Fatigue life evaluation method for low-pressure turbine shaft

A low-pressure turbine shaft, fatigue life technology, applied in the direction of instrument, design optimization/simulation, calculation, etc., can solve the problem of reducing the fatigue life evaluation accuracy of low-pressure turbine shaft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

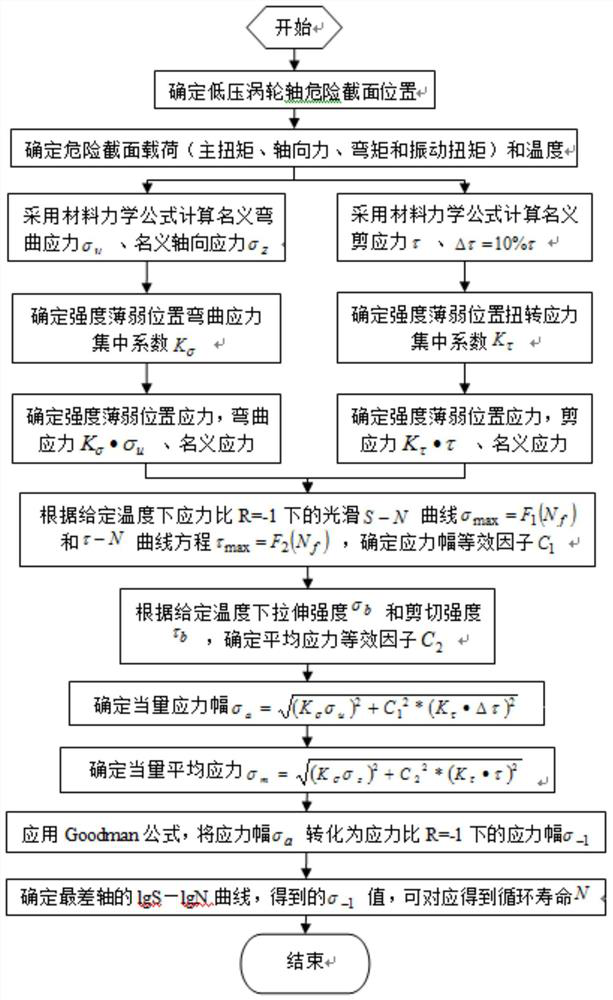

Method used

Image

Examples

Embodiment Construction

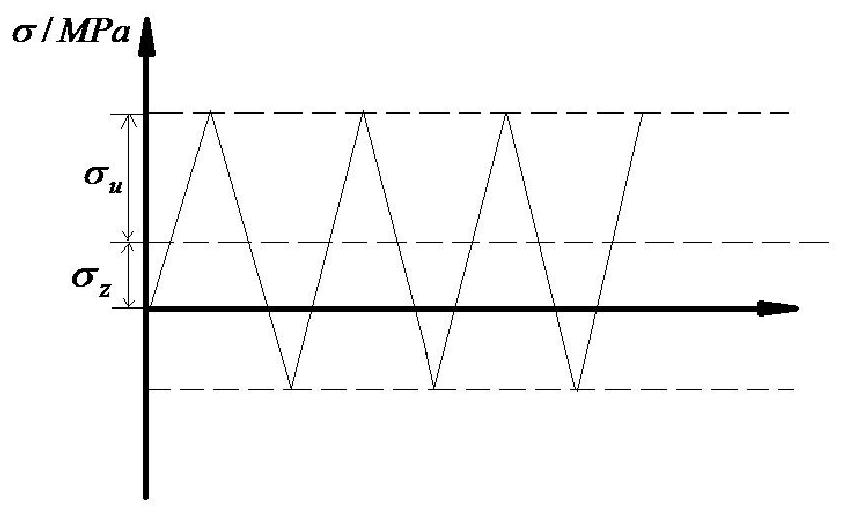

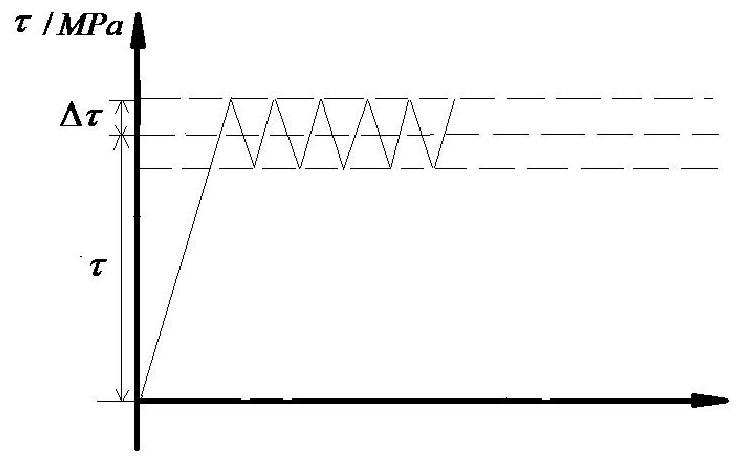

[0029] In this application, according to the Goodman formula mean stress σ m and tensile strength σ b Positively correlated, the stress amplitude σ a and tensile fatigue strength σ -1 There is a positive correlation, the tensile stress is corrected by the tensile property, and the shear stress is corrected by the torsional property. when and When , it is reasonable to synthesize the tensile stress and shear stress into the equivalent stress by using the deformation energy theory; when and When , the tensile stress and shear stress are synthesized into the equivalent tensile stress σ by using the deformation energy theory eq It is partial safety, and the tensile stress and shear stress are synthesized into the equivalent shear stress τ by using the deformation energy theory eq It is more dangerous. Therefore, the tensile and torsional properties of materials should be considered in the equivalent synthesis of tensile stress and shear stress.

[0030] 1) Use the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com