Method for predicting remaining service life of T-shaped tail portion of rotor of pumped-storage power generation motor

A technology for generating electric motors and pumped storage, which is applied in the fields of electrical digital data processing, special data processing applications, instruments, etc., and can solve the problems of not being able to meet the fatigue analysis requirements of the tail of the generating motor T, and the operating conditions of the motor are not appropriate enough and not considered.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

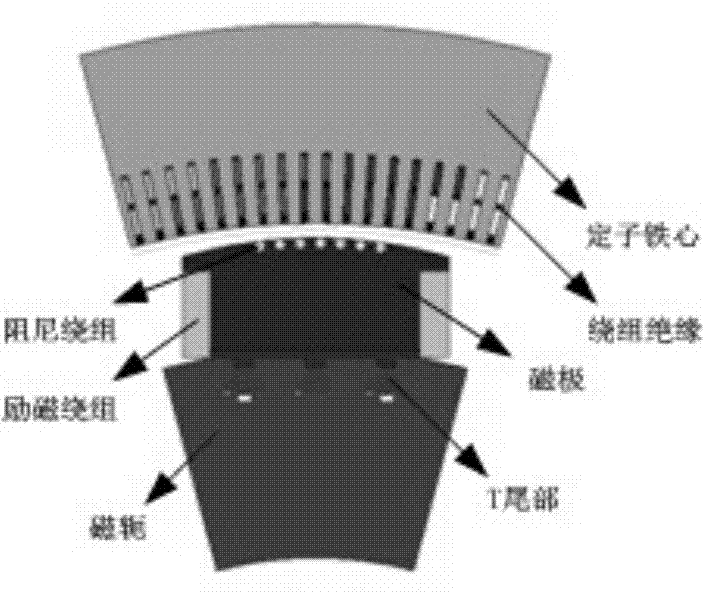

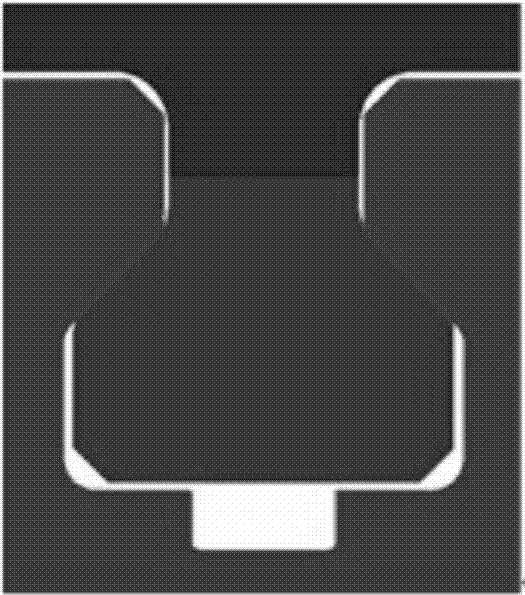

[0047] Taking a 300MW generator motor in Guangzhou Pumped Storage Power Station as the research object, the generator motor has 12 magnetic poles, and the number of slots per pole and phase is 6. Each slot is divided into upper and lower layers of windings, and the windings are connected in the form of wave windings. Section 1 The pitch is 16, the second pitch is 20, the number of parallel branches is 4, the rated current is 10713A, and the rated speed is 500rpm. Stress concentration will occur between the tail of the magnetic pole T and the tail slot of the yoke T during operation. Fatigue damage may occur due to the role of the rotor, and in severe cases, it may cause cracking at the tail of the T (for example, a cracking accident at the tail of the rotor T occurred in the Dinovic Power Station in the United Kingdom in 1994). The invention provides a method for predicting the remaining service life of the tail of the rotor T of a pumped storage generator motor. The analysis f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com