Mixed flow type hydroturbine weight-bearing bracket fatigue life test and analysis method

A technology of fatigue life and test analysis, which is applied in the direction of analyzing materials, using applied repetitive force/pulsation force to test material strength, measuring devices, etc., to achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

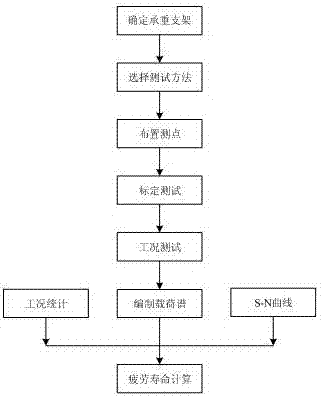

[0026] see figure 1 , a method for testing and analyzing the fatigue life of a bearing bracket of a Francis turbine in the present embodiment, comprising the following steps:

[0027] 1. The main load-bearing support is determined according to the structure of the Francis turbine unit. The lower frame is selected for the umbrella-type unit, and the upper frame is for the suspension unit. In order to ensure a large strain at the measuring point; arrange the measuring point on each load-bearing support leg or on the web of the interval support leg, the measuring point is arranged on the same plane as the thrust bearing, and at least 2 measuring points are arranged at the same position, Using the strain gauge electrical measurement method, paste the resistance strain gauge to the relevant measuring point...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com