Non-pneumatic safety tire

A safety tire, non-inflation technology, applied in non-pneumatic tires, tire parts, vehicle parts, etc., can solve problems such as unfavorable improvement of tire heat dissipation performance and weight reduction, unfavorable tire life, and impact on anti-skid effect. Damping effect and impact resistance, weight reduction, life-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

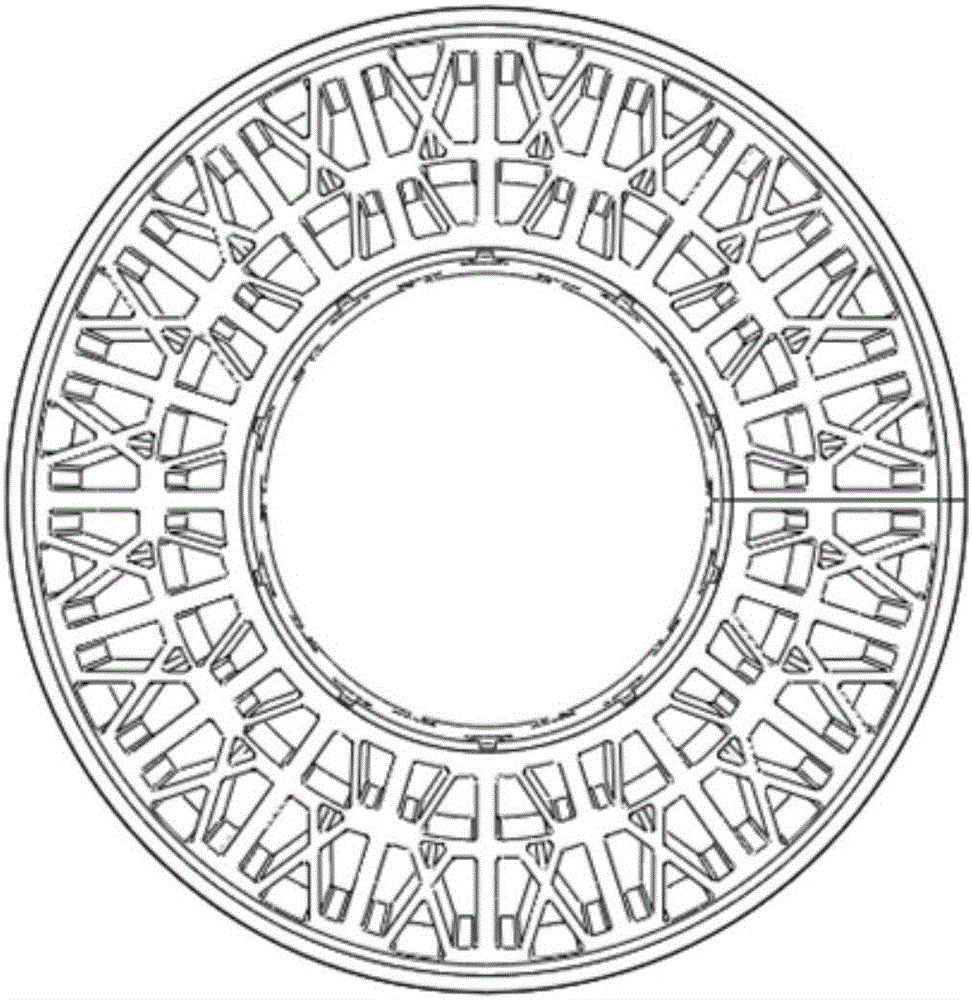

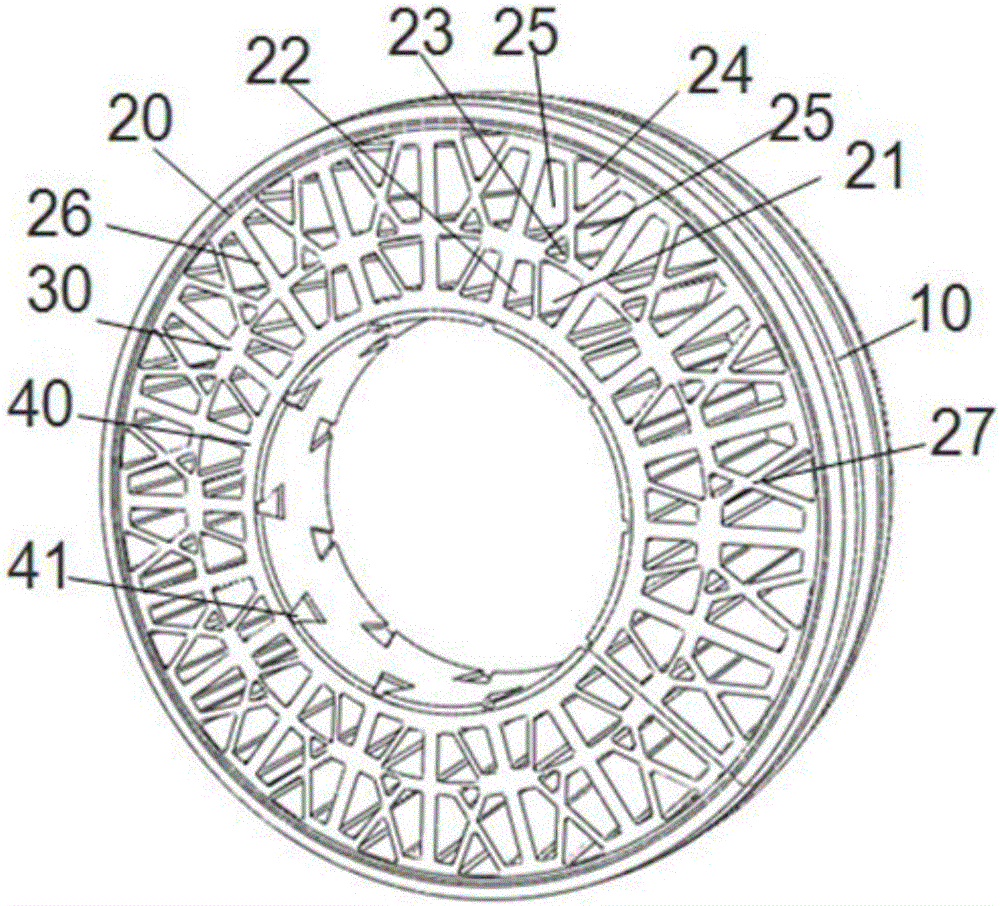

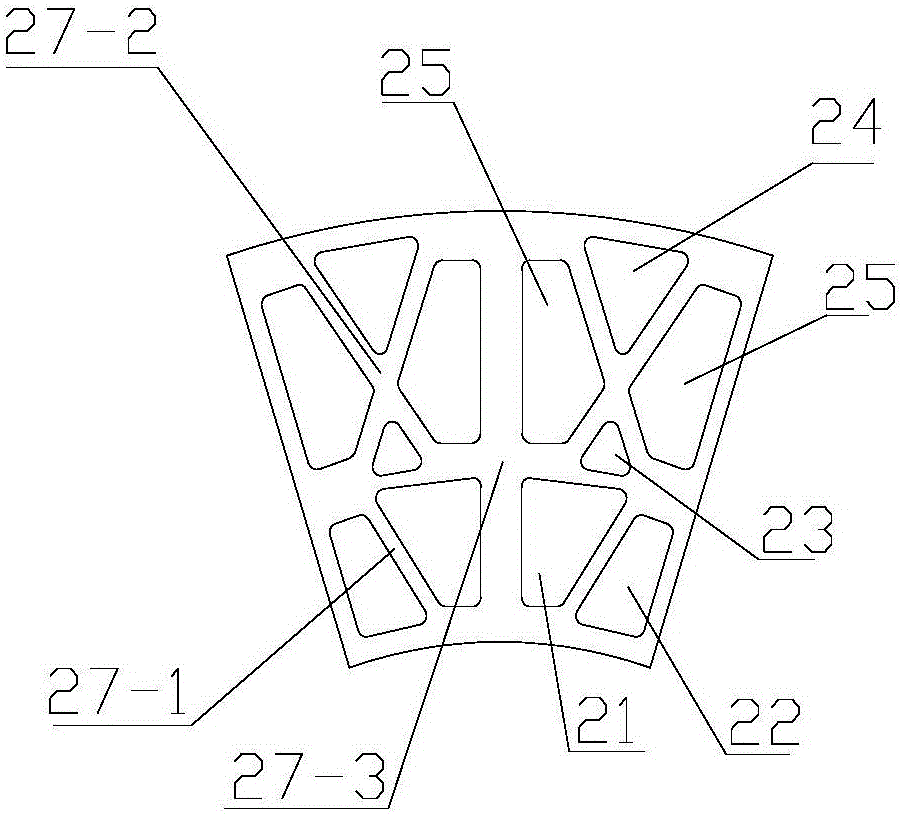

[0037] Such as Figures 1 to 3 As shown, this embodiment provides a non-inflatable safety tire, which includes a tread 10, an outer ring 20, a support body 30 and an inner ring 40 from outside to inside, and the tread 10 is glued or vulcanized on the outer ring 20 Above, the support body starts from the outer ring 20 and is arranged radially and circumferentially between the outer ring 20 and the inner ring 40. On the support body 30, multiple sets of damping units and support ribs are distributed along the circumferential direction. 27. Each set of shock absorbing units is composed of two sets of shock absorbing structures, and the two sets of shock absorbing structures are arranged circumferentially with the radial axis as the axis of symmetry.

[0038]The shock absorbing structure is made up of a first shock absorbing hole 21, a second shock absorbing hole 22, a third shock absorbing hole 23, a fourth shock absorbing hole 24 and a fifth shock absorbing hole 25; the first sh...

Embodiment 2

[0041] This embodiment provides a kind of air-free safety tire, such as Figure 1-3 As shown, there are tread 10, outer ring 20, support body 30 and inner ring 40 from outside to inside, the tread 10 is bonded or vulcanized on the outer ring 20, and the support body starts from the outer ring 20, Arranged between the outer ring 20 and the inner ring 40 in the radial and circumferential directions, multiple sets of damping units and support ribs 27 are distributed on the support body 30 in the circumferential direction, and each set of damping units consists of two sets of damping units. Structural composition, two sets of shock absorbing structures are arranged circumferentially with the radial axis as the axis of symmetry.

[0042] The shock absorbing structure is made up of a first shock absorbing hole 21, a second shock absorbing hole 22, a third shock absorbing hole 23, a fourth shock absorbing hole 24 and a fifth shock absorbing hole 25; the first shock absorbing hole 21 ...

Embodiment 3

[0045] Such as Figure 1-3 As shown, this embodiment provides a non-inflatable safety tire, which includes a tread 10, an outer ring 20, a support body 30 and an inner ring 40 from outside to inside, and the tread 10 is glued or vulcanized on the outer ring 20 Above, the support body starts from the outer ring 20 and is arranged radially and circumferentially between the outer ring 20 and the inner ring 40. On the support body 30, multiple sets of damping units and support ribs are distributed along the circumferential direction. 27. Each set of shock absorbing units is composed of two sets of shock absorbing structures, and the two sets of shock absorbing structures are arranged circumferentially with the radial axis as the axis of symmetry.

[0046] The shock absorbing structure is made up of a first shock absorbing hole 21, a second shock absorbing hole 22, a third shock absorbing hole 23, a fourth shock absorbing hole 24 and a fifth shock absorbing hole 25; the first shock...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com