Method and system for predicting fatigue life of steel rail

A fatigue life and life evaluation technology, applied in special data processing applications, instruments, electrical and digital data processing, etc., can solve problems such as rail fatigue damage, serious accidents, rail body cracks, etc., to achieve high accuracy and reduce safety hazards. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

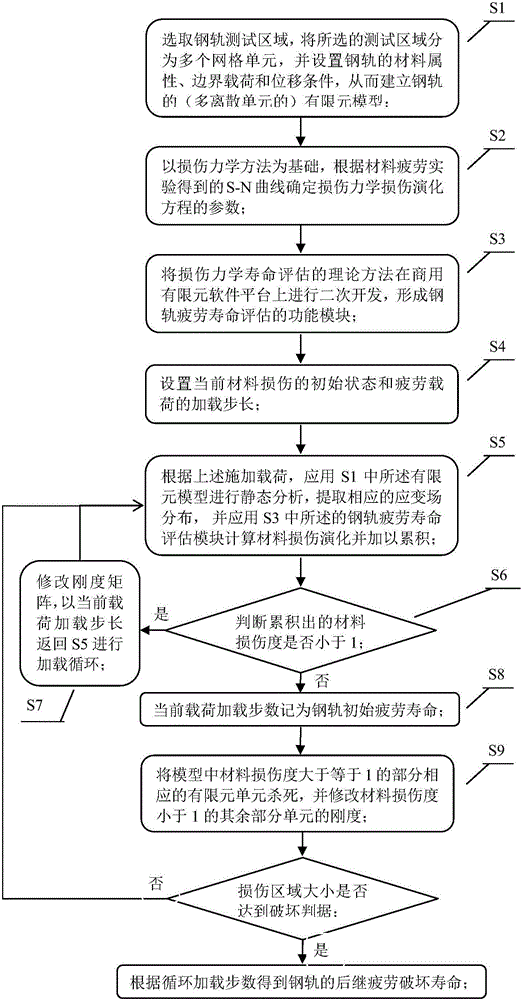

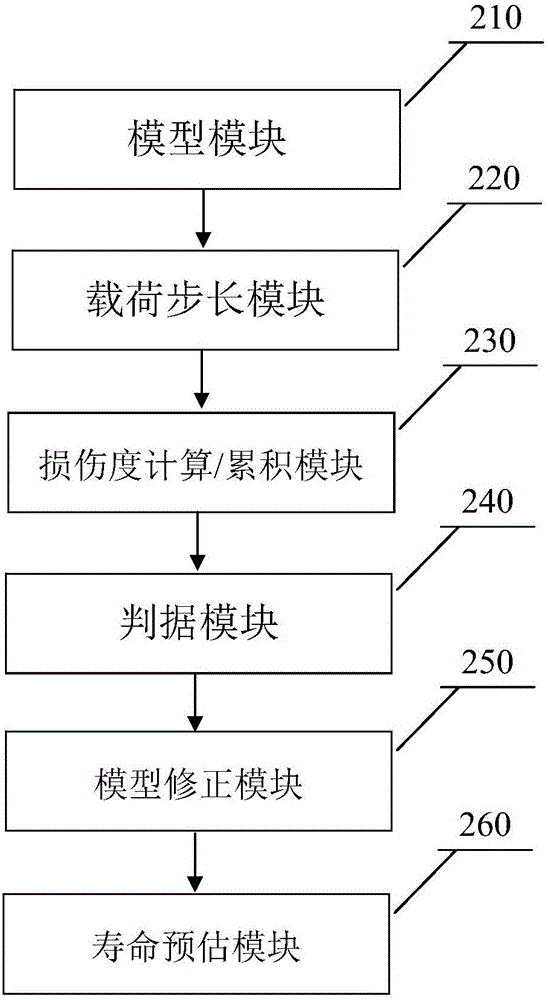

[0040] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings.

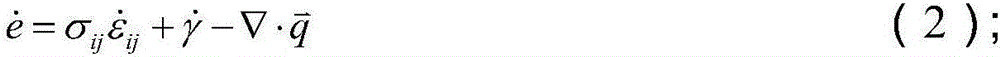

[0041] It is generally believed that the fatigue damage process of metal materials is an irreversible thermodynamic process. Damage mechanics is based on continuum mechanics and thermodynamics. According to the law of conservation of energy, the damage evolution equation and the damage constitutive relation are derived from the free energy and dissipation potential of the system, thus forming a more rigorous macroscopic damage analysis mechanical system, which is more accurate It reflects the damage evolution process of the material, forms a practical fatigue life prediction method, and realizes the theoretical prediction of the fatigue life of the material.

[0042] The first law of thermodynamics characterizes the conservation of energy and can be written as:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com