A special cutting mechanism for a willow splitter

A technology of cutting mechanism and willow splitter, which is applied in the direction of wood splitting device, mechanical equipment, sugarcane machining, etc., can solve the problems of buried safety hazards, unsafe manual operation, and slow splitting speed, so as to reduce enterprise costs and improve Cutting efficiency, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

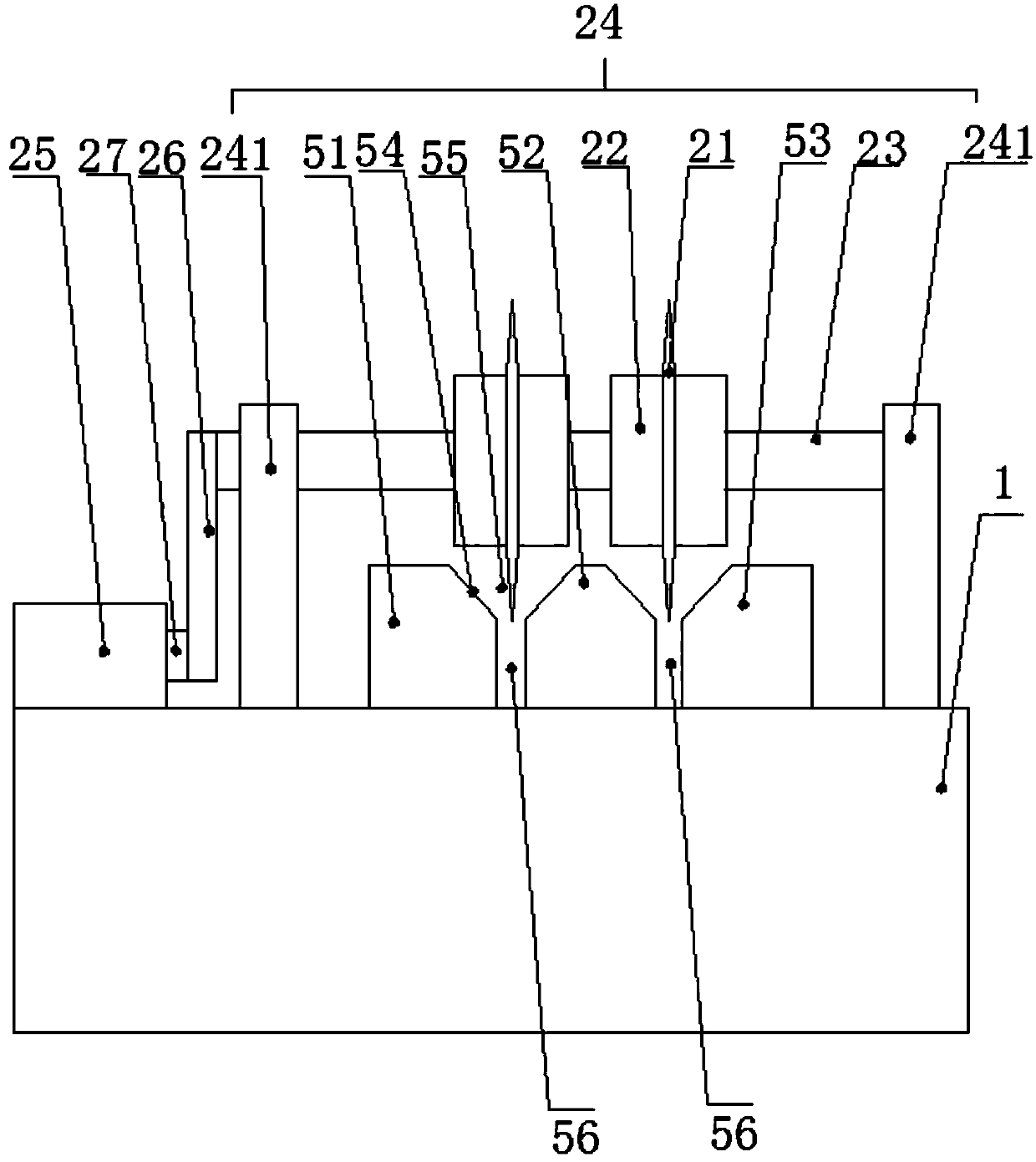

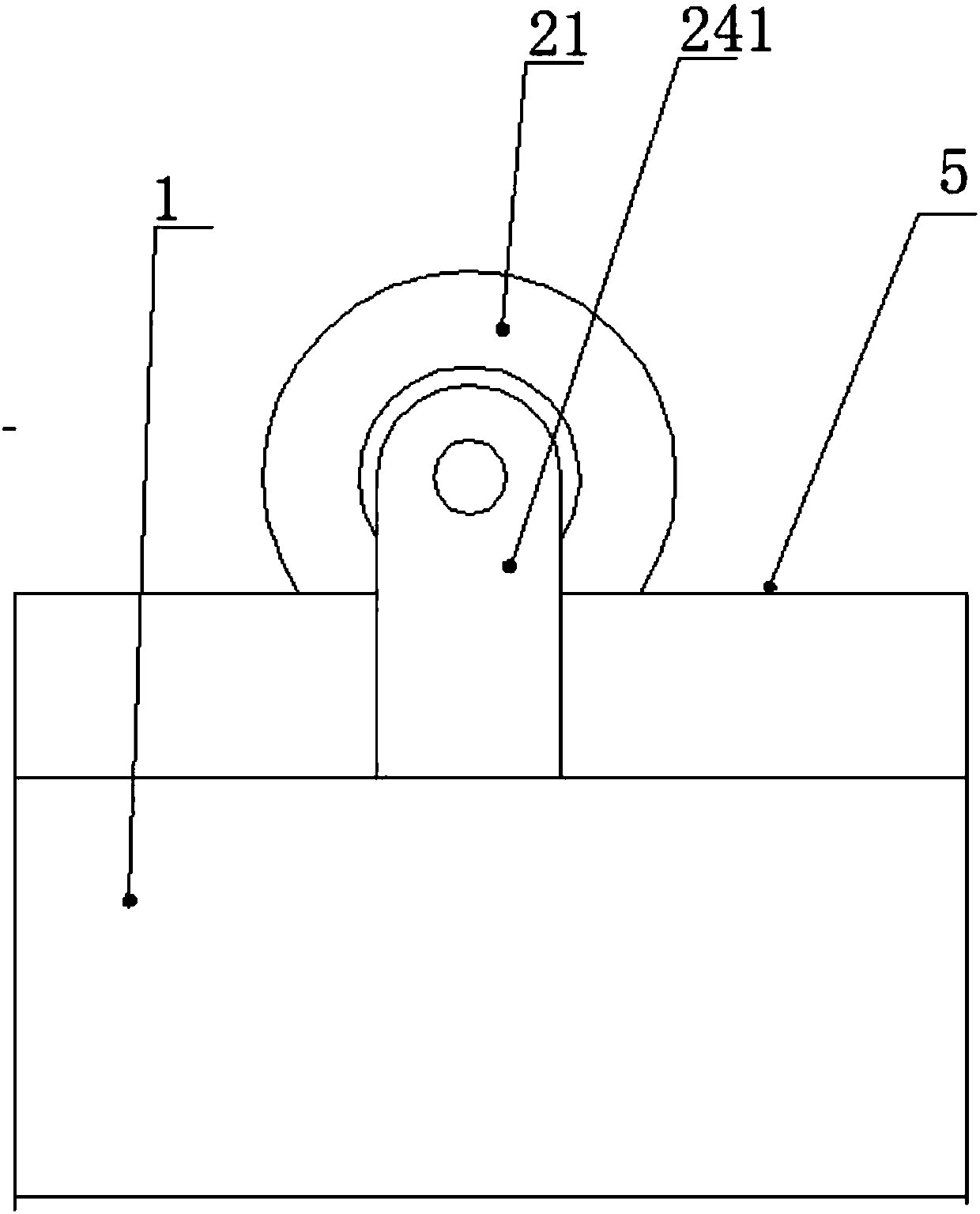

[0023] A special cutting mechanism for a willow splitter, which includes a splitting knife, a pressure wheel, a rotating shaft, a cutting bracket, a cutting motor, a transmission belt, a working platform and a wicker fixing mechanism; the working platform is a square structure, and the wicker fixing mechanism set on the working platform;

[0024] The wicker fixing mechanism is composed of three fixing blocks, including a first fixing block, a second fixing block and a third fixing block, the top ends of the first fixing block and the third fixing block are provided with an inclined surface, and the first fixing block is provided with an inclined surface. A fixed block and a third fixed block are separately arranged on both sides of the second fixed block, and the first fixed block and the third fixed block are arranged axially symmetrically with the second fixed block as the axis of symmetry; the second fixed block Both sides of the top are provided with inclined surfaces; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com