Rubber spring damper and manufacturing method thereof

A technology of rubber springs and shock absorbers, applied in the direction of springs/shock absorbers, shock absorbers, springs, etc., can solve the problems of easy corrosion stress, concentration, etc., to increase product strength, reduce resistance and wear, and have good damping. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

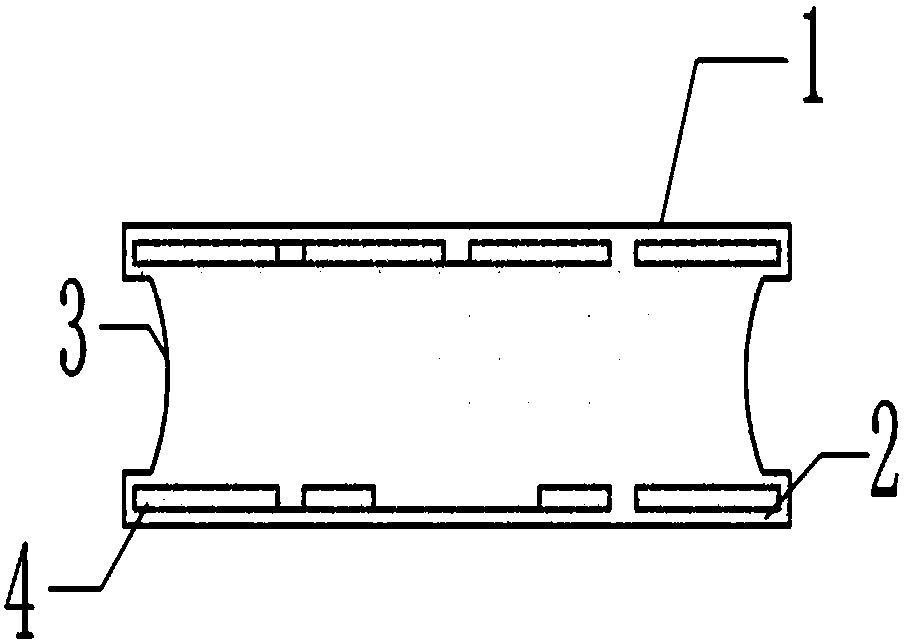

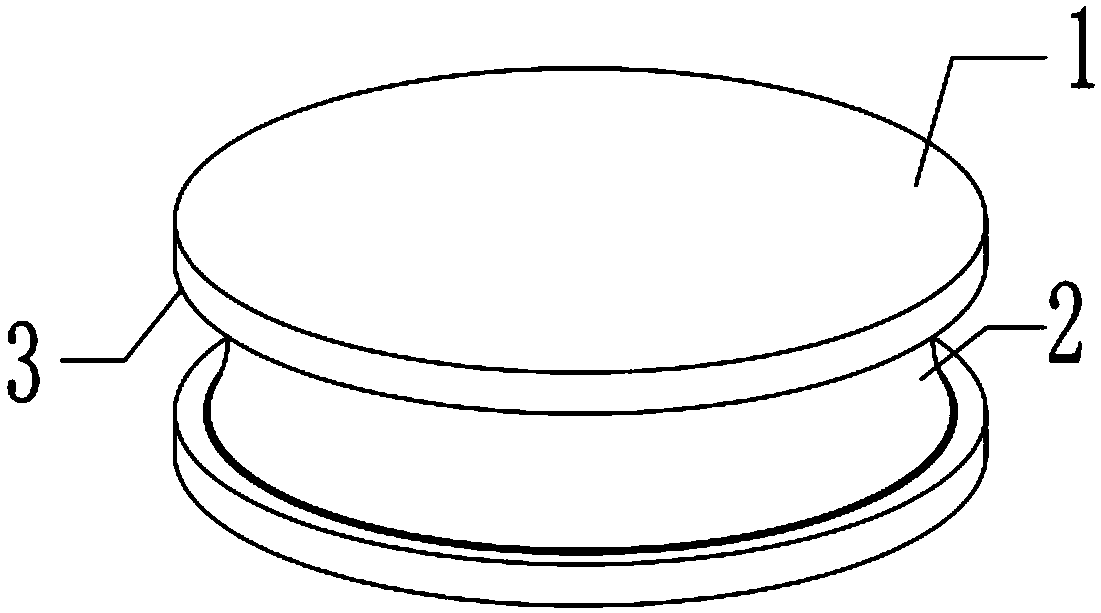

[0025] like figure 1 Shown is a schematic diagram of the structure of the rubber spring of this embodiment. The rubber spring includes a rubber spring body 1 , at least two surface layers 2 , a vibration-damping waist 3 , and two pieces of reinforcing skeleton material 4 .

[0026] Among them, the product process design is mainly used. The process design mainly adopts two-stage molding method, one-stage forming low-temperature high-pressure molding to finalize the product. At this time, the rubber material has completely wrapped the reinforcing skeleton material inside, and the rubber has no vulcanization characteristics. Two-stage molding is vulcanized at high temperature and high pressure, the rubber molecules are cross-linked, and the rubber material reacts chemically with the adhesive on the reinforcing skeleton surface, so that the two are connected together. High-temperature and high-pressure vulcanization makes the performance of the rubber material meet the requiremen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com