Transparent combustion chamber with square interior passage

A combustion chamber and inner channel technology, which is used in jet propulsion devices, rocket engine devices, machines/engines, etc., can solve the problems of real flow field influence, combustion chamber pressure distortion, and channels that cannot be well flushed, and can be disassembled. Convenient and fast, good sealing effect, and the effect of protecting quartz glass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

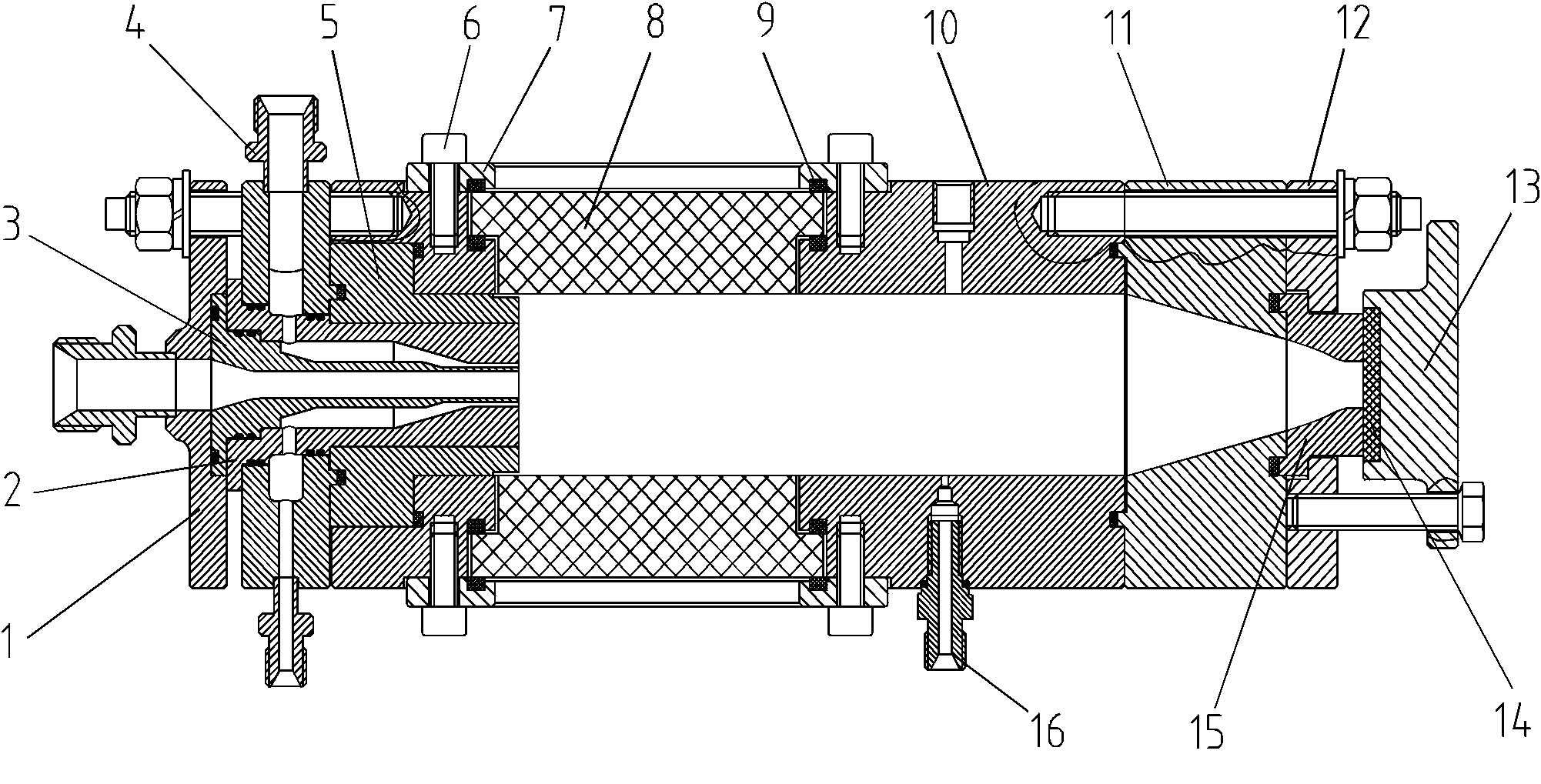

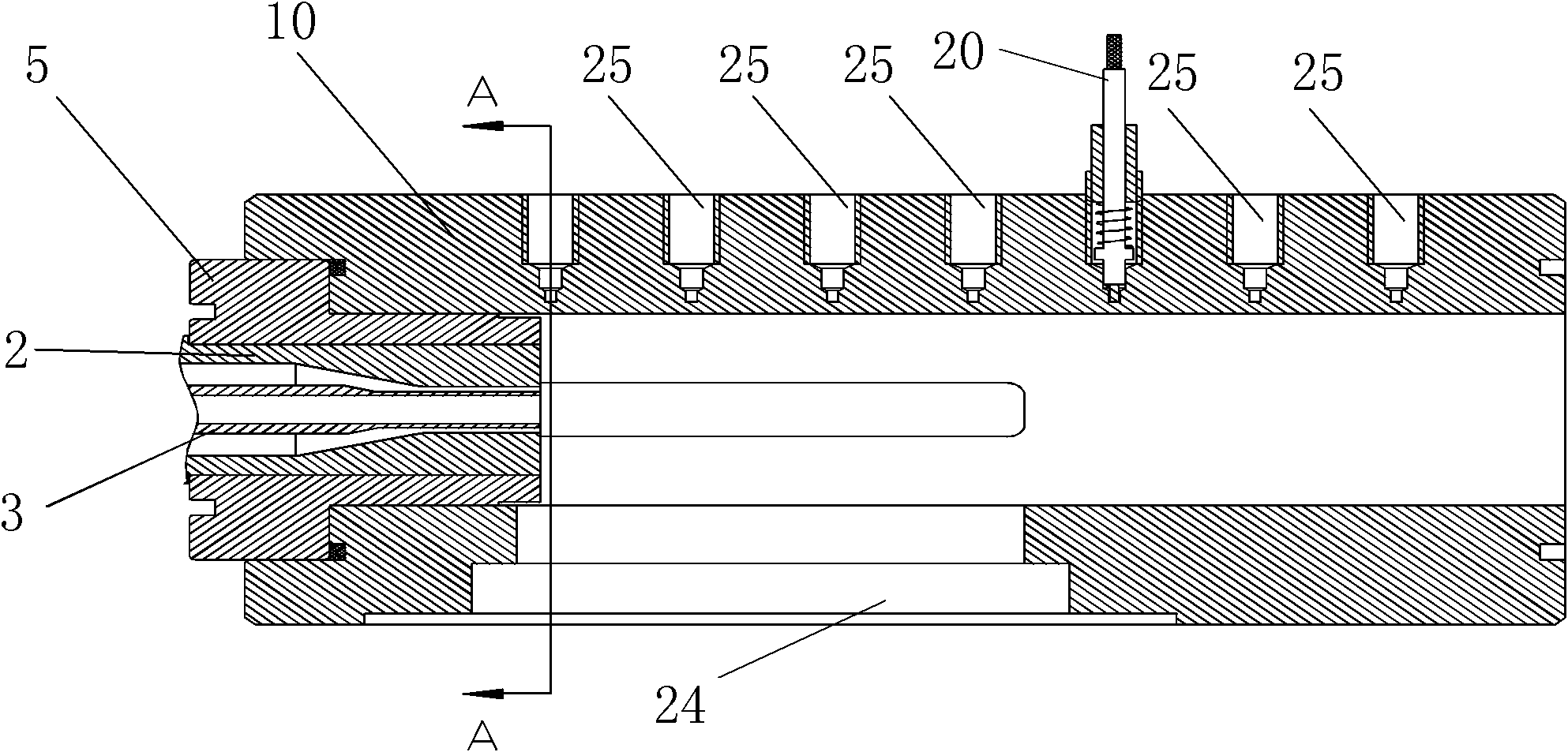

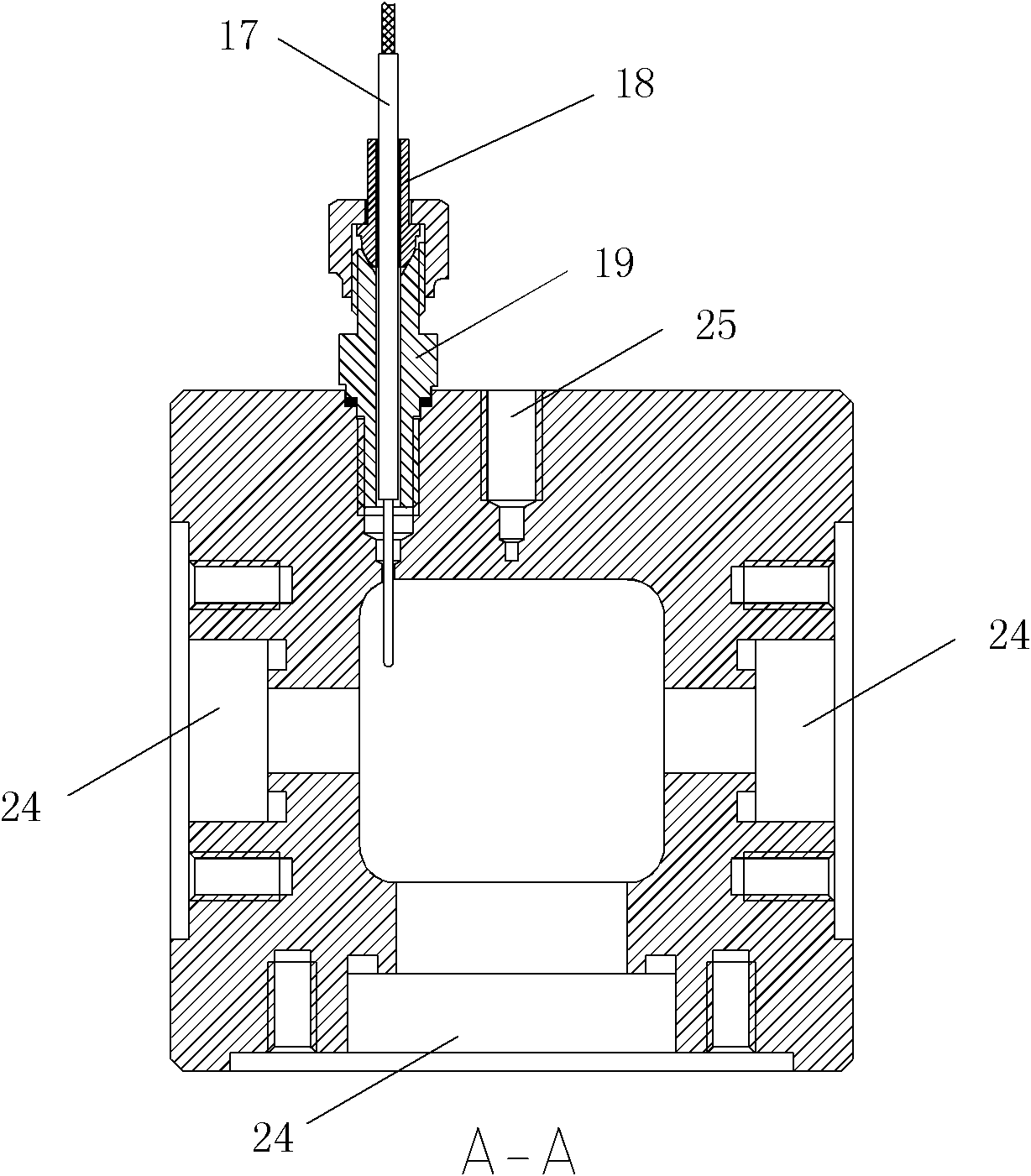

[0035] The invention is a transparent combustion chamber with a square inner channel, which is divided into a head mechanism, a body mechanism of the combustion chamber, an observation window mechanism and a guide mechanism.

[0036] The head mechanism includes an oxidant chamber 1, a fuel nozzle 2, an oxygen nozzle 3 and a fuel chamber 4, such as figure 1 As shown, the outlets of the oxygen nozzle 3 and the fuel nozzle 2 are both circular cross-sections, which are convenient for processing. The two are sealed with an O-ring, and the gap between the oxygen nozzle 3 and the fuel nozzle 2 is fitted. To ensure coaxiality, there is a fuel channel between the oxygen nozzle 3 and the fuel nozzle 2, the fuel enters through the fuel channel, and enters the transparent combustion chamber along the fuel nozzle 2, and the oxygen nozzle 3 is attached to the surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com