Preparation process of TiCN multilayer composite coating layer on slotting cutter surface of steam turbine rotor

A technology of steam turbine rotor and wheel groove milling cutter, which is applied in the direction of metal material coating process, coating, ion implantation plating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

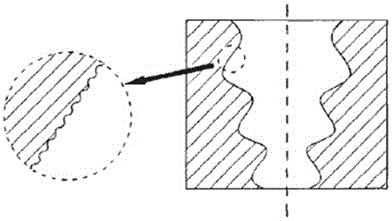

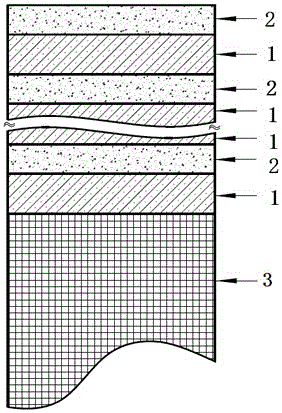

[0024] The technical scheme of the coating preparation process adopted in the present invention is: according to the rotor material, tool material, cutting processing method, tool geometry ( figure 1 ), cutting processing requirements, etc. for coating design, including coating composition, coating structure, and coating process. The coating adopts a multi-layer structure, with TiN and TiCN as alternating coatings, and an alternating coating of TiN coating 1 and TiCN coating 2 with 50 layers is prepared on the surface of the groove milling cutter ( figure 2 ), TiN is the bottom layer, and the outermost layer is TiCN. The TiN / TiCN multi-layer composite coating is deposited by cathodic arc technology, the deposition temperature is low, and there is no damage to the tool substrate 3. The prepared coating has small thermal stress, uniform and dense surface, and good finish. TiN is used as the base layer and intermediate transition layer to ease the intrinsic stress of coating gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com