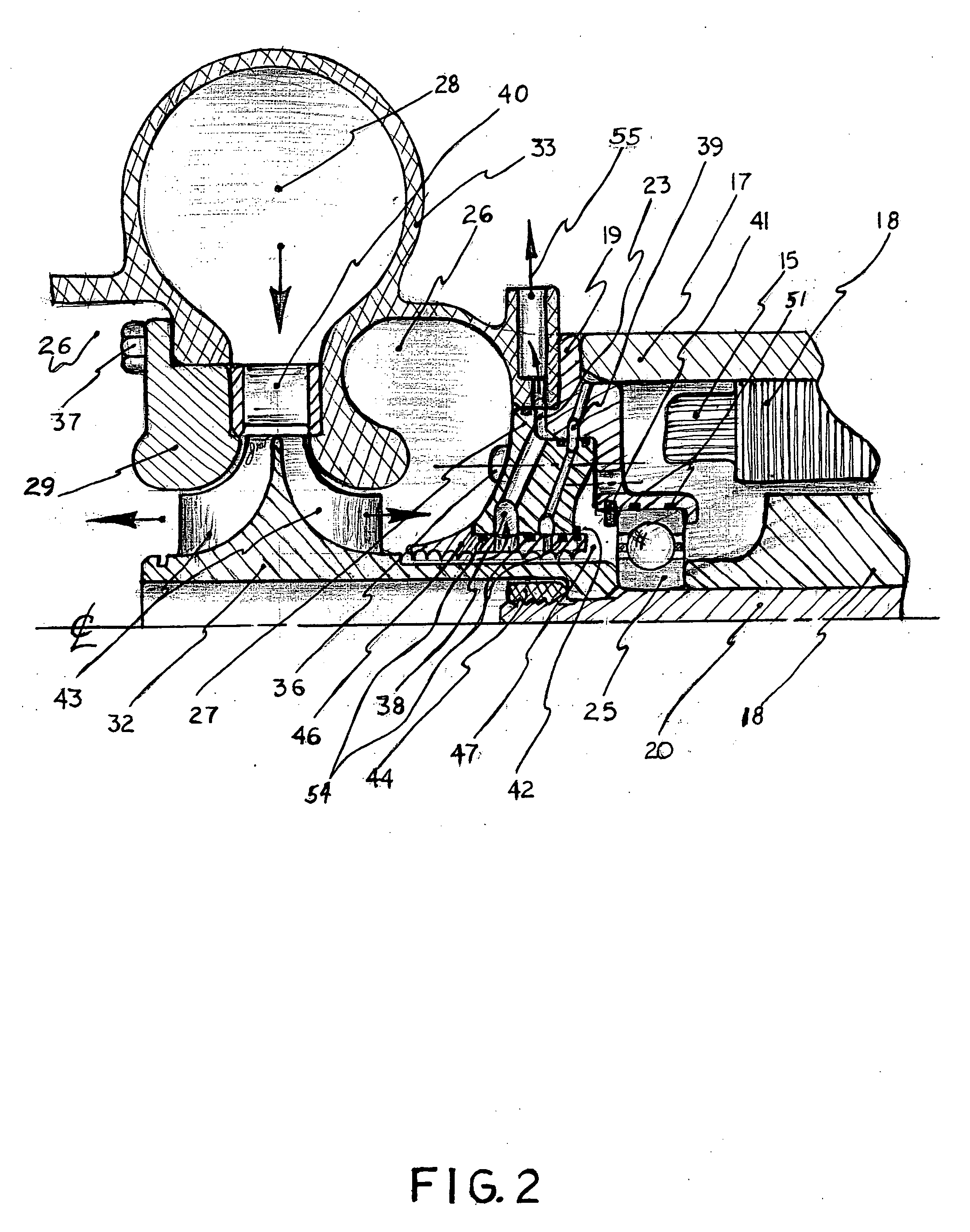

Rankine - microturbine for generating electricity

InactiveUS20060220388A1Improve output power efficiencyReduce installation costsEngine manufactureEngine fuctionsMicro gas turbineEngineering

An electrical output power generation system is provided. A gas turbine engine rotor spool with at least one alternator rotor and steam turbine rotor are integrated and within a engine body having a combustor or external heat source having fluid communication with the bladed compressor rotor and a gas turbine bladed rotor of the said rotor spool. The alternator rotor has permanent magnets retained and positioned in close proximity and co-axial to the electrical stator having iron laminat and electrical wires. Relative rotational motion between the electrical stator and alternator rotor cause magnetic flux and subsequent electricity to be generated. The steam energy to drive the said rotor spool integrated steam turbine rotor can be from the gas turbine engine exhaust waste heat and or thru external heat energy sources.

Owner:T M A POWER

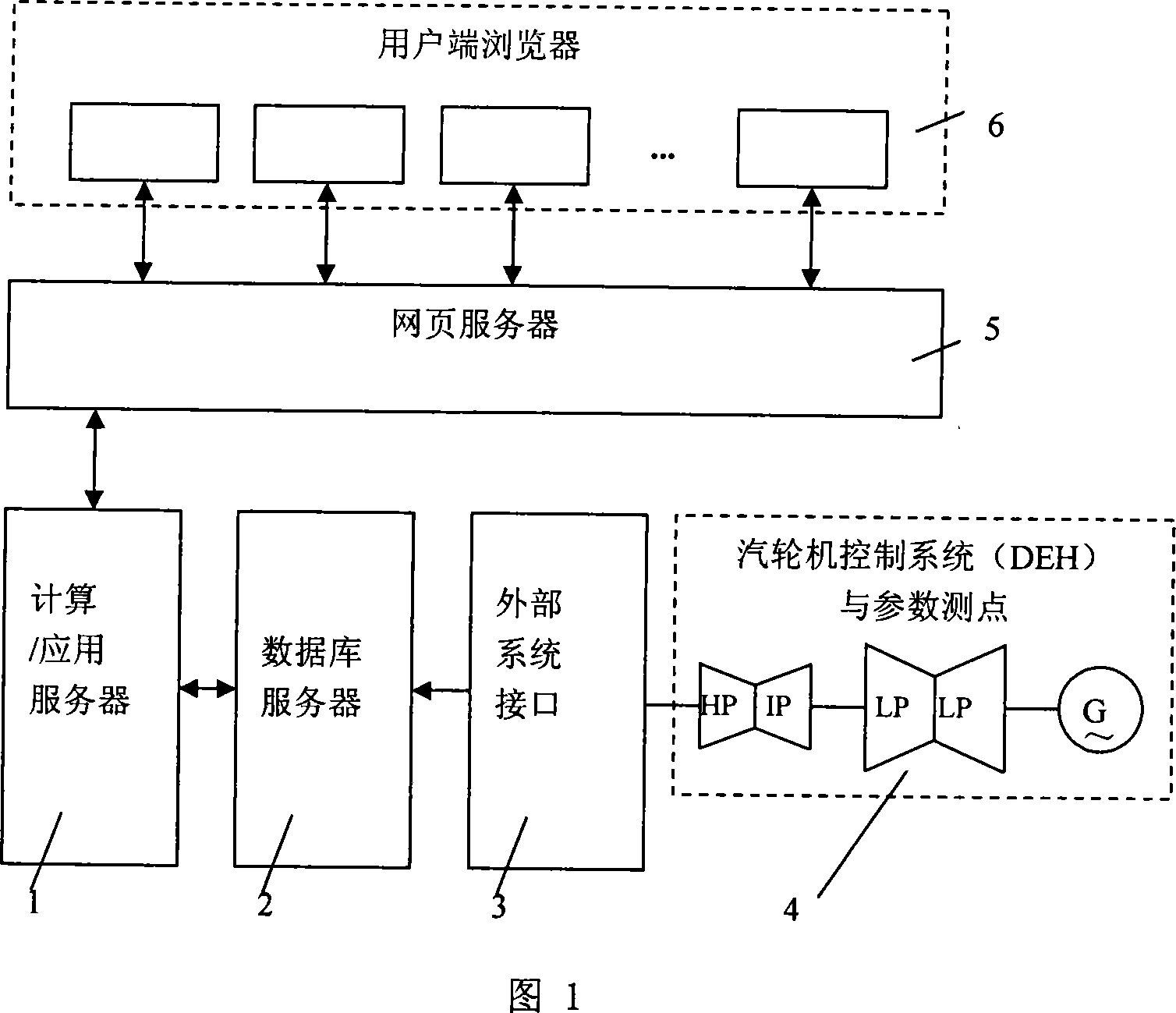

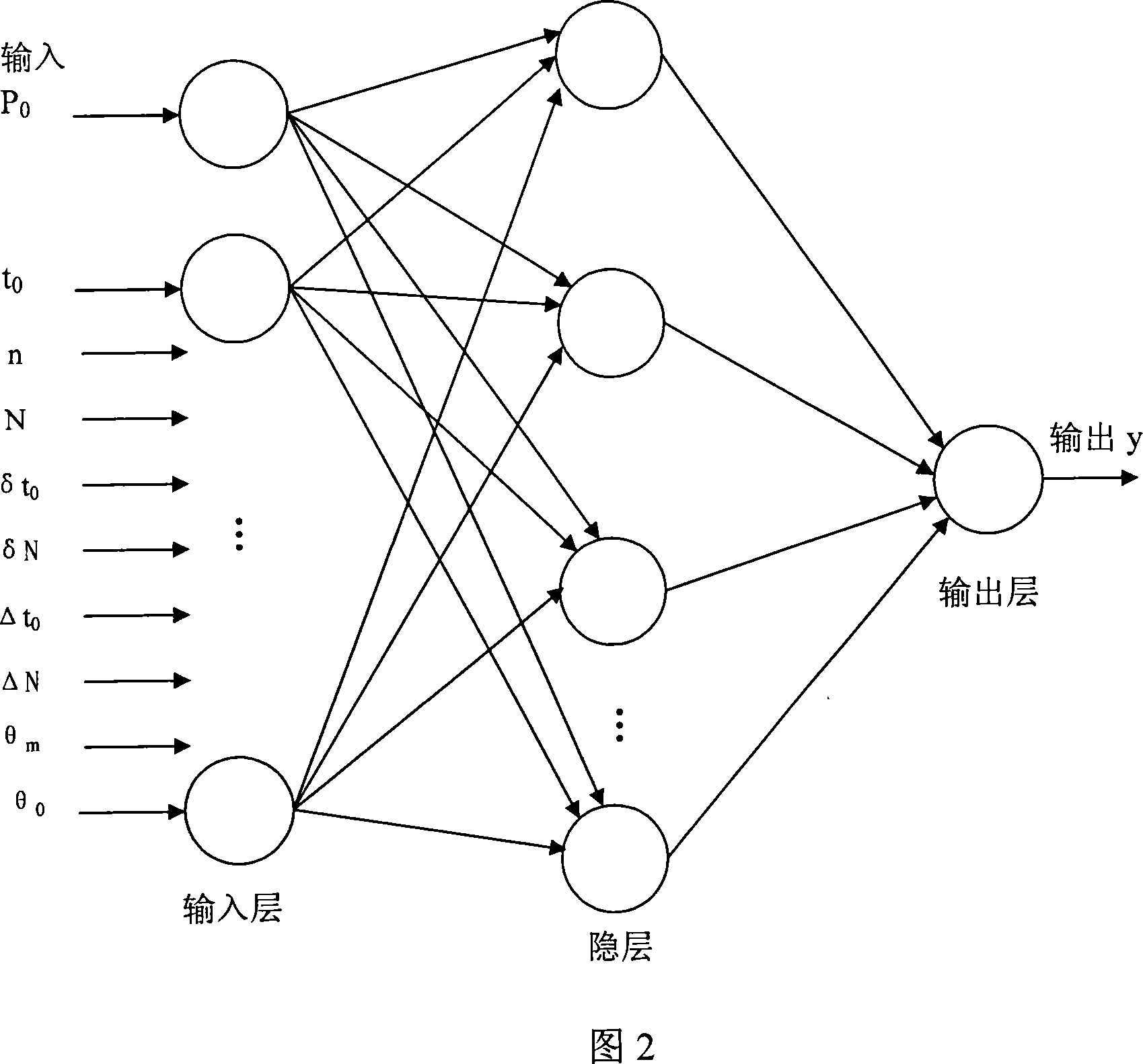

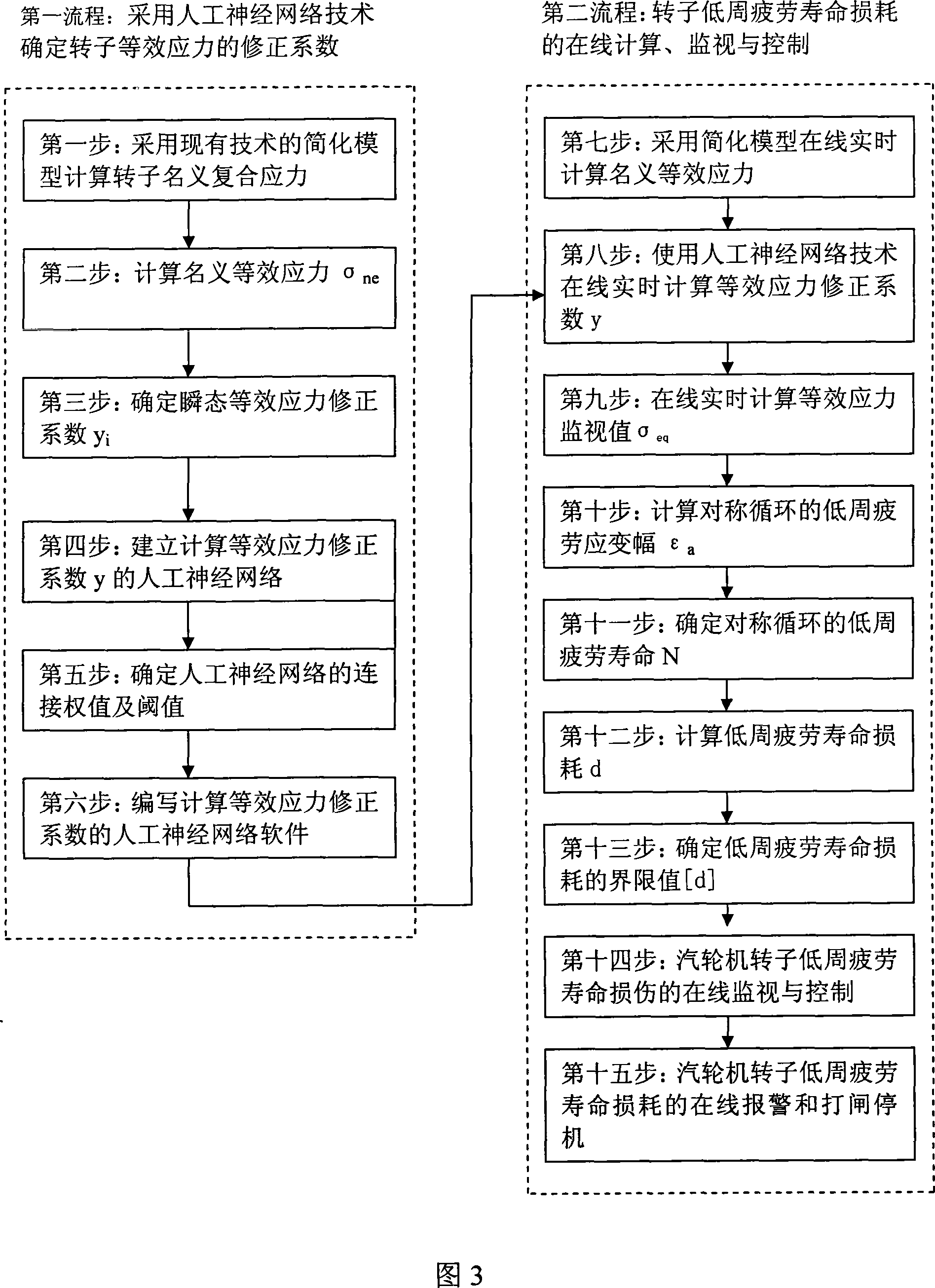

Method and system for on-line monitoring steam turbine roter low-cycle fatigue life consumption

ActiveCN101042059AReduced loss of low cycle fatigue lifeReduced cycle fatigue life lossMachines/enginesSafety/regulatory devicesNerve networkLow-cycle fatigue

It relates to a turbine rotor low cycle fatigue durability loss on line monitoring system, featuring in its computation, application server and software, database server, outside system interface, turbine control system DEH and parameter testing point, web server and user browser that connects with the computation and application server and each end item user browser respectively, with the computation and application server connecting with the data base server which connects with the turbine control system DEH and parameter testing point through the outside system interface. It is made of two processes, with the no.1 using artificial nerve network to determine turbine rotor equivalent stress coefficient, the no.2 process being on line computation, monitoring and control of the turbine rotor cycle fatigue loss. It realizes the working times of the turbine rotor of 10000 times.

Owner:SHANGHAI POWER EQUIP RES INST

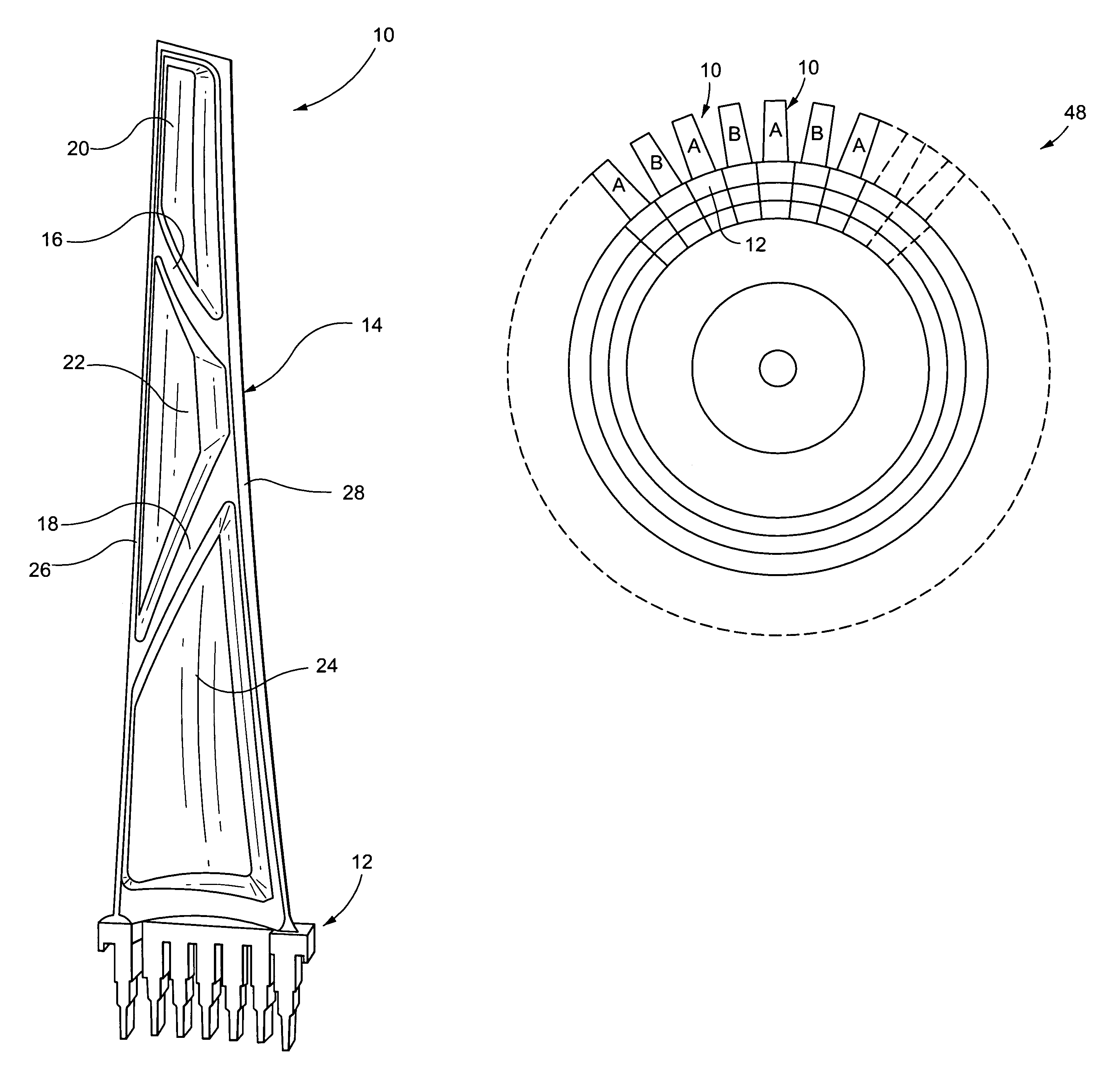

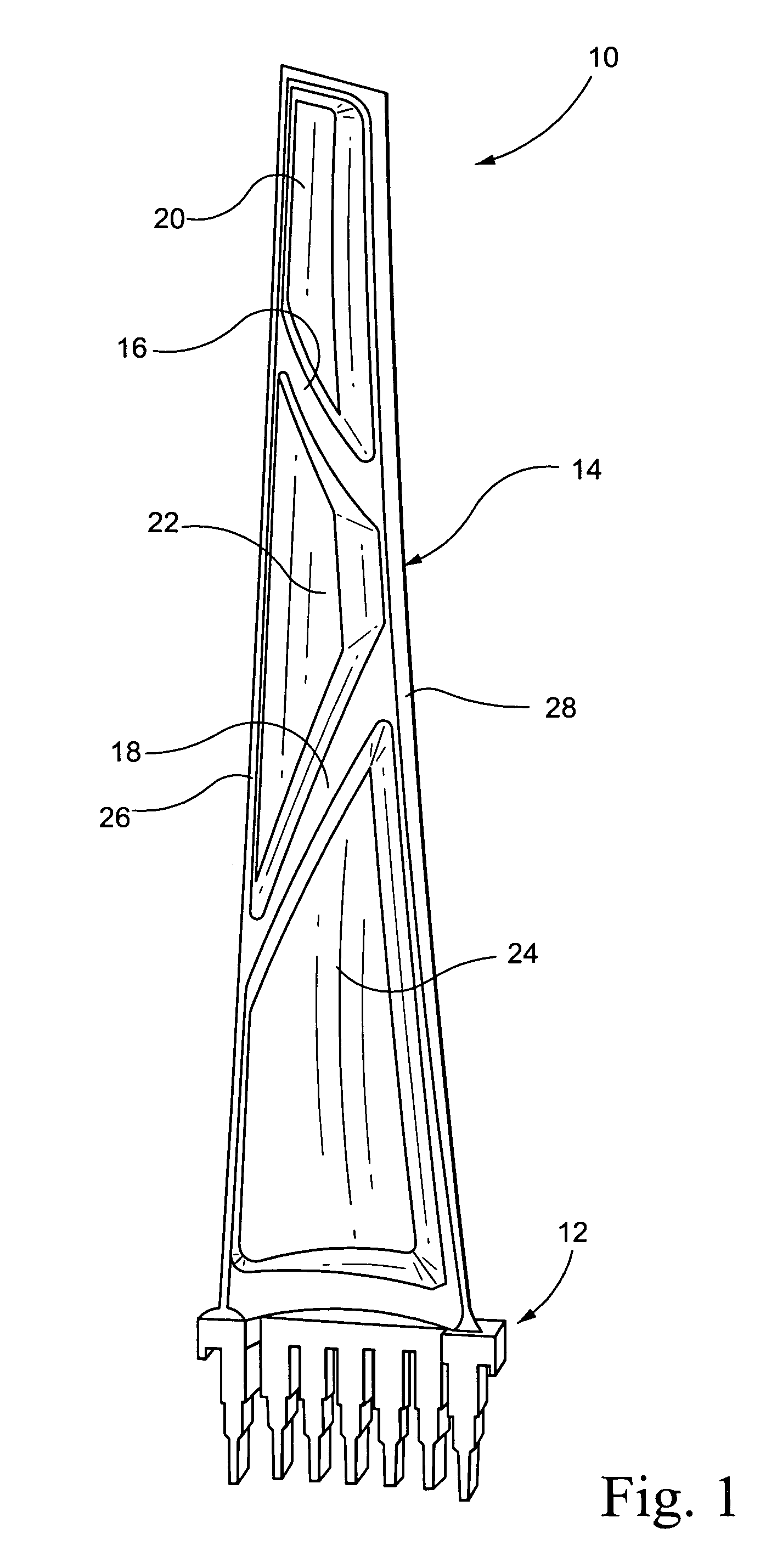

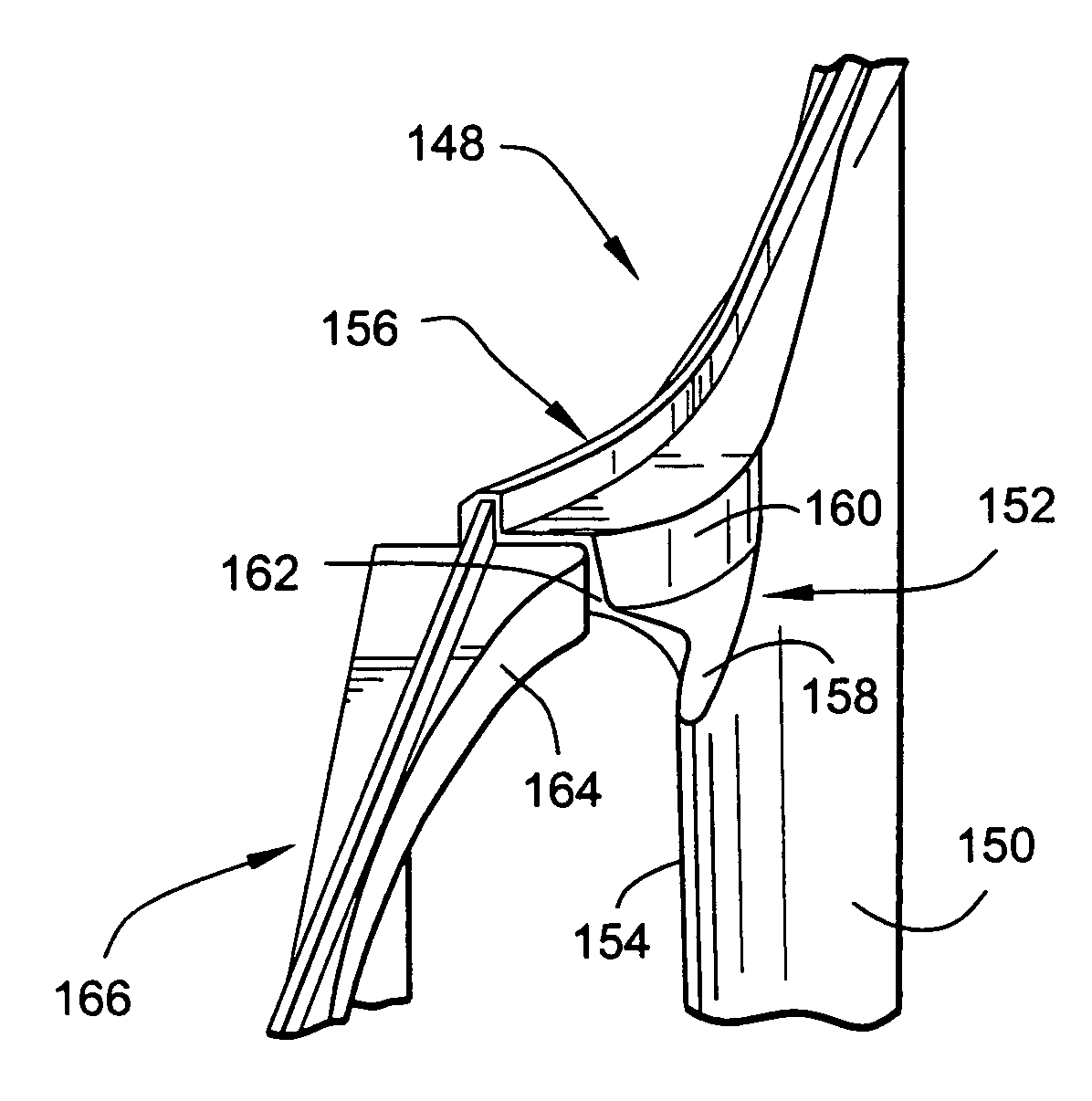

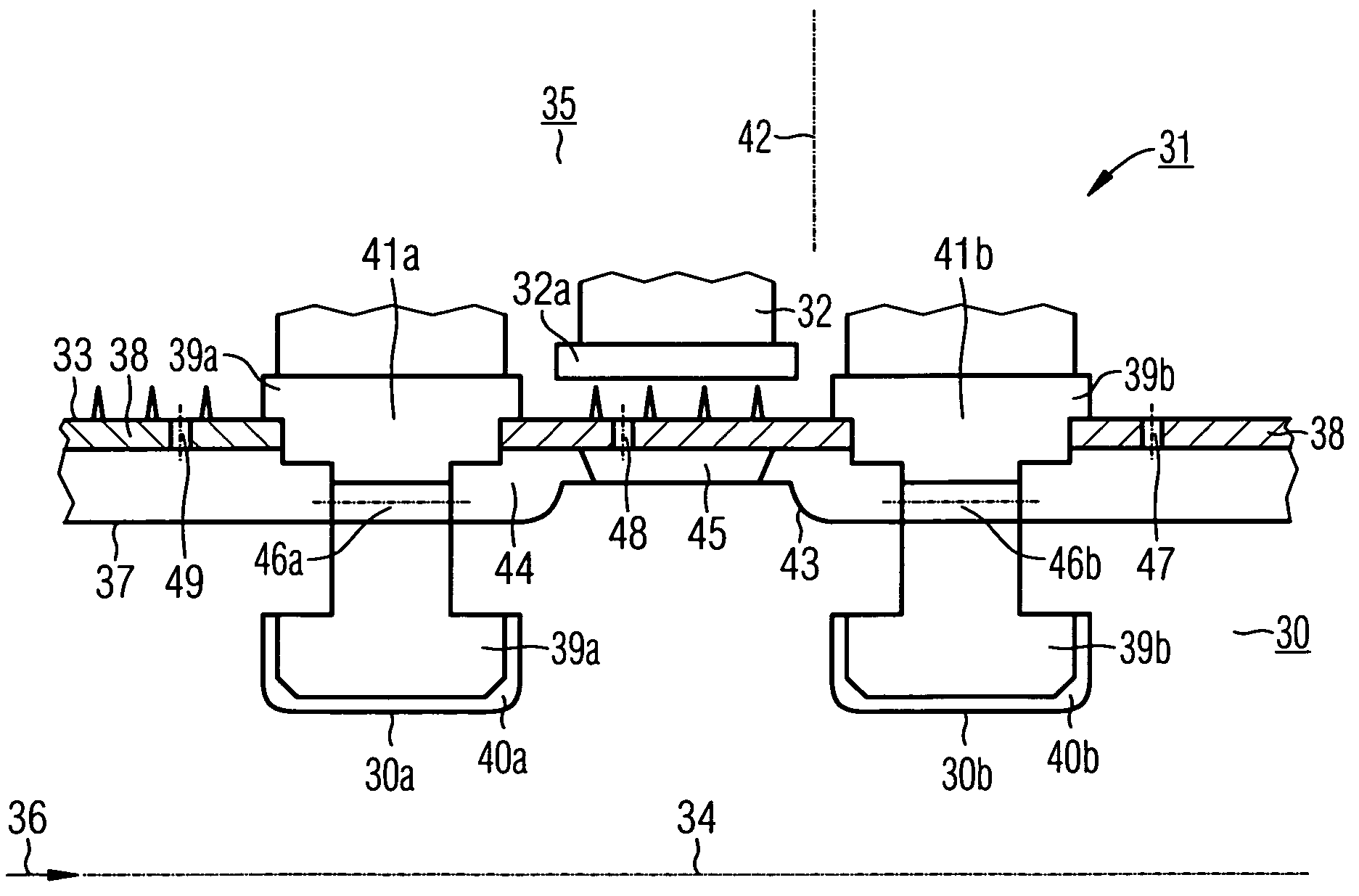

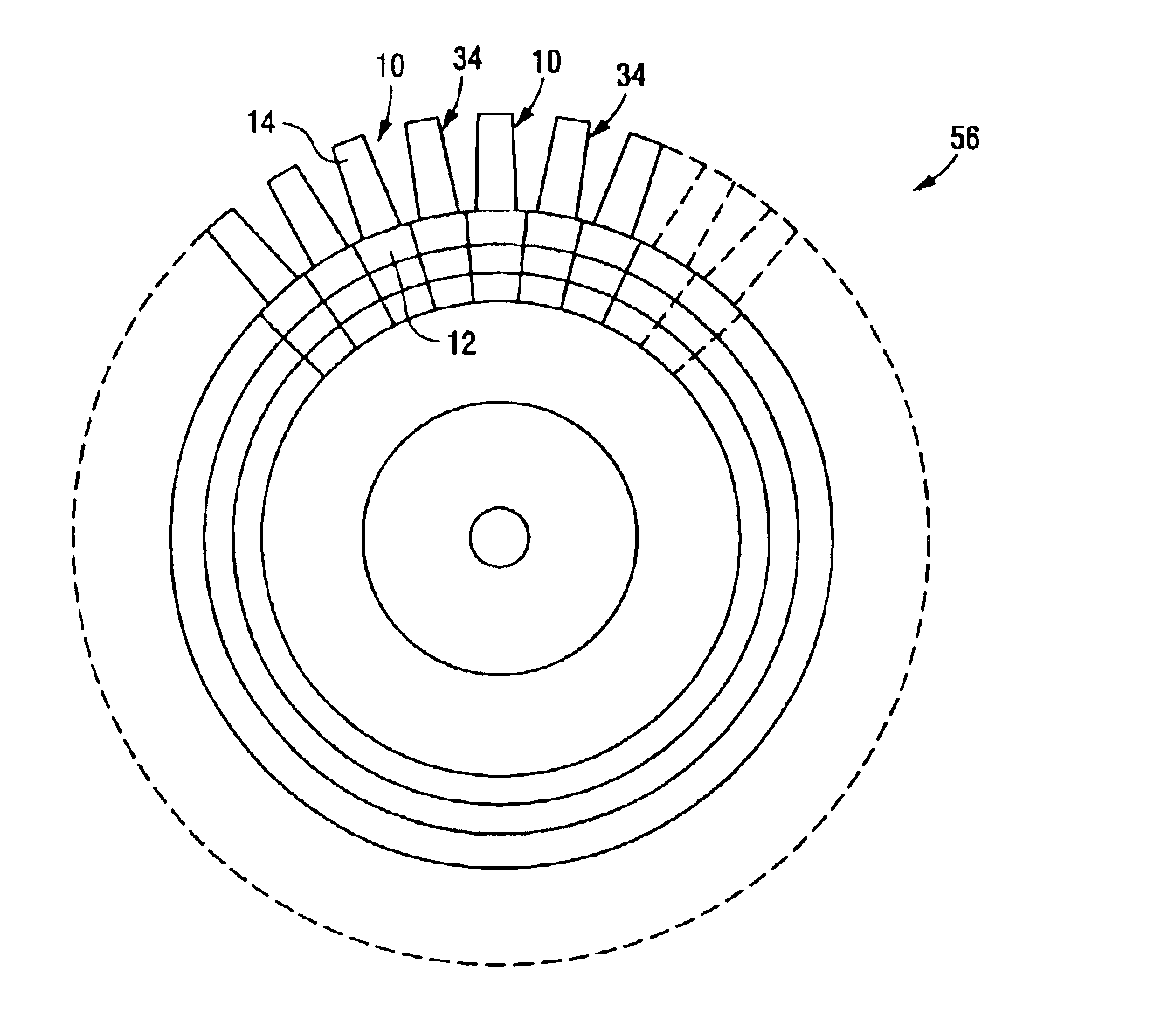

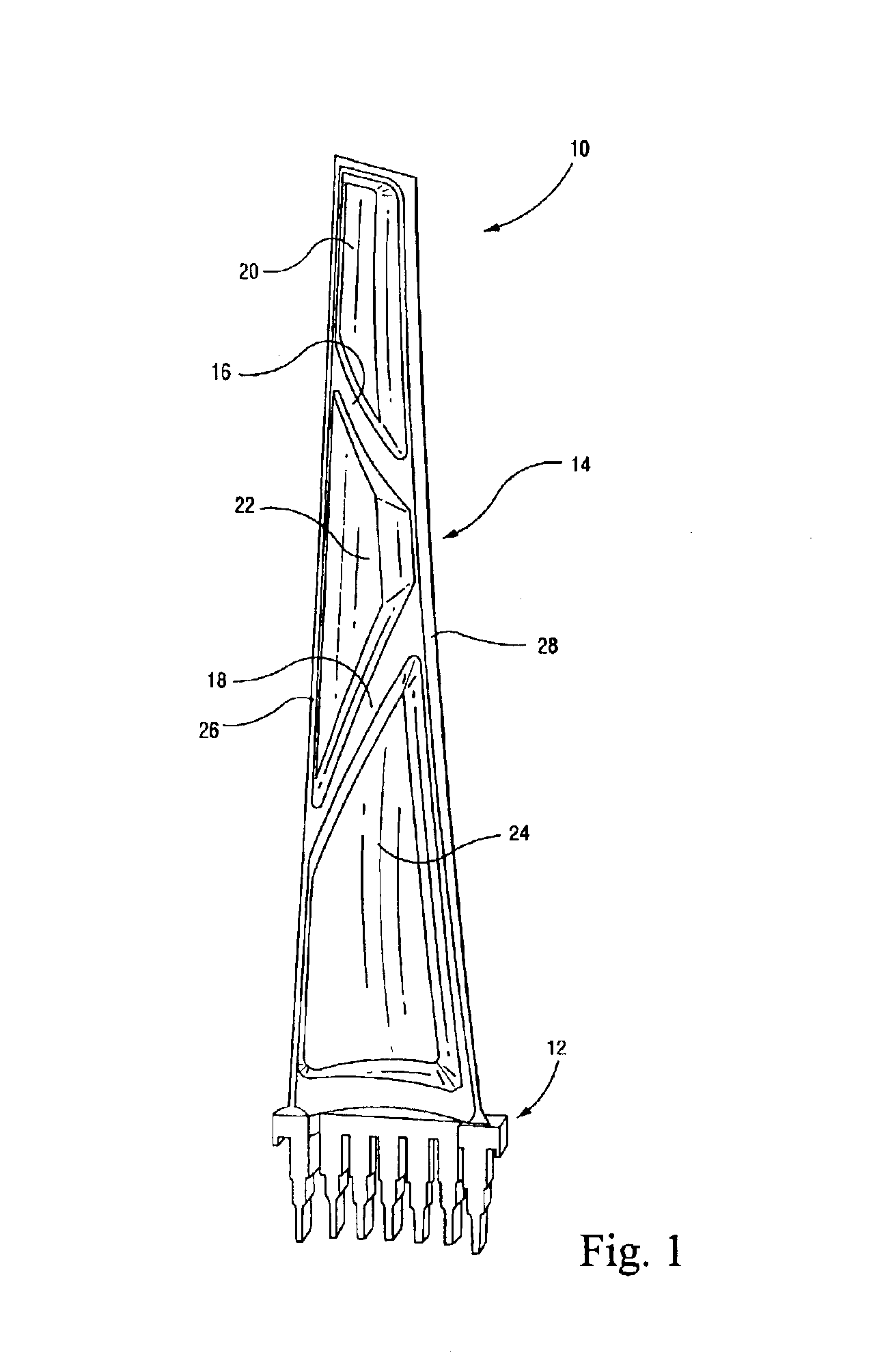

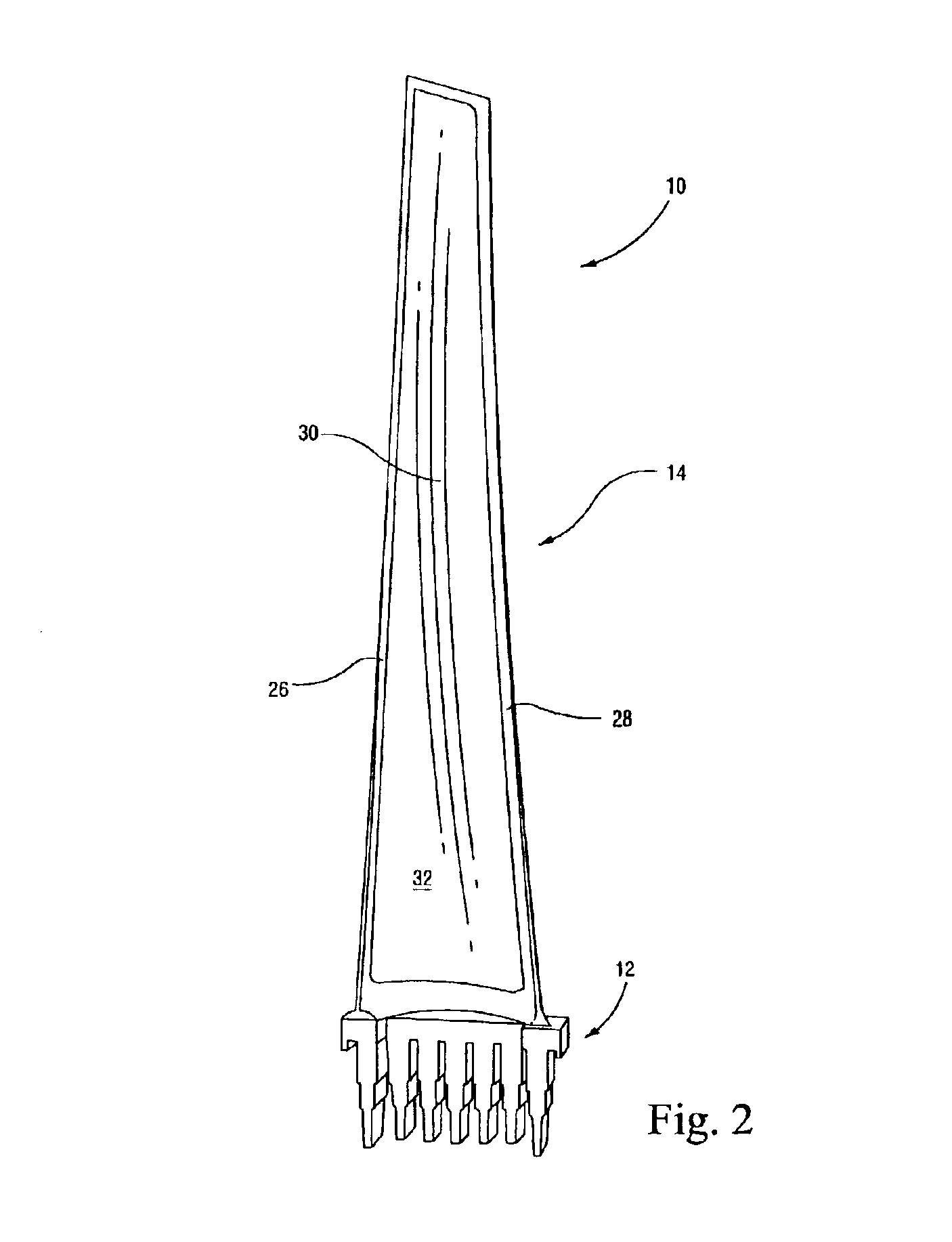

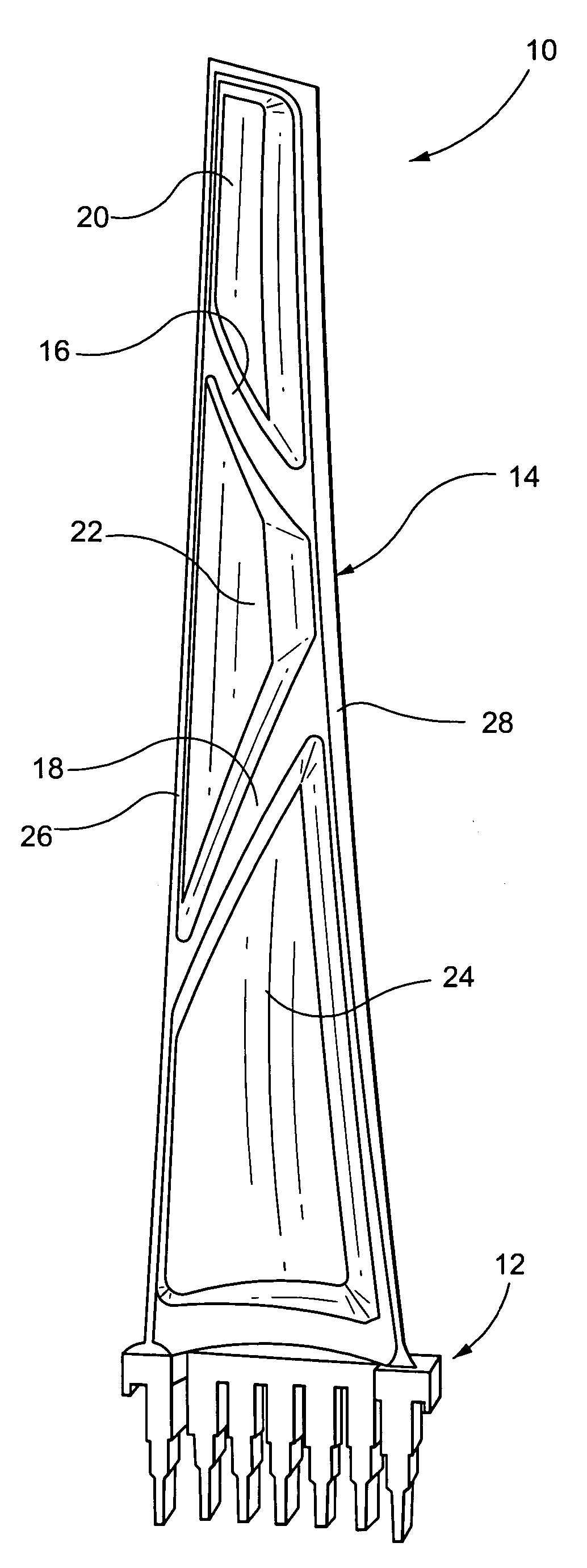

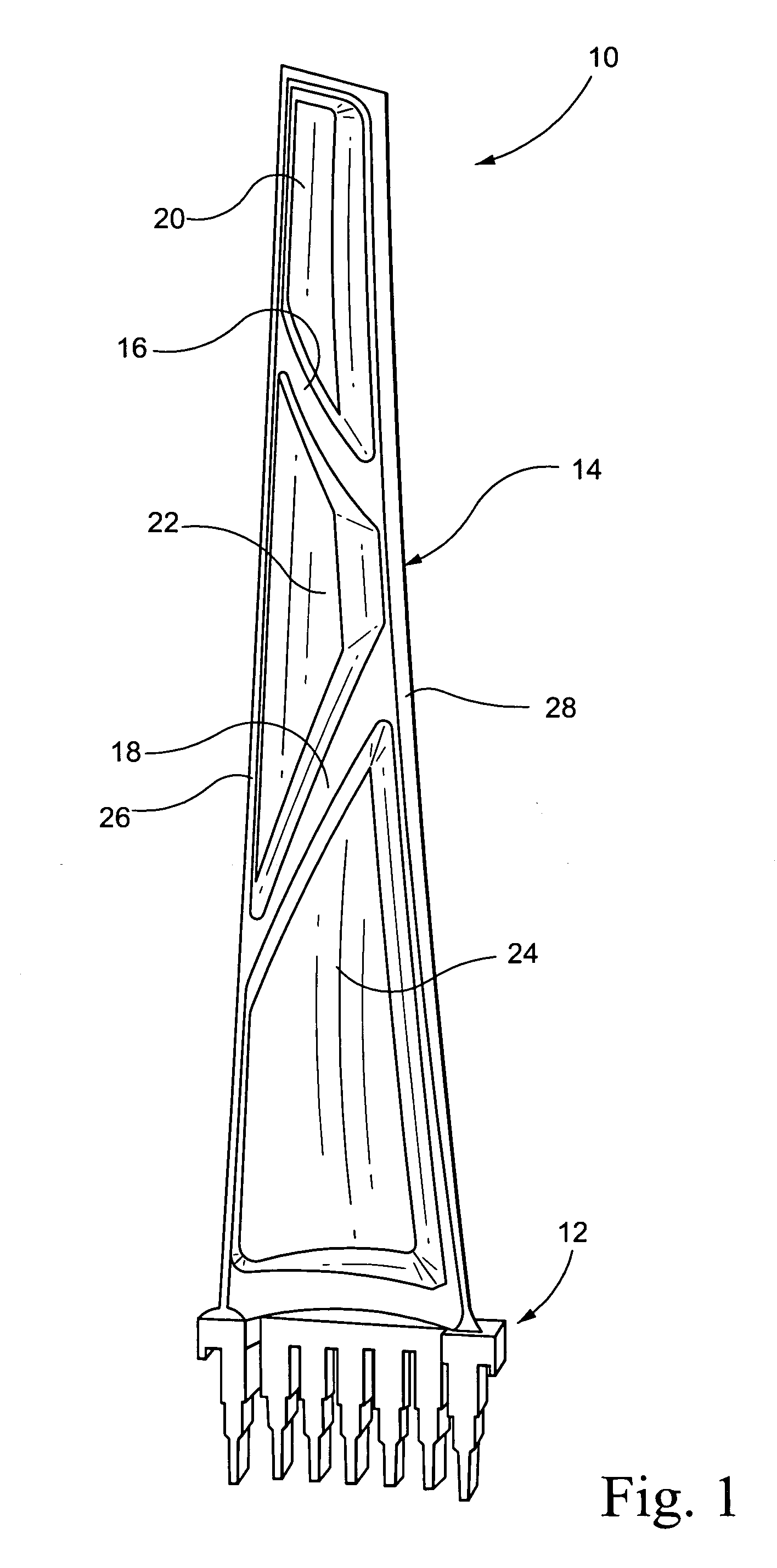

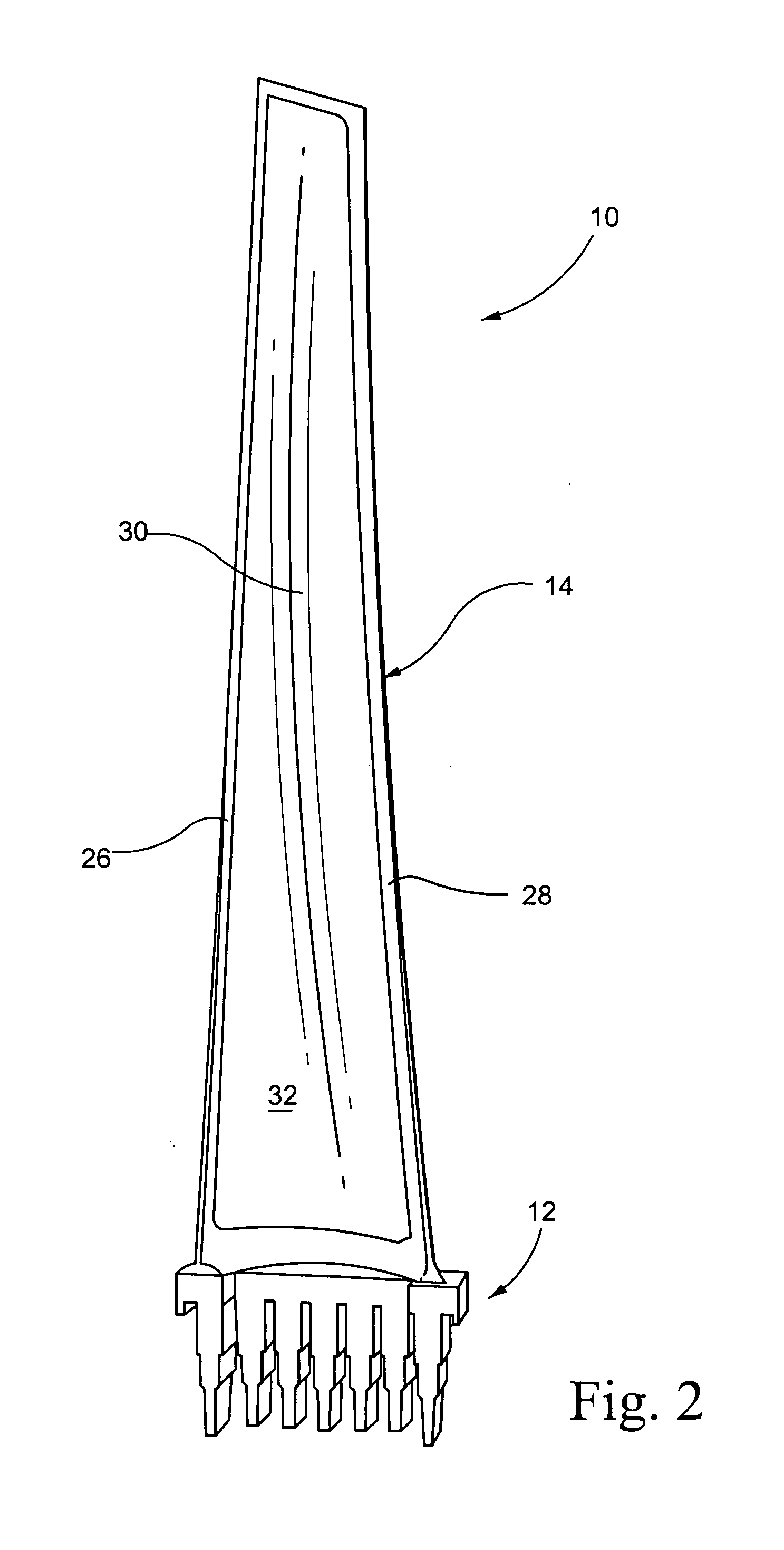

Mixed tuned hybrid blade related method

InactiveUS7147437B2Reducing and more effectively damping vibrationIncrease dampingPropellersRotary propellersFilling materialsSteam turbine blade

A steam turbine blade includes a shank portion and an airfoil portion. The airfoil portion is formed with at least one pocket filled with a polymer filler material chosen as a function of natural frequency impact on the turbine blade or as a function of the damping characteristics of the filler materials. A steam turbine rotor wheel includes a plurality of blades secured about a circumferential periphery of the wheel, each blade having one or more pockets in the airfoil portion, the plurality of blades divided into two groups of blades. The pockets of one group of blades are filled with one or more polymer filler materials, and the pockets of the other group of blades filled with one or more polymer filler materials, wherein the polymer filler materials in the one group of blades creates different natural frequencies or damping characteristics in the blades of the one group than the polymer filler materials in the blades of the other group. The two groups of blades are assembled on the rotor wheel in accordance with a predetermined pattern.

Owner:GENERAL ELECTRIC CO

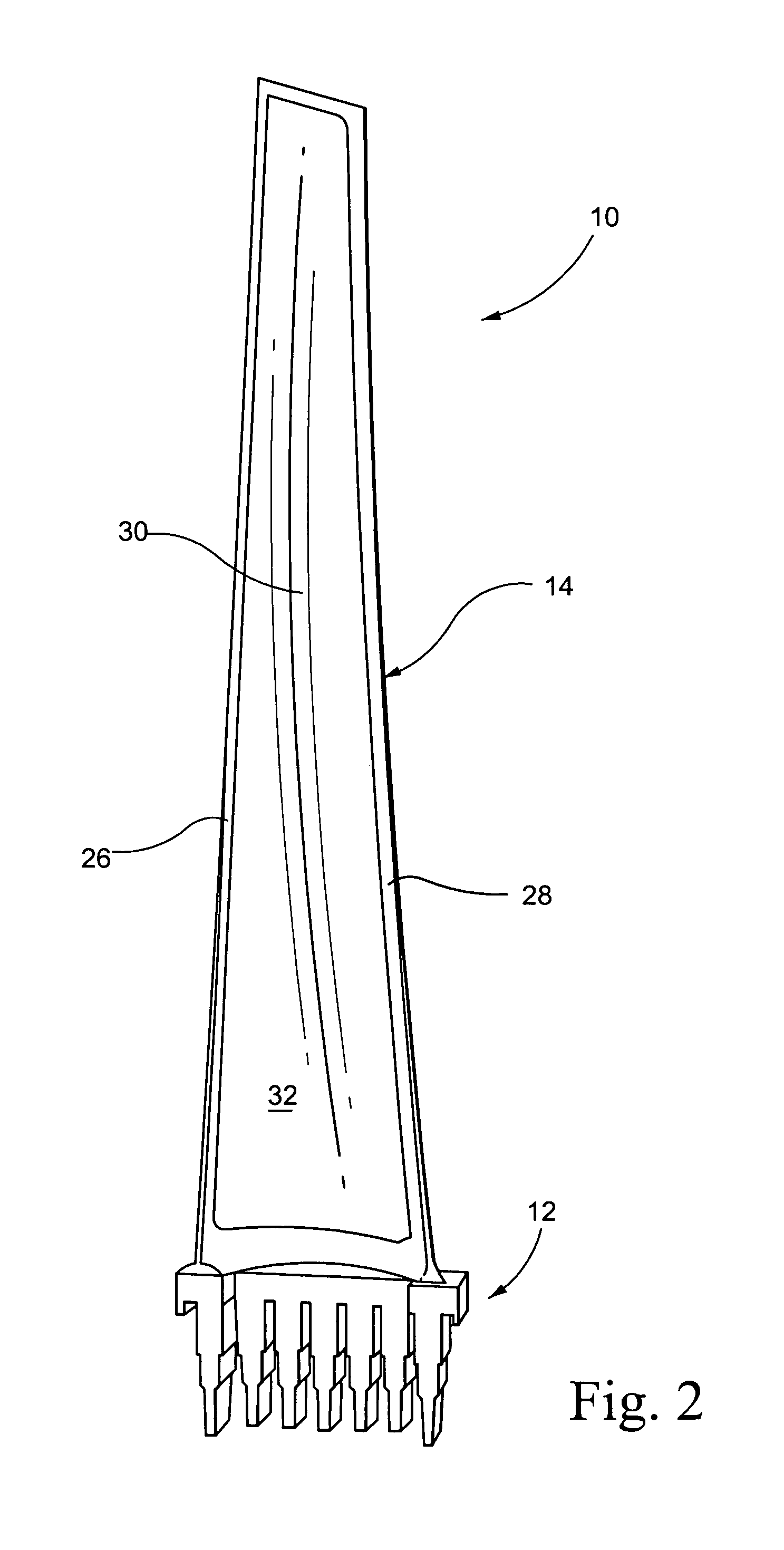

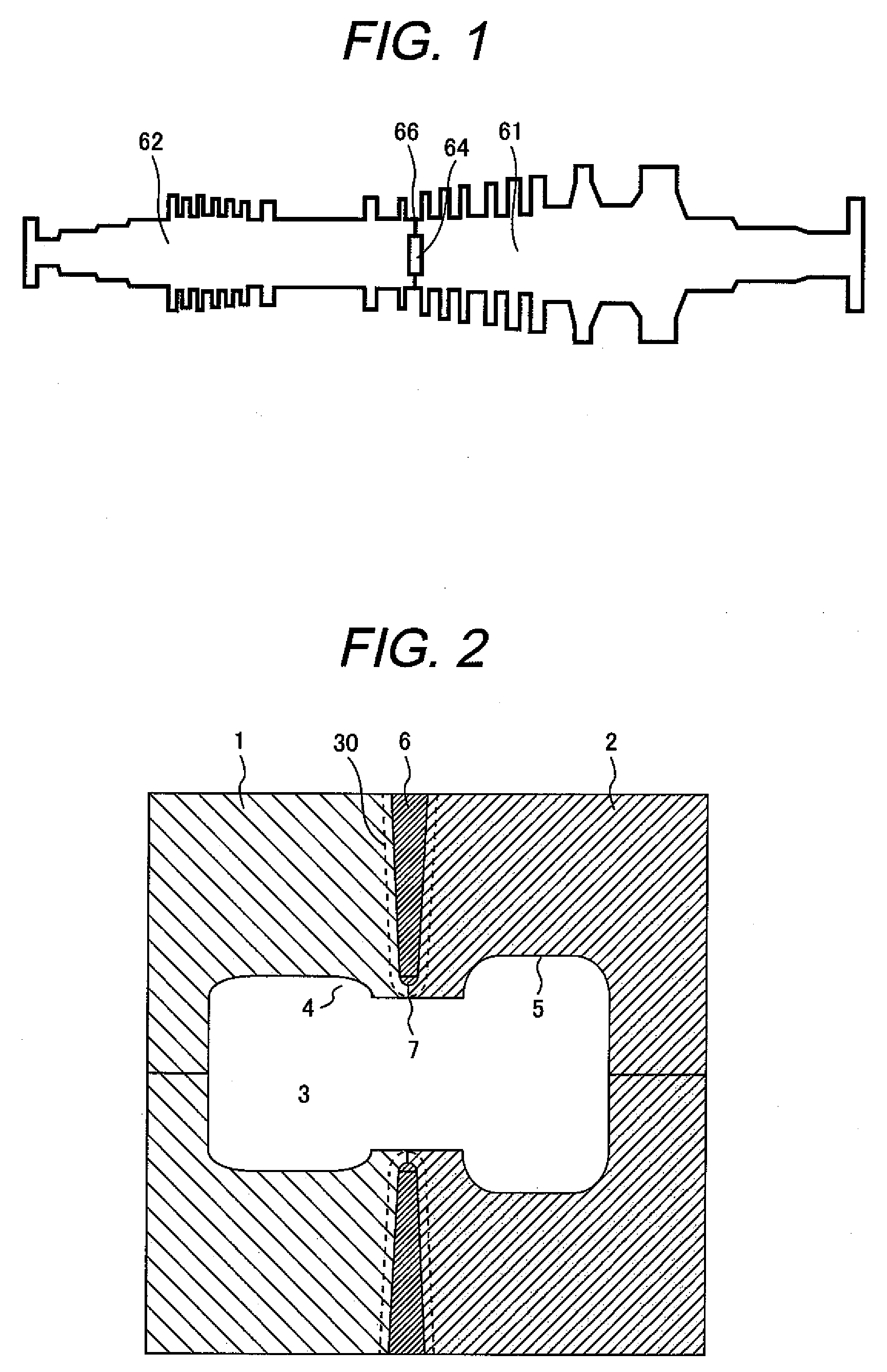

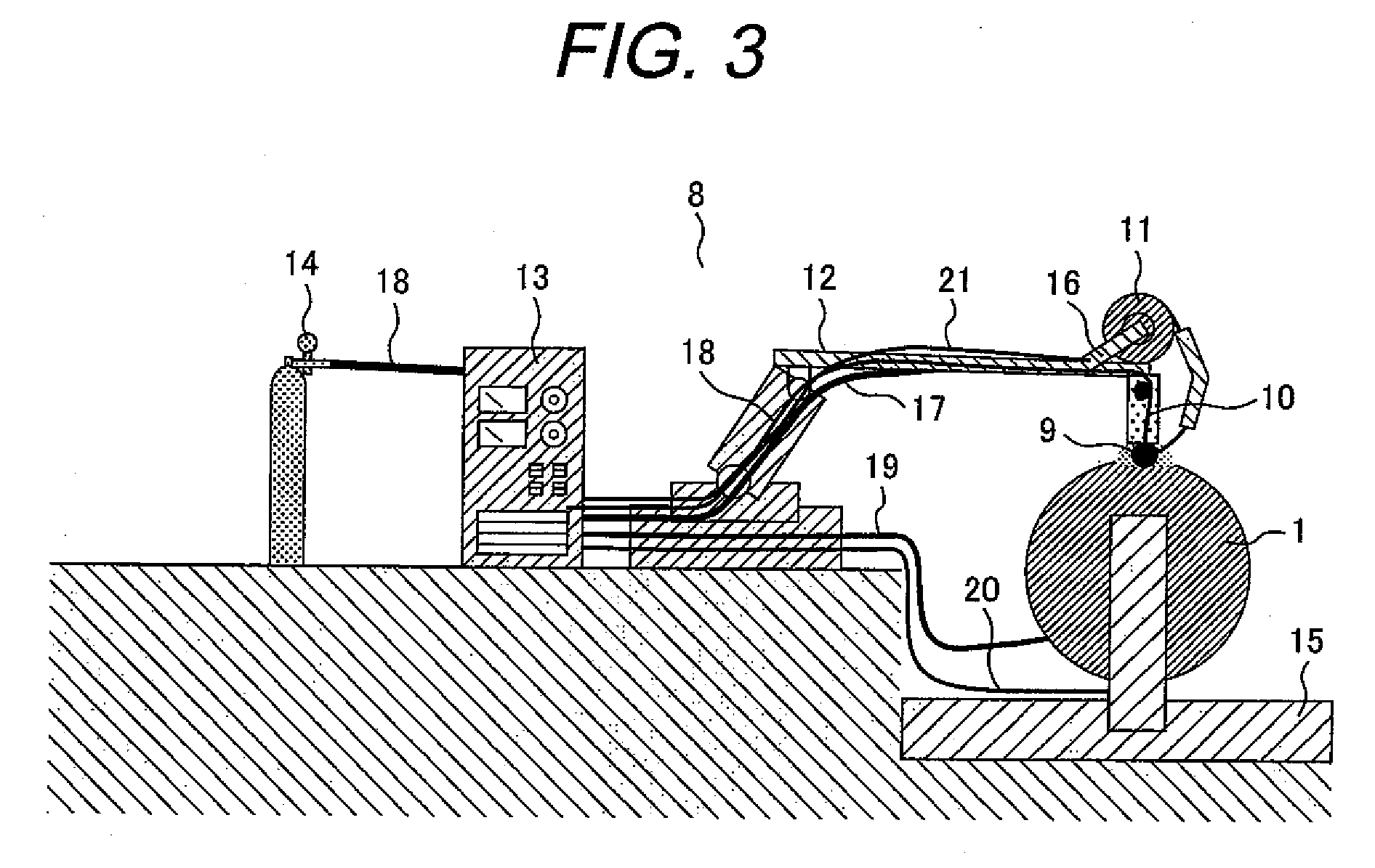

Steam turbine rotor blade assembly

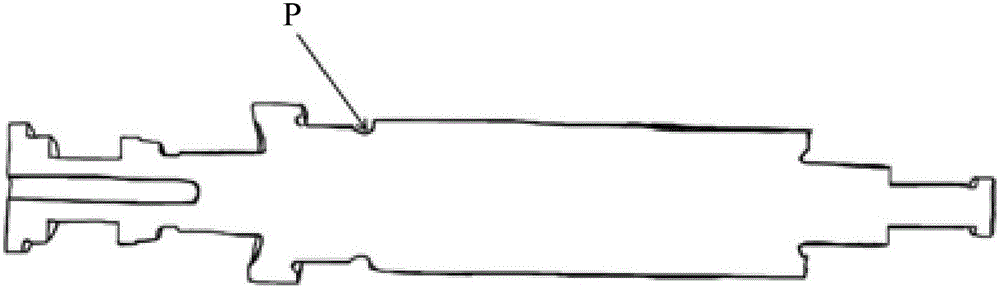

ActiveUS20090097980A1Reduce vibration stressHigh positioning accuracyPropellersPump componentsSteam turbine rotorTurbine rotor

The present invention is a steam turbine rotor blade assembly including: an airfoil; a shroud provided at a tip of the airfoil; a blade root (dovetail) projecting toward a radially internal circumferential side of a turbine rotor and fitted to a root attachment provided on an outer circumferential portion of the turbine rotor; a platform provided between the airfoil and the blade root; a pin provided between the blade root and the root attachment; a bore formed between respective surfaces of the shrouds facing each other and included in the respective adjacent rotor blades; and a bar-like member provided in the bore.

Owner:MITSUBISHI POWER LTD

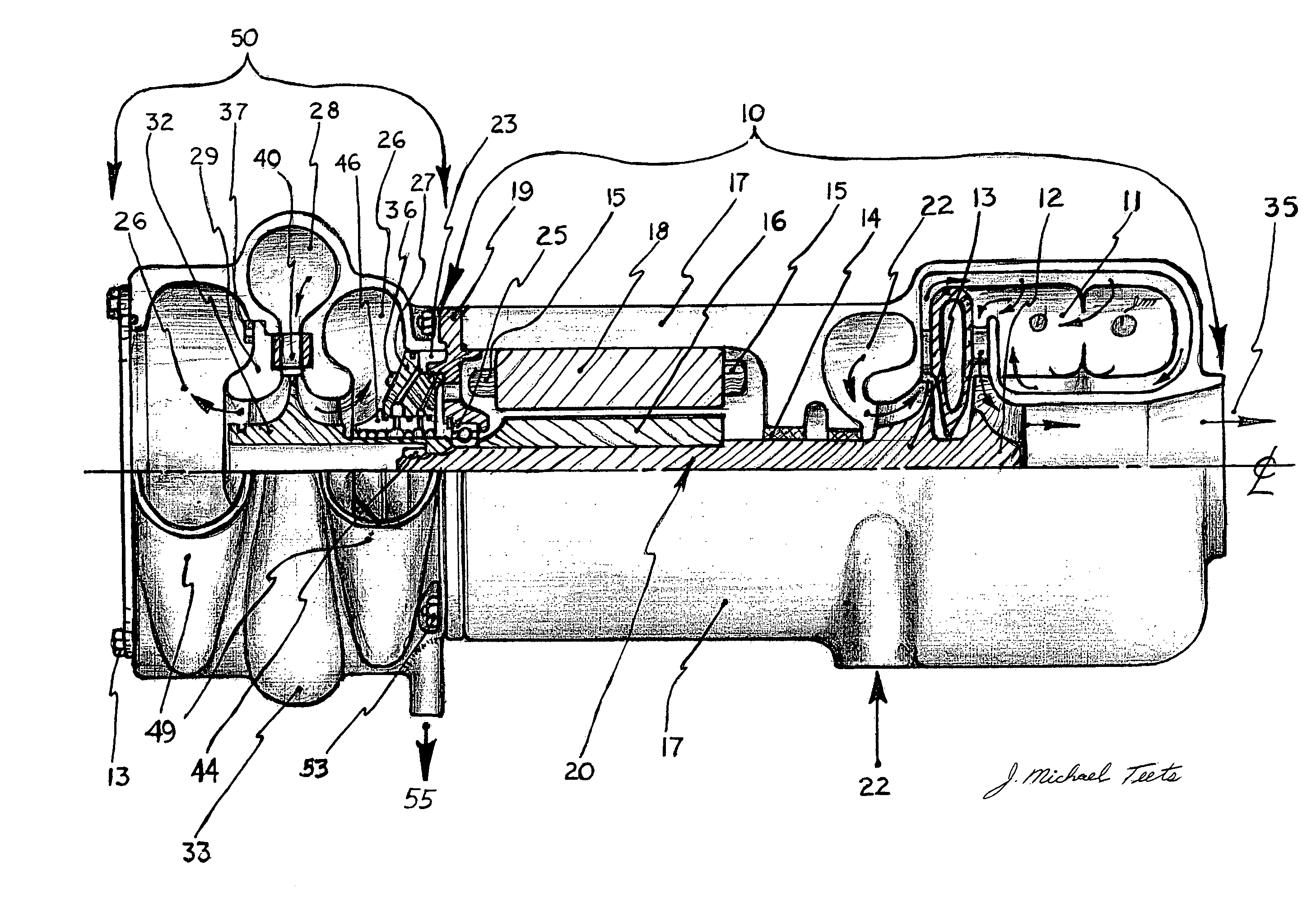

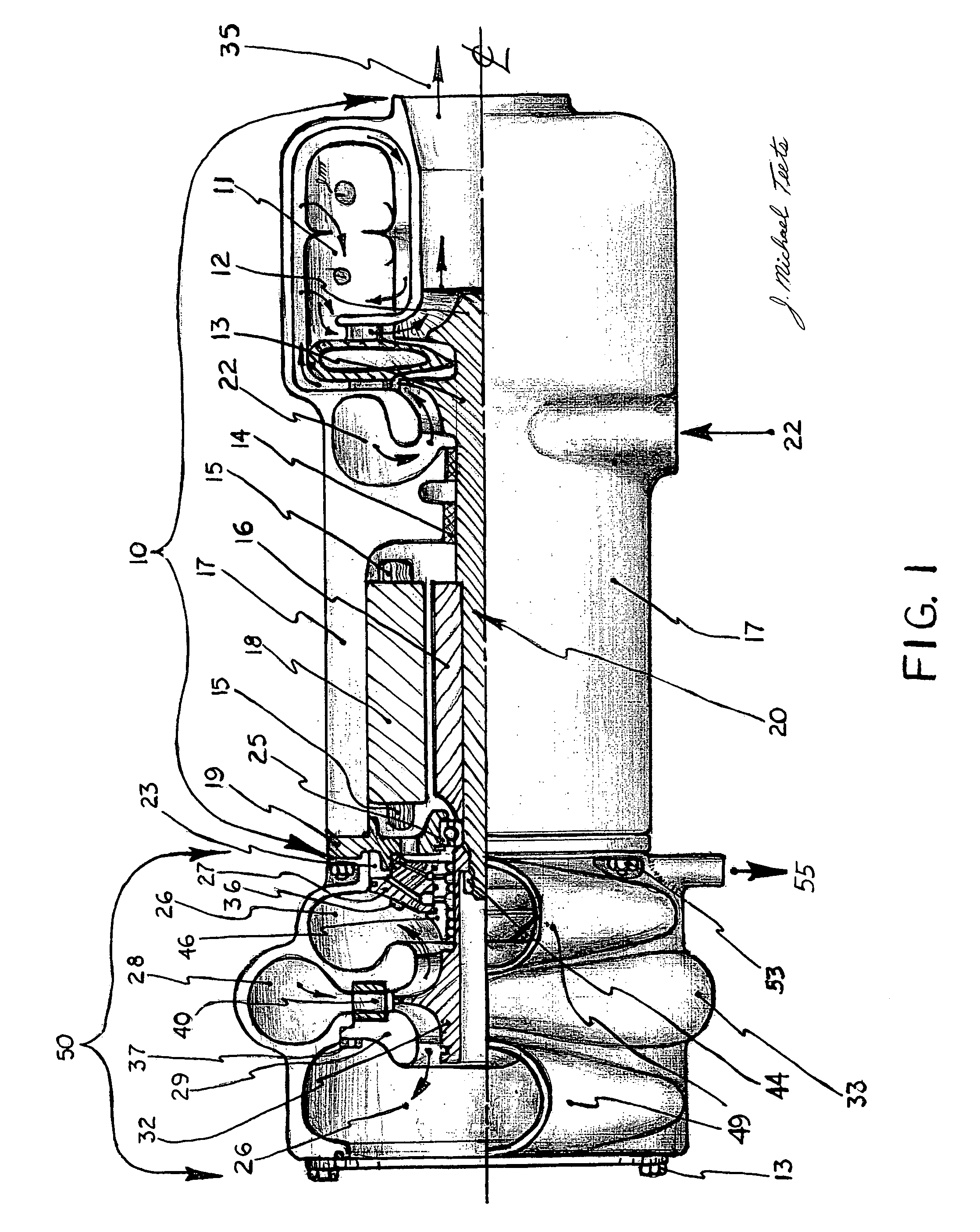

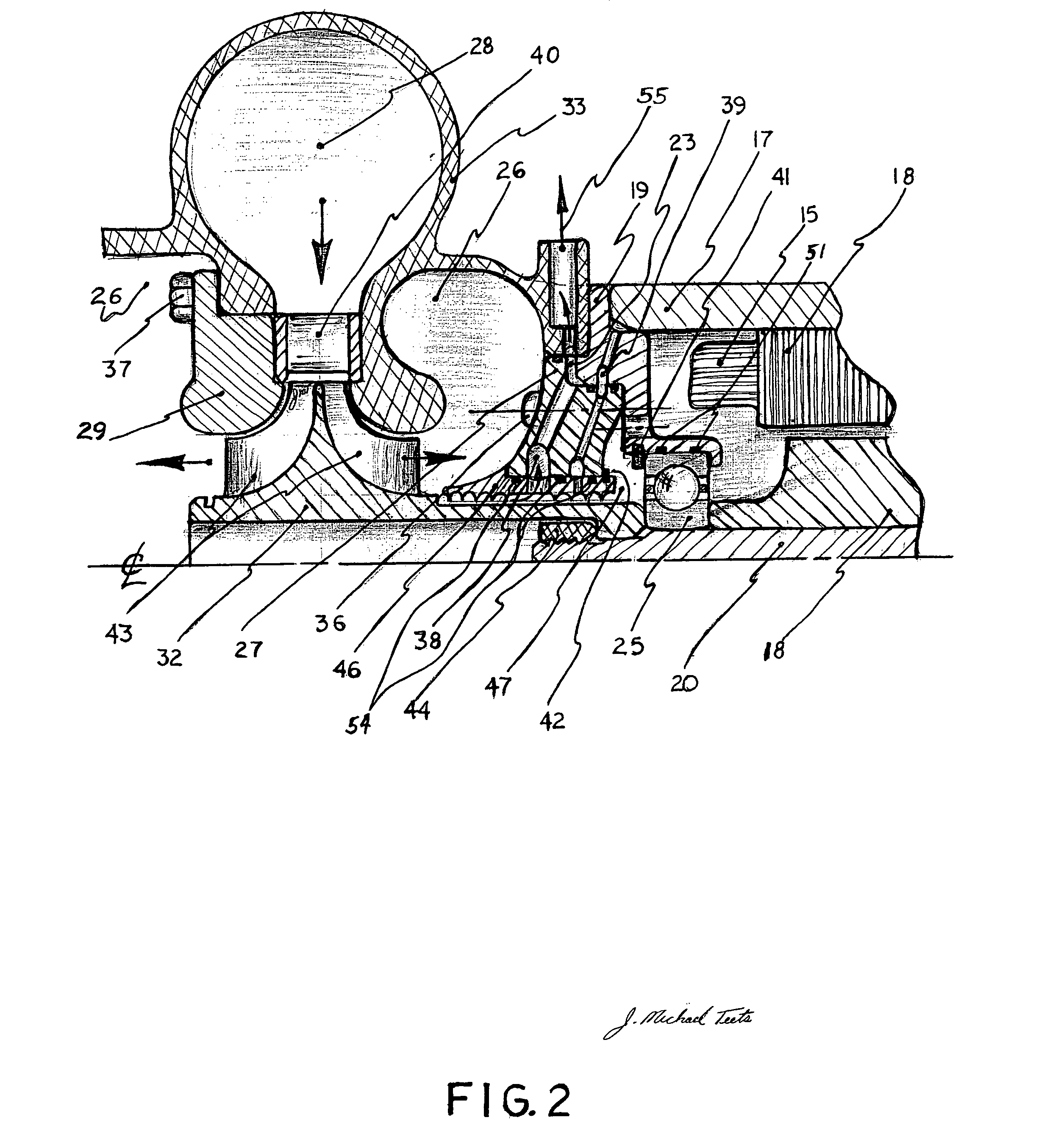

Rankine-microturbine for generating electricity

InactiveUS7211906B2Improve output power efficiencyReduce installation costsEngine manufactureEngine fuctionsEngineeringElectric power

An electrical output power generation system is provided. A gas turbine engine rotor spool with at least one alternator rotor and steam turbine rotor are integrated and within a engine body having a combustor or external heat source having fluid communication with the bladed compressor rotor and a gas turbine bladed rotor of the said rotor spool. The alternator rotor has permanent magnets retained and positioned in close proximity and co-axial to the electrical stator having iron laminat and electrical wires. Relative rotational motion between the electrical stator and alternator rotor cause magnetic flux and subsequent electricity to be generated. The steam energy to drive the said rotor spool integrated steam turbine rotor can be from the gas turbine engine exhaust waste heat and or thru external heat energy sources.

Owner:T M A POWER

Integral cover bucket design

InactiveUS7097428B2Avoids erosion and corrosionImproving reliability and efficiencyPropellersPump componentsImpellerLeading edge

A bucket for use on a steam turbine rotor wheel, the bucket comprising a shank portion and an airfoil portion, the airfoil portion having a radially outer tip with a tip cover adapted to be engaged, in use, by a similar tip cover on an adjacent bucket, wherein a radial step is formed in the tip cover and the airfoil portion along a leading edge of the airfoil portion.

Owner:GENERAL ELECTRIC CO

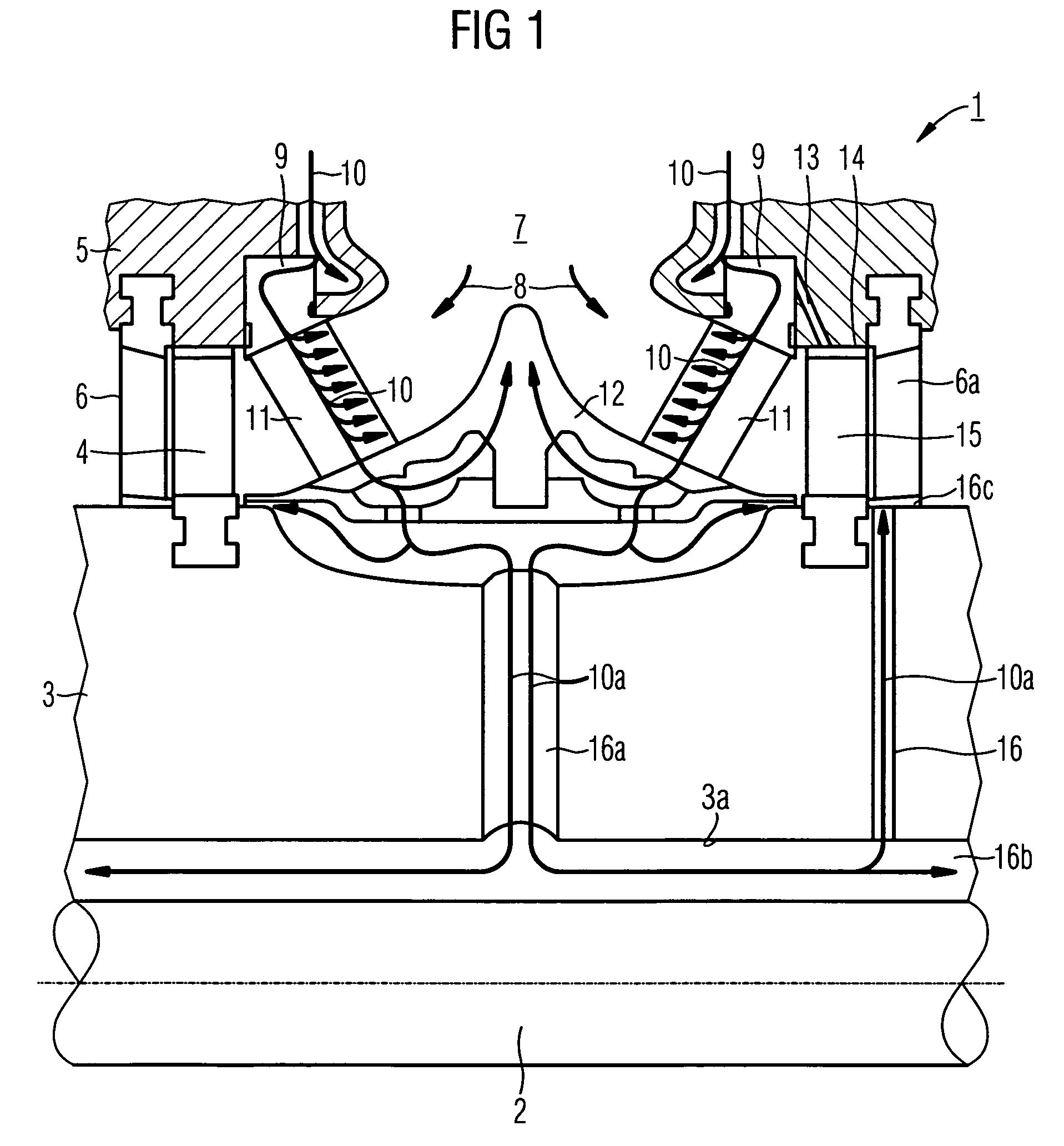

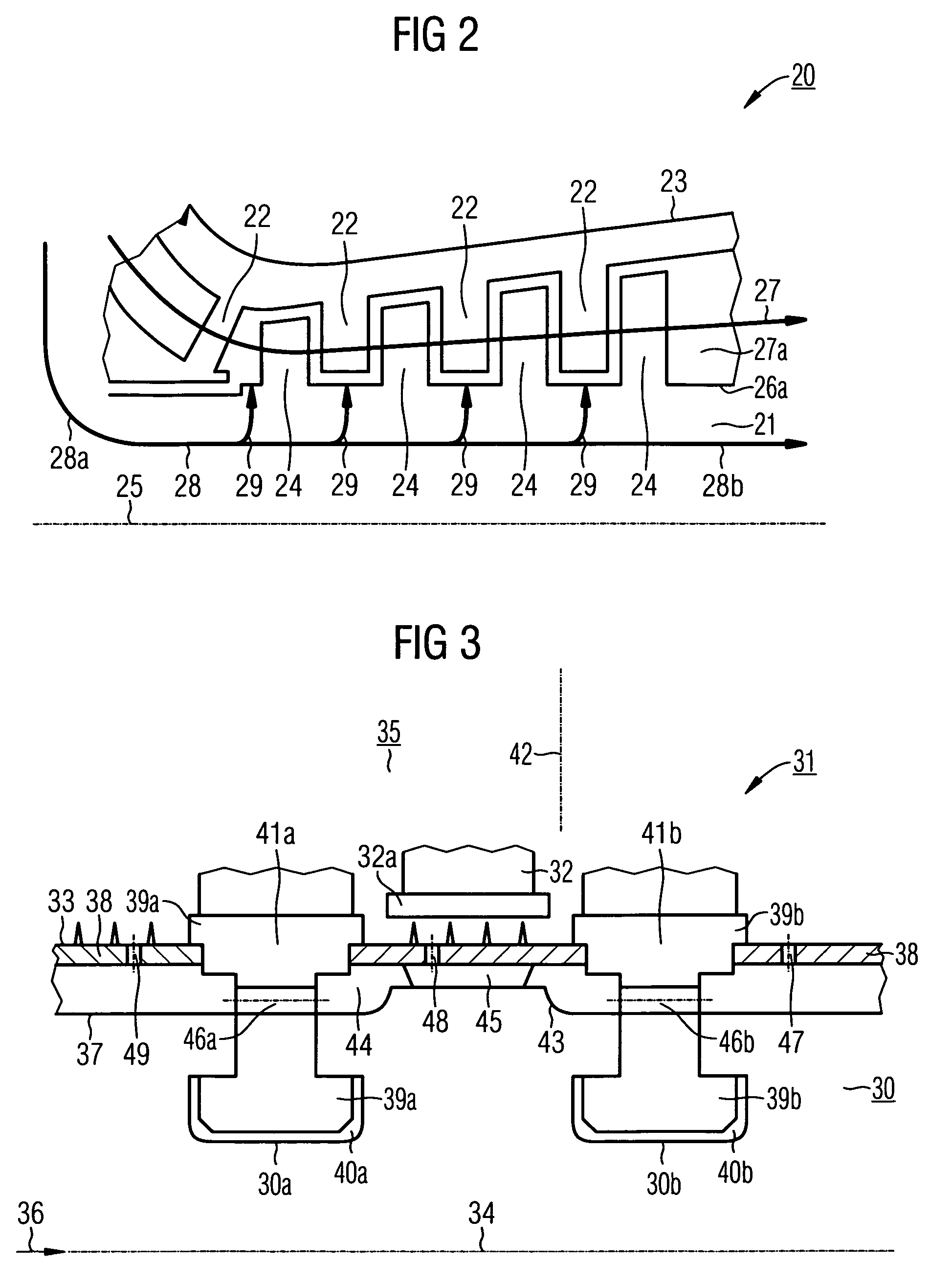

Steam turbine rotor, steam turbine and method for actively cooling a steam turbine rotor and use of active cooling

InactiveUS7101144B2Economic feasibilityImprove efficiencyPump componentsEngine fuctionsActive coolingEngineering

The proposed steam turbine rotor extends along an axial extent and includes: an outer side which adjoins an outer space which is intended to receive a main flow of a fluid working medium, a first location along the outer side, at which a first blade is held, a second location along the outer side, at which a second blade is held, the second location being arranged behind the first location along the axial extent. To ensure sufficient cooling, there is at least one integrated passage, which extends continuously at least between a first region arranged in front of the first location and a second region arranged behind the second location The invention proposes a method and a use in which a fluid cooling medium is guided in a corresponding way.

Owner:SIEMENS AG

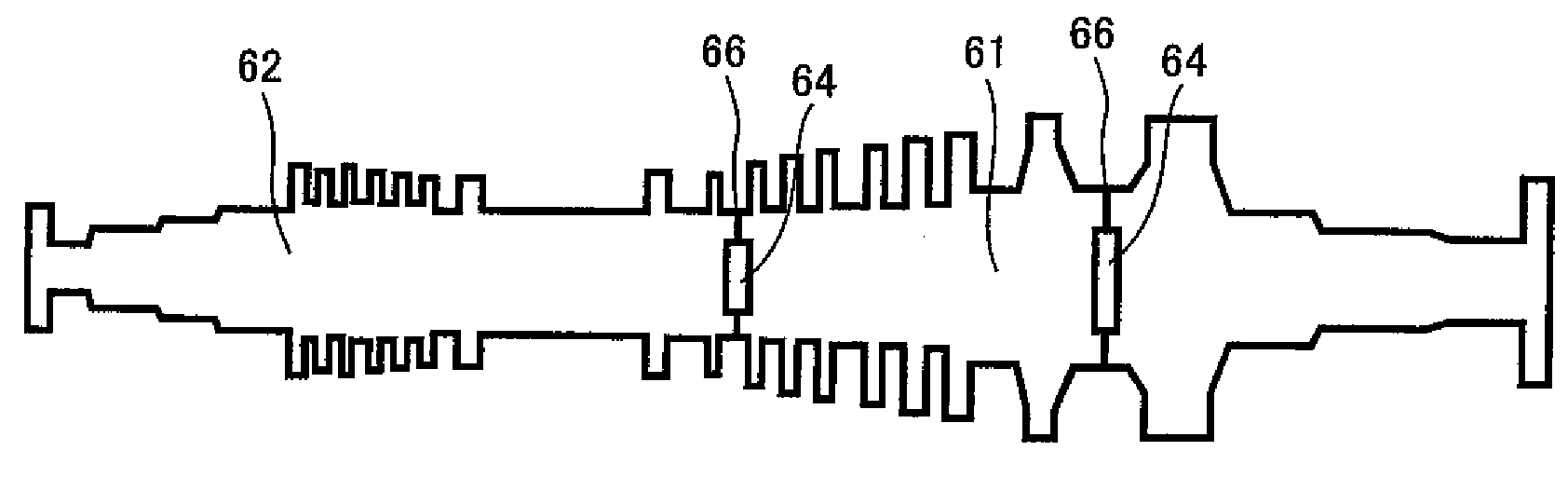

Mixed tuned hybrid bucket and related method

InactiveUS6854959B2Suppressing aero-elastic responseAffects its aerodynamic propertyPropellersEngine manufactureImpellerEngineering

A steam turbine rotor wheel includes a plurality of buckets secured about a circumferential periphery of the wheel, each bucket comprising a shank portion and an airfoil portion, the plurality of buckets including two groups of buckets having respective different predetermined resonant frequencies. A method of reducing vibration in a row of buckets on a steam turbine rotor wheel includes a) providing a first group of buckets with a first predetermined natural frequency range; b) providing a second group of buckets with a second predetermined natural frequency range different than the first predetermined natural frequency range; and c) assembling buckets of the first and second groups of buckets in alternating fashion on the rotor wheel.

Owner:GENERAL ELECTRIC CO

Renovation technique of steam turbine rotor shaft fracture

InactiveCN1990169AImprove performanceStrong repair process adaptabilityLaser beam welding apparatusDynamic balanceMachining

The invention discloses a restoring technique of cracked automobile wheel shaft, which comprises the following steps: manufacturing new piece; assembling and connecting new piece; manufacturing entire piece mechanically; proceeding lossless defectoscopic detection and dynamic balance of rotor; fusing to cover the mechanic connection and interface part through laser.

Owner:SHENYANG DALU LASER TECH

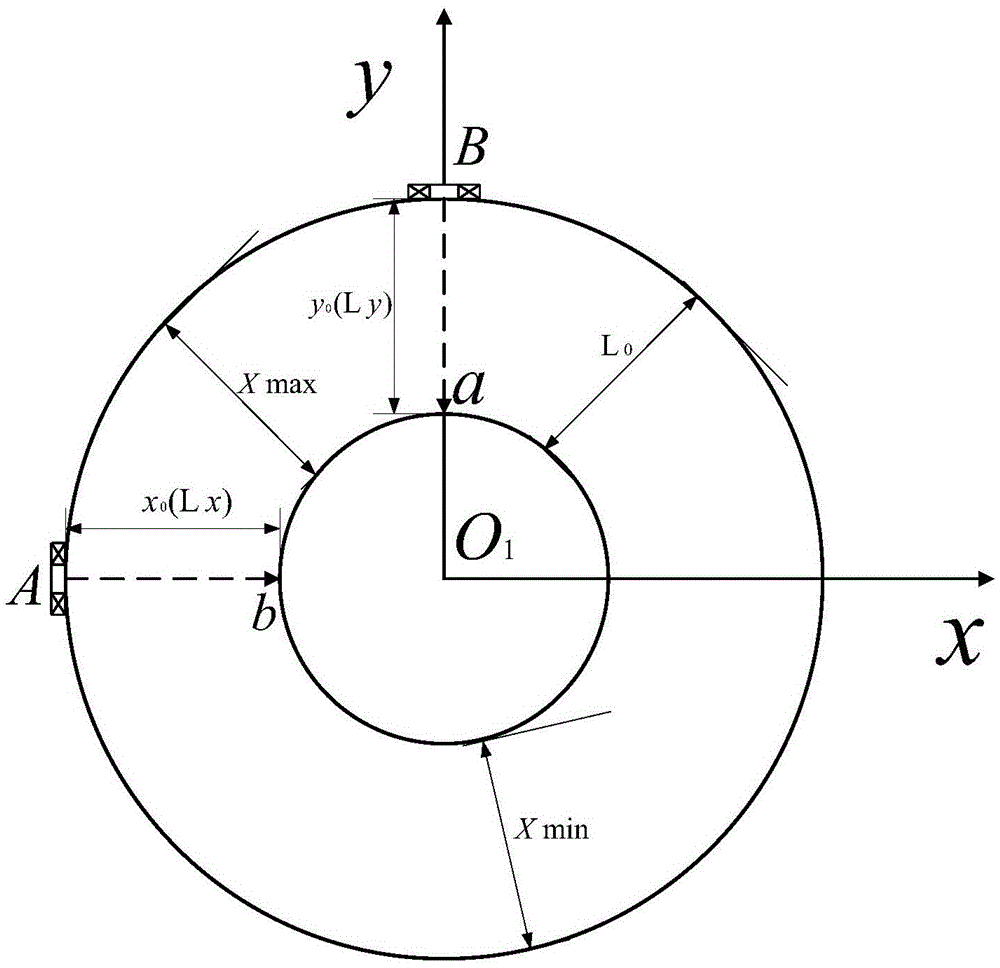

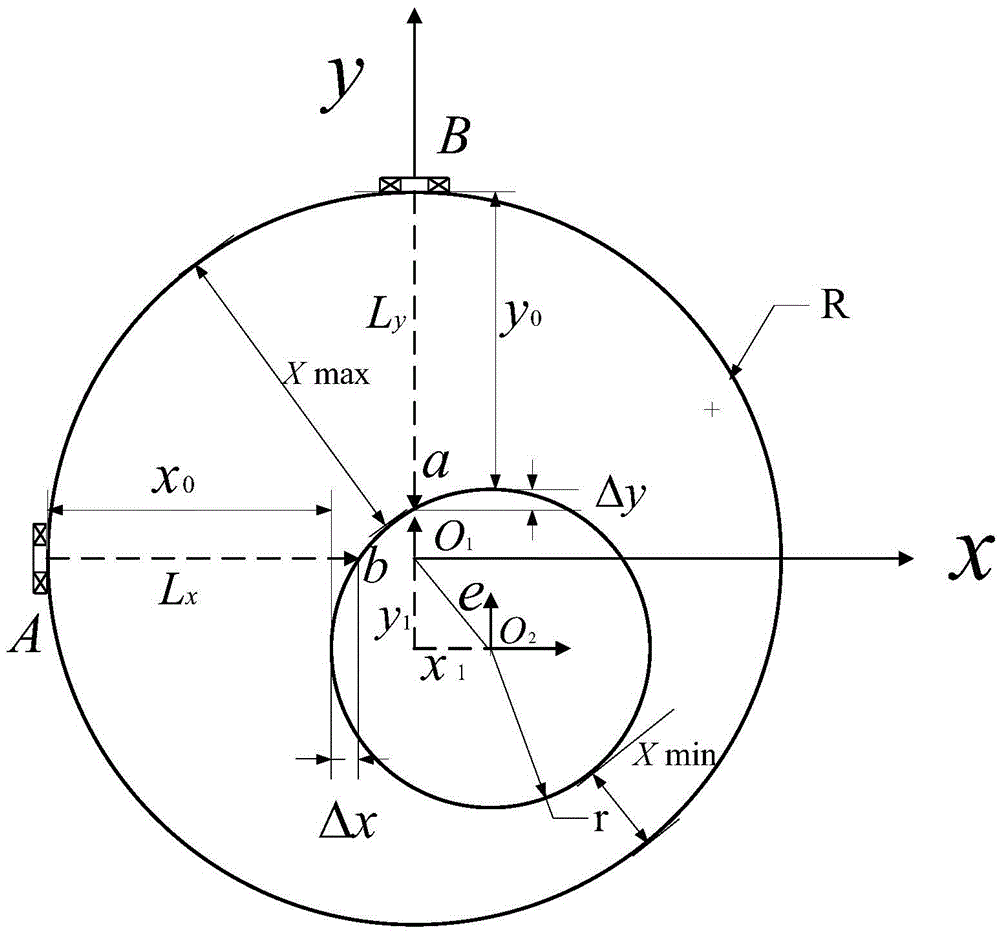

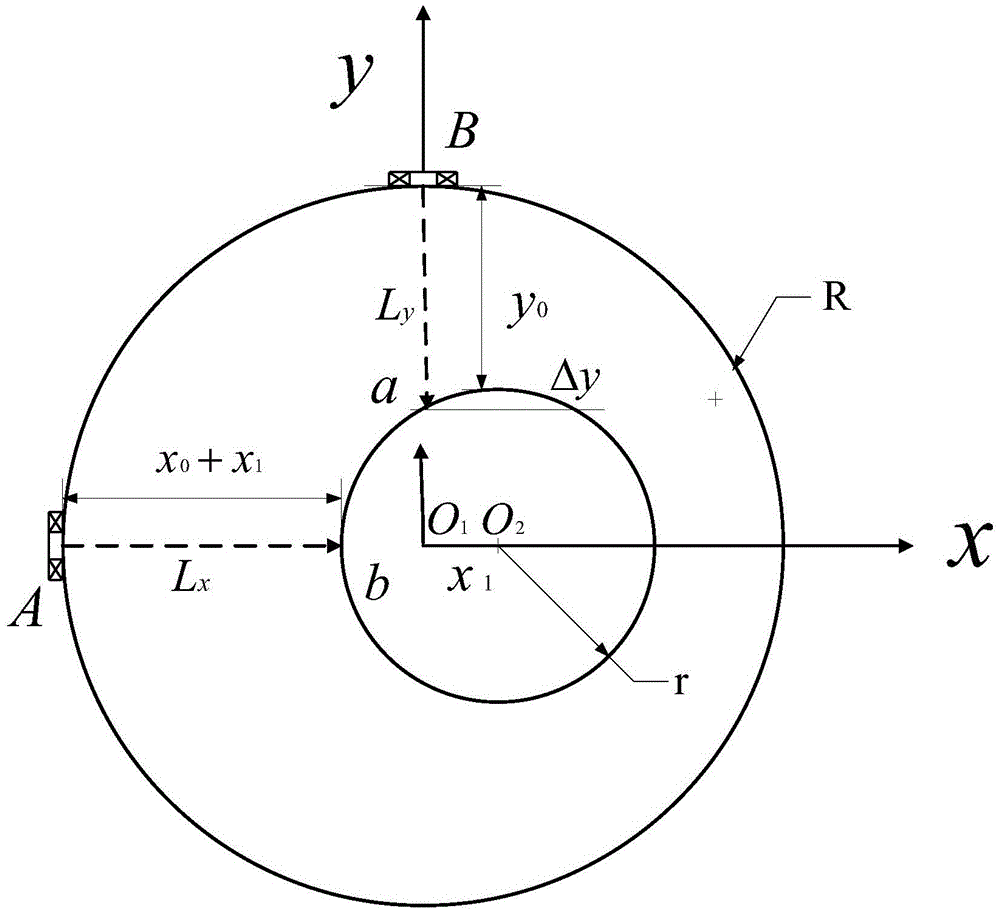

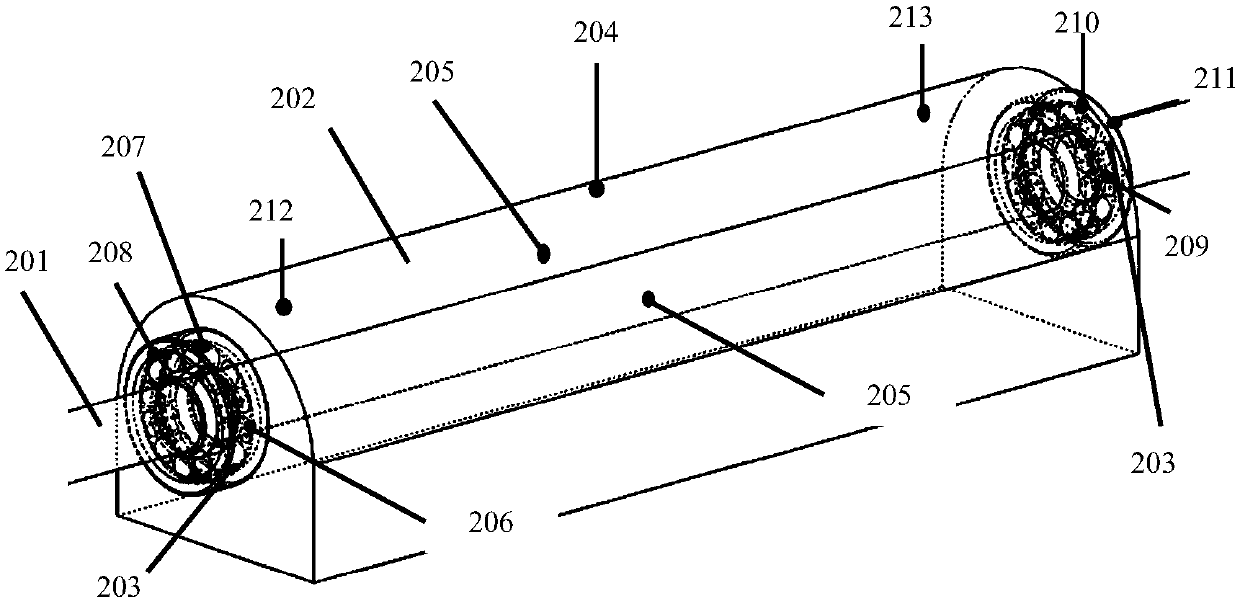

Real-time dynamic measurement method for measuring radial clearance between steam turbine rotor and stator

ActiveCN105526878ARealize non-contact measurementFast and accurate real-time dynamic online monitoringUsing optical meansObservational errorEngineering

The invention provides a real-time dynamic measurement method for measuring radial clearance between a steam turbine rotor and a stator. The method is characterized in that the method comprises the steps of determining distance measurement devices for radial clearance, determining radial clearance between the rotor and the stator, determining the radial clearance between the rotor and the stator, determining the distance from an emitter to the surface of the rotor, calculating vertical offset amount of the rotor when the center of the rotor shifts, calculating horizontal offset amount of the rotor when the center of the rotor shifts, calculating the rotor offset amount at any position and calculating the radial clearance between the steam turbine rotor and the stator. The method can carry out dynamic measurement on the rotor labyrinth clearance and blade top labyrinth clearance of a running steam turbine accurately and quickly, thereby solving the problem that the measuring error of the radial clearance between the steam turbine rotor and the stator is large and the radial clearance cannot be measured online dynamically and accurately, ensuring safe and economical operation of the machine set and saving halt overhaul time.

Owner:NORTHEAST DIANLI UNIVERSITY

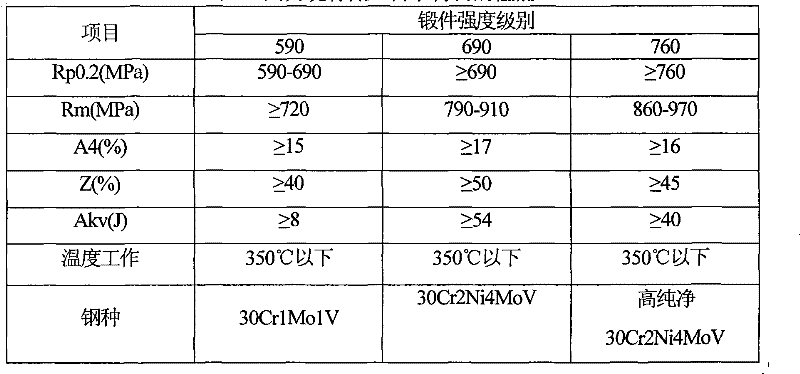

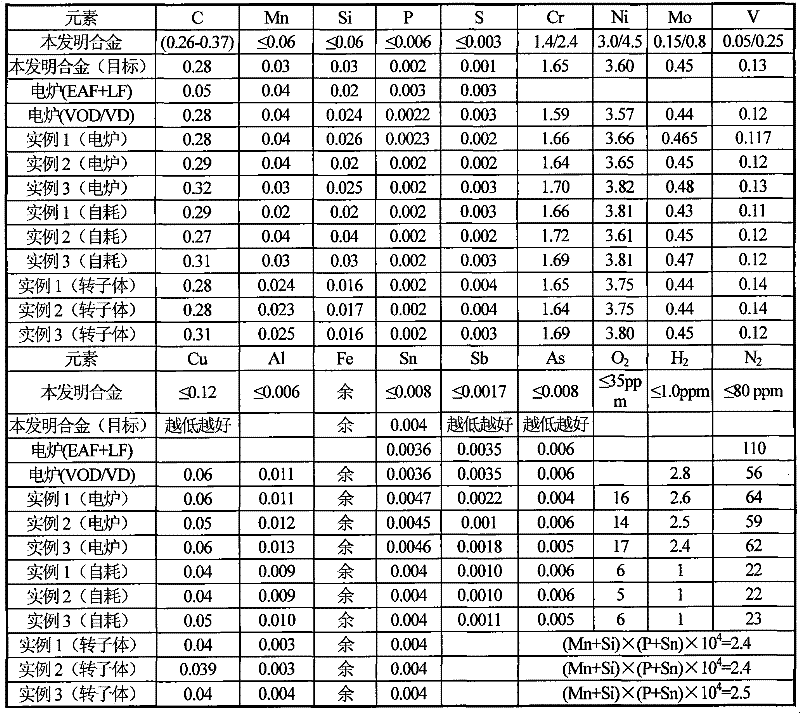

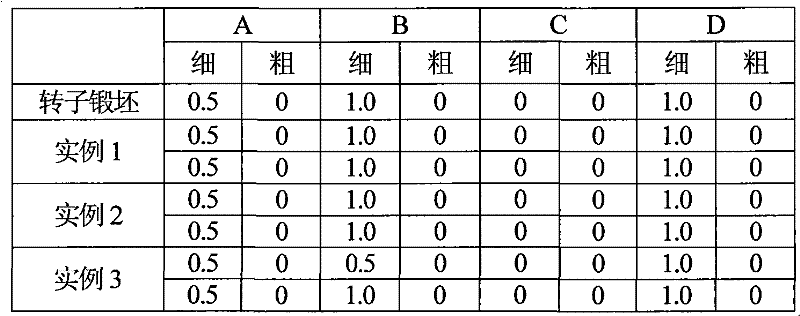

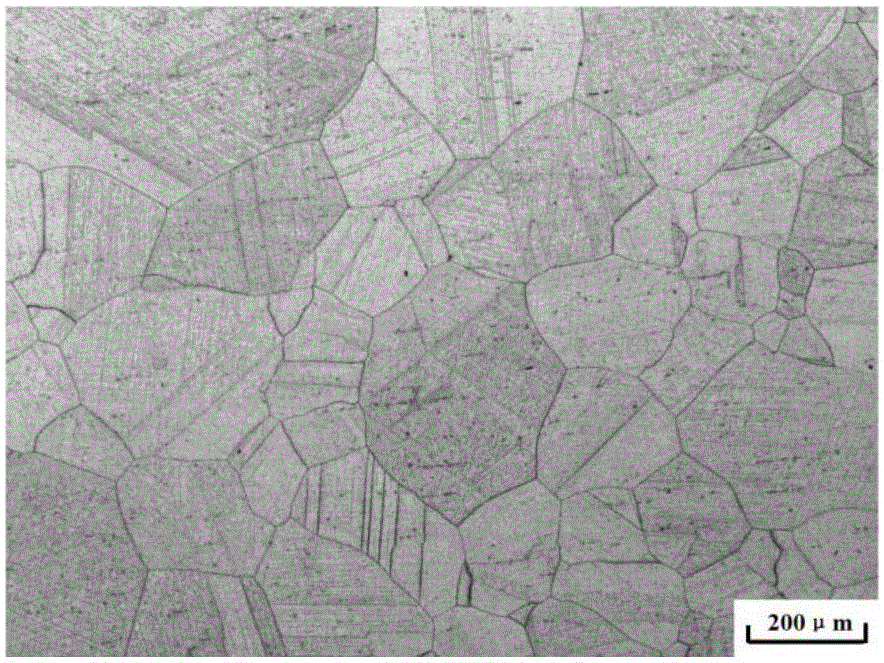

Ultra-pure alloy and method for manufacturing turbine rotor forging by using same

ActiveCN102234744AMeet the use requirementsGood effect of removing inclusionsQuenching agentsChemical compositionWorking environment

The invention provides an ultra-pure alloy which comprises the following chemical components in percentage by weight: 0.26-0.37 of C, less than or equal to 0.06 of Mn, less than or equal to 0.06 of Si, less than or equal to 0.006 of P, less than or equal to 0.003 of S, 1.4-2.4 of Cr, 3.0-4.5 of Ni, 0.15-0.8 of Mo, 0.05-0.25 of V, less than or equal to 0.12 of Cu, less than or equal to 0.006 of Al, less than or equal to 0.008 of Sn, less than or equal to 0.0017 of Sb, less than or equal to 0.008 of As, less than or equal to 35ppm of O, less than or equal to 1.0ppm of H, less than or equal to 80ppm of N and the balance of Fe and inevitable impurities. The invention also provides a method for manufacturing a turbine rotor forging by using the alloy. In the method, the obtained low-pressure rotor forging can bear the work environments with the temperature of above 400 DEG C and high stress for a long term through improvement of the existing electric furnace smelting and forging technology.

Owner:宝武特种冶金有限公司

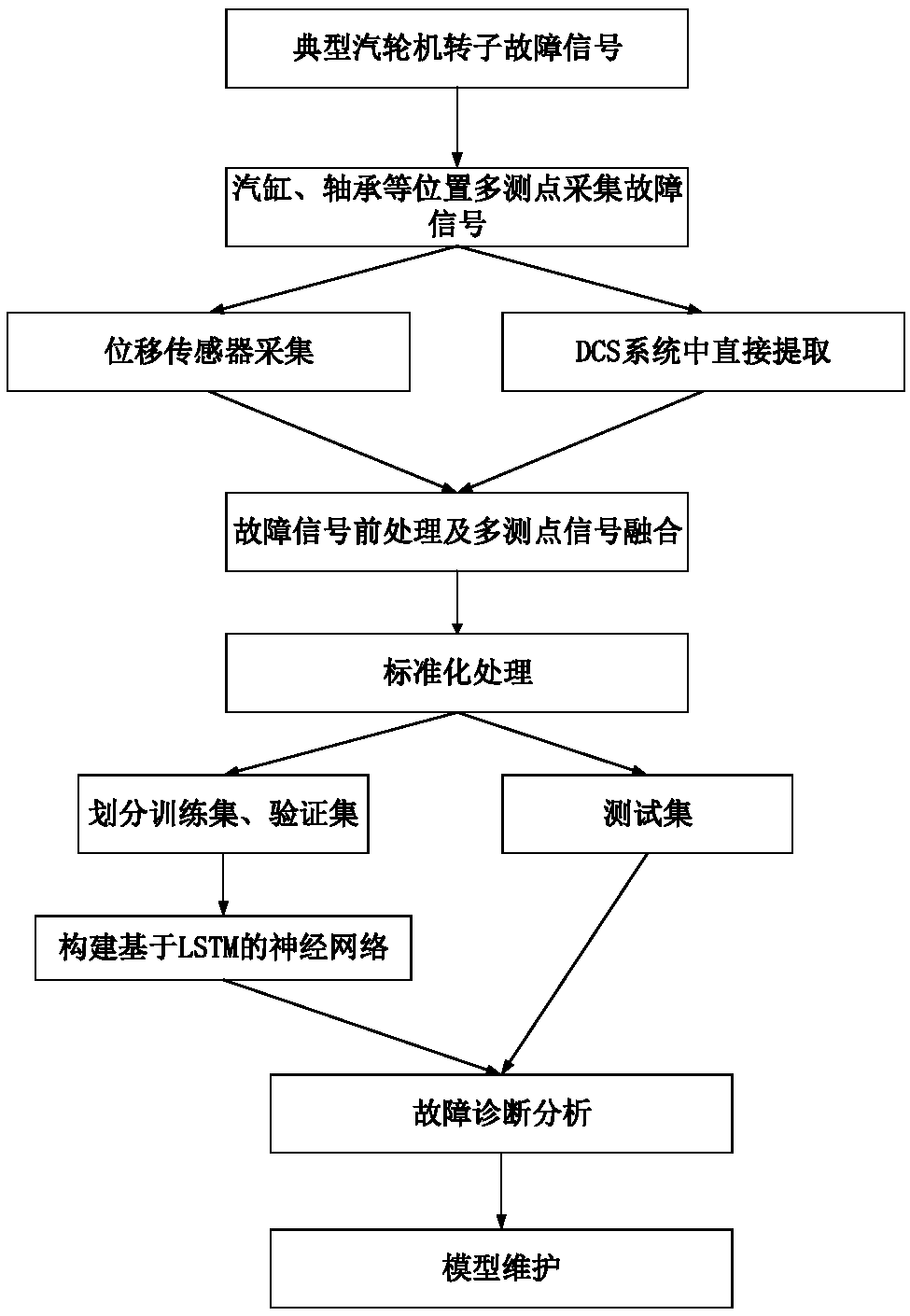

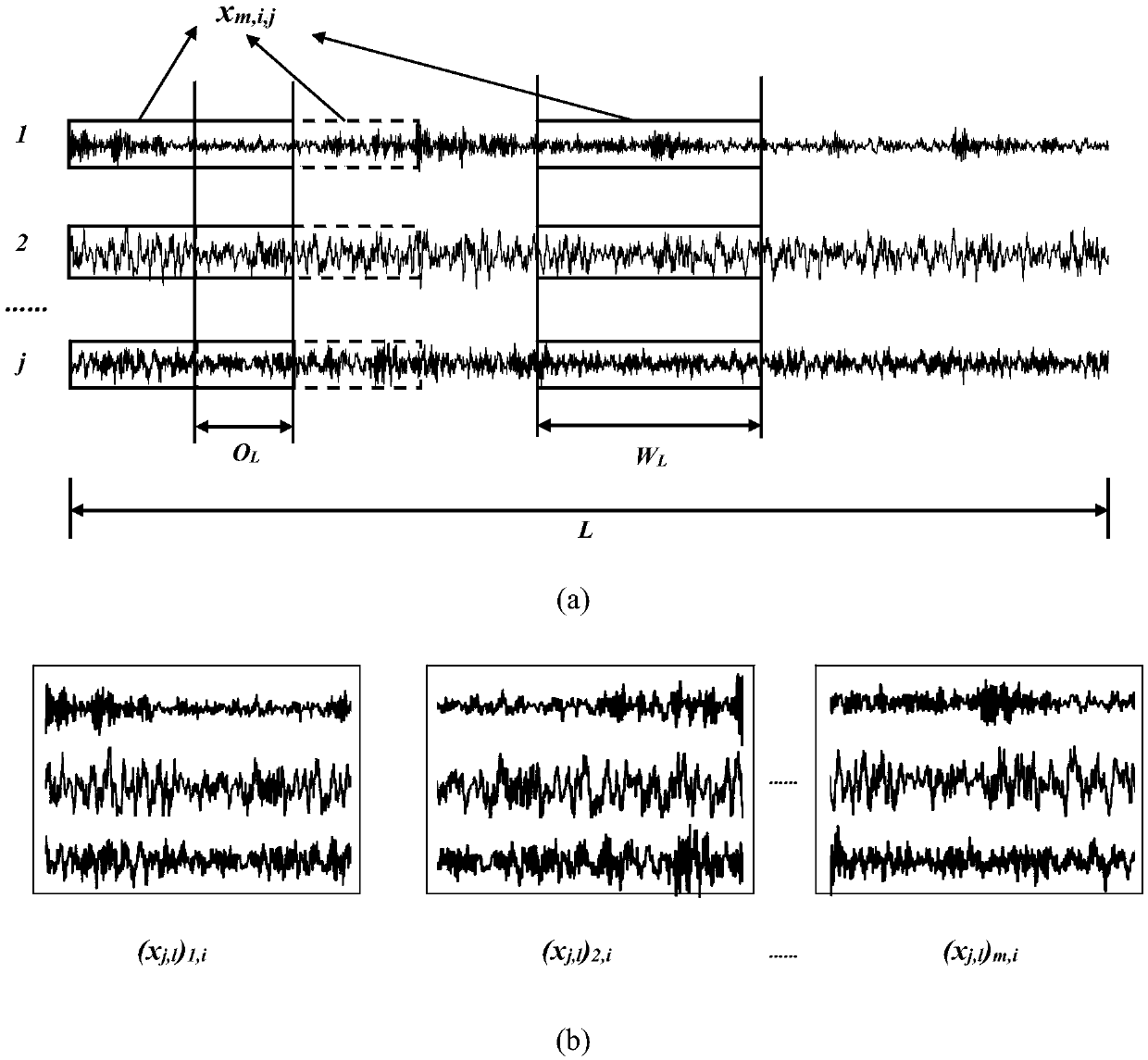

Steam turbine rotor fault diagnosis method based on LSTM

ActiveCN109555566AGuaranteed Timing DependencyGuaranteed fault feature extractionEngine fuctionsCharacter and pattern recognitionDiagnosis methodsEngineering

The invention discloses a steam turbine rotor fault diagnosis method based on LSTM, and belongs to the technical field of mechanical fault diagnosis. Firstly, multi-point acquisition sensors are deployed and controlled, and vibration signals of various typical turbine rotor faults are collected as a training set and a verification set. Secondly, the steam turbine rotor vibration signals are extracted from a power plant DCS system to serve as a testing set. Thirdly, the training set, the testing set and the verification set realize fusion of multi-point signal data and data enhancement throughsignal division, stacking and other operations. Fourthly, a neural network based on the LSTM is constructed, the training set and the verification set are used for completing training of the network,and finally, maintenance of a diagnostic model is achieved in cooperation with an actual diagnostic task, and finally the steam turbine rotor fault diagnosis is realized on the testing set.

Owner:XI AN JIAOTONG UNIV

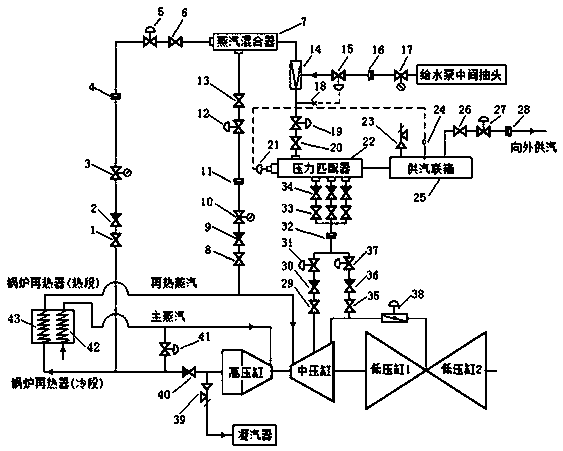

Heating system of large-scale pure condensing-type steam turbine generator set and heating method

PendingCN108868921AAvoid overheatingAvoid temperatureLighting and heating apparatusSteam useEngineeringHigh pressure

The invention discloses a heating system of a large-scale pure condensing-type steam turbine generator set and a heating method. The heating system of the large-scale pure condensing-type steam turbine generator set comprises two high-pressure steam extraction pipelines, a steam mixer, a pressure matcher, two low-pressure steam extraction pipelines, a steam supply header, a high-pressure cylinder,a medium-pressure cylinder and a low-pressure cylinder; the cold section and hot section of a boiler reheater are connected to the steam mixer through two high-pressure steam extraction pipelines respectively, the situation that the overtemperature or excessively-low temperature phenomenon of the boiler reheater is caused by single steam extraction from the cold section or hot section of the boiler reheater is avoided, and meanwhile the problems are solved that due to the single steam extraction from the cold section or hot section of the boiler reheater, the steam feeding and discharging amount of a steam turbine is unbalanced, and the axial force change of a rotor of the steam turbine is large, and the safety of the steam turbine is endangered; the combined steam extraction is achievedthrough the two high-pressure steam extraction pipelines, so that when the steam supply temperature does not meet the steam supply temperature requirement due to the steam extraction of the cold section of the boiler reheater, the effect of increasing the steam supply temperature can be achieved by increasing the steam supply ratio of the hot section of the boiler reheater.

Owner:ELECTRIC POWER RES INST OF GUANGXI POWER GRID CO LTD

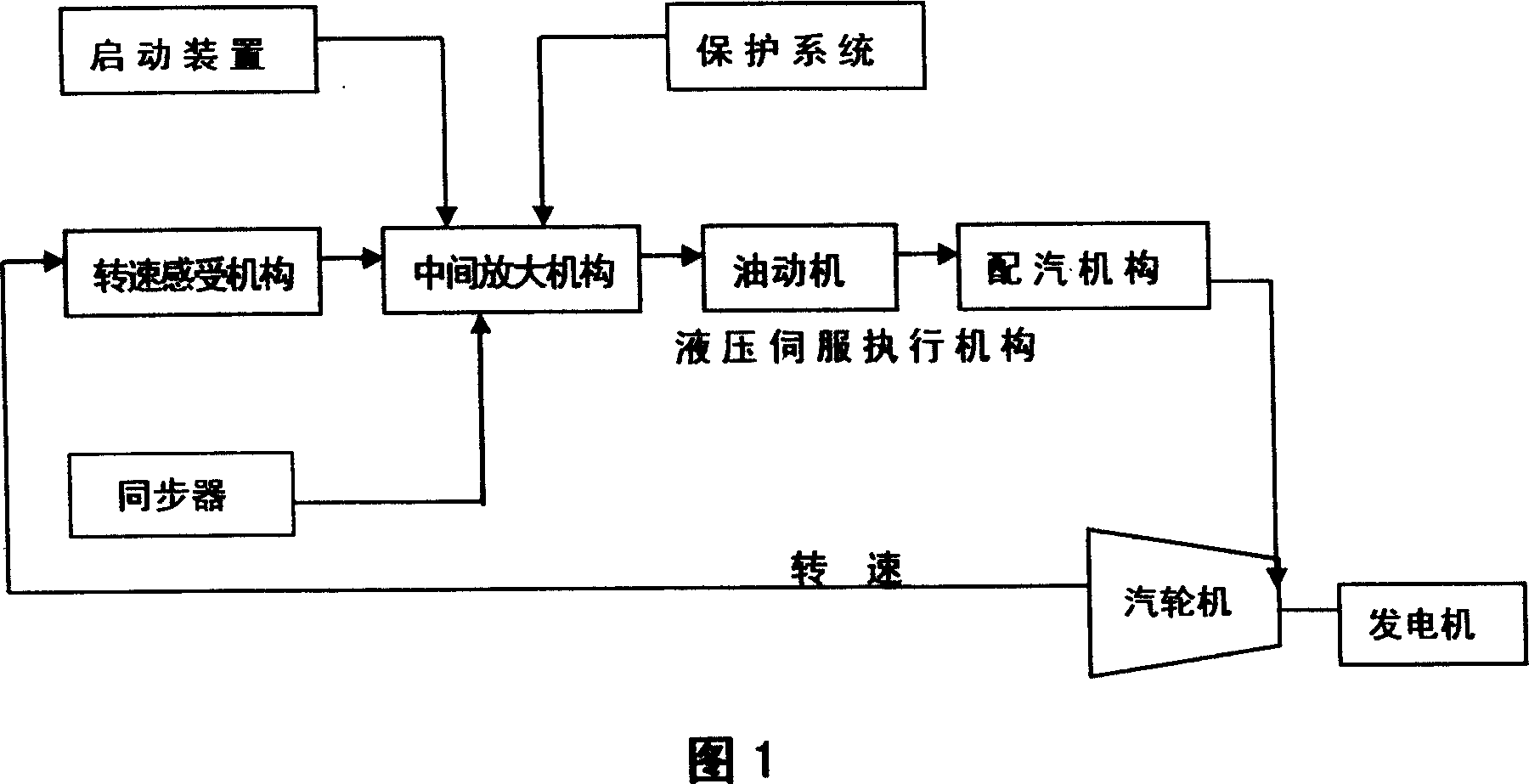

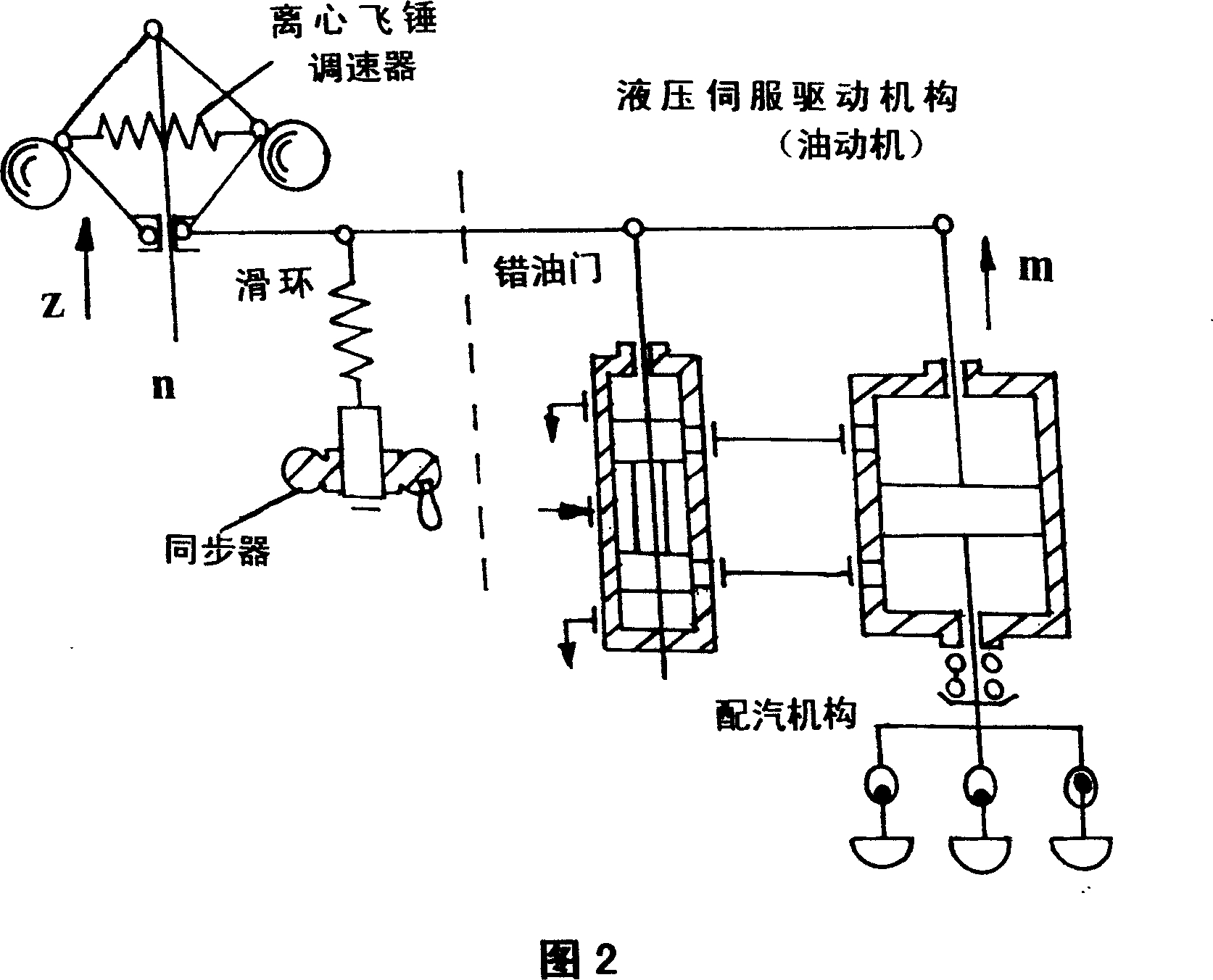

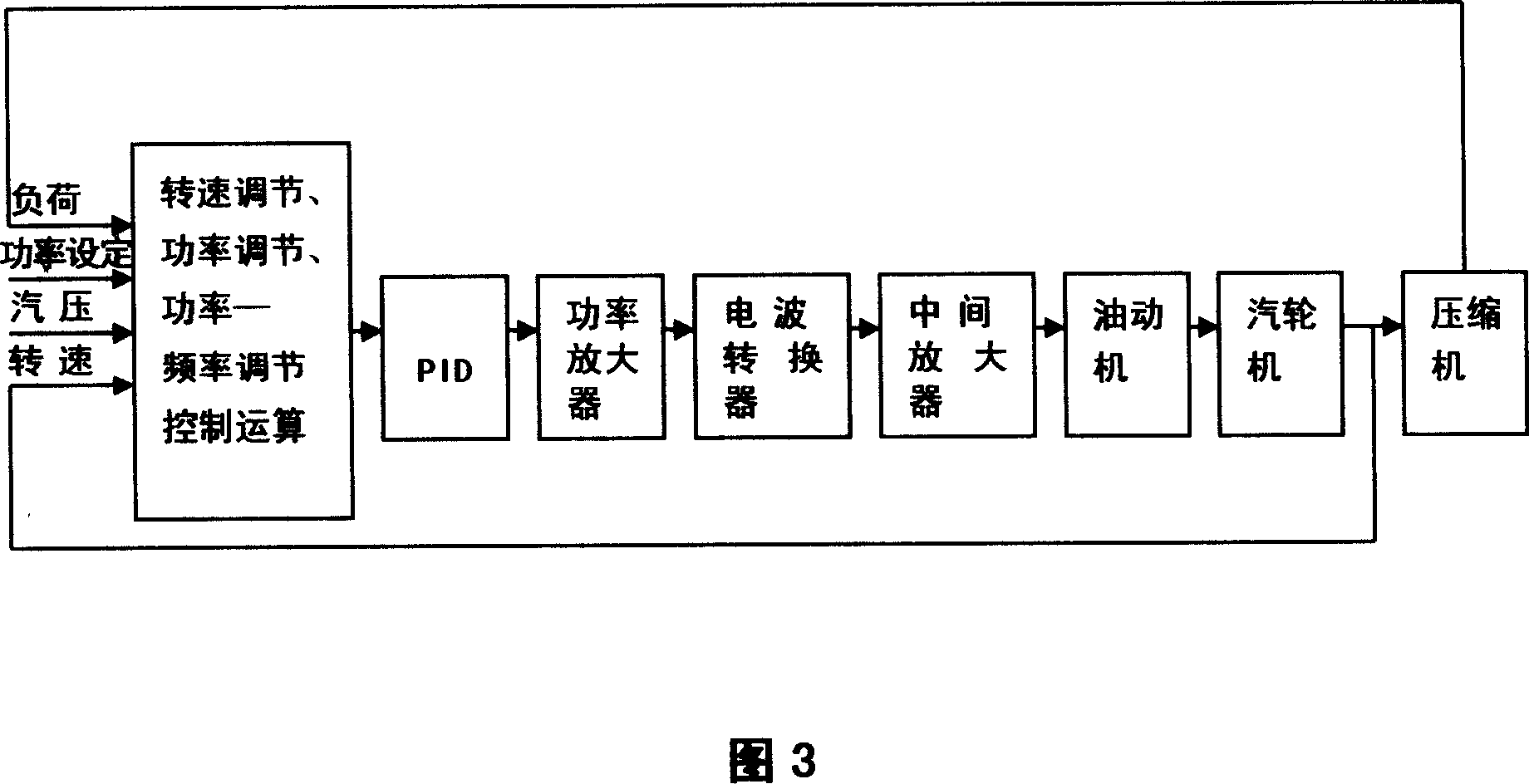

Speed adjustment control system of steam turbine

InactiveCN1959067AImprove responsivenessQuick responseMachines/enginesEngine componentsSpeed control systemControl signal

A speed controlling device of steam turbine consists of rotation speed sensing mechanism, intermediate amplifying mechanism, synchronizer, start-up unit, oil supplier and valve actuating mechanism. It is featured as calibrating relation of air intake flow on steam turbine to stroke of oil supplier to be approximately linear relation, utilizing synchronizer to act on intermediate amplifier to generate control signal for controlling stroke of oil supplier so as to change rotary speed of steam turbine.

Owner:沈阳创思达自动化系统有限公司

Mixed tuned hybrid blade related method

InactiveUS20060029501A1Reducing and more effectively damping vibrationIncrease dampingPropellersOther chemical processesImpellerFilling materials

A steam turbine blade includes a shank portion and an airfoil portion. The airfoil portion is formed with at least one pocket filled with a polymer filler material chosen as a function of natural frequency impact on the turbine blade or as a function of the damping characteristics of the filler materials. A steam turbine rotor wheel includes a plurality of blades secured about a circumferential periphery of the wheel, each blade having one or more pockets in the airfoil portion, the plurality of blades divided into two groups of blades. The pockets of one group of blades are filled with one or more polymer filler materials, and the pockets of the other group of blades filled with one or more polymer filler materials, wherein the polymer filler materials in the one group of blades creates different natural frequencies or damping characteristics in the blades of the one group than the polymer filler materials in the blades of the other group. The two groups of blades are assembled on the rotor wheel in accordance with a predetermined pattern.

Owner:GENERAL ELECTRIC CO

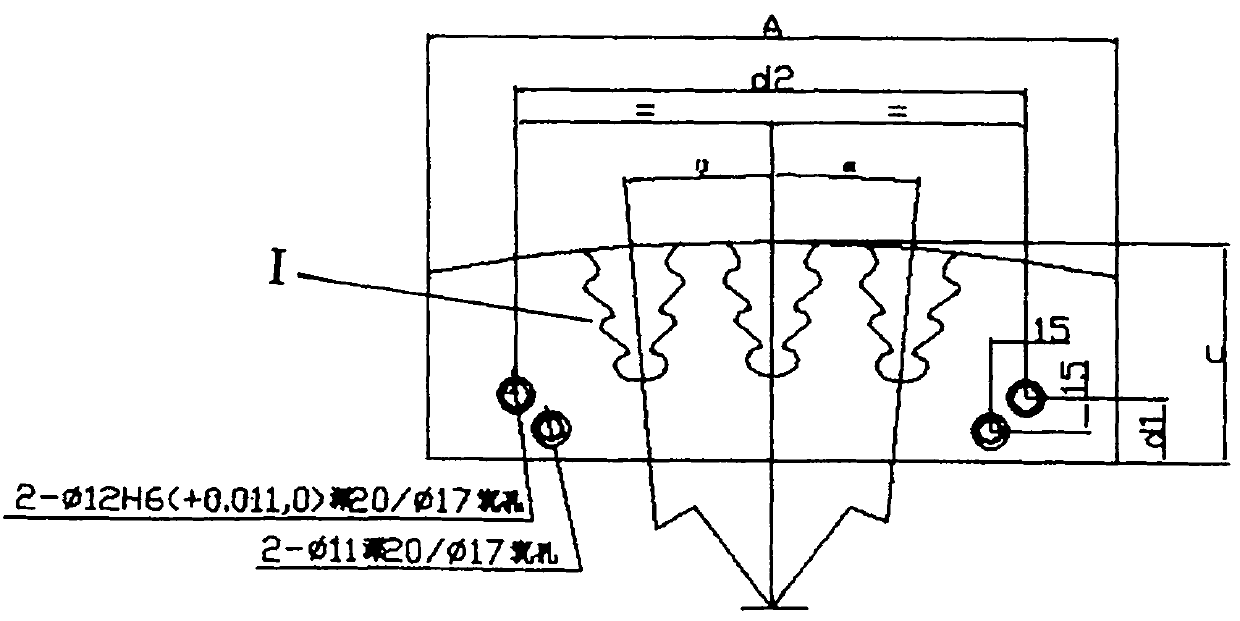

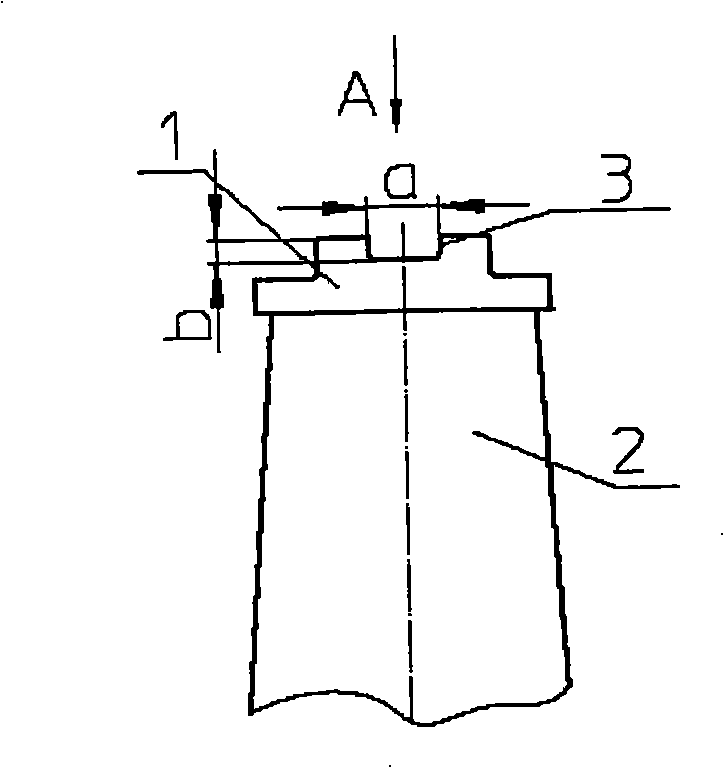

Steam turbine blade fitting measuring tool and processing technology thereof

ActiveCN101947723AAvoid Batch Quality IssuesShorten the manufacturing cycleMetal working apparatusImpellerSteam turbine blade

The invention discloses a steam turbine blade fitting measuring tool and a processing technology thereof. The fitting measuring tool is a fake impeller simulating an arc of steam turbine rotor impeller, the fake impeller is provided with a plurality of blade assembling slots distributed in a radial manner, the contour line, the radial radius and the circumferential graduation of the assembling slot are all consistent with those of the assembling slot of real impeller, and the bottom of the slot is provided with a blade locking screw hole and screws. The fitting measuring tool is used for the pre-assembly of blades, in order to inspect the quality indexes of assembly in advance, avoid the quality-related problem of blades in batch, reduce maintenance rate, enable blades to meet the assembly requirement in production workshop, enhance working efficiency, shorten assembly period of unit, and lower economic losses.

Owner:DONGFANG TURBINE CO LTD

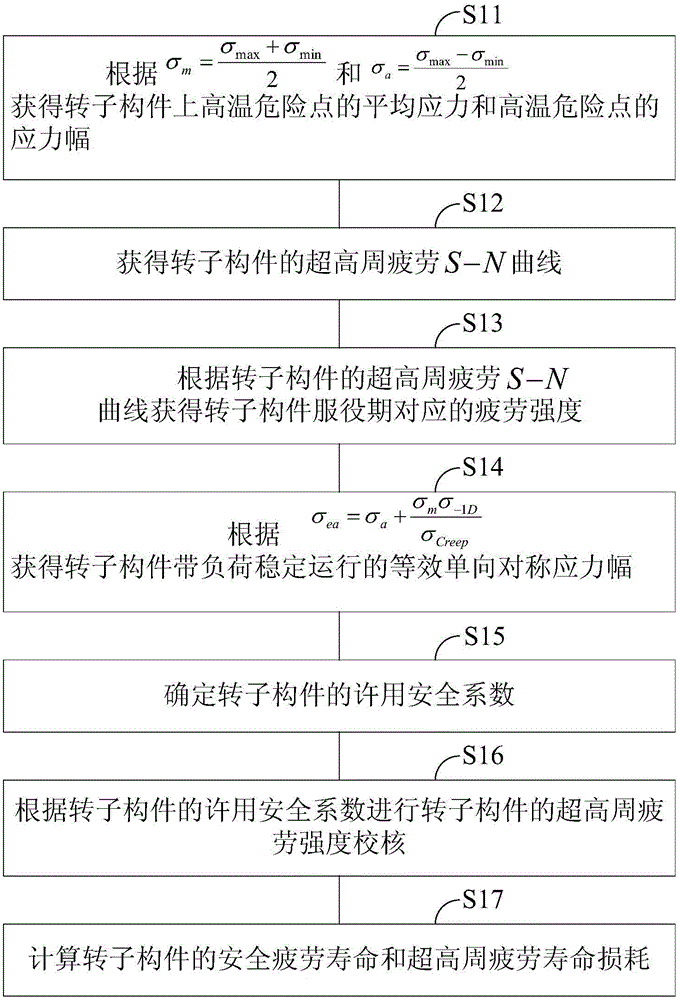

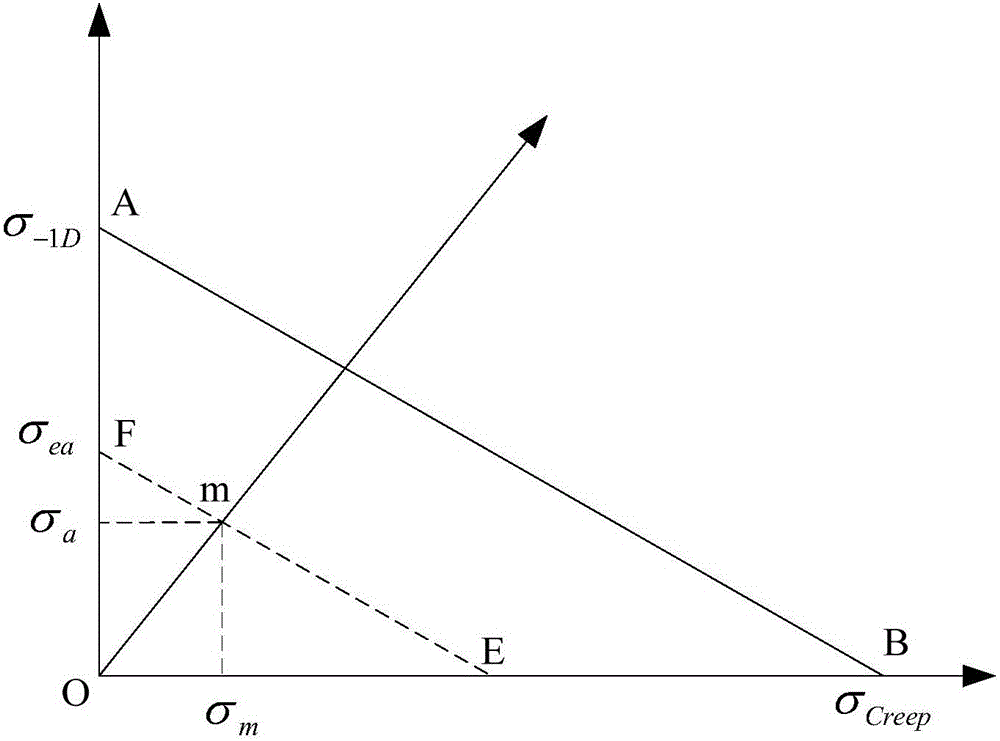

Method for assessing ultra-high cycle fatigue strength and fatigue life of steam turbine rotor

ActiveCN106202630AExact fatigue strengthAccurate Fatigue LifeDesign optimisation/simulationSpecial data processing applicationsEngineeringFatigue life assessment

The invention discloses a method for assessing ultra-high cycle fatigue strength and fatigue life of a steam turbine rotor. The method comprises the following steps of: obtaining mean stress of high-temperature dangerous points and stress amplitude of the high-temperature dangerous points on a rotor component according to sigma<m>=(sigma<max>+sigma<min>) / 2 and sigma=(sigma<max>-sigma<min>) / 2; obtaining an ultra-high cycle fatigue S-N curve of the rotor component; obtaining fatigue strength corresponding to a service period of the rotor component according to the ultra-high cycle fatigue S-N curve of the rotor component; obtaining an equivalent unidirectional symmetric stress amplitude of on-load stable operation of the rotor component according to sigma<ea>=sigma+(sigma<m>*sigma<-1D>) / sigma<Creep>; determining an allowable security coefficient of the rotor component; checking the ultra-high cycle fatigue strength of the rotor component according to the allowable security coefficient of the rotor component; and calculating a security fatigue life and an ultra-high cycle fatigue life loss of the rotor component. The method for assessing the ultra-high cycle fatigue strength and fatigue life of the steam turbine rotor can realize the quantitative calculation and assessment of the high-temperature ultra-high cycle fatigue strength, fatigue life and loss.

Owner:SICHUAN UNIV

Heat-resisting alloy for 700-DEG C ultra-supercritical steam turbine rotor and preparation method thereof

ActiveCN105112728AImprove stabilityImprove performanceBlade accessoriesMachines/enginesAlloyImpurity

The invention relates to heat-resisting alloy for a 700-DEG C ultra-supercritical steam turbine rotor and a preparation method thereof, and belongs to the technical field of heat-resisting alloy. The alloy comprises the following ingredients by weight percent: 0.04 to 0.06 percent of C, 19 to 21 percent of Cr, 8.6 to 9.0 percent of Mo, 11 to 13 percent of Co, 0.40 to 0.80 percent of W, 1.10 to 1.30 percent of Al, 1.20 to 1.40 percent of Ti, 0.20 to 0.50 percent of Nb, less than or equal to 0.15 percent of Fe, 30 to 50ppm of B, 0.01 percent of Zr, 0.002 percent of Mg and the balance of Ni and impurities; wherein, the content of Al and Ti needs to satisfy the following condition: (Al+Ti) is more than or equal to 2.5 percent and less than or equal to 2.6 percent, and Ti / Al is more than or equal to 1.0 or less than or equal to 1.1. A VIM, VAR and ESR triplet process is used for smelting the alloy, soft-sheath forging is adopted, and the heat-resisting alloy has advantages that the comprehensive performance is excellent and the alloy is suitable for manufacturing the 700-DEG C ultra-supercritical steam turbine rotor.

Owner:CENT IRON & STEEL RES INST

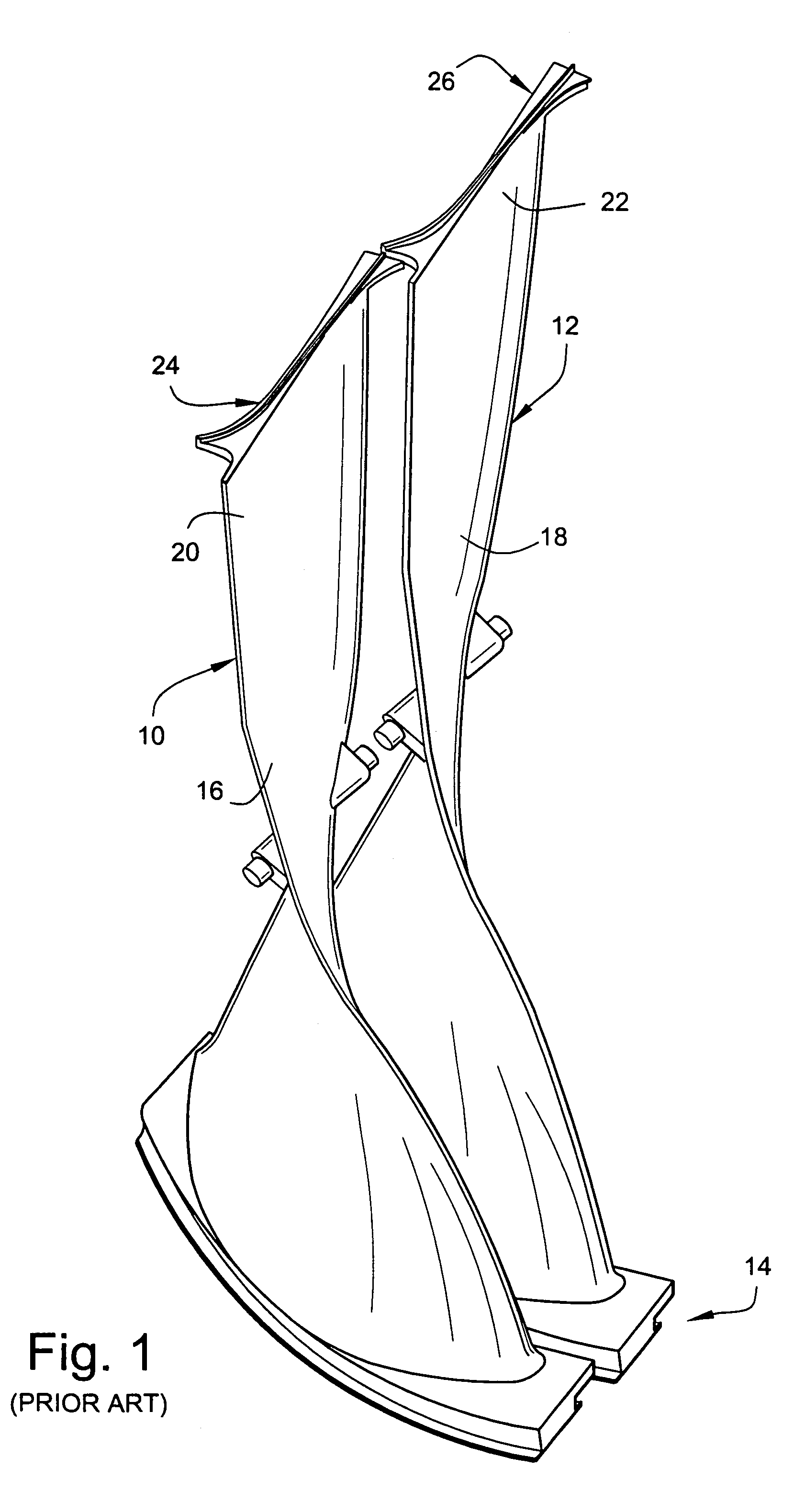

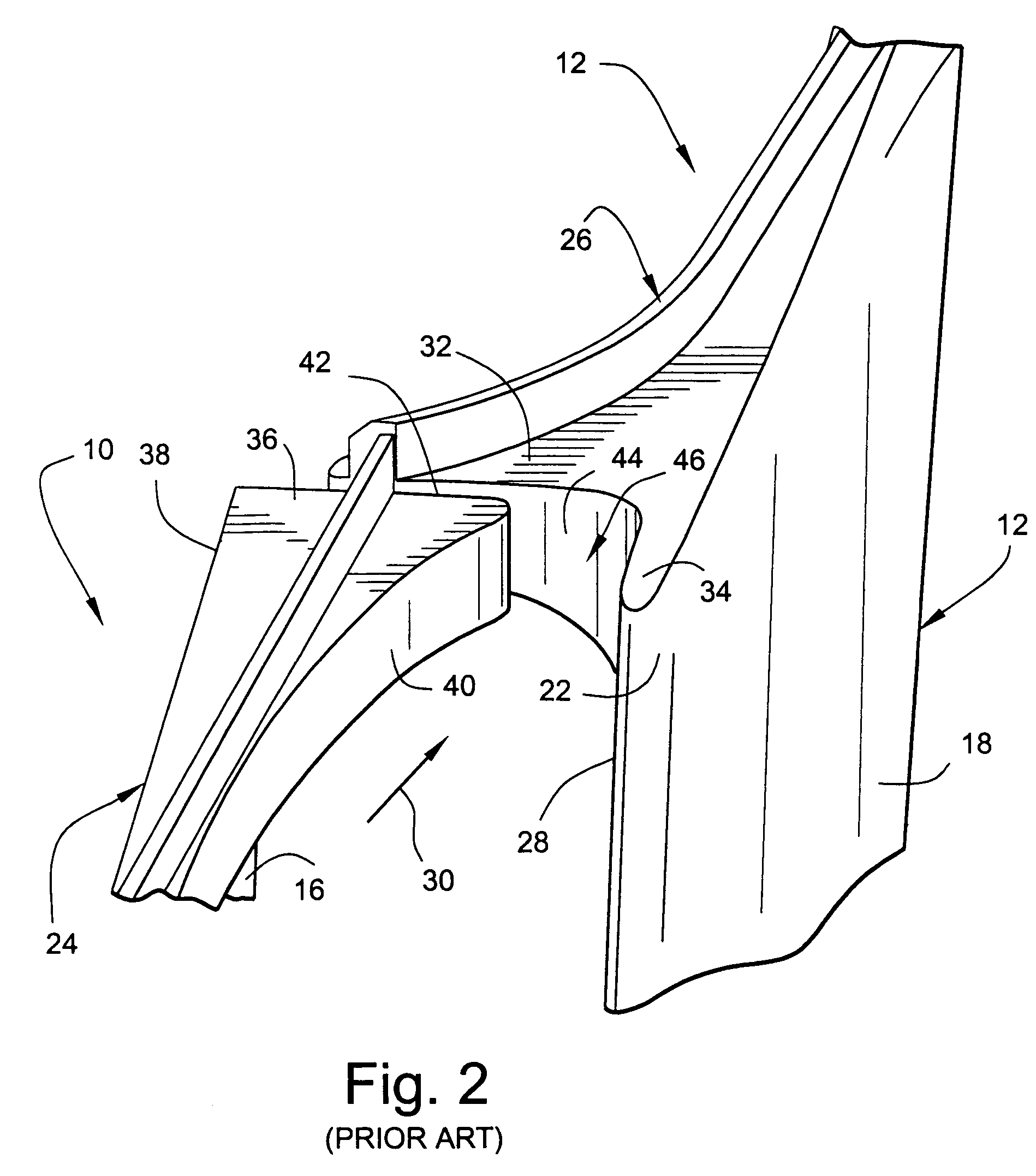

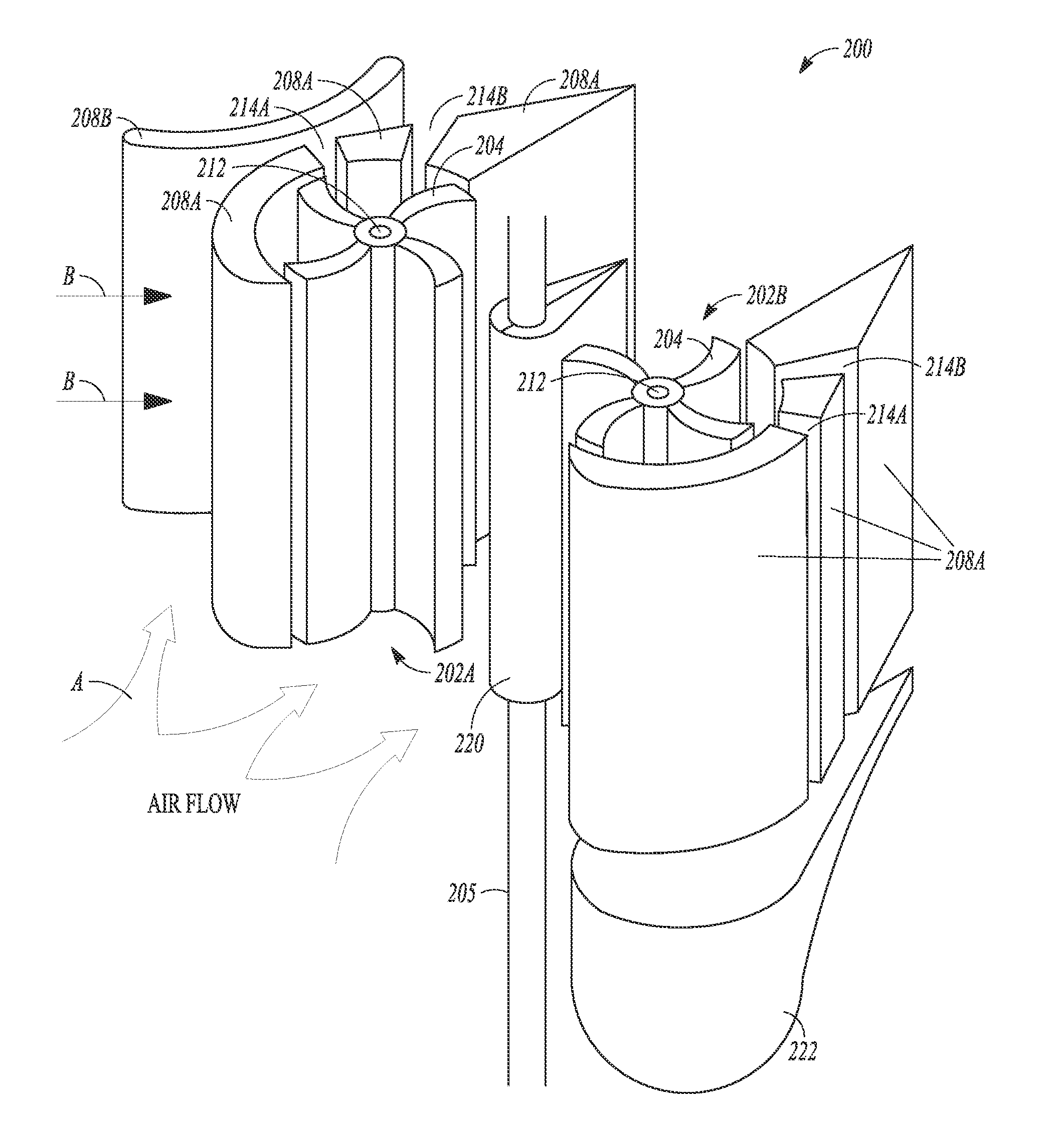

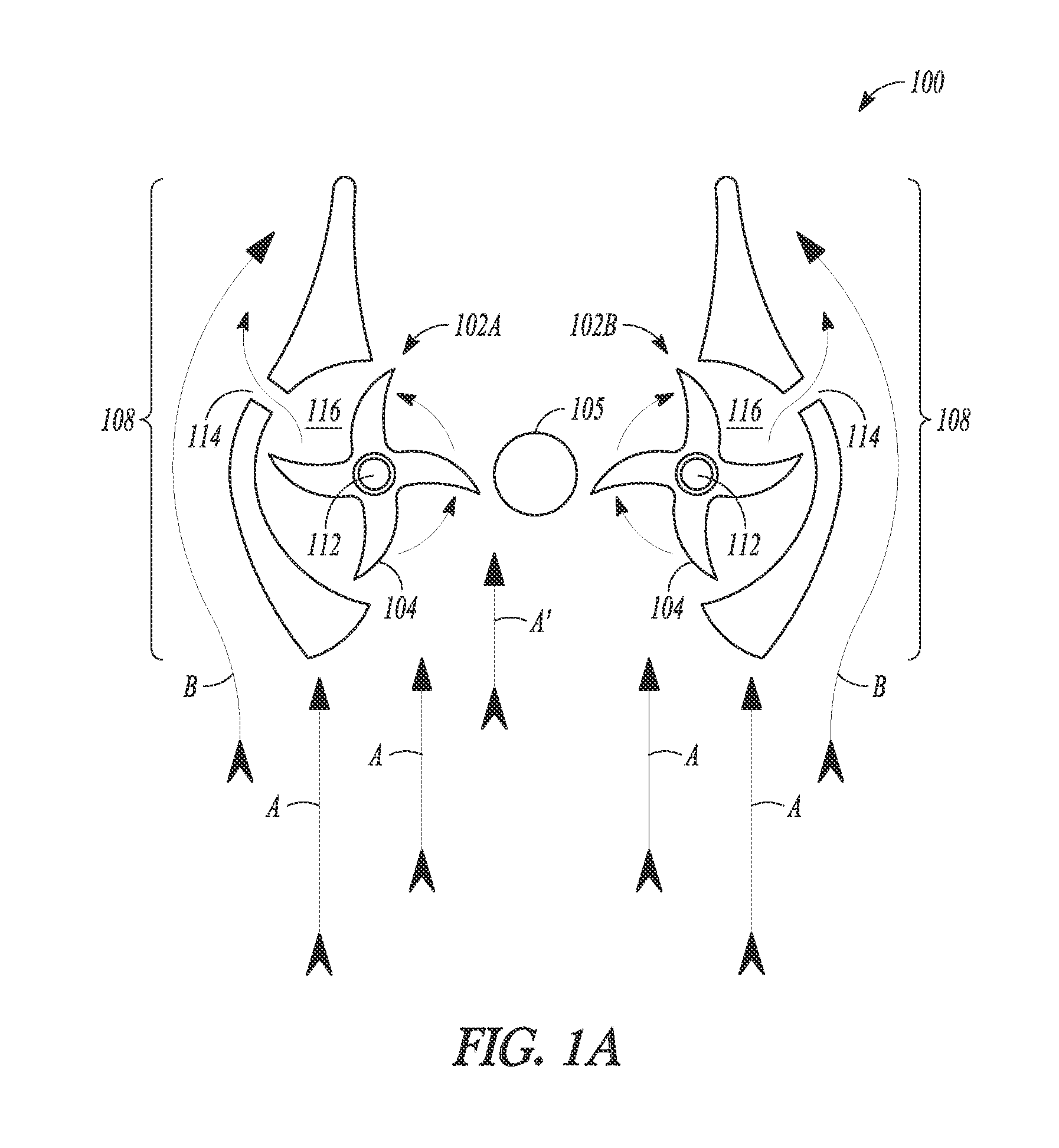

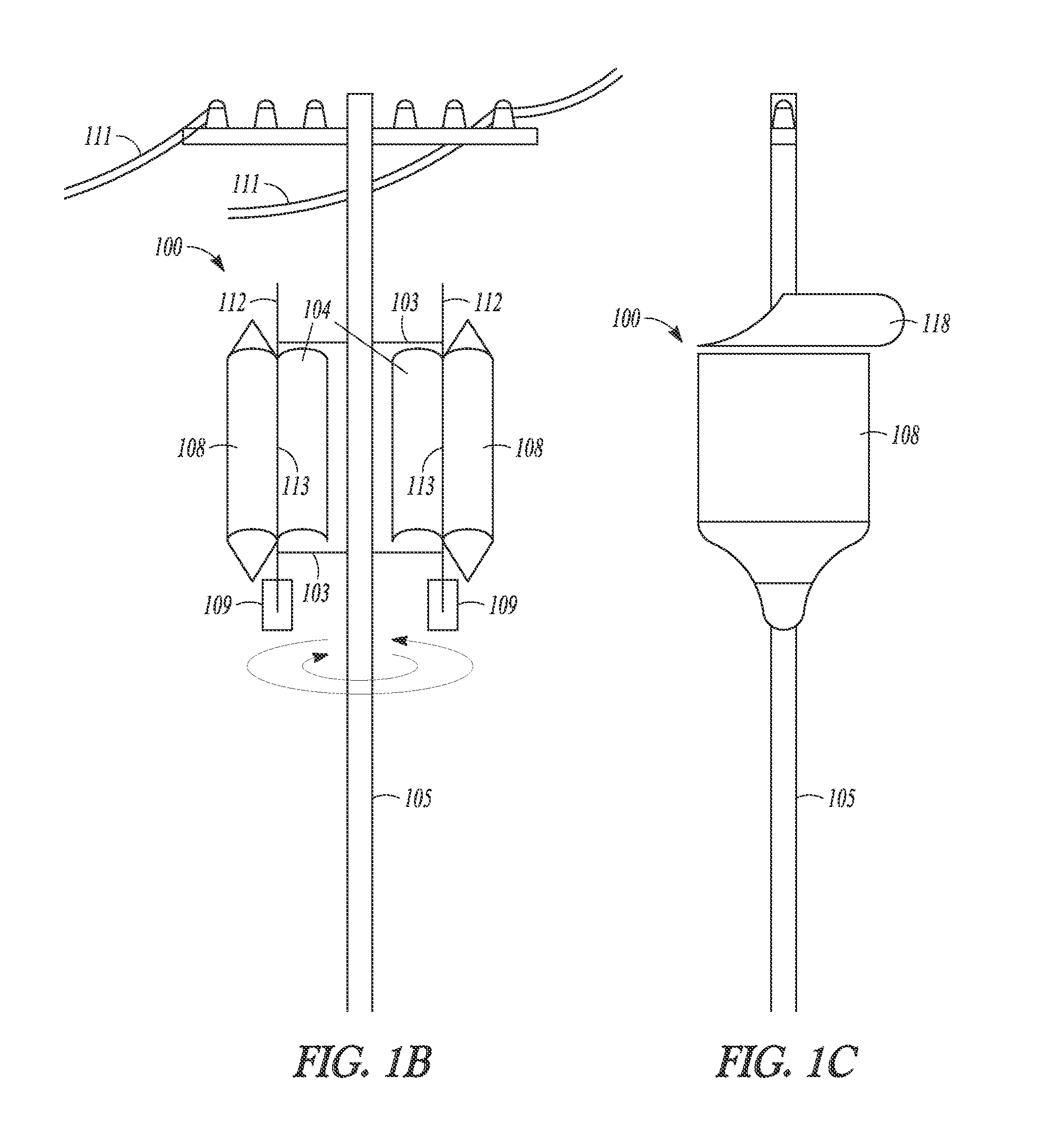

Wind turbine

A vertical axis wind turbine system is provided that converts wind enemy into electrical or mechanical enemy. The turbine comprises at least one turbine rotor with a plurality of curved blades for receiving head-on wind generated airflow. Shield means mountable around at least a portion of the rotor serve to protect the upstream-moving blades from head-on wind airflow and thereby reduce drag. In one embodiment, load compensation means are provided to adjust the moment of inertia of the turbine rotor. One or more of the turbine rotor blades is hollow and defines a closed volume for holding a fluid, the fluid being displaceable in use through baffle means towards or away from the vertical axis of the rotor as the rotational velocity of the rotor changes.

Owner:POOLE THOMAS BERSTREETCAR

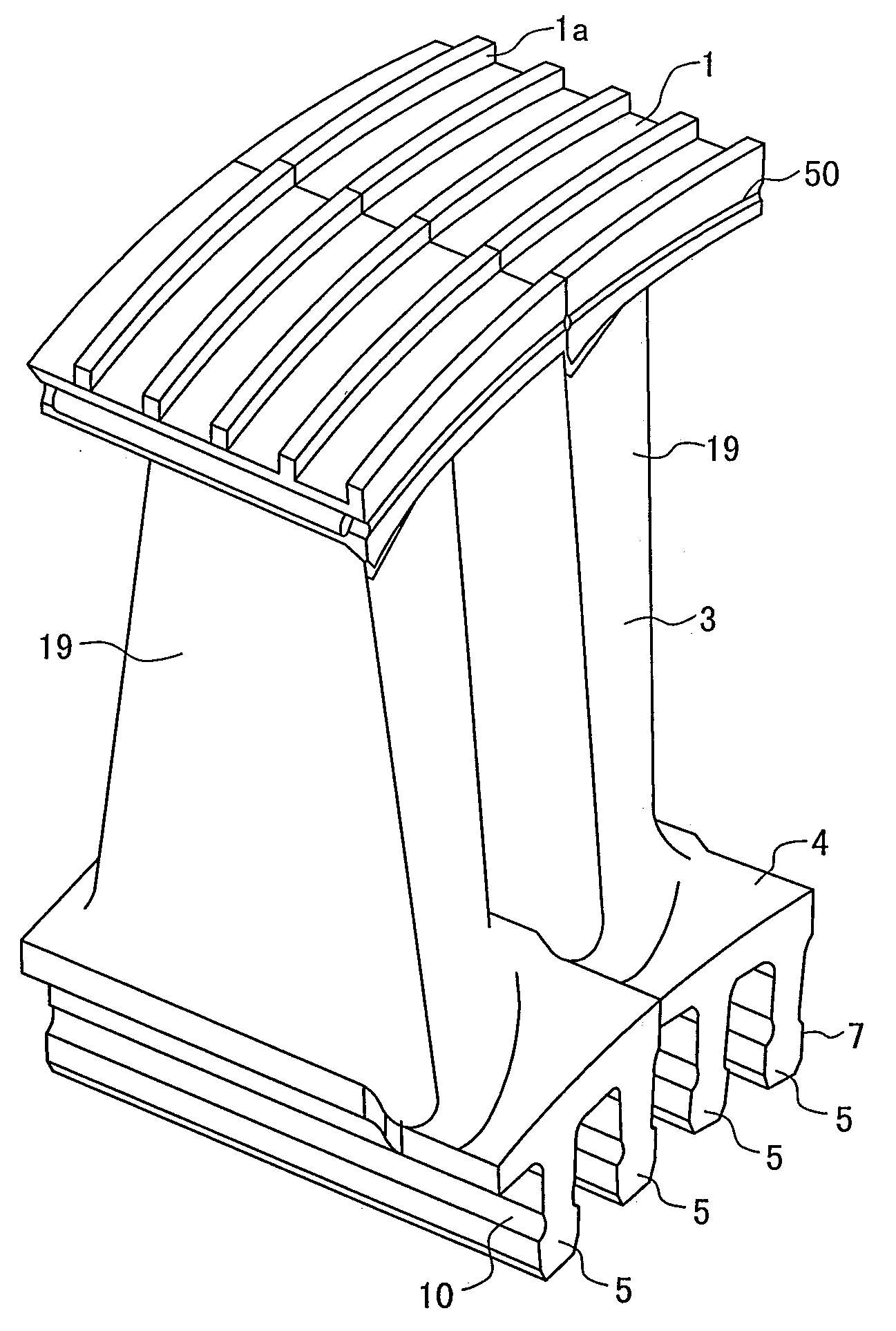

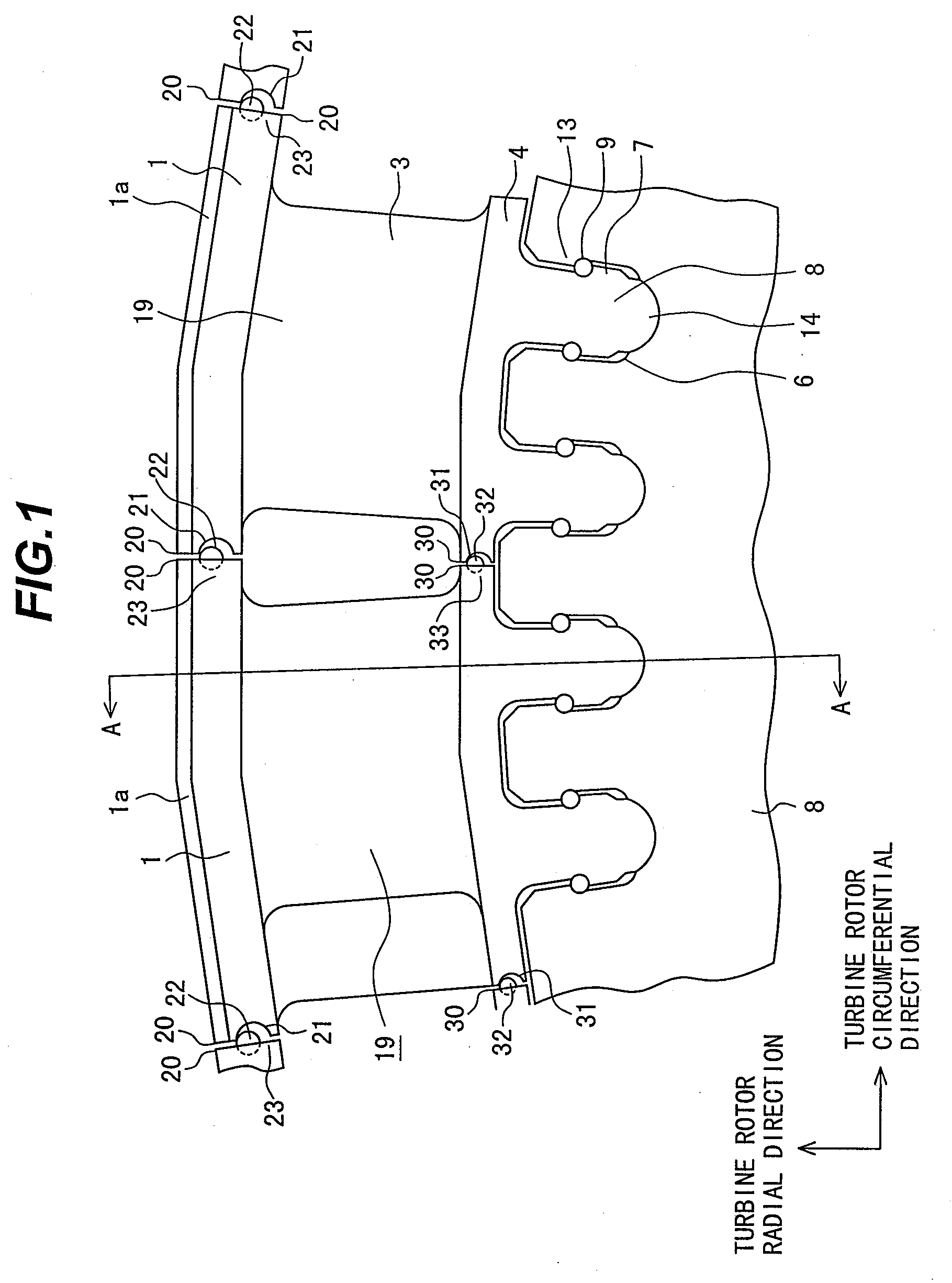

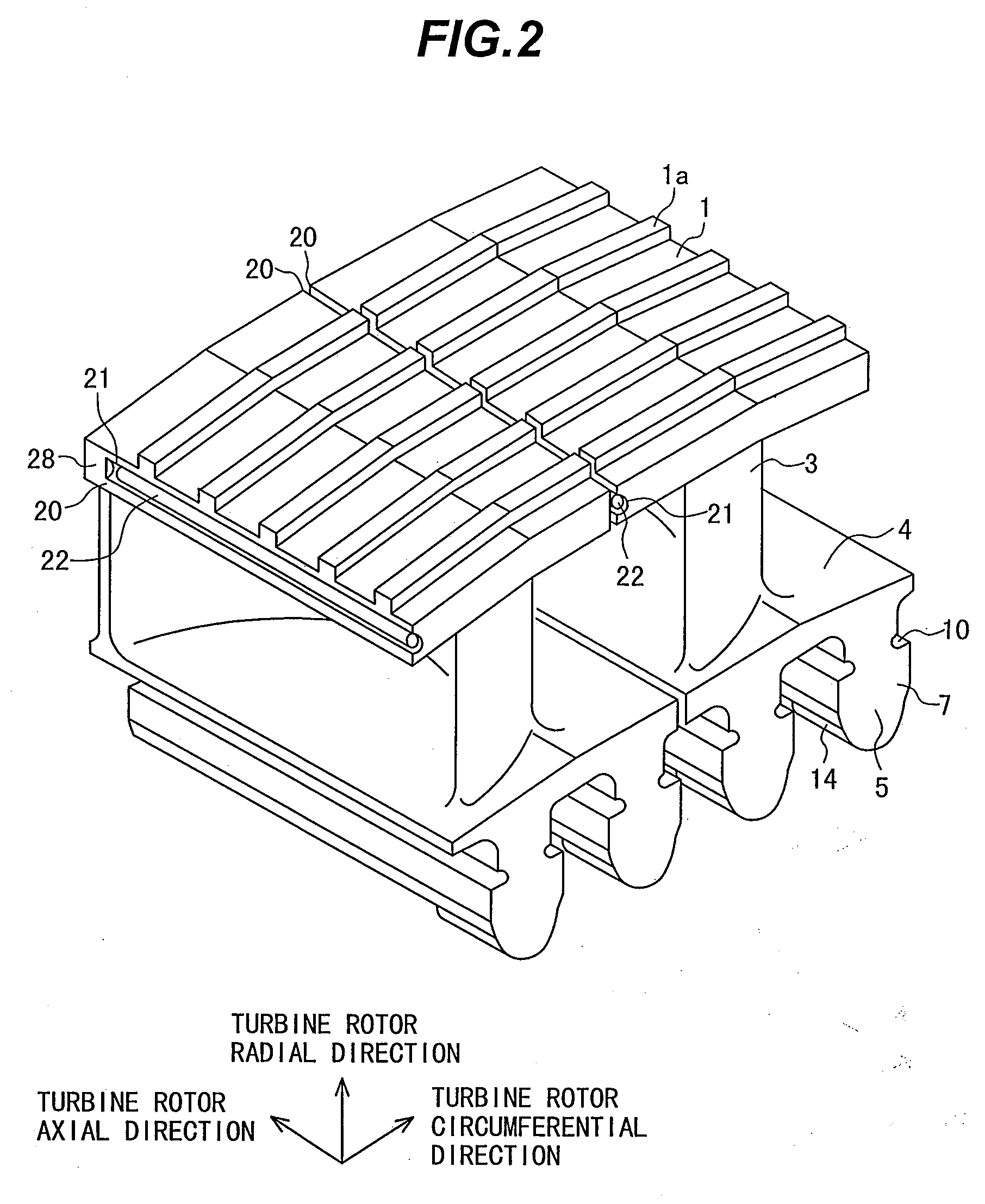

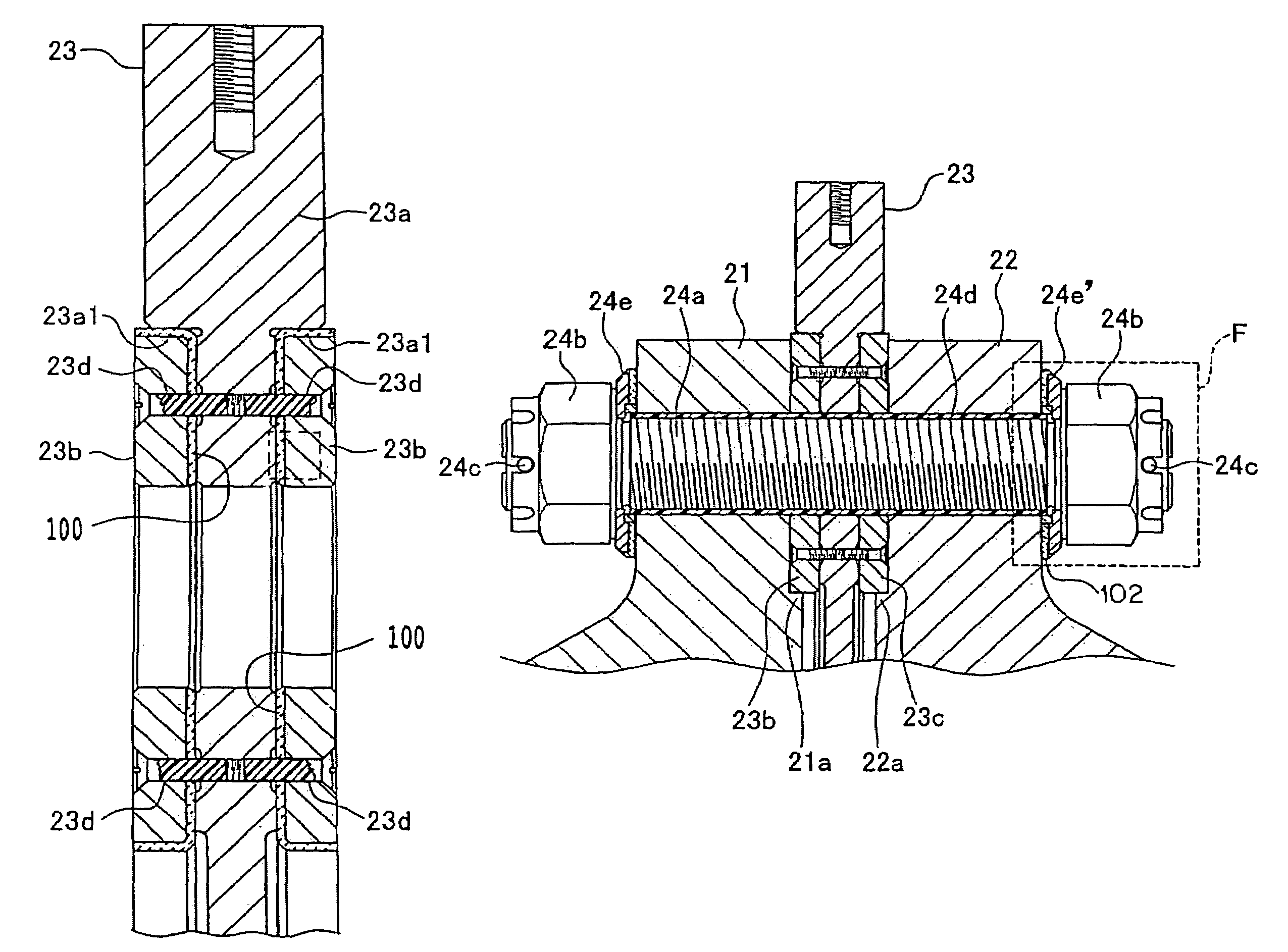

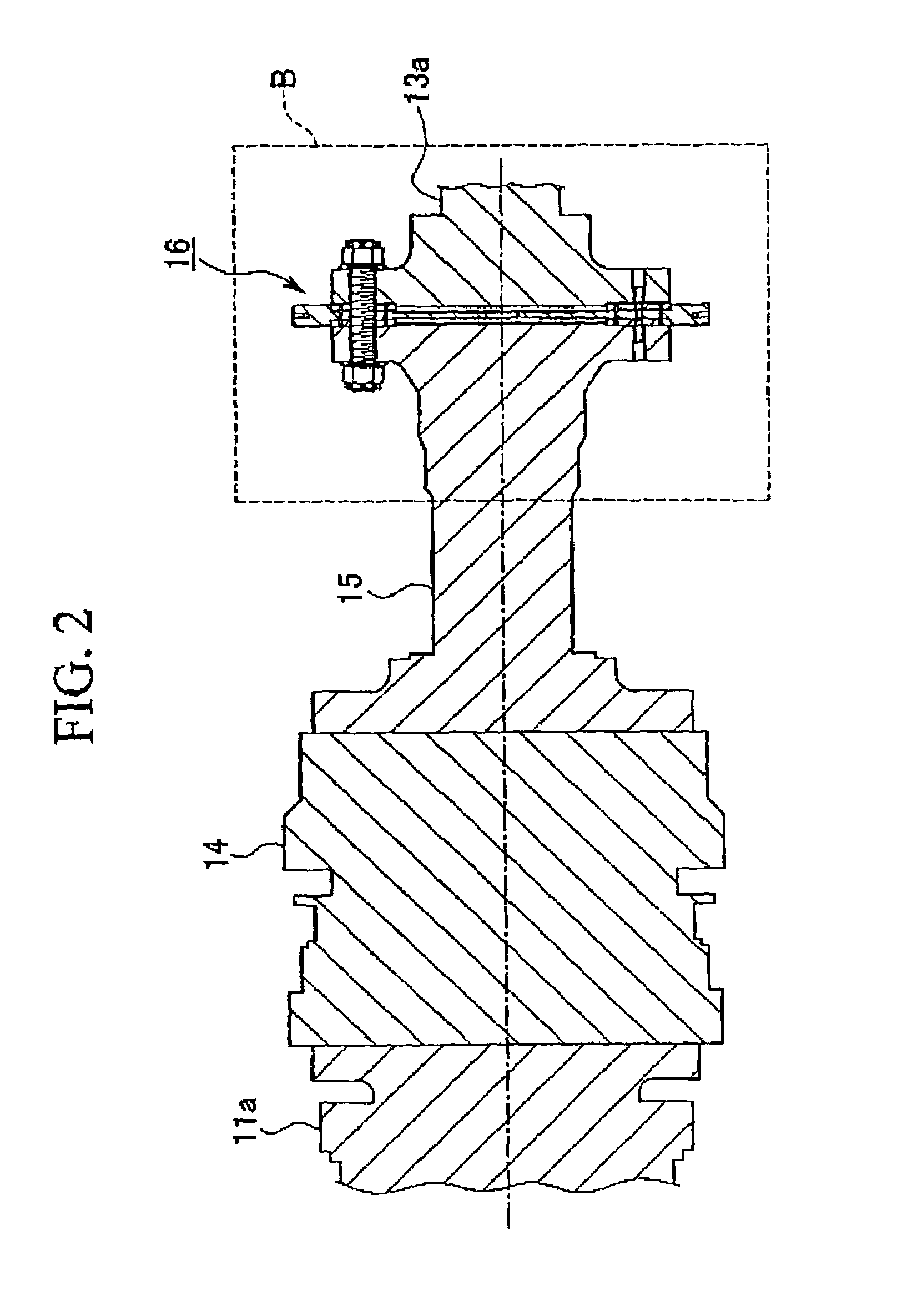

Turbine Rotor

InactiveUS20100028155A1Improve welding reliabilityBlade accessoriesReaction enginesHigh pressureSteam turbine rotor

An object of the present invention is to provide a turbine rotor with high reliability of strength. The turbine rotor includes two rotors which are connected at the butted portions of the rotors via a weld without forming penetration beads. Specifically, the turbine rotor includes a rotor for low pressure, a rotor for high pressure, and a center hole formed at a center portion of the turbine rotor. The rotors for low pressure and for high pressure are integrated together into a steam turbine rotor by welding respective ends of the rotors to each other. The respective ends of the rotors are in contact with each other via at least two contact faces in a radial direction and an axial direction of the turbine rotor. At least parts of the respective ends are welded together.

Owner:HITACHI LTD

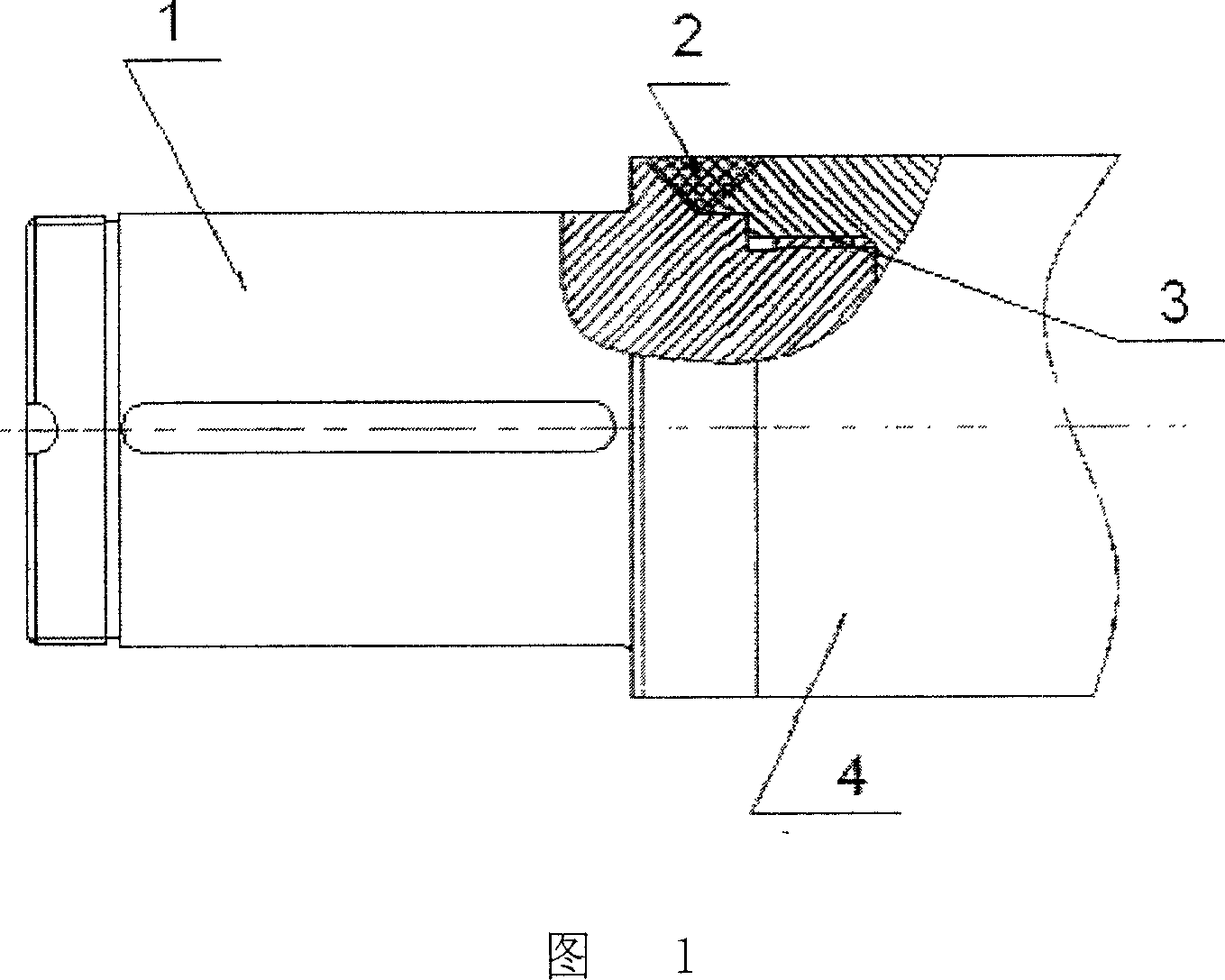

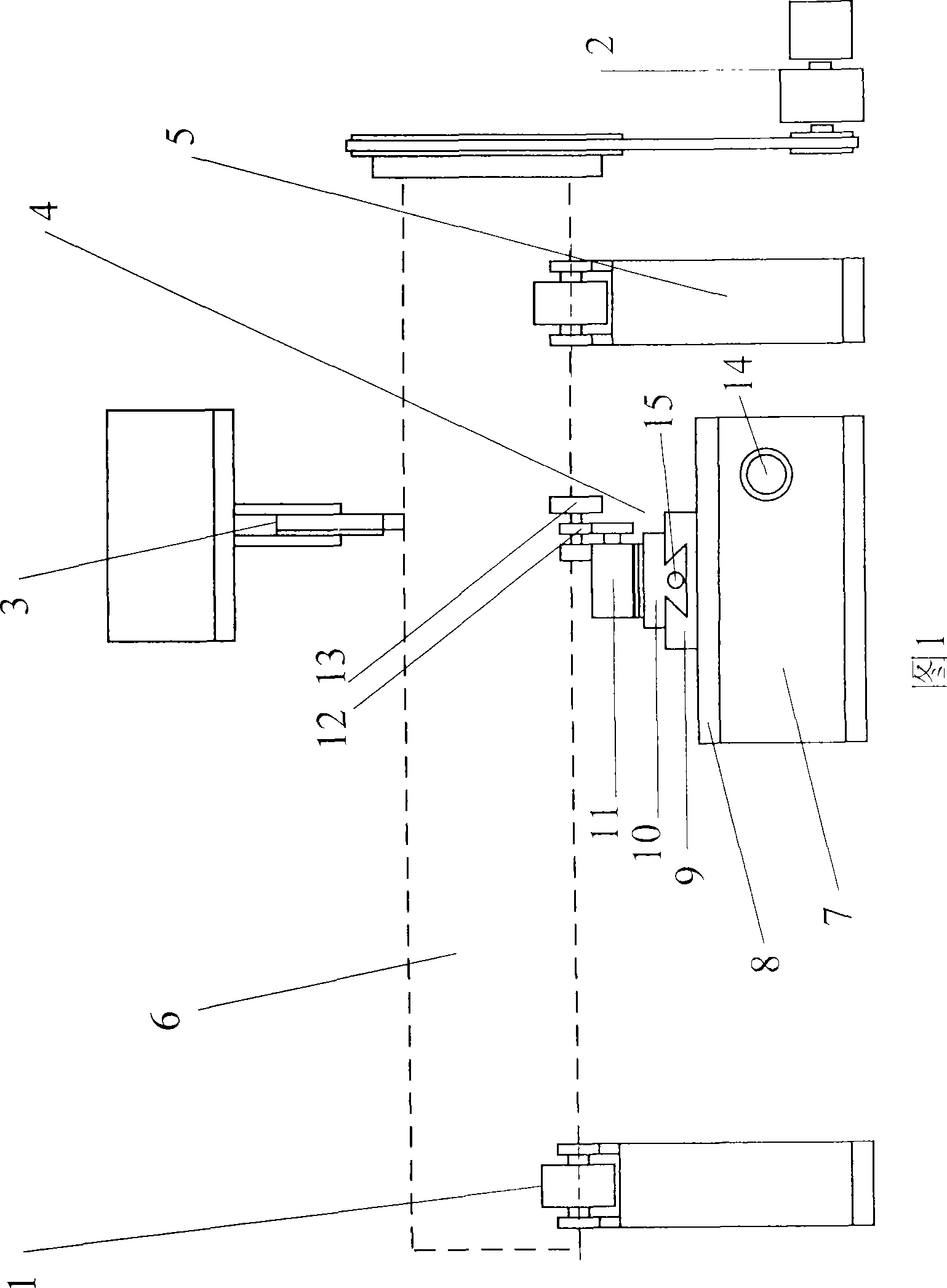

Apparatus for repairing generator rotor shaft neck

ActiveCN101428384ALight in massReduce production efficiencyRevolution surface grinding machinesPower stationReduction drive

The invention discloses a repairing device for a shaft neck of a power generator rotor, which belongs to repairing devices for a mechanical shaft, and the repairing device solves the problems that the production efficiency is low, the quality of welding, polishing and polishing is poor, and the precision required after repairing is not achieved in the prior art. The repairing device comprises support frames (1 and 5) of the power generator rotor, a power generator rotor (6) and a driving motor and a decelerator (2) of the power generator rotor, wherein, a welding machine (3) is arranged on one side of the power generator rotor (6), a bracket (7) of a grinding mechanism is arranged on the other side of the power generator rotor (6), a lifting table (8) capable of lifting in the vertical direction is arranged on the bracket (7) of the grinding mechanism, a fixed block (9) and a movable block (10) are arranged on the lifting table (8), the movable block (10) in the swallow-tailed groove of the fixed block (9) can feed forwards or exit backwards along the horizontal direction through driving a leading screw (15), a grinding head driving motor (11) is fixedly arranged on the movable block (10), and a grinding head (13) is arranged on the output shaft thereof. The repairing device is suitable for reparation of the shaft diameter of the steam turbine rotor after abrasion in the power station.

Owner:STATE GRID CORP OF CHINA +1

Rotor coupling having insulated structure

InactiveUS7530757B2Prevent galvanic corrosionPotential of each rotor can be reducedMolten spray coatingCombination enginesElectricityCoupling

A rotor coupling having insulated structure which can assuredly prevent galvanic corrosion of beating members, rotors and the like which is caused by shaft voltage, is provided in a shaft system that requires insulation. A generator is disposed in between a steam turbine and a gas turbine or a rotating machinery such as another steam turbine. The rotor coupling having insulated structure is employed in power generating equipment in which a generator is disposed in between a steam turbine and a gas turbine or a rotating machinery such as another steam turbine, a generator rotor and a rotating machinery rotor are connected, a first grounding electrode is provided to the steam turbine rotor, and a second grounding electrode is provided to the generator rotor, wherein both the rotors between the generator and the steam turbine are connected in an electrically insulated state.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

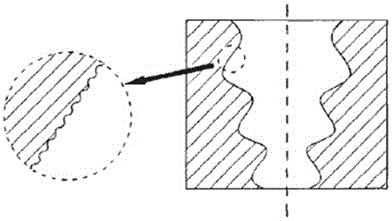

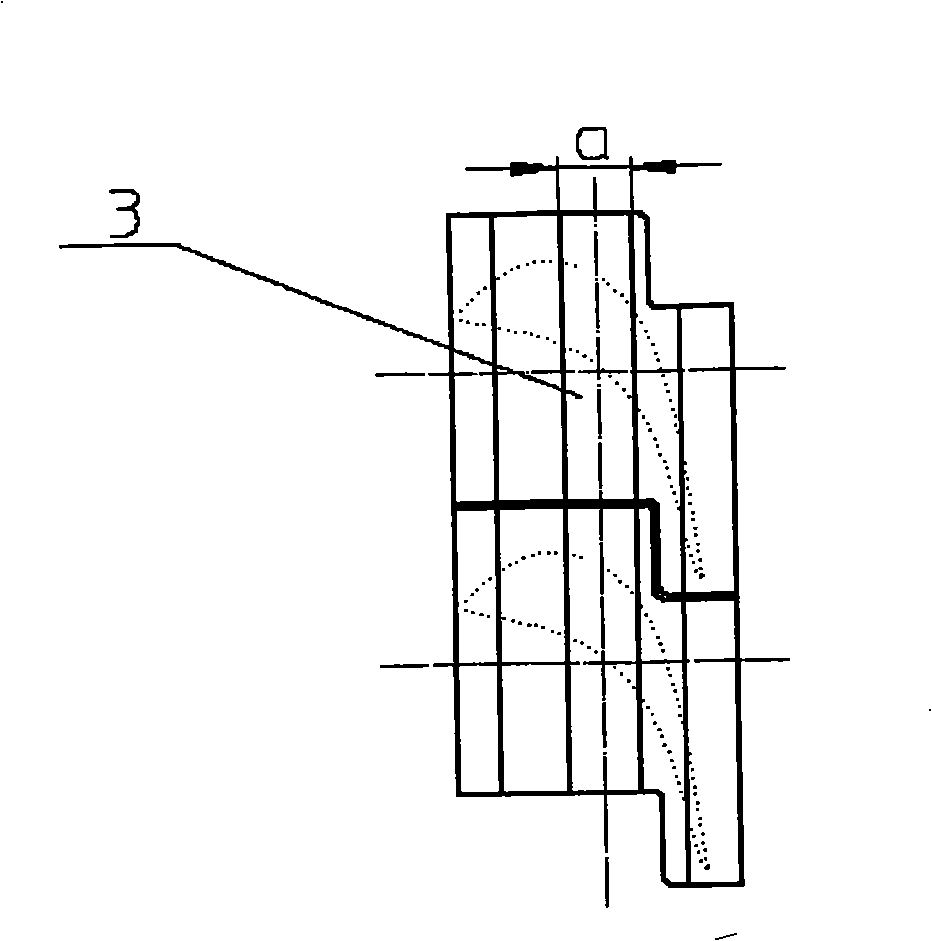

Steam turbine rotor blades cover band structure and its machining process

ActiveCN101285404AImprove orderImprove work efficiencyBlade accessoriesMachines/enginesImpellerProcess module

The invention discloses a shroud structure of a turbine rotor blade and the processing technology of the same. A plurality of rotor blades with blade tips are arranged on a blade wheel of a turbine rotor, the blade tips of adjacent rotor blades are in fit with each other to combine a ring and form the shroud; when the turbine is static and the rotor blade is not twisted, two axial end surfaces of the shroud are indented, when the turbine runs and the rotor blade is twisted, two axial end surfaces of the shroud are on the same level. The processing technology comprises the steps of: (1) processing a plurality of pre-twisted process modules each of which comprises two module-shaped parts of the whole structure, the two module-shaped parts are alternative in parallel with the alternative distance equal to the alternative distance between two adjacent blade tips after the blades are twisted; (2) arranging all blades on the blade wheel, lathing a circular groove which matches with the pre-twisted process modules in width on a peripheral surface of the shroud; (3) twisting and putting the blades in the pre-twisted process modules; (4) lathing two axial end surfaces of the shroud to be on the same level; (5) dismounting the pre-twisted blocks (6) lathing the peripheral surface of the shroud.

Owner:DONGFANG TURBINE CO LTD

Zoning Control Method of Anti-fatigue Life of Steam Turbine Rotor

InactiveCN102278152AGuaranteed economyOptimal Rate of ChangeMachines/enginesEngine startersLow loadPeak value

A steam turbine rotor anti-fatigue life partition control method, the method is the following steps: (1), start the steam turbine unit of the power plant, record the structural size and operating parameters of the steam turbine rotor; (2), finite element modeling, Thermal calculations and simulation calculations under variable working conditions; (3), peak stress calculations in different temperature zones, and material fatigue characteristics analysis; (4), formulating rush rotation, medium-speed warm-up, constant-speed warm-up, grid-connected low-load warm-up, Six-stage optimized operation control plan for cutting cylinders and entering sliding pressure operation; (5) Draw optimized start-up curves, and organize construction personnel to operate the start-up and operation of steam turbine units on site. The invention reasonably distributes the anti-fatigue life loss, optimizes the change rate of operating parameters under variable working conditions, shortens the start-up time, ensures the economy of the start-up process, and meets the flexibility requirements of the peak-shaving demand of the power grid.

Owner:STATE GRID HUNAN ELECTRIC POWER CO LTD ELECTRIC POWER SCI RES INST +1

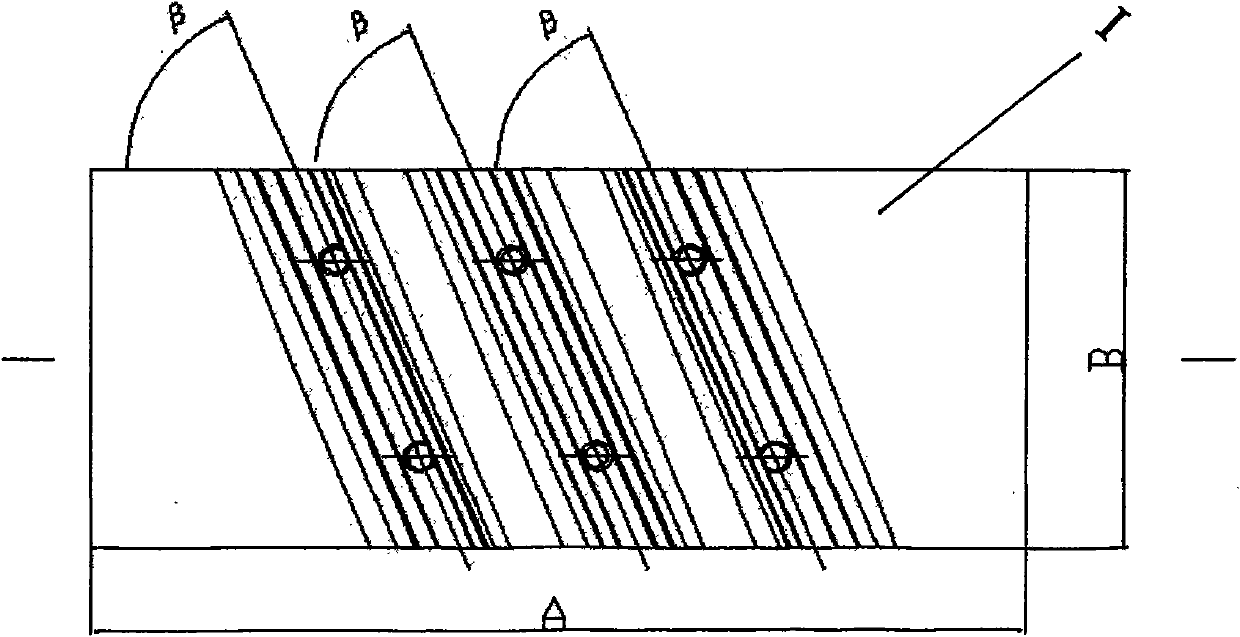

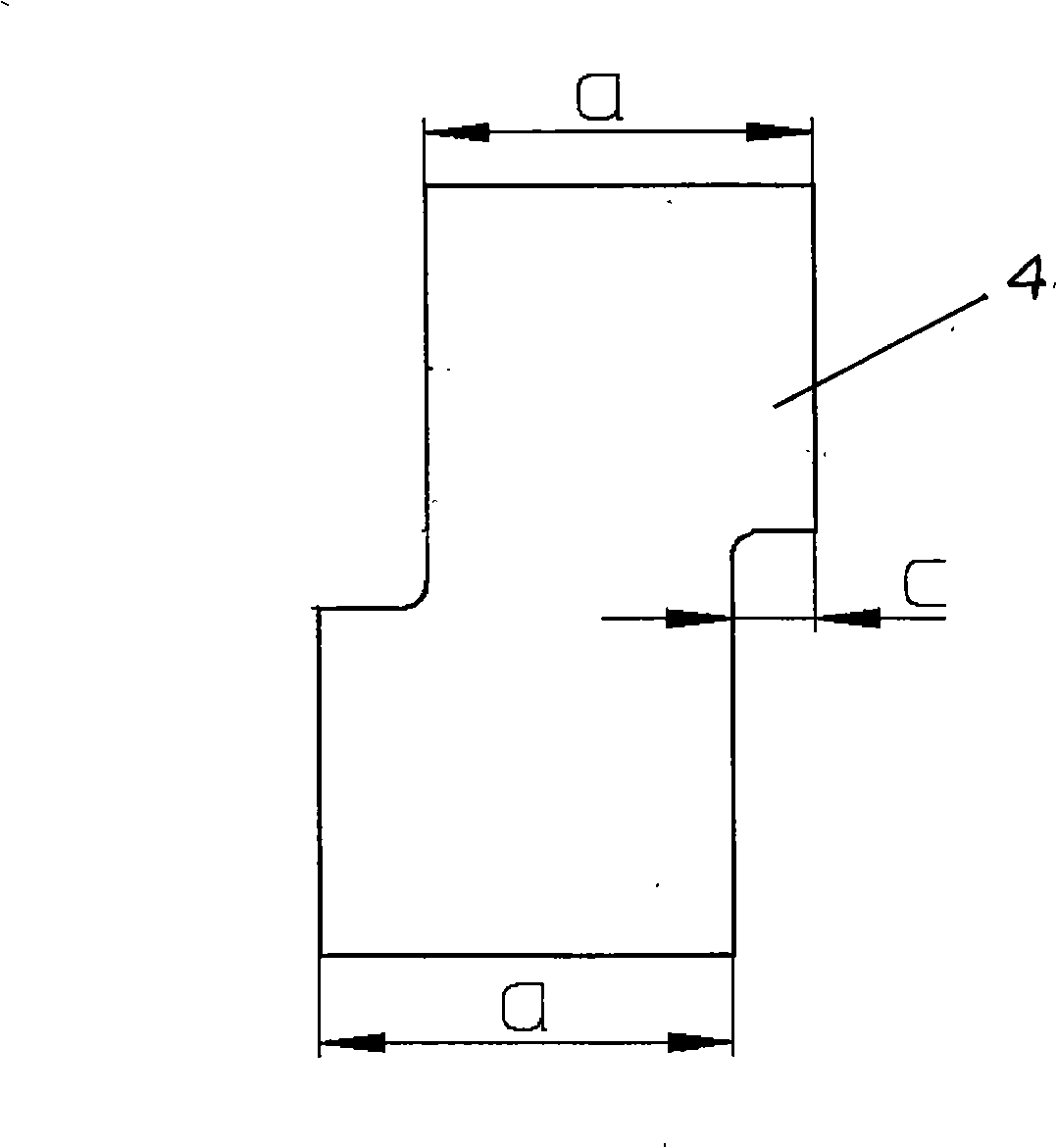

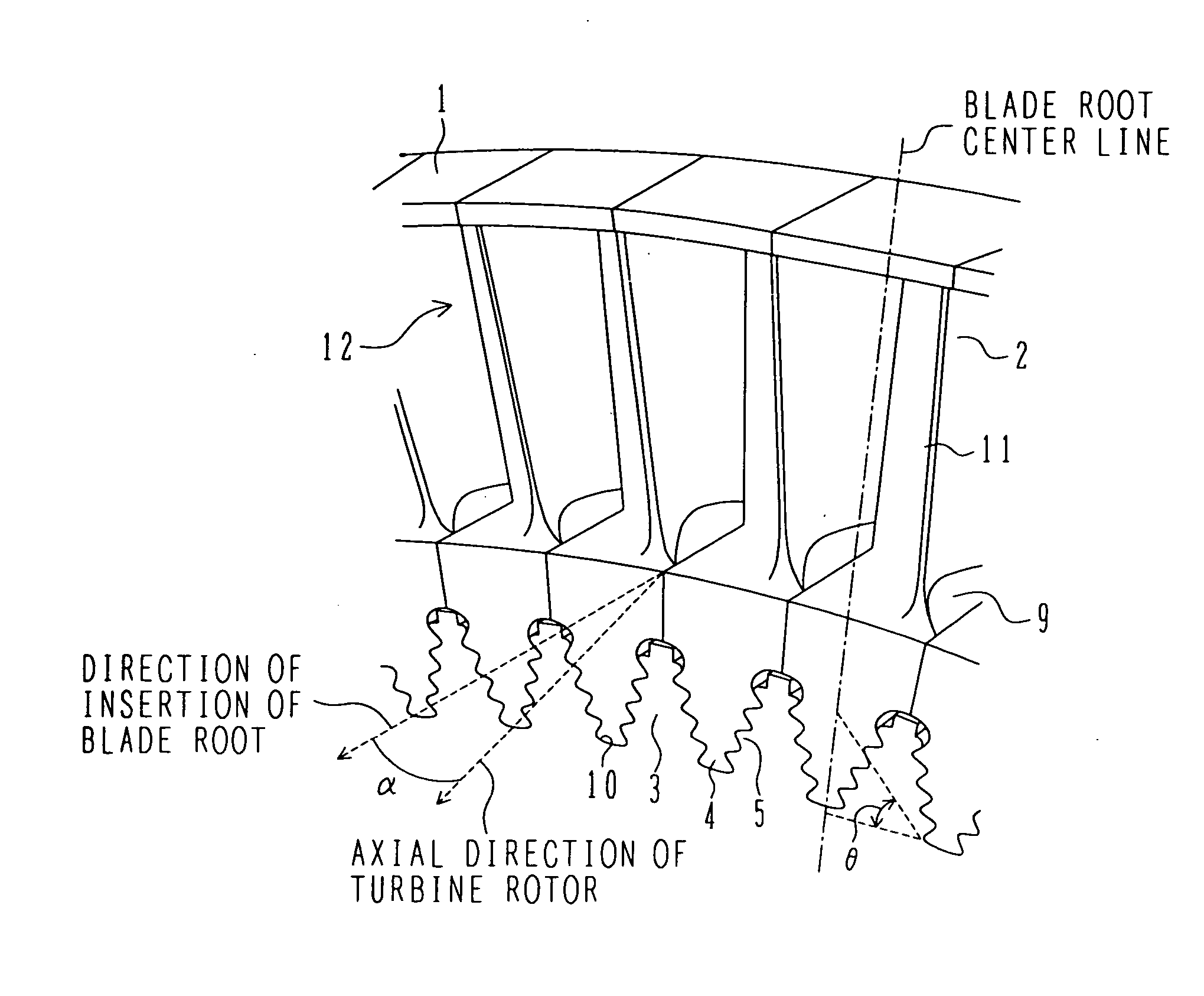

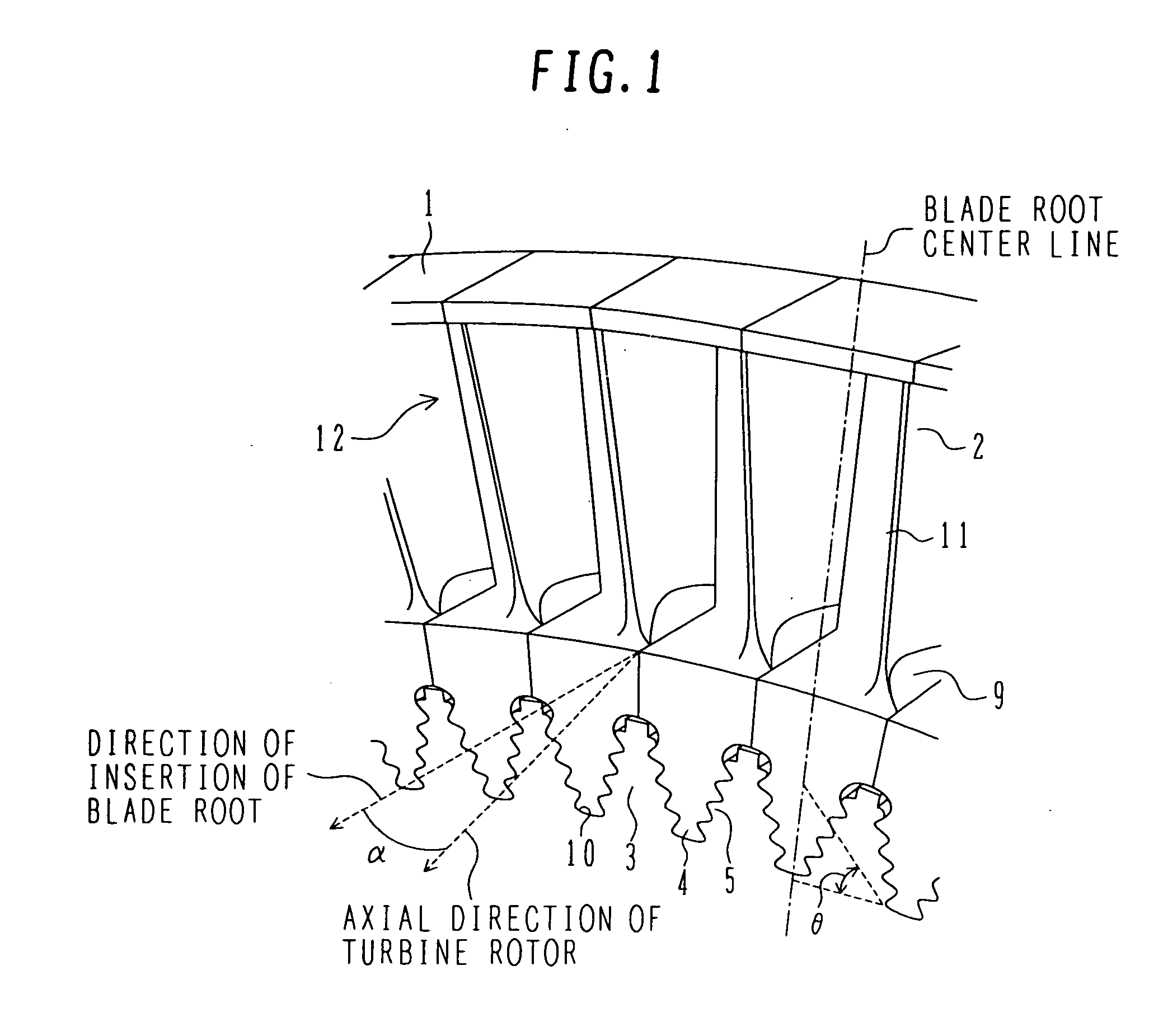

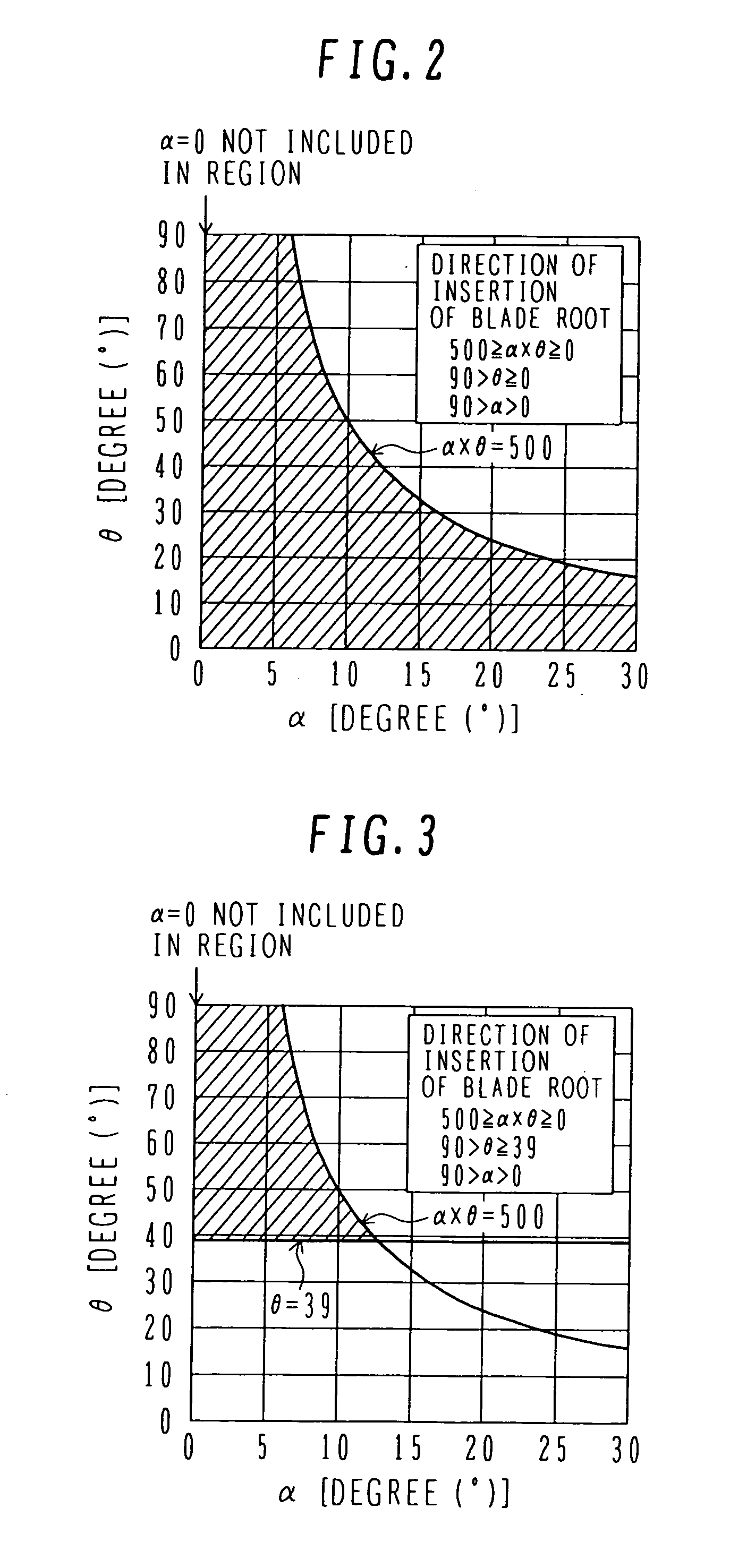

Steam turbine blade, steam turbine rotor, steam turbine with those blades and rotors, and power plant with the turbines

ActiveUS20060222501A1Suppress peak stressSuppress fatiguePropellersEngine manufactureSteam turbine bladeEngineering

A steam turbine blade in which the turbine blade has a blade root of the axially-inserted fir tree type and a larger number of turbine blades can be attached in a restricted outer peripheral region of a turbine rotor by arranging the blade root to be oriented in a direction forming a predetermined angle α larger than 0° relative to the axial direction of the turbine rotor. The steam turbing blade can suppress peak stresses generated at the bottoms of notches formed in the blade root and a blade groove and also suppress fretting fatigue from being induced by contact between peak stress generating areas and areas opposed to the peak stress generating areas at the notch bottoms. The steam turbine blade includes an airfoil, and a blade root attached to a turbine rotor and having plural stages of hooks in the radial direction of the turbine rotor.

Owner:MITSUBISHI POWER LTD

Damage repair method for marine steam turbine rotor

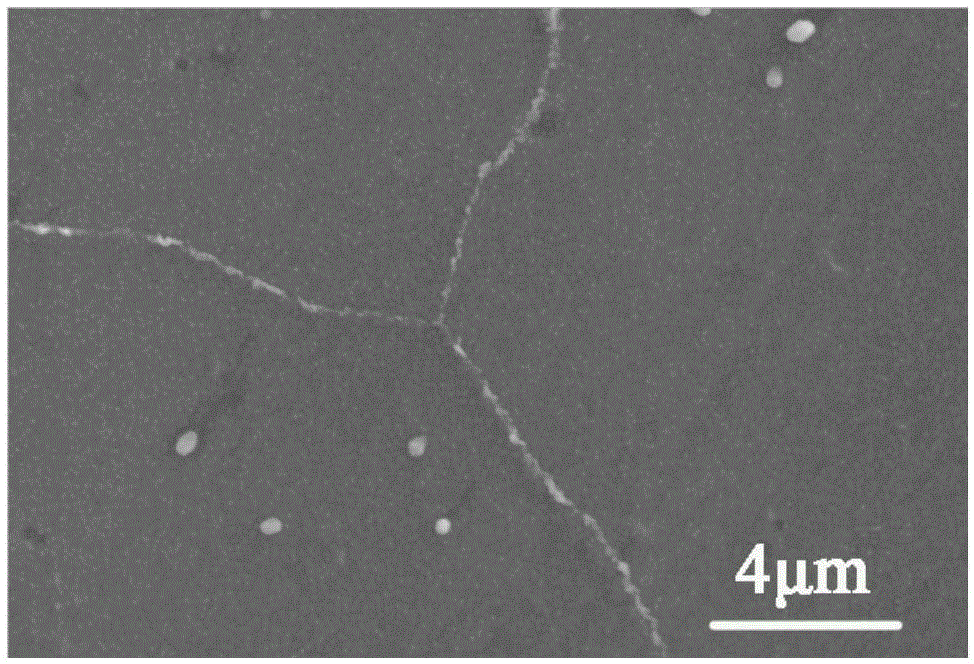

ActiveCN105018926ANot easy to wearSolve the problem that the surface of the impeller disc is easily eroded by steamArc welding apparatusMetallic material coating processesElectrical resistance and conductanceImpeller

The invention relates to a damage repair method for a marine steam turbine rotor. When the damage repair method repairs damage defects such as corrosion pits and erosion pits with large depths (the depths are at least 0.3mm) in a steam seal shaft neck and an impeller disk surface of the marine steam turbine rotor, firstly a resistance heat energy micro arc surfacing technology is adopted for welding repair for the damage defects; after the welded steam turbine rotor is reconditioned, a solid laser prepares a wear-resisting corrosion protection coating on the surface of the steam turbine rotor by using a laser cladding technology, and then the required sizes of the steam seal shaft neck and the impeller disk surface of the steam turbine rotor are achieved after processing. As the functional coating prepared by using the resistance heat energy micro arc surfacing technology and the laser cladding technology is adopted, the appearance is uniform, the structure is compact, and a cladding layer and a base material form metallurgical bonding; moreover, the dilution rate is low, and the problems that the steam seal shaft neck of the steam turbine rotor is easy to wear and the impeller disk surface is easily eroded by steam are effectively solved.

Owner:QINGDAO QIANJIN SHIPYARD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com