Plastic gear contact fatigue life evaluation method considering temperature influence

A technology for plastic gear and life evaluation, applied in design optimization/simulation, calculation, computer-aided design, etc., can solve the problems of fatigue life and friction and wear that remain in the empirical formula stage, and the difficulty of predicting the bearing capacity and failure mode of plastic gears. , to achieve the effect of reducing accidents and economic damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0063] The main parameters of the gear pair geometry are as follows:

[0064]

[0065] The small gear is the driving wheel and the material is carburized steel 18CrNiMo7-6; the big gear is the driven wheel and the material is POM (M90-44). The basic parameters of the material are as follows:

[0066]

[0067] Step 1. Test the tensile mechanical properties of plastic gear materials with temperature changes

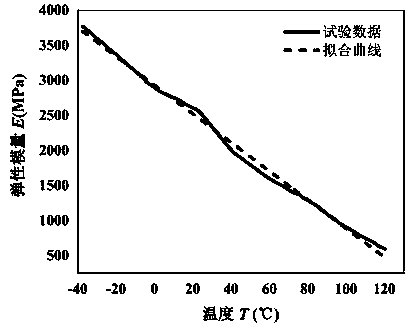

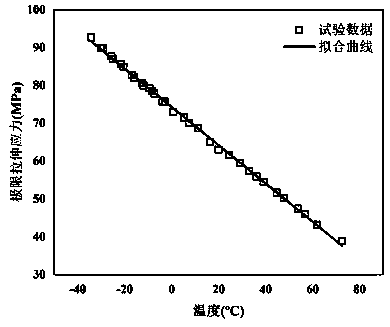

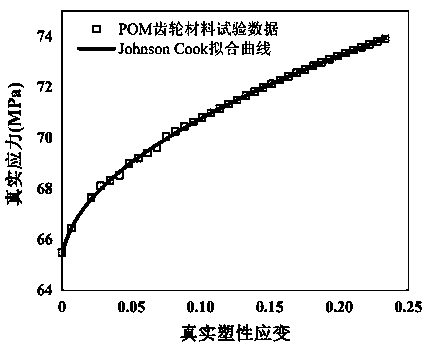

[0068] According to the standard GB1040-92 plastic tensile performance test method, the elastic modulus, ultimate tensile stress and true plastic stress-strain curve of POM gear material with temperature change are obtained, see Figure 1-3 .

[0069] Step 2: Establish the thermo-elastoplastic constitutive equation of plastic gear material

[0070] The thermoelastic constitutive equation of the plastic gear material at the elastic stage is:

[0071] σ=(αT+E 0 )ε

[0072] The thermoplastic constitutive equation of plastic gear material at the plastic stage is:

[0073]

[0074] T *m =(T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com