Barrier film, manufacturing method thereof and display device

A manufacturing method and technology of a display device, which are applied in the manufacture of semiconductor/solid state devices, semiconductor devices, electrical components, etc., can solve problems such as fracture of inorganic layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

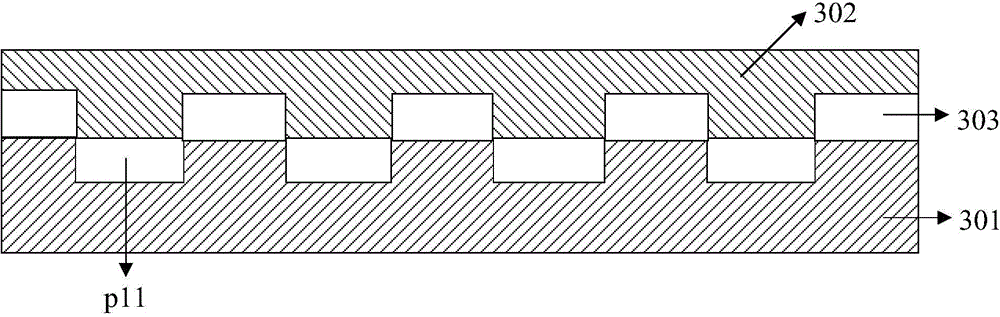

[0022] An embodiment of the present invention provides a barrier film, the barrier film includes a first organic film layer and a second organic film layer, the first organic film layer is formed with a first groove, and the first organic film layer is provided with There is at least one inorganic film layer, the inorganic film layer fills the first groove, and the thickness of the inorganic film layer is less than or equal to the depth of the first groove; the inorganic film layer is provided with the A second organic film layer, the second organic film layer is a planarization layer.

[0023] Specifically, such as image 3 as shown, image 3 A schematic diagram of a barrier film provided in Embodiment 1 of the present invention, the barrier film includes a first organic film layer 301, a second organic film layer 302, and an inorganic film layer 303, and the first organic film layer 301 is formed with a first groove p31 , the inorganic film layer 303 disposed on the first ...

Embodiment 2

[0026] Figure 4 It is a schematic diagram of a barrier film provided in Embodiment 2 of the present invention. The barrier film includes a first organic film layer 401, a second organic film layer 402, an inorganic film layer 403 and an organic film layer 404; the first organic film layer 401 is formed with a first groove p41, which is arranged on the first organic film layer 401 The inorganic film layer 403 on the top fills the first groove p41, and the thickness of the inorganic film layer 403 is less than or equal to the depth of the first groove p41; the organic film layer 404 and the inorganic film layer 403 are alternately stacked at intervals, and the layers of the inorganic film layer 403 The number is at least two layers, the first organic film layer 401 is adjacent to the inorganic film layer 403 arranged thereon, the second organic film layer 402 is adjacent to the inorganic film layer 403 stacked on the organic film layer 404, and the second The organic film laye...

Embodiment 3

[0037] Embodiment 3 of the present invention provides a display device, including a flexible substrate and a light-emitting device disposed on the flexible substrate, the flexible substrate includes a first surface and a second surface oppositely arranged, and the light-emitting device is disposed on the flexible substrate. On the first surface, a first thin film is disposed on the light emitting device, and the first thin film includes the barrier film described in the above embodiments.

[0038] Such as Figure 7 As shown, it is a schematic diagram of a display device provided by Embodiment 3 of the present invention. The display device includes a flexible substrate 701 and a light emitting device 702 disposed on the flexible substrate 701. The light emitting device 702 in the embodiment of the present invention is an OLED device, and the flexible The substrate 701 includes a first surface and a second surface opposite to each other. The light emitting device 702 is disposed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com