Fume Hood Sensor Bonding Fixture

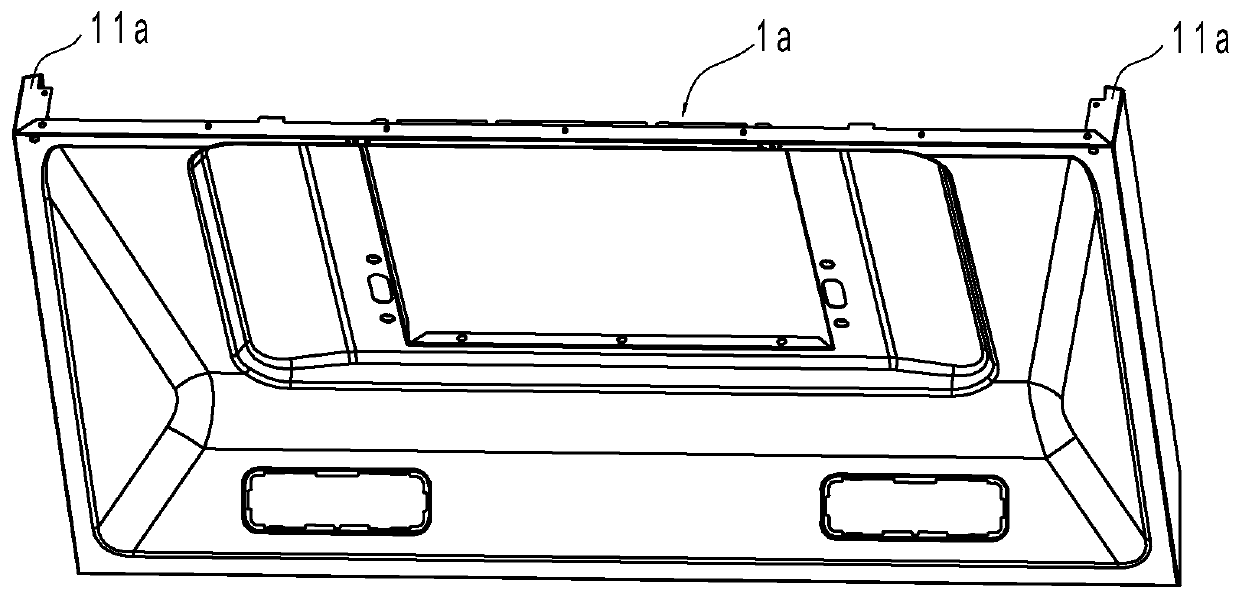

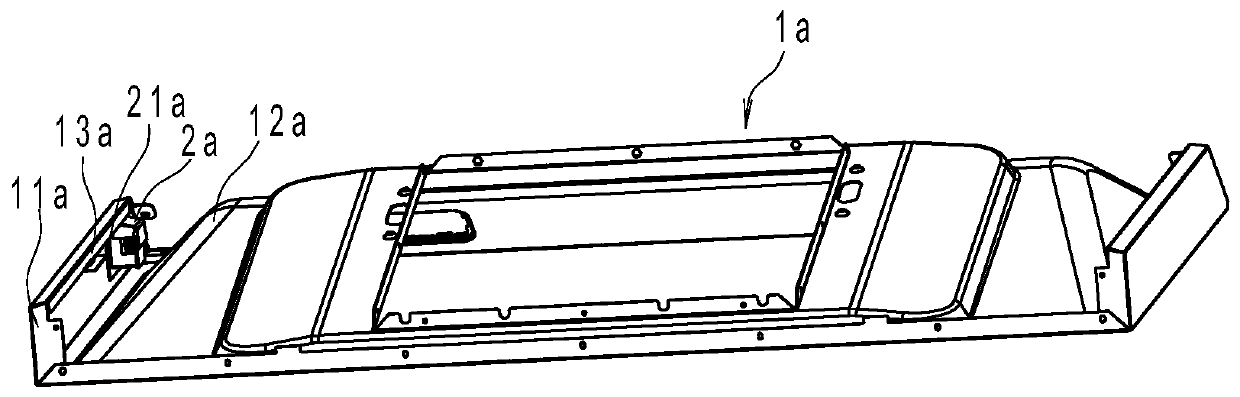

A technology of sensors and smoke hoods, which is applied to home appliances, oil fume removal, and household stoves/stoves. It can solve problems such as product quality degradation, low work efficiency, and deformation of the raised part 12a, and achieve product quality assurance and labor intensity reduction. , The effect of improving the bonding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

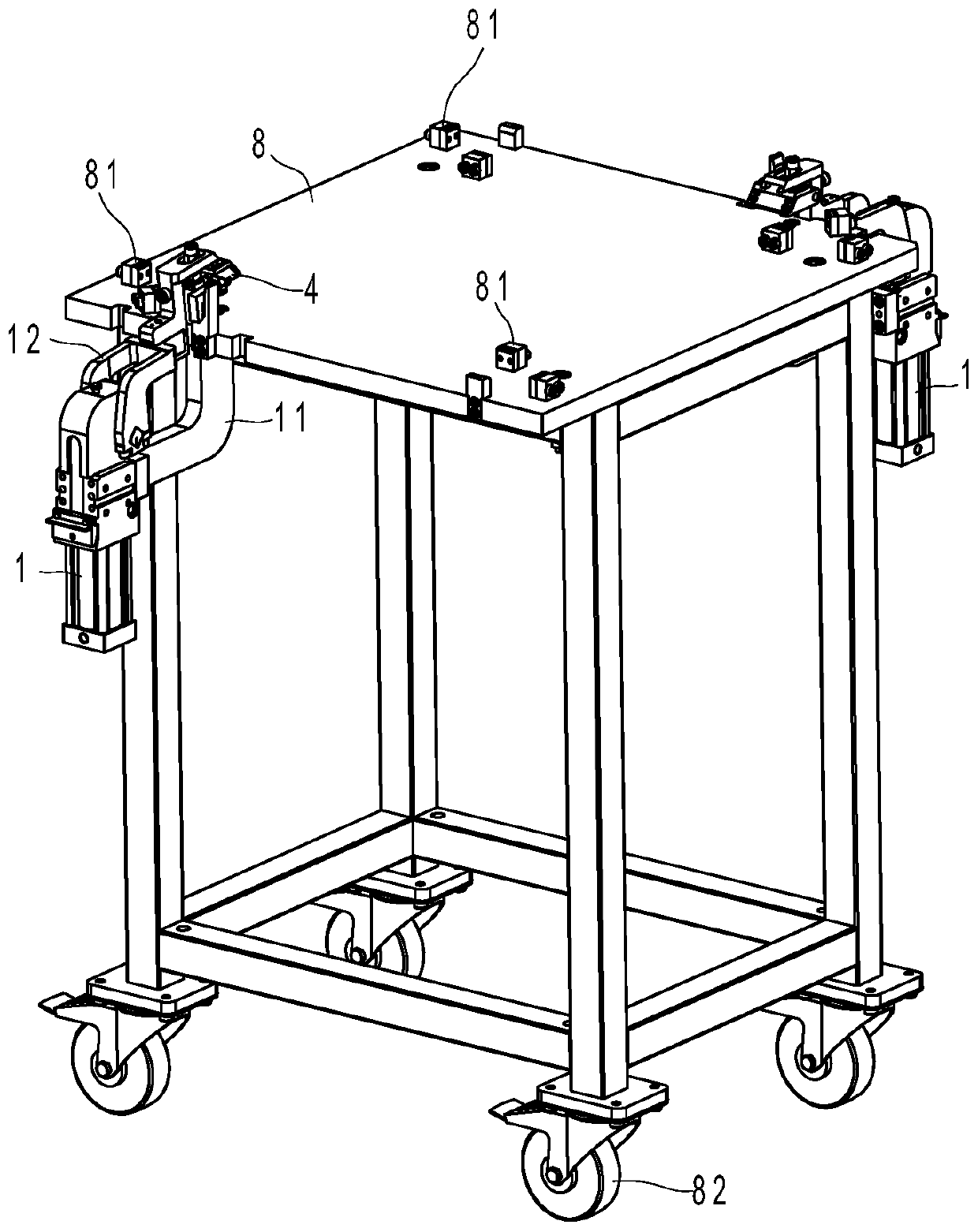

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0026] like image 3 , Figure 4 and Figure 5 As shown, the fume collecting hood sensor bonding fixture in this embodiment includes a workbench 8, a driving cylinder 1, a support 3, a suction cup 4, a reset member 51, a guide block 7 and a pull rod 6, and the upper end surface of the workbench 8 is provided with a The positioning block 81 of the outer frame 1a of the smoke collecting hood is positioned; the bottom end of the workbench 8 is provided with a pulley 82, which is convenient for moving.

[0027] A workbench 8 in this embodiment has two sets of driving cylinders 1, and correspondingly, there are two sets of positioning blocks 81 with the same structure, and the following description is made for one set.

[0028] The driving cylinder 1 is located on one side of the workbench 8. The driving cylinder 1 in this embodiment is the JCK ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com