Transmission gear fatigue life assessment method based on defect modeling

A fatigue life, transmission gear technology, applied in the field of fatigue life evaluation of transmission gears based on defect modeling, can solve the problems of not meeting the actual engineering application standards, and can not reasonably consider the impact of crack fatigue life, etc., to achieve fast remanufacturing Effects of reusability judgment, improvement of fatigue analysis efficiency, and complexity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with accompanying drawing.

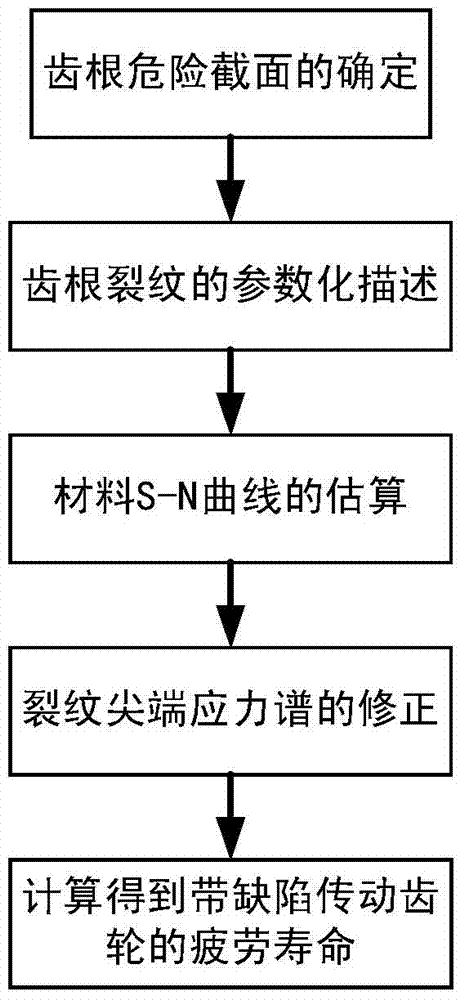

[0046] Such as figure 1 As shown, the fatigue life analysis method of transmission gears based on defect modeling in the present invention analyzes the geometric characteristics of cracks, parametrically expresses them and introduces them into the dangerous section of the tooth root, and uses the fatigue life analysis method based on local stress to perform fatigue life evaluation. , the specific steps are as follows:

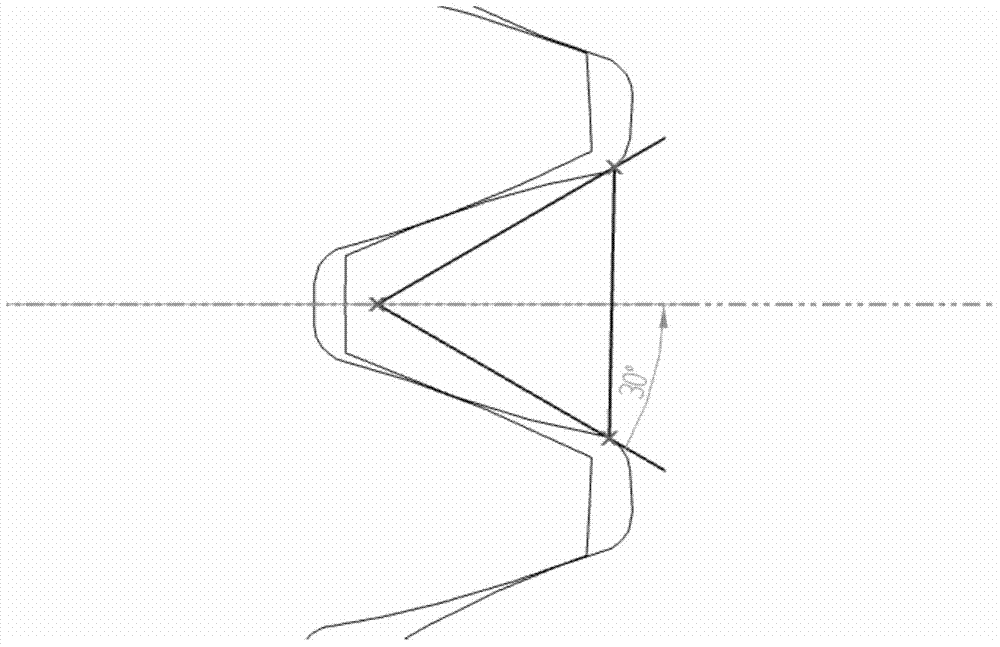

[0047] (1) Analyze the dangerous cross-section where root cracks are most likely to occur

[0048] The dangerous section of the tooth root described in the present invention is based on the attached figure 2 It is determined by the 30° tangent line theory shown above. A point on the center line of the gear tooth is used as a tangent line to the root fillet, and the direct connection line between the two tangent points is the dangerous section.

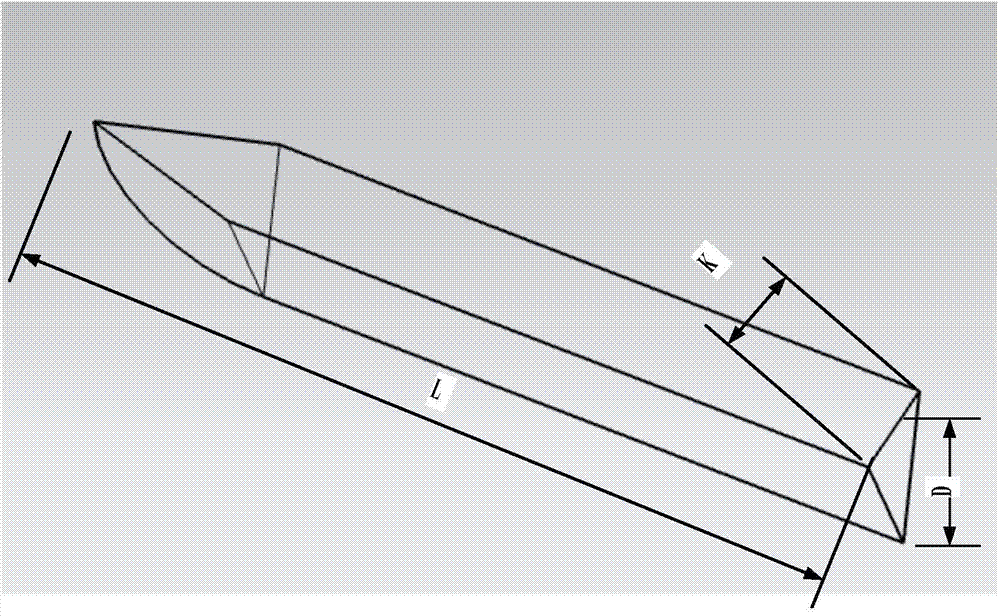

[0049] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com