Patents

Literature

85 results about "Fatigue life assessment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-cycle creep and fatigue life evaluation method under conditions of high temperature and multiaxial spectrum load

ActiveCN103926152AEasy accessReduce testing costsMaterial strength using tensile/compressive forcesFatigue damageCreep stress

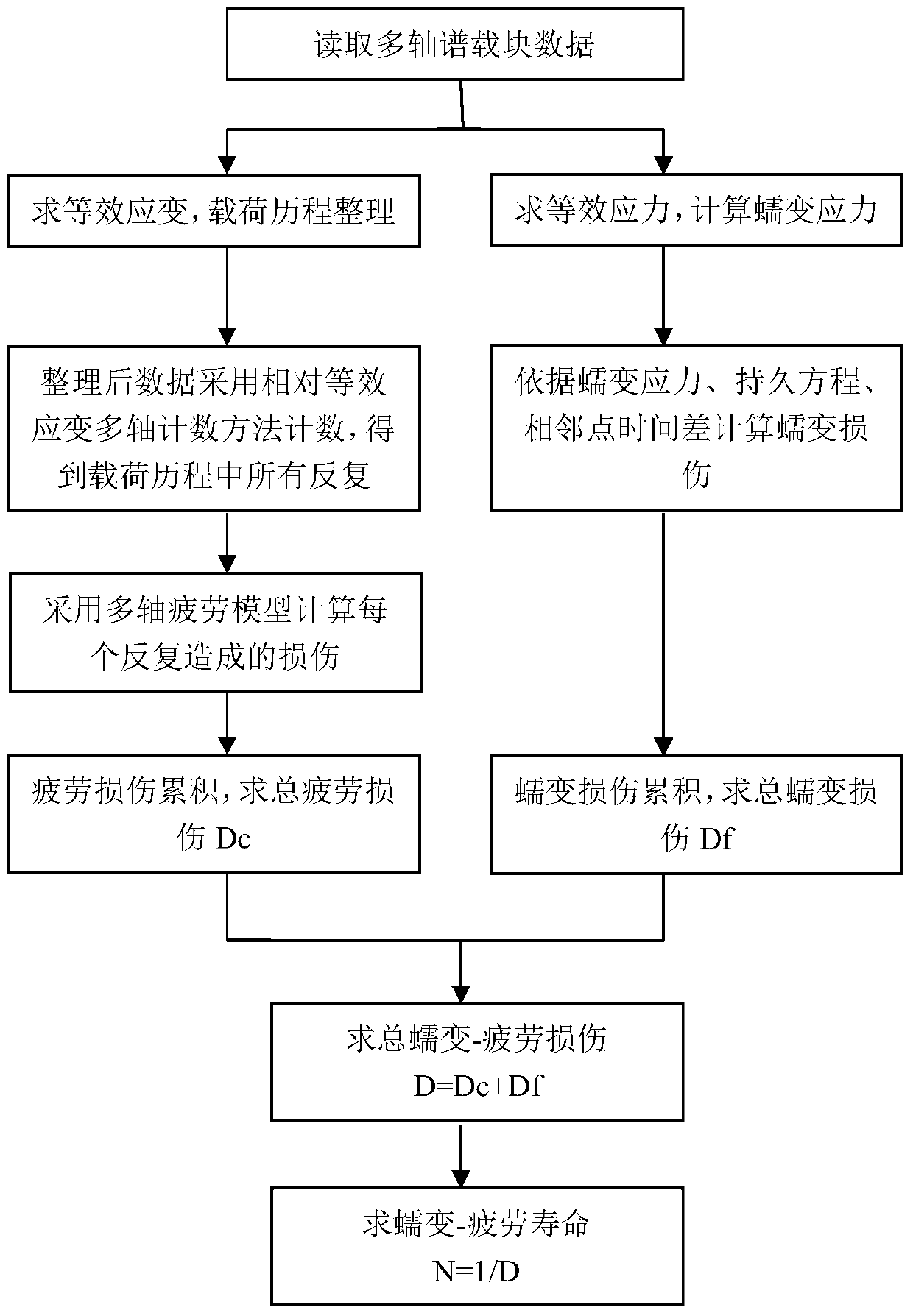

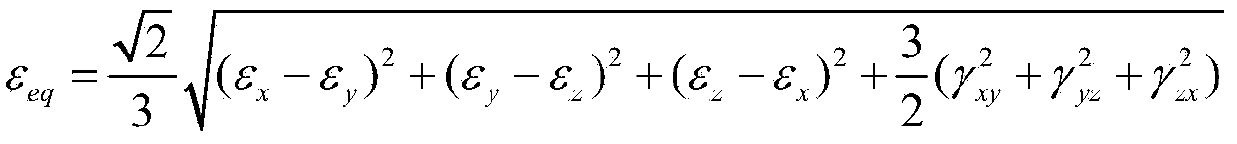

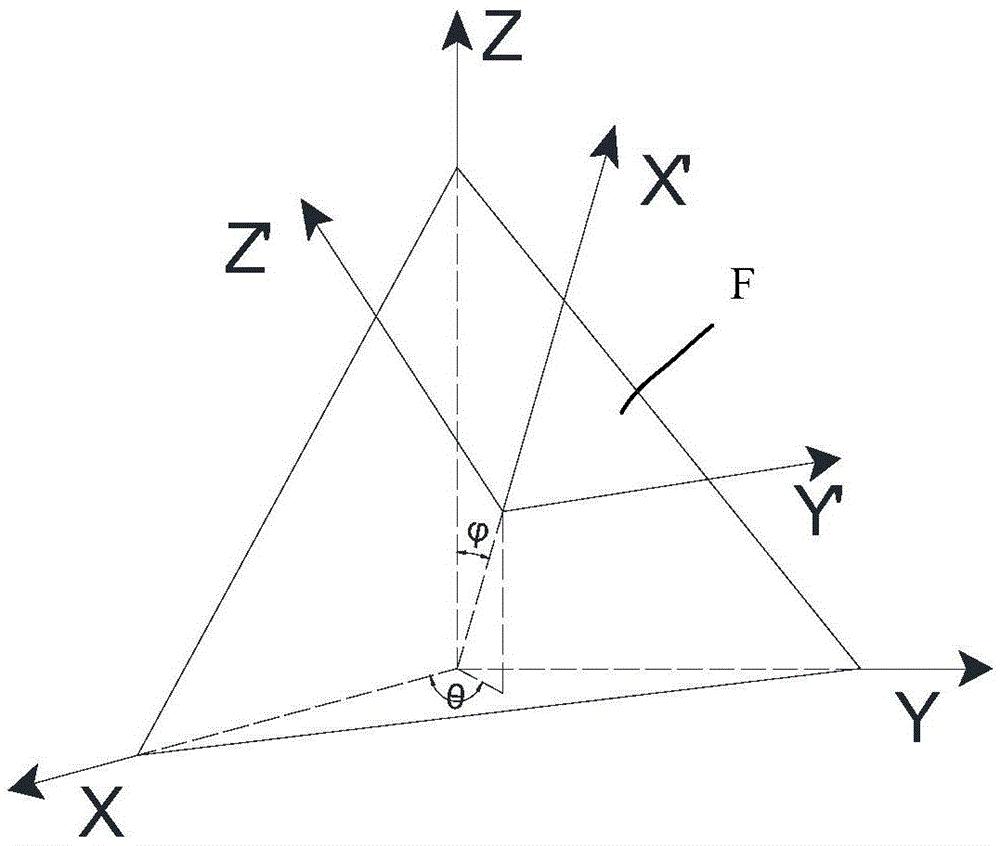

The invention relates to a low-cycle creep and fatigue life evaluation method under the conditions of high temperature and multiaxial spectrum load. The method comprises the following steps of reading a stress strain history in a multiaxial loading spectrum data block, working out equivalent strain, and finishing a loading history; repeatedly extracting by adopting a relative equivalent strain multi-axis counting method; working out all repeated fatigue damage by adopting a unified multiaxial fatigue damage life prediction model; accumulating the fatigue damage to work out the total fatigue damage; working out equivalent creep stress by utilizing the original loading history; working out creep damage Dc according to the equivalent creep stress and the stress history by combining a creep lasting equation; working out the total damage D caused by a multiaxial load spectrum block at the high temperature; and estimating the multiaxial creep and fatigue life. According to the method, the fatigue damage under the multiaxial stress and the creep damage under the multiaxial stress can be respectively calculated in the whole loading spectrum data block, the fatigue material constant at the room temperature is adopted in the calculation of the fatigue damage, and lasting equation material constant recommended by specification is adopted in the calculation of the creep damage; through experimental verification, the method has a good prediction effect.

Owner:BEIJING UNIV OF TECH

Method for evaluating fatigue life of aged reinforced concrete bridge

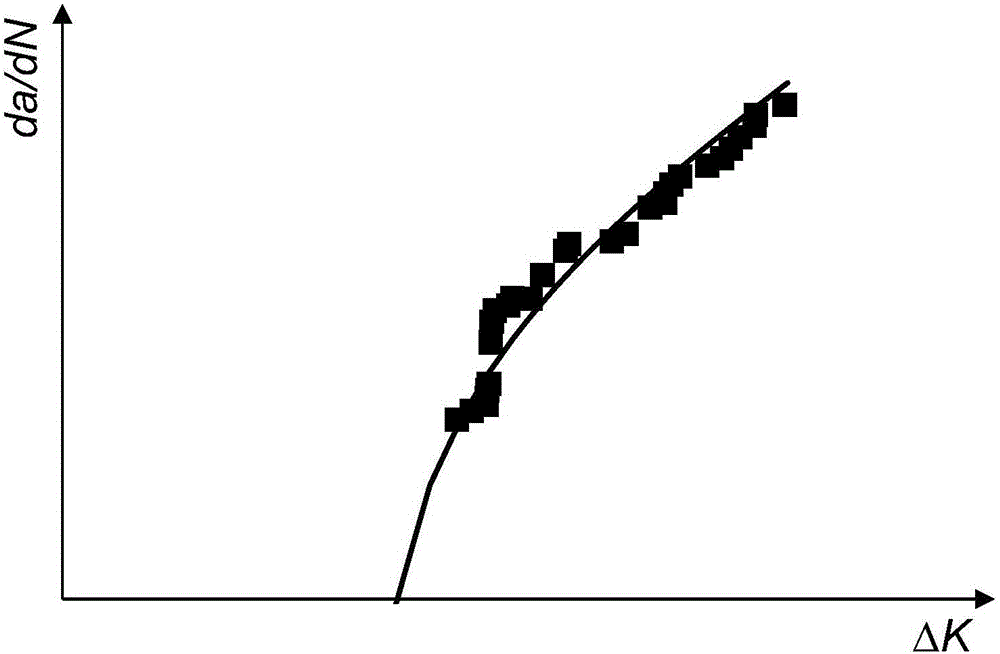

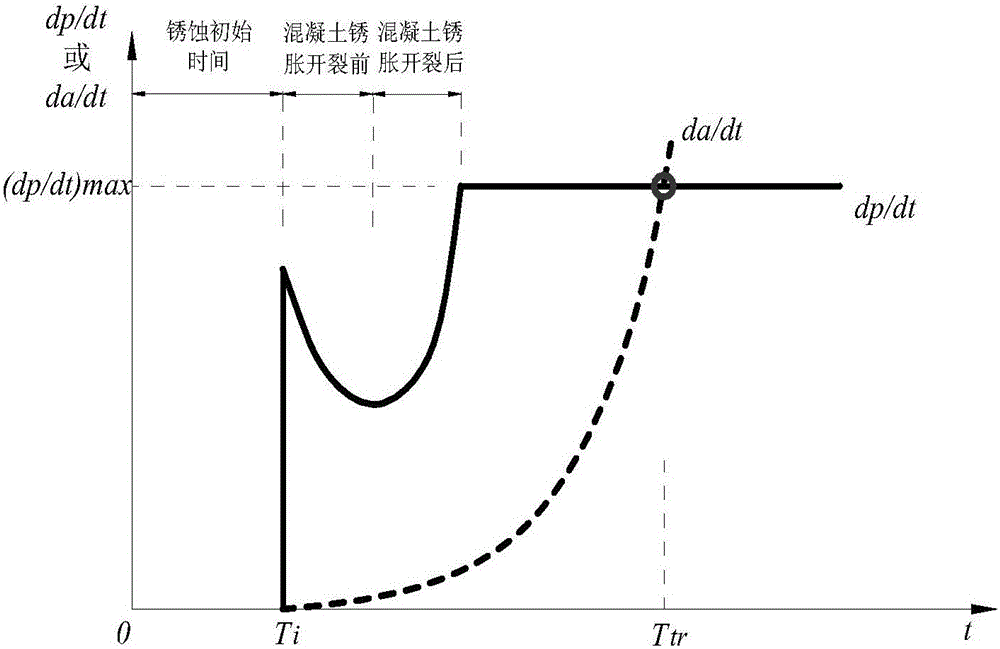

ActiveCN105825030AThe prediction method is reasonableGeometric CADForecastingStress concentrationCrazing

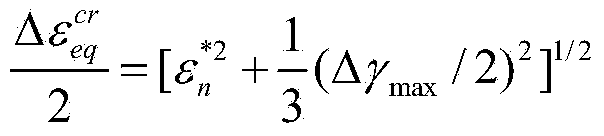

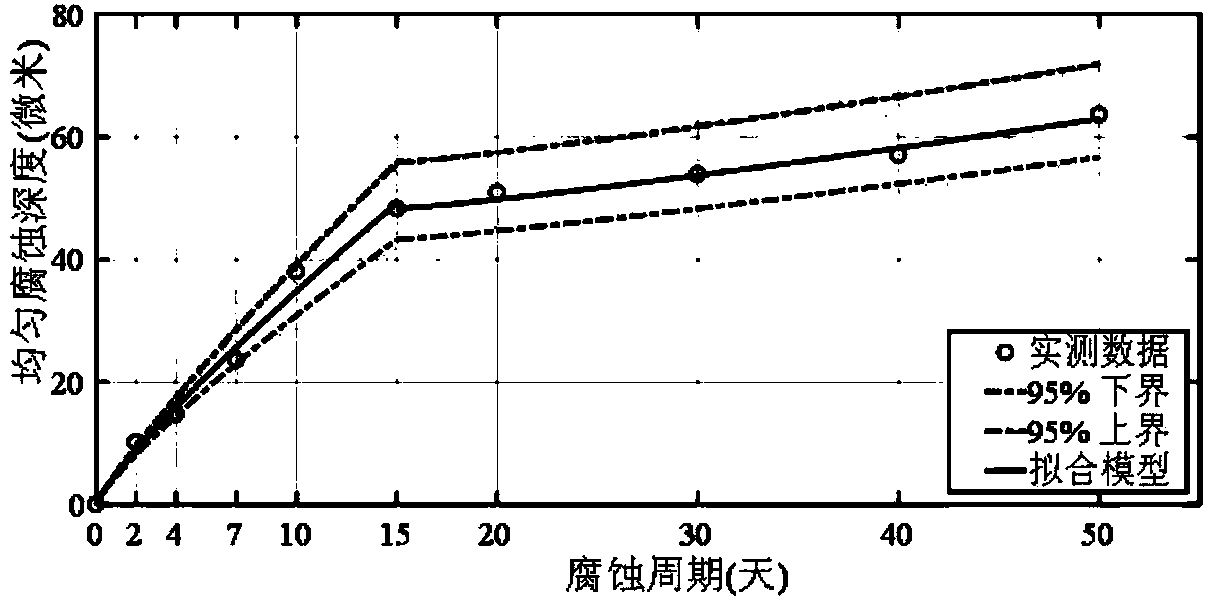

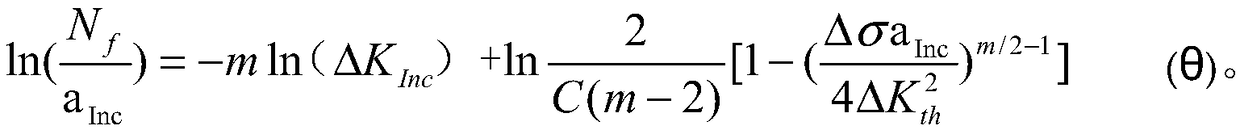

The invention discloses a method for evaluating the fatigue life of an aged reinforced concrete bridge. The method comprises the following steps of obtaining initial corrosion time of reinforcement in concrete based on the second diffusion law of Fick, and considering the influence of concrete cracking due to corrosion expansion in a corrosion rate model; adopting a small crack growth and near threshold growth analysis and determining relevant parameters of fatigue crack propagation rate of materials by developing a fatigue crack propagation test of reinforced concrete materials; performing a corrosion fatigue test or finite element analysis on corroded reinforcement to obtain stress concentration factors at different corrosion levels, and integrating into a stress intensity factor model to obtain the fatigue crack propagation rate of the reinforcement under the influence of corrosion; comparing the magnitude of a corrosion pit growth rate and the fatigue crack propagation rate and gradually converting into a single growth analysis on fatigue cracks of the reinforcement; meanwhile, combining with vehicle load observing information to realize life evaluation of a bridge at different service stages. The prediction method disclosed by the invention is reasonable and high in popularization, and can provide technical support for evaluating the life of the concrete bridges.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

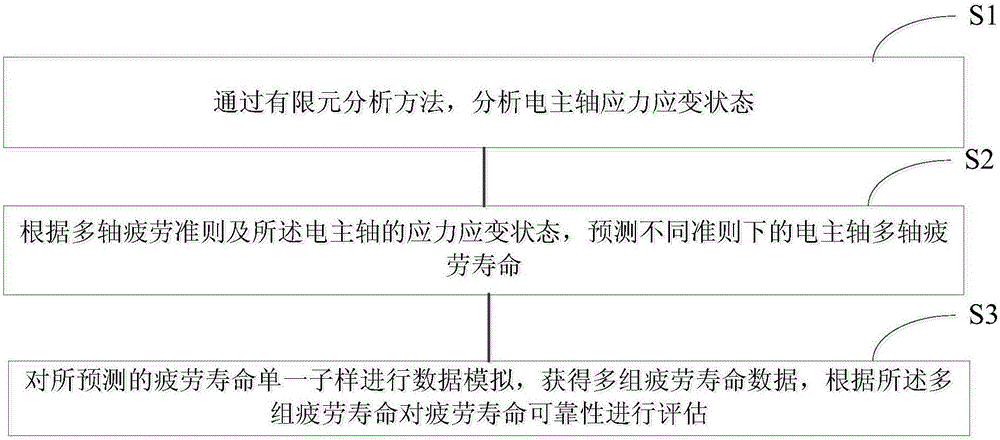

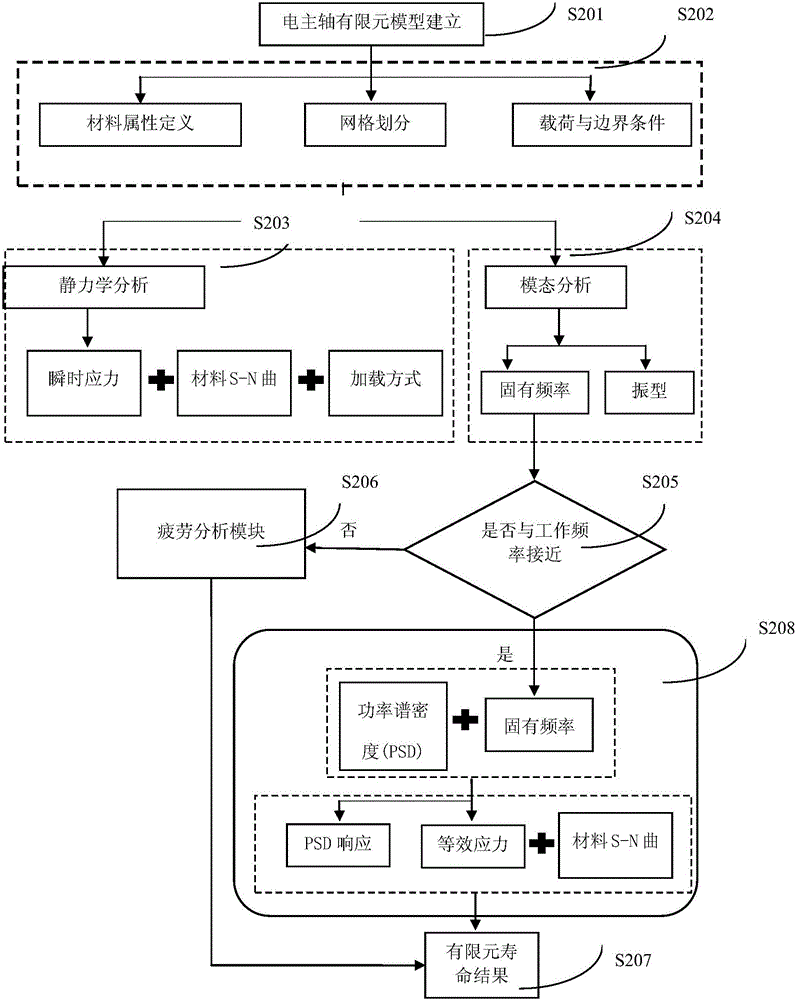

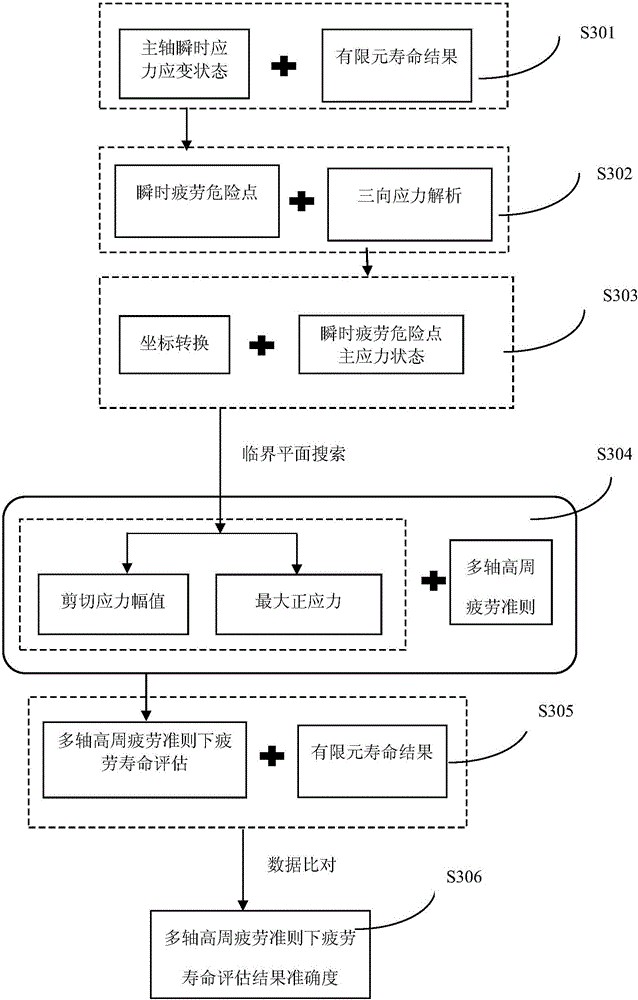

Electric spindle multi-axial fatigue life prediction method and fatigue life reliability assessment method

ActiveCN106202647AHelp follow-up workAvoid high feesDesign optimisation/simulationSpecial data processing applicationsData simulationElement analysis

The invention provides an electric spindle multi-axial fatigue life prediction method and a fatigue life reliability assessment method, and aims to solve the problems that the single-axial fatigue life in the prior art cannot express the electric spindle practical application status; the multi-axial fatigue life prediction method comprises the following steps: using a finite element analysis method to analyze electric spindle stress strain status; predicting the electric spindle multi-axial fatigue life under different rules according to the multi-axial fatigue rules and the electric spindle stress strain status. Data simulation is carried out for a fatigue life single subsample on said basis, thus obtaining multi-group fatigue life data, and assessing the fatigue life reliability according to the multi-group fatigue life data. The method can carry out assessment and reliability research on electric spindle fatigue life under the single subsample according to the simulation result, thus providing technology and data supports for spindle fatigue life assessment in real processing production, and providing basis data for spindle precision life assessment.

Owner:UNIV OF SCI & TECH BEIJING

Evaluation method for fatigue damage and service life of horizontal axis wind turbine blade

ActiveCN102607831AGet actual lifespanShort cycleMachine part testingStrength propertiesFatigue damageImpeller

The invention discloses a test method for the fatigue damage and the service life of a horizontal axis wind turbine blade, aiming to obtain a more exact blade fatigue performance parameter by adopting a test detection and computational analysis means having low cost and high efficiency so as to meet the requirements of blade design, research and development and detection. The method is characterized in that on the basis of the characteristic that the impeller speed of a horizontal axis wind turbine is lower, and the period change frequency of various fatigue loads is also lower, a series of steps of carrying out static loading testing on the wind turbine blade to obtain a stress / strain amplitude distribution condition under the effect of various fatigue loads and analyzing by combining a material property curve and a cumulative damage theory are adopted to realize the evaluation to the blade fatigue performance. Compared with the traditional horizontal axis wind turbine blade fatigue testing technology, the method has the advantages of short period, low cost, capability of obtaining a final service life parameter of the blade, and the like.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

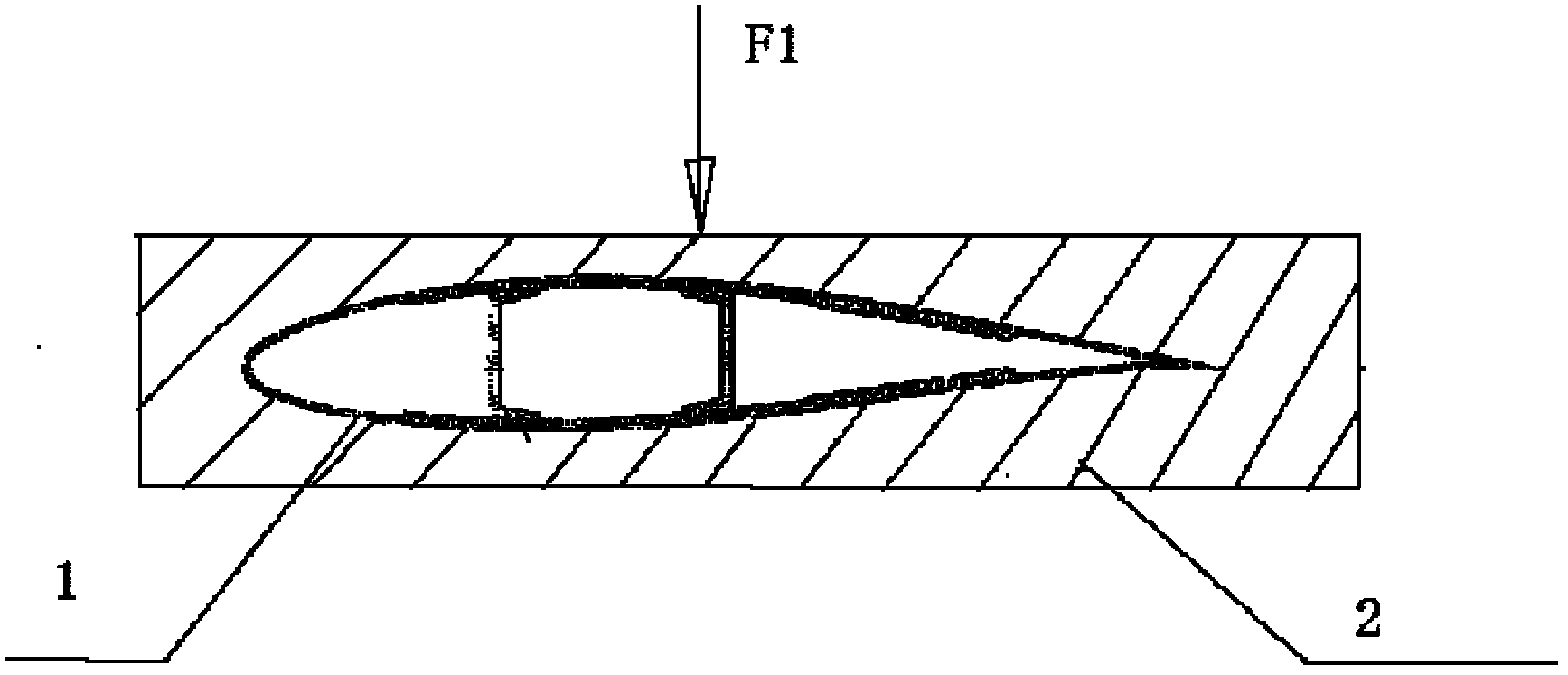

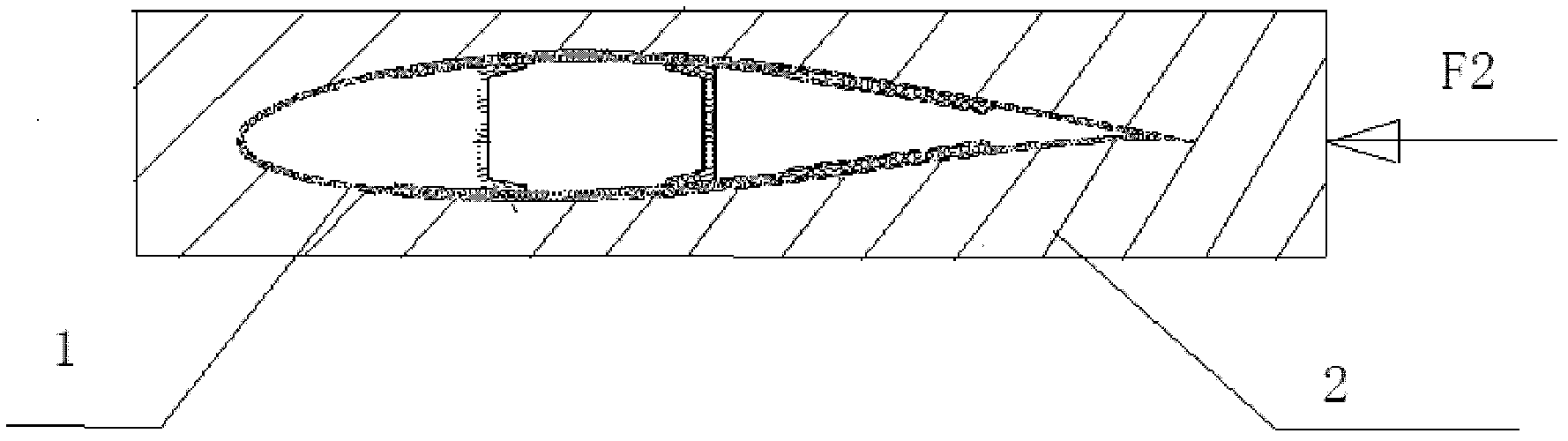

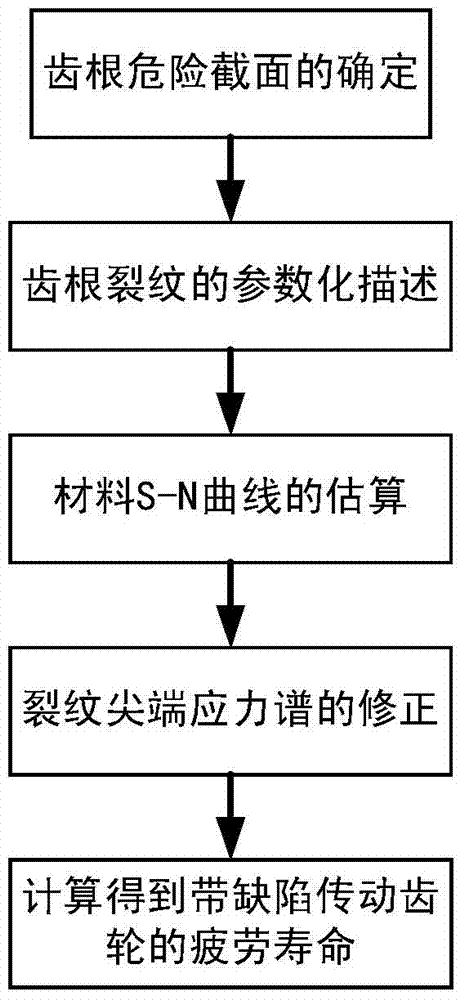

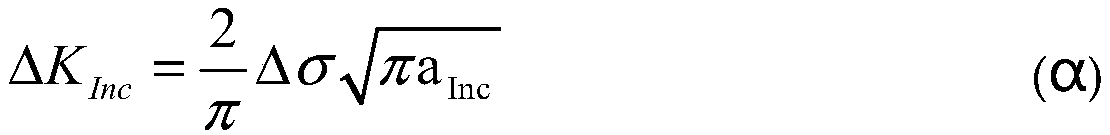

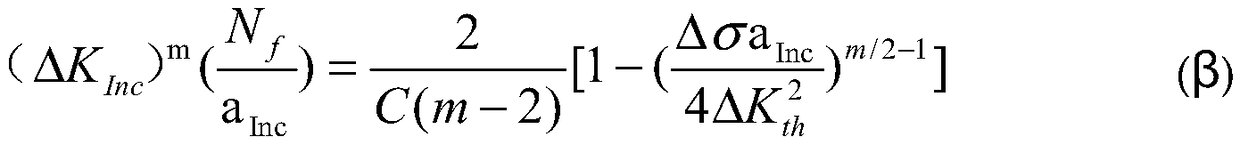

Transmission gear fatigue life assessment method based on defect modeling

InactiveCN103616179AImprove fatigue analysis efficiencyReduce fatigue life analysis complexityMachine gearing/transmission testingFatigue damageEstimation methods

The invention discloses a transmission gear fatigue life assessment method based on defect modeling. The method includes the following steps that (1), crack occurrence rules and reasonable crack forms are analyzed, and the method for introducing cracks into a gear model is researched; (2), material fatigue characteristic parameters are obtained through test data fitting or a numerical value estimation method; (3), a stress spectrum under the condition of working situations of a gear containing the cracks is calculated by using a finite element method, and the stress spectrum is corrected according to obtaining conditions of the material fatigue characteristic parameters; (4), fatigue life under the condition of working situations of a gear containing the cracks is calculated by using the reasonable fatigue damage accumulation theory. The fatigue life assessment method based on defect modeling is provided for the transmission gear, and an effective detection basis is provided for the remanufacturing process of a gear recycled part.

Owner:GUANGXI UNIV

Method for assessing detail fatigue crack propagation of steel bridge

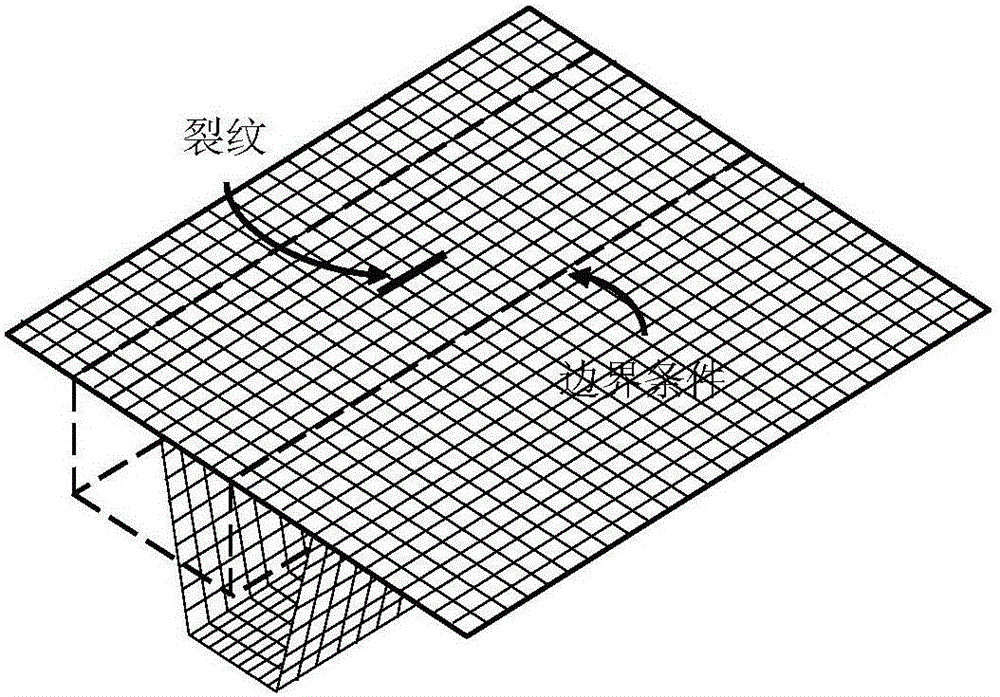

ActiveCN106055784AGuaranteed reliabilityImprove computing efficiencySpecial data processing applicationsStress intensity factorElement analysis

The invention discloses a method for assessing the detail fatigue crack propagation of a steel bridge. Aiming at a steel bridge which is widely used in a road bridge system and is severe in fatigue crack dangers, the method comprises the steps: firstly building a bridge model and a local zone crack submodel through finite elements, obtaining an existing bridge load according to the definition and sampling of a vehicle and other random variables, and obtaining the boundary conditions of the submodel based on the whole bridge finite element analysis and the submodel technology; secondly updating the submodel through employing local remeshing, and carrying out the crack propagation finite element analysis; thirdly extracting a stress intensity factor amplitude, calculating a mean crack propagation rate, a mean crack propagation angle, the circulating number of times of each crack propagation step, the mean number of the stress intensity factor amplitude caused by a single vehicle, and the fatigue life; finally achieving the simulation of the fatigue crack of the steel bridge and the assessment of the fatigue life, so as to guide the subsequent maintenance and reinforcing operation.

Owner:SOUTHEAST UNIV

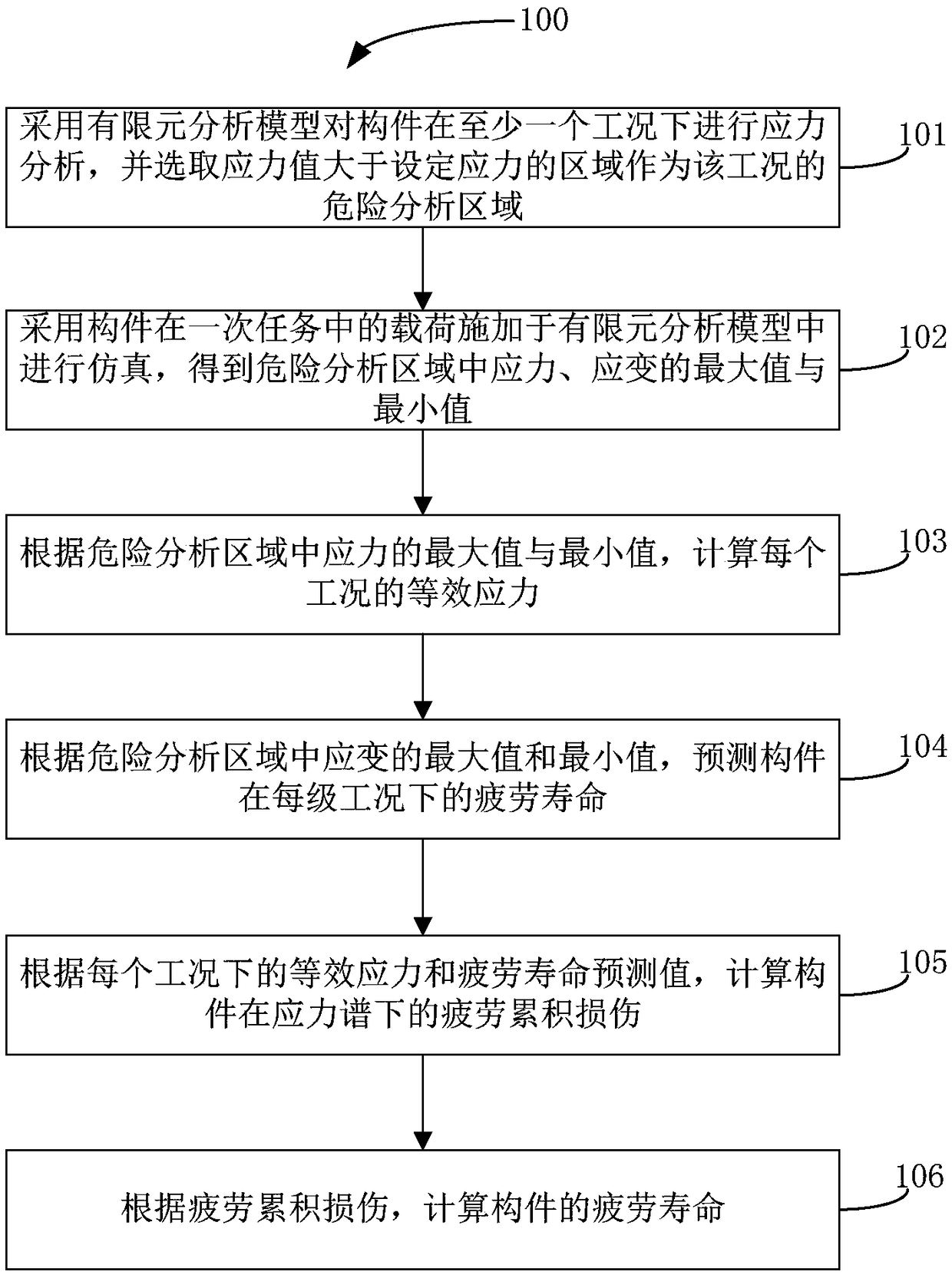

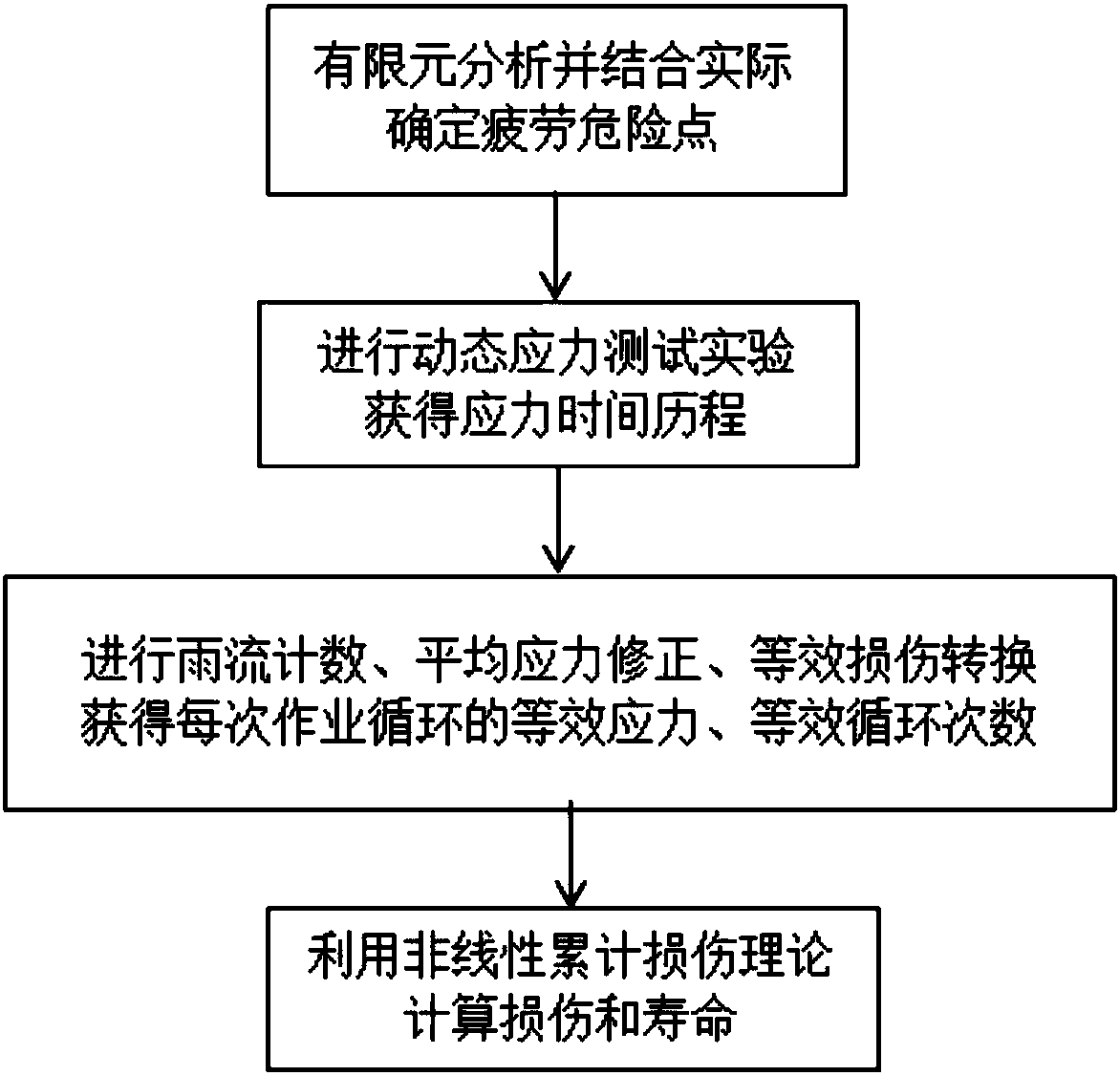

Fatigue life assessment method of components based on nonlinear fatigue damage accumulation theory

InactiveCN109033709AAccurate calculationHigh accuracy of fatigue life predictionDesign optimisation/simulationSpecial data processing applicationsFatigue damageElement analysis

The invention discloses a fatigue life evaluation method of a component based on a nonlinear fatigue damage accumulation theory, which comprises the following steps of: adopting a finite element analysis model to carry out stress analysis on the component under at least one working condition, and selecting a region with a stress value greater than a set stress as a hazard analysis region under theworking condition; obtaining the maximum and minimum of stress and strain in the hazard analysis area by simulating the load on the finite element analysis model of the component in one mission. According to the maximum and minimum value of stress in the hazard analysis area, the equivalent stress of each working condition is calculated. According to the maximum and minimum value of strain in thehazard analysis area, the fatigue life prediction value of the component under each working condition is predicted. According to the equivalent stress and fatigue life predicted under each working condition, the fatigue cumulative damage of the member under stress spectrum is calculated. According to the accumulated fatigue damage, the fatigue life of the component is calculated.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

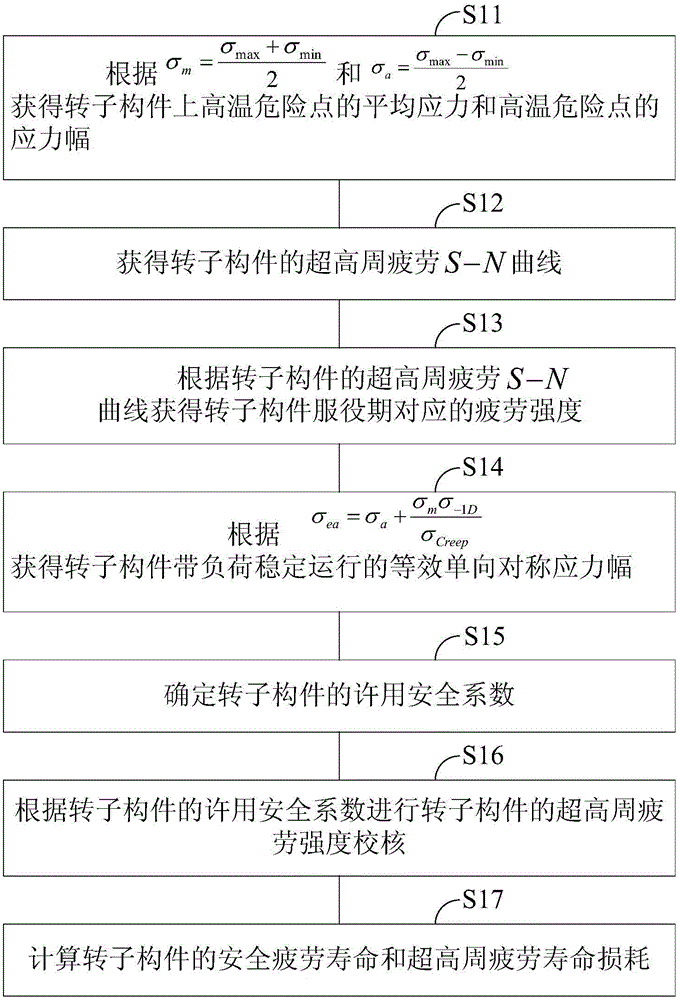

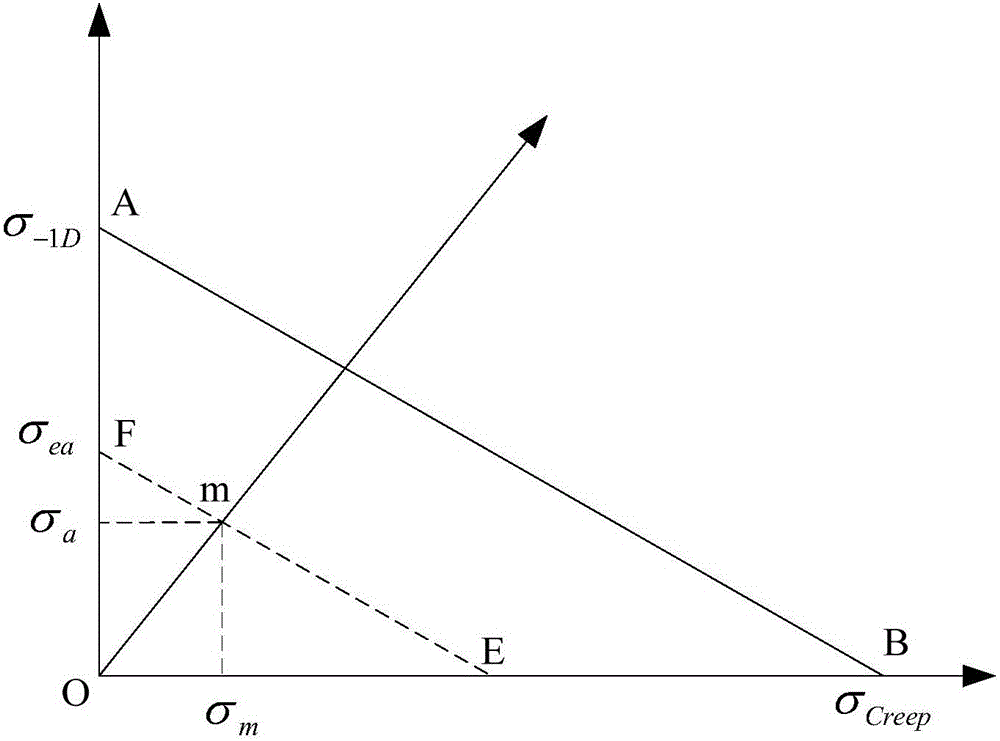

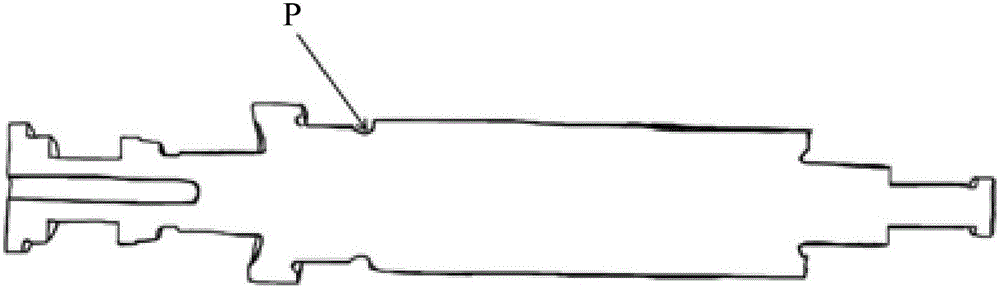

Method for assessing ultra-high cycle fatigue strength and fatigue life of steam turbine rotor

ActiveCN106202630AExact fatigue strengthAccurate Fatigue LifeDesign optimisation/simulationSpecial data processing applicationsEngineeringFatigue life assessment

The invention discloses a method for assessing ultra-high cycle fatigue strength and fatigue life of a steam turbine rotor. The method comprises the following steps of: obtaining mean stress of high-temperature dangerous points and stress amplitude of the high-temperature dangerous points on a rotor component according to sigma<m>=(sigma<max>+sigma<min>) / 2 and sigma=(sigma<max>-sigma<min>) / 2; obtaining an ultra-high cycle fatigue S-N curve of the rotor component; obtaining fatigue strength corresponding to a service period of the rotor component according to the ultra-high cycle fatigue S-N curve of the rotor component; obtaining an equivalent unidirectional symmetric stress amplitude of on-load stable operation of the rotor component according to sigma<ea>=sigma+(sigma<m>*sigma<-1D>) / sigma<Creep>; determining an allowable security coefficient of the rotor component; checking the ultra-high cycle fatigue strength of the rotor component according to the allowable security coefficient of the rotor component; and calculating a security fatigue life and an ultra-high cycle fatigue life loss of the rotor component. The method for assessing the ultra-high cycle fatigue strength and fatigue life of the steam turbine rotor can realize the quantitative calculation and assessment of the high-temperature ultra-high cycle fatigue strength, fatigue life and loss.

Owner:SICHUAN UNIV

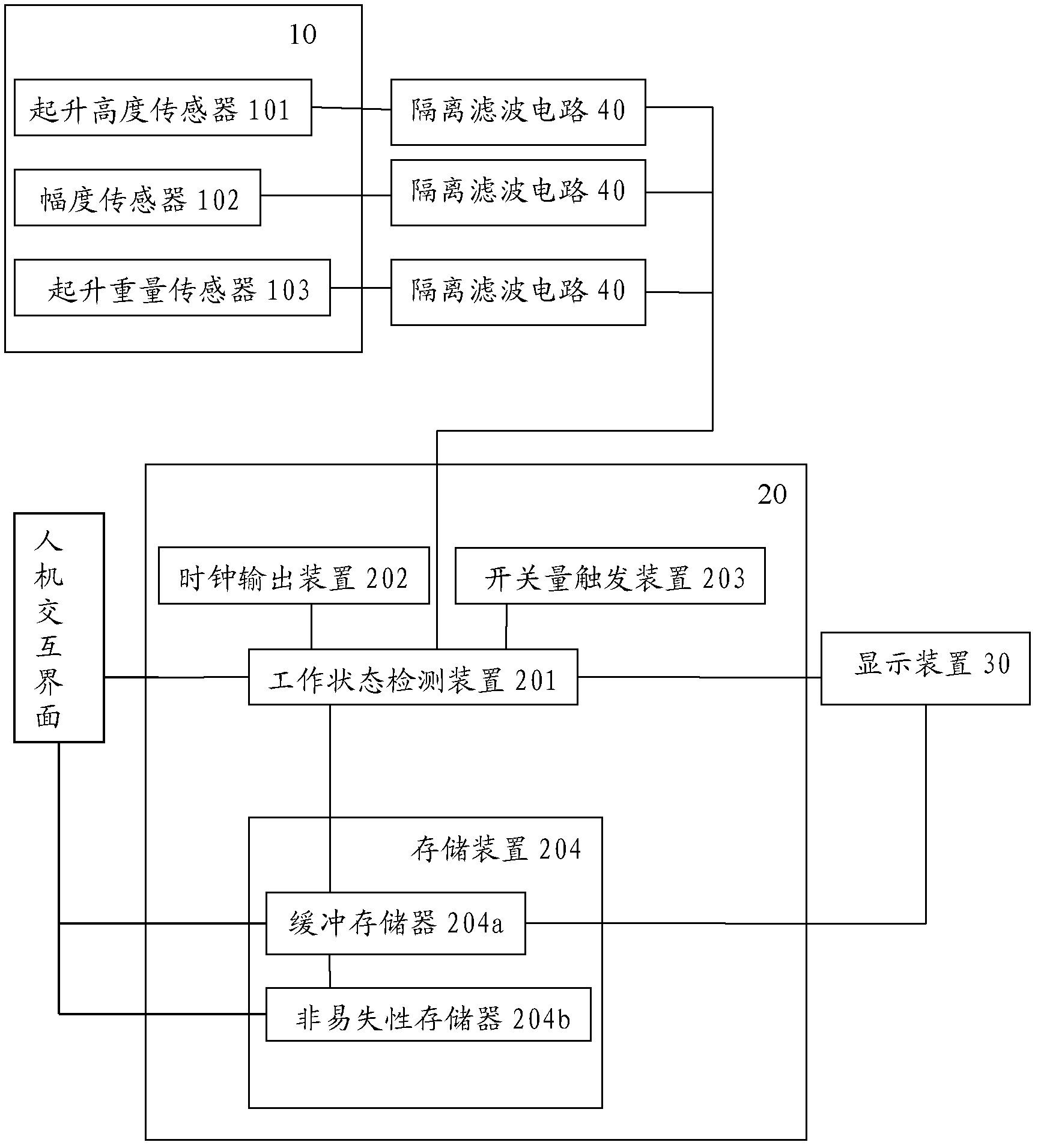

Crane load spectrum data acquisition system, method thereof, and fatigue life assessment system

The invention relates to a crane load spectrum data acquisition system. The crane load spectrum data acquisition system comprises a data acquisition device, a data processing device and a display device, wherein the data acquisition device acquires the condition data of a crane; the data processing device is used for receiving the condition data from the data acquisition device, and selects and stores the condition data respectively; and the display device is used for displaying the condition data according to user requests. Actually measured load spectrum data of the crane can be obtained through applying the above technical scheme in the invention, so the assessment is accurate. The invention also relates to a crane load spectrum data acquisition method and a fatigue life assessment system.

Owner:GUANGZHOU ACAD OF SPECIAL EQUIP INSPECTION& TESTING

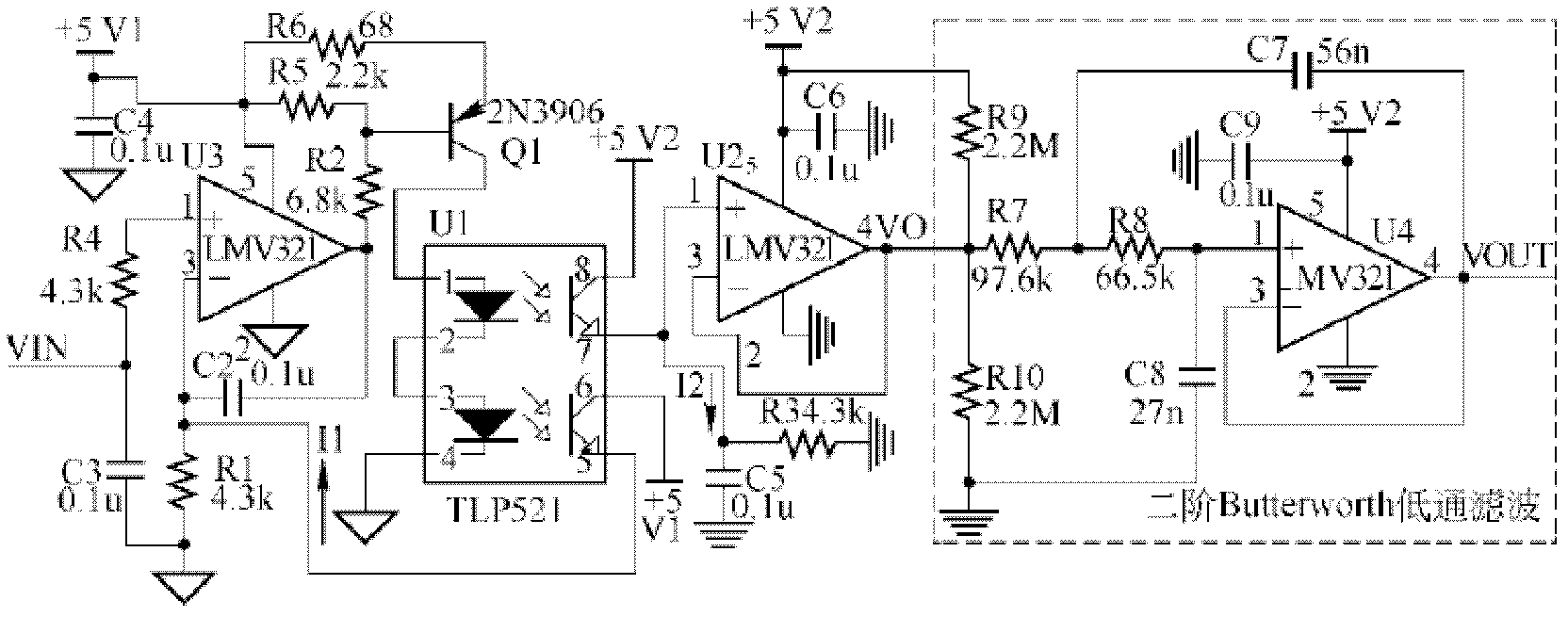

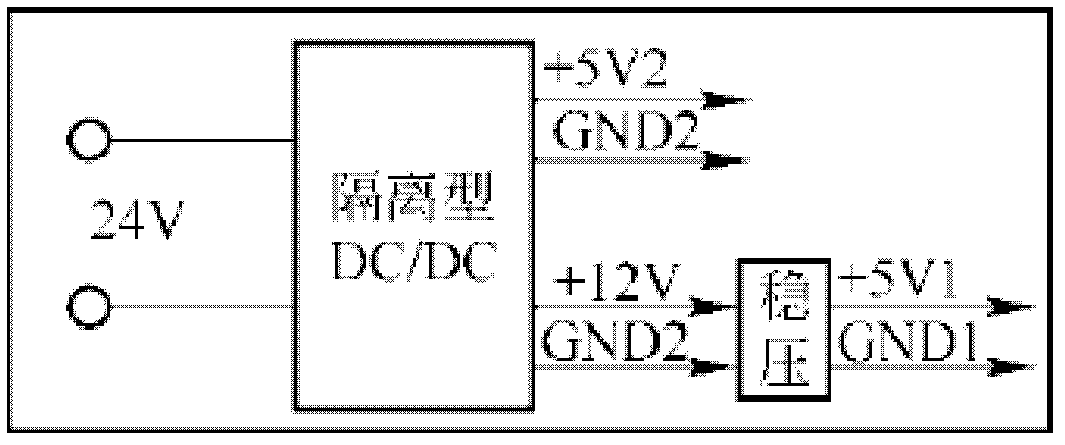

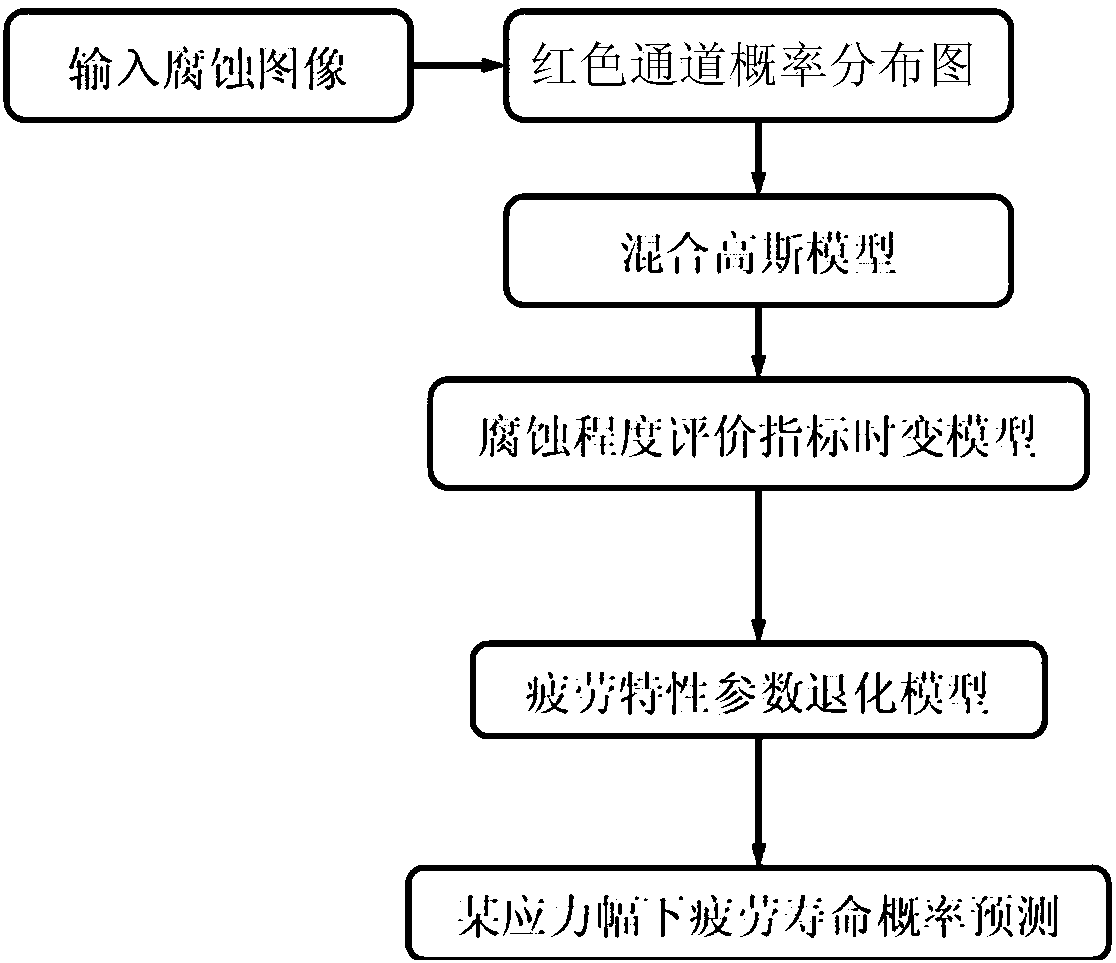

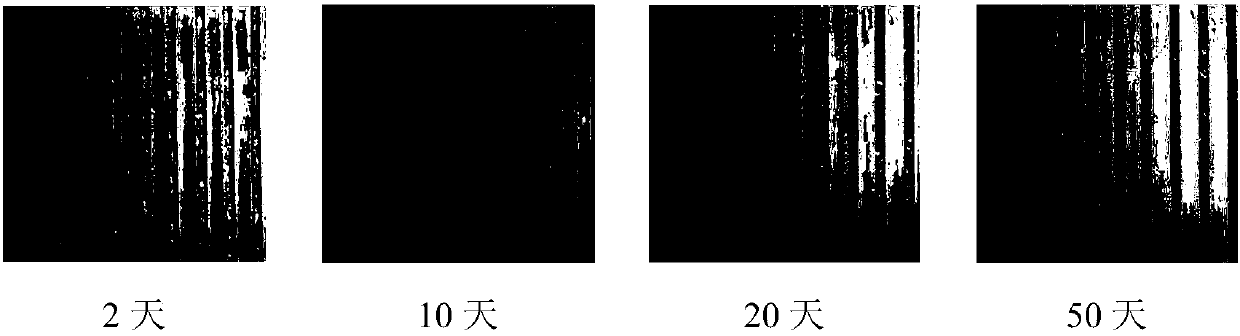

Method for monitoring and recognizing pulling rope corrosion and evaluating fatigue life on basis of computer vision

ActiveCN108225906AImprove accuracyImprove stabilityWeather/light/corrosion resistanceStrength propertiesPattern recognitionData set

The invention provides a method for monitoring and recognizing pulling rope corrosion and evaluating a fatigue life on the basis of computer vision. The method comprises the following steps: shootingan image of a corroded high-strength steel wire by a perspective inspection window at an anchoring end of a pulling rope, extracting image characteristics from the image, then building a corrosion-degree evaluation model, then building a fatigue-life characteristic energy number evaluation model, matching with a performance degrading state of the corrosion and the fatigue of the steel wire under an artificially accelerated corrosion test, and finally finishing the corrosion-state recognition and the fatigue-life evaluation of the in-service pulling rope. The method provided by the invention has the beneficial effects that the recognition accuracy is high, the speed is fast and the cost is low; the requirement for real-time data processing of online monitoring and early warning of corrosionand fatigue of the pulling rope also can be met, i.e., the image acquired by a consumer-grade ordinary camera is directly recognized without data-set updating; the automation, intelligentization, accuracy and robustness of corrosion monitoring and recognition and fatigue-life evaluation of the pulling rope are improved, and a solution is provided for automatic monitoring and recognition of the corrosion and the fatigue of the pulling rope of a bridge structure.

Owner:HARBIN INST OF TECH

Fatigue life assessment method for mechanical parts

ActiveCN106153311AImprove accuracyImprove rationalityMachine part testingSpecial data processing applicationsFatigue damageFatigue life assessment

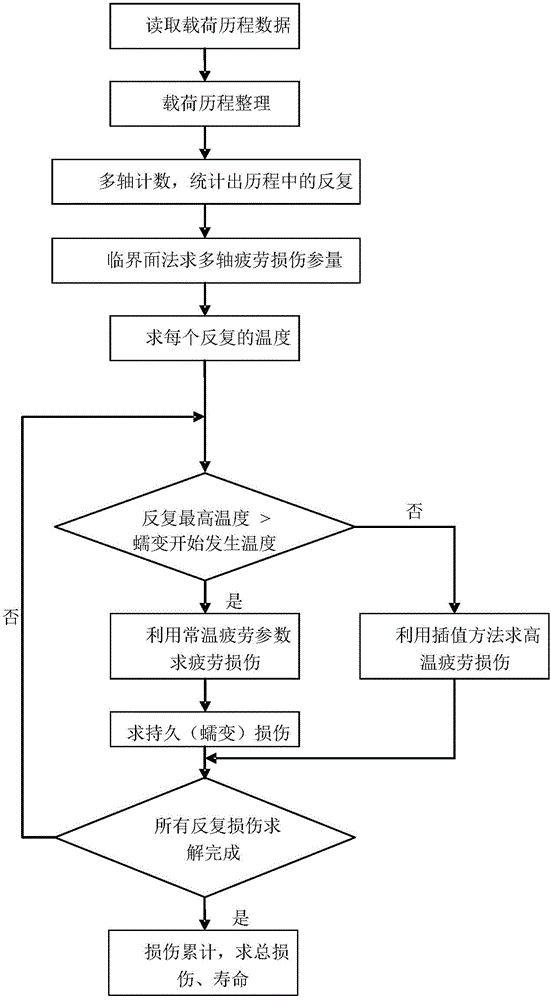

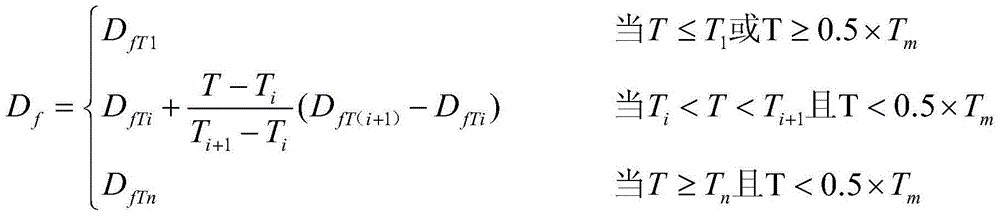

The invention aims to provide a fatigue life assessment method for mechanical parts. The fatigue life assessment method comprises the steps that load history data are acquired; load histories of the load history data are repeatedly counted; a critical plane and damage parameters of the critical plane are determined on the basis of a critical plane method; each load history is repeatedly counted, if the maximum temperature T of each load history is lower than the creep originating temperature, the fatigue damage Df1 is assessed, and if the maximum temperature T reaches the creep originating temperature, the fatigue damage Df2 is assessed and the creep damage Dc is assessed; the total damage is assessed according to the formula that D is equal to the sum of sigma Df1, sigma Df2 and sigma Dc; and the fatigue life is assessed according to the total damage.

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

Fatigue life assessment method based on engineering machinery structure

ActiveCN107609235ASimple calculationImprove calculation accuracySpecial data processing applicationsElement analysisFinite element analyse

Owner:DALIAN UNIV OF TECH

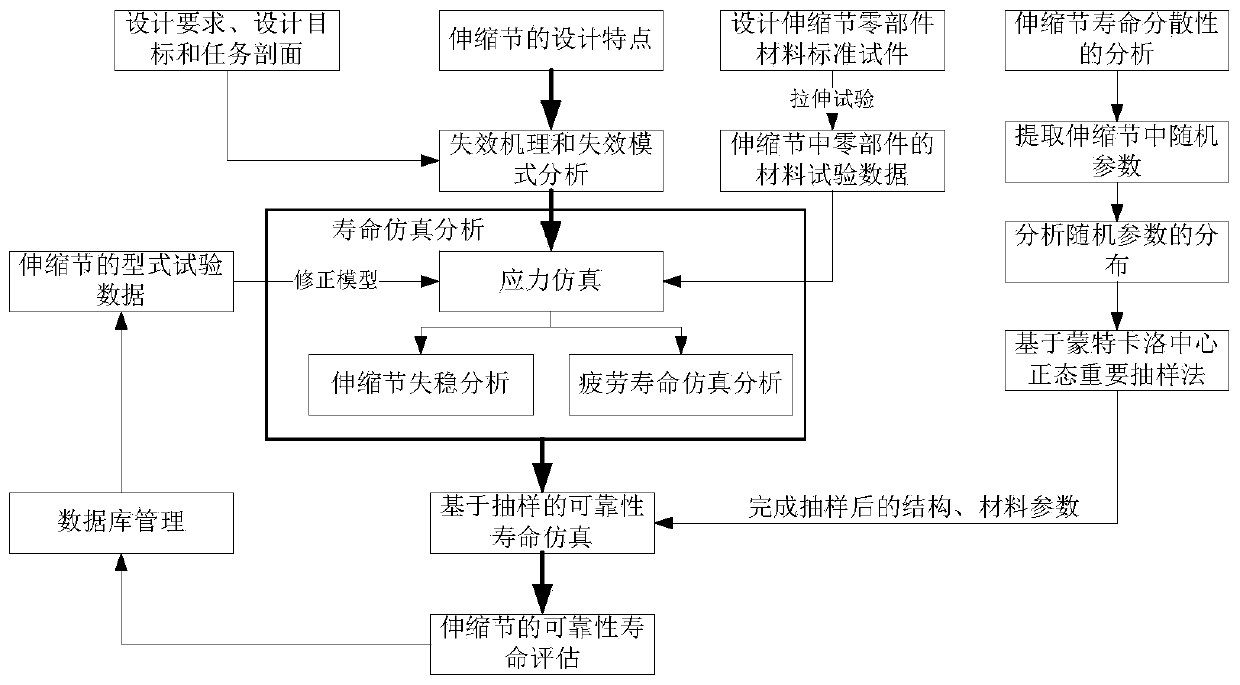

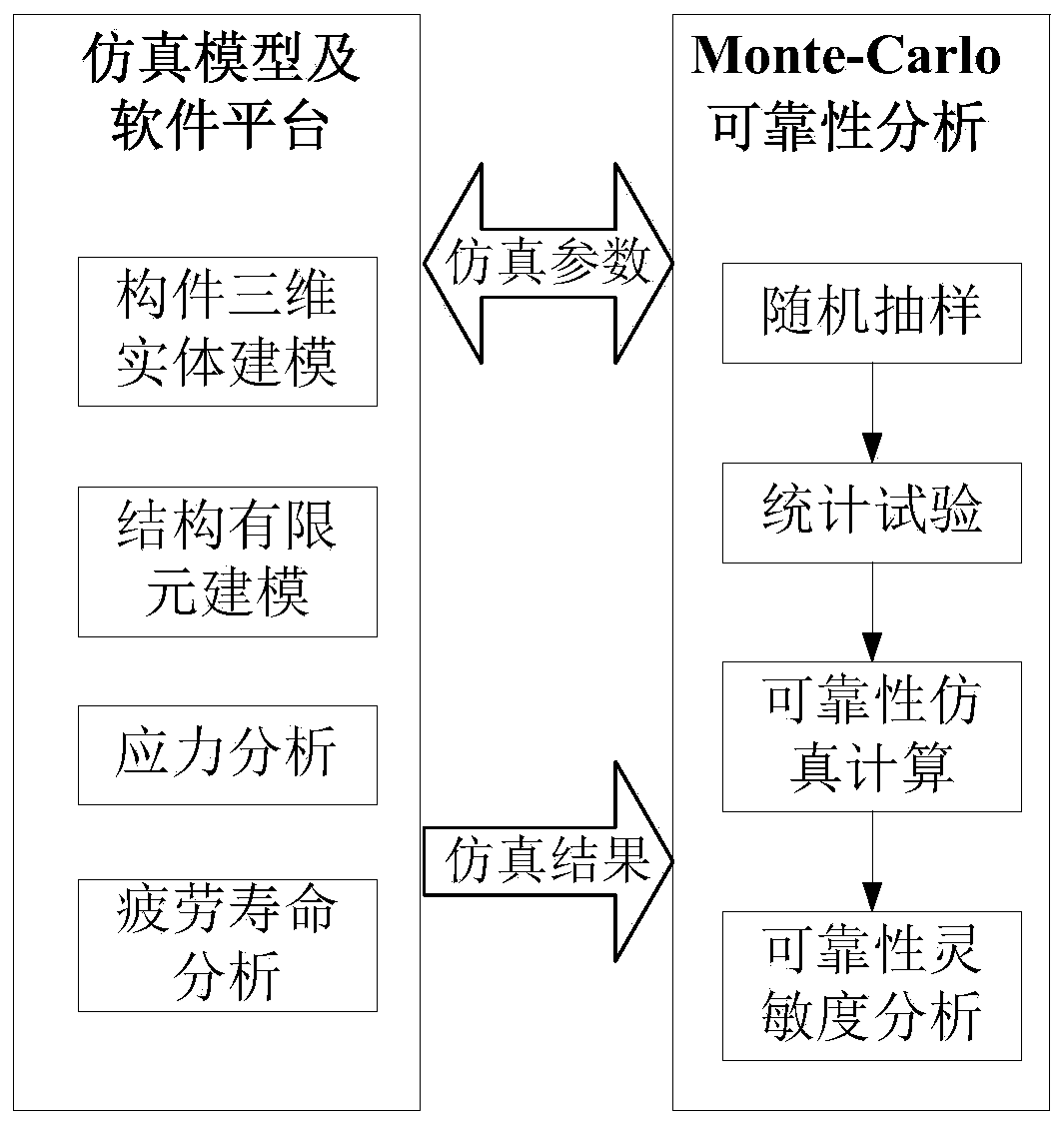

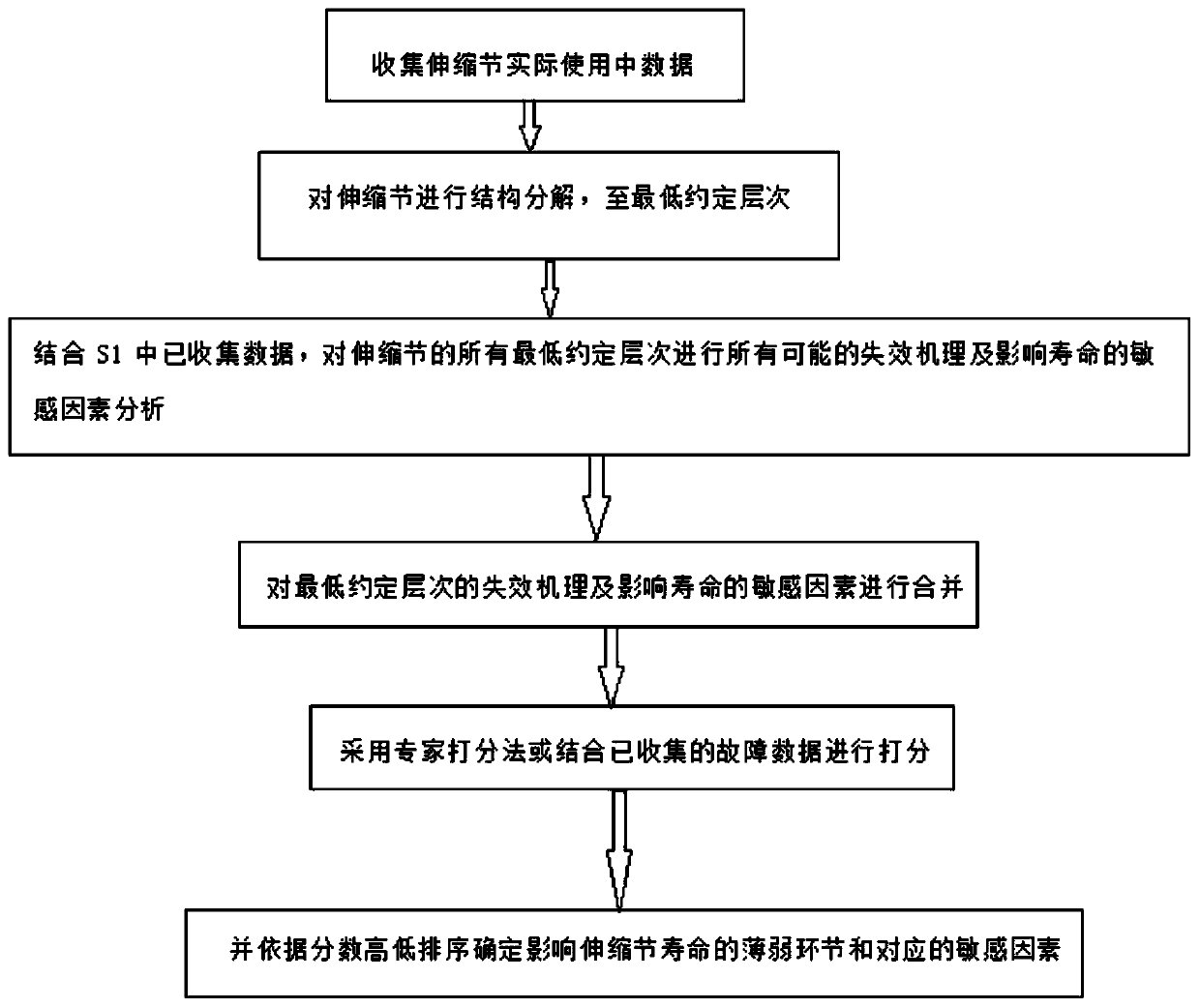

Expansion joint reliability fatigue life assessment method

ActiveCN110069860AIncrease the probability of valueHigh probabilityDesign optimisation/simulationSpecial data processing applicationsElement modelFatigue life assessment

The expansion joint reliability fatigue life assessment method comprises the following specific steps that 1, determining weak links of the fatigue life of an expansion joint product, corresponding failure mechanisms and sensitive factors influencing the fatigue life; step 2, performing nonlinear simulation analysis and fatigue life analysis, and establishing a finite element model of the expansion joint; step 3, determining key parameters influencing the fatigue life of the expansion joint according to the sensitive factors determined in the step 1; carrying out statistical distribution fitting on each key parameter by applying an actual measurement value, and finishing multiple random sampling of the key parameters by adopting a Monte Carlo important sampling method; and 4, evaluating the reliability fatigue life of the expansion joint, inputting sample parameters obtained after multiple times of random sampling into the established expansion joint finite element model, carrying outstatistical distribution fitting on a fatigue life analysis result, and obtaining the reliability fatigue life of the expansion joint under a given confidence coefficient.

Owner:CHINA AERO POLYTECH ESTAB

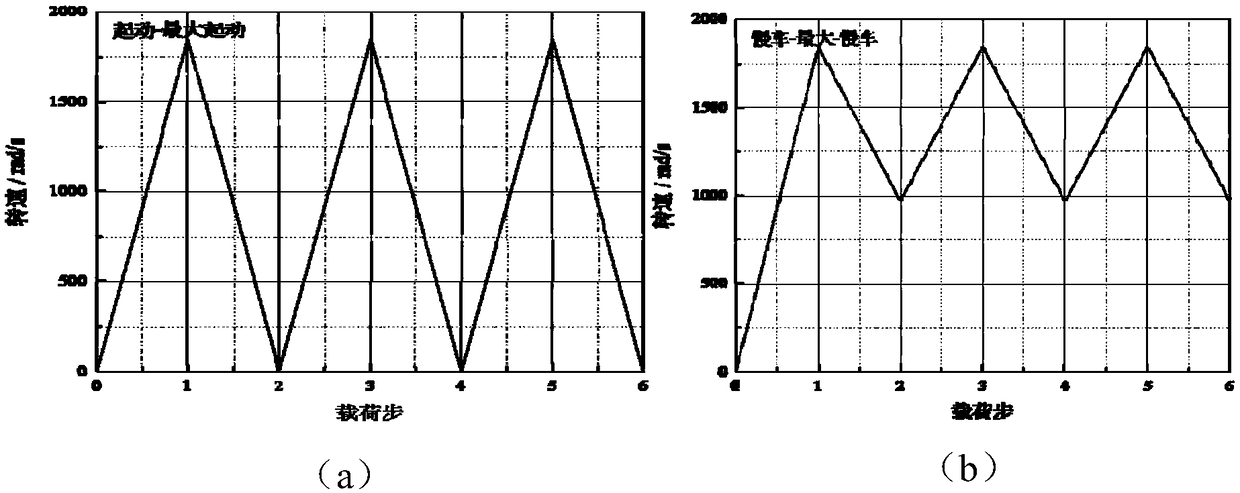

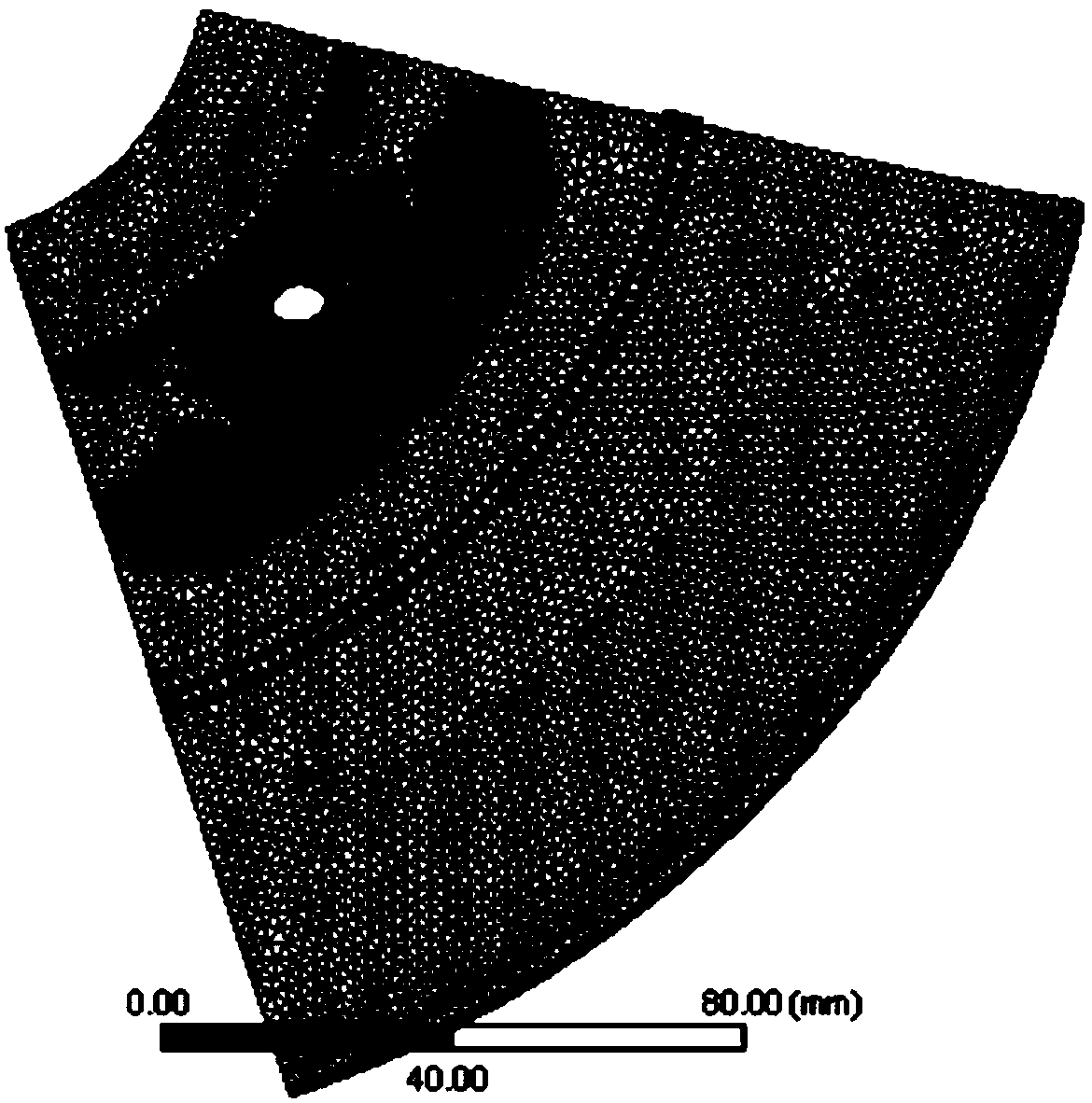

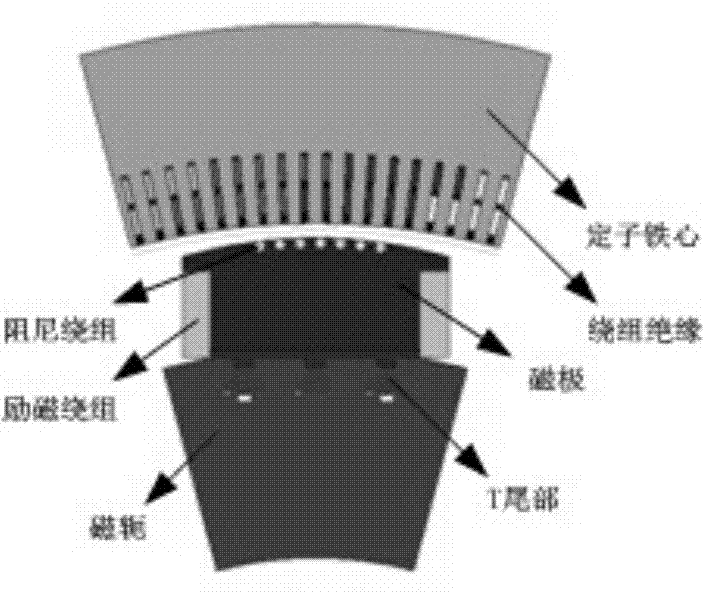

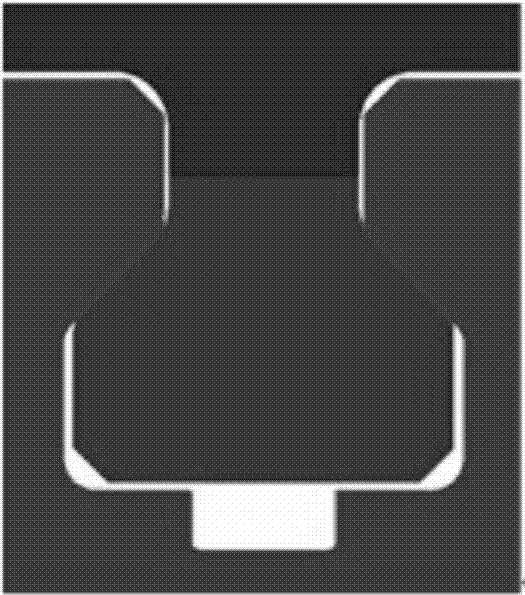

Method for predicting remaining service life of T-shaped tail portion of rotor of pumped-storage power generation motor

ActiveCN104200057ASafe and stable operationSpecial data processing applicationsElectric machineryEngineering

A method for predicting the remaining service life of the T-shaped tail portion of a rotor of a pumped-storage power generation motor comprises the following steps that (1), an electromagnetic field calculation is carried out, wherein excitation source input, namely electromagnetic force, needed by structure field calculation, is obtained through the electromagnetic field calculation; (2) the structure field calculation is carried out; (3), a corrected S-N curve is drawn; (4) the fatigue life of the T-shaped tail portion of the rotor of the pumped-storage power generation motor is predicted through the corrected S-N curve obtained in the step (3) and calculation results of the step (1) and the step (2), and namely prediction of the remaining service life of the T-shaped tail portion of the rotor of the pumped-storage power generation motor is achieved. According to the method for predicting the remaining service life of the T-shaped tail portion of the rotor of the pumped-storage power generation motor, an accumulation effect, not considered in the field of electrical machinery, of multiple working conditions on fatigue failures and S-N curve correction both are used for evaluating the fatigue life of the T-shaped tail portion of the motor of the pumped-storage power generation motor, and accurate prediction of the fatigue life is achieved.

Owner:CHINA THREE GORGES UNIV

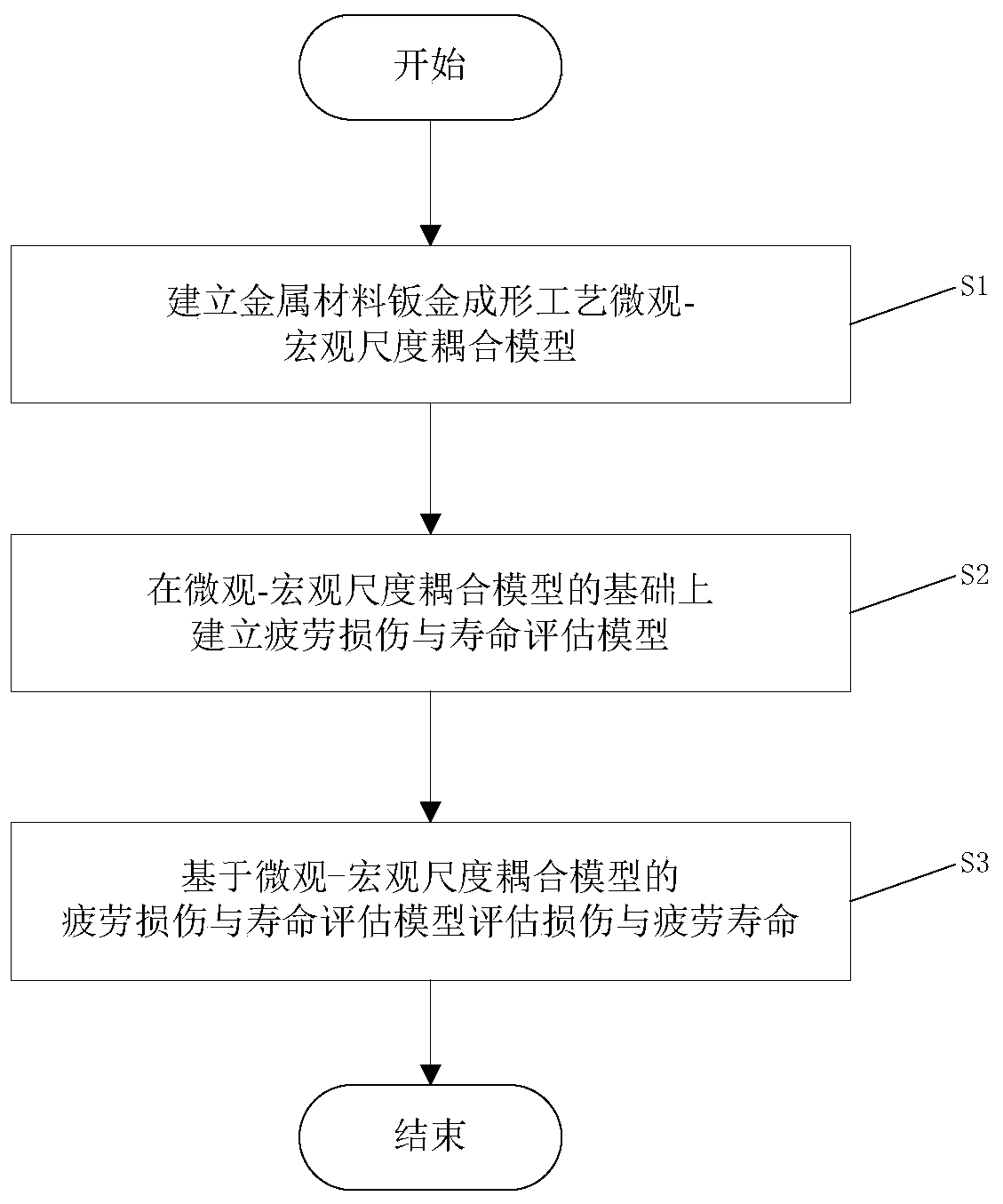

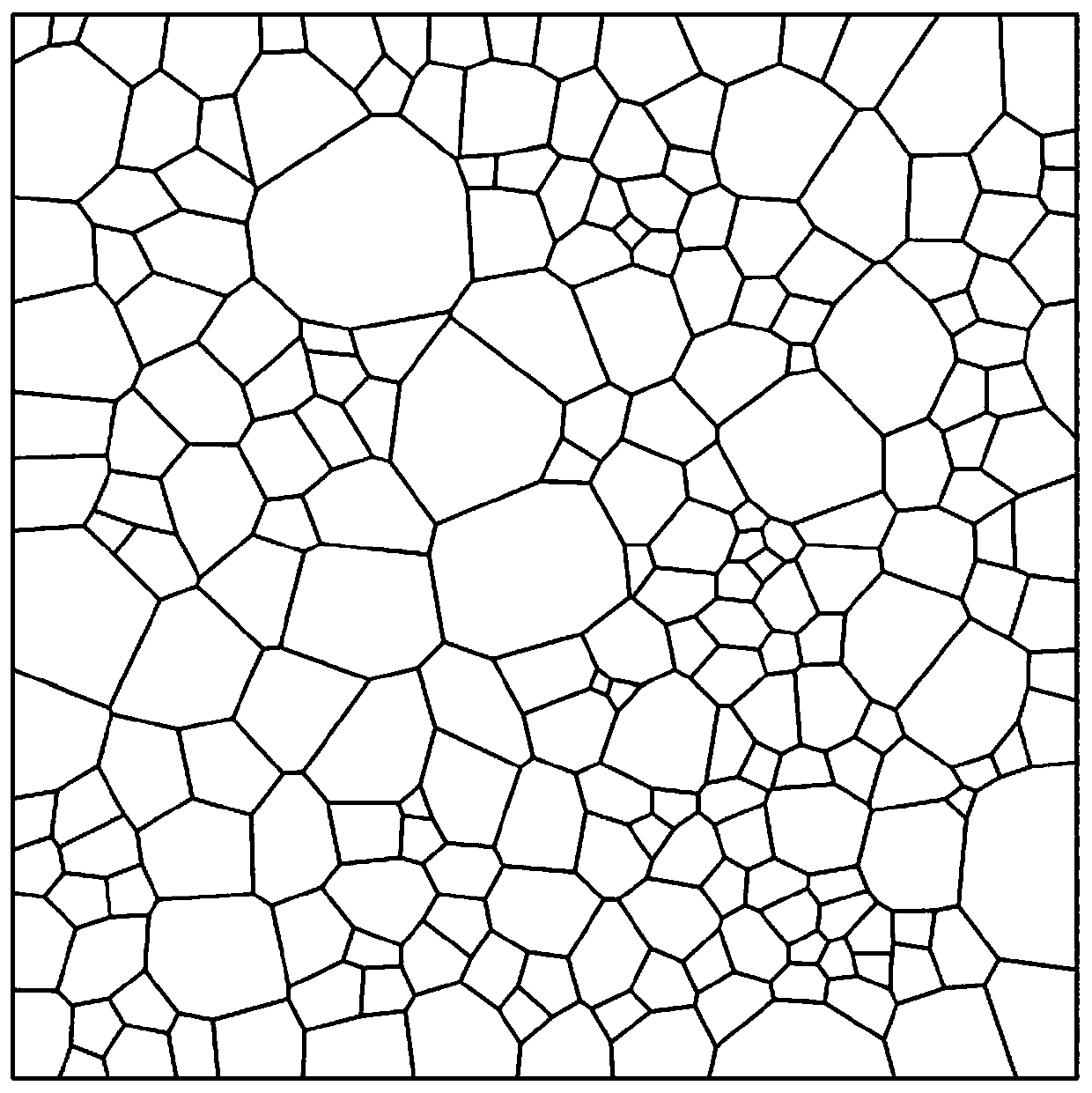

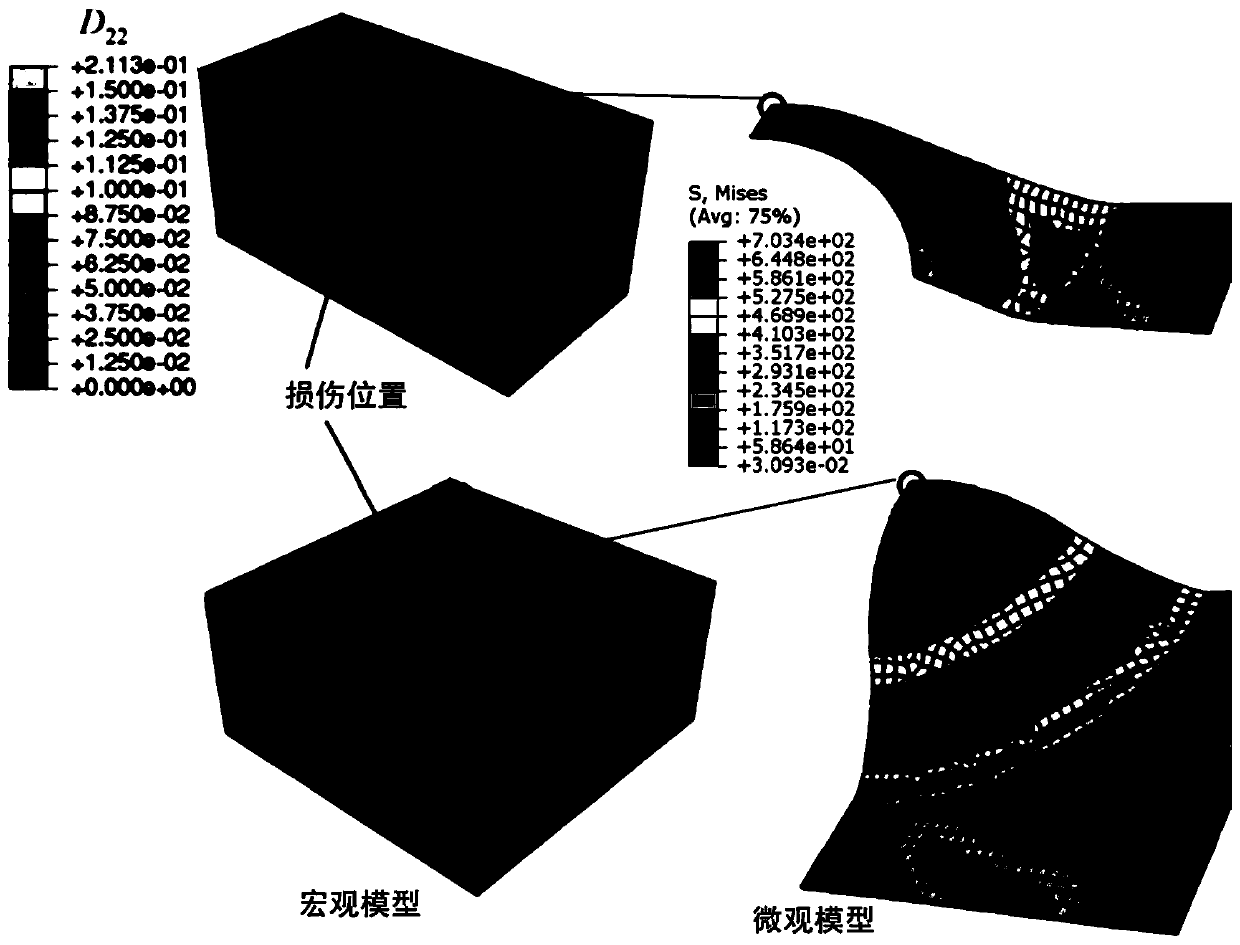

Method for evaluating damage and fatigue life of microscopic-macroscopic scale sheet metal forming process model

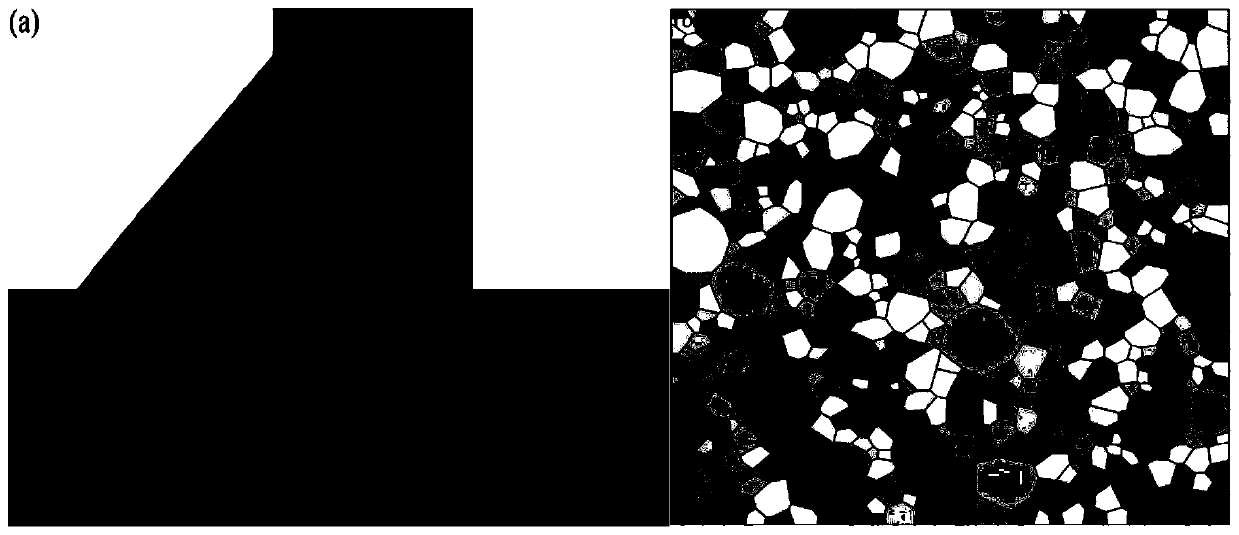

ActiveCN110211645ADesign optimisation/simulationChemical data visualisationFatigue damageMacroscopic scale

The invention discloses a method for evaluating damage and fatigue life of a microscopic-macroscopic scale sheet metal forming process model. According to the method of the invention, a microscopic plastic constitutive model is established and macro geometry is coupled; furthermore sheet metal forming process simulation is performed; based on sheet metal forming process simulation, a microscopic-macroscopic coupling fatigue damage model is established for performing fatigue life simulation; a sheet metal forming process and a fatigue failure mechanism are researched, thereby supplying theoretical guidance and technology optimization basis for engineering application. Sheet metal forming process material performance and plastic deformation evolution distribution are researched in a microscopic aspect. Influence and contribution degree of microscopic characteristics such as crystal grain size and orientation distribution and precipitated phase distribution to the sheet metal forming process are researched. Furthermore the macroscopic model and process researching fatigue damage are coupled, and the component fatigue life is evaluated. The invention provides the reliable high-efficiency calculating model and the evaluating method. Establishment of the related model and the algorithm has important science innovation and high engineering application value.

Owner:SICHUAN UNIV

Wireless intelligent fatigue monitoring system based on life annual ring bionic mechanism

InactiveCN102175472AAchieving real-time monitoring of issuesOptimize layoutStructural/machines measurementMaterial strength using repeated/pulsating forcesFatigue damageWireless transmission

The invention relates to a wireless intelligent fatigue monitoring system based on a life annual ring bionic mechanism and belongs to the technical field of engineering structure safety monitoring. The system is characterized in that a process of simulating the annual ring bionic mechanism comprises the following steps: firstly, collecting a local stress signal of a to-be-monitored object by using an embedded micro-process technique; secondly, extracting the stress signal fatigue alternating characteristic parameters by using a fatigue load spectrum rain-flow method, thereby acquiring fatigue characteristic parameters including a strain amplitude, a cycle index and a stress status; managing the data; based on the fatigue characteristic parameters, estimating the fatigue damage accumulated state and fatigue life of the to-be-monitored object and early warning the fatigue damage; and lastly, using a wireless transmission unit to remotely transmit a processing result. The wireless intelligent fatigue monitoring system has the advantage of conveniently realizing the real-time monitoring for engineering fatigue, including realizing the accumulated fatigue damage analysis, life estimation and early warning algorithm. Besides, the principle is clear, the integrated degree is high, the arrangement is convenient, the result is reliable and the cost is low.

Owner:DALIAN UNIV OF TECH

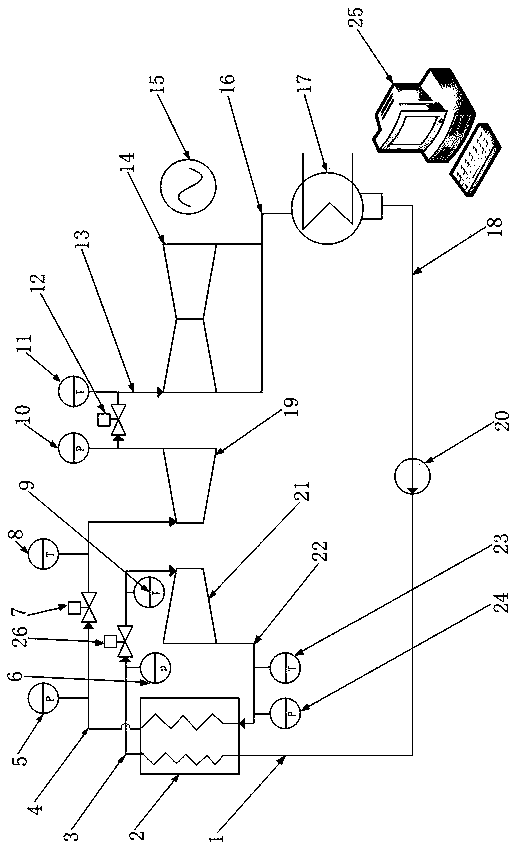

Online life assessment system and method of thermal power plant steam pipeline

PendingCN109870295AAvoid Sampling Economic LossImprove securityMachine part testingThermometer applicationsSocial benefitsEconomic benefits

The invention relates to an online life assessment system and method of a thermal power plant steam pipeline. The system comprises a utility boiler, a low pressure cylinder, an electric generator, anintermediate pressure cylinder, a high pressure cylinder and a computer; the life of the steam pipeline can be assessed online as required, the metal technical supervisory means is enriched, and meanwhile, improvement on the running security of the generator is facilitated; preliminary life assessment can be performed and risk pre-warning can be performed on the basis of not damaging the existingsteam pipeline; a great deal of temperature and pressure data are recorded and analyzed, and combined with large and small corrected metal detection data and microstructural detection results, and thus deformation-fatigue life assessment is achieved via a rebuilt algorithm preset in the computer. According to the system and method provided by the invention, manpower resource liberation and a greatdeal of metal detection work are achieved by combining with the actual steam pipeline life assessment, and meanwhile, the pipeline sampling economic losses without purposes and within a large range are avoided, so that the system and method have good economic benefits and social benefits, and the problem in present high-temperature high-pressure metal key life assessment is solved.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

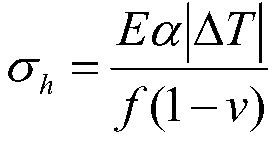

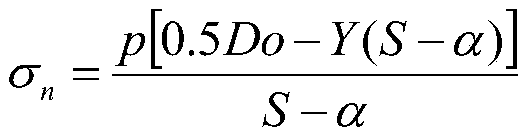

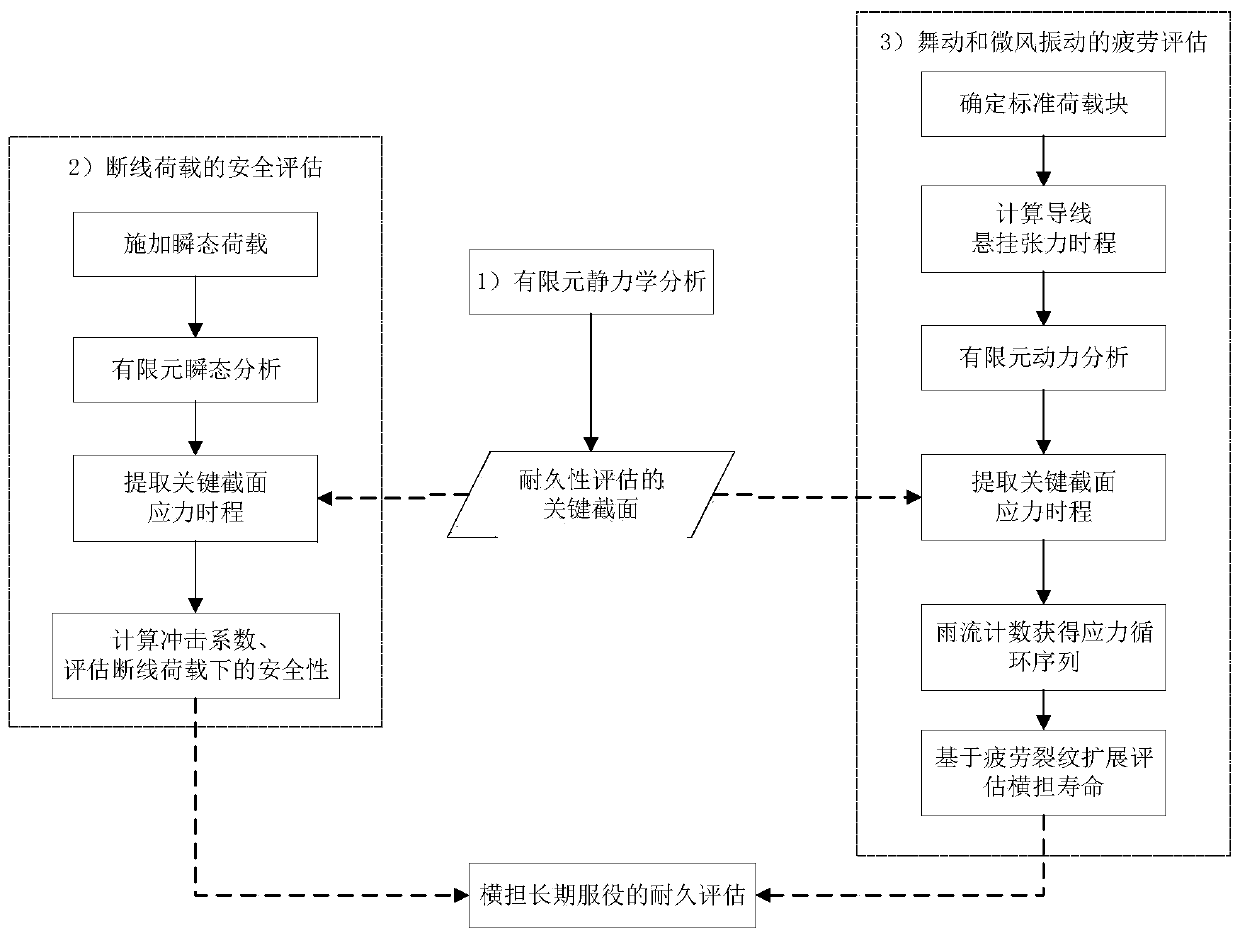

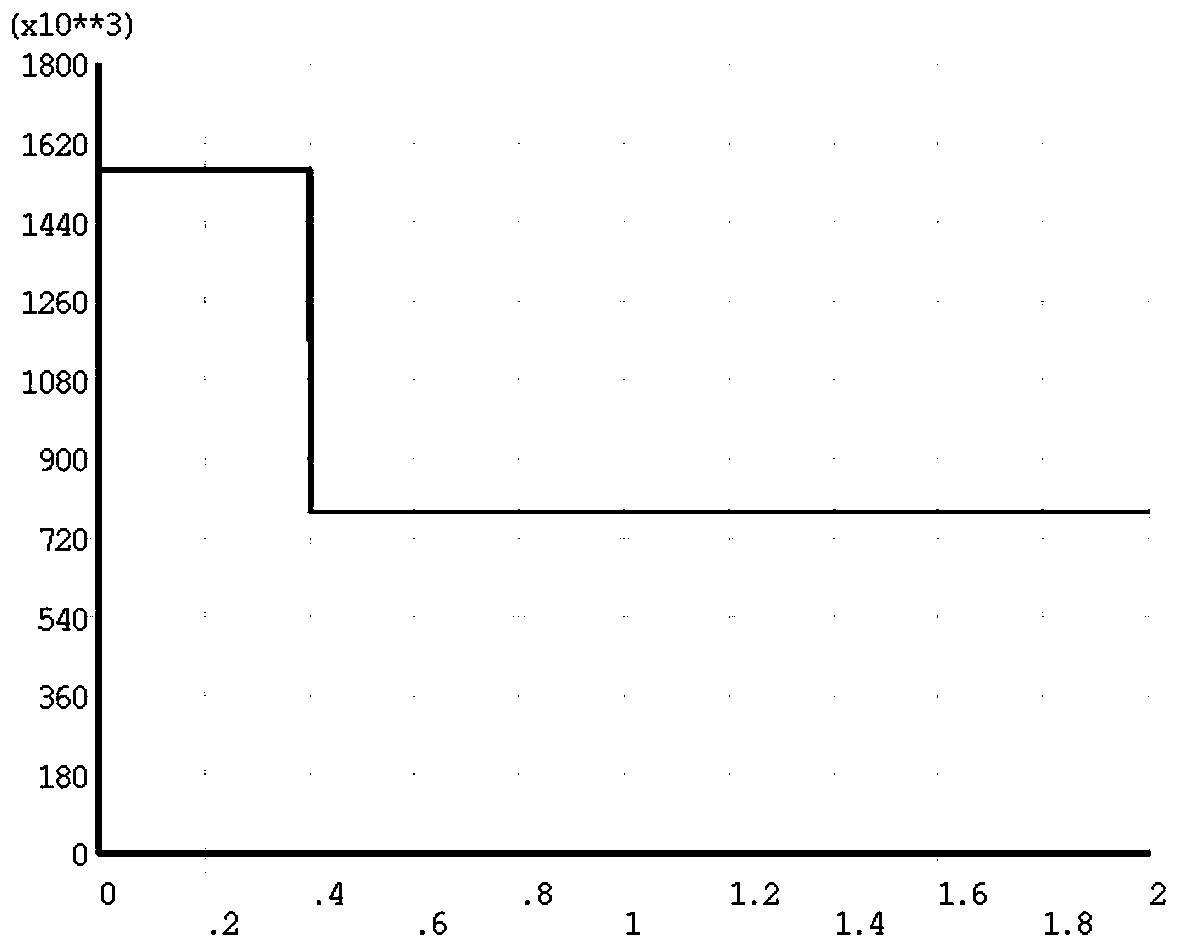

Method and device for evaluating the durability of a composite insulating cross arm

The invention discloses a method and device for evaluating the durability of a composite insulating cross arm, and the method comprises the steps: carrying out the finite element analysis of the stress response of a composite cross arm under the action of a static load, and finding a key cross section for durability evaluation; for three key load factors influencing the service durability of the composite cross arm, namely a broken line load, conductor galloping and breeze vibration, adopting different evaluation strategies for evaluation; for the line breaking working condition, applying a line breaking load to the cross arm, acquiring the dynamic stress response of the key section, calculating the impact coefficient and evaluating safety; selecting a standard load block of galloping andbreeze vibration, carrying out dynamic analysis on a cross arm under the action of conductor galloping and breeze vibration to obtain a dynamic stress response of a key section, and carrying out fatigue life evaluation. According to the method, the durability of the cross arm under the combined action of various loads can be evaluated, the nonlinear development process of damage can be reflected,and the method is accurate and reliable compared with a traditional estimation method.

Owner:STATE GRID JIANGSU ELECTRIC POWER CO ELECTRIC POWER RES INST +4

Probability fatigue reliability evaluation method for high-speed rail bearing

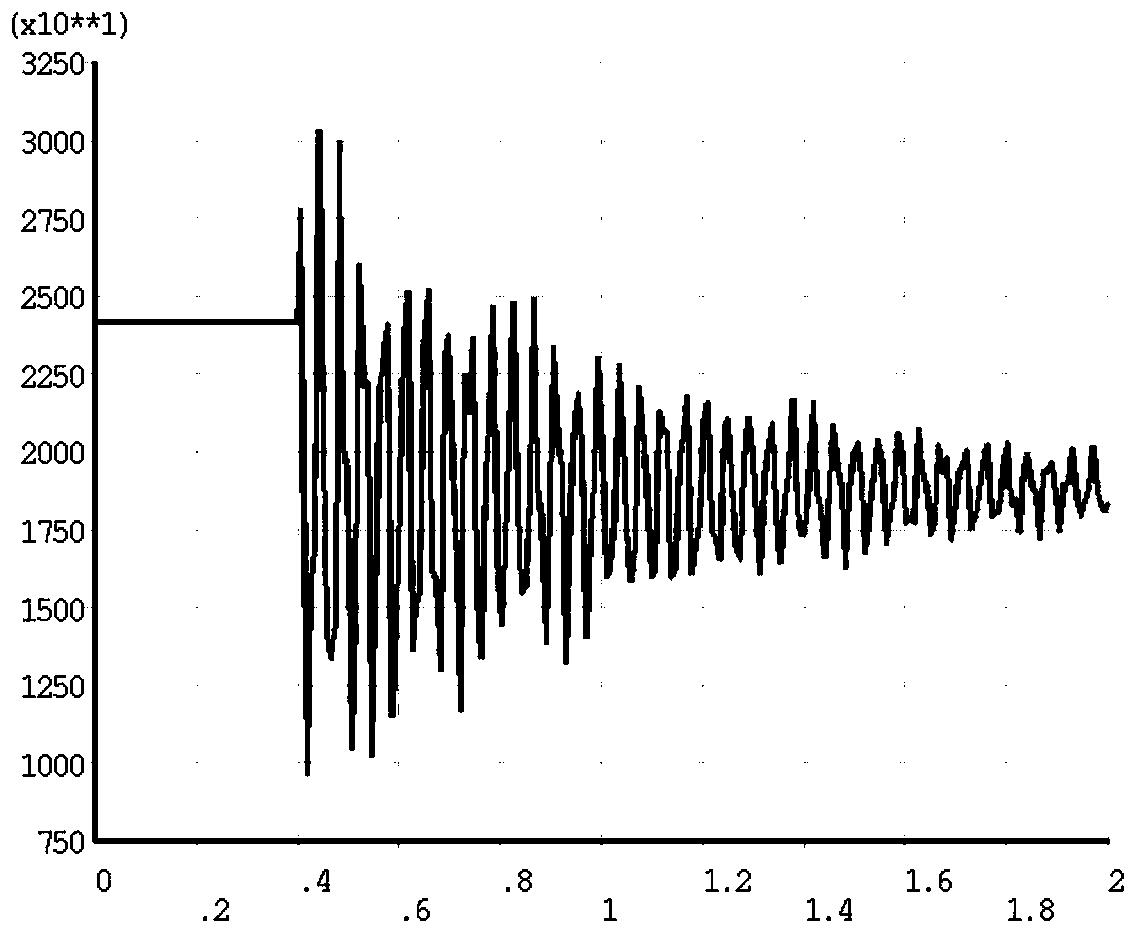

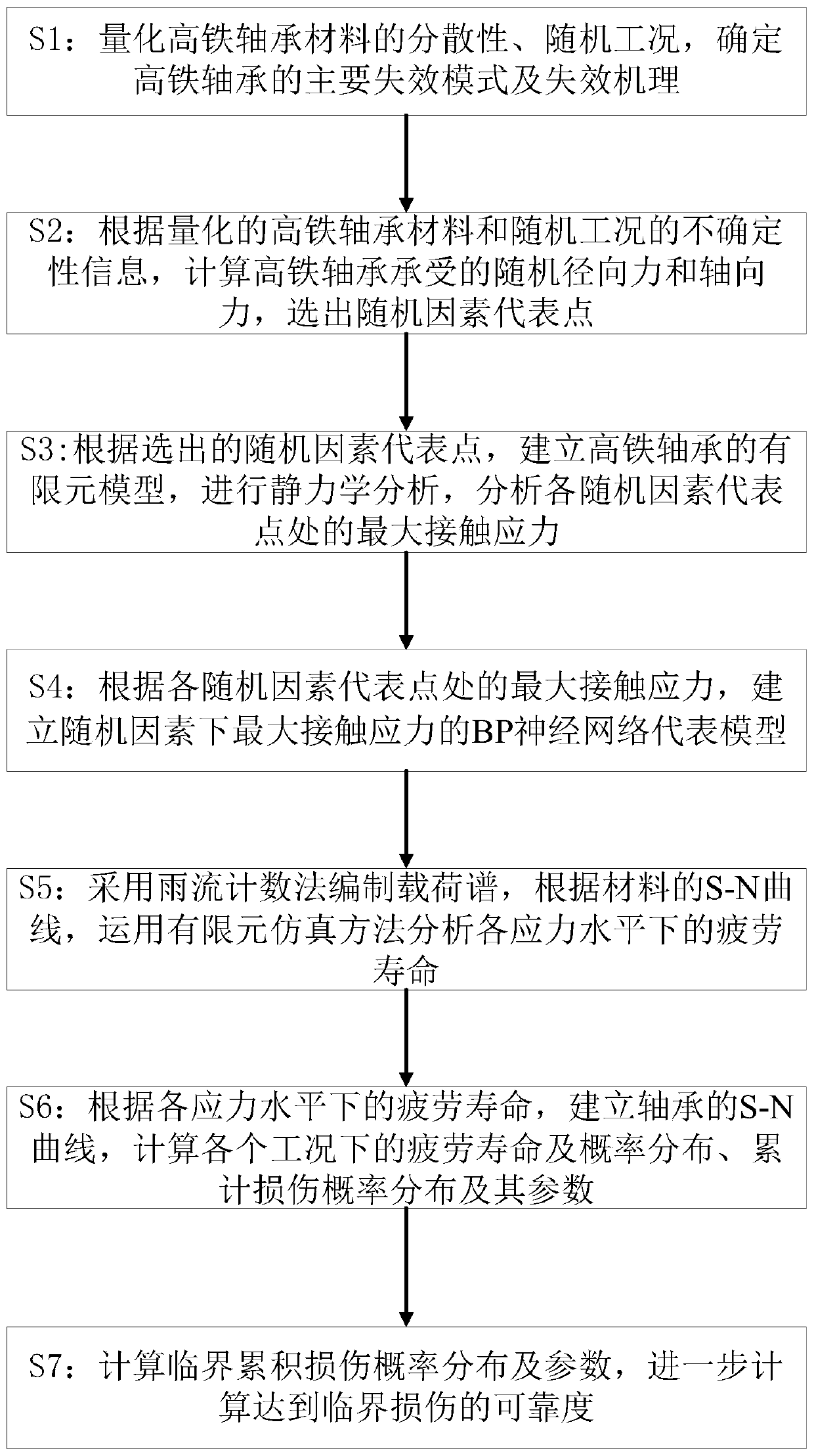

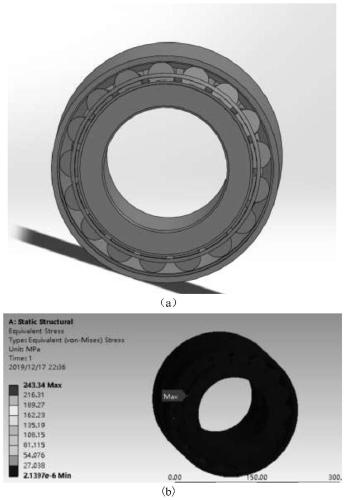

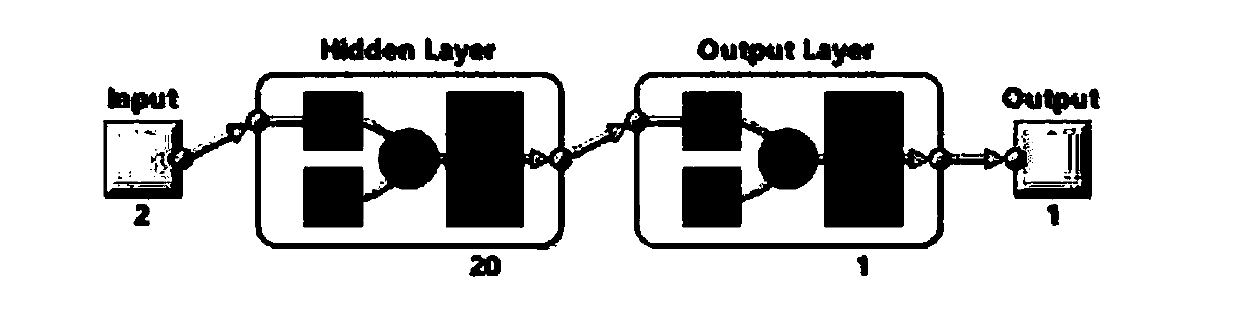

The invention discloses a probability fatigue reliability evaluation method for a high-speed rail bearing, and the method comprises the steps: firstly carrying out the quantification of the dispersibility of a material and the randomness of a load for the complex correction of an L10 life formula, and selecting a random factor representative point based on a number theory point selection method; secondly, establishing a three-dimensional finite element simulation model of the high-speed rail bearing according to the selected representative points, further analyzing the contact stress of the bearing under the influence of random factors, and establishing a BP neural network agent model of the maximum contact stress; compiling an S-N curve of the material through a load spectrum; a finite element simulation method is used for analyzing the fatigue life of the bearing, the accumulated damage of the bearing and the reliability smaller than the critical damage are further calculated according to the fatigue damage accumulation principle, so that an effective method is provided for high-precision and high-efficiency depiction of failure physics and fatigue life evaluation of the high-speed rail bearing.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

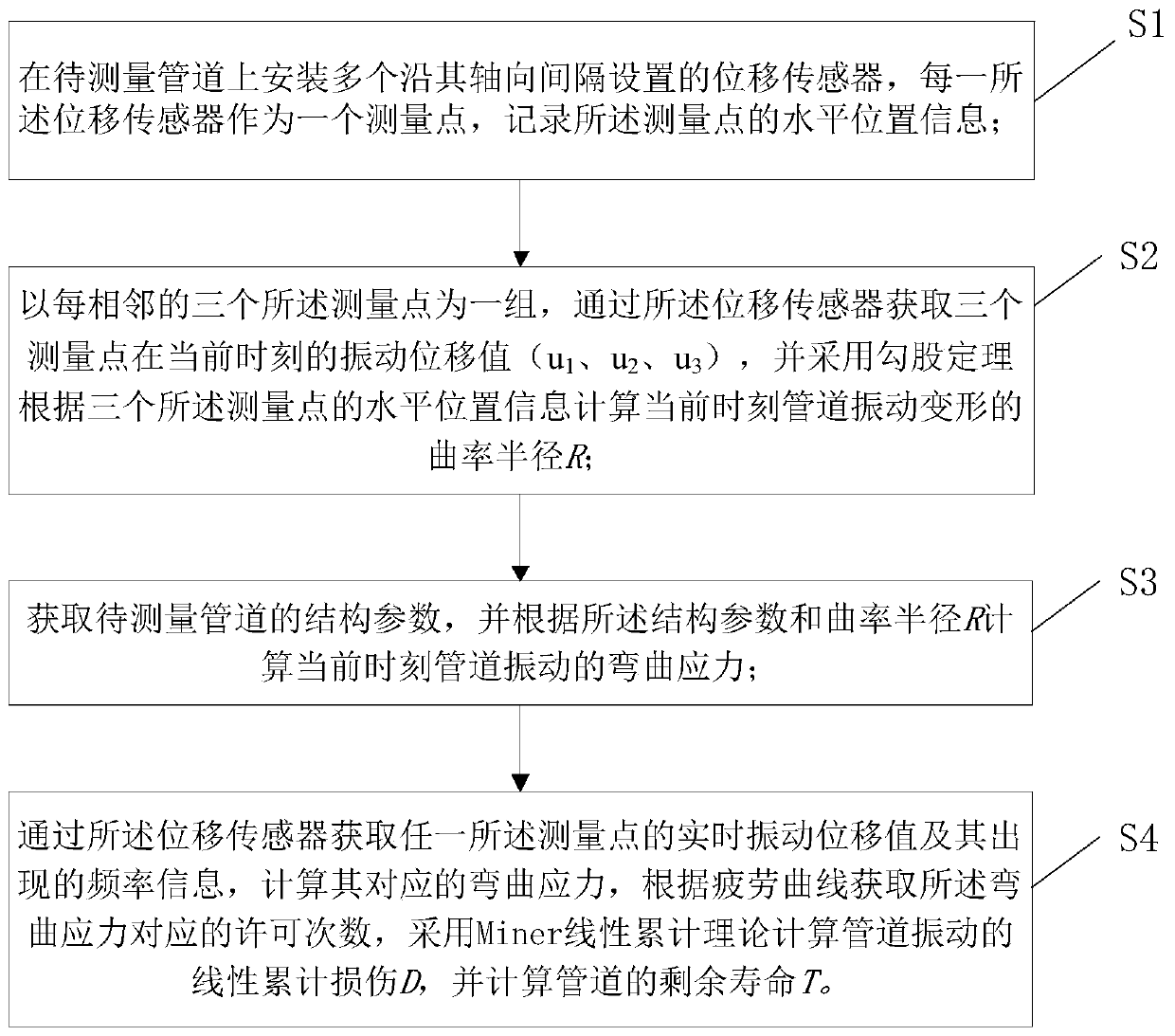

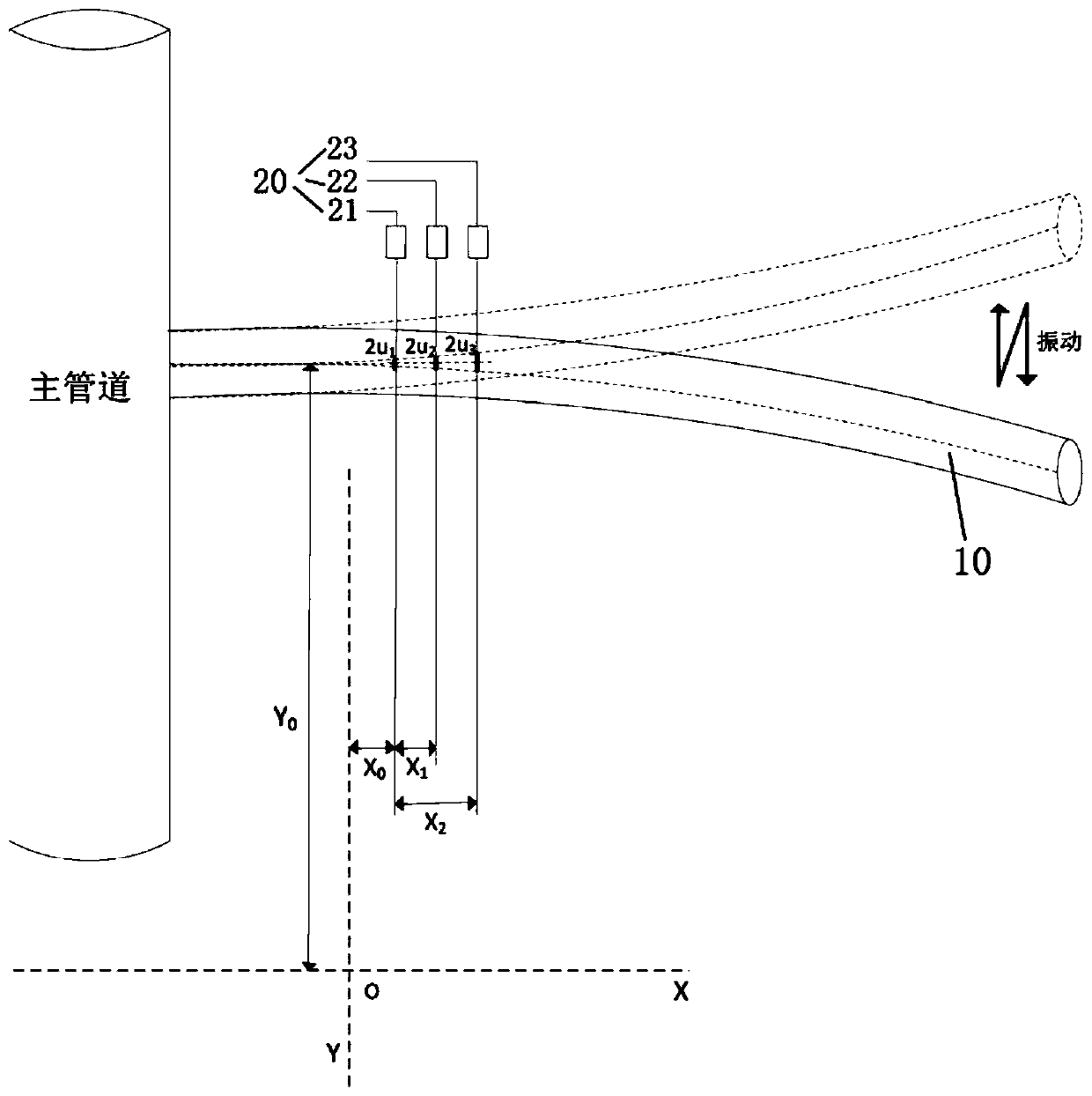

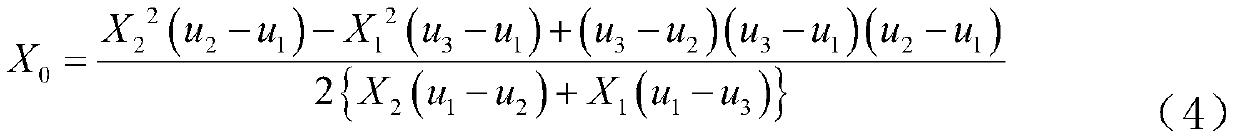

Small pipe vibration stress measurement and fatigue life evaluation method for nuclear power plant

ActiveCN110108455ASolve high radiationSolve temperature problemsMachine part testingSubsonic/sonic/ultrasonic wave measurementStress measurementStress measures

The invention provides a small pipe vibration stress measurement and fatigue life evaluation method for a nuclear power plant. The method comprises the steps that S1) displacement sensors arranged along the axial direction of a pipe at interval are mounted on the pipe, and each displacement sensor serves as a measurement point; S2) the displacement sensors obtain vibration displacement values of the corresponding measurement points, the vibration deformation radius of curvature of the pipe at present time is calculated according to horizontal position information of the measurement points by means of the Pythagoras theorem; S3) structure parameters of the pipe to be measured are obtained; and the vibration bending stress of the pipe at the present time is calculated according to the structural parameters and the radius of curvature; and S4) the displacement sensor obtains real-time vibration displacement value and frequency information of any measurement point, a Miner linear accumulation theory is used to calculated linear accumulated damage of pipe vibration, and residual life of the pipe is calculated. A non-contact measurement manner is used to calculate the vibration bending stress and fatigue life of the pipe rapidly, and the technical effect is good.

Owner:中广核工程有限公司 +2

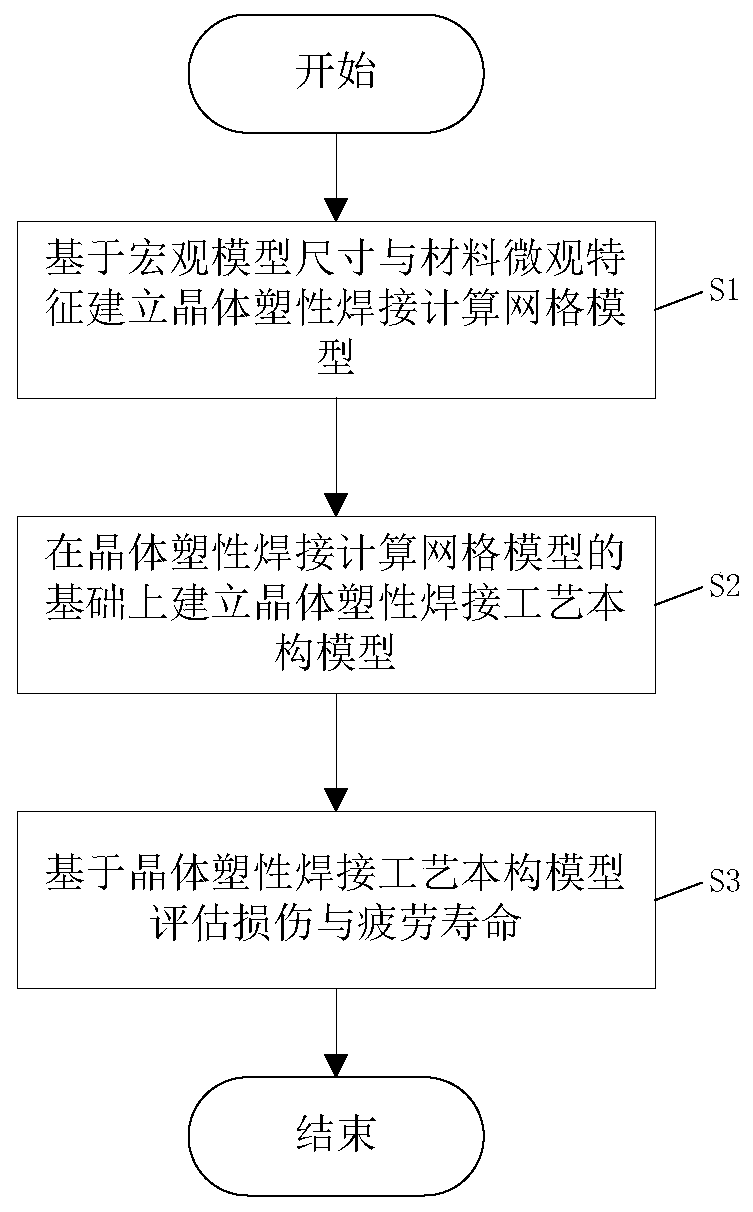

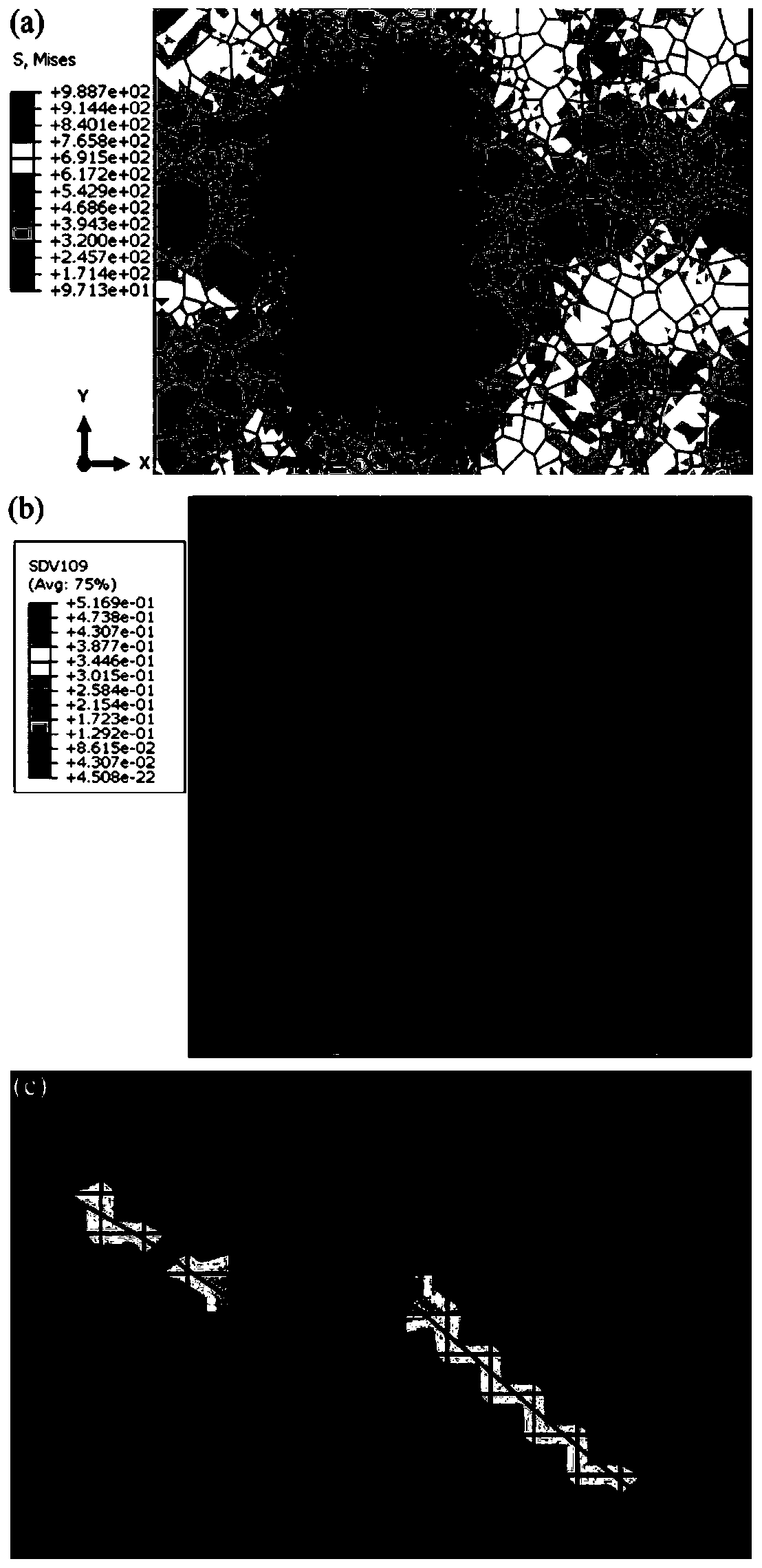

Damage and fatigue life evaluation method based on crystal plastic welding process model

ActiveCN110232243AFix damageSolve the problem of longevityDesign optimisation/simulationSpecial data processing applicationsCouplingEngineering

The invention discloses a damage and fatigue life evaluation method based on a crystal plastic welding process model. According to a crystal plastic constitutive model of the welding process and the calculation method, the influence of a crystal slip system and polycrystalline plastic strain on the welding process performance of the material is considered. A mesoscopic layer welding process damageand fatigue life evaluation model is established. The influence of the microscopic characteristics of the material on the welding process performance and the influence on the damage and fatigue lifeof a welding joint can be researched from the perspective of mesoscopic view. Through a macro-mesoscopic coupling calculation model, the relationship between welding process and material property evolution process is clarified, and the influence and degree of welding process on material damage and fatigue life are further determined, which provides important for studying the damage evolution and fatigue failure process of materials after welding process. The method has important scientific significance and engineering application value.

Owner:SICHUAN UNIV

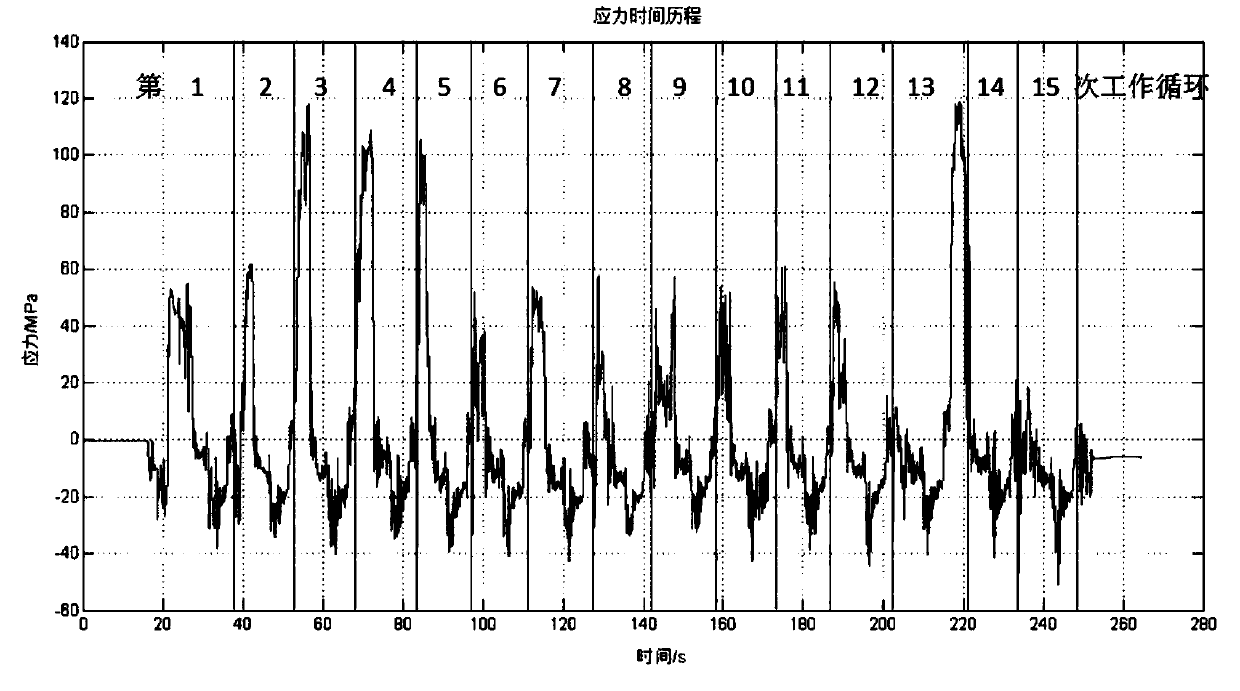

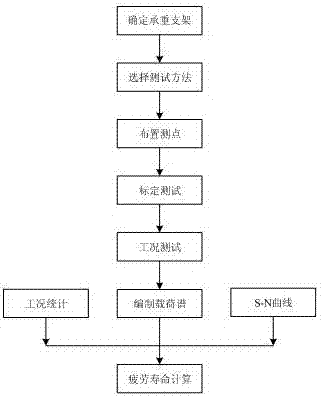

Mixed flow type hydroturbine weight-bearing bracket fatigue life test and analysis method

ActiveCN106990002ALarge strainTrue Effective Fatigue Life AssessmentMaterial strength using repeated/pulsating forcesLoad rejectionLoad time

The invention discloses a mixed flow type hydroturbine weight-bearing bracket fatigue life test and analysis method, which is characterized by comprising: determining a main weight-bearing bracket according to the structure form of a mixed flow type hydroturbine unit, measuring the strain at the surface of the weight-bearing bracket, ejecting the rotating part of the unit in a shutdown state, obtaining a strain value when the gravity of the rotating part of the unit is applied on the bracket, obtaining actual force applied on the bracket, carrying out strain measurement during a starting process, a load applying process, a load rejection process and a shutdown process, calculating the force applied on the weight-bearing bracket, counting the load-time processes of each working condition by using a cyclic counting method, counting the operating times of various working conditions, obtaining a bracket material S-N curve, and according to the working conditions, the load spectrum and the S-N curve, calculating the bracket fatigue life according to linear cumulative damage. According to the present invention, with the method, the actual force applied on the bracket can be rapidly and accurately measured, the fatigue life evaluation can be really and effectively performed on the weight-bearing bracket, and the weight-bearing bracket fatigue life analysis accuracy is improved.

Owner:STATE GRID CORP OF CHINA +2

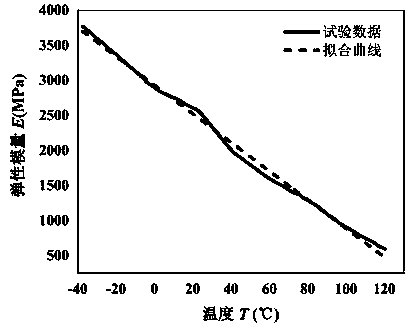

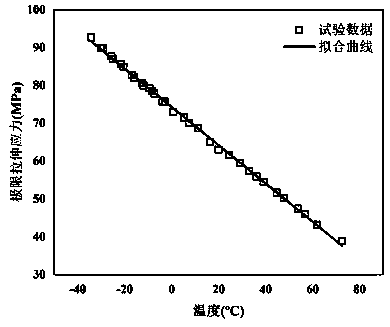

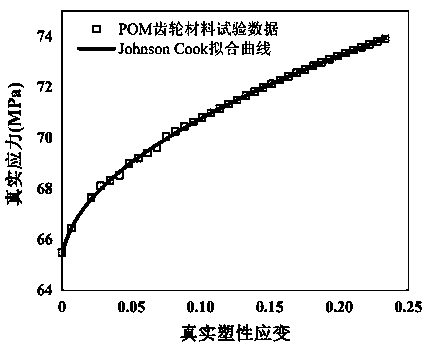

Plastic gear contact fatigue life evaluation method considering temperature influence

PendingCN111144044AReduce accidentsReduce economyDesign optimisation/simulationElement modelGear wheel

The invention discloses a plastic gear contact fatigue life evaluation method considering temperature influence. The method comprises the following steps: step 1, testing plastic temperature-related mechanical behaviors according to standards; 2, fitting a plastic thermoelastic-plastic constitutive equation according to the test data, and writing a subprogram UMAT of ABAQUS; 3, determining the temperature of the plastic gear in the operation process by calculation or test; 4, establishing a two-dimensional gear complete thermal coupling contact finite element model on the ABAQUS platform; 5, fitting a limit tensile stress equation changing along with temperature according to the material test parameters, and obtaining plastic fatigue parameters according to the conversion relation betweenthe tensile yield limit and the fatigue parameters; and step 6, calculating the fatigue life of the plastic gear by using a Brown-Miller multi-axis fatigue criterion. The method has the technical effect that the problem of contact fatigue failure of the plastic gear under the influence of the operating temperature is solved.

Owner:CHONGQING UNIV

Ultra-high cycle fatigue life forecasting method of high-strength titanium alloy electron beam welding joint

ActiveCN109142529AHigh cycle fatigue lifeWeekly fatigue life avoidanceAnalysing solids using sonic/ultrasonic/infrasonic wavesMetallurgyWelding defect

The invention discloses an ultra-high cycle fatigue life forecasting method of a high-strength titanium alloy electron beam welding joint. According to the method, ultra-high cycle fatigue performances of the high-strength titanium alloy electron beam welding joint are acquired by the aid of an ultrasonic fatigue test, electron beam welding defect size parameters are introduced based on nano-crackpropagation theories, an ultra-high cycle fatigue life loss equation is built, and ultra-high cycle fatigue service lives of high-strength titanium alloy welding structures of different electron beamwelding defects are quantitatively forecasted. The ultra-high cycle fatigue service life loss equation containing electron beam welding defect size parameters is built through the ultrasonic fatiguetest, electron beam welding defect sizes are acquired through metallographic profile or non-destructive inspection, and the ultra-high cycle fatigue service lives of the high-strength titanium alloy welding structures of different electron beam welding defects can be quantitatively forecasted. According to the method, a lot of ultra-high cycle fatigue tests of electron beam welding joints are avoided, ultra-high cycle fatigue service life assessment can be completed, and the method has the advantages of simplicity, rapidness and economical property.

Owner:FOSHAN UNIVERSITY

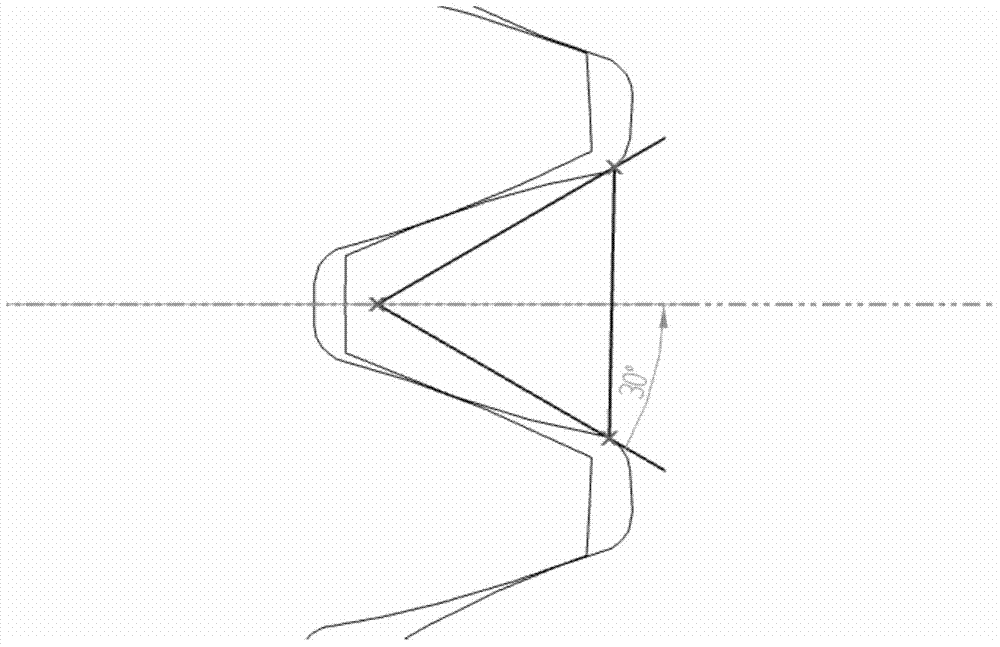

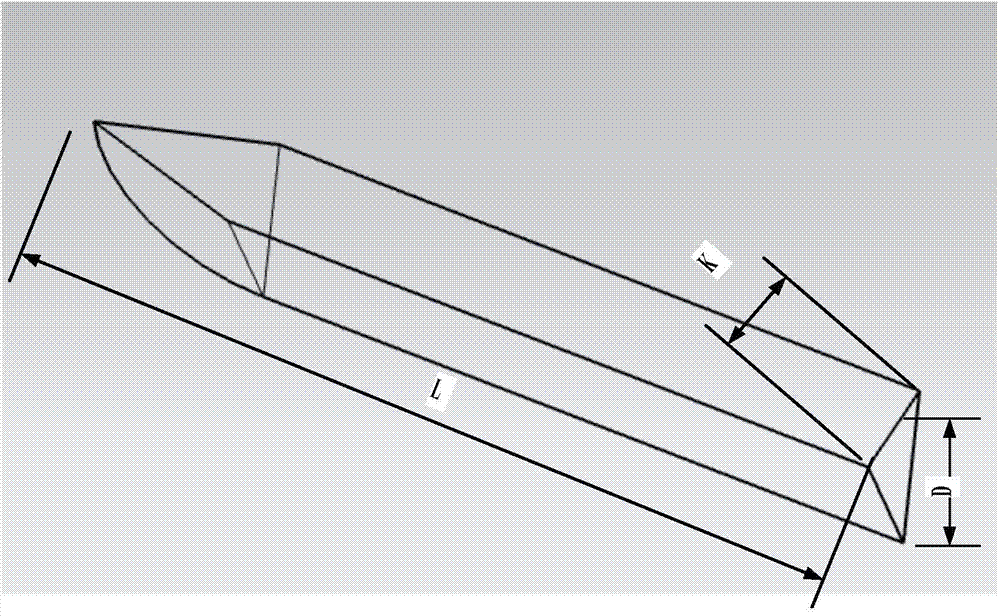

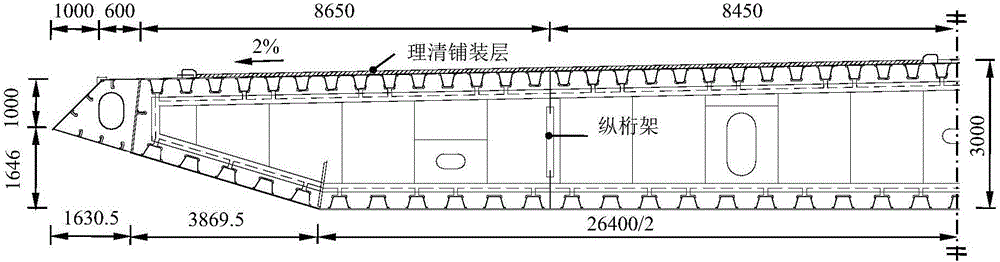

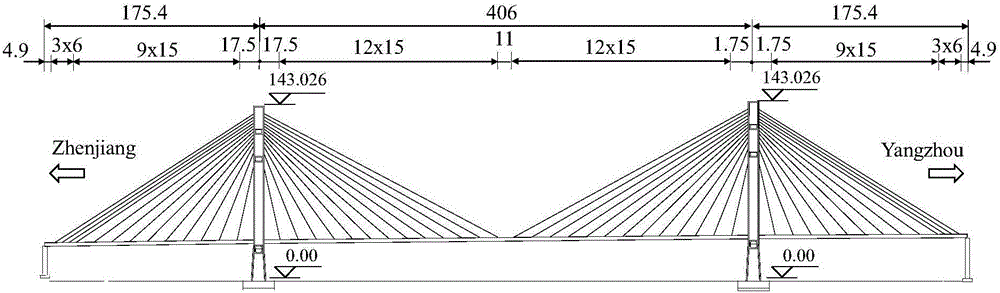

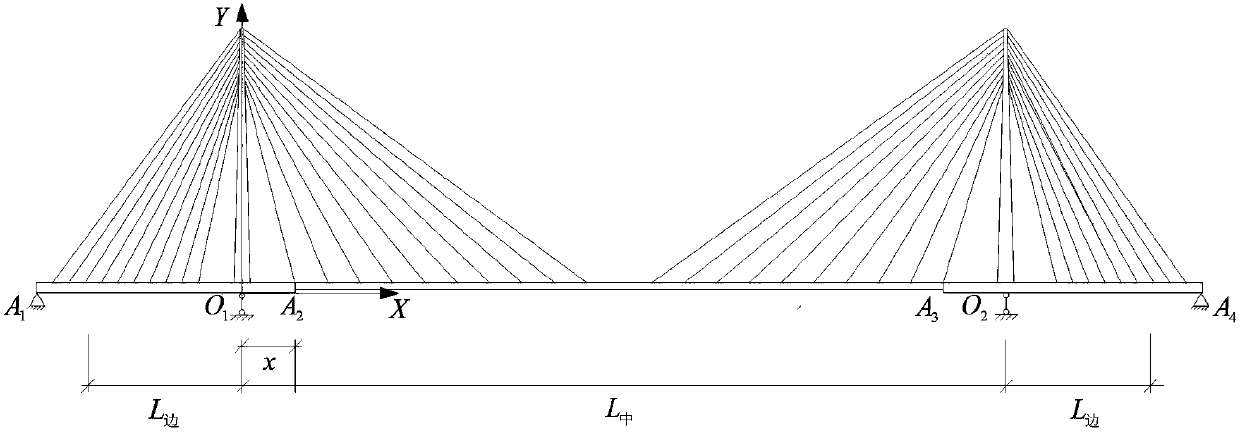

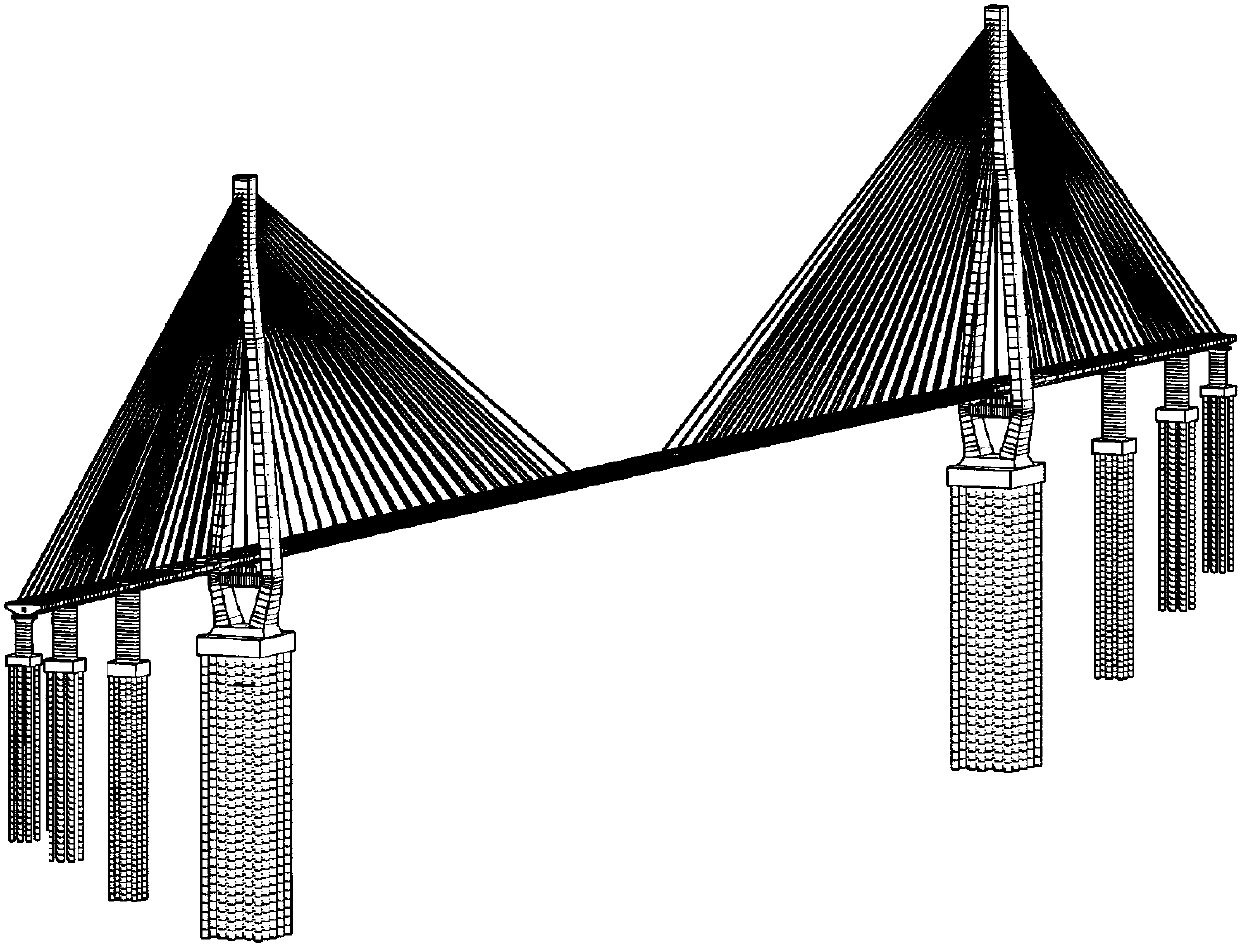

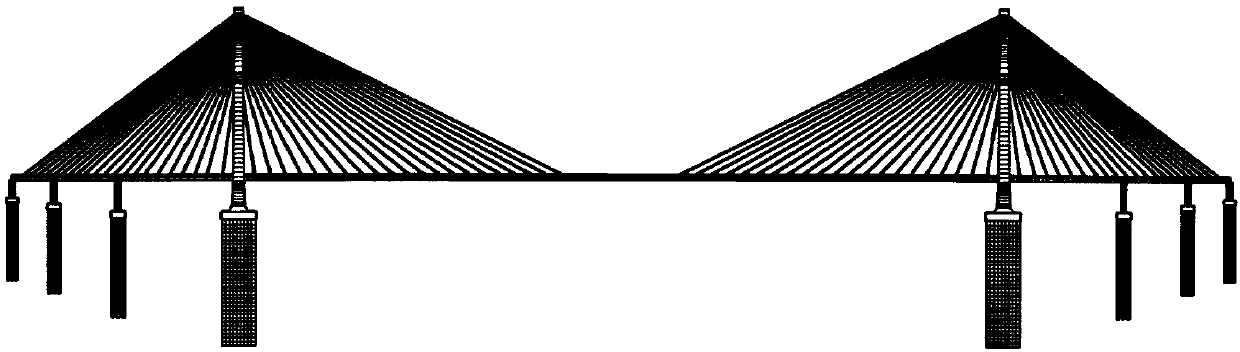

Optimization method of position of steel-concrete combined section of large-span cable-stayed bridge based on fatigue service life assessment

ActiveCN108038338ASolve the hidden danger of fatigue damageSolve critical issues involving fatigue lifeDesign optimisation/simulationSpecial data processing applicationsFatigue damageStructural fatigue

The invention relates to optimization of the position of a steel-concrete combined section of a large-span cable-stayed bridge. The section bending moment of the steel-concrete combined section of thelarge-span cable-stayed bridge, the fatigue service life of a shear connecting piece of the steel-concrete combined section, the pier additional bending moment of the steel-concrete combined sectionin the construction state and the steel beam manufacturing cost are selected as four targets, the position of the steel-concrete combined section serves as a decision variable, and a multi-target function of the optimized position of the steel-concrete combined section is established; the multi-target function is solved through a genetic algorithm, and the optimized position of the steel-concretecombined section is obtained. Compared with the prior art, the optimization method of the steel-concrete combined section of the large-span cable-stayed bridge is disclosed from the perspective of structure fatigue damage, and the hidden hazard that the shear connecting piece of the steel-concrete combined section of the large-span cable-stayed bridge generates fatigue damage is eliminated.

Owner:WUHAN UNIV OF TECH

Highway steel bridge fatigue analysis method based on actually measured stress spectrum

InactiveCN110455563AAccurate and reliable fatigue life assessmentProne to driftStructural/machines measurementStrength propertiesBridge engineeringFatigue damage

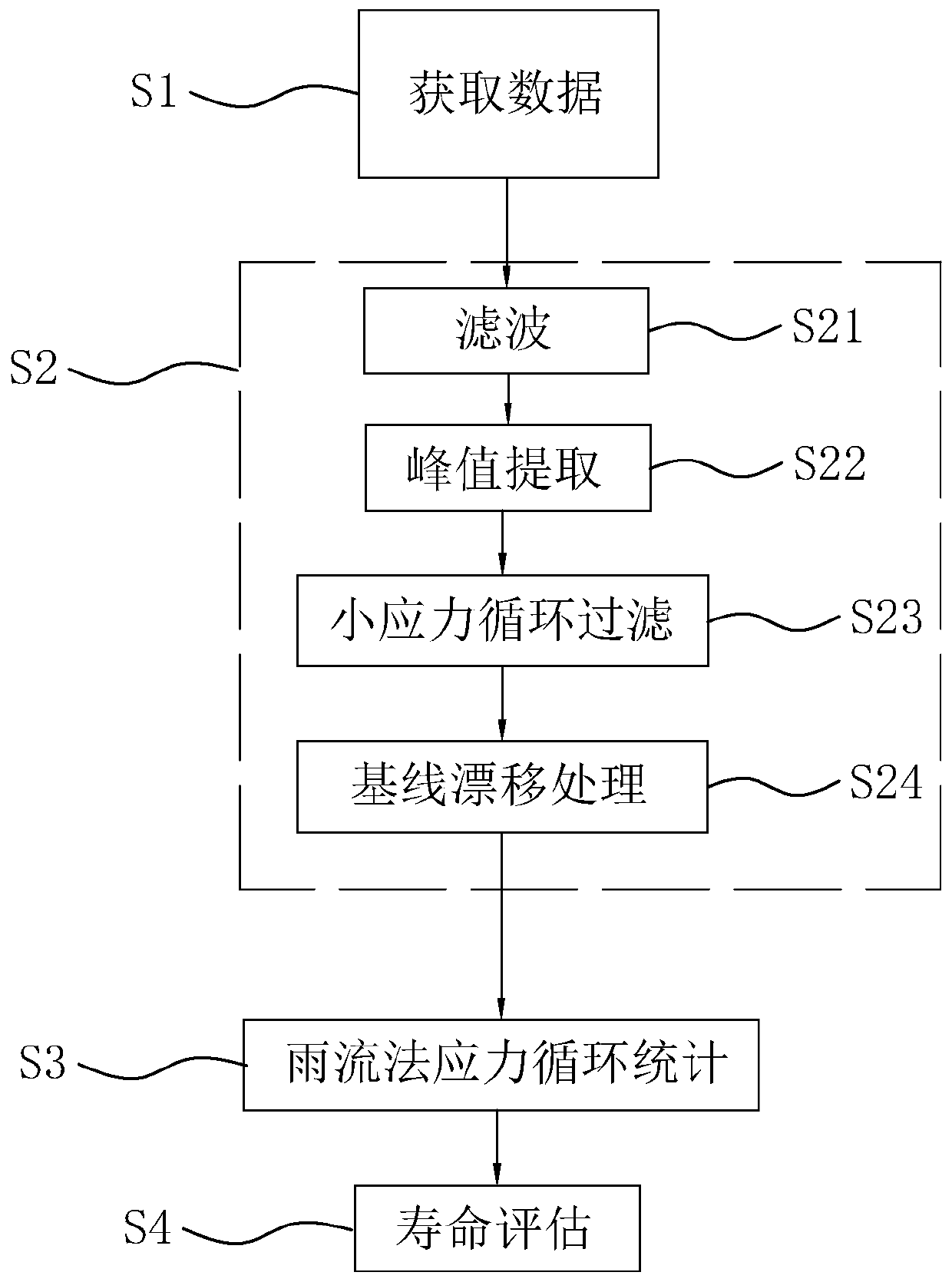

The invention relates to the technical field of the road bridge engineering detection, and discloses a highway steel bridge fatigue analysis method based on an actually measured stress spectrum. The technical problem that the strain detection data collected through the current actual measurement method has multiple idle clutter is solved. The method comprises the following steps: S1, acquiring data; S2, processing a strain data signal: S21 filtering; S22, peak value extracting; S23, small stress circular filtering; S24, base line drift processing; S3, performing rain-flow method stress circular counting, thereby obtaining stress spectrum through the rain-flow method counting; and S4, evaluating a fatigue problem by utilizing a fatigue life evaluation theory, and computing fatigue damage and residual life of each measurement point. According to above technical scheme, the fatigue strain monitoring data is acquired and collected through an actual measurement method, and then the filtering, the peak extraction, the small stress circular filtering and the baseline drifting processing and like operations are performed on the acquired fatigue strain monitoring data, and finally, the fatigue damage and the residual life of each measurement point are computed, thereby reaching an aim of improving the evaluation accuracy and reliability.

Owner:上海市市政公路工程检测有限公司

Evaluation method, device and system for fatigue life of weld joint of wagon body

ActiveCN109684663AImprove forecast accuracyGeometric CADSustainable transportationSimulationWeld seam

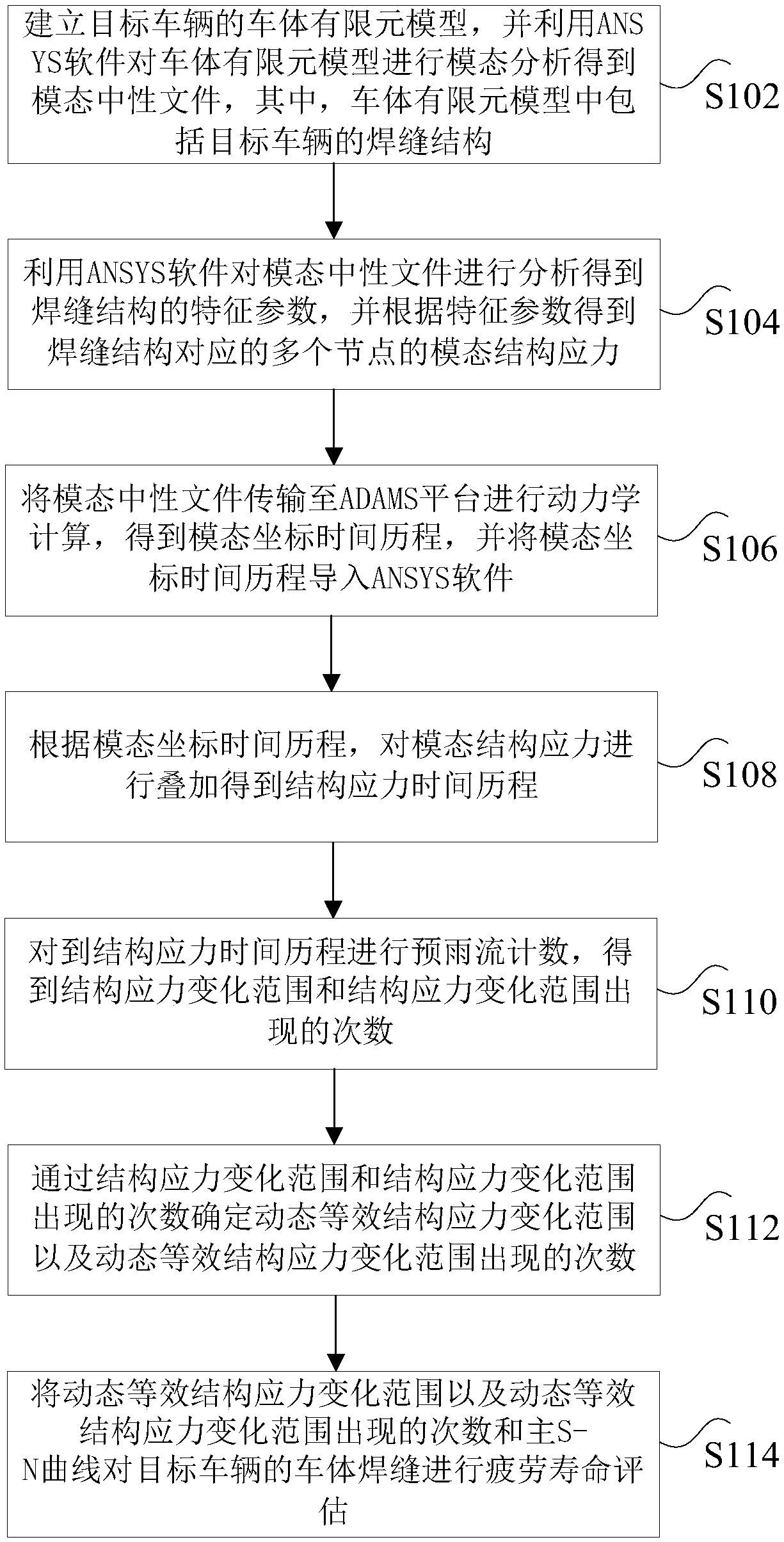

The invention discloses a method, a device and a system for evaluating fatigue life of a welding seam of a wagon body. The method comprises the following steps: obtaining characteristic parameters ofa weld joint structure based on ANSYS software, and obtaining modal structure stress of a plurality of nodes of the weld joint structure according to the characteristic parameters; Transmitting the modal neutral file to an ADAMS platform to obtain a modal coordinate time history; Superposing the modal structural stress to obtain a structural stress time history; Carrying out pre-rain flow countingon the structural stress time history to obtain a structural stress change range and the occurrence frequency of the structural stress change range; Determining a dynamic equivalent structure stresschange range and the occurrence frequency of the dynamic equivalent structure stress change range; Dynamic equivalent structure stress change range, occurrence frequency of dynamic equivalent structure stress change range and main S-N curve are used to evaluate the fatigue life of the vehicle body weld joint. The technical problem that in the prior art, the prediction precision of truck body weldjoint fatigue is low is solved.

Owner:CRRC QIQIHAR ROLLING CO LTD

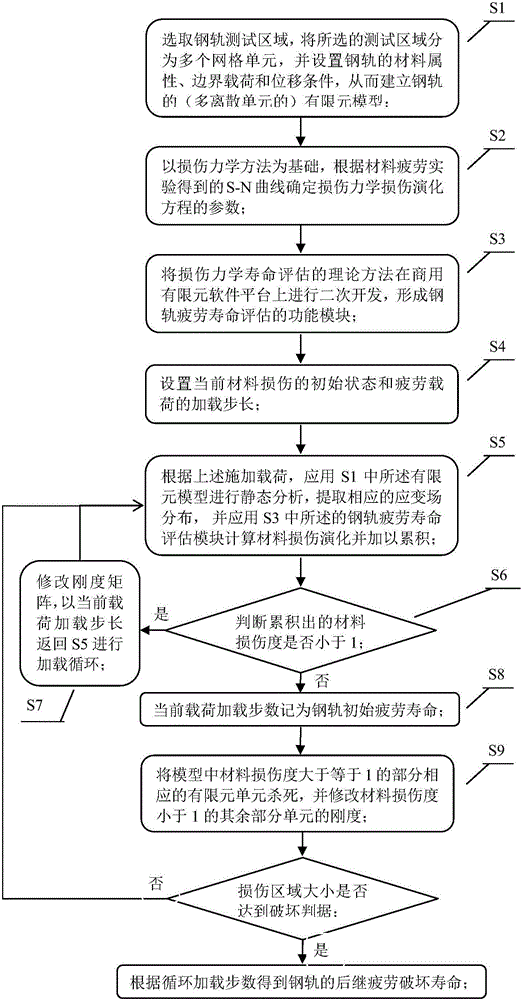

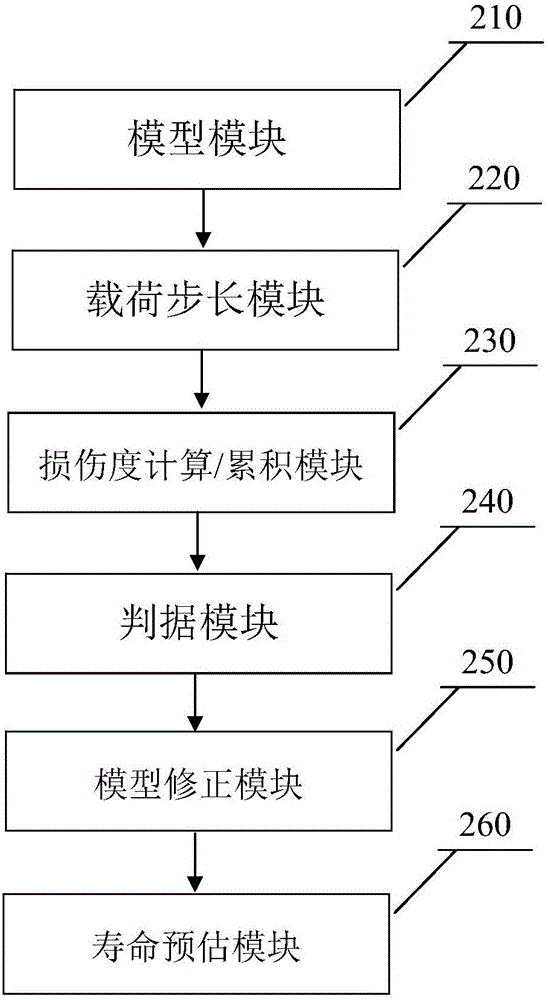

Method and system for predicting fatigue life of steel rail

InactiveCN106202863AReduce potential safety hazardsImprove accuracyDesign optimisation/simulationSpecial data processing applicationsElement modelEngineering

The invention provides a method for predicting the fatigue life of a steel rail. According to the method, a steel rail testing area is selected, a damage mechanics method is taken as a basis, damage evolution equation parameters of damage mechanics are determined according to an S-N curve of material fatigue, a theoretical life assessment method of damage mechanics is subjected to secondary development on a commercial finite element software platform, a function module for fatigue life assessment of the steel rail is formed, and theoretical assessment of the fatigue life of the steel rail is obtained through calculation by the aid of a finite element model. With the implementation of the method and the system, the fatigue life of the steel rail can be theoretically predicted, higher accuracy is realized, and the purpose of reducing potential safety hazards during use of the steel rail can be achieved.

Owner:张铮 +1

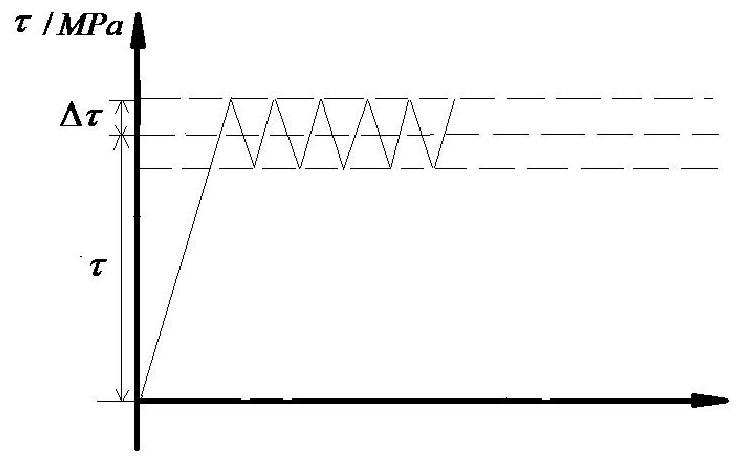

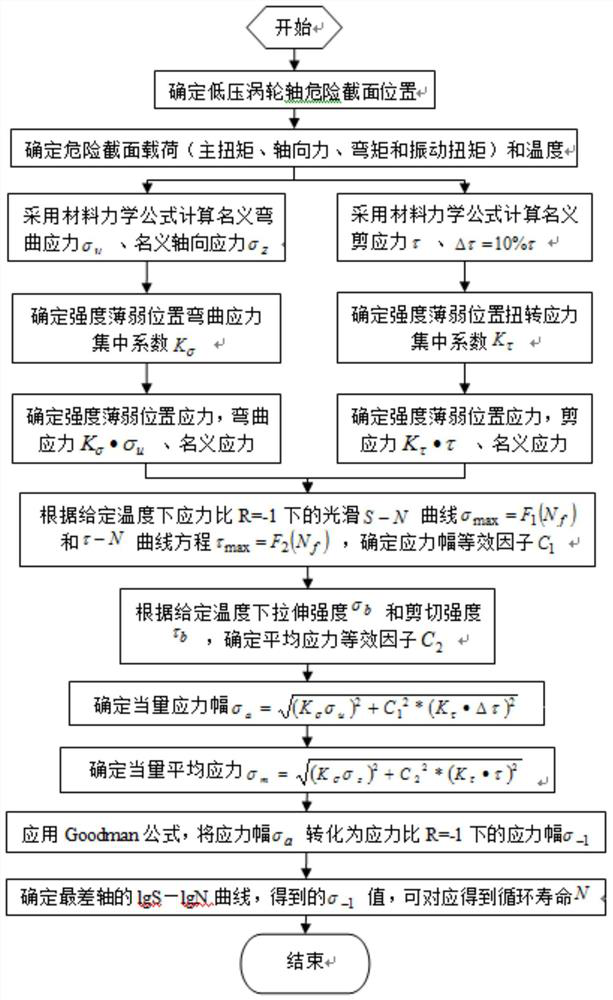

Fatigue life evaluation method for low-pressure turbine shaft

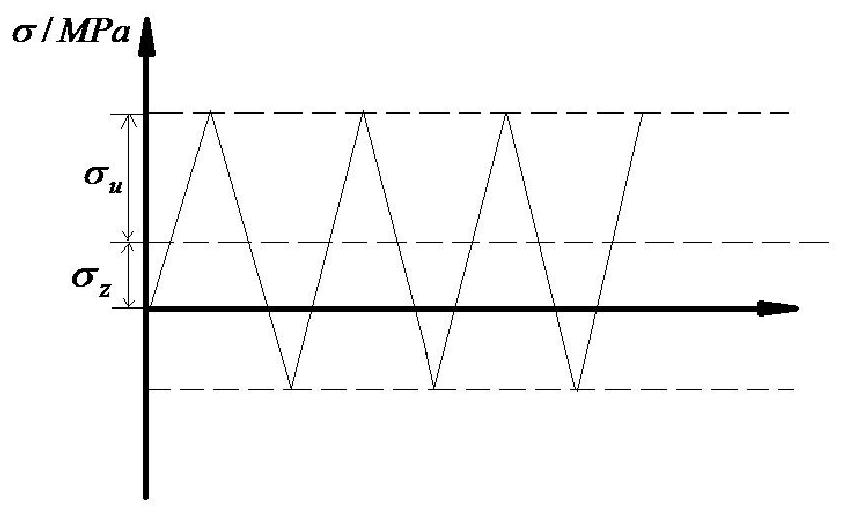

ActiveCN112199848AImproving the Accuracy of Fatigue Life AssessmentDesign optimisation/simulationSpecial data processing applicationsStress concentrationShear stress

The invention provides a fatigue life evaluation method for a low-pressure turbine shaft, and the method comprises the steps: obtaining a stress amplitude equivalent factor C1 = F1(Nf) / F2(Nf) according to a smooth SN curve sigma max = F1(Nf) and a tau-N curve equation tau max = F2(Nf) under the condition that the stress ratio R of a material used by the low-pressure turbine shaft at a given temperature is equal to -1; calculating an average stress equivalent factor C2 = sigma b / tau b according to the tensile strength sigma b and the shear strength tau b of the material used by the low-pressureturbine shaft at the given temperature; according to the stress amplitude equivalent factor C1, the bending stress sigma u, the vibration torque shear stress delta tau, the bending stress concentration coefficient K sigma and the torsional stress concentration coefficient K tau, calculating an equivalent stress amplitude sigma a by utilizing a formula; according to the average stress equivalent factor C2, the axial stress sigma z, the main torque shear stress tau, the bending stress concentration coefficient K sigma and the torsional stress concentration coefficient K tau, calculating an equivalent stress amplitude sigma a by utilizing a formula; converting the equivalent stress amplitude sigma a and the equivalent stress amplitude sigma m into symmetrical cyclic stress sigma-1; and evaluating the fatigue life of the low-pressure turbine shaft according to the symmetric cyclic stress sigma-1.

Owner:AECC SICHUAN GAS TURBINE RES INST

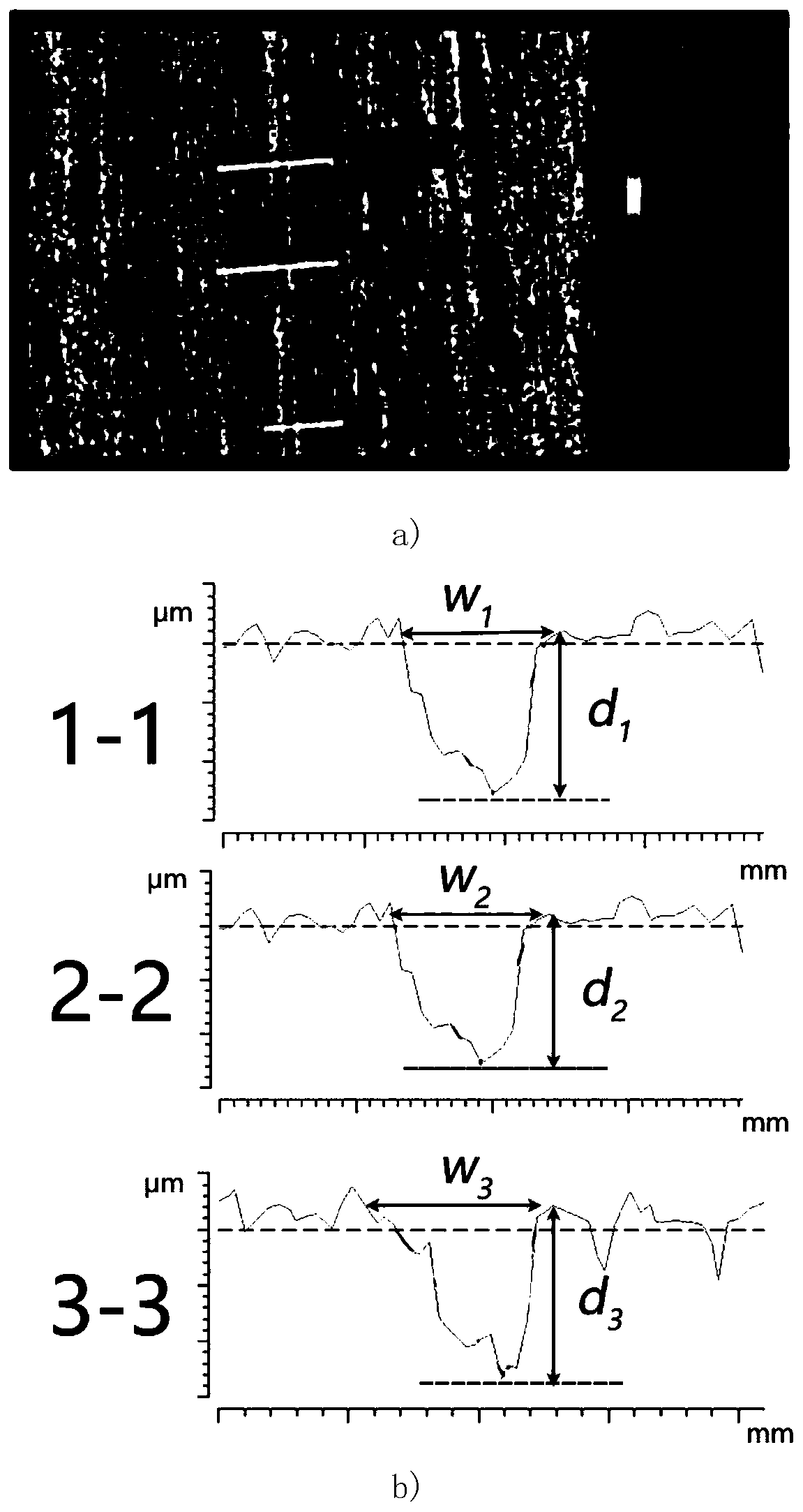

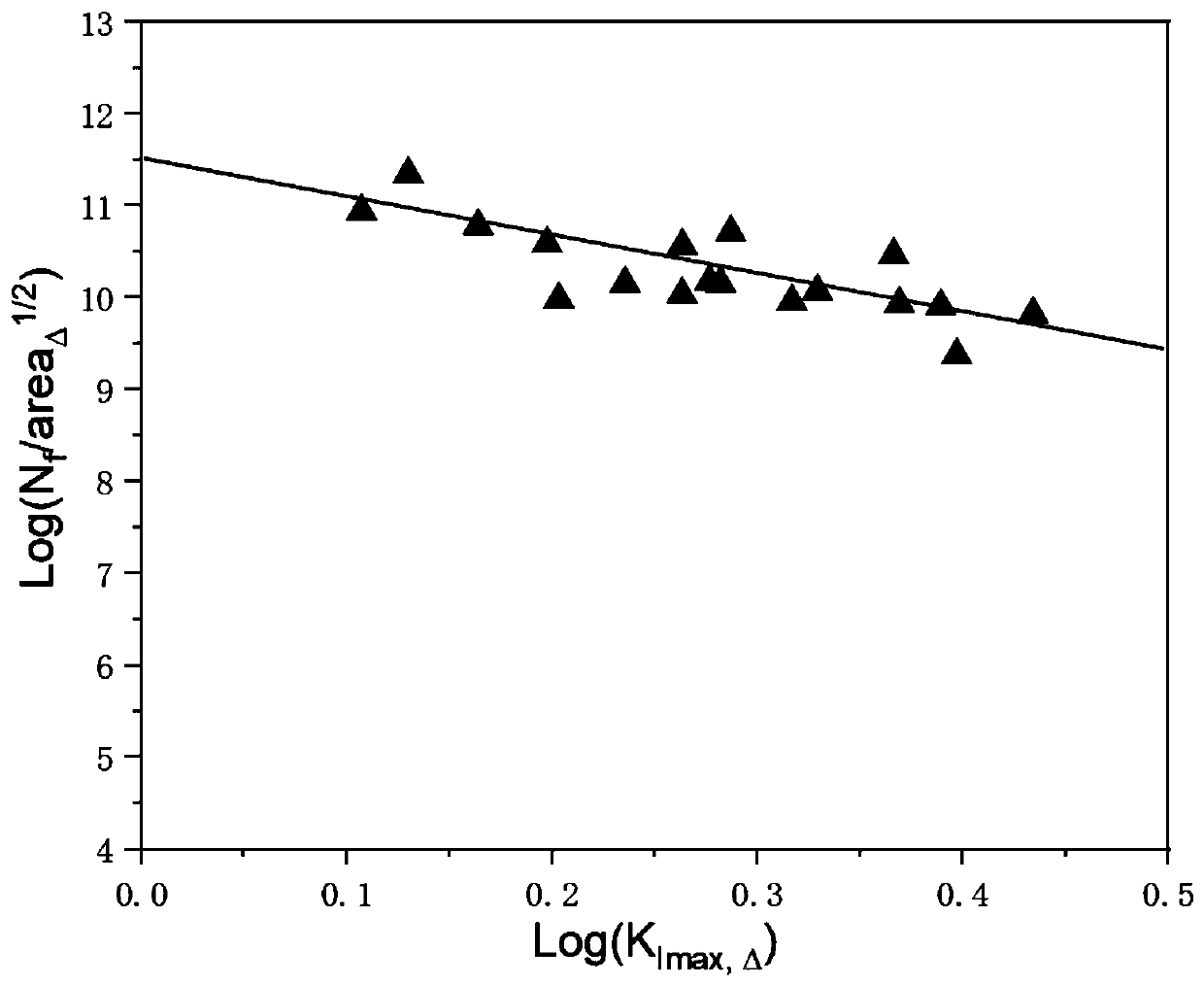

Titanium alloy fatigue life prediction method based on microscopic scratches

InactiveCN110907269AAddressing Fatigue Life EffectsSimple methodMaterial strength using repeated/pulsating forcesFatigue damageMetallic materials

The invention discloses a titanium alloy fatigue life prediction method based on microscopic scratches, belongs to the technical field of metal material fatigue life prediction, and relates to the titanium alloy fatigue life prediction method based on the microscopic scratches. The prediction method is based on the Murakami theory, fatigue damage quantitative characterization parameters caused byevaluation of microscopic scratches are provided, and the fatigue damage quantitative characterization parameters are defined as the square root of the cross section triangle area of the microscopic scratches. The corresponding fatigue damage parameters can be obtained by measuring the depth and width data of the cross section of the microscopic scratch, and a titanium alloy fatigue life prediction model considering the influence of the microscopic scratch is established in combination with a Paris formula. According to the prediction model, the fatigue life of the titanium alloy under the microscopic scratches can be predicted only by measuring the depth and width data of the sections of the microscopic scratches. The method is a practical and novel method for evaluating the fatigue lifeof the titanium alloy blade considering the microscopic scratches, and is simple and convenient to test.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com