Apparatus for repairing generator rotor shaft neck

A generator rotor and journal technology, applied in the field of repair equipment for mechanical shafts, can solve problems such as low production efficiency, high labor intensity, and failure to achieve repair accuracy, and achieves improved repair quality, reduced labor intensity, and improved production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

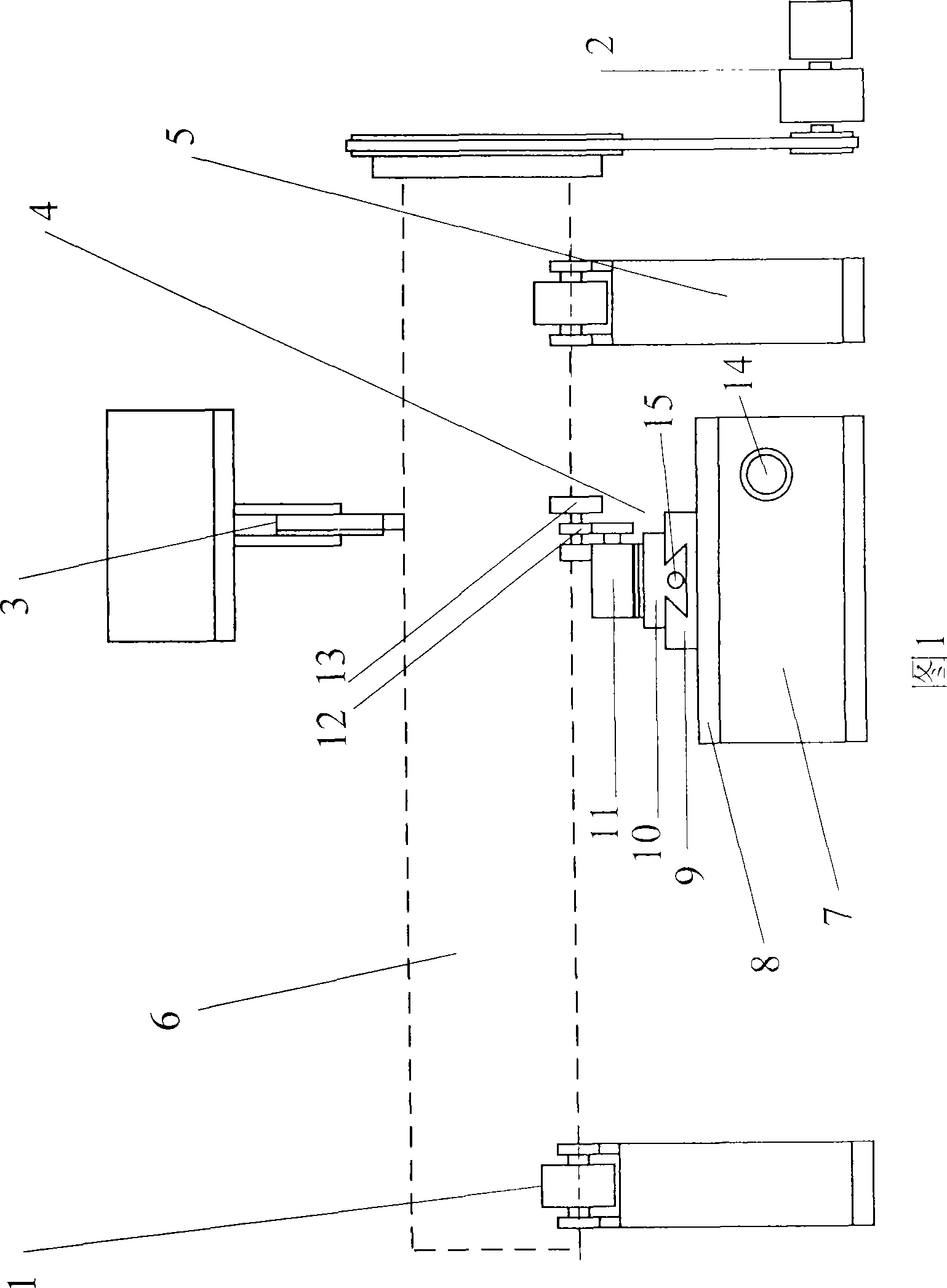

[0010] A repairing device for generator rotor shaft journal, comprising a generator rotor support frame 1, a support frame 5, a generator rotor 6, a drive motor and a reducer 2 for the generator rotor, wherein the drive motor can adopt a variable frequency motor for stage adjustment, a transmission belt is set between the drive motor of the generator rotor and the output shaft of the reducer 2, and one end of the generator rotor 6, and a welding machine 3 is set on one side of the generator rotor 6, and the welding system can be horizontally The direction of horizontal movement, the horizontal movement distance depends on the repair range, the maximum is not more than 1000mm, but the actual application is about 200mm. The speed of the lateral and horizontal movement of the welding system matches the rotation speed of the rotor 6, so that the welding spots take a spiral trajectory, ensuring effective and reasonable overlapping of the deposited metal, and realizing the welding re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com