Steam turbine rotor blades cover band structure and its machining process

A technology of moving blades and steam turbines, which is applied in the direction of supporting components of blades, machines/engines, mechanical equipment, etc., and can solve problems such as increasing unit noise, reducing steam work efficiency, and consuming energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

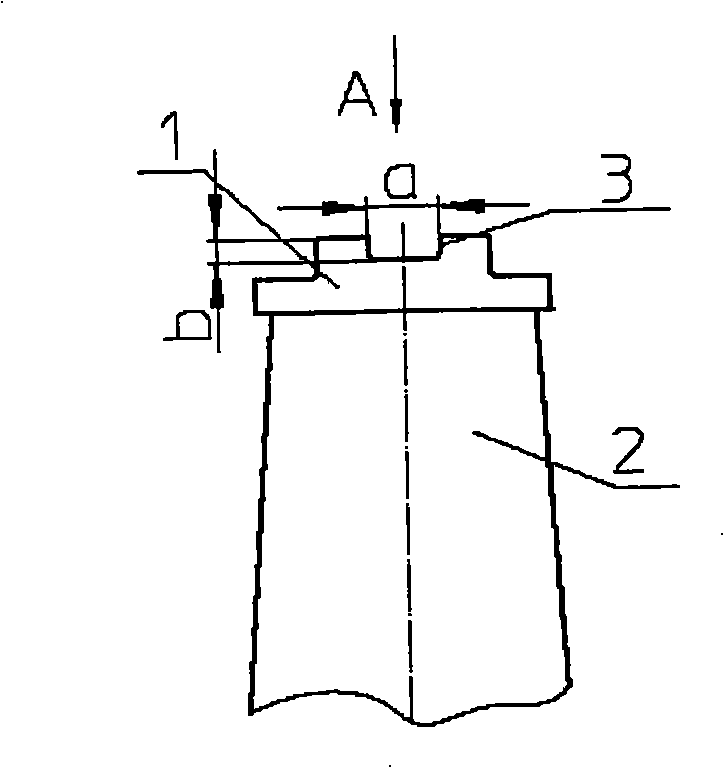

[0031] see figure 1 , figure 2 : The shroud 1 is located on the top of the blade body 2. When processing the blades, a machining allowance is reserved on the end faces of the inlet and outlet steam sides and the top surface of the shroud 1, and then all the blades are packed into the impeller so that the shrouds of all blades 1 is combined to form a ring to form a shroud, and an annular process groove 3 is turned on the outer peripheral surface of the shroud (ie, the top surface of the blade shroud), the groove has a width of a and a depth of b.

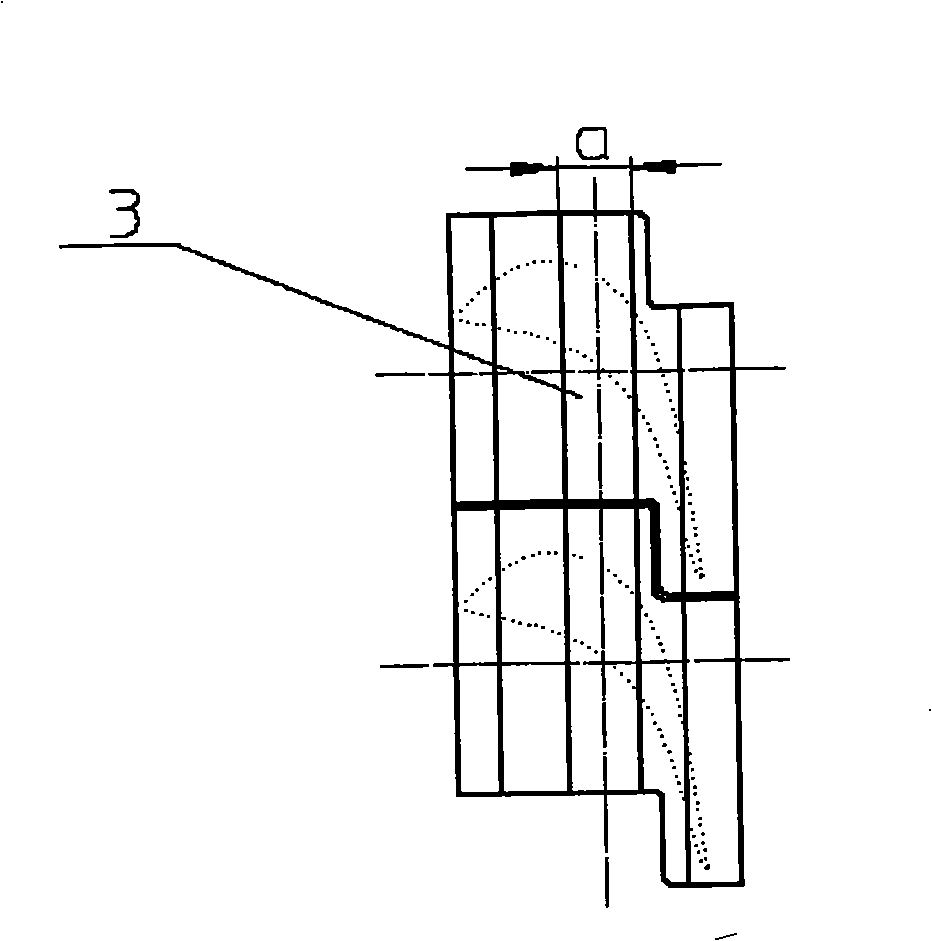

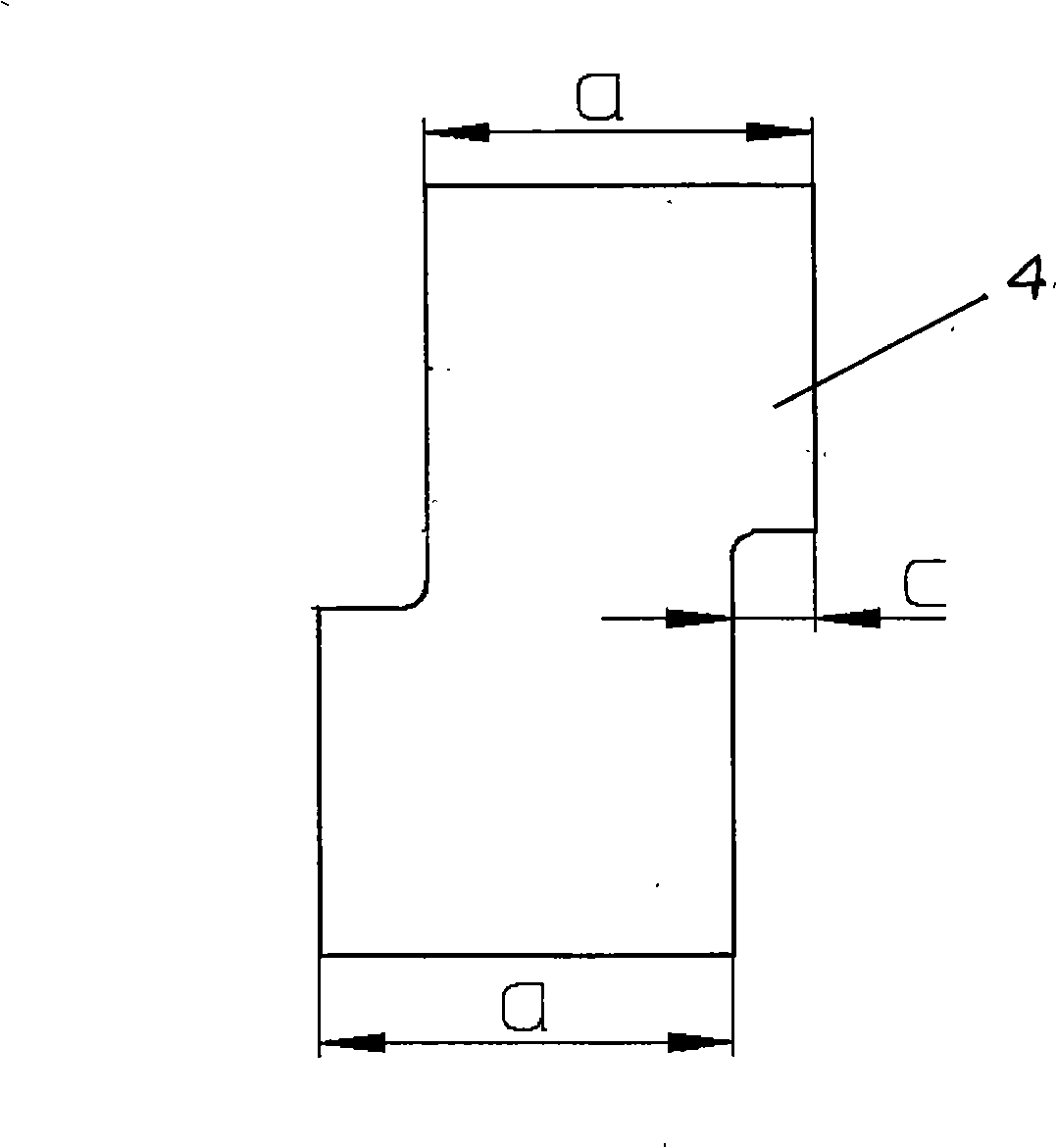

[0032] see image 3 , Figure 4 : Process a batch of process blocks 4, the geometric dimensions of the process block 4 are compatible with the process tank 3, the process block 4 has two block parts of the overall structure, and the two block parts are parallel and dislocated, and the dislocation distance C is equal to the blade torsion The dislocation distance between the two adjacent leaf crowns.

[0033] See Fig. 5: apply ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com