Titanium alloy fatigue life prediction method based on microscopic scratches

A technology of fatigue life and prediction method, which is applied in the direction of measuring device, using repeated force/pulsation force to test material strength, instruments, etc., to achieve the effect of simple method and convenient test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

[0032] In the embodiment, the material is TC17 titanium alloy.

[0033] The method comprises the steps of:

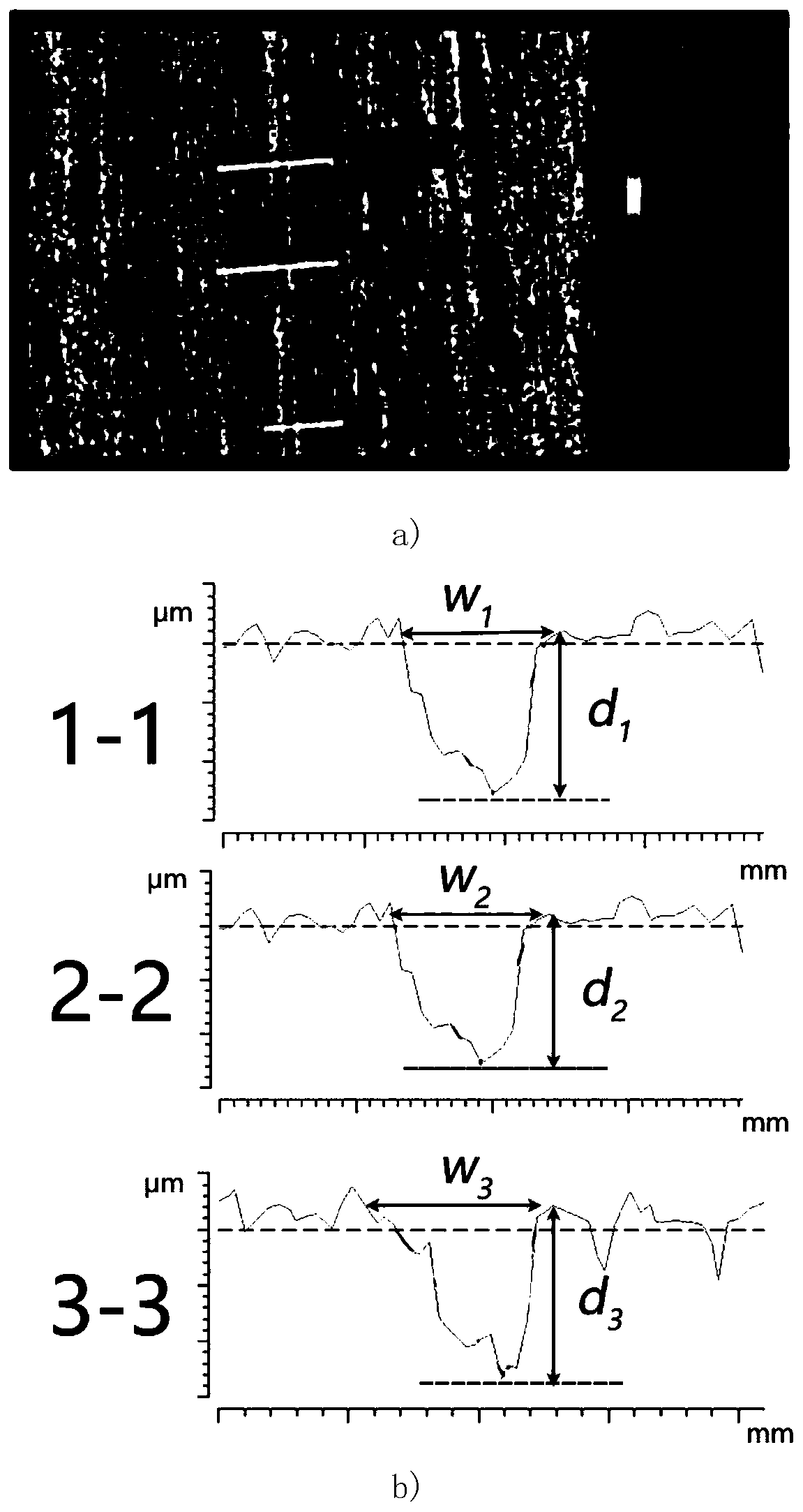

[0034] Step 1: Use the ZYGO three-dimensional interferometer to observe the microscopic scratches on the surface of the sample, such as figure 1 As shown in a), it is determined that there is a scratch in the observation area.

[0035] Step 2: Determine the width W and depth D of the scratch.

[0036] Select three scratch sections with larger dimensions as measurement targets, namely section 1-1, 2-2, 3-3, see figure 1 a); Measure the width and depth data of the three sections respectively to obtain w 1 ,w 2 ,w 3 and d 1 , d 2 , d 3 ,See figure 1 b); then the width W and depth D of the scratch can be calculated by formula (1).

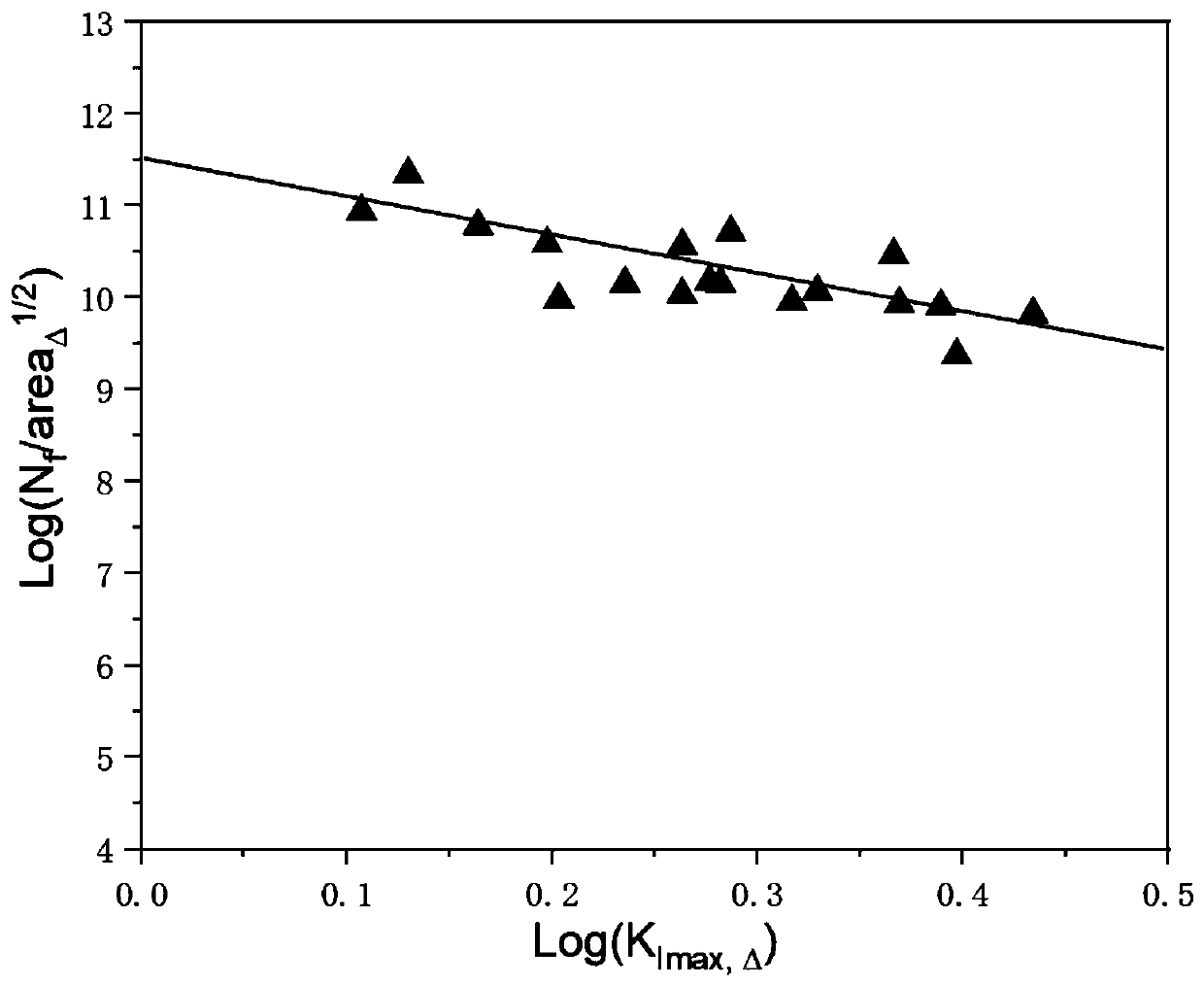

[0037] The Murakami theory defines the surface defect damage parameter as the square root of the area obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com