Patents

Literature

340results about "Chemical data visualisation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

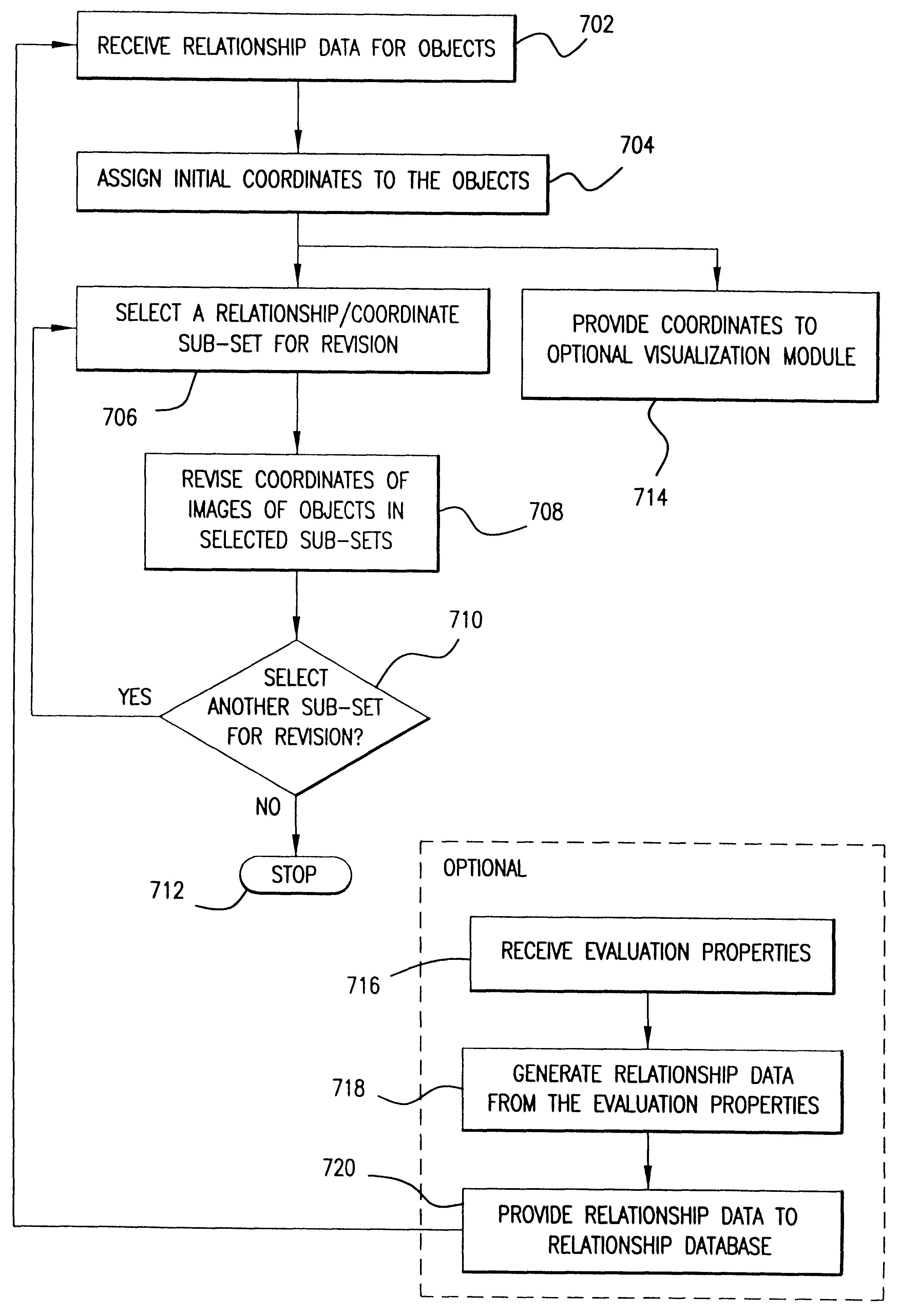

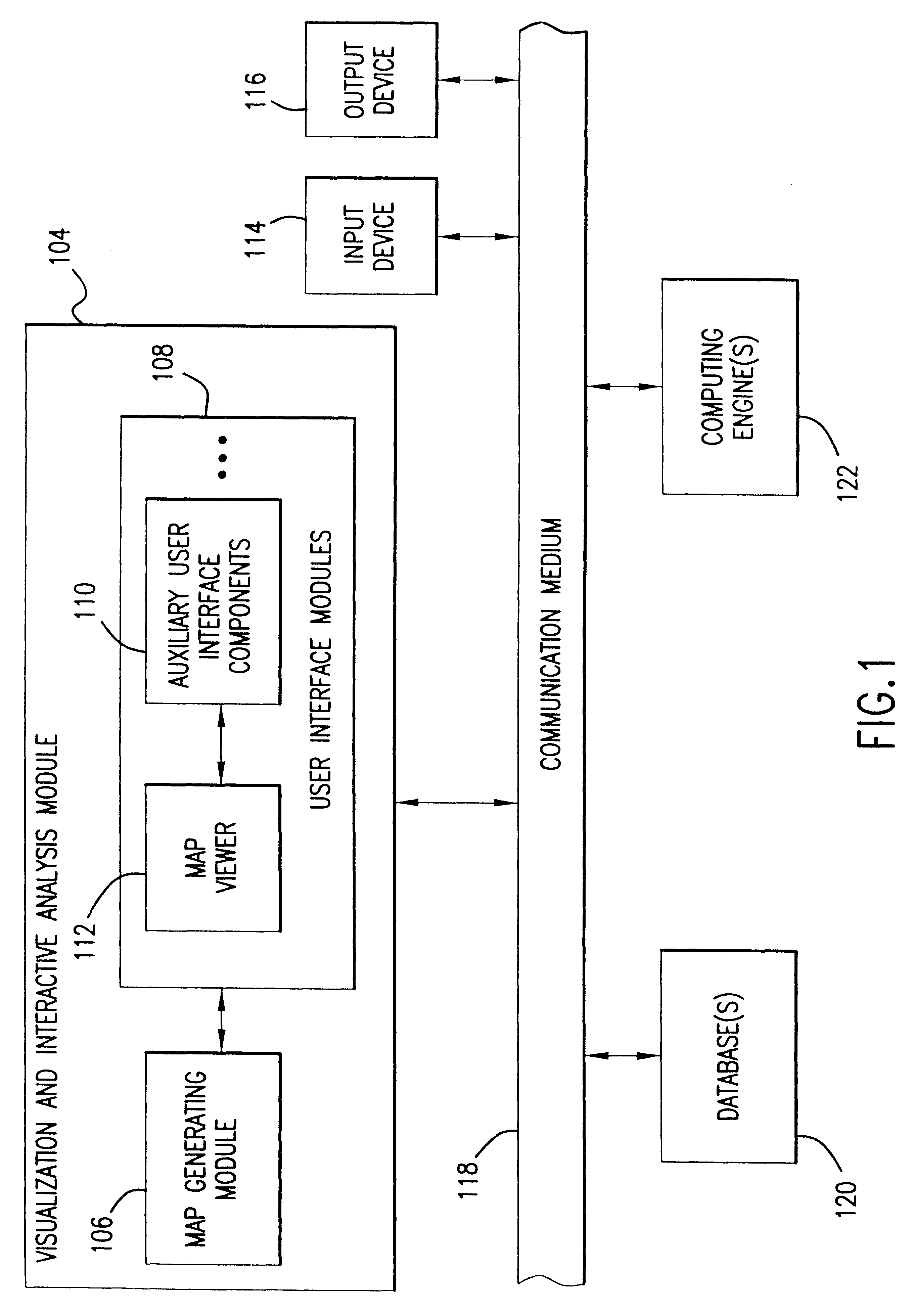

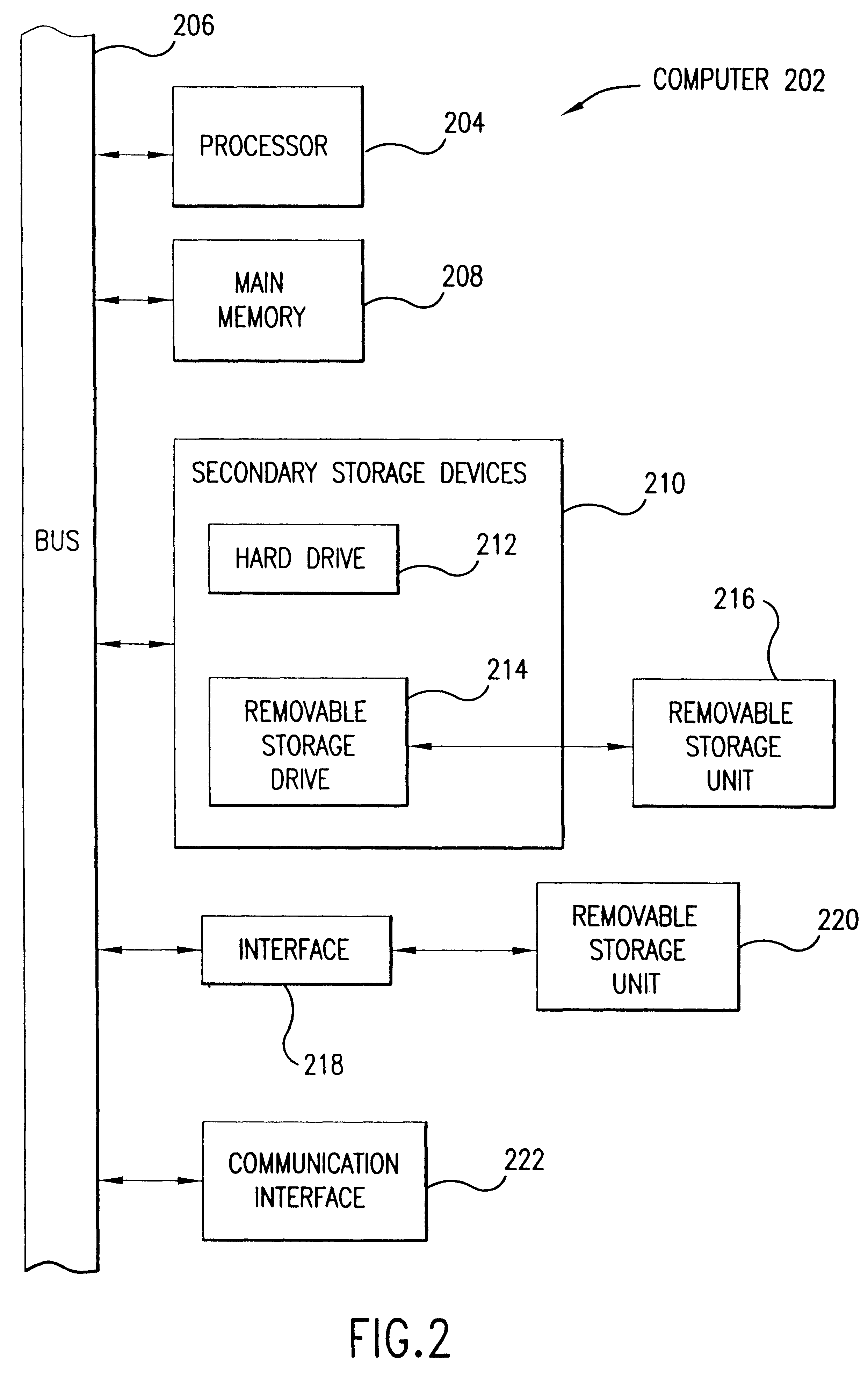

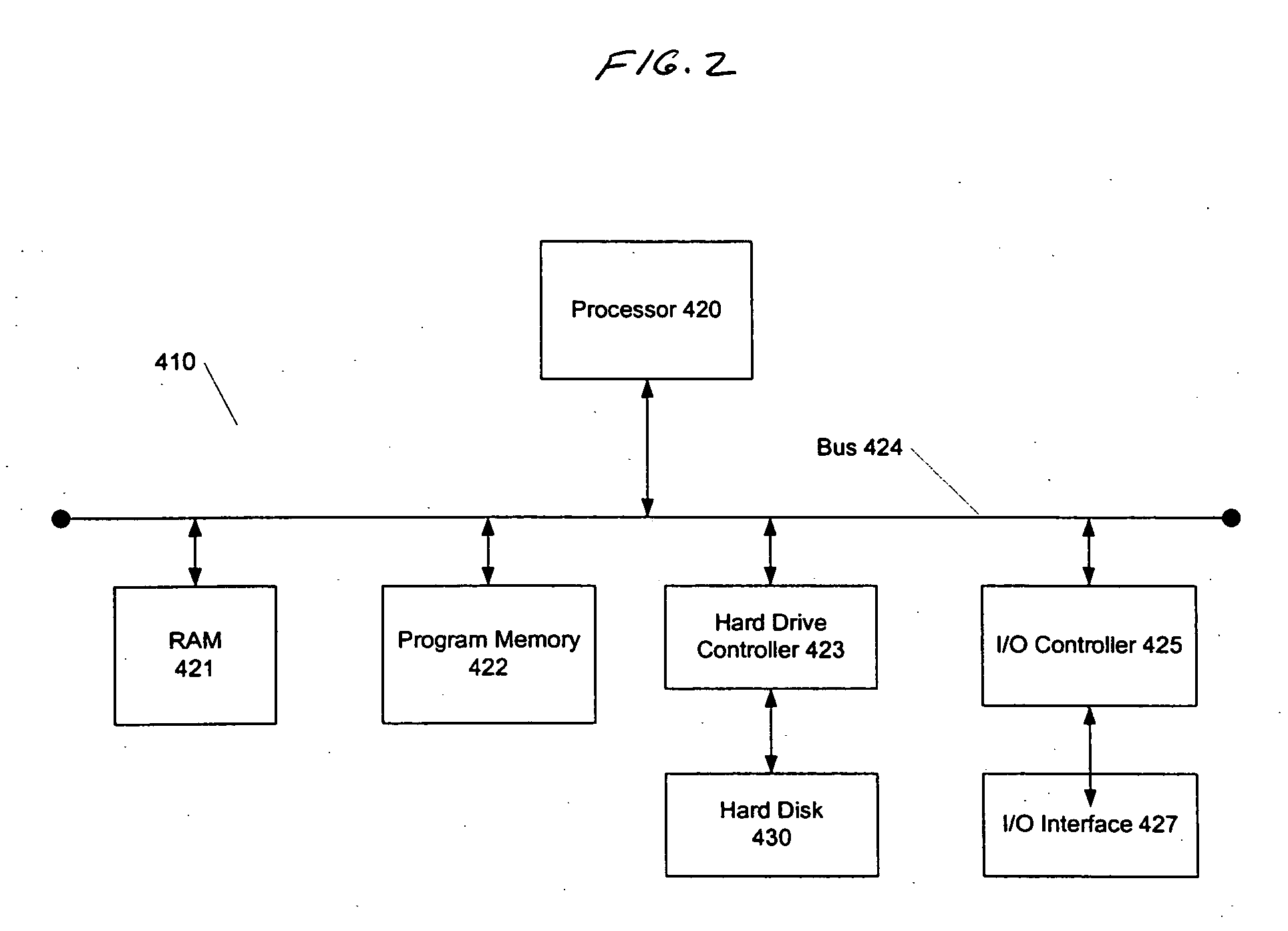

System, method, and computer program product for representing proximity data in a multi-dimensional space

A system, method and computer program product for representing precise or imprecise measurements of similarity / dissimilarity (relationships) between objects as distances between points in a multi-dimensional space that represents the objects. Self-organizing principles are used to iteratively refine an initial (random or partially ordered) configuration of points using stochastic relationship / distance errors. The data can be complete or incomplete (i.e. some relationships between objects may not be known), exact or inexact (i.e. some or all of the relationships may be given in terms of allowed ranges or limits), symmetric or asymmetric (i.e. the relationship of object A to object B may not be the same as the relationship of B to A) and may contain systematic or stochastic errors. The relationships between objects may be derived directly from observation, measurement, a priori knowledge, or intuition, or may be determined indirectly using any suitable technique for deriving proximity (relationship) data.

Owner:3 DIMENSIONAL PHARMA

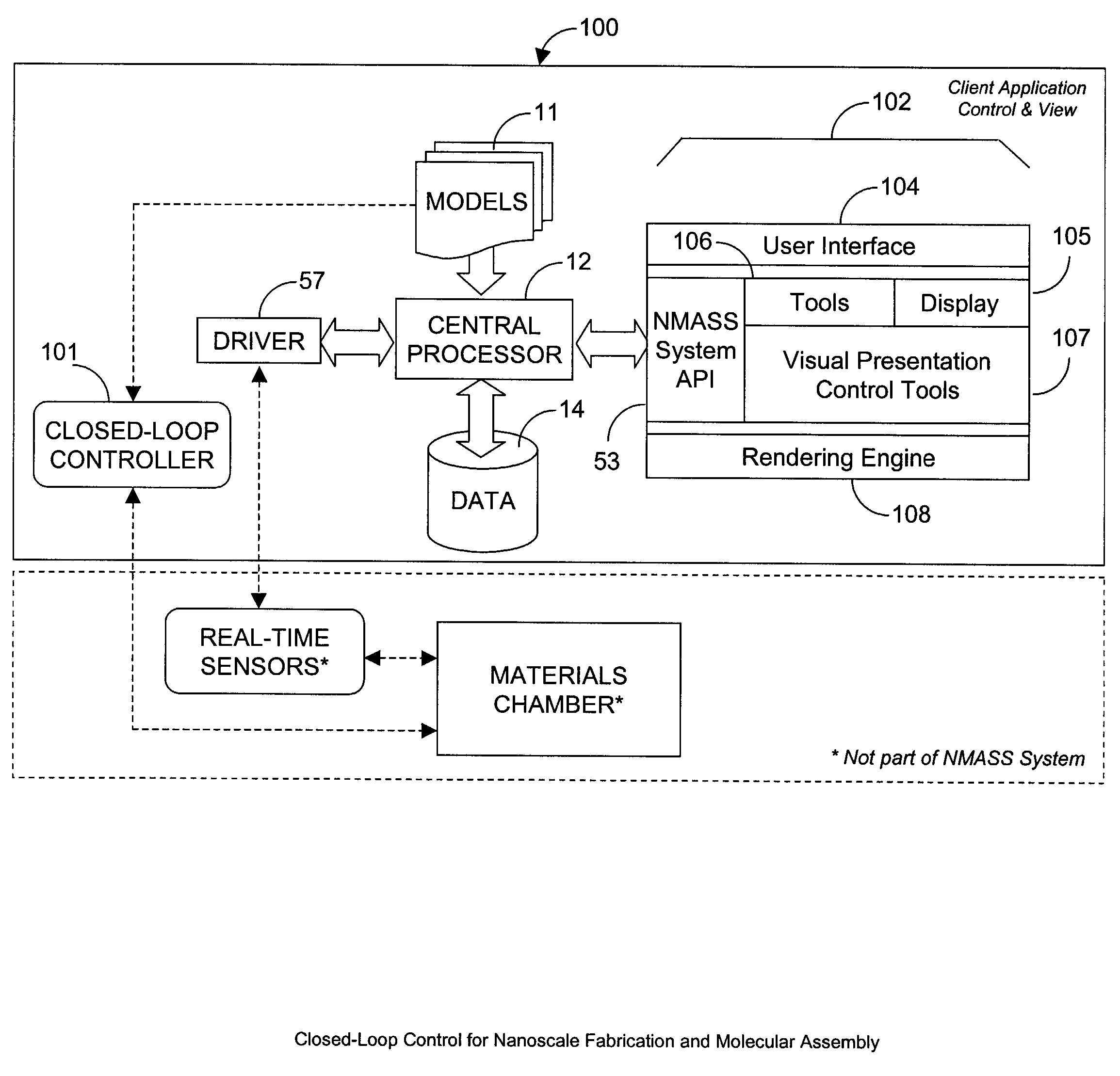

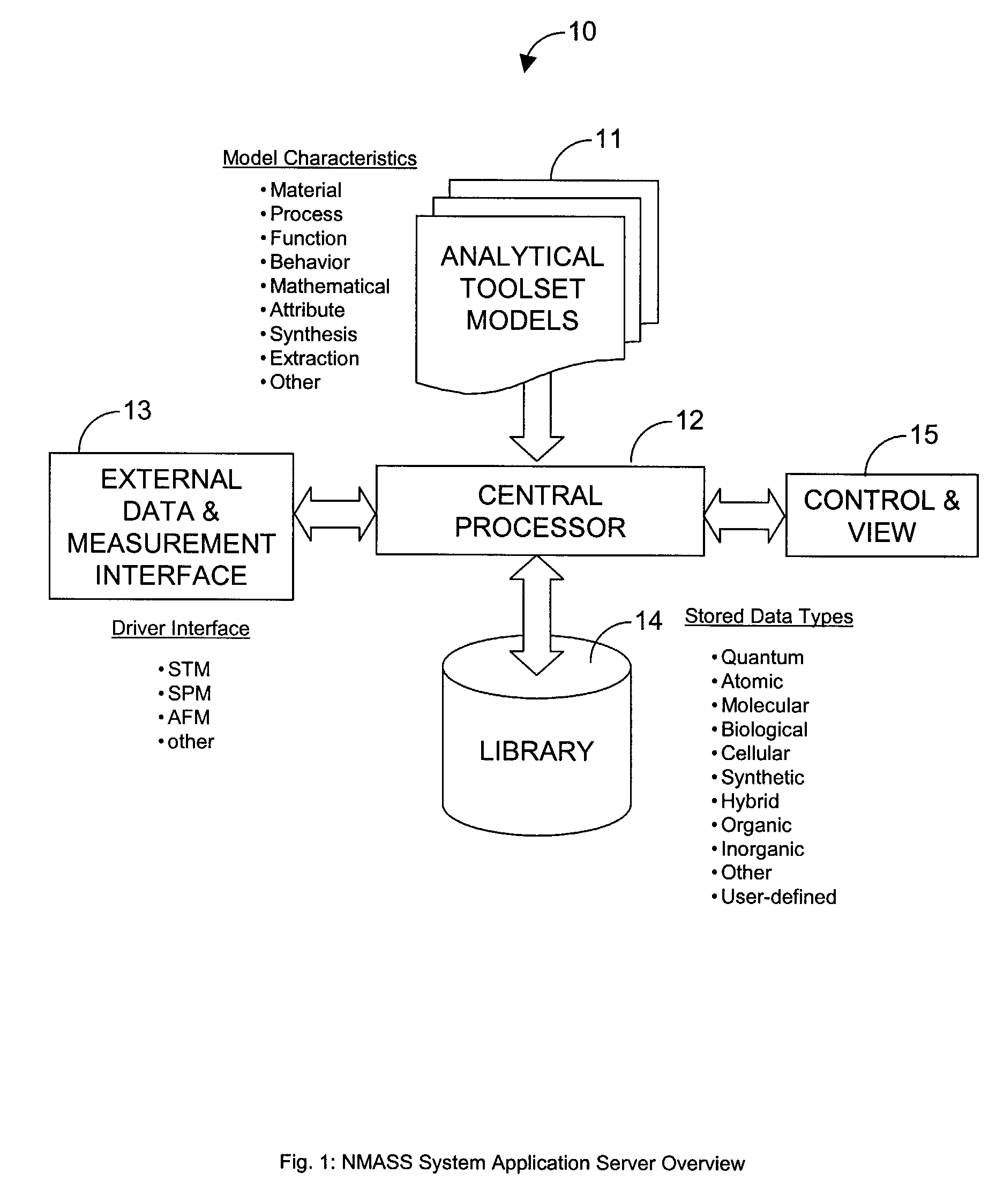

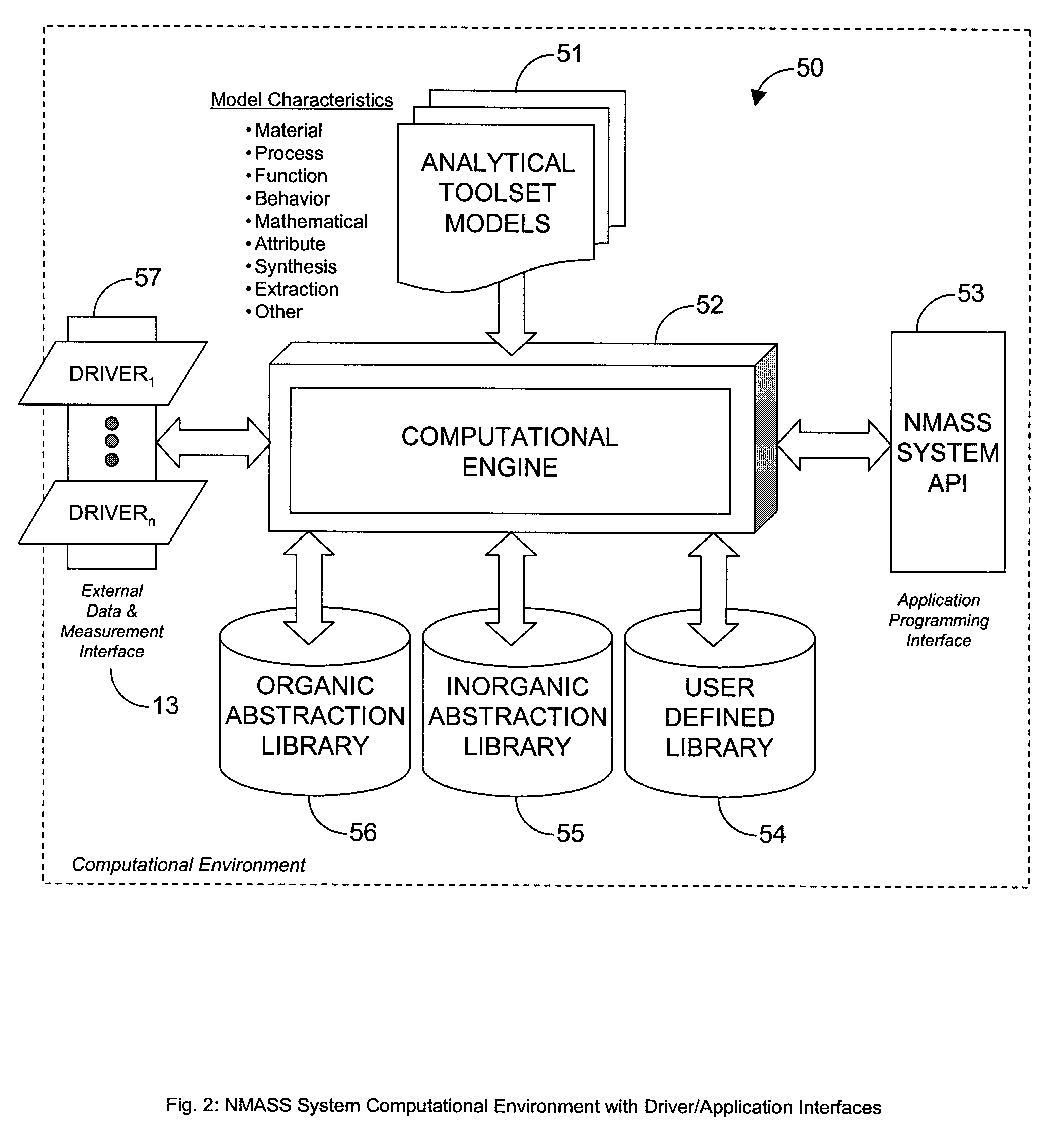

System, Method, and Product for Nanoscale Modeling, Analysis, Simulation, and Synthesis (NMASS)

InactiveUS20030139907A1Chemical property predictionSimulator controlPerformance functionLinear control

Abstract of Disclosure A computer-based system is described that provides users with the ability to develop high-fidelity digital quantitative representations of physical and chemical phenomena, and to employ an optimization-based approach to control associated physiochemical processes. The system includes a computational environment, intuitive user interface(s), integrated software libraries, analytical tools, and visualization / rendering engine that together provide an integrated framework for nanoscale modeling, analysis, simulation, and synthesis. Additionally, the system includes an optimal linear control synthesis methodology that incorporates a first order dynamic mathematical representation (of the conceptual molecular system) suitable for applying various pragmatic control system techniques including optimization of structured singular values, linear quadratic performance functions, Lyapunov criteria, or similar, for the purposes of nanoscale fabrication and molecular assembly.

Owner:MCCARTHY ROBERT J

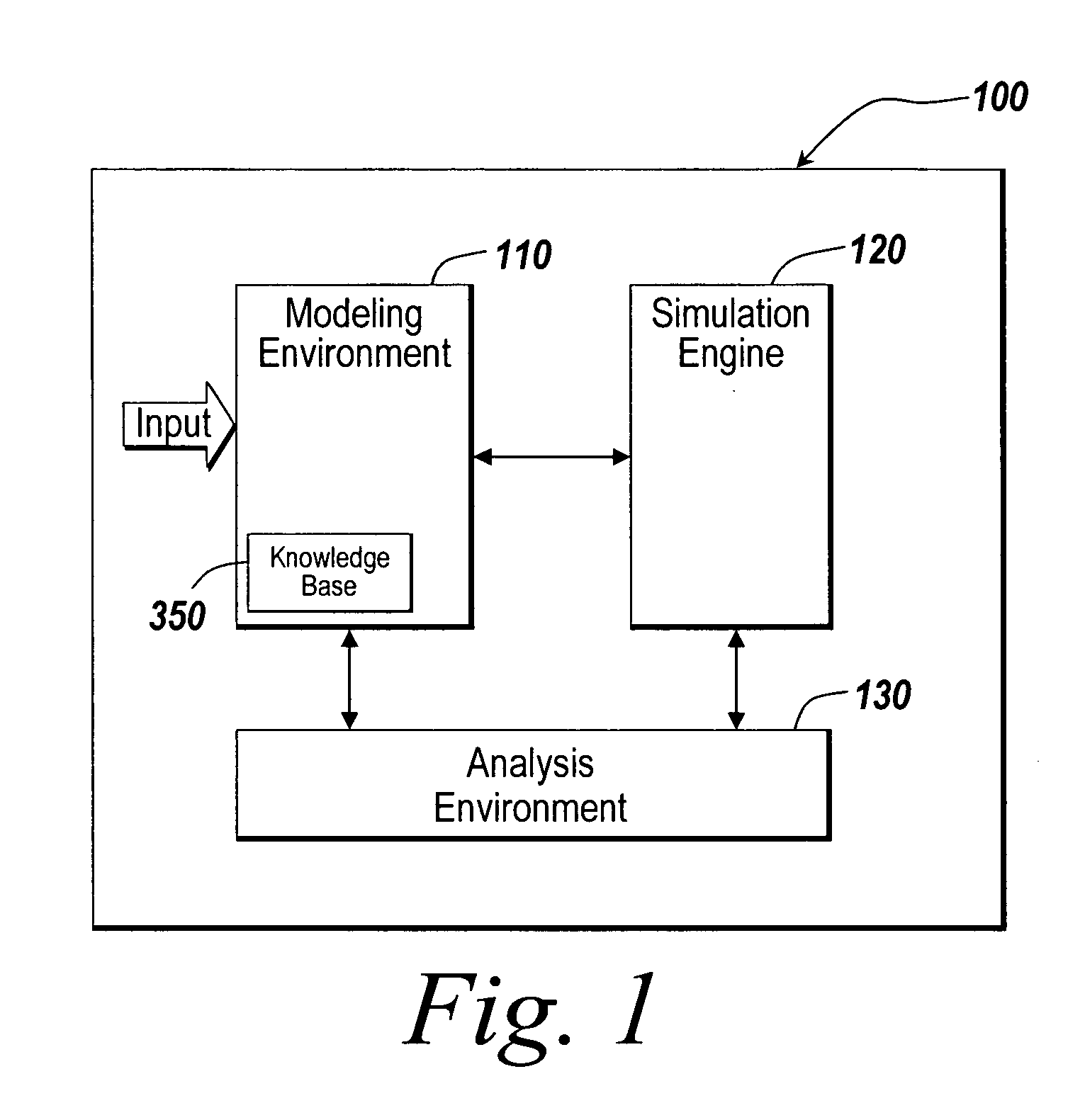

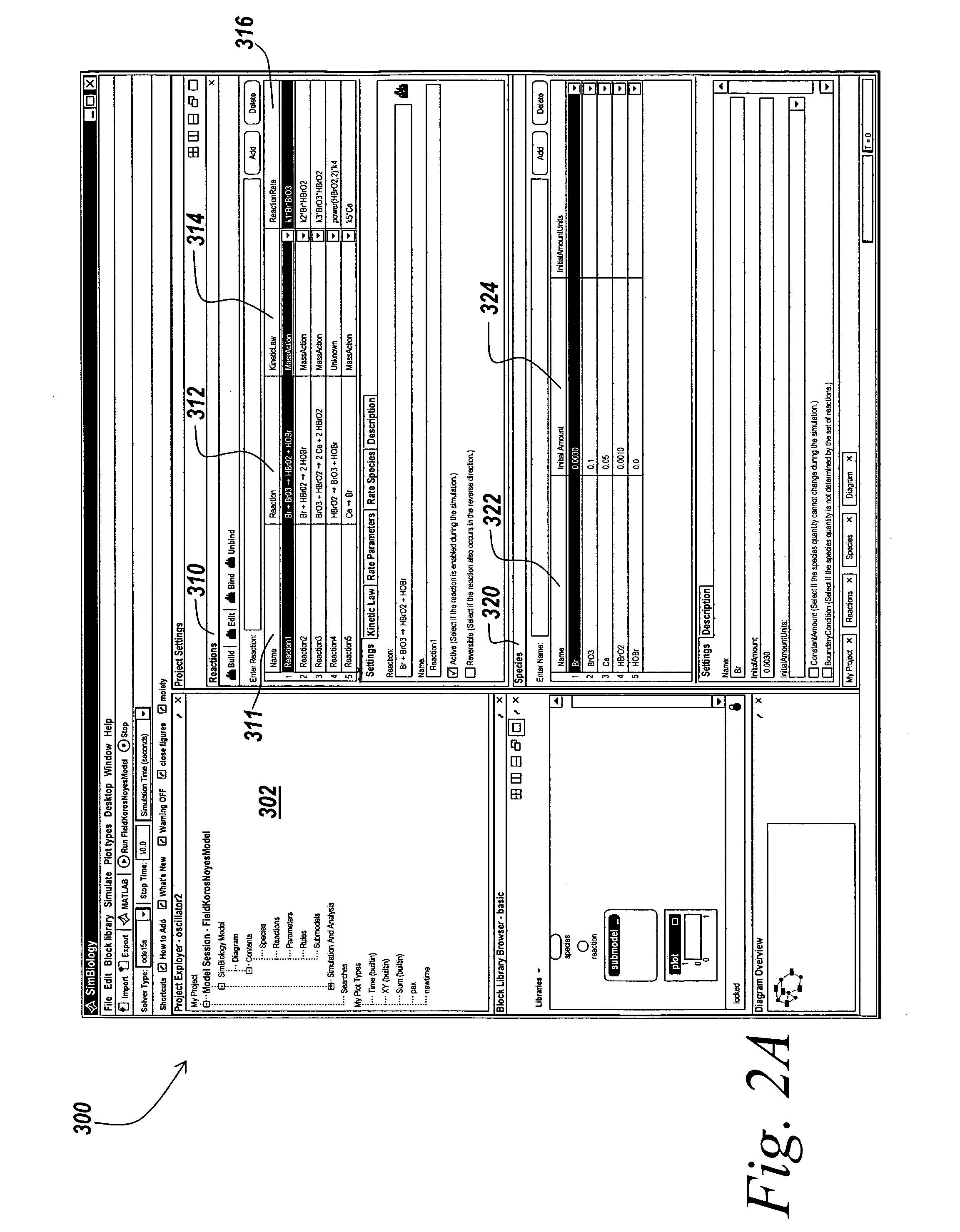

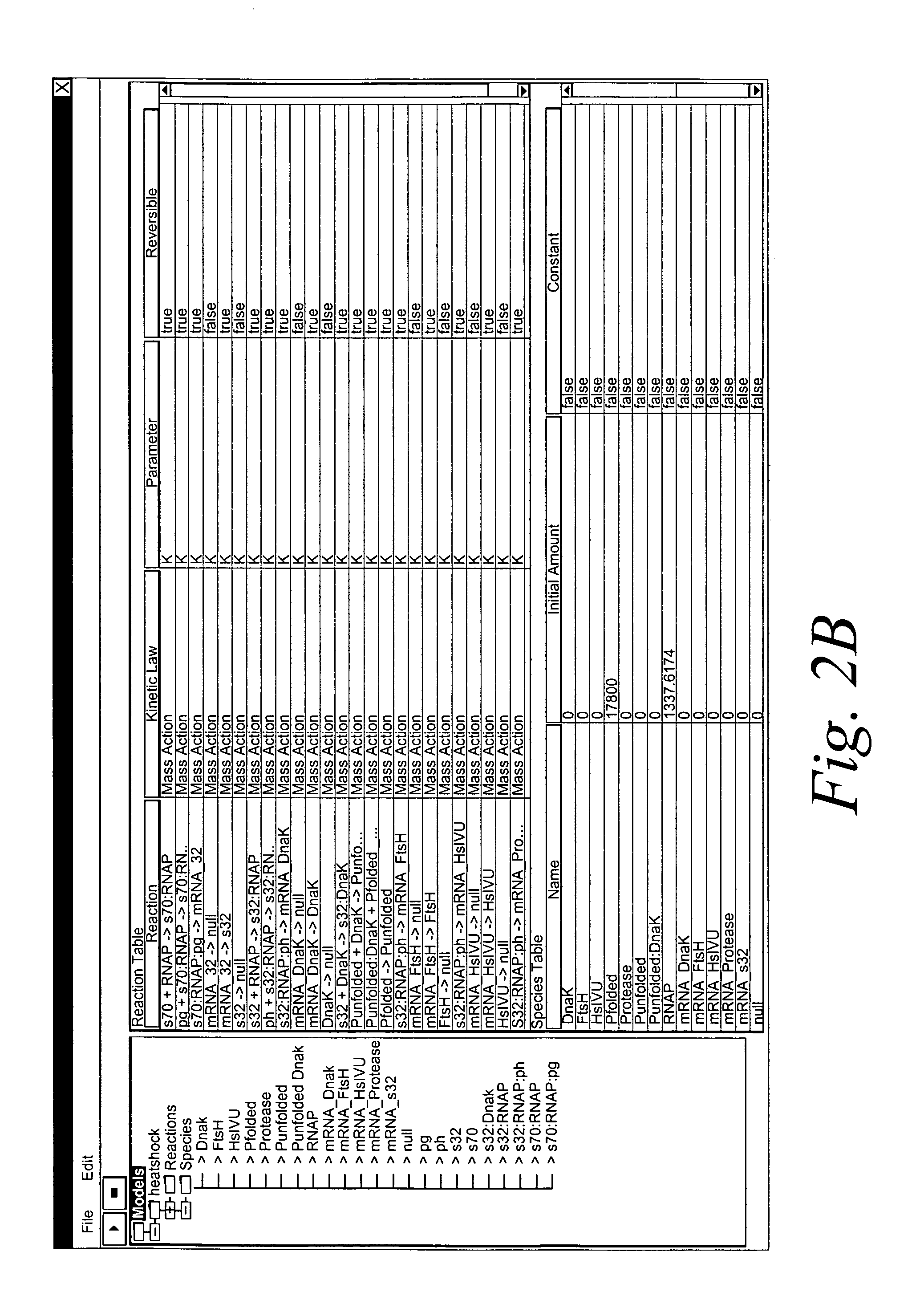

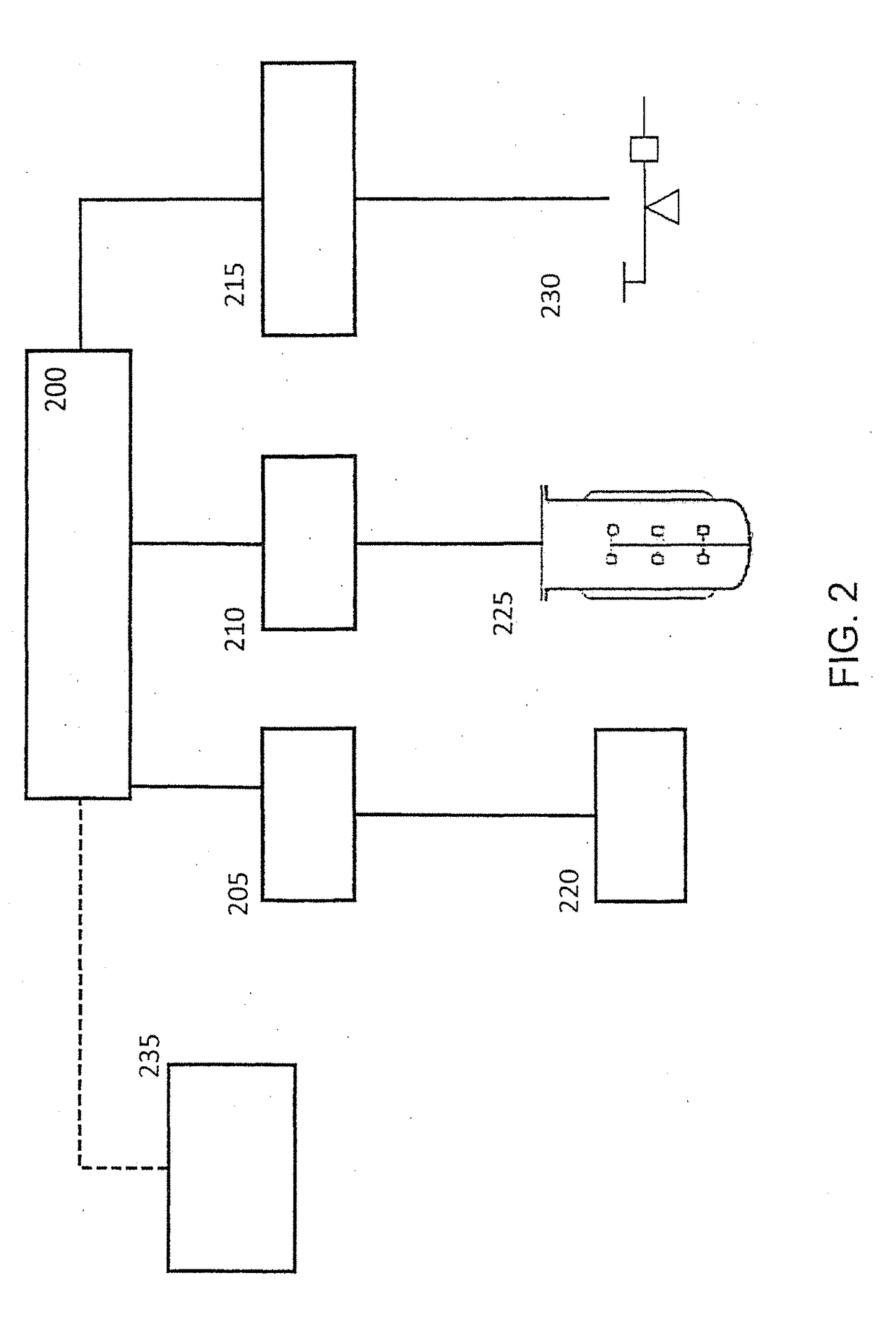

Block diagram explorer in a method and apparatus for integrated modeling, simulation and analysis of chemical and biological systems

ActiveUS20070250299A1Easy constructionData visualisationAnalogue computers for chemical processesGraphicsGraphical user interface

A system for modeling, simulating and analyzing chemical and biochemical reactions includes a modeling environment for constructing a model of a chemical or biochemical system comprising a plurality of chemical reactions. The system also includes a simulation engine accepting as input said constructed model of the chemical or biochemical system and generating as output an expected result. The modeling environment includes a block diagram explorer for displaying a block diagram in a graphical user interface describing the system as a hierarchical network of interconnected blocks. Each block represents a species participating one of the chemical reactions or one of said chemical reactions in the system. The block diagram explorer allows for a user to manipulate and modify the graphical parameters of the block diagram representation to provide insight into the functionality and operation of the system being modeled.

Owner:THE MATHWORKS INC

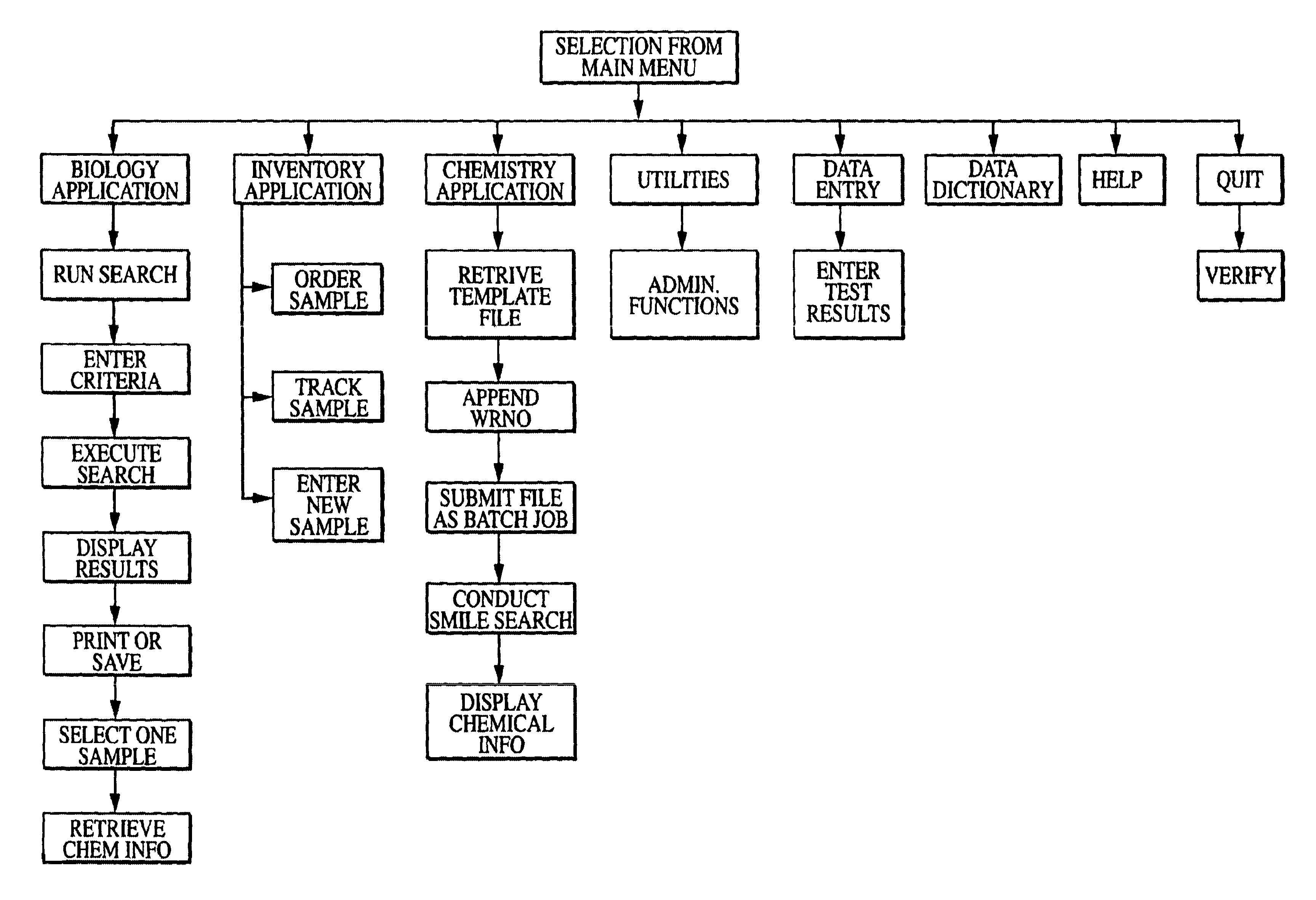

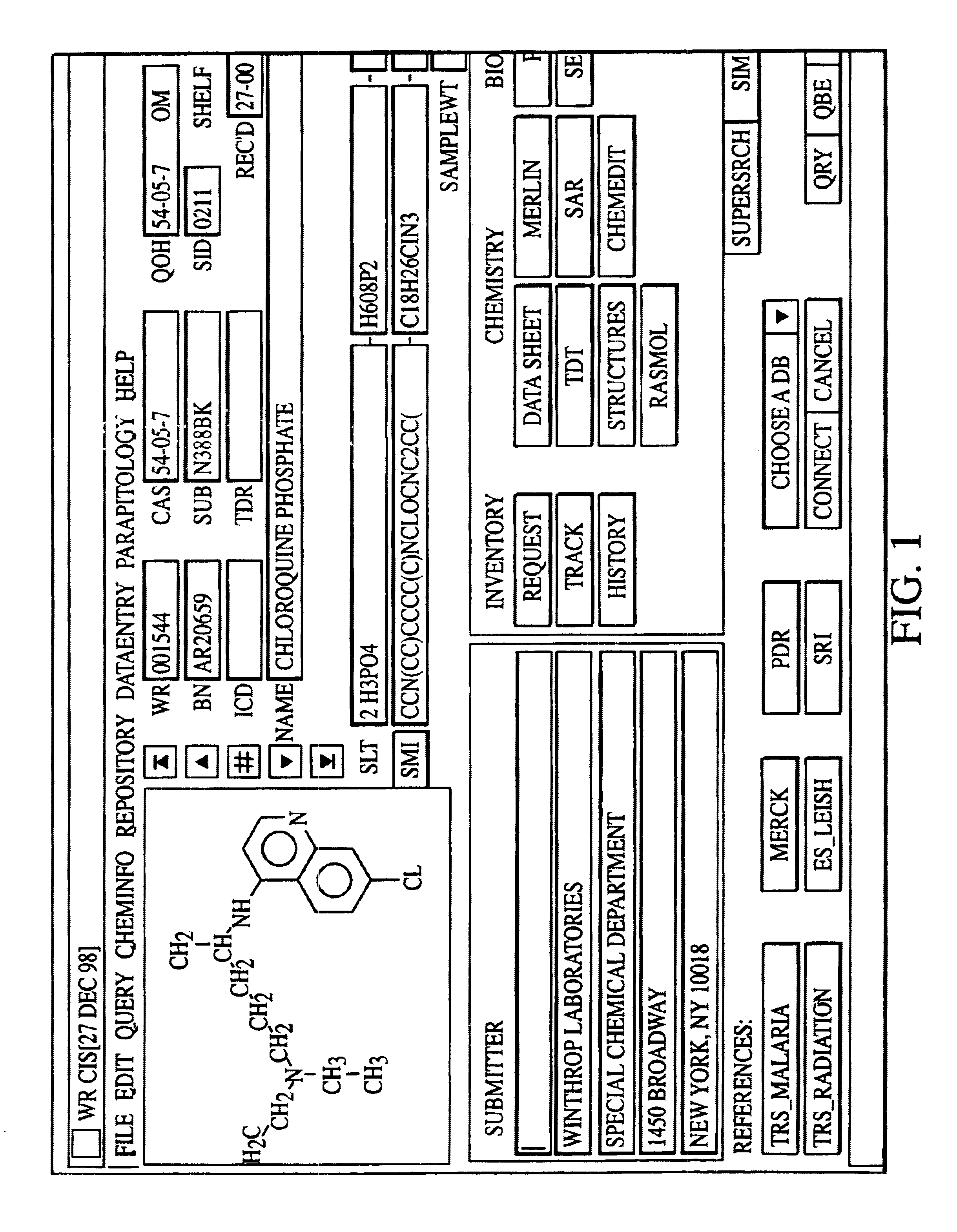

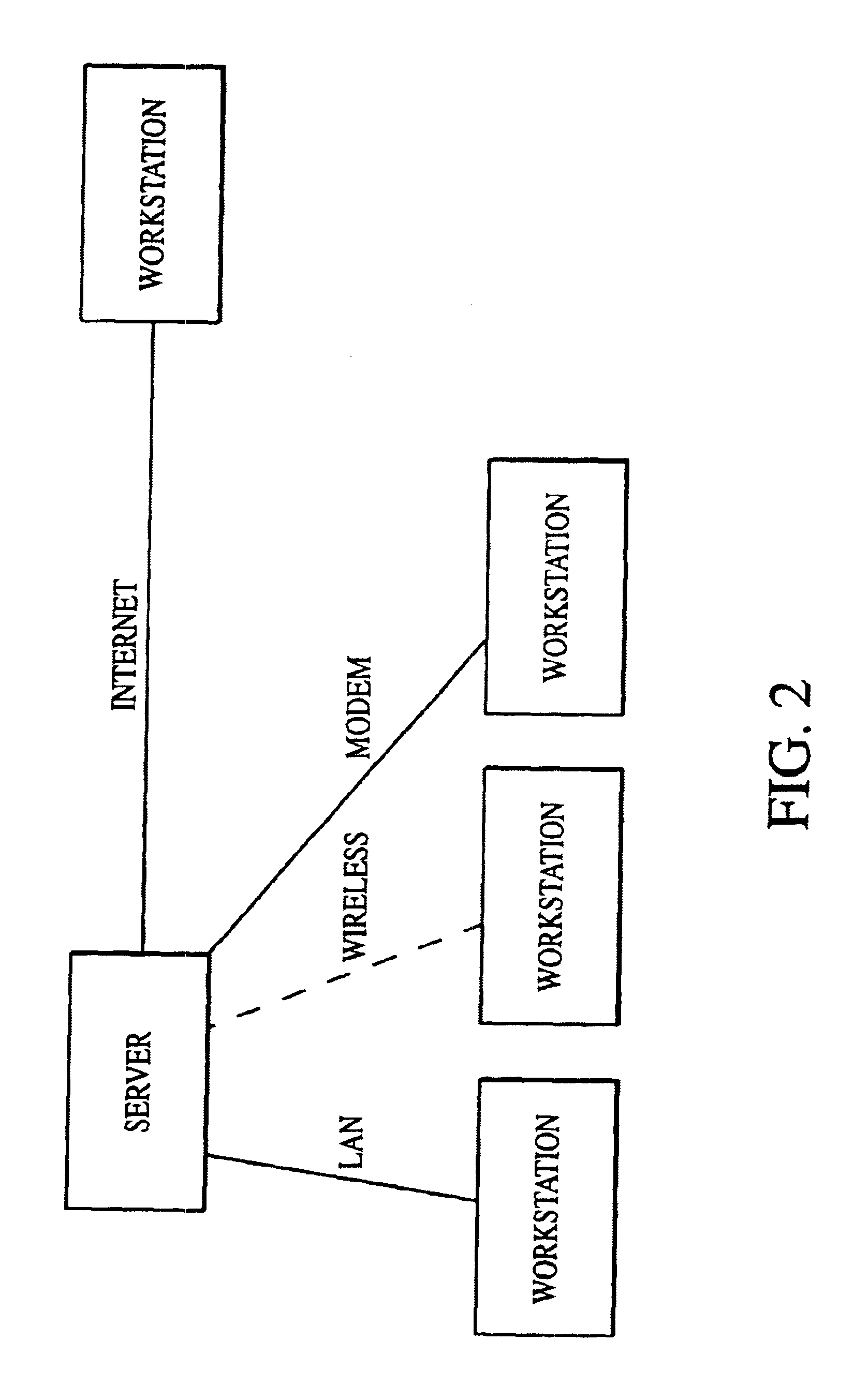

Chemical information systems

InactiveUS6654736B1Easy to useData processing applicationsCheminformatics data warehousingGraphicsGraphical user interface

A chemical information system having a graphical user interface that allows manipulation of multiple databases having related material and information. The system includes a server and multiple workstations communicating with the server. The databases reside on the server, which may include multiple servers.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

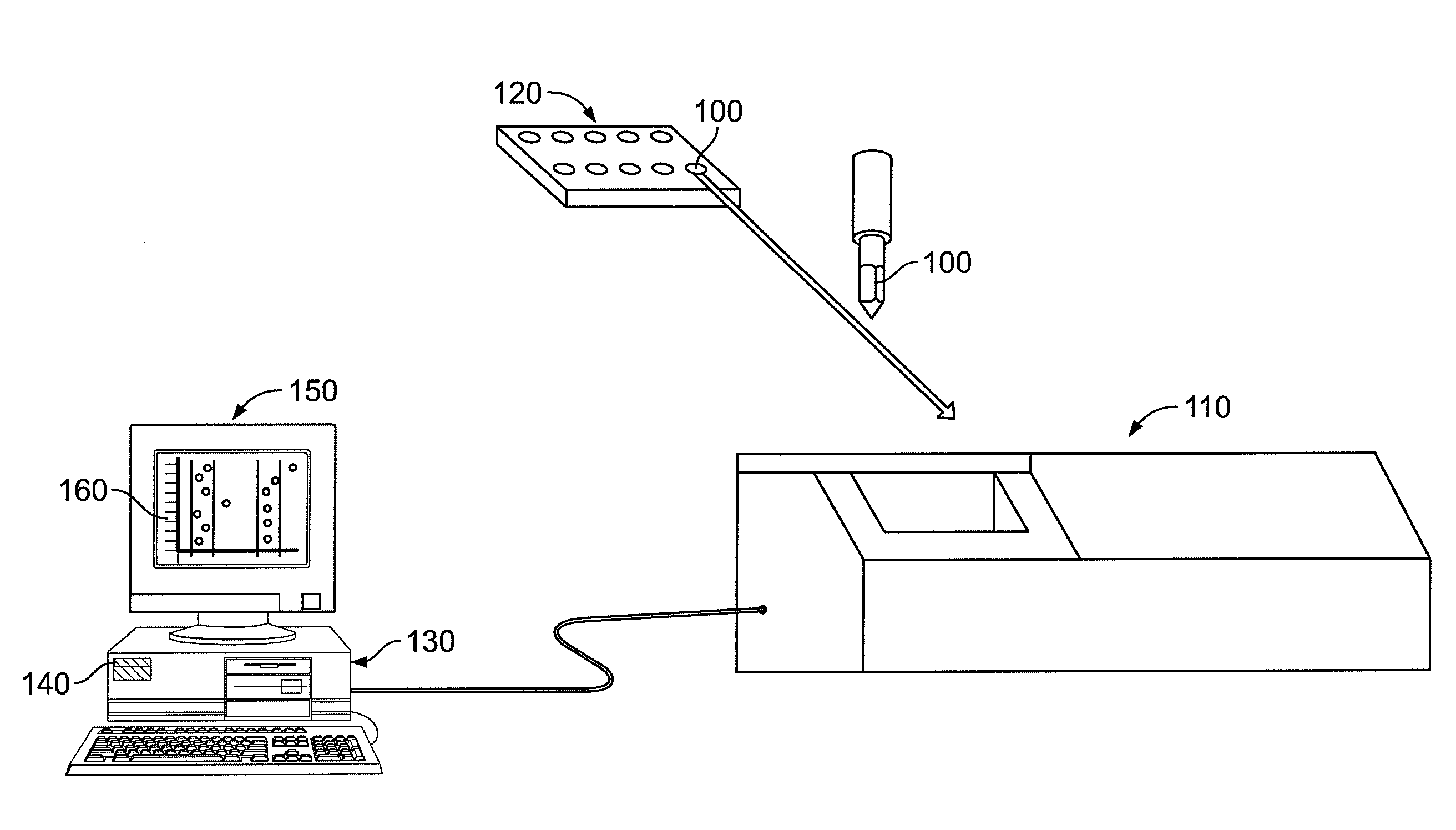

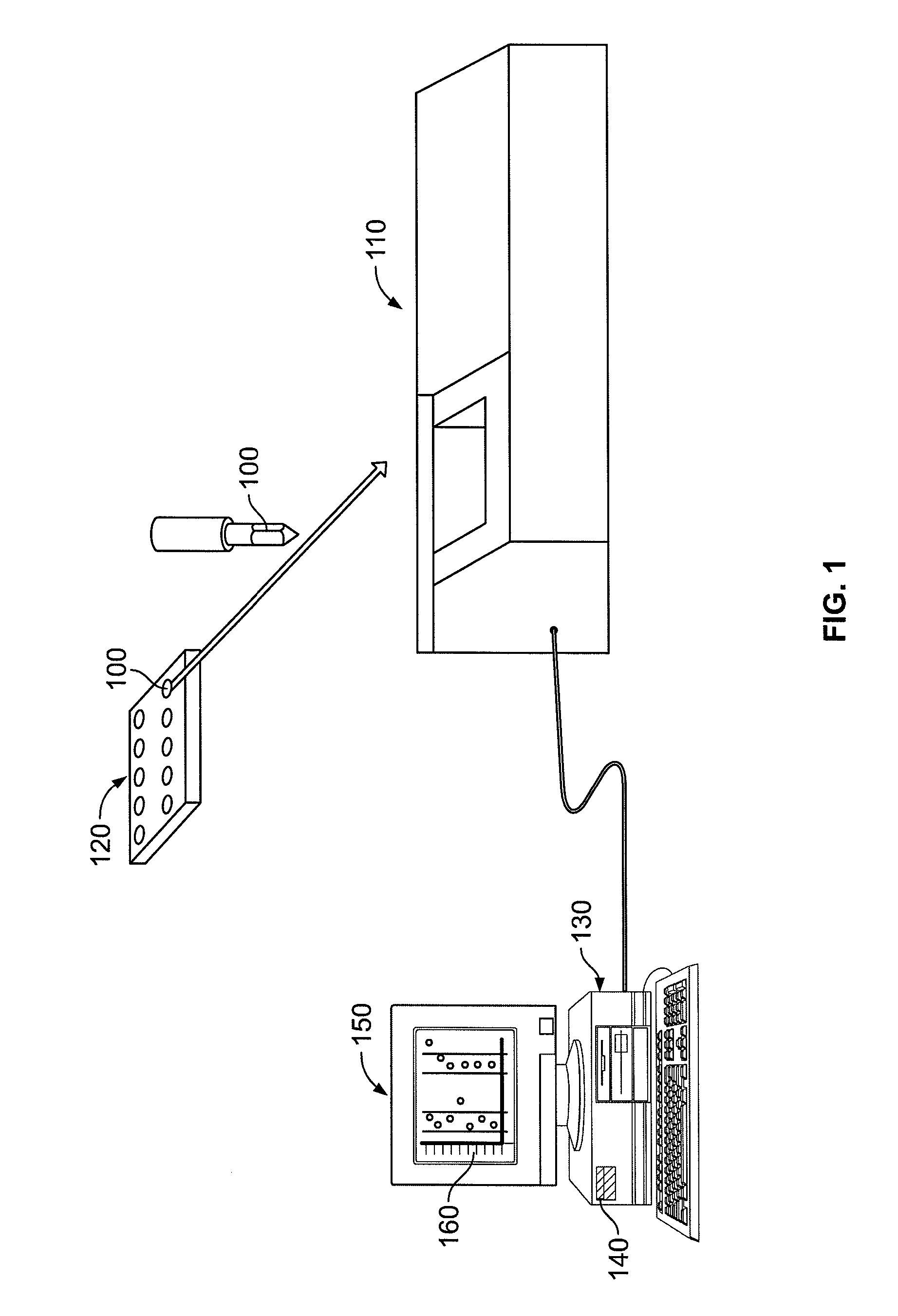

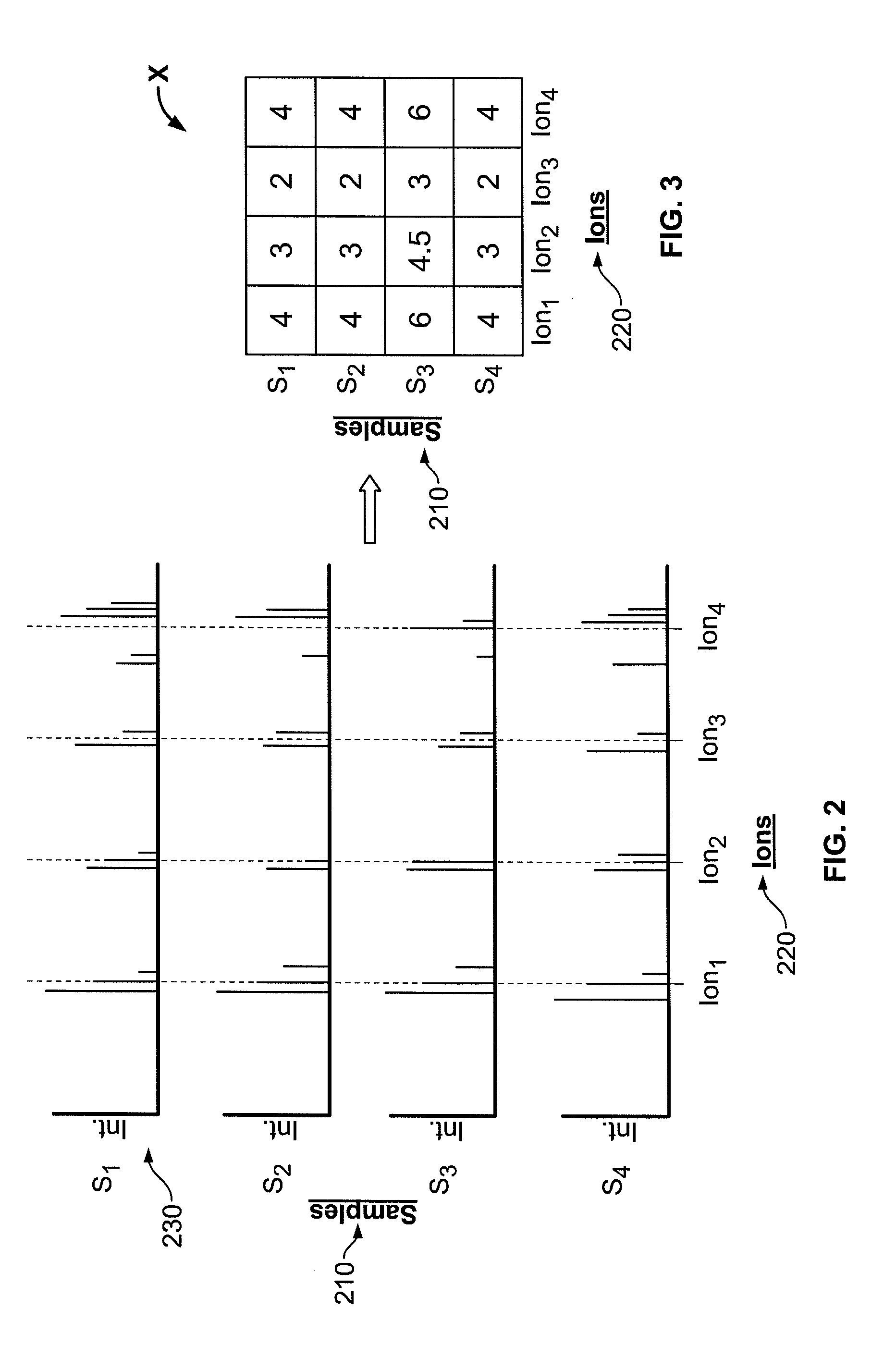

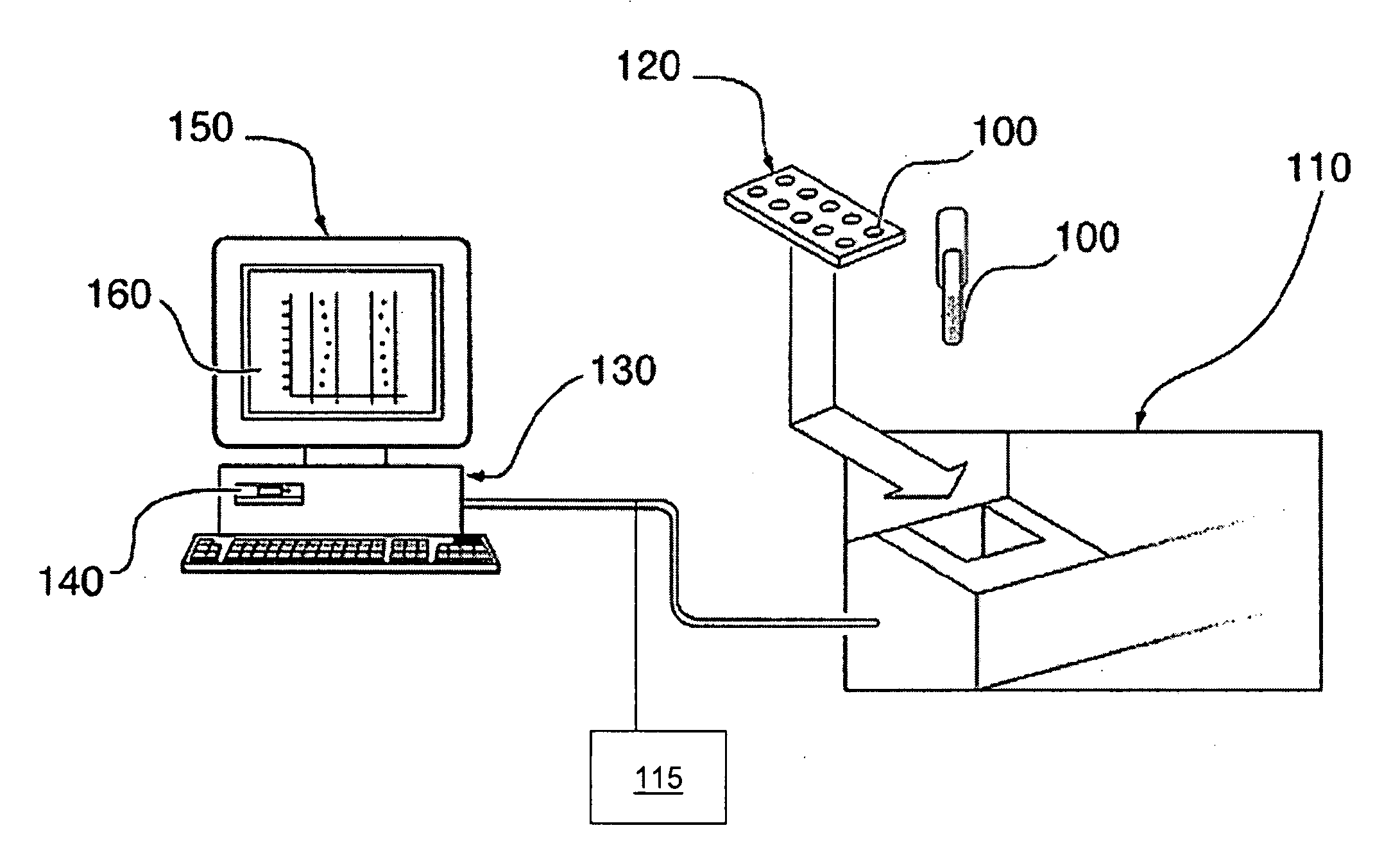

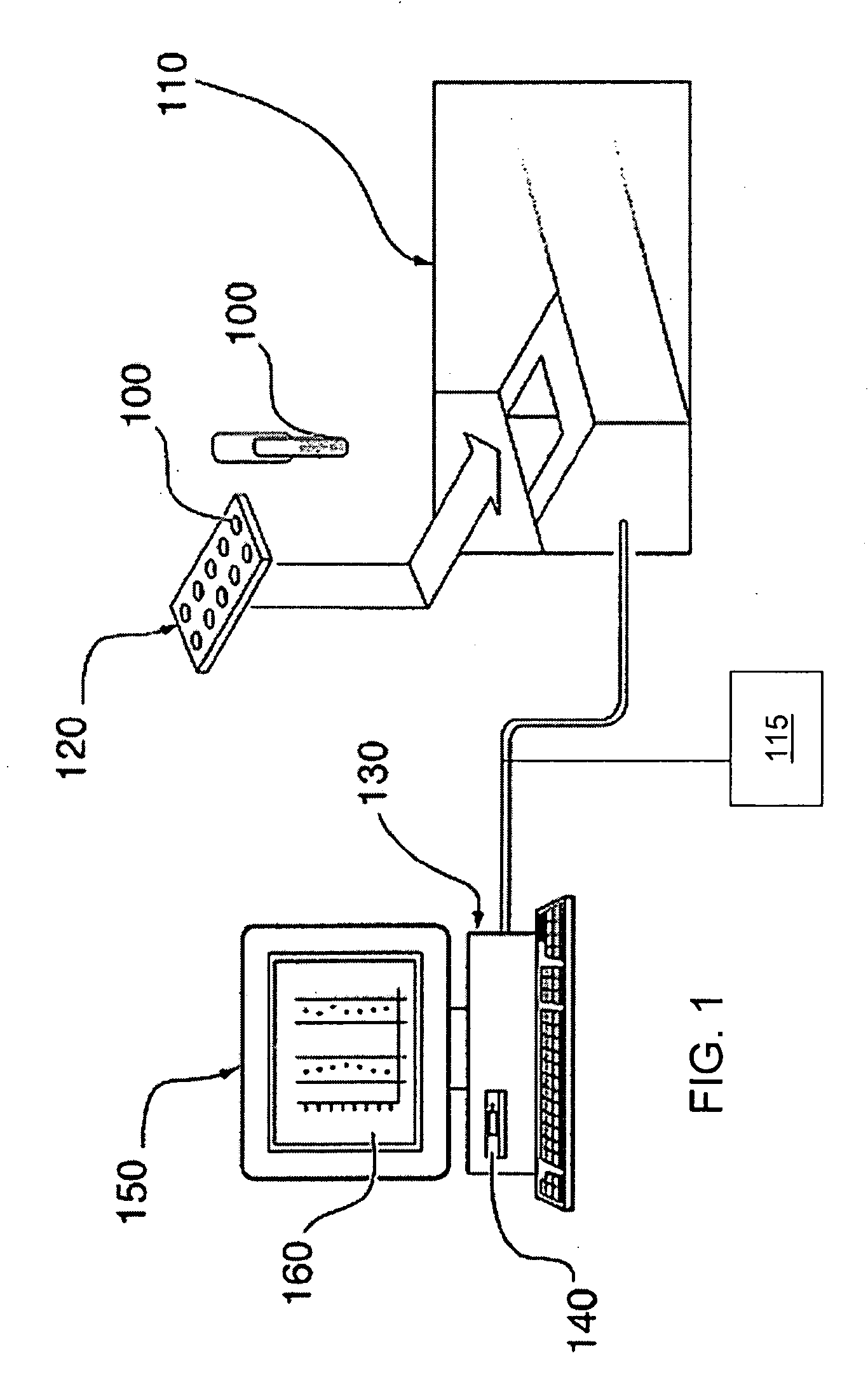

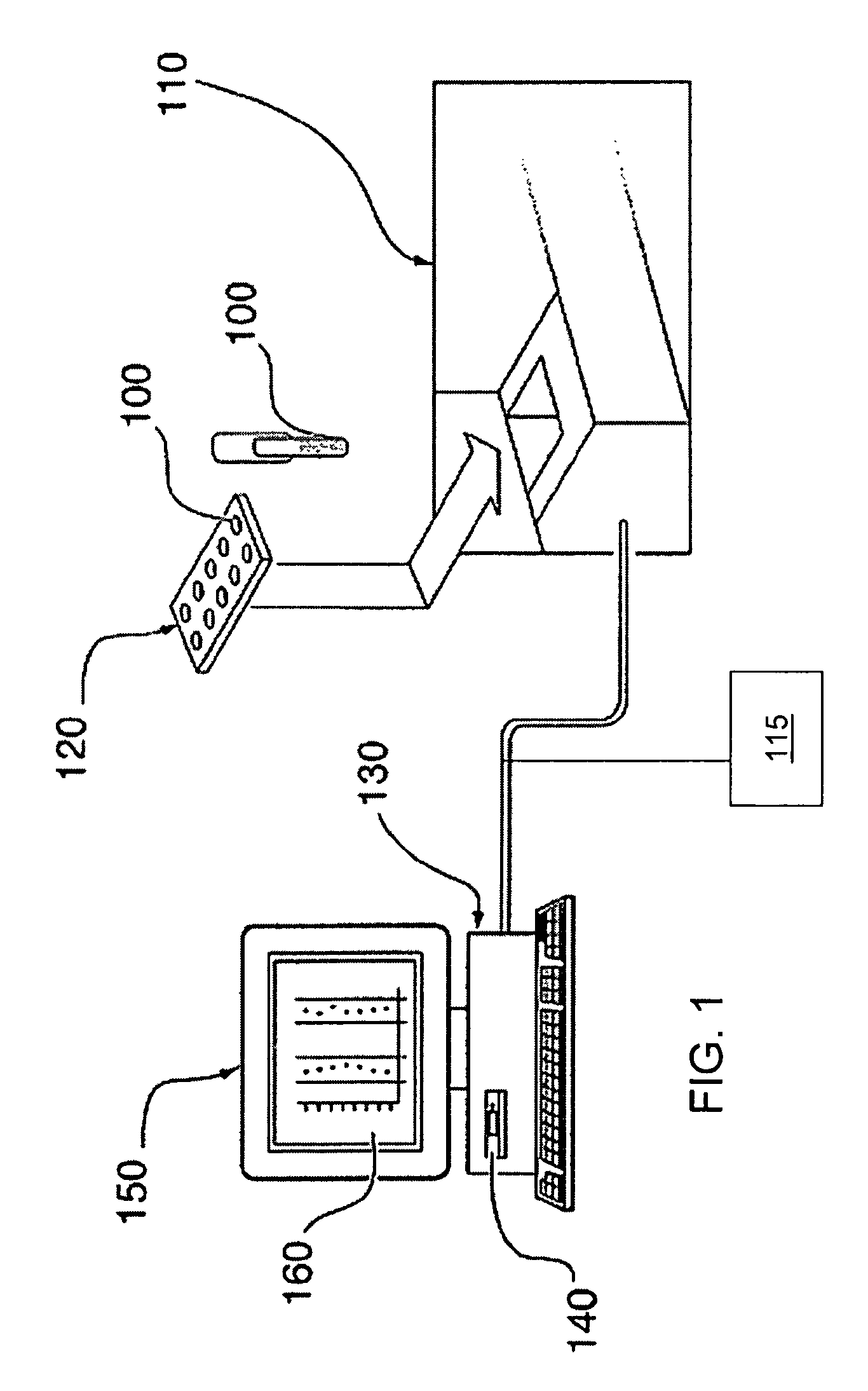

System, method, and computer program product for analyzing spectrometry data to identify and quantify individual components in a sample

ActiveUS7561975B2Molecular entity identificationParticle separator tubesCorrelation functionMetabolomics data

A system is provided for analyzing metabolomics data received from an analytical device across a group of samples. The system automatically receives a data matrix corresponding to each of the samples, wherein the data matrix includes rows corresponding to each of the samples and columns corresponding to a group of ions present in the respective samples. A processor is provided for determining a characteristic value corresponding to at least one of a group of components present in the samples, wherein the components are made up of at least a portion of the group of ions, using at least one of a correlation function and a factorization function. A user interface is in communication with the processor for displaying a visual indication of the characteristic value such that a user may receive a visual indication of the types of components present in the samples.

Owner:METABOLON

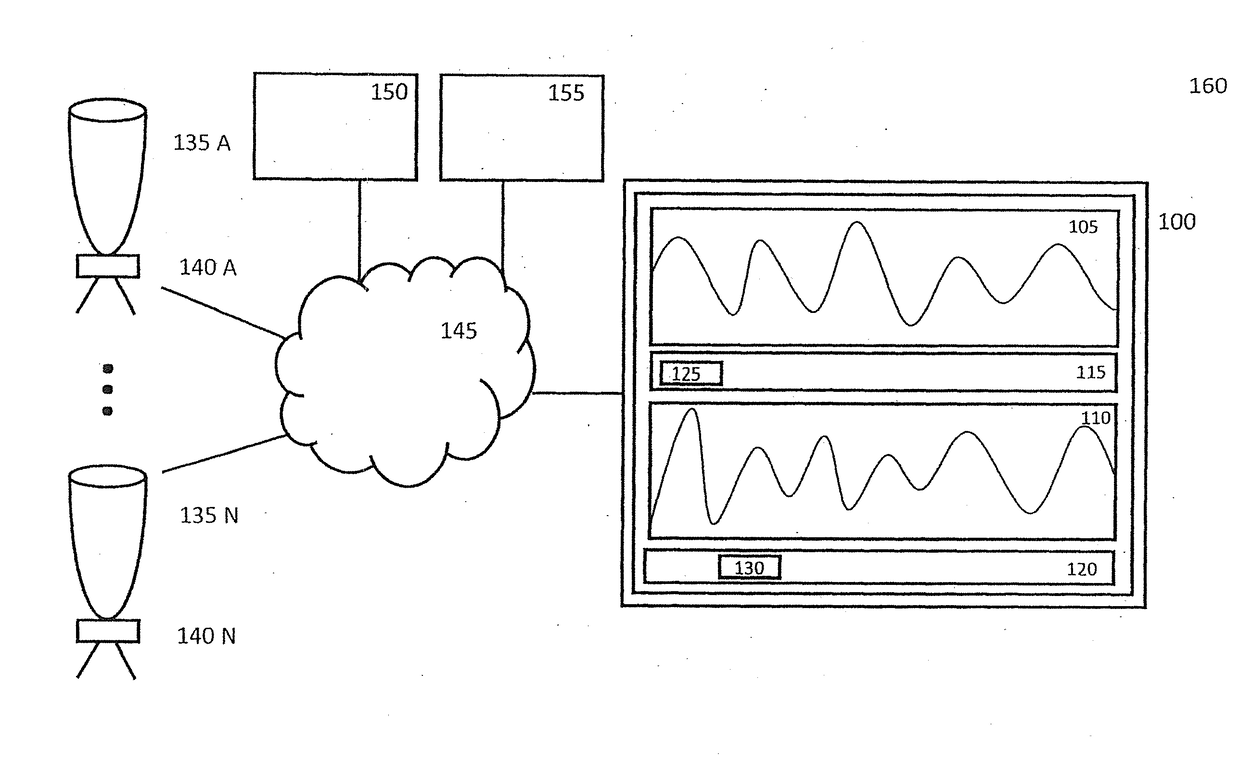

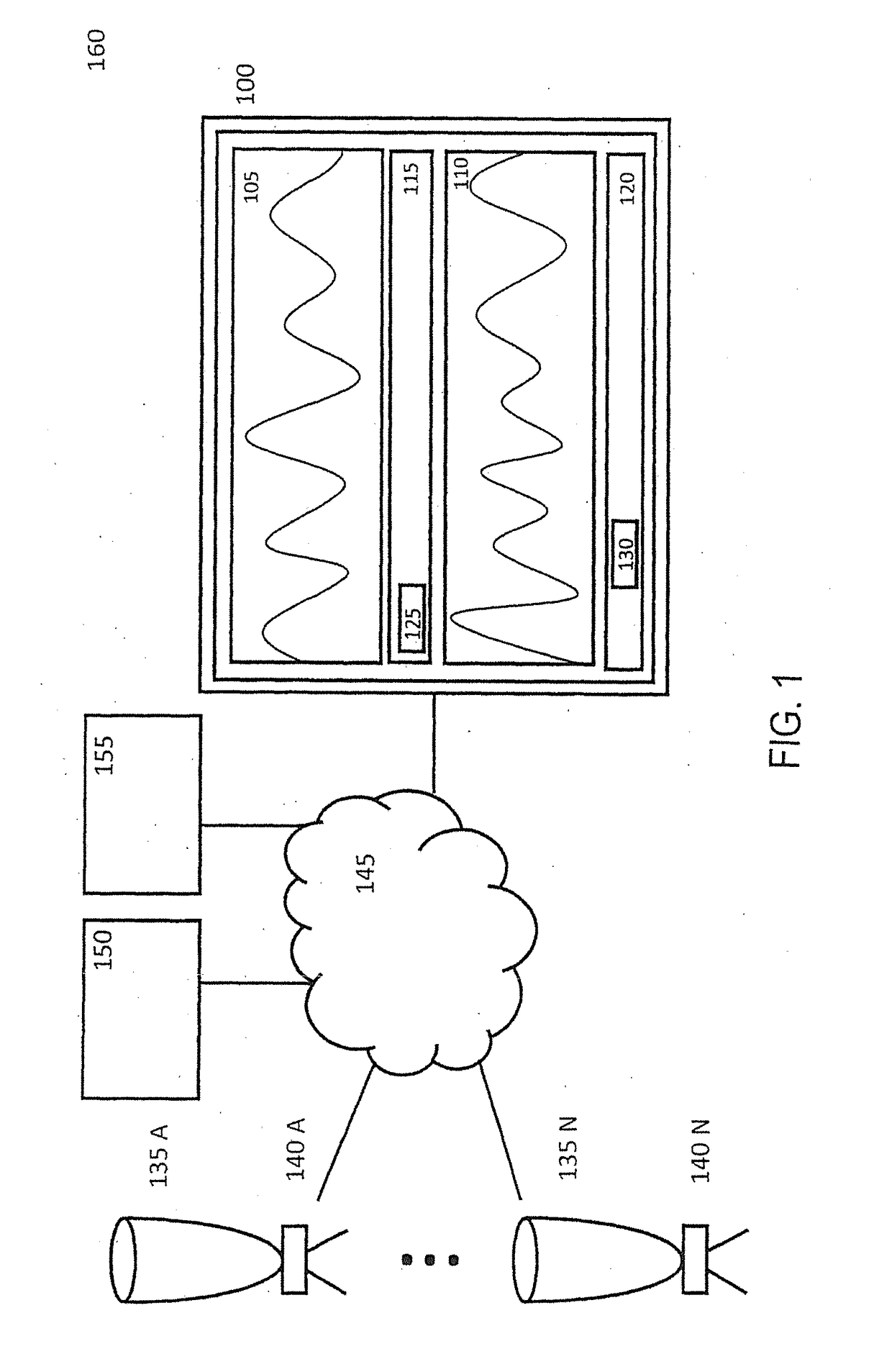

System, method, computer program product and user interface for controlling, detecting, regulating and/or analyzing biological, biochemical, chemical and/or physical processes

ActiveUS20170277829A1Efficiently and more quicklySeparationTesting/monitoring control systemsData visualisationComputerized systemTemporal correlation

The invention relates to a computer system, a computer-implemented method, a computer program product and a user interface for controlling, detecting, regulating, and / or analyzing biological, biochemical, chemical and / or physical processes, comprising at least two units which are designed to receive a substance or material in order to carry out at least one biological, biochemical, chemical, and / or physical process on said substance. Each unit has at least one sensor which is designed to detect measurement data relating to the process. Additionally, the computer system comprises at least one display unit via which the measurement data of the two units is displayed in respective temporal correlations which allows information to be obtained on a relationship inherent in the displayed measurement data.

Owner:SARTORIUS STEDIM BIOTECH GMBH

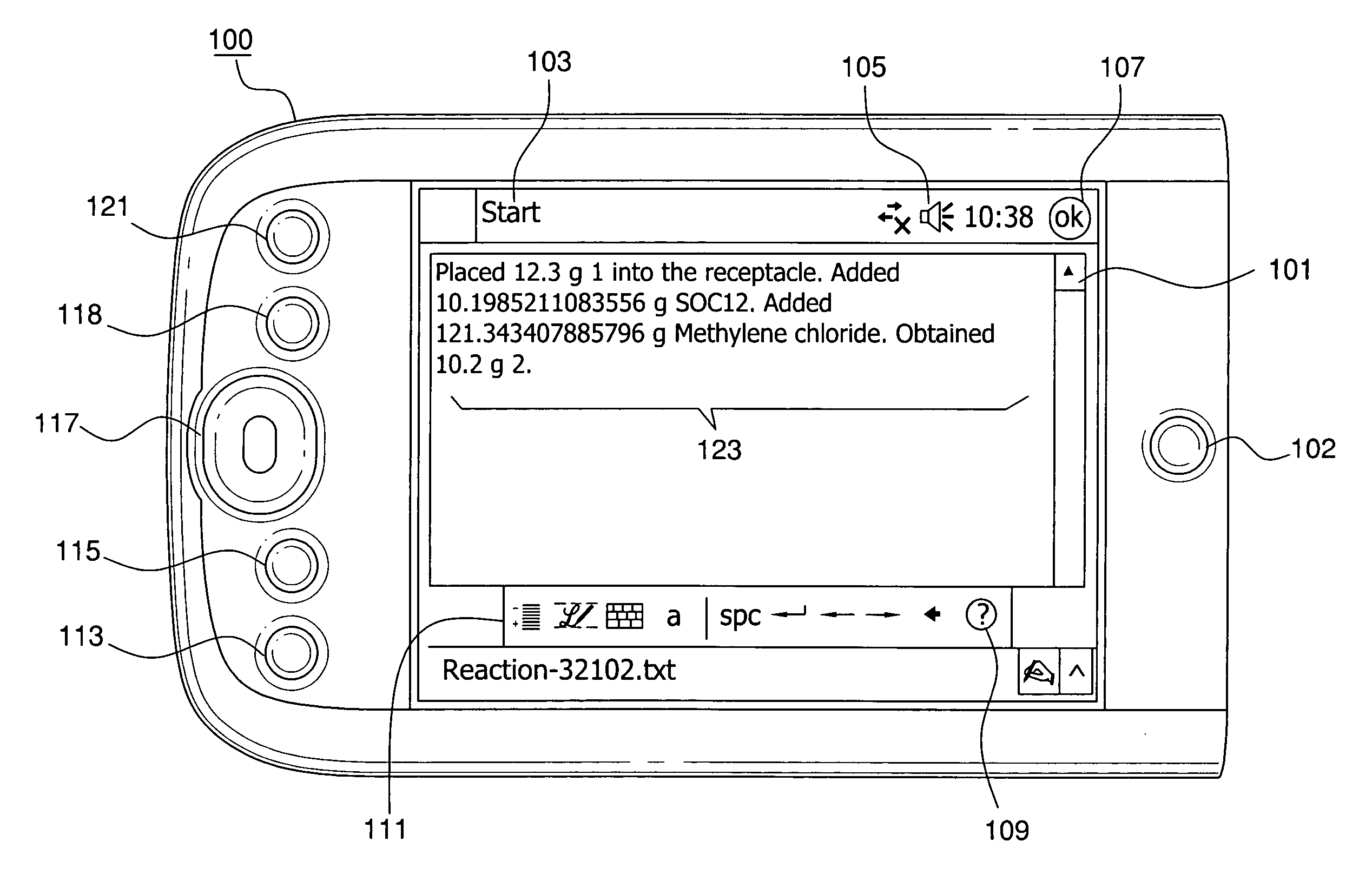

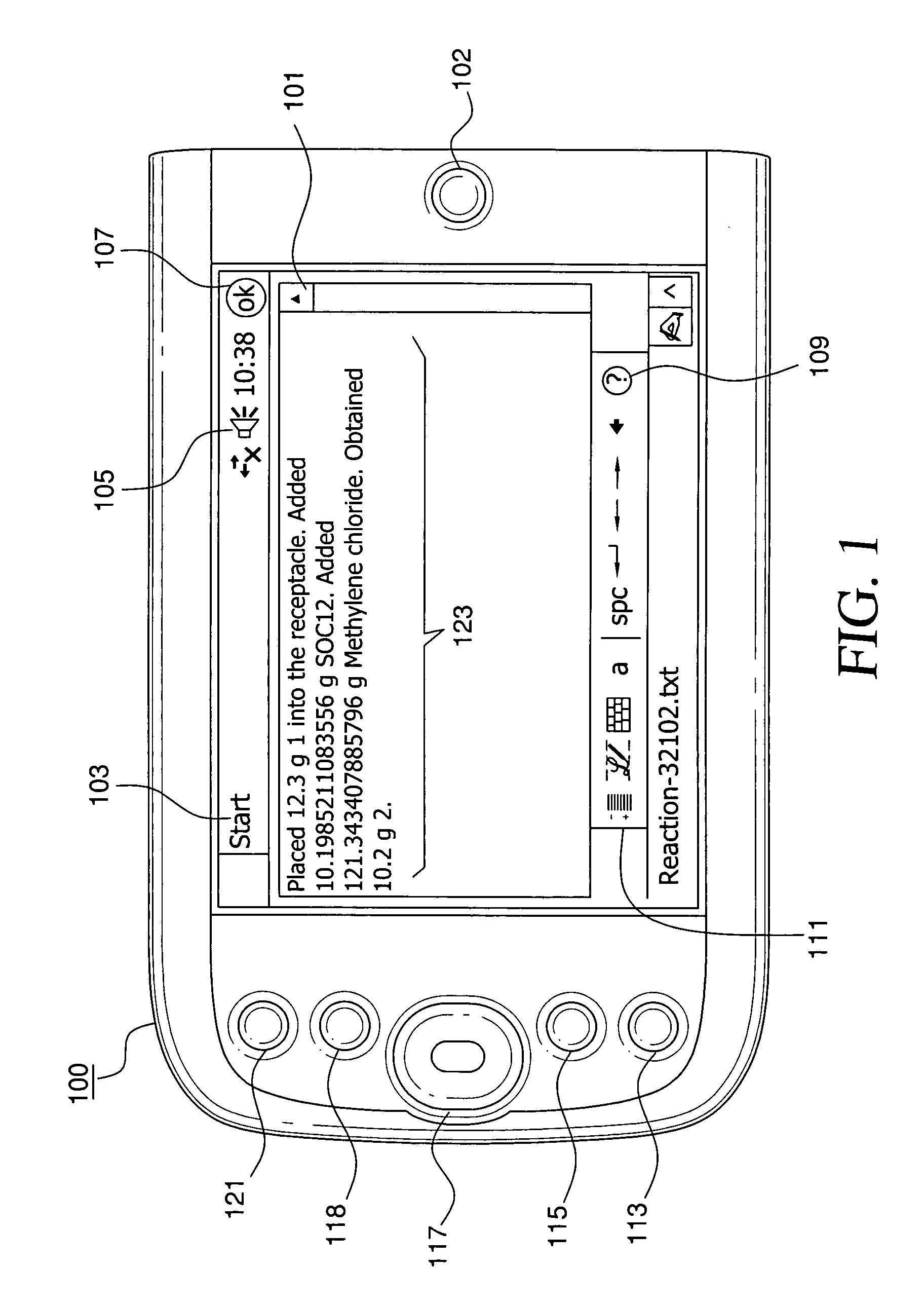

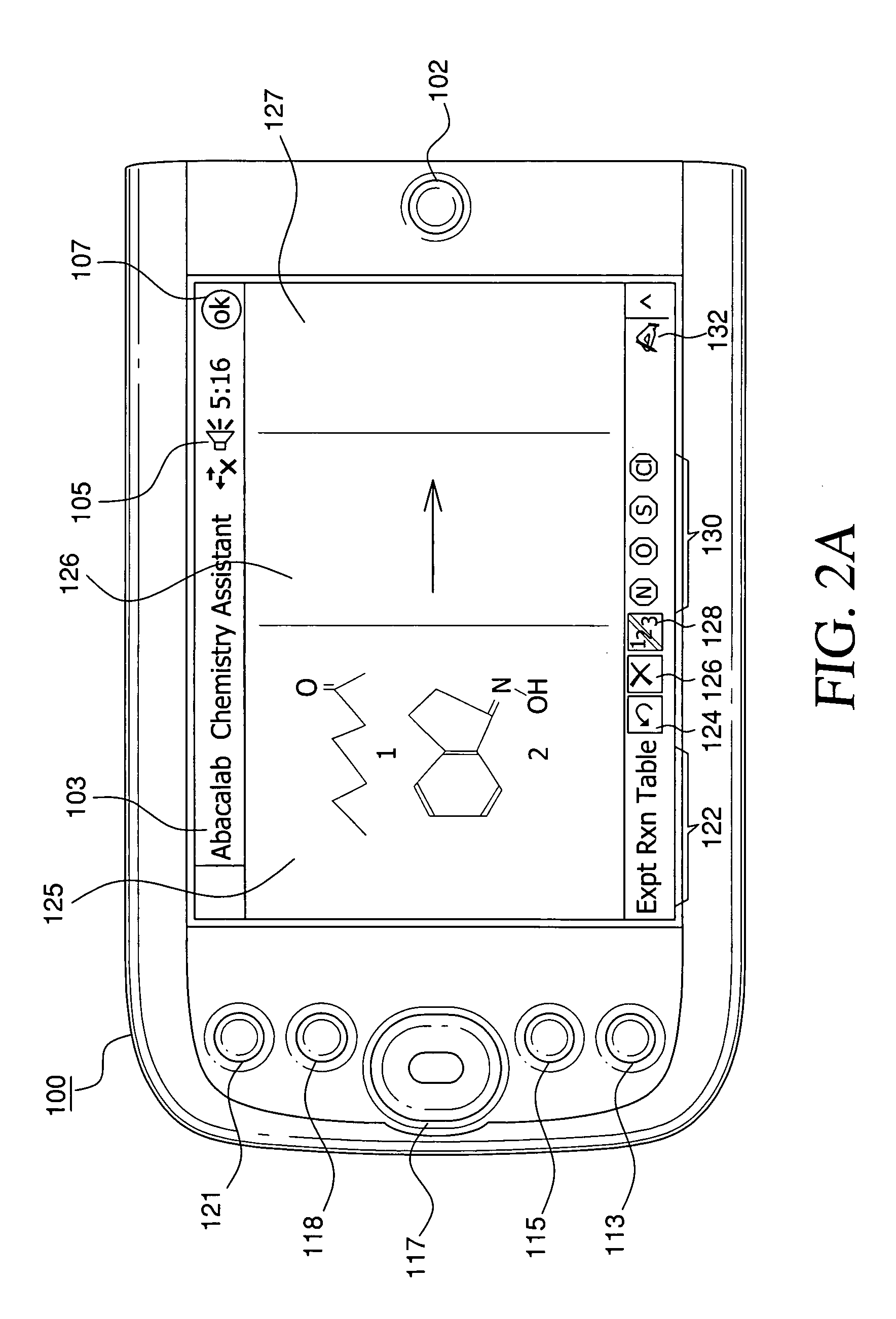

Apparatus and method for mobile graphical cheminformatic

InactiveUS20070192747A1Efficient searchEasy accessCheminformatics data warehousingMultiple digital computer combinationsGraphicsComputer science

The present invention is a pocket-sized, portable computing apparatus that performs frequently used laboratory calculations, provides a look-up function for commonly used data and procedures, and provides note-taking and data capture for record-keeping. The present invention displays data in a form that a chemist finds most convenient and manipulates this data with functions a chemist typically utilizes in his work. In addition, the present invention provides a user interface that is compatible with traditional methods for formula manipulations and chemistry workflows and that increases the efficiency of the user in performing laboratory tasks.

Owner:ABACALAB

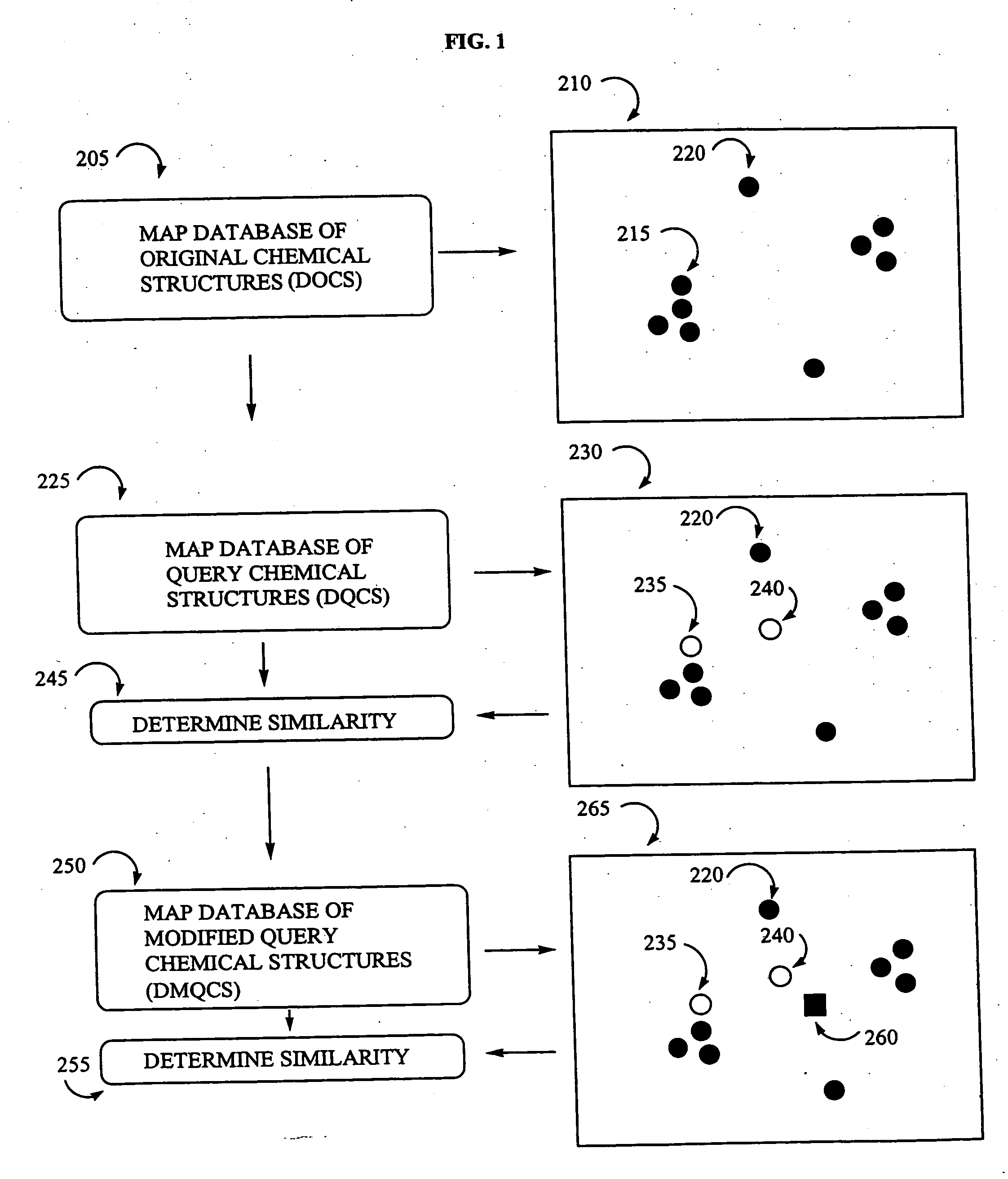

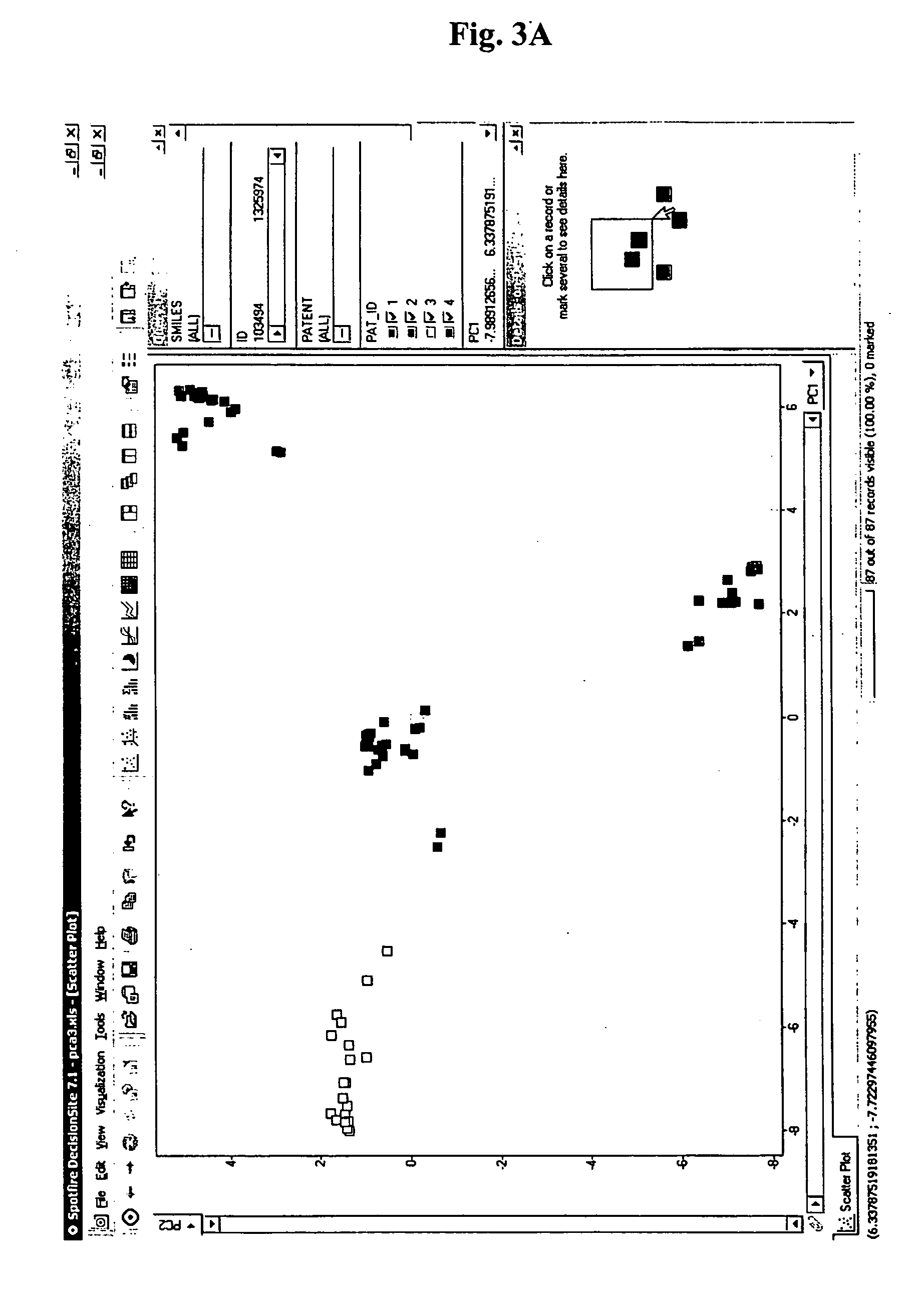

Visualization of databases

InactiveUS20050065733A1Diffusion transfer processesData processing applicationsChemical structureDatabase

This invention relates to computer-based methods, systems, and databases for visualizing chemical structure relatedness.

Owner:VERTEX PHARMA INC

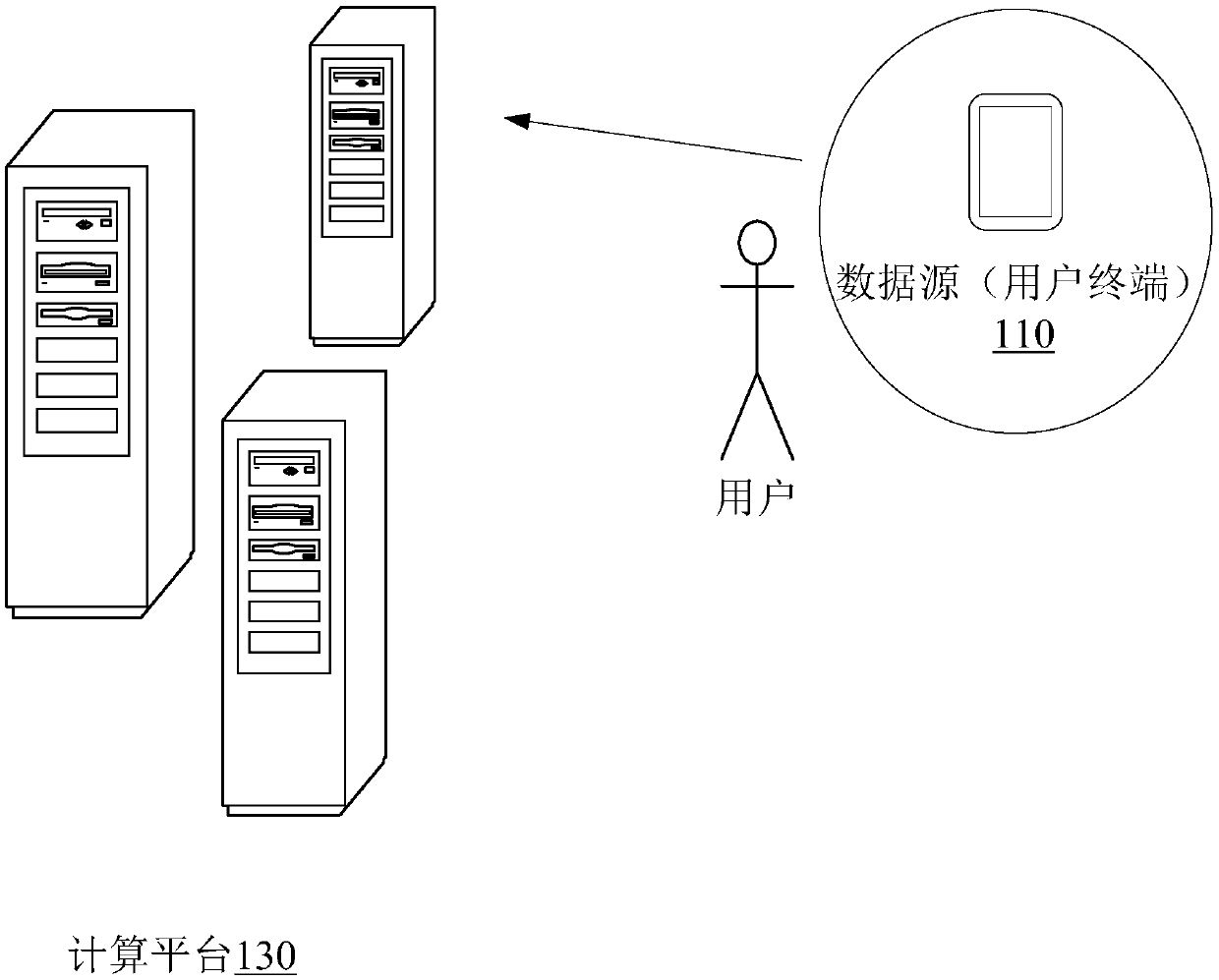

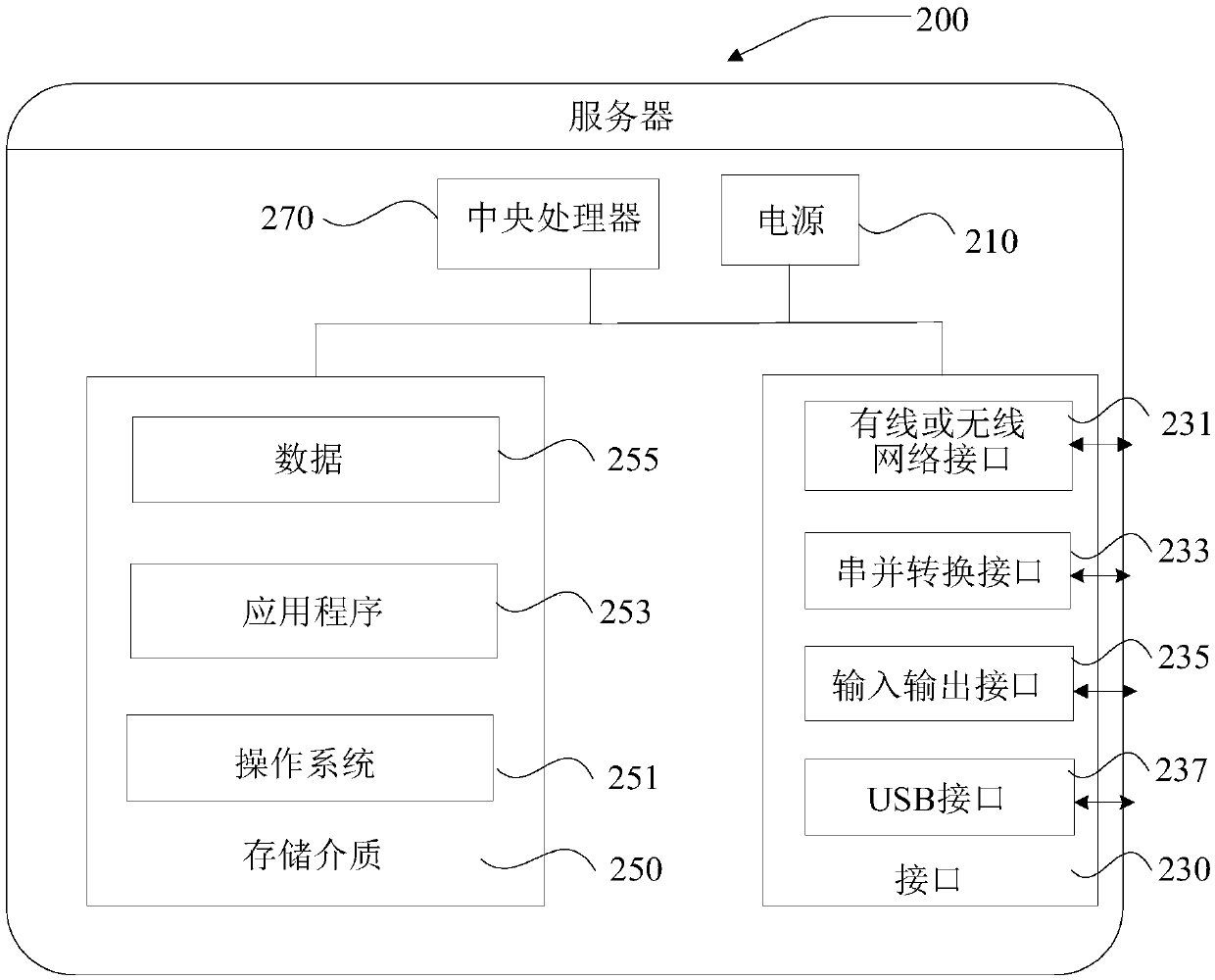

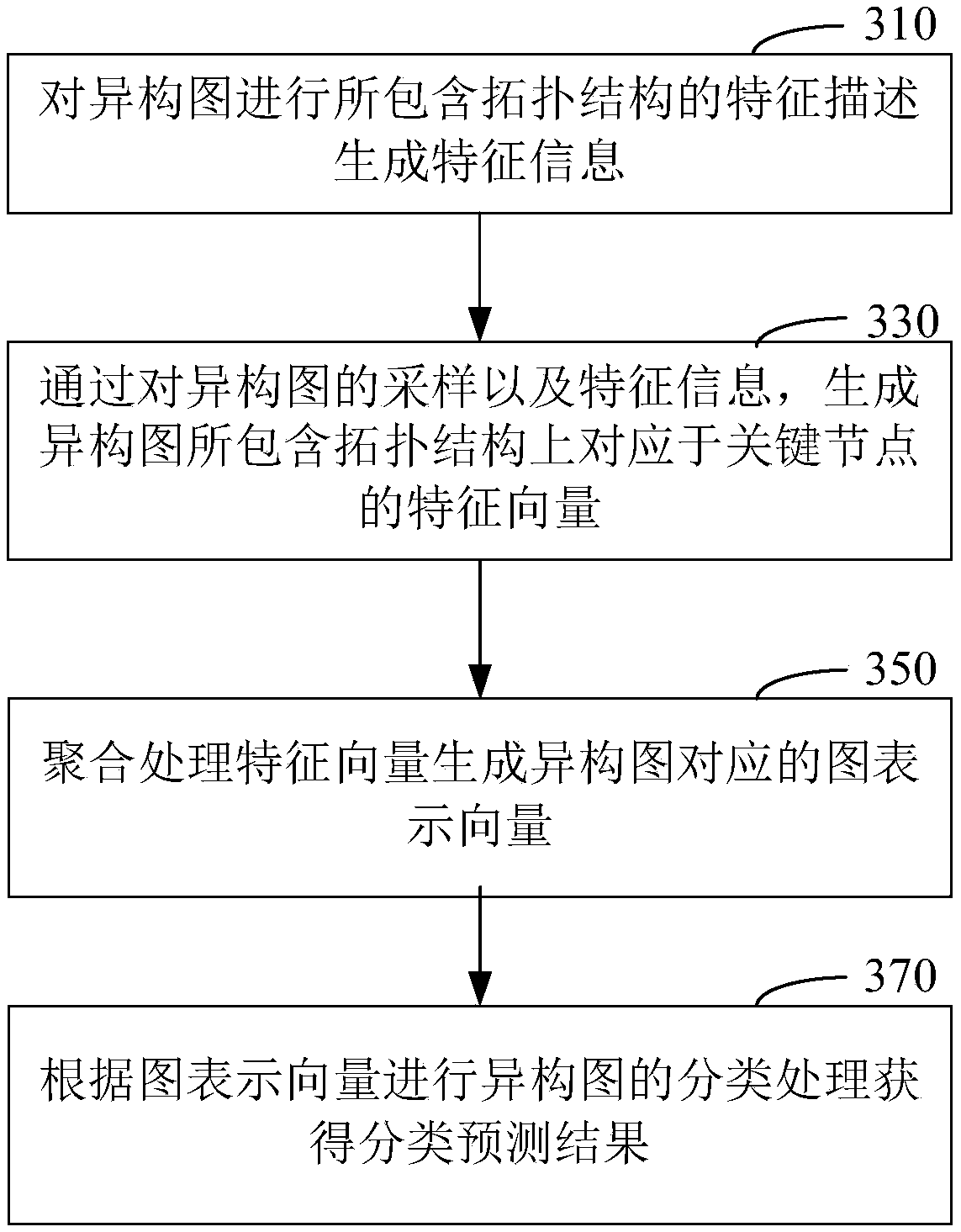

Method, device and equipment for identifying isomerism graph and property of molecular spatial structure

ActiveCN110263780AImprove the effectiveness of analytical processingChemical property predictionCheminformatics data warehousingFeature vectorStructure property

The invention discloses a method and a device for identifying isomerism graph and property corresponding to a molecular space structure, and machine equipment. The method comprises the following steps: carrying out feature description containing a topological structure on a heterogeneous graph to generate feature information; through sampling the isomerism graph and the feature information, generating a feature vector, corresponding to a key node, on a topological structure contained in the isomerism graph; performing aggregation processing on the feature vectors to generate graph representation vectors corresponding to the isomerism graphs; and according to the graph representation vector, performing classification processing on the isomerism graph to obtain a classification prediction result. Therefore, the identification of the graphical representation corresponding to the heterogeneous graph, such as the molecular spatial structure, can be realized through the neural network, the analysis and processing performance related to the isomerism graph is effectively improved, the neural network is not limited to the classification and identification of network data any more, and the application scene is greatly expanded.

Owner:TENCENT TECH (SHENZHEN) CO LTD +1

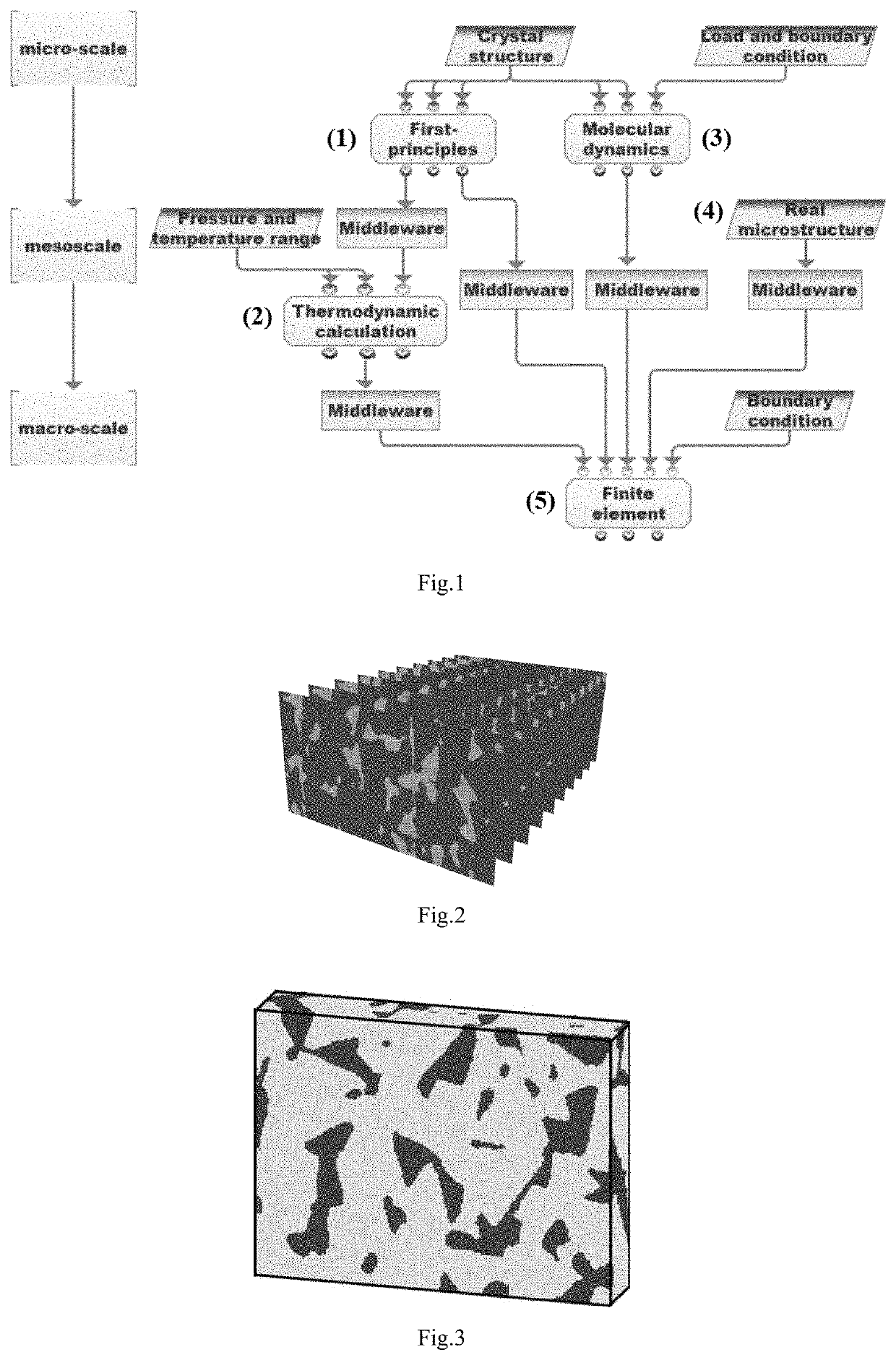

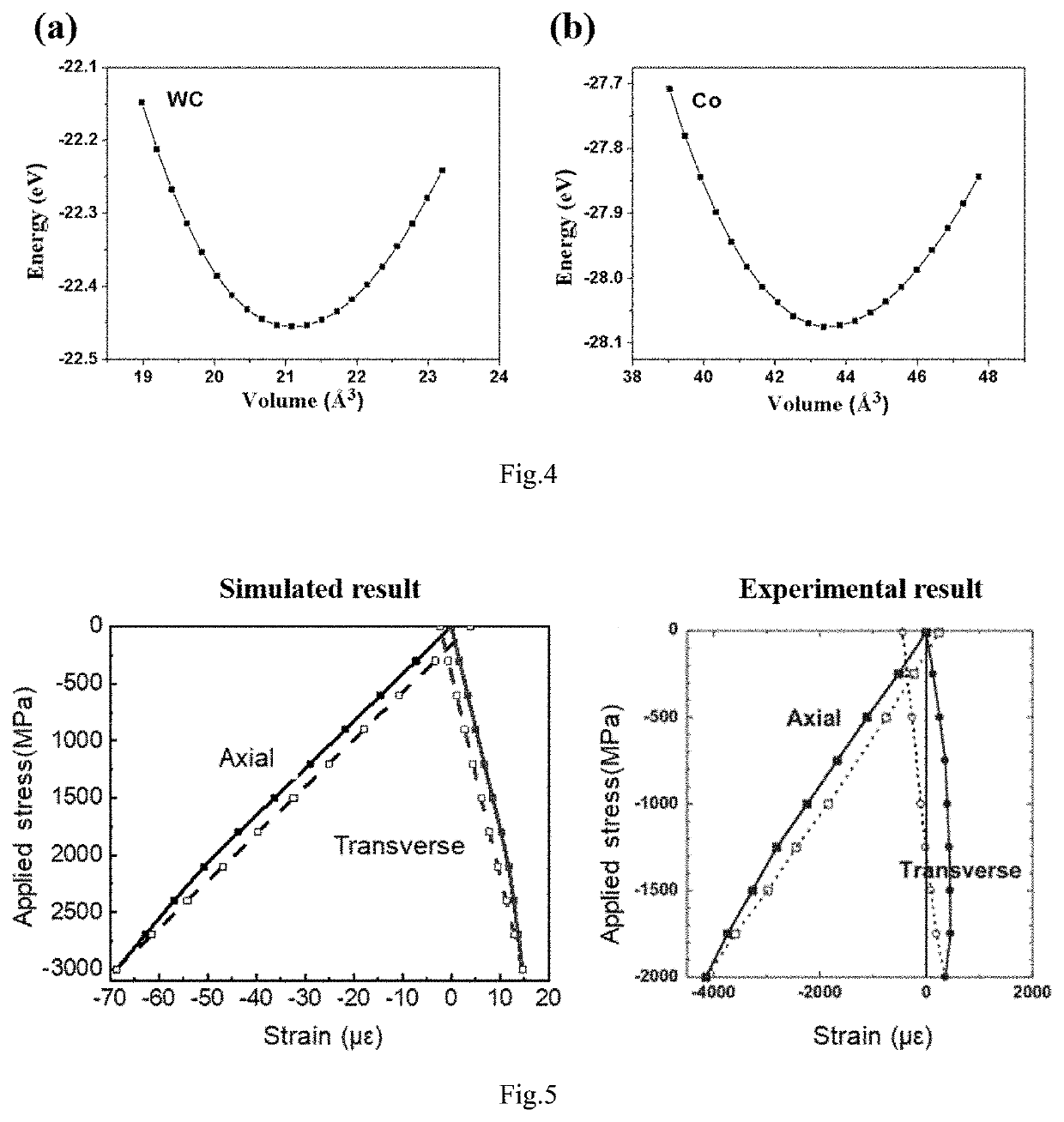

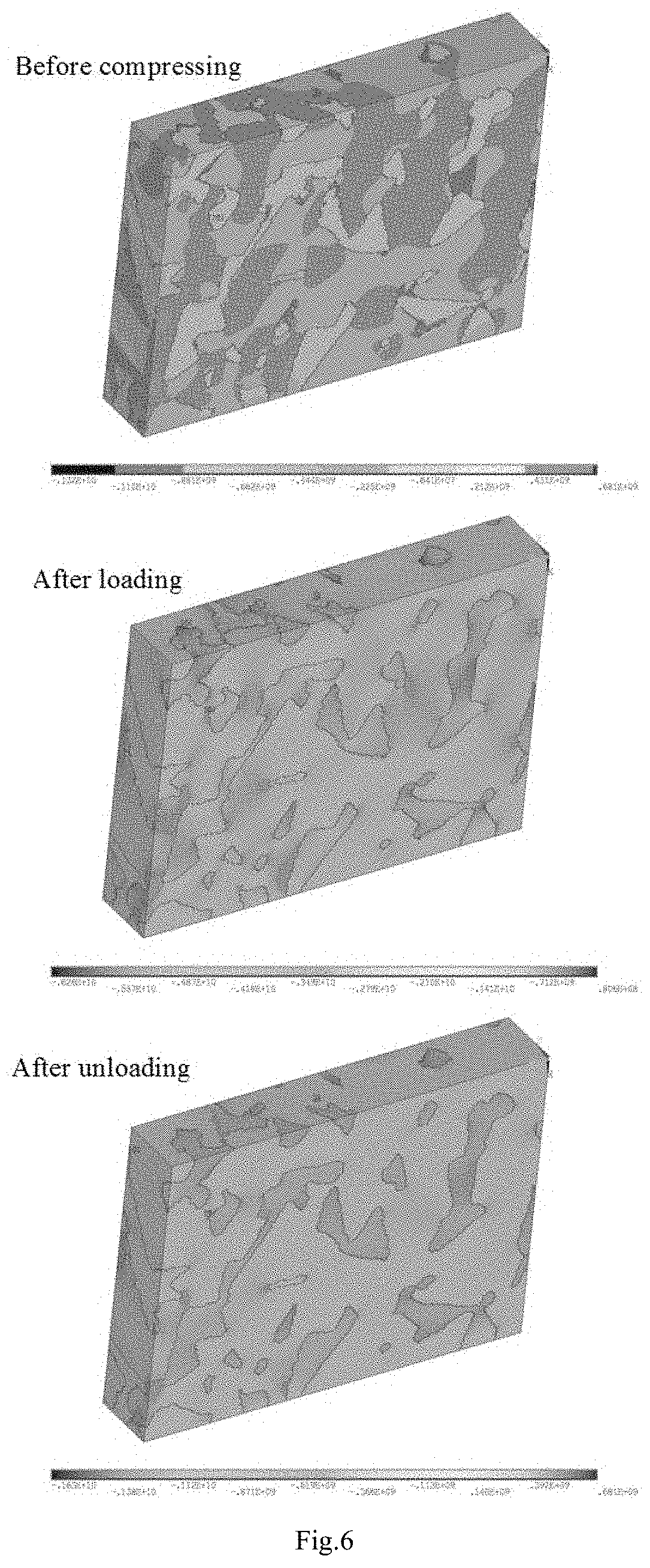

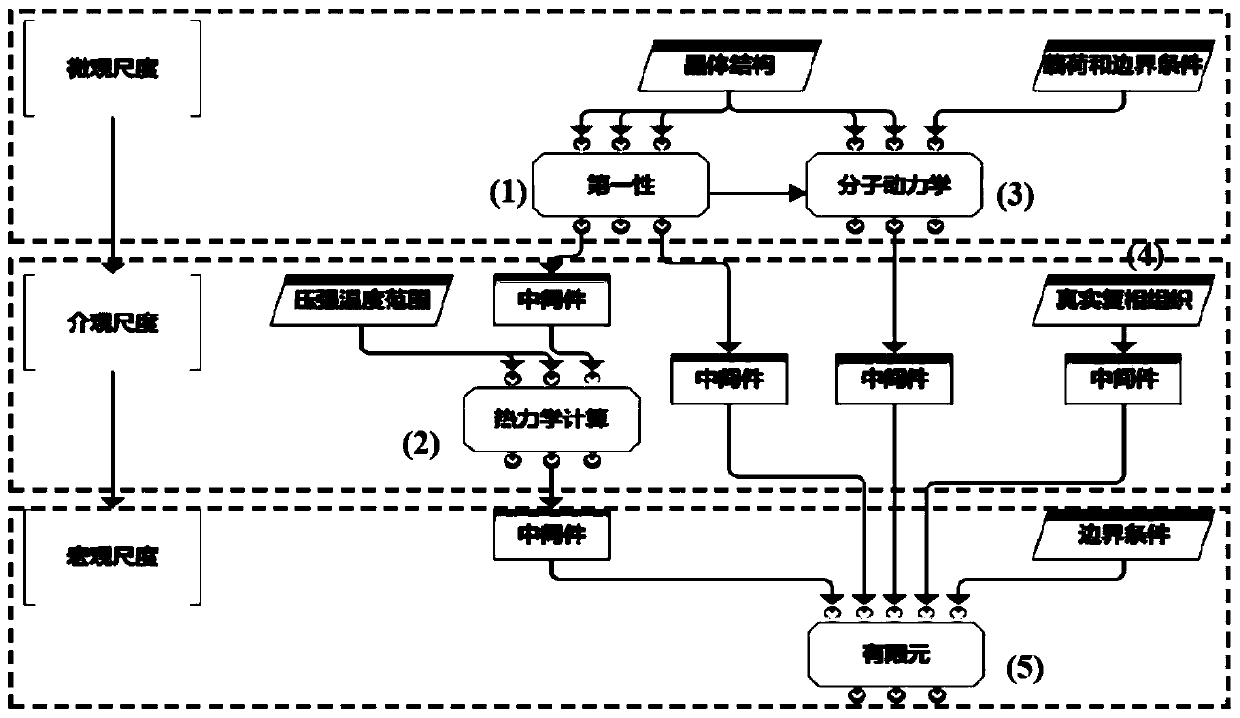

Multi-scale method for simulating mechanical behaviors of multiphase composite materials

PendingUS20210118530A1Plasticity of hard and brittle ceramic phase is negligibleWay accurateChemical property predictionDesign optimisation/simulationMicro structureMacroscopic scale

A computer simulation analysis method suitable for describing the mechanical behavior of multiphase composites based on the real microstructure of materials relates to a multidisciplinary field such as computational material science, simulation and high throughput calculation. Through the first-principles calculation under nano scale, the molecular dynamics simulation under micro scale, and the thermodynamic calculation under mesoscopic scale, various physical parameters needed for the finite element simulation under macro scale can be obtained, including the elastic and plastic physical parameters of each phase in the composite at different temperature and different grain sizes. Focused ion beam experiment and image processing are adopted to obtain real material microstructure. Through the parameter coupling and parameter transfer among the calculated results of various scales, combining the microstructure of the material, stress-strain relationship, stress distribution and its evolution law, plastic deformation and other mechanical behaviors of the multiphase composites under complex stress and different temperature can be simulated.

Owner:BEIJING UNIVERSITRY OF TECH

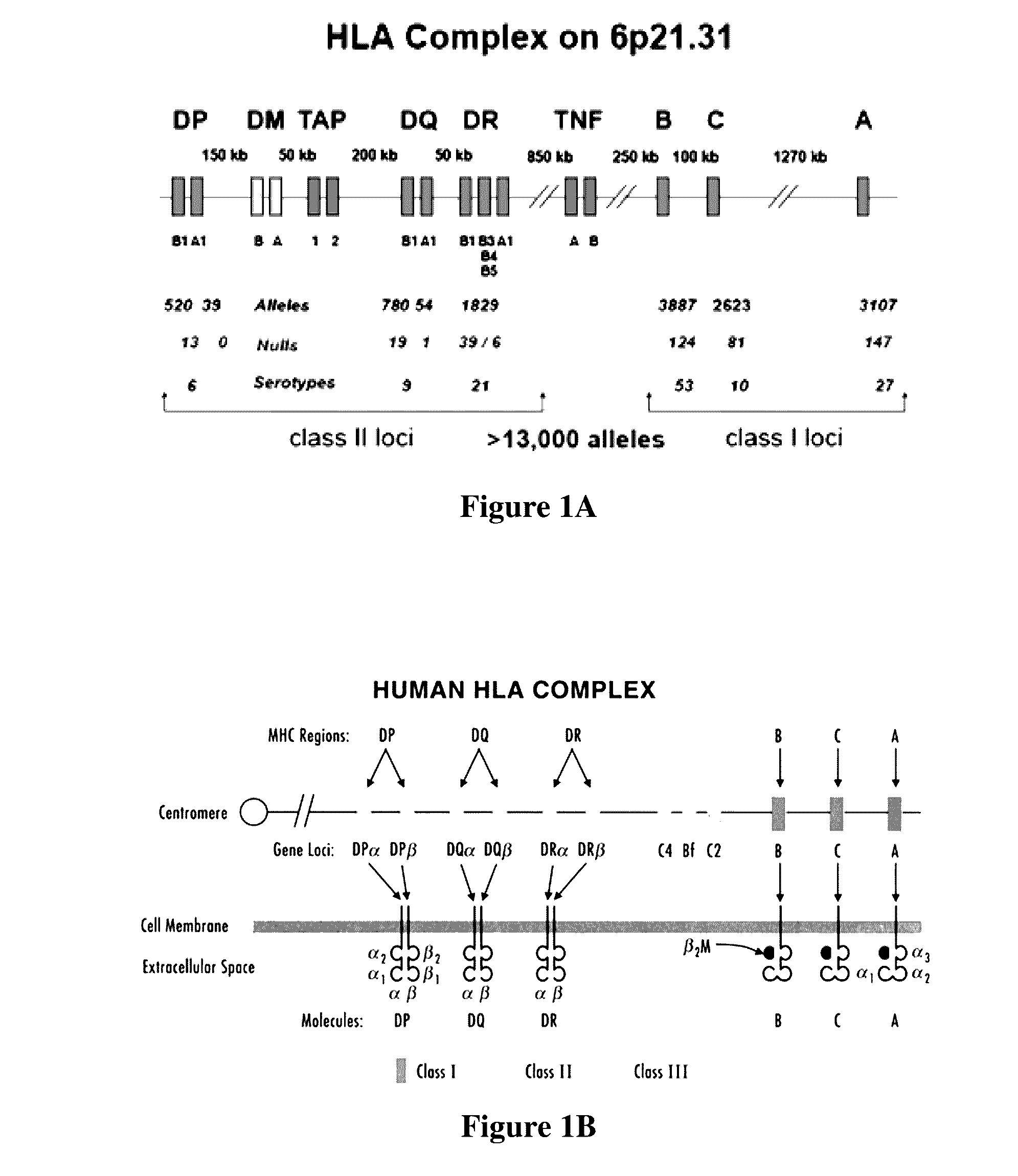

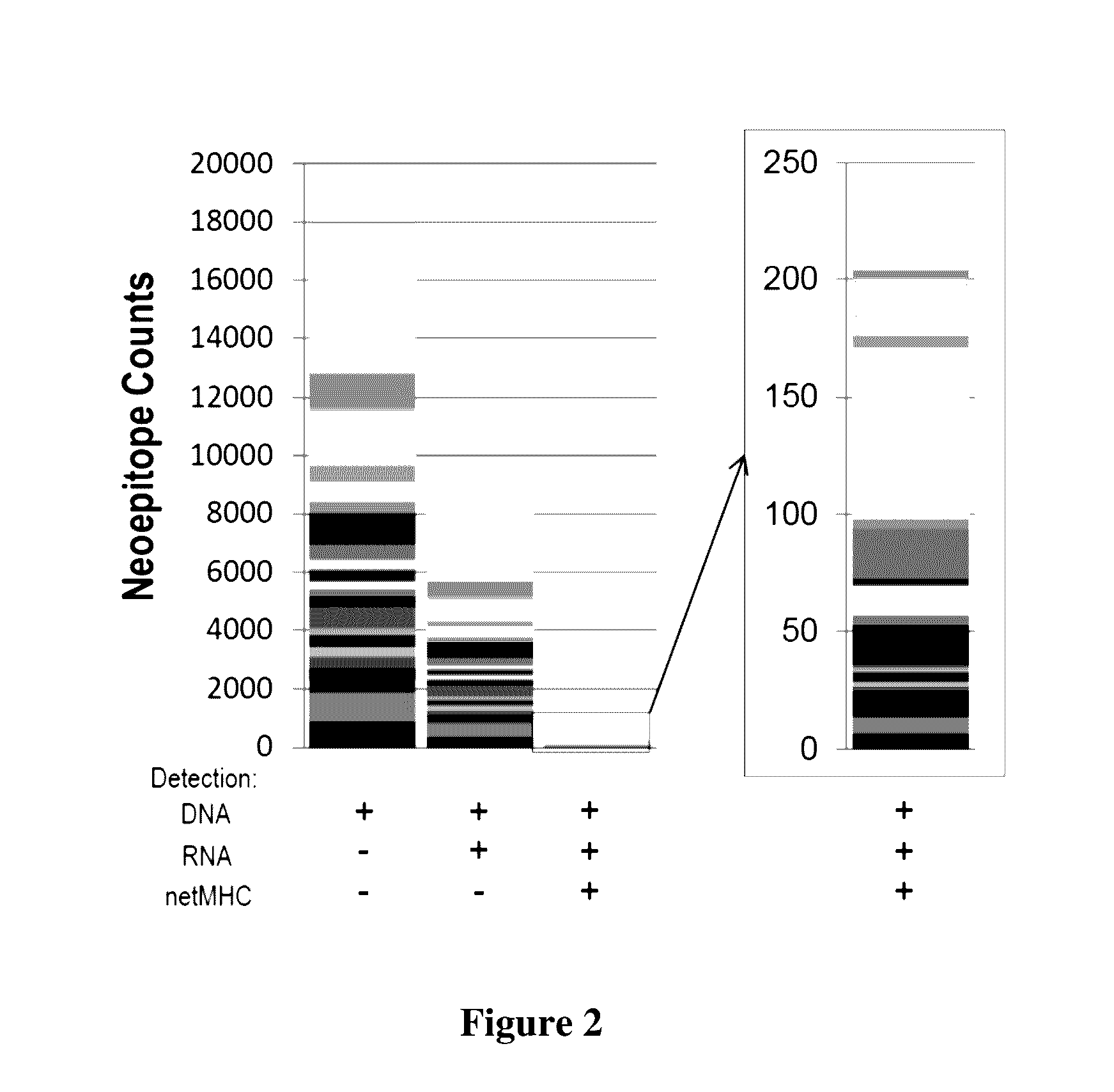

Compositions And Methods For Viral Cancer Neoepitopes

ActiveUS20170028044A1Improving cancer neoantigen presentationEasy to demonstrateWhole-cell/virus/DNA/RNA ingredientsChemical data visualisationBiologyRecombinant virus

Methods and compositions for preparation and use of recombinant viruses or other recombinant expression systems are presented in which neoepitopes are first identified in a patient- and cancer-specific manner and then further filtered by HLA-match to the patient. Selected neoepitopes are then expression using sequence elements that direct the expressed neoepitope to the HLA-type (MHC-I and / or MHC-II subtype) that has desirable affinity to the filtered neoepitope.

Owner:NANTOMICS LLC

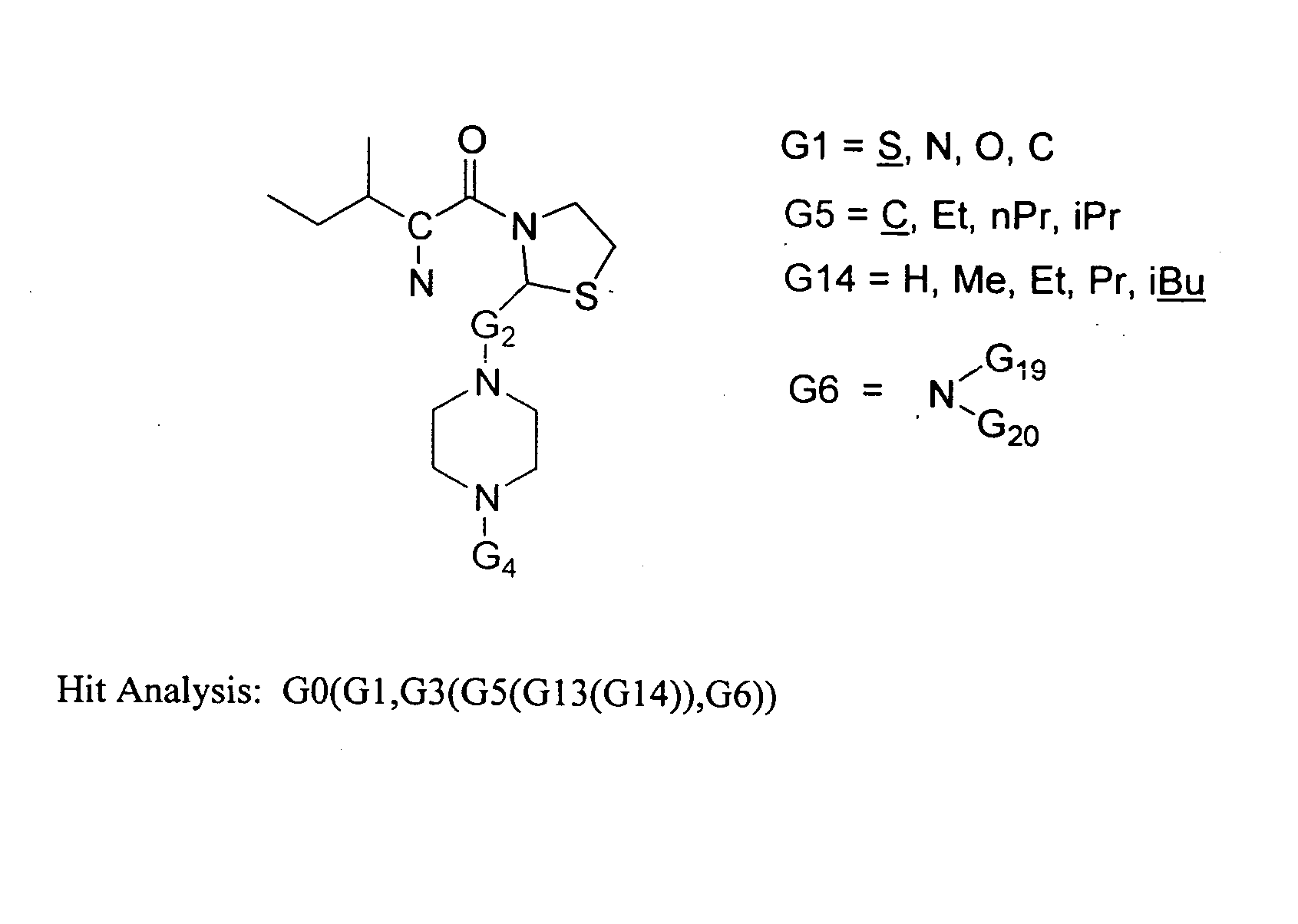

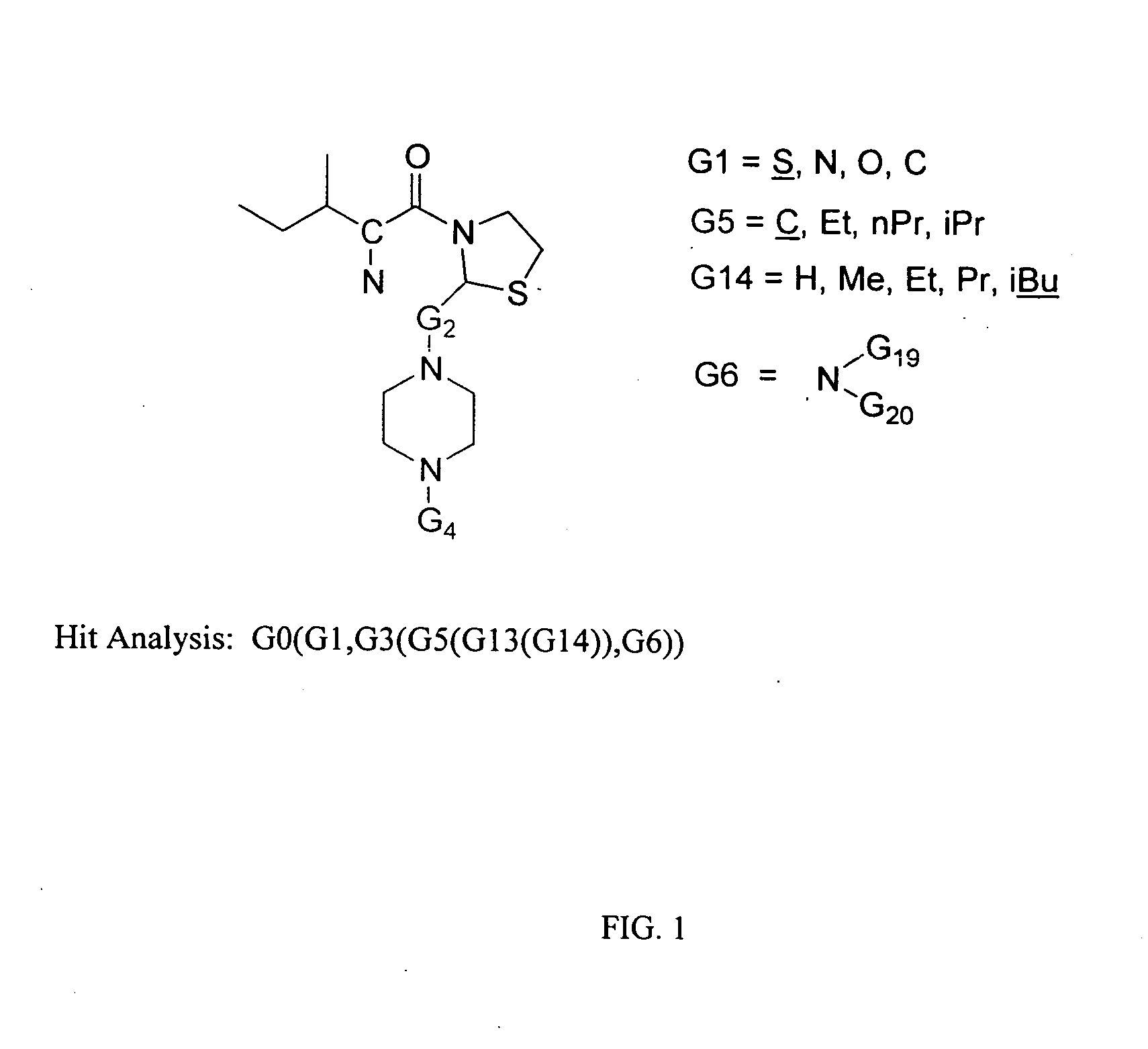

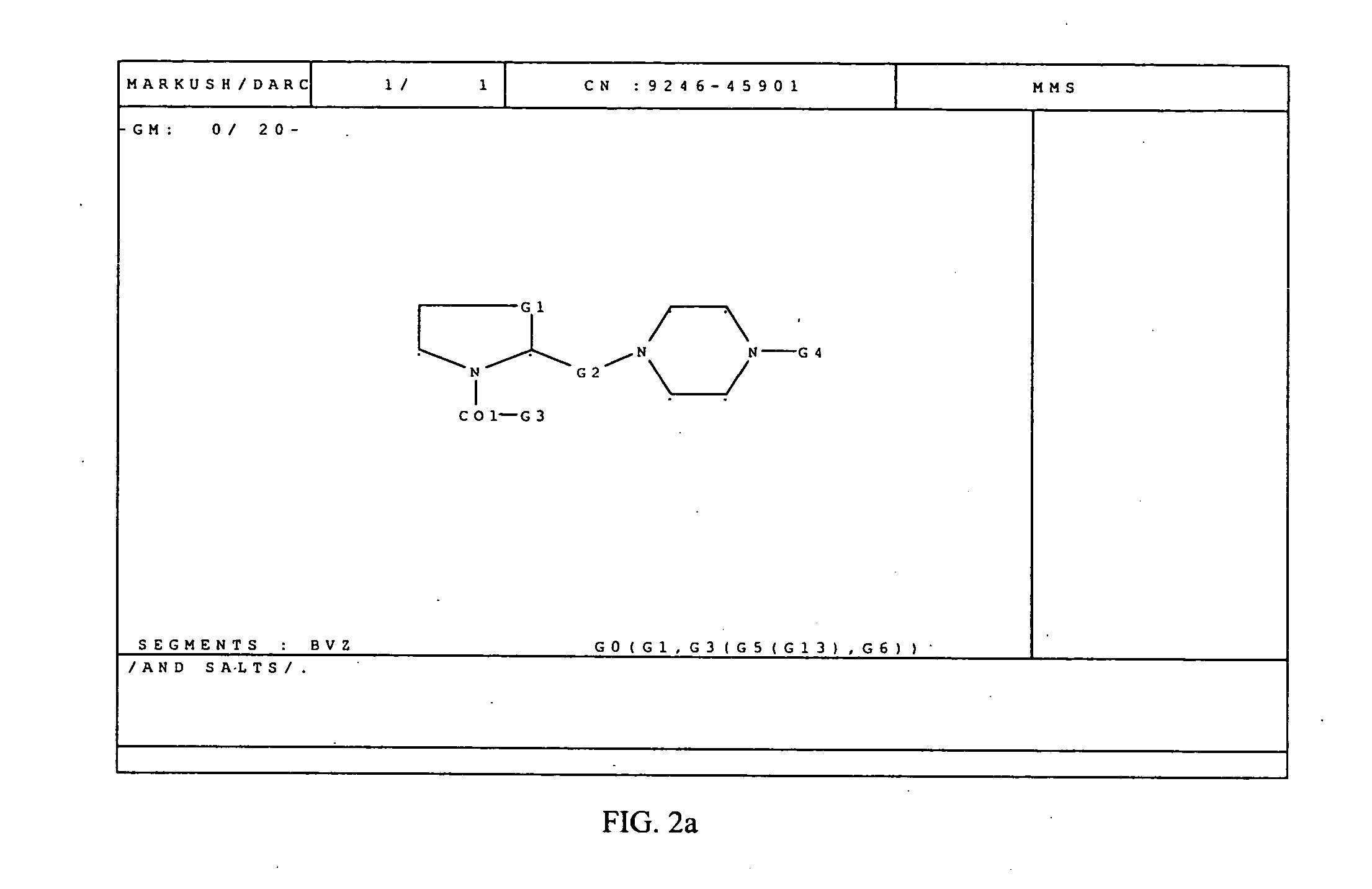

Display for Markush chemical structures

InactiveUS20050010603A1Digital data processing detailsNatural language data processingChemical structureCompound (substance)

A display for results of query chemical structures containing Markush chemical groupings, wherein a two-dimensional chemical structure the resulting Markush groupings in the results may be displayed in a multiplicity of colors, line styles, shadings, and combinations thereof, in the structure, wherein each separate Markush grouping and various Markush substituent thereof in the database results in an easy to understand manner.

Owner:BERKS ANDREW

Multi-scale simulation method for mechanical behaviors of multi-phase composite material

ActiveCN110210103AImprove continuityRealize simulationChemical property predictionDesign optimisation/simulationMacroscopic scaleFirst principle

Owner:BEIJING UNIV OF TECH

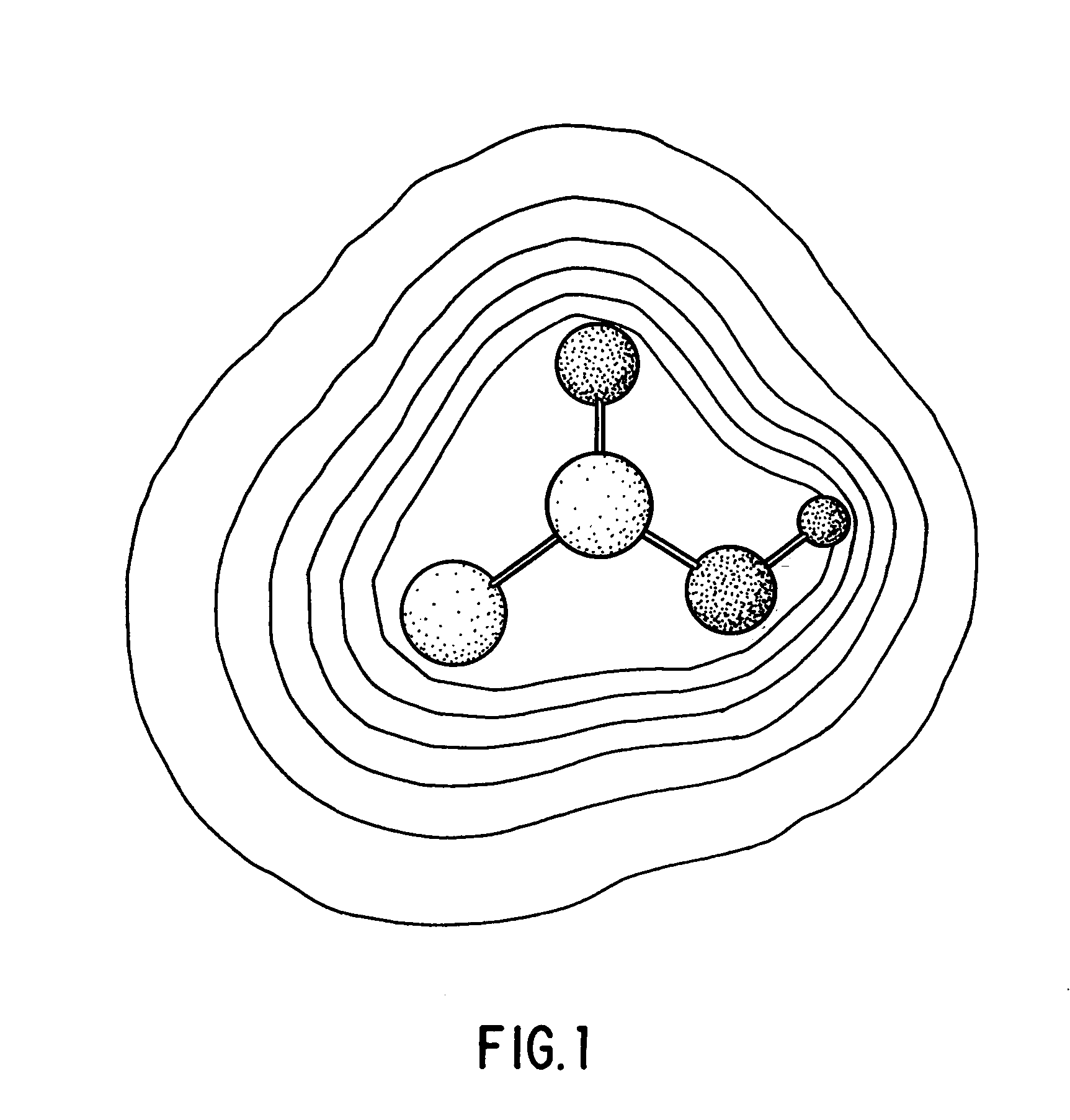

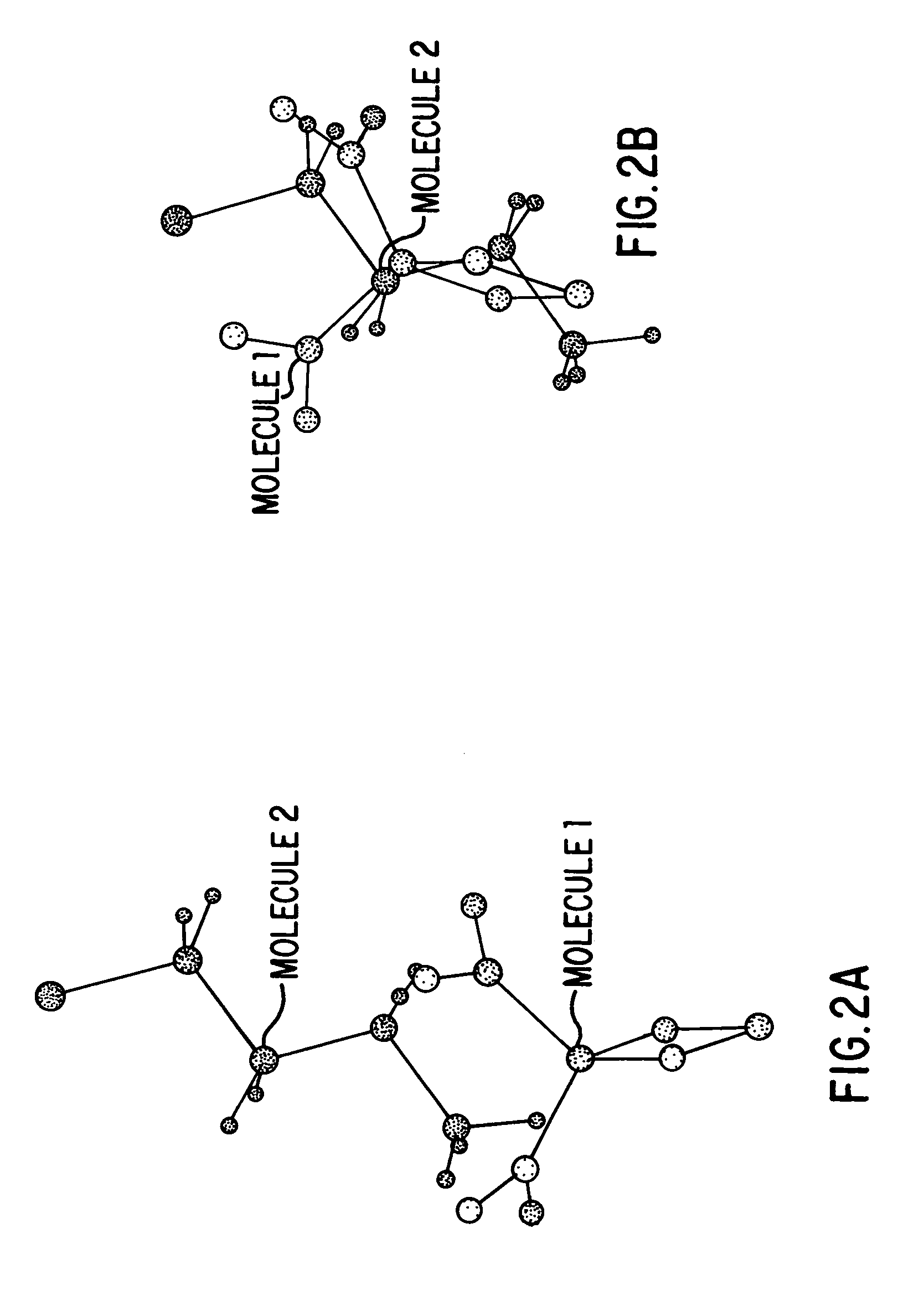

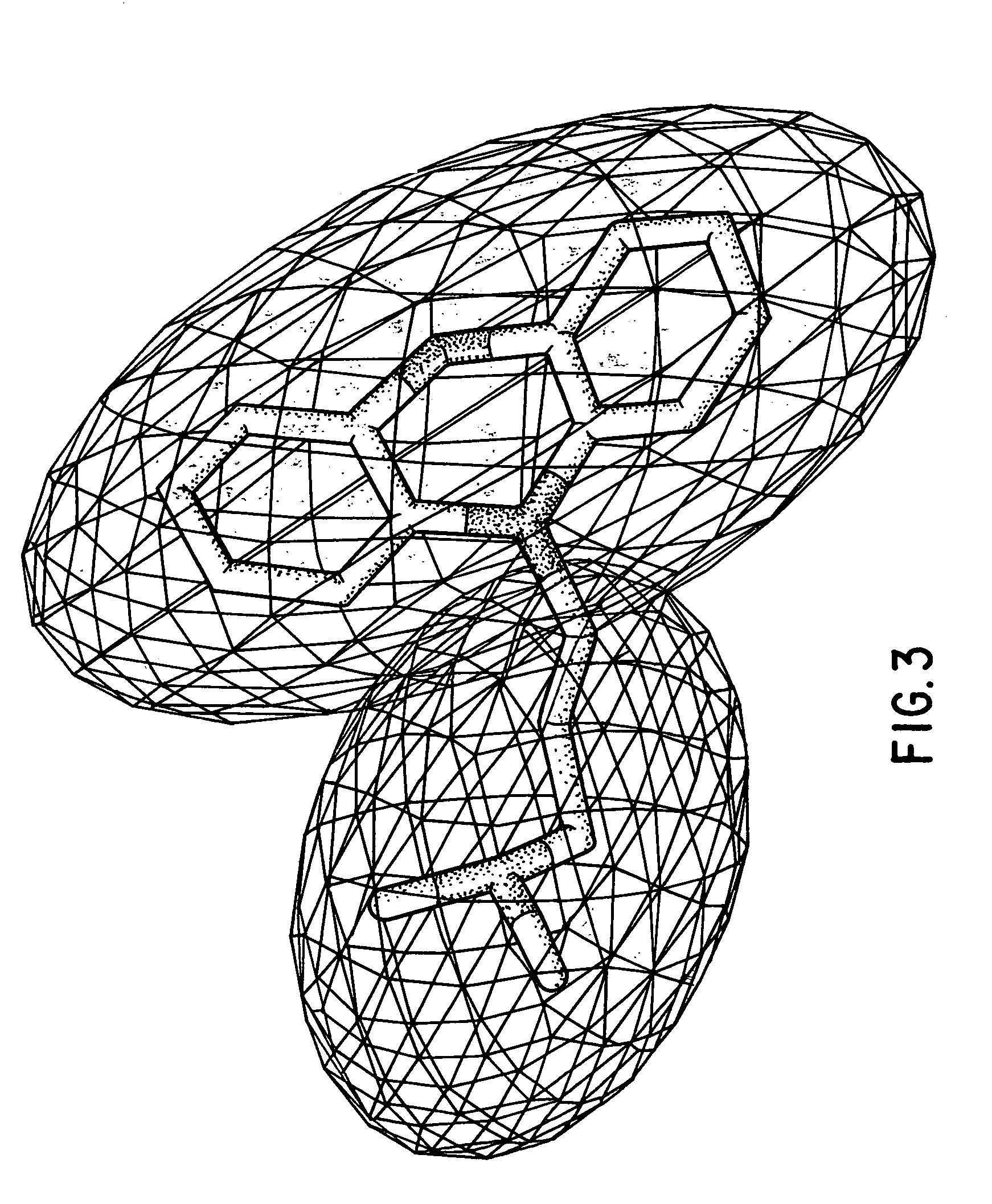

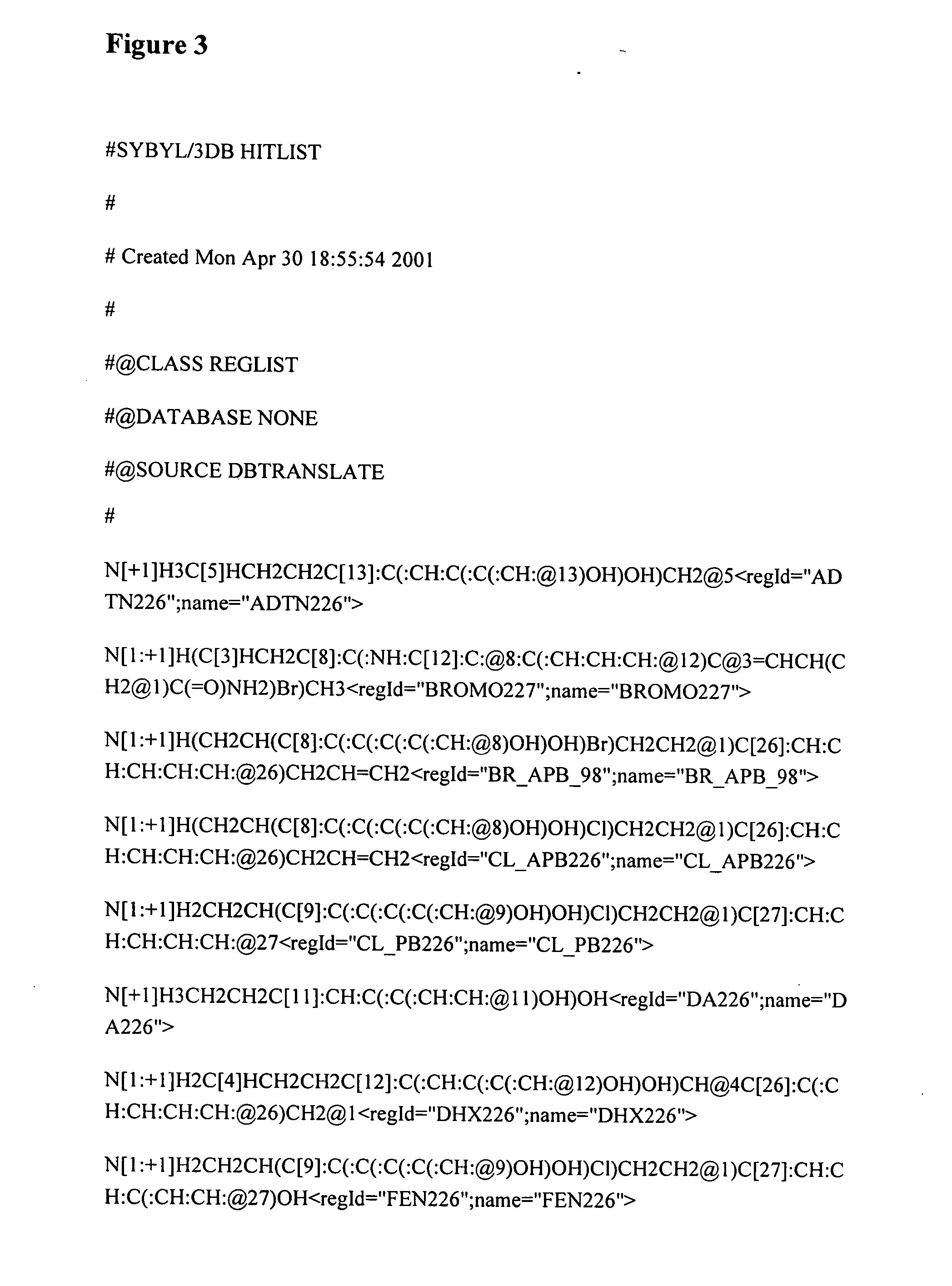

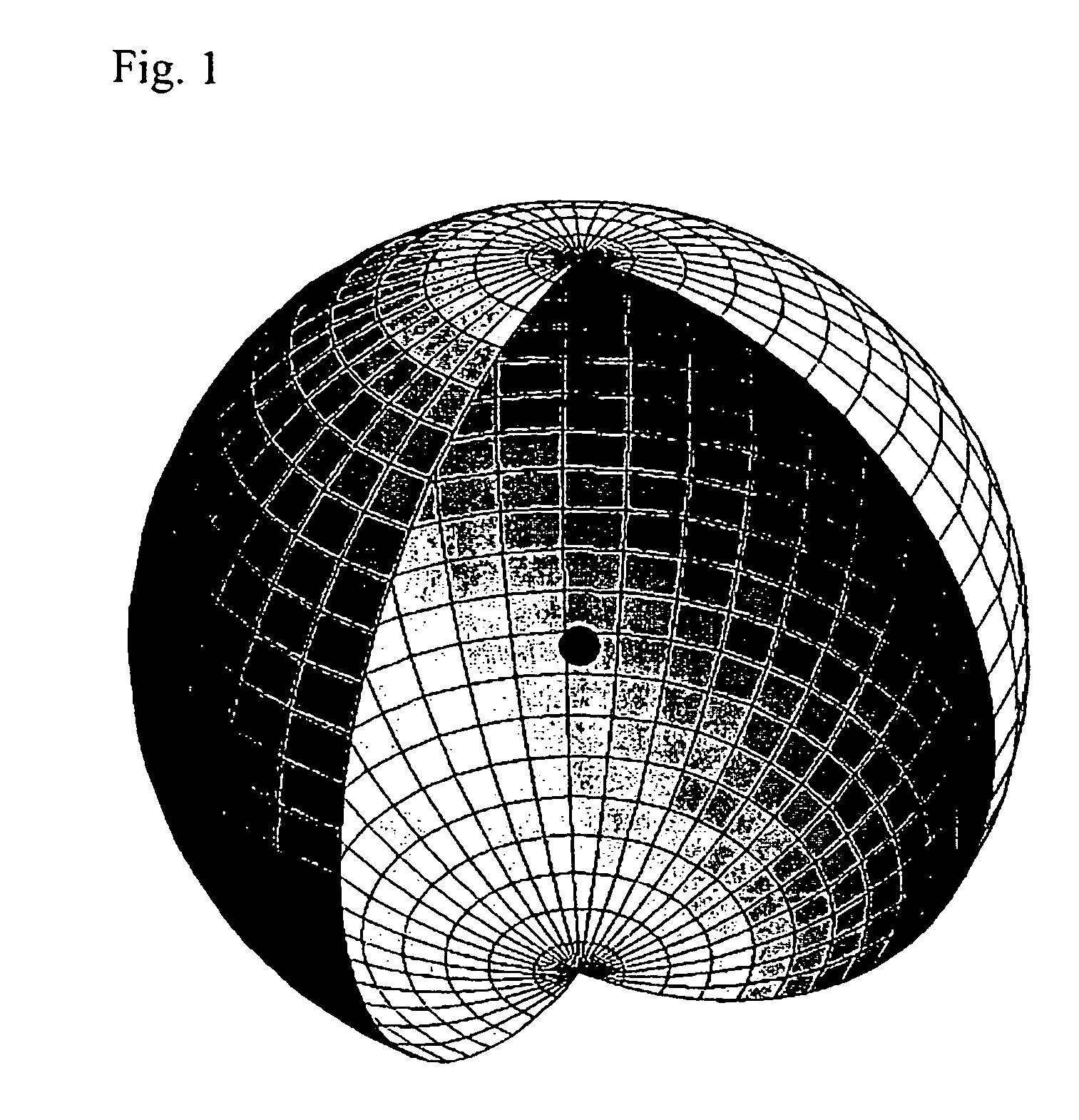

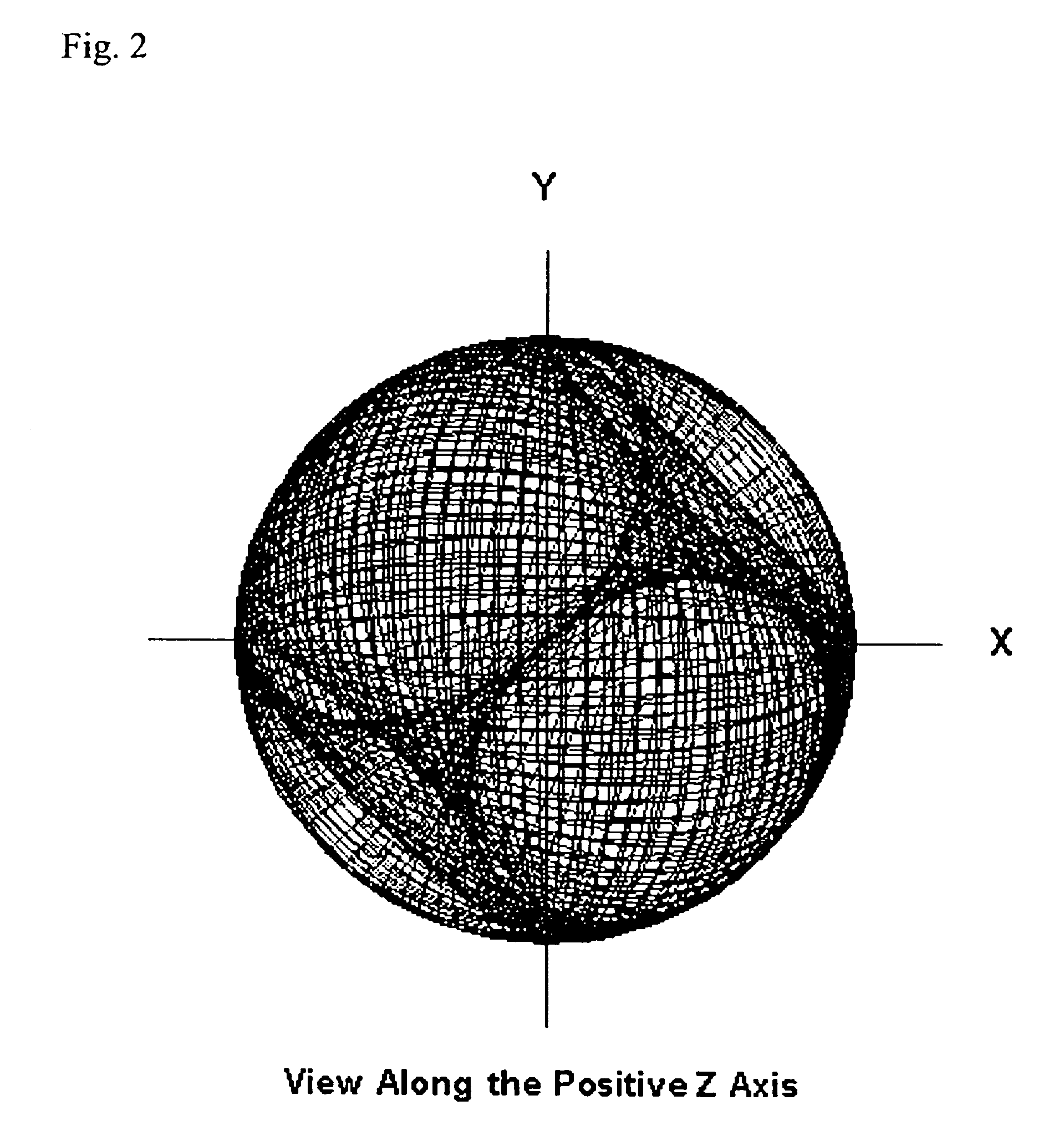

Method for determining a shape space for a set of molecules using minimal metric distances

I describe several techniques for characterizing molecules based on the shapes of their fields. The minimal distance between two molecular fields is used as a shape-based metric, independent of the underlying chemical structure, and a high-dimensional shape space description of the molecules is generated. I then show how these attributes can be used in creating, characterizing, and searching databases of molecules based on field similarity. In particular, they allow searches of a database in sublinear time. Next, I extend the utility of this approach by describing a way to automatically break molecules into a series of fragments by using an ellipsoidal Gaussian decomposition. Not only can these fragments then be analyzed by the shape metric technique described above, but the parameters of the decomposition themselves can also be used to further organize and search databases. The most immediate application of these techniques is to pharmaceutical drug discovery and design.

Owner:OPENEYE SCIENTIFIC SOFTWARE

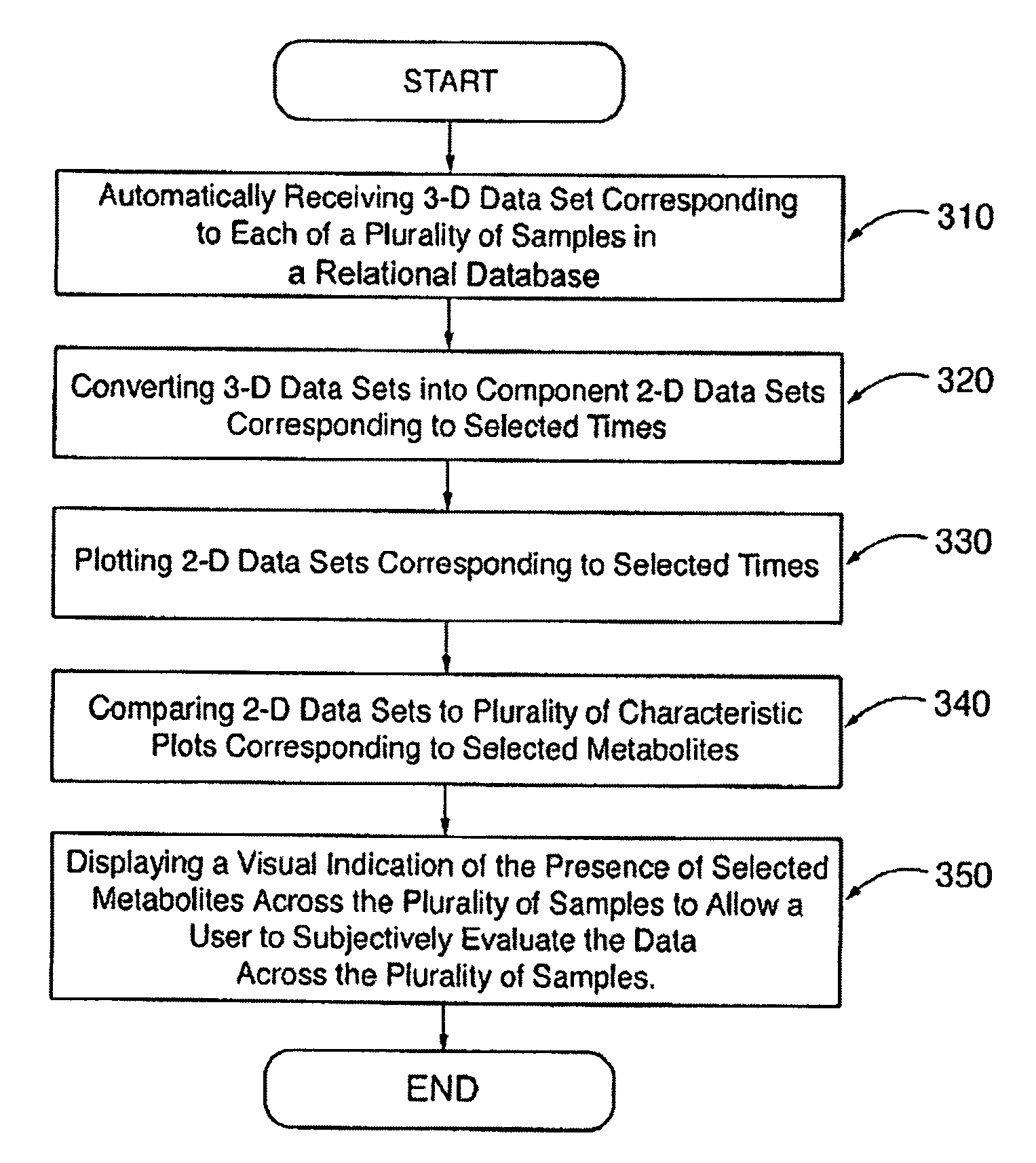

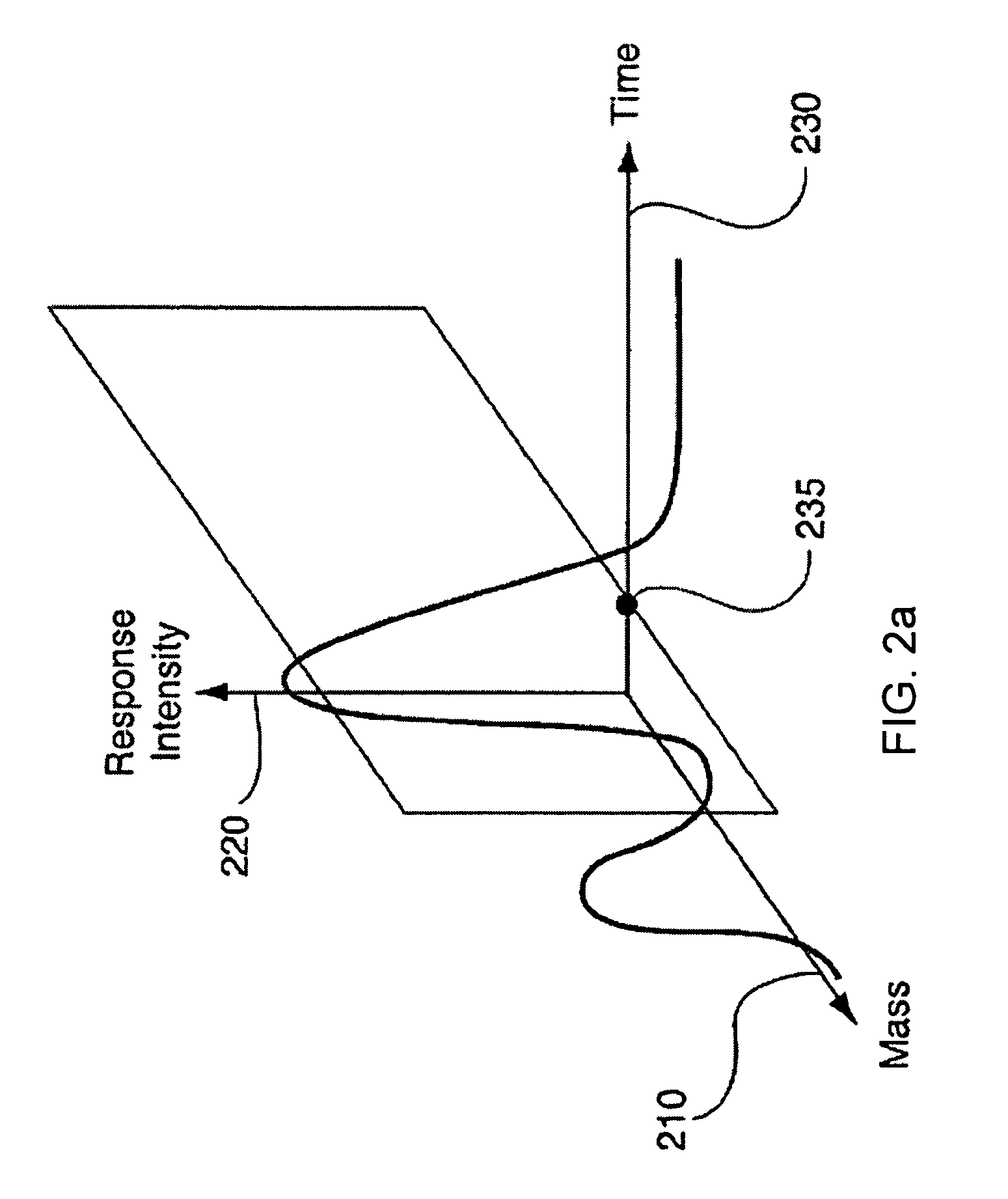

System and Method for Analyzing Metabolomic Data

ActiveUS20090093971A1Easy to determineEasy to compareMolecular entity identificationData visualisationMetaboliteData set

The present invention generates a visual display of metabolomic data compiled by a database and associated processor. More particularly, the present invention provides a database for automatically receiving a three-dimensional spectrometry data set for a group of samples. The present invention also provides a processor device for manipulating the data sets to produce plots that are directly comparable to a plurality of characteristic plots corresponding to a plurality of selected metabolites. Furthermore, the processor device may generate a visual display indicating the presence of the selected metabolites across the group of samples. Thus, the present invention enables a user to analyze a series of complex data sets in a visual display that may indicate the presence of the selected metabolites across the group of samples. Furthermore, the visual display generated by embodiments of the present invention also expedites the subjective analysis of the spectrometry data sets.

Owner:METABOLON

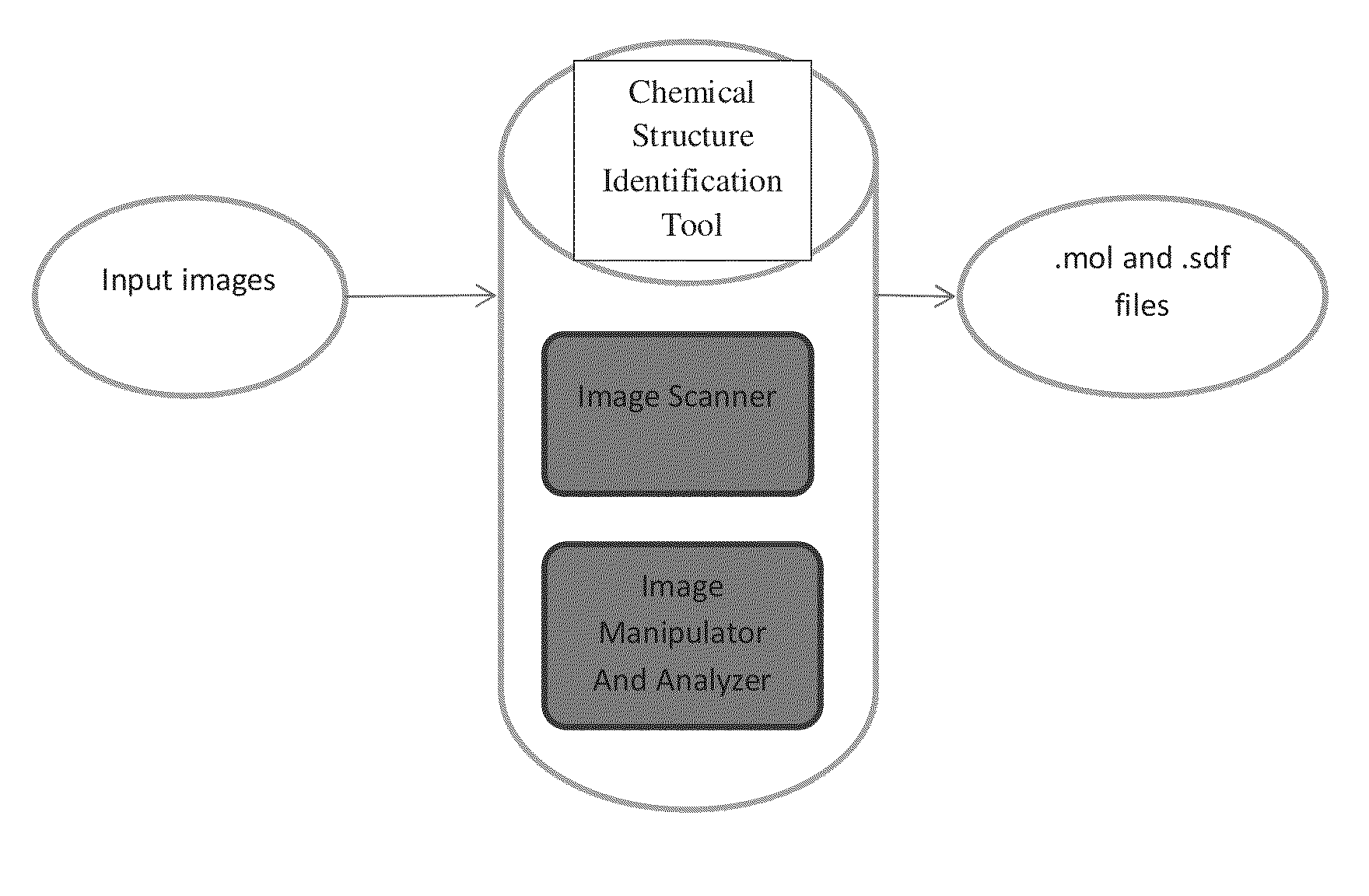

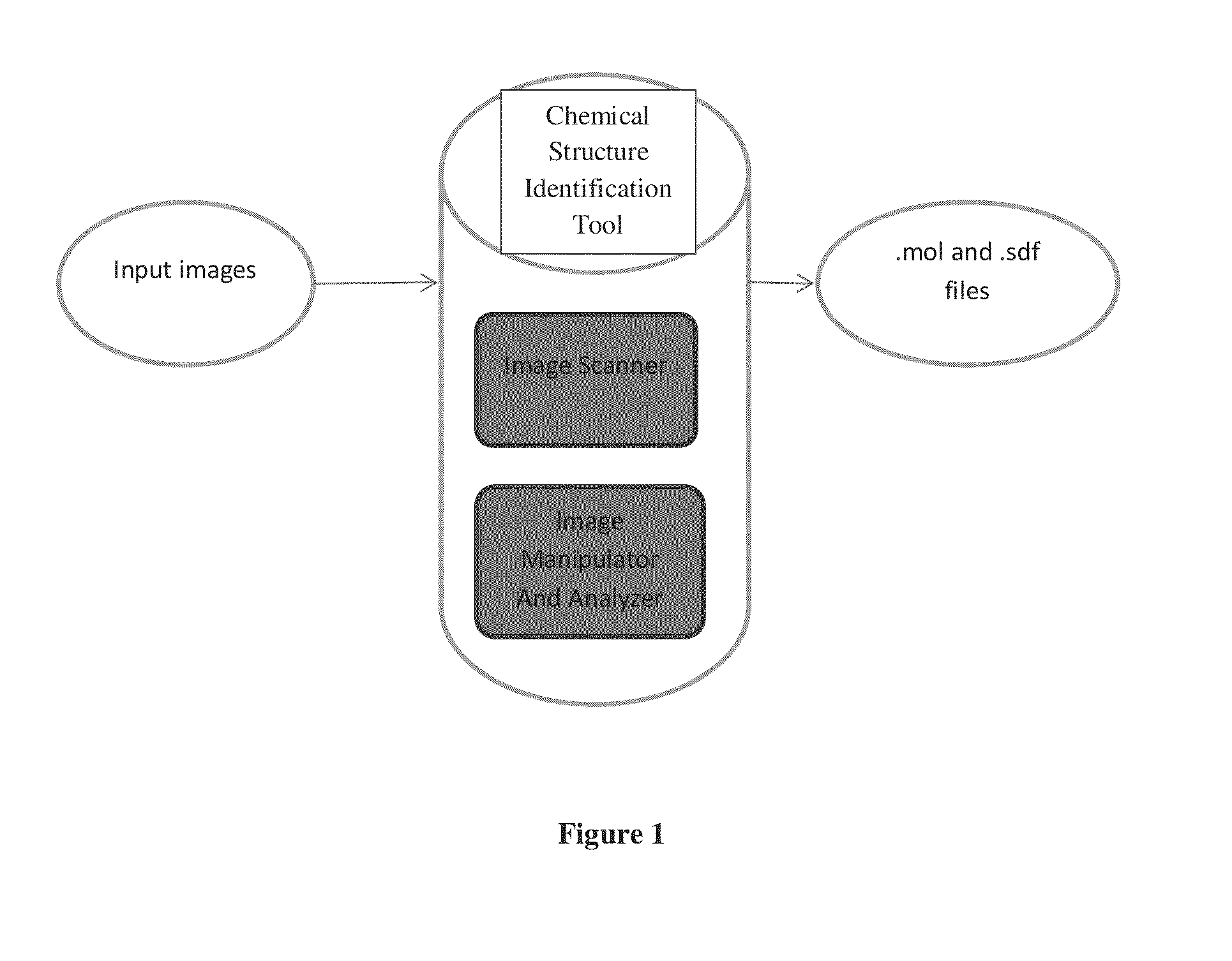

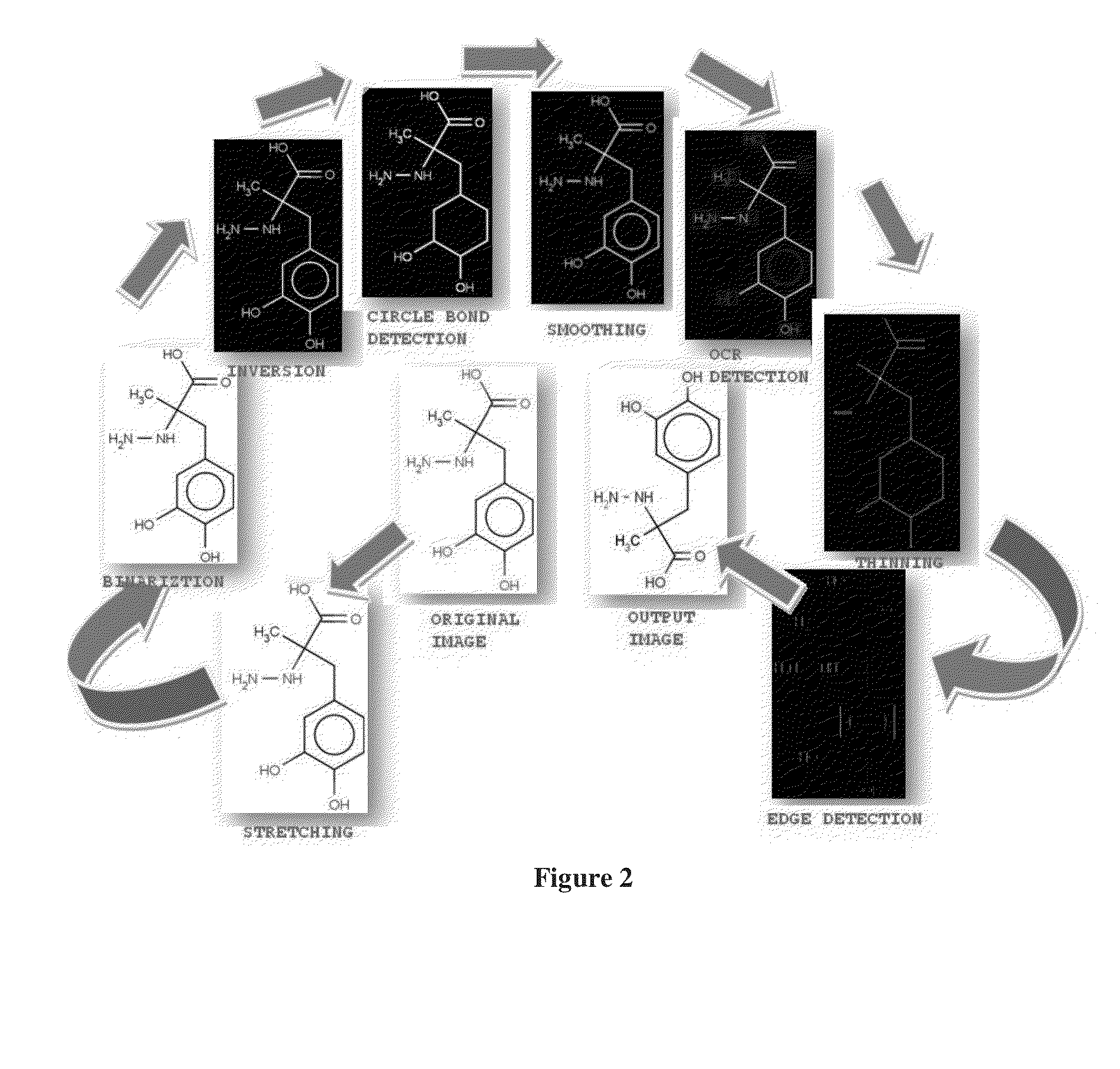

Chemical structure recognition tool

ActiveUS20140301608A1Chemical data visualisationCharacter recognitionChemical structureImage contrast

A method of extracting and then reusing / remodeling chemical data from a hand written or digital input image without manual inputs using Chemical Structure Recognition Tool (CSRT) is disclosed herein. It comprises loading said input image, converting said input image into a grayscale image i.e. stretching of loaded input image, converting said grayscale image into a binary image i.e. binarisation, smoothing to reduce noise within said binary image, recognizing circle bond to identify presence of a circle inside a ring, predicting OCR region to find zones containing text, image thinning to identify specific shapes within said binary image, edge detection to detect image contrast, detecting double and triple bond, and obtaining output files.

Owner:COUNCIL OF SCI & IND RES

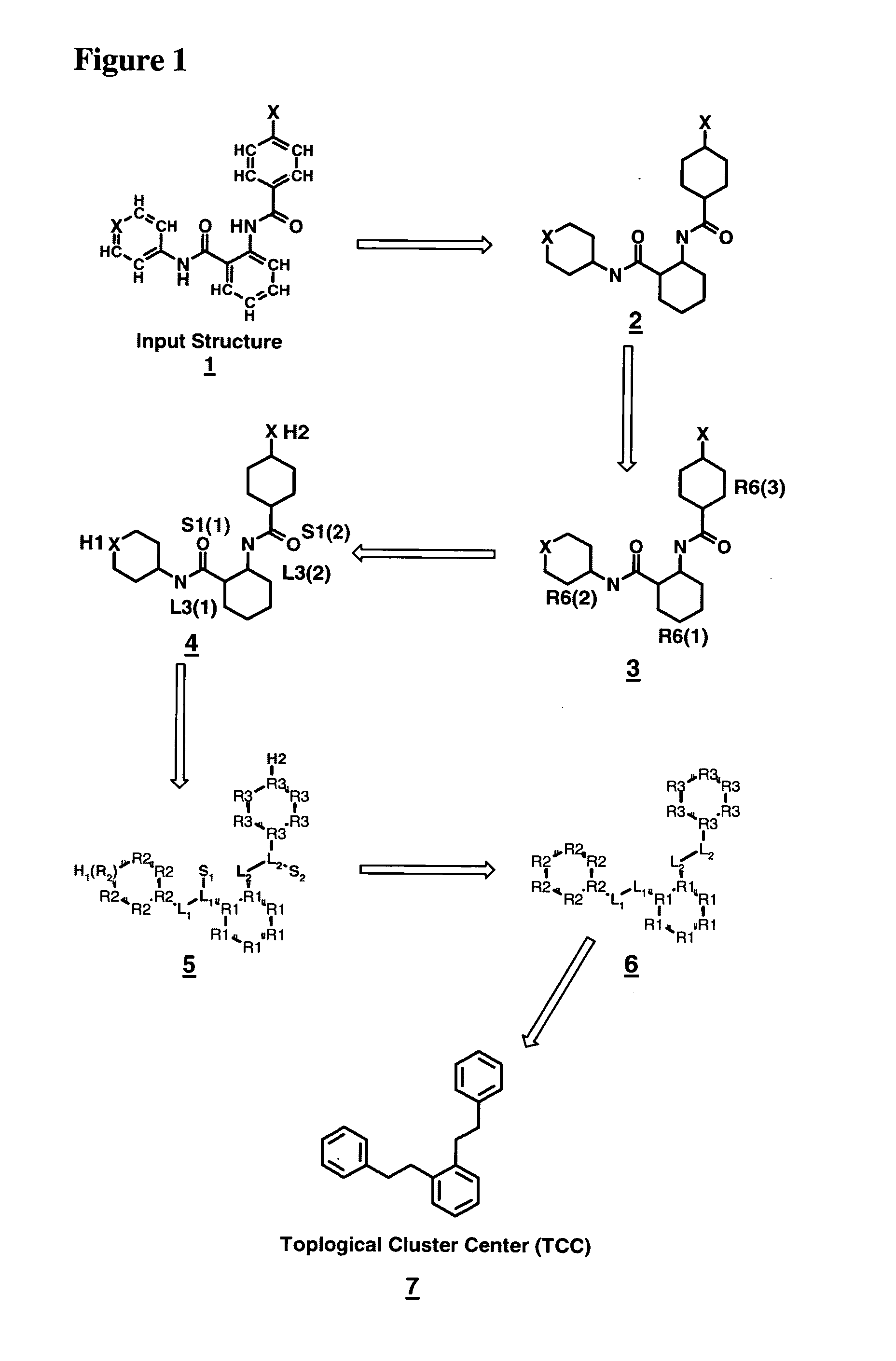

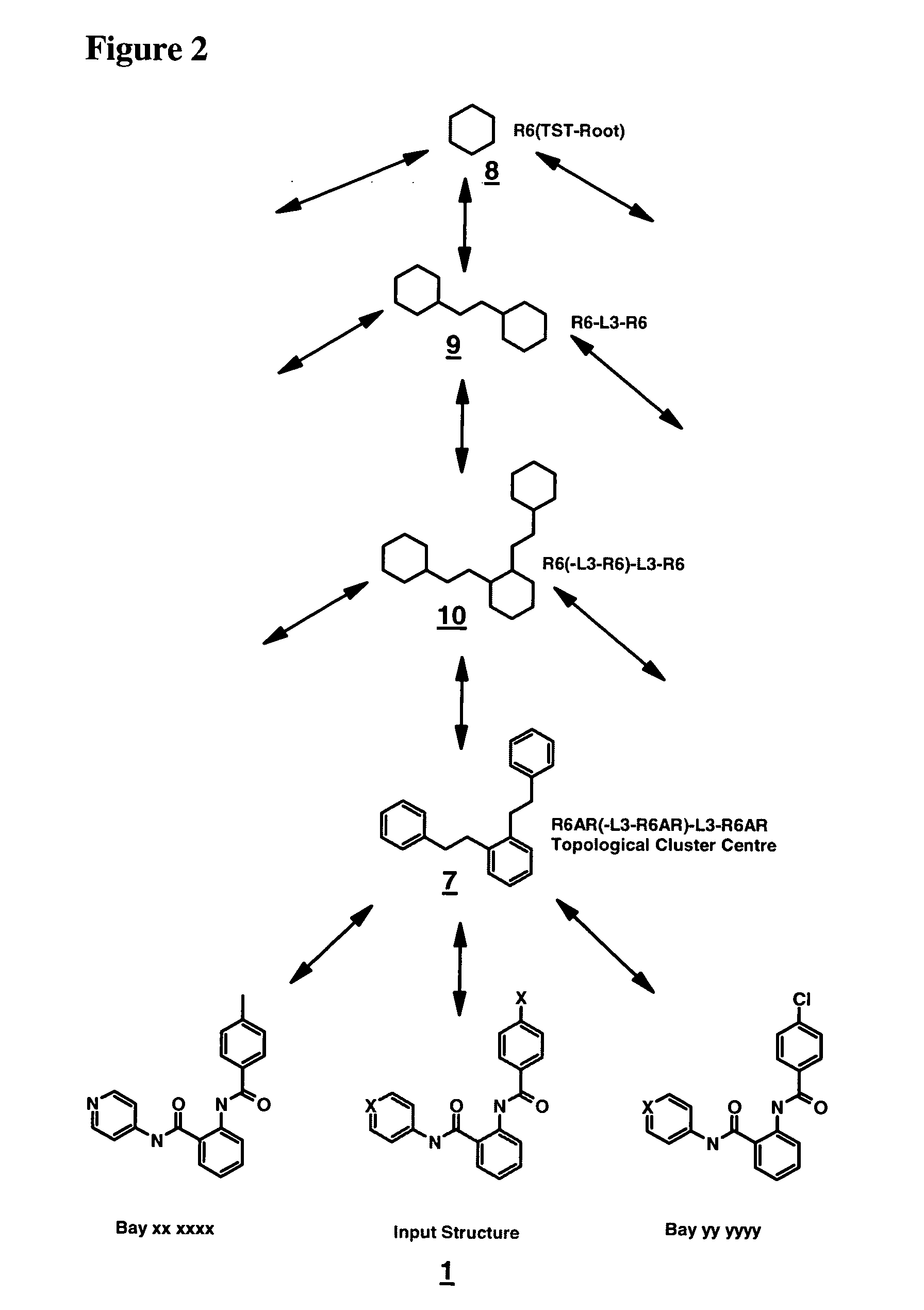

Method for generating a hierarchical topological tree of 2D or 3D-structural formulas of chemical compounds for property optimisation of chemical compounds

InactiveUS20070043511A1Easy to handleOrganic chemistry methodsBiological testingCADA compoundChemical compound

The invention concerns a new method for automatically and dynamically generating hierarchical topological trees of 2D- or 3D-structural formulas for structurally characterized chemical compounds, especially drug-like molecules, wherein the molecular graph of each 2D- or 3D-structure for a chemical compound is analyzed in terms of topological key features, the Largest Topological Substructure (LTS) and the proper Topological Cluster Centre (TCC) are created for each molecular graph, the ranking of the classes of topological key features and / or the ranking within each class of topological key features present in the TCC is used to generate a connected hierarchical Topological Sequence Path (TSP) of sentinel molecules from each molecular graph, and different molecular graphs and their Topological Sequence Paths (TSPs) share common vertices for common topological key features thus growing a Topological Structure Tree (TST), each chemical compound from the input stream is attached as a leaf node to the appropriate Largest Topological Substructure (LTS) node in the tree.

Owner:BAYER SCHERING PHARMA AG

Multi-dimensional predicting method for strength of braided ceramic base composite material

ActiveCN109920495AAccurately predict strengthChemical data visualisationComputational theoretical chemistryYarnMultiple-scale analysis

The invention provides a multi-dimensional predicting method for strength of a braided ceramic base composite material. Firstly a parameterization method is used for establishing a braided ceramic base composite material single-cell model which comprises yarns and a matrix, and then period grid dividing is performed. Afterwards a mesomechanics method is used for simulating the mechanics behavior of the yarn unit. Furthermore a strain conversion matrix is used for converting a yarn element stiffness matrix from a local coordinate system to an integral coordinate system. Finally through applyingan increment type periodic boundary condition, a micro-stress and a strain field of a single cell are calculated. A volume averaging method is used for obtaining a microscopic stress and strain of the braided ceramic base composite material. If a failure unit band which penetrates through the single cell is formed, failure of the braided ceramic base composite material is determined, and the single-cell average stress is the strength of the braided ceramic base composite material. According to the multi-dimensional predicting method, the multidimensional analysis method in which macrography and mesography are combined is utilized. The strength of the braided ceramic base composite material can be accurately predicted without dependence to a large number of experiments with time consumption and high cost.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

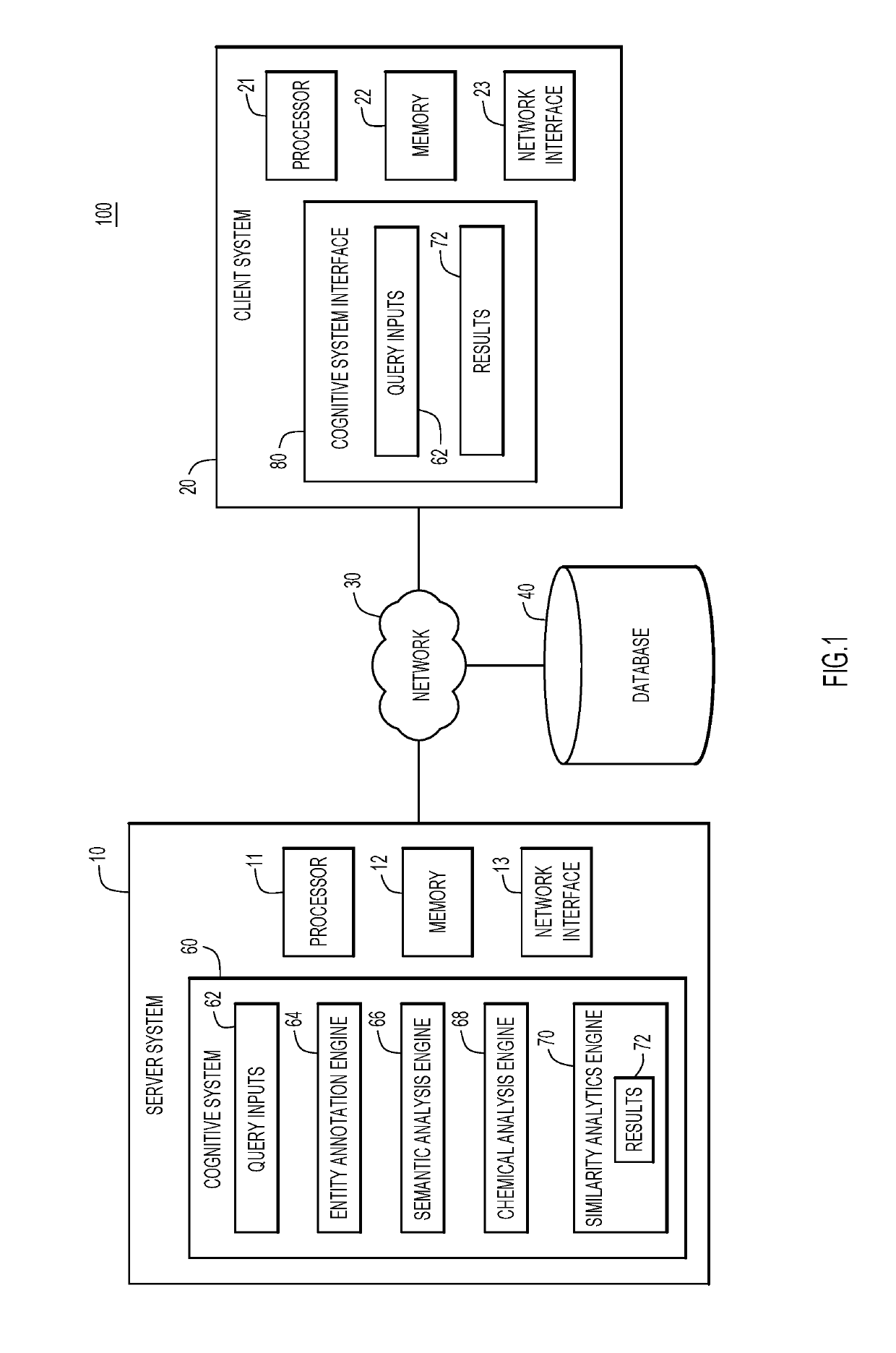

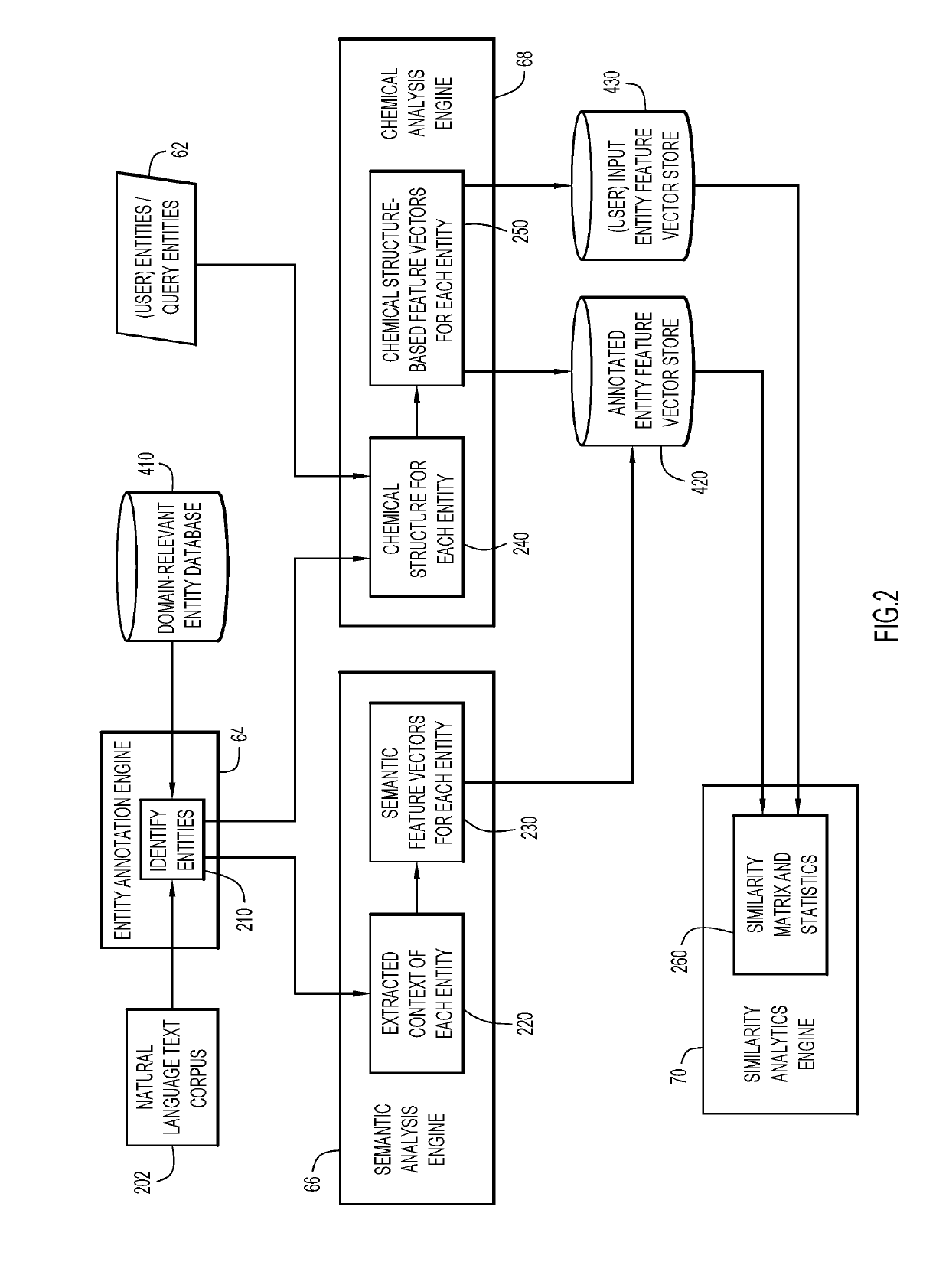

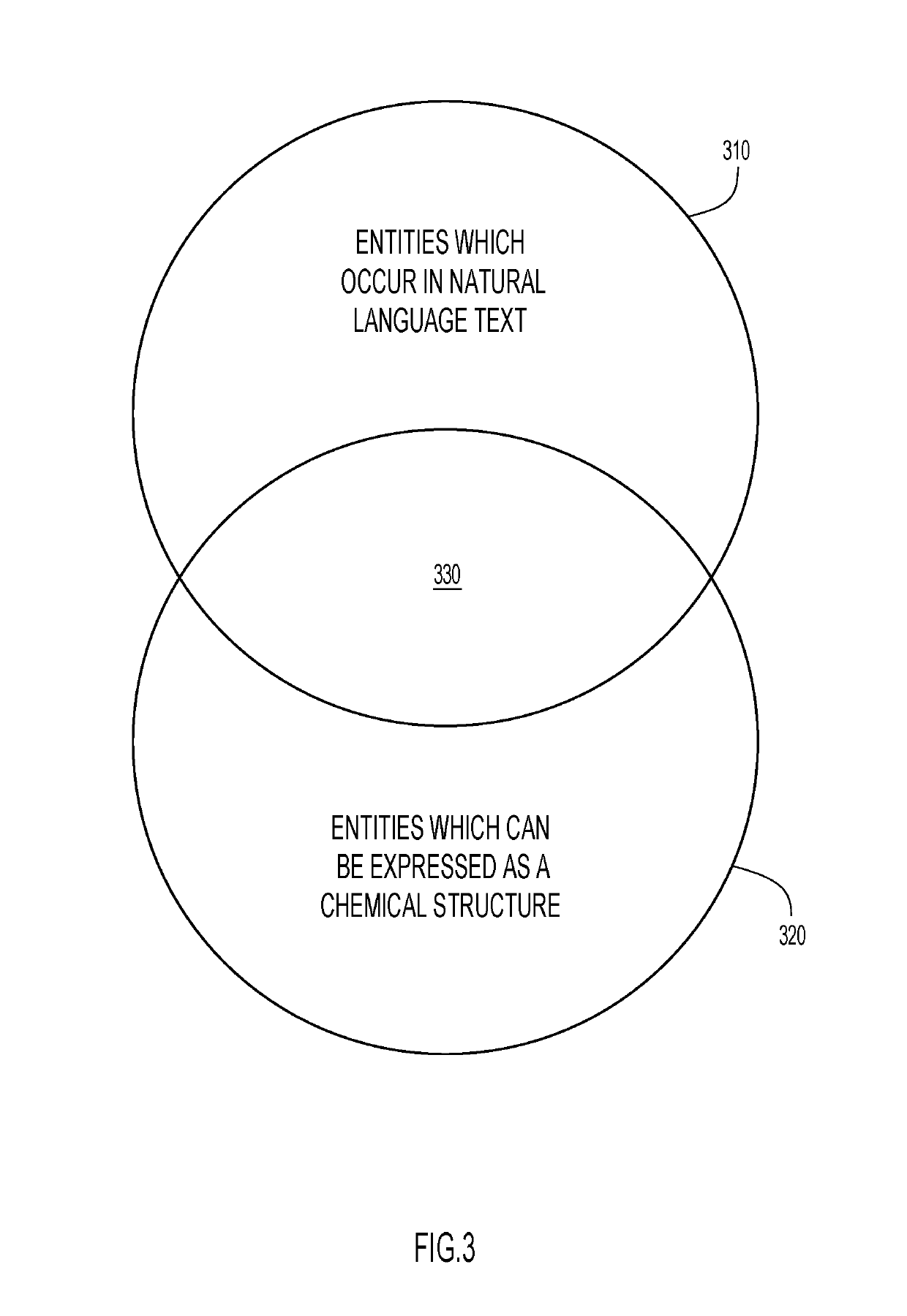

Combining chemical structure data with unstructured data for predictive analytics in a cognitive system

According to embodiments of the present invention, an entity may be represented by an unstructured feature vector comprising a plurality of features extracted from unstructured data using semantic analysis and a structural feature vector comprising a plurality of features from chemical structure data. A similarity matrix may be used to compare entities and generate a similarity score, based on both the unstructured feature vector and the structural feature vector for each entity. In some aspects, a user may enter a query (from which a chemical structural feature vector is dynamically generated) to compare against entities having unstructured and / or structural feature vectors, stored in a database.

Owner:IBM CORP

System and Method for Identifying Similar Molecules

ActiveUS20080004810A1Improve computing efficiencyChemical structure searchBiological testingComputer science

A vectorization process is employed in which chemical identifier strings are converted into respective vectors. These vectors may then be searched to identify molecules that are identical or similar to each other. The dimensions of the vector space can be defined by sequences of symbols that make up the chemical identifier strings. The International Chemical Identifier (InChI) string defined by the International Union of Pure and Applied Chemistry (IUPAC) is particularly well suited for these methods.

Owner:GLOBALFOUNDRIES US INC

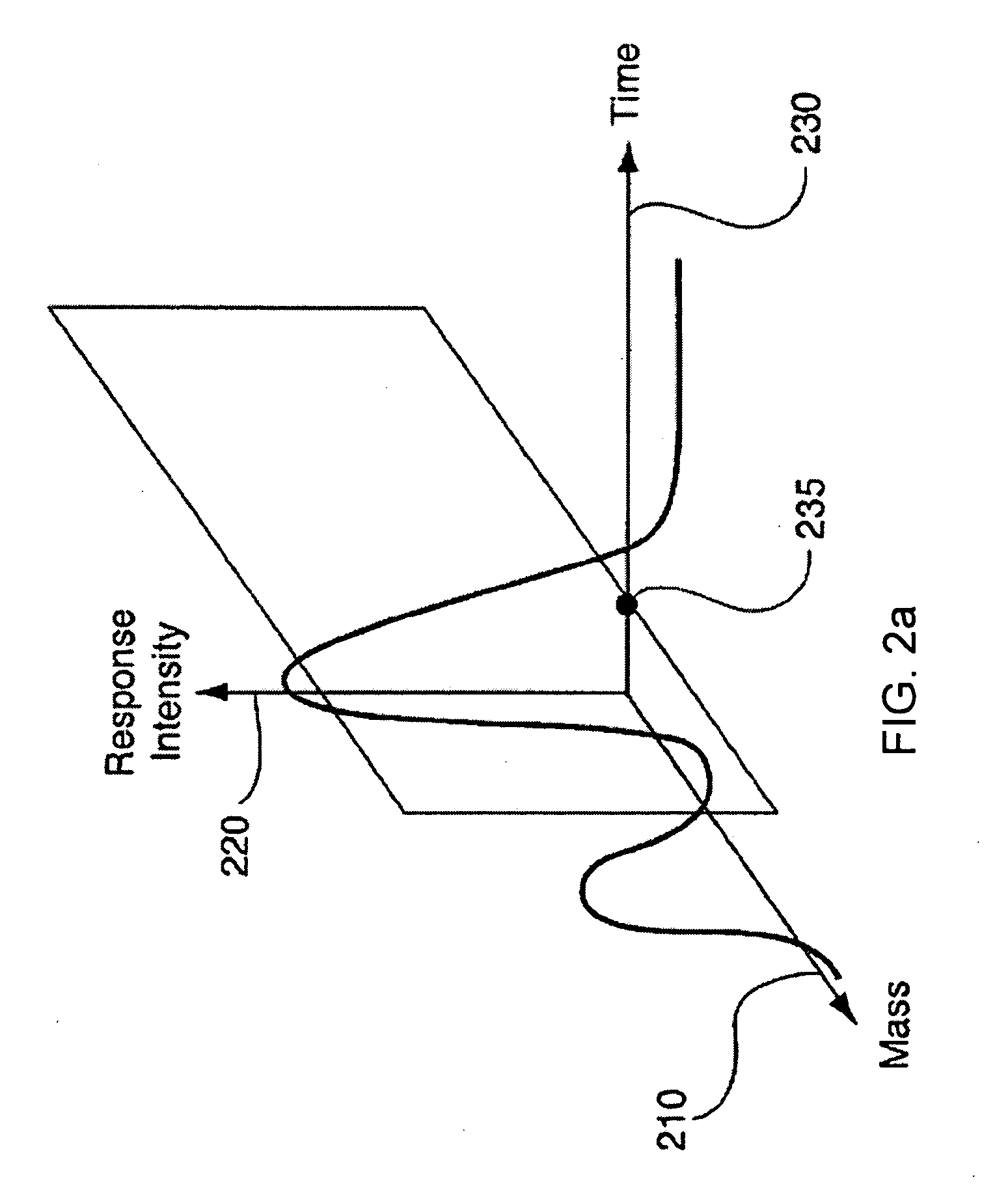

System and method for analyzing metabolomic data

ActiveUS7949475B2Easy to determineEasy to compareMolecular entity identificationData visualisationData setMetabolite

The present invention generates a visual display of metabolomic data compiled by a database and associated processor. More particularly, the present invention provides a database for automatically receiving a three-dimensional spectrometry data set for a group of samples. The present invention also provides a processor device for manipulating the data sets to produce plots that are directly comparable to a plurality of characteristic plots corresponding to a plurality of selected metabolites. Furthermore, the processor device may generate a visual display indicating the presence of the selected metabolites across the group of samples. Thus, the present invention enables a user to analyze a series of complex data sets in a visual display that may indicate the presence of the selected metabolites across the group of samples. Furthermore, the visual display generated by embodiments of the present invention also expedites the subjective analysis of the spectrometry data sets.

Owner:METABOLON

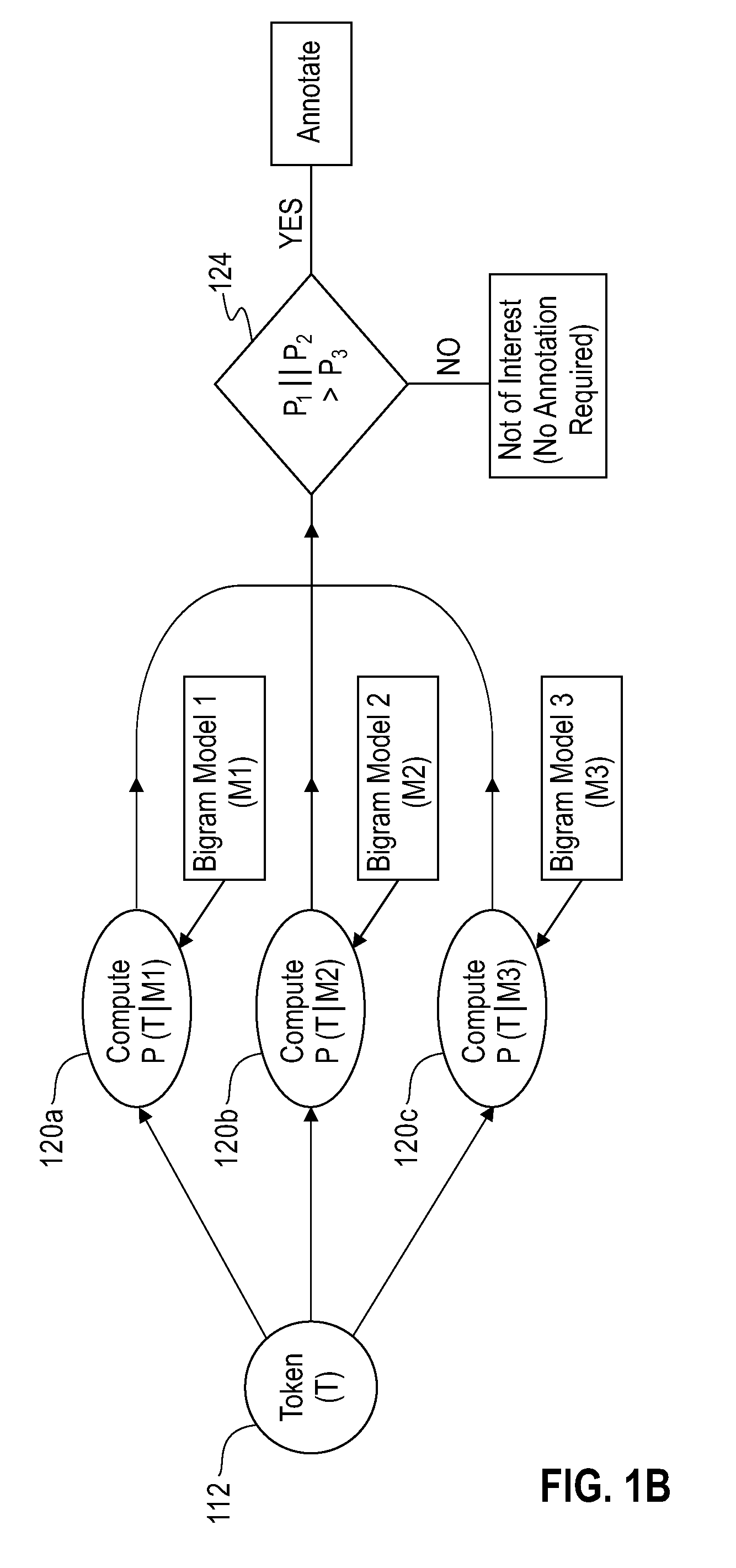

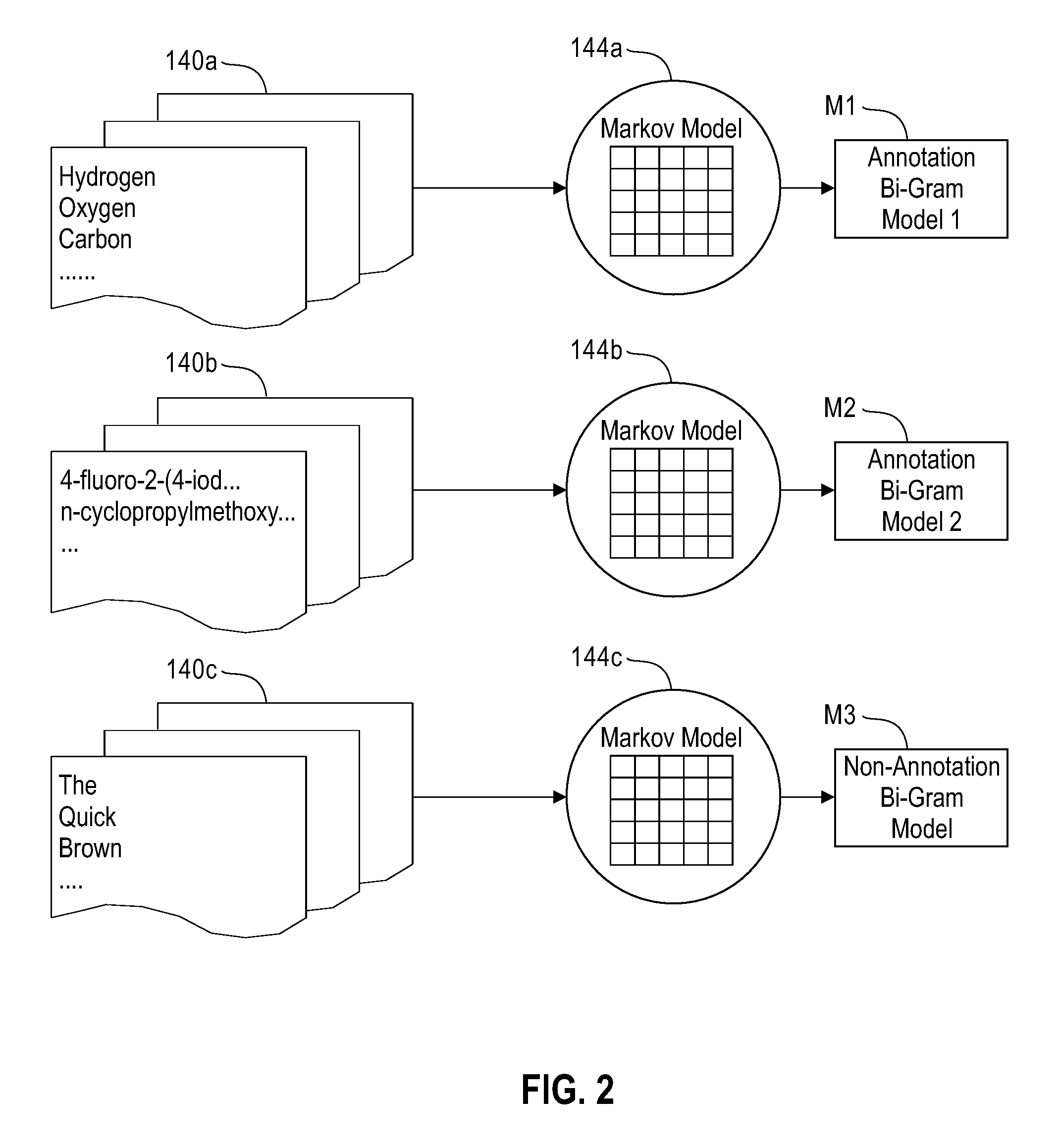

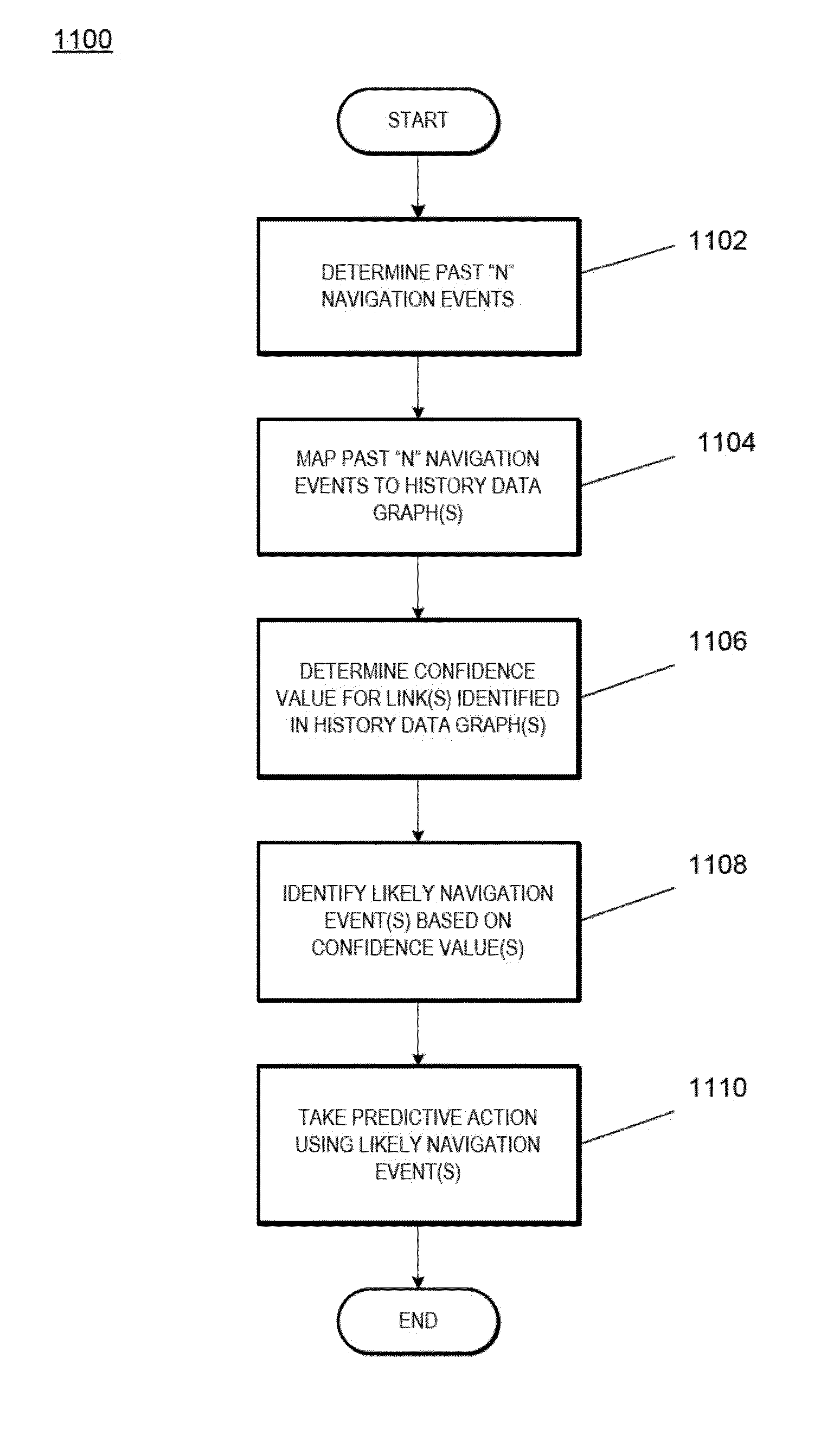

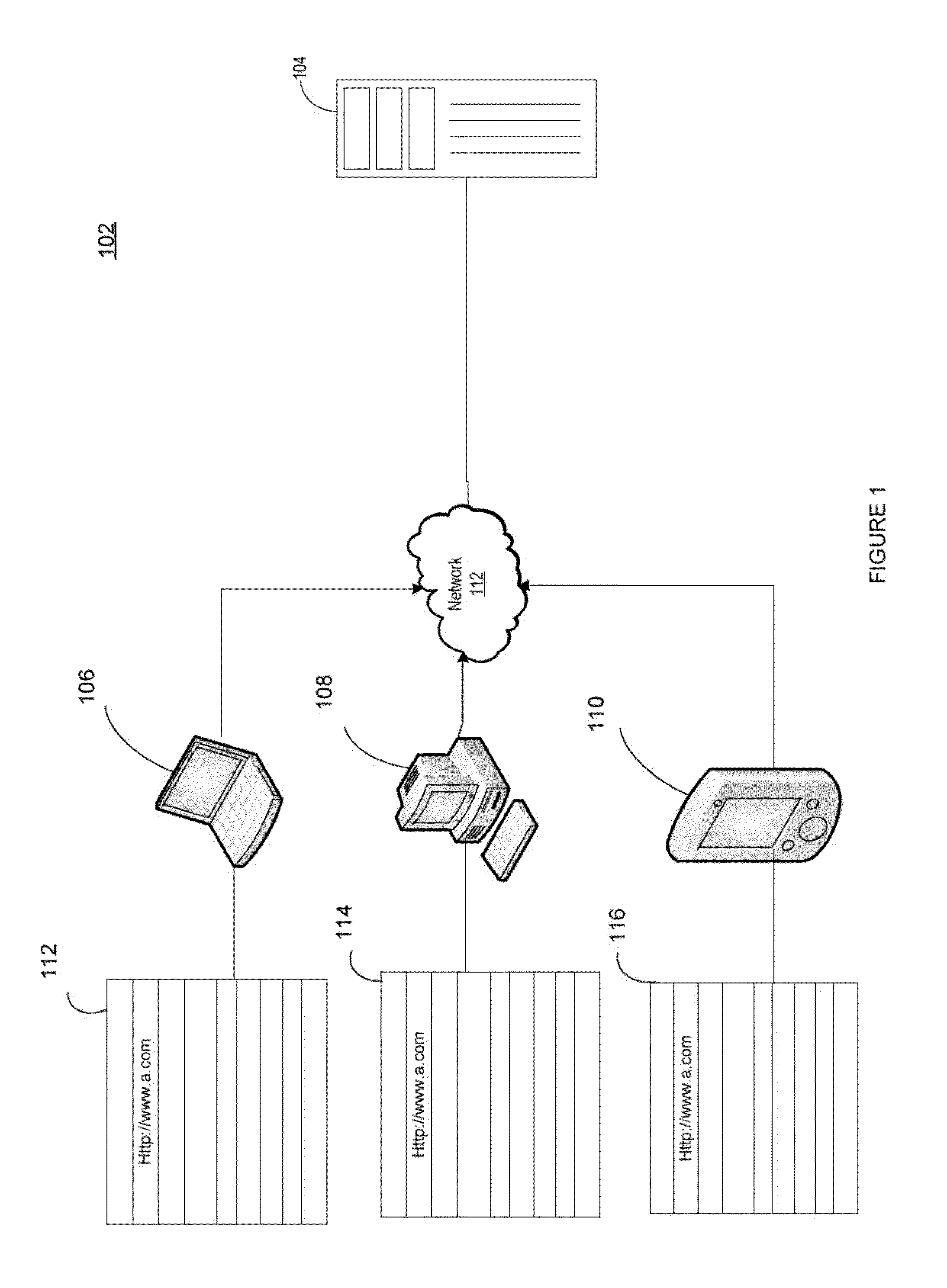

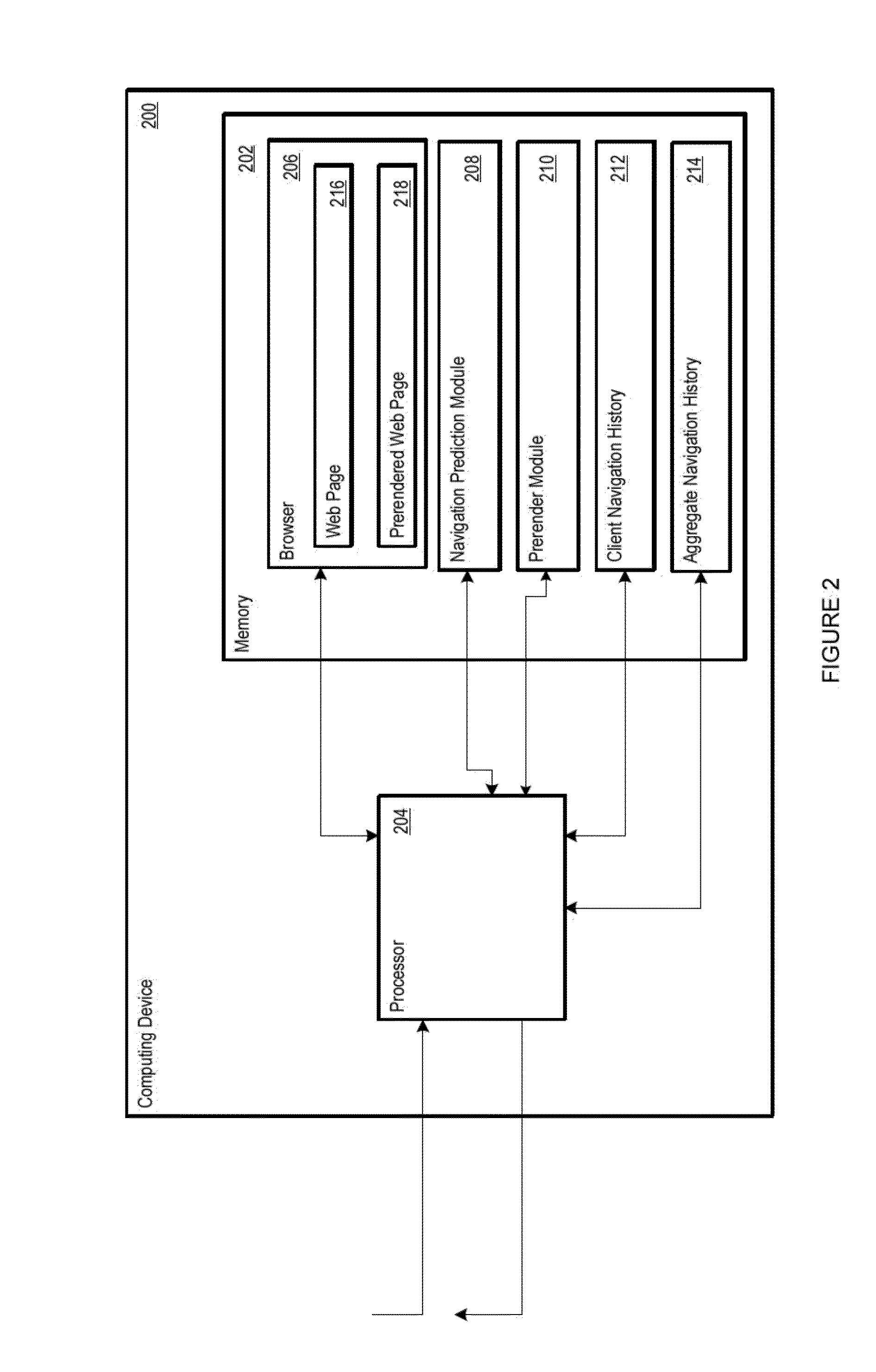

Predicting user navigation events in a browser using directed graphs

ActiveUS8600921B2Delay minimizationWeb data indexingDigital data processing detailsDirected graphText entry

A method and system for predicting a next navigation event are described. Aspects of the disclosure minimize the delay between a navigation event and a network response by predicting the next navigation event. The system and method may then prerender content associated with the next navigation event. For example, the method and system may predict a likely next uniform resource locator during web browsing to preemptively request content from the network before the user selects the corresponding link on a web page. The methods describe a variety of manners of predicting the next navigation event, including examining individual and aggregate historical data, text entry prediction, and cursor input monitoring.

Owner:GOOGLE LLC

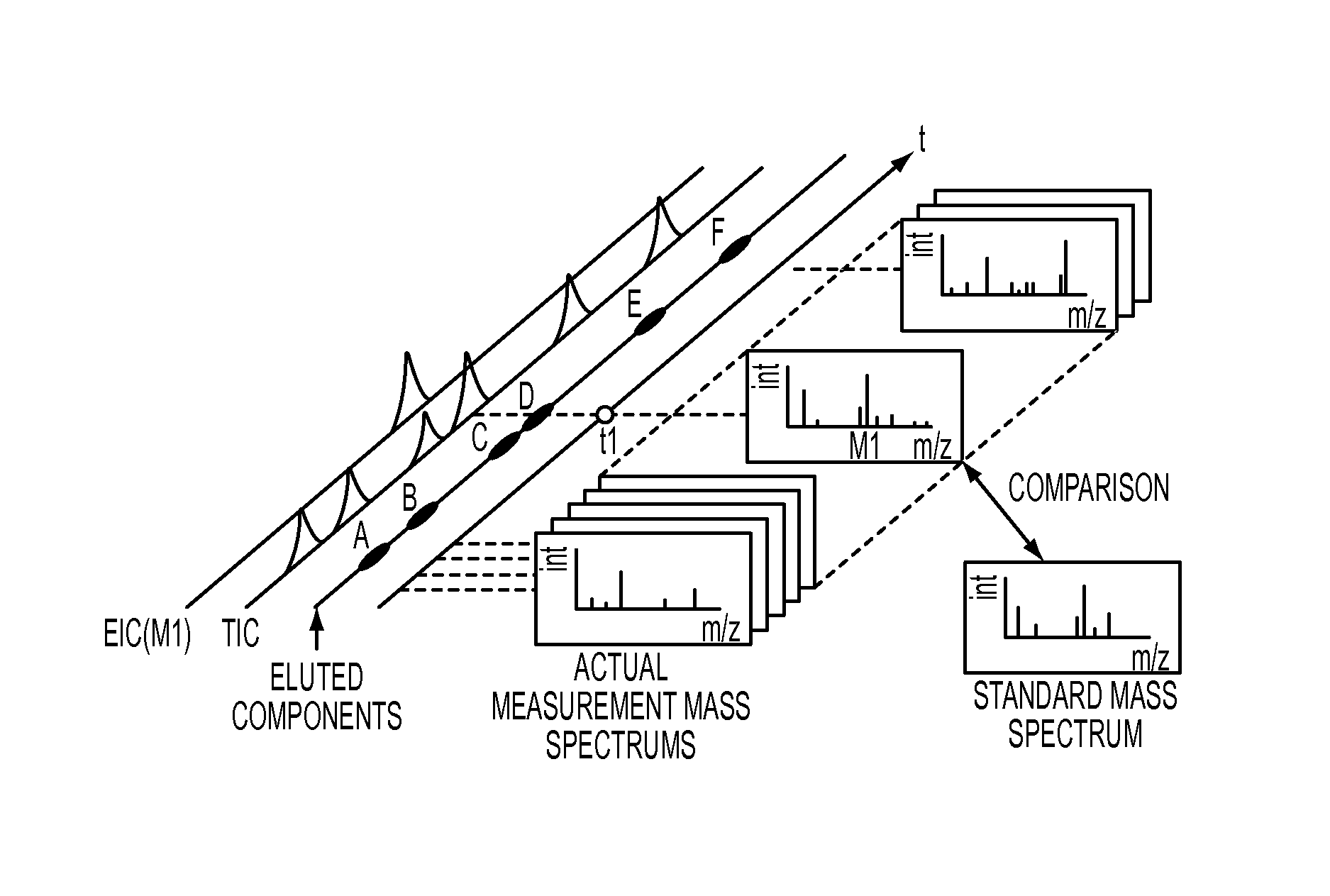

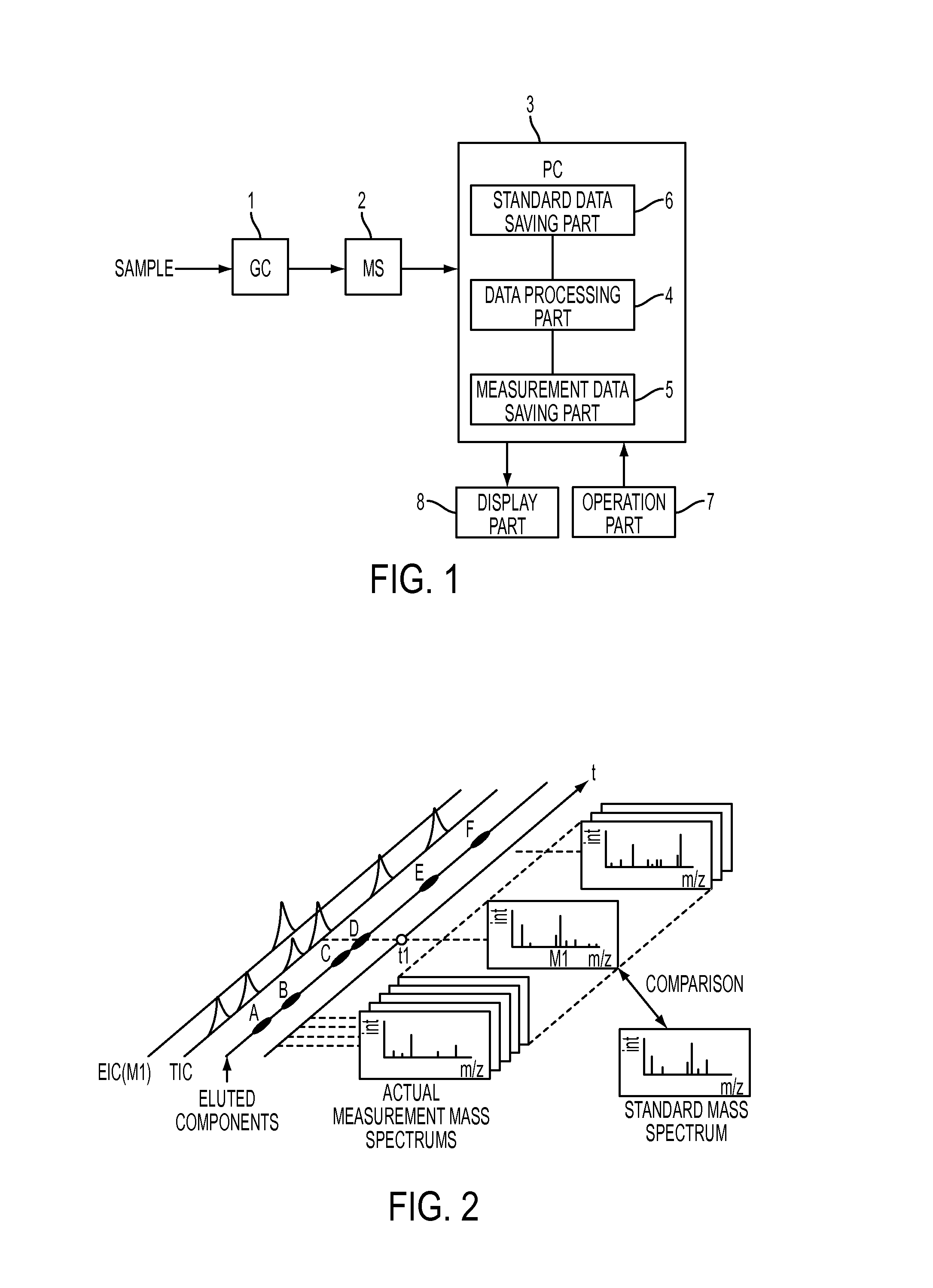

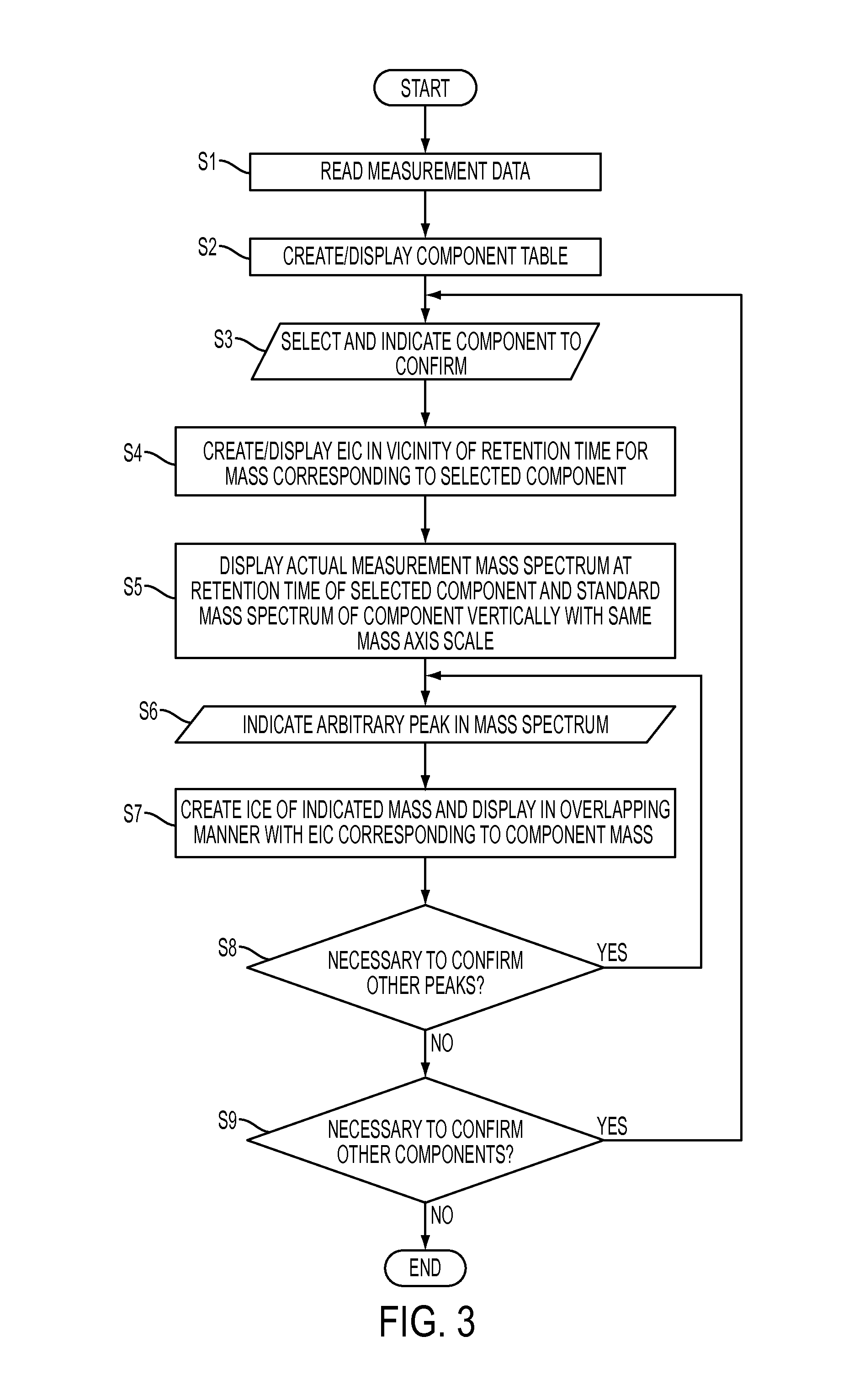

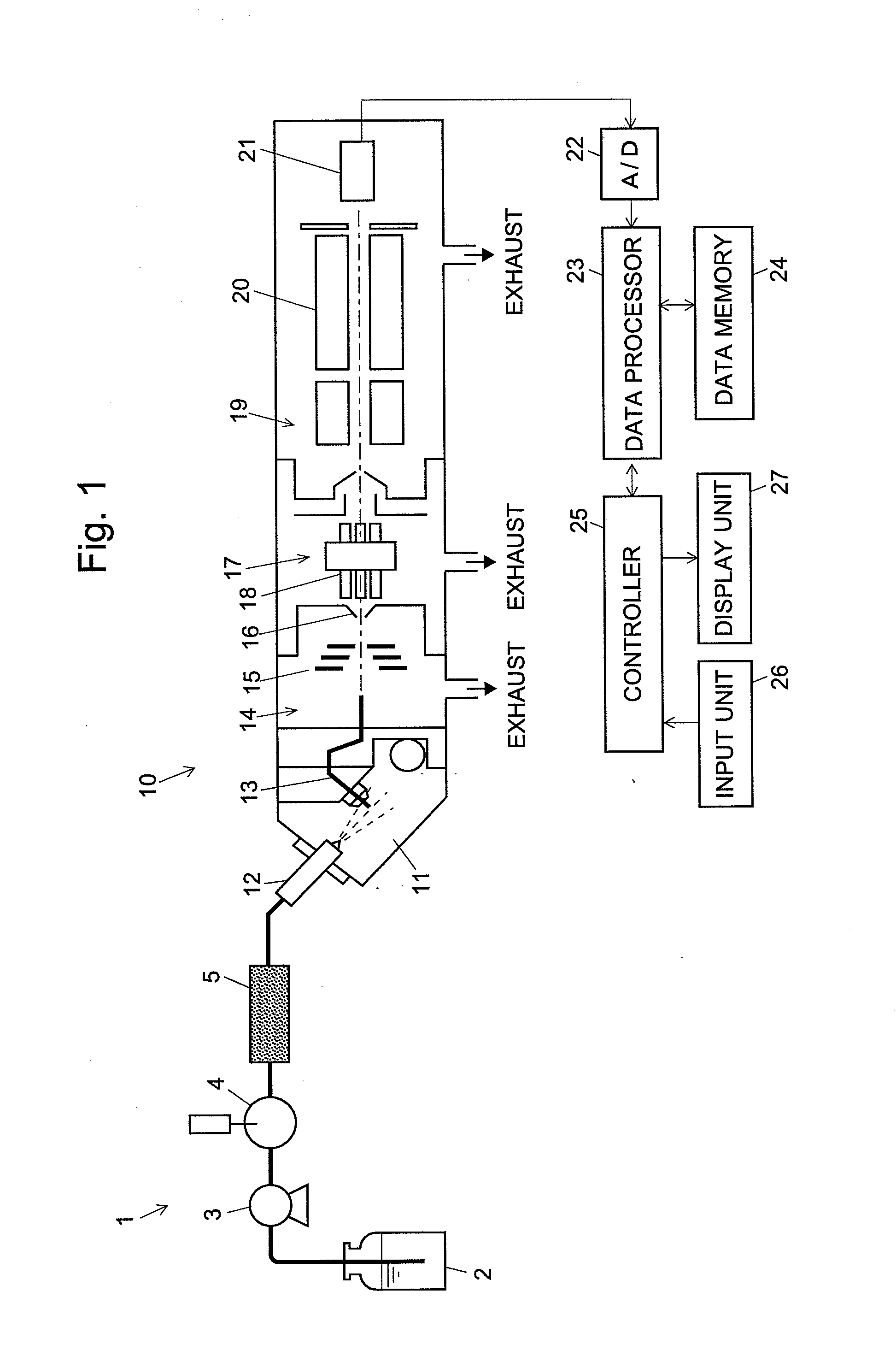

Chromatograph mass spectrometry data processing device

InactiveUS20140012515A1Improve efficiencyEasy to operateParticle separator tubesMolecular entity identificationRetention timeMass Spectrometry-Mass Spectrometry

When an analyst designates an arbitrary component on a component table displayed in a component table display area, an EIC of the characteristic mass in the vicinity of the retention time of the component is created and is displayed in a chromatogram display area. In addition, an actual measurement mass spectrum at the retention time of the designated component and a pure standard mass spectrum of the component are aligned vertically in the same mass axis scale and displayed in a mass spectrum display area. Further, when the mass axis of one of the mass spectra is magnified / reduced by a dragging operation of a mouse or by a magnification / reduction button, the mass axis of the other mass spectrum is concurrently magnified / reduced.

Owner:SHIMADZU CORP

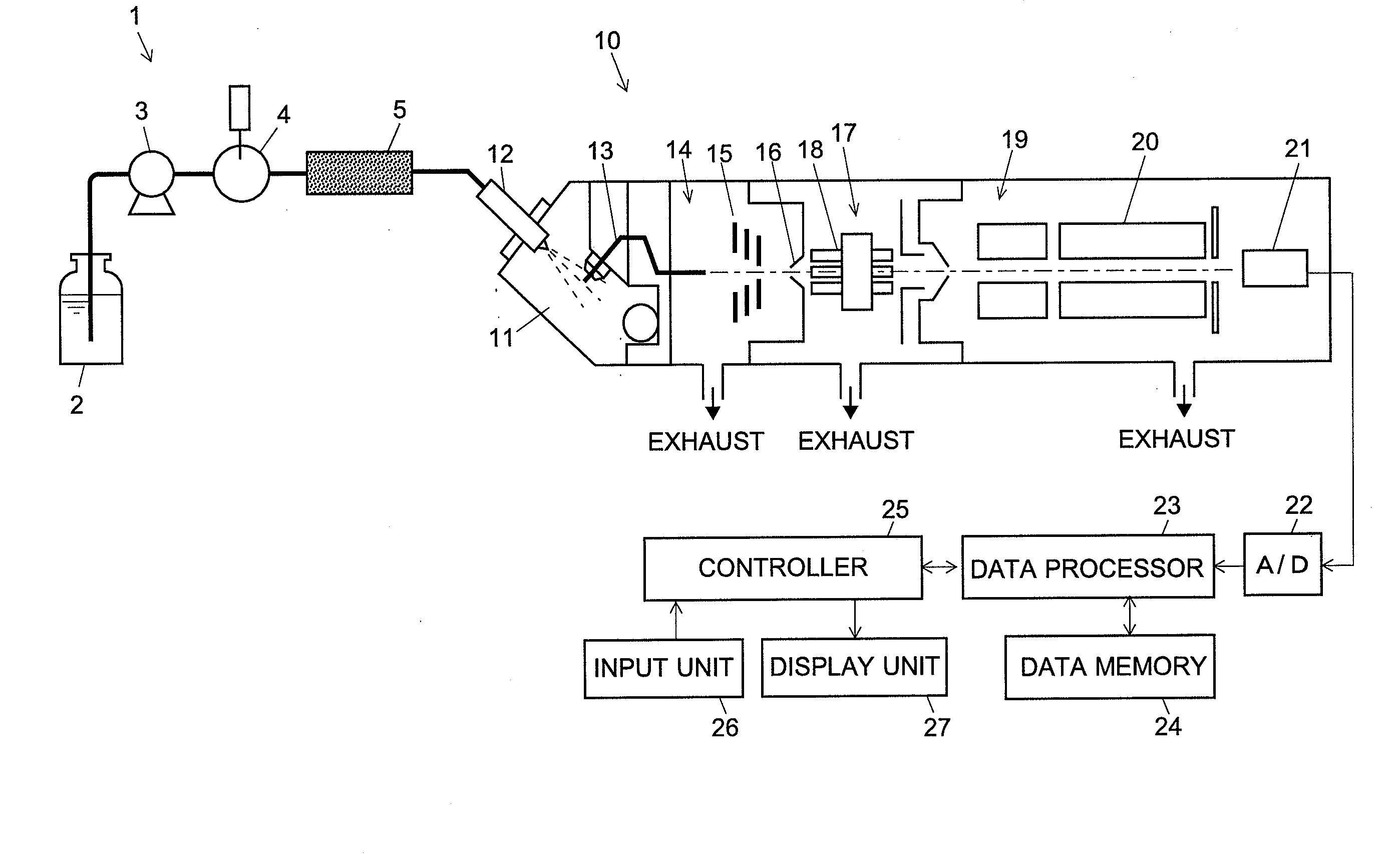

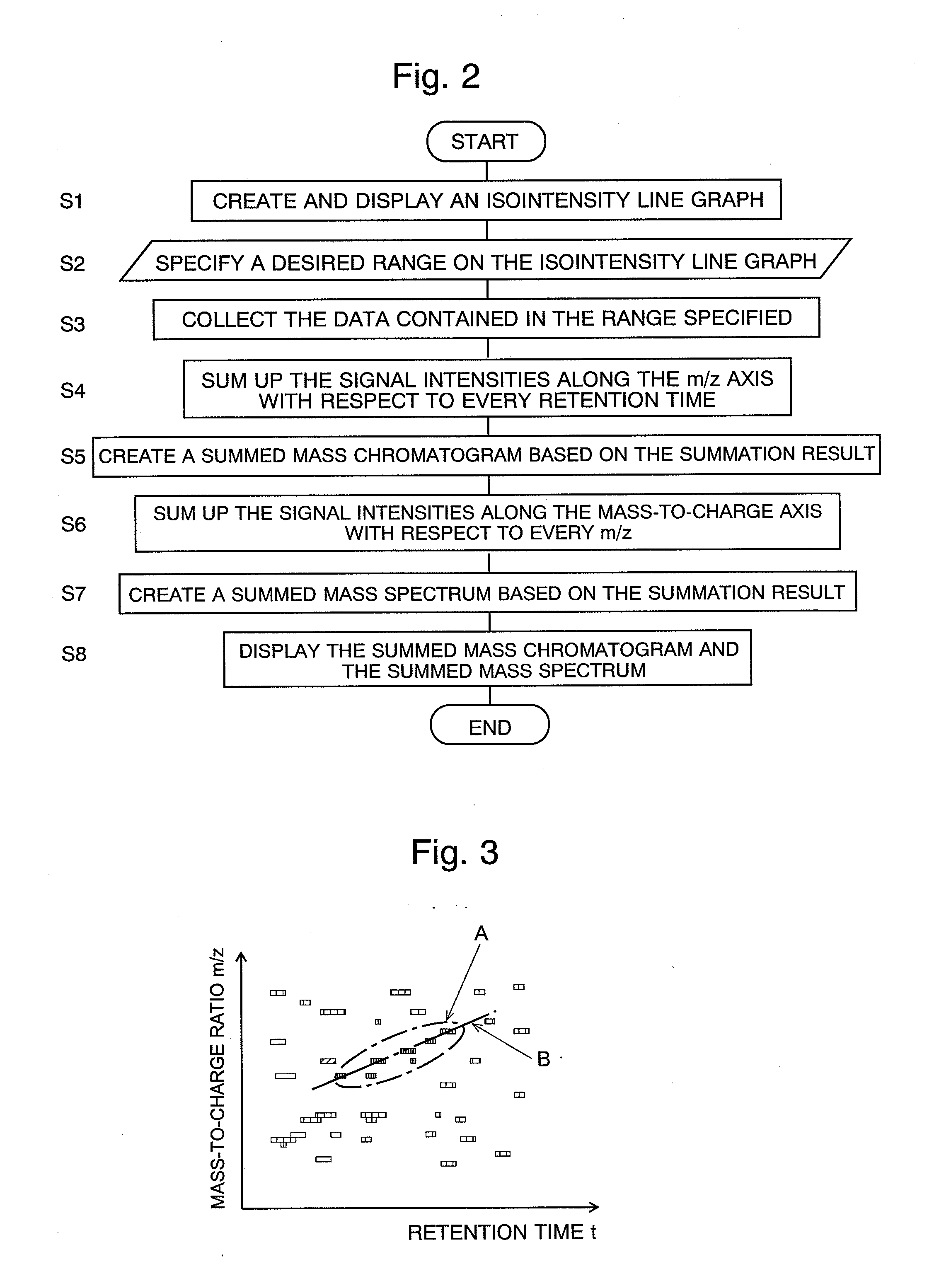

Chromatograph mass analysis data processing apparatus

InactiveUS20090001261A1Easy to operateSimplify manipulationMolecular entity identificationComponent separationRelevant informationRetention time

A chromatograph mass analysis data processing apparatus is provided for obtaining pertinent information, with a simple operation, on a compound series including a plurality of compounds whose structures and characters are similar. Based on the data obtained by a chromatograph mass analysis, a two-dimensional isointensity line graph is created and displayed with a retention time and a mass-to-charge ratio on the two axes and with a signal intensity represented with a contour (S1). When the operator specifies a desired range by a drag operation or the like through a mouse (S2), the data contained in the range specified are collected (S3), the signal intensities along the mass-to-charge ratio axis direction are summed up for every retention time to create a summed mass chromatogram based on the summed value (S4 and S5). Simultaneously, the signal intensities along the retention time axis direction are summed up for every mass-to-charge ratio to create a summed mass spectrum based on the summed value (S6 and S7). These are then displayed on the same screen of the isointensity line graph (S8).

Owner:SHIMADZU CORP

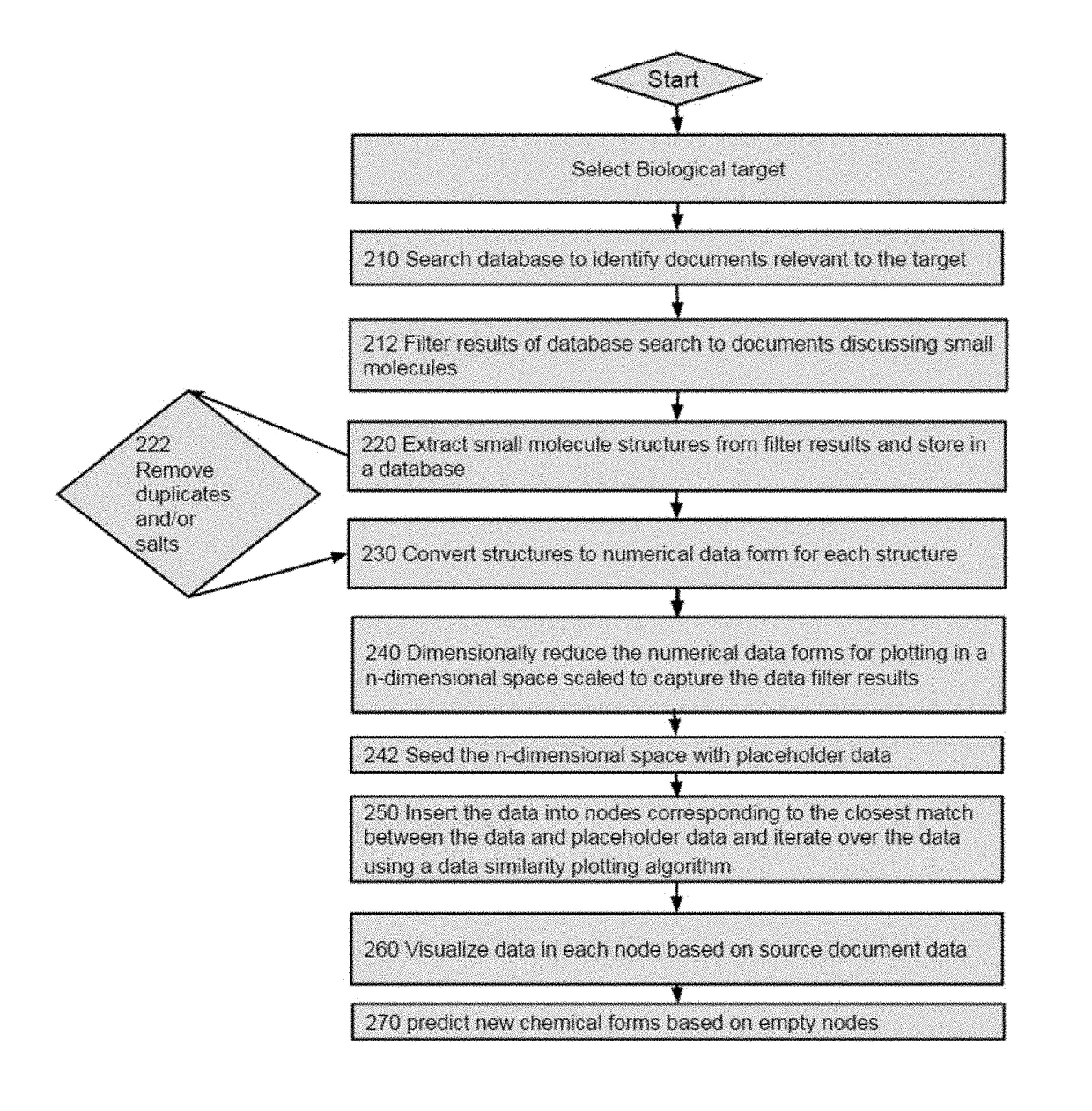

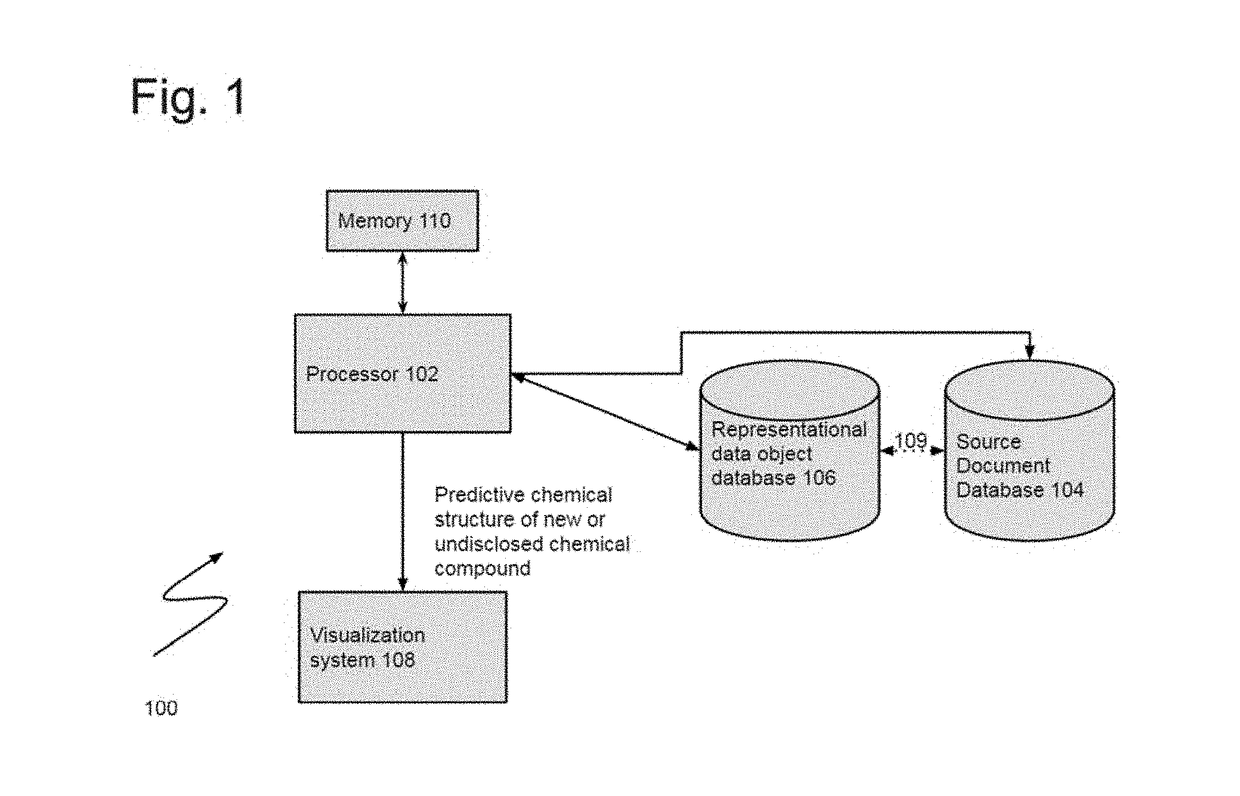

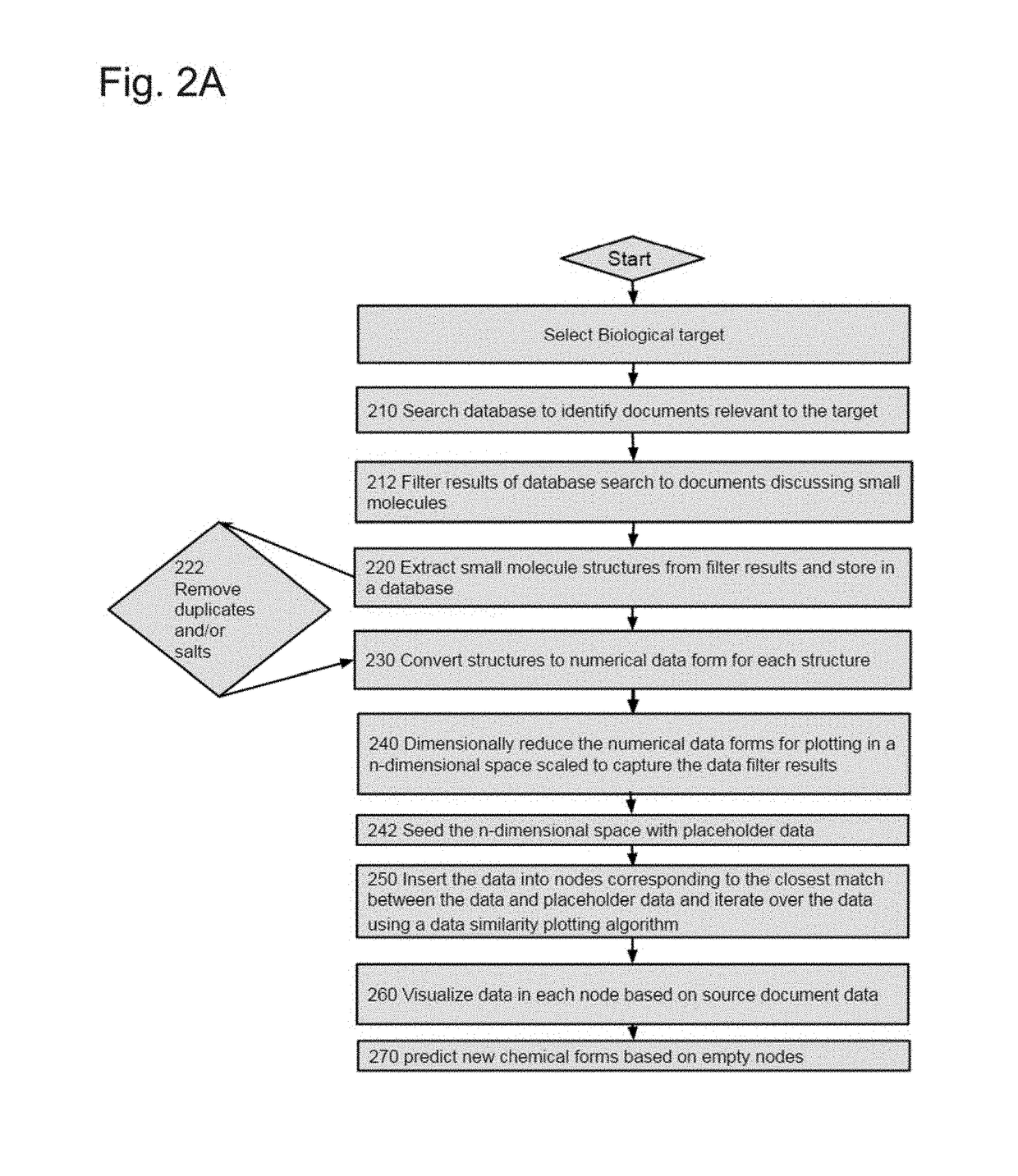

System and method for evaluating chemical entities using and applying a virtual landscape

ActiveUS10013467B1Data processing applicationsChemical data visualisationData setLandscape assessment

The present invention concerns a system and method for analyzing the relationship between representational data found in source documents through creation and manipulation of a virtual manifold, such as a node array. Furthermore, the present invention concerns predicting new representational data based on the representational data found within the source documents. The system and method further utilizes a processor configured to carry out a series of steps in order to create, maintain and manage associations between source documents, the representational identifiers found within the source documents, and any converted coded forms of the representational identifiers. In one implementation, the invention generates data sets highlighting undisclosed or unknown representational identifiers that are not described in the source documents, yet which indicate the relationship between disclosed representational identifiers described in the source documents and which occupy prescribed places within the virtual manifold.

Owner:ACCENCIO LLC

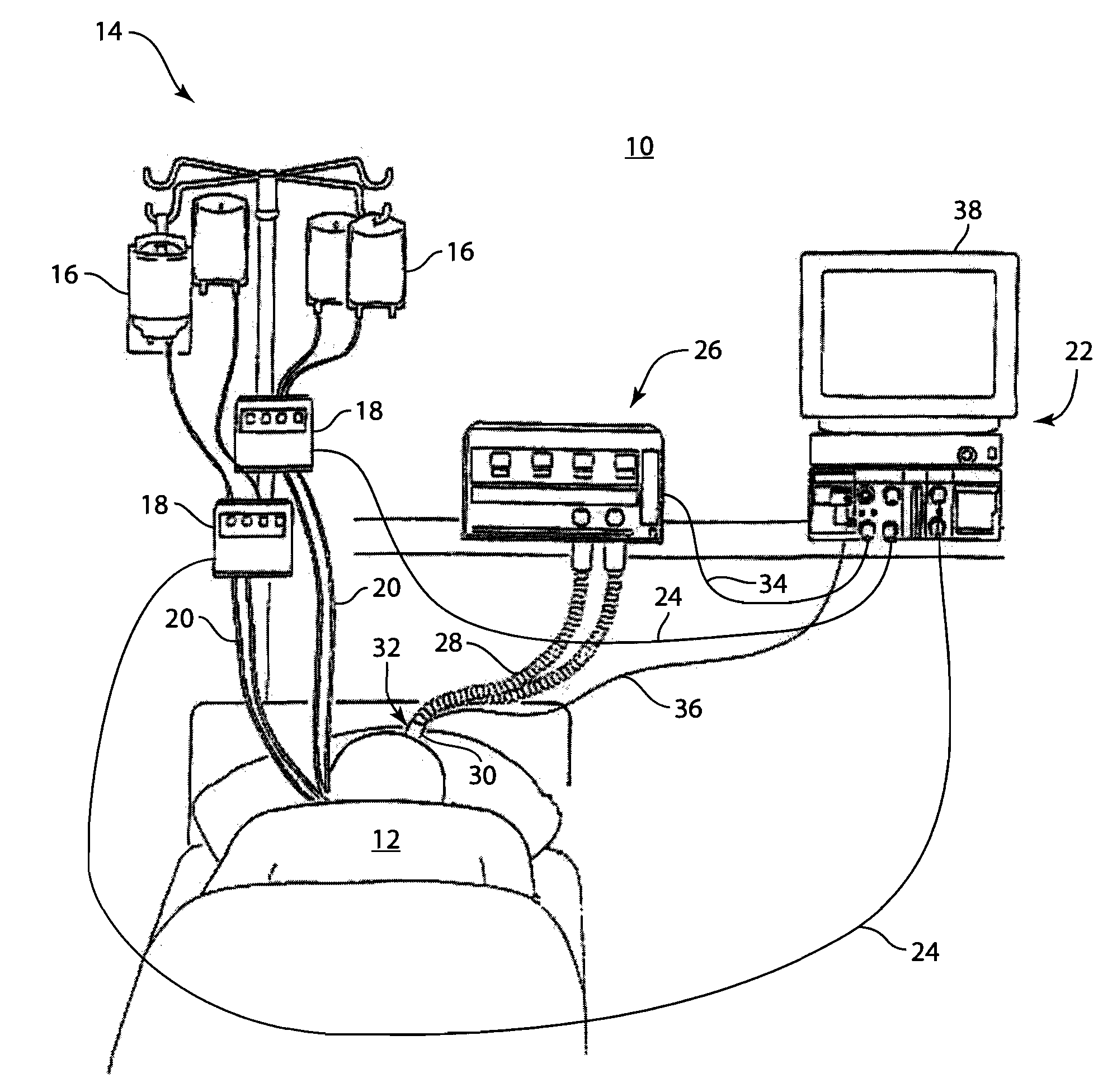

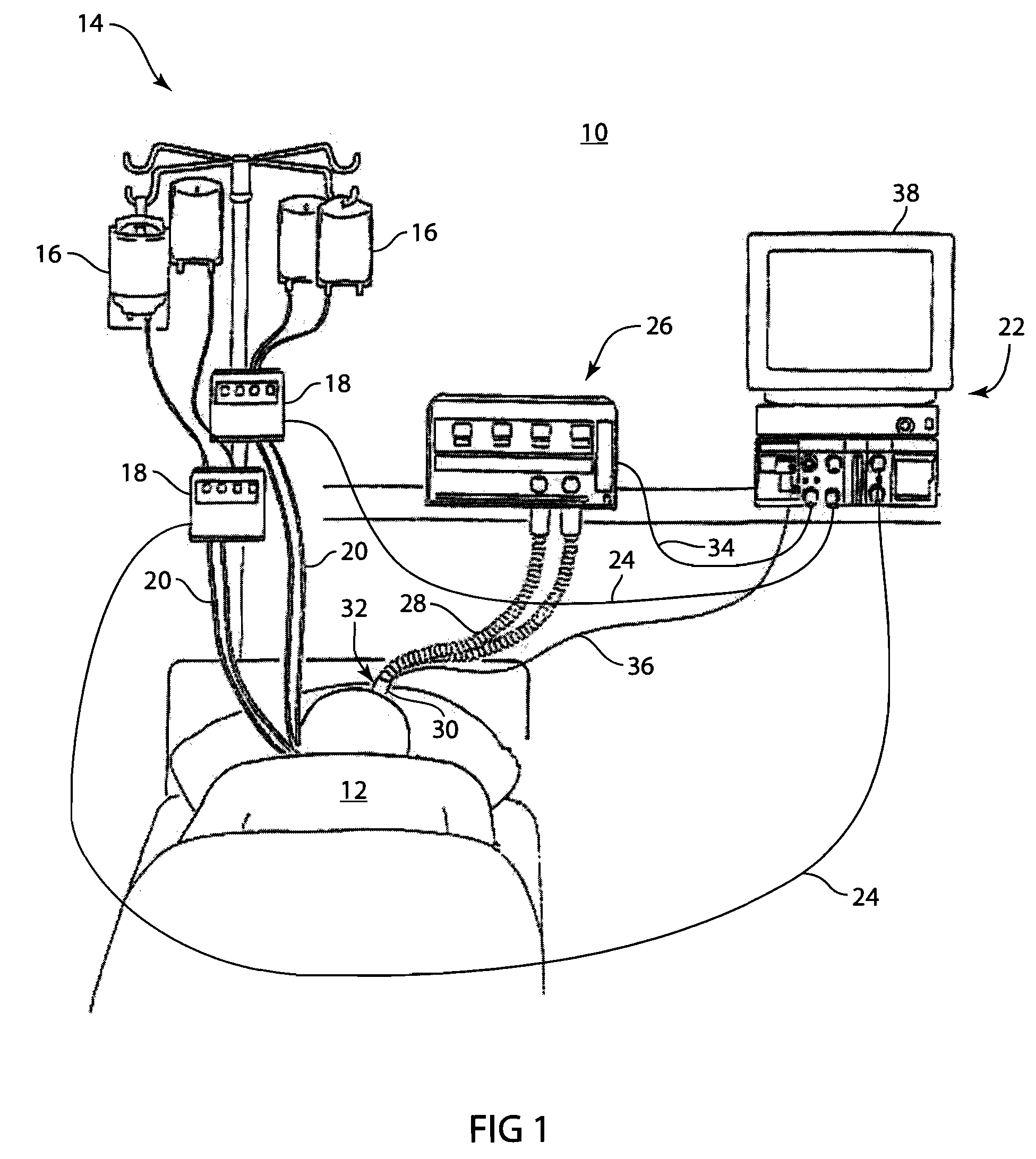

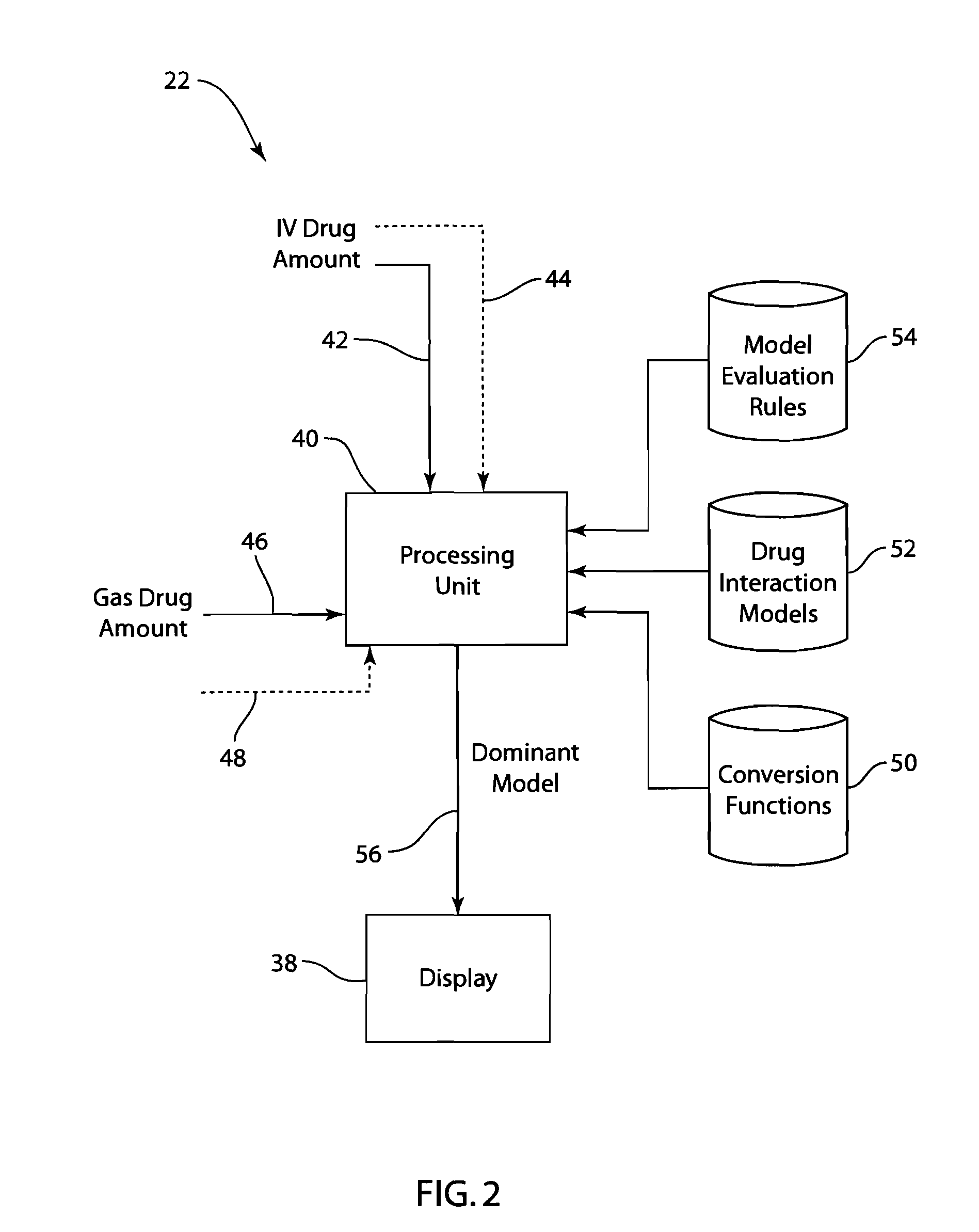

System and Method of Modeling the Pharmacodynamic Effect to Drugs Delivered to a Patient

A system and method of modeling the pharmacodynamic effect of drugs delivered to a patient. The system includes a model database comprising a first drug interaction model and a second drug interaction model. A processing unit determines a first pharmacodynamic effect and a second pharmacodynamic effect and using a dominance rule to compare the first pharmacodynamic effect and a second pharmacodynamic effect to determine a dominant interaction model. A graphical display connected to the processing unit presents the determined dominant interaction model. The method includes the steps of obtaining first, second, and third drug concentrations, applying a first model that models a first pharmacodynamic effect, applying a second model that models a second pharmacodynamic effect and comparing the first pharmacodynamic effect to the second pharmacodynamic effect to determine which of the first model and the second model is the dominant pharmacodynamic model, and presenting the determined dominant pharmacodynamic model on a graphic display.

Owner:GENERAL ELECTRIC CO

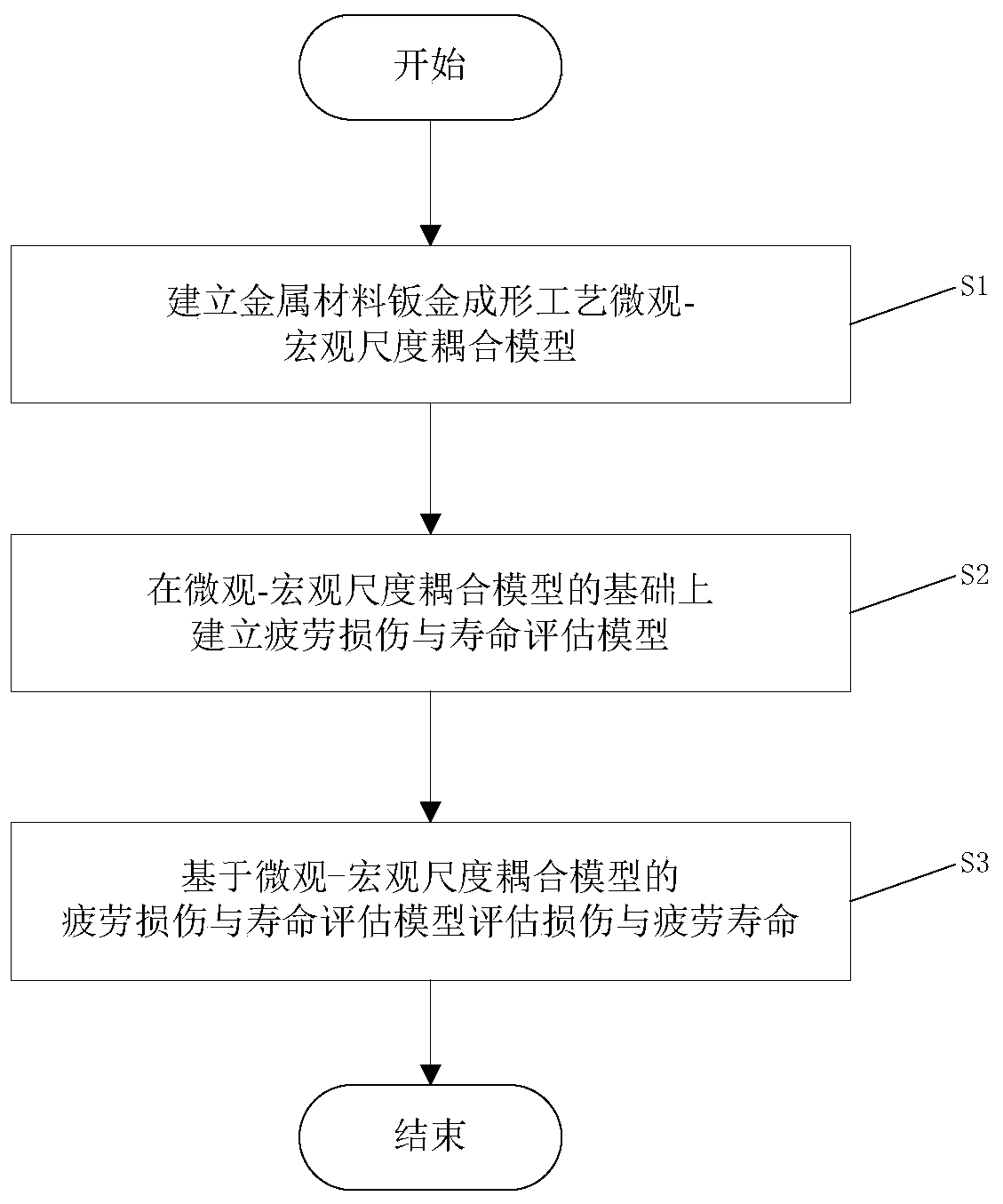

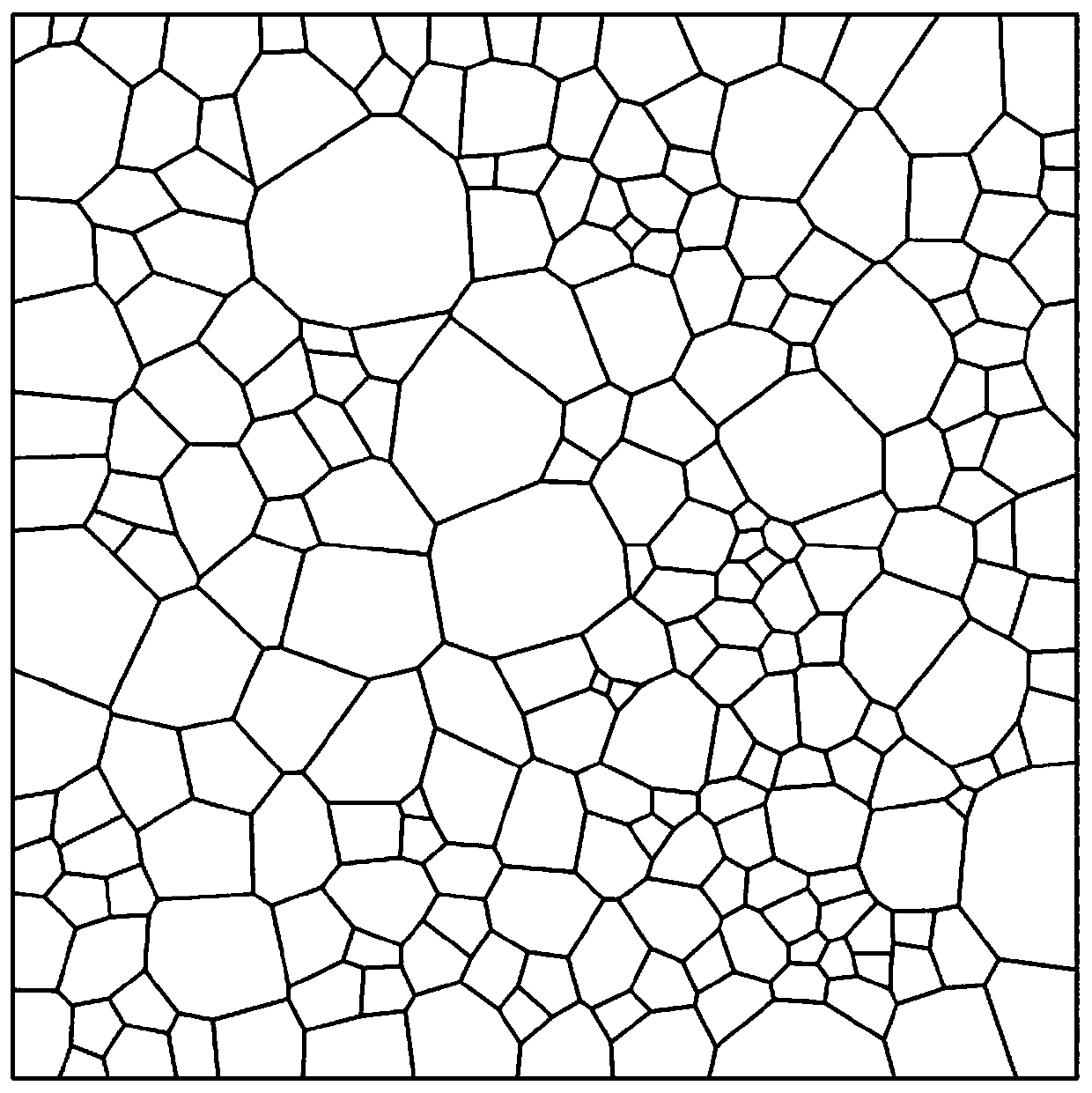

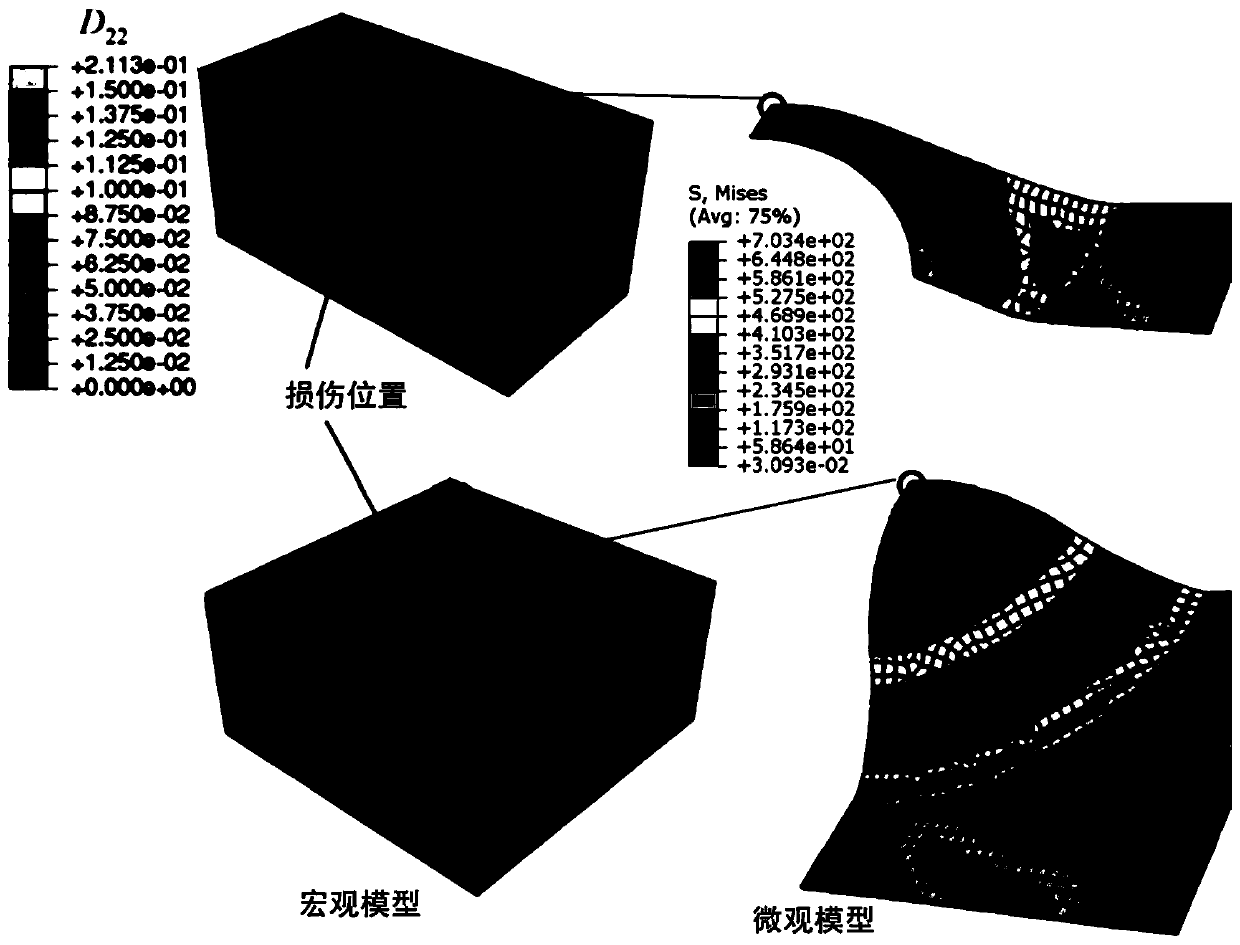

Method for evaluating damage and fatigue life of microscopic-macroscopic scale sheet metal forming process model

ActiveCN110211645ADesign optimisation/simulationChemical data visualisationFatigue damageMacroscopic scale

The invention discloses a method for evaluating damage and fatigue life of a microscopic-macroscopic scale sheet metal forming process model. According to the method of the invention, a microscopic plastic constitutive model is established and macro geometry is coupled; furthermore sheet metal forming process simulation is performed; based on sheet metal forming process simulation, a microscopic-macroscopic coupling fatigue damage model is established for performing fatigue life simulation; a sheet metal forming process and a fatigue failure mechanism are researched, thereby supplying theoretical guidance and technology optimization basis for engineering application. Sheet metal forming process material performance and plastic deformation evolution distribution are researched in a microscopic aspect. Influence and contribution degree of microscopic characteristics such as crystal grain size and orientation distribution and precipitated phase distribution to the sheet metal forming process are researched. Furthermore the macroscopic model and process researching fatigue damage are coupled, and the component fatigue life is evaluated. The invention provides the reliable high-efficiency calculating model and the evaluating method. Establishment of the related model and the algorithm has important science innovation and high engineering application value.

Owner:SICHUAN UNIV

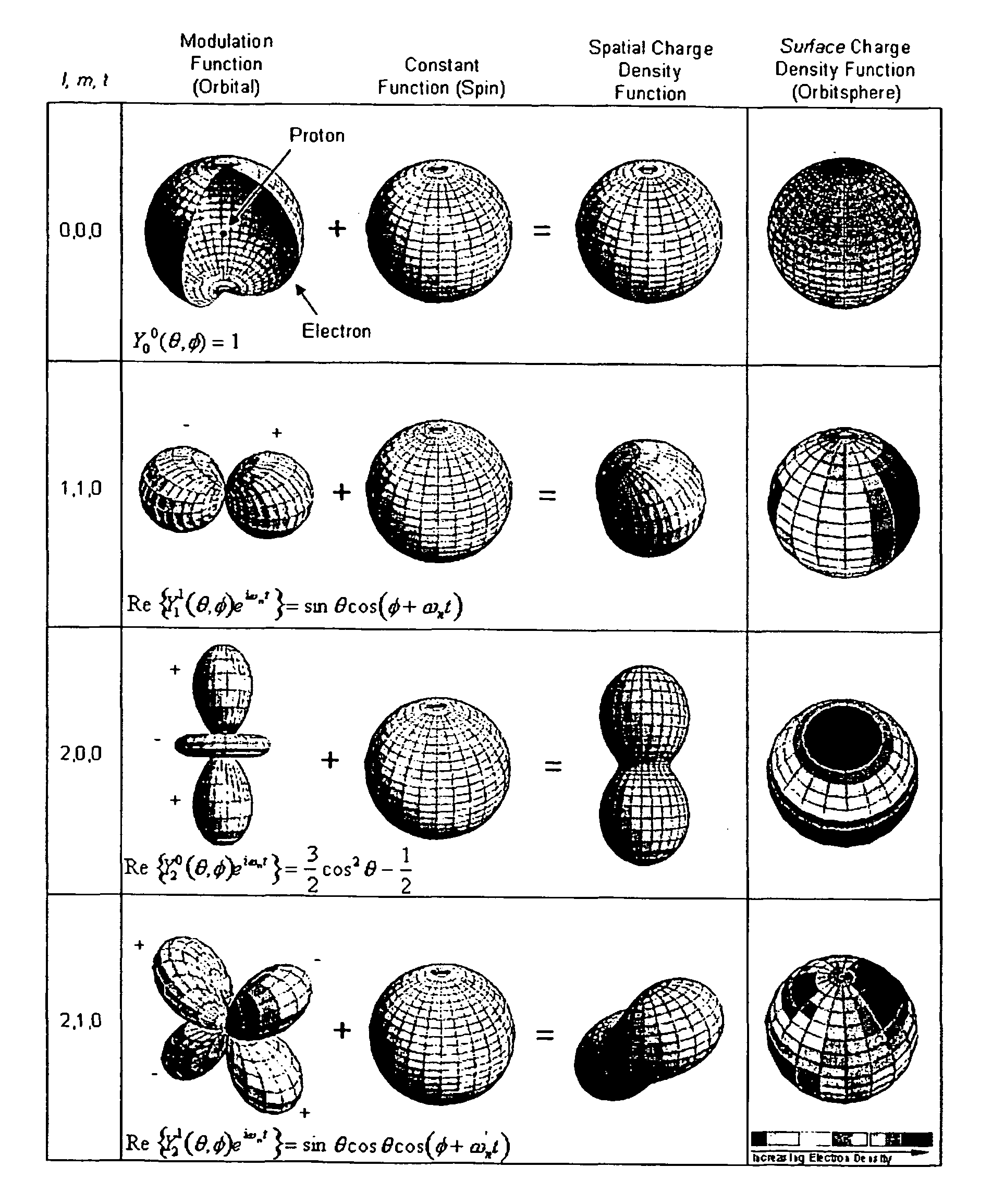

Method and system of computing and rendering the nature of the excited electronic states of atoms and atomic ions

InactiveUS7689367B2Chemical property predictionRadiation/particle handlingDisplay deviceMaxwell's equations

A method and system of physically solving the charge, mass, and current density functions of excited-state atoms and atomic ions using Maxwell's equations and computing and rendering the nature of excited-state electrons using the solutions. The results can be displayed on visual or graphical media. The display can be static or dynamic such that electron spin and rotation motion can be displayed in an embodiment. The displayed information is useful to anticipate reactivity and physical properties. The insight into the nature of excited-state electrons can permit the solution and display of those of other atoms and atomic ions and provide utility to anticipate their reactivity and physical properties as well as spectral absorption and emission to lead to new optical materials and light sources.

Owner:BRILLIANT LIGHT POWER

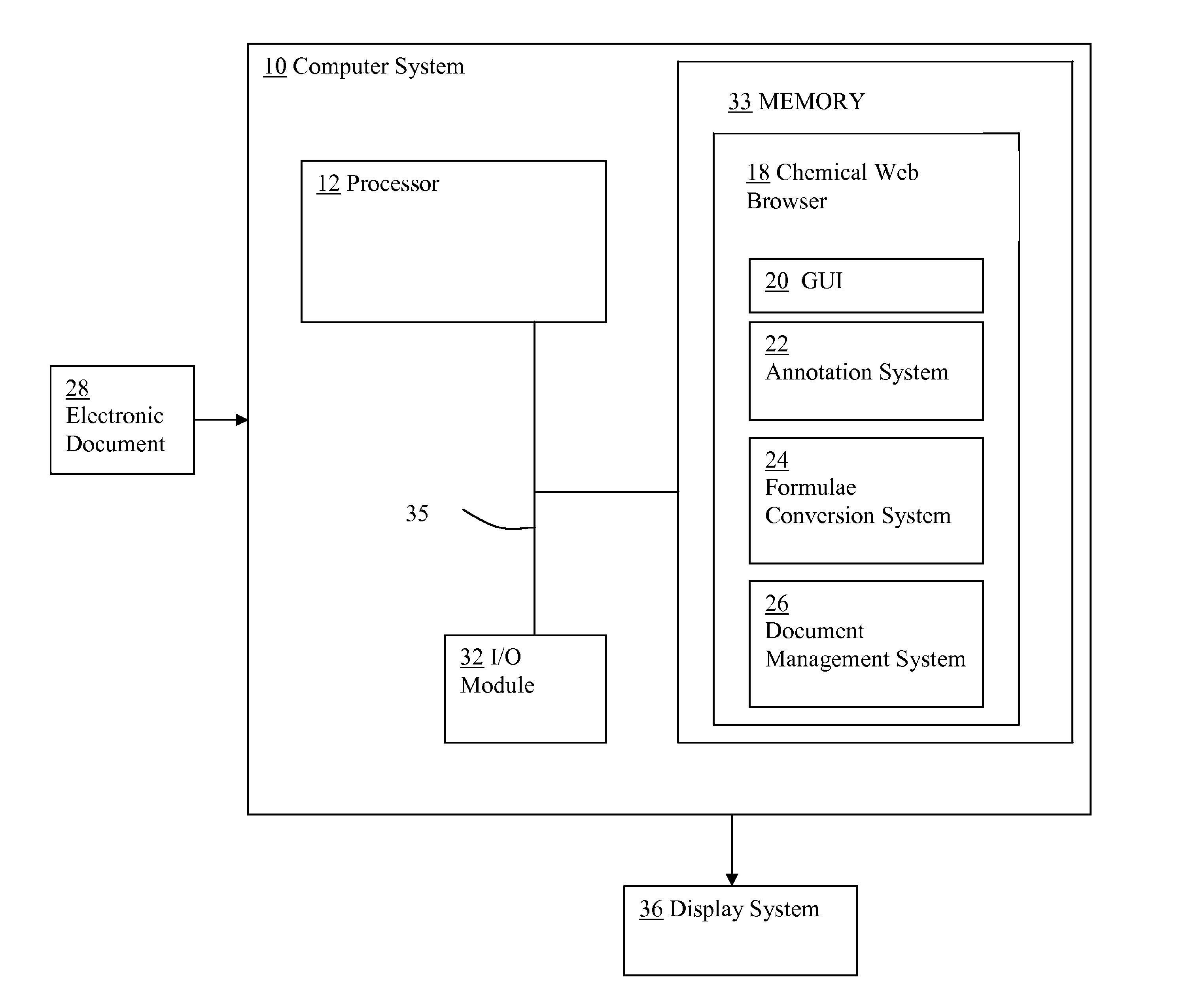

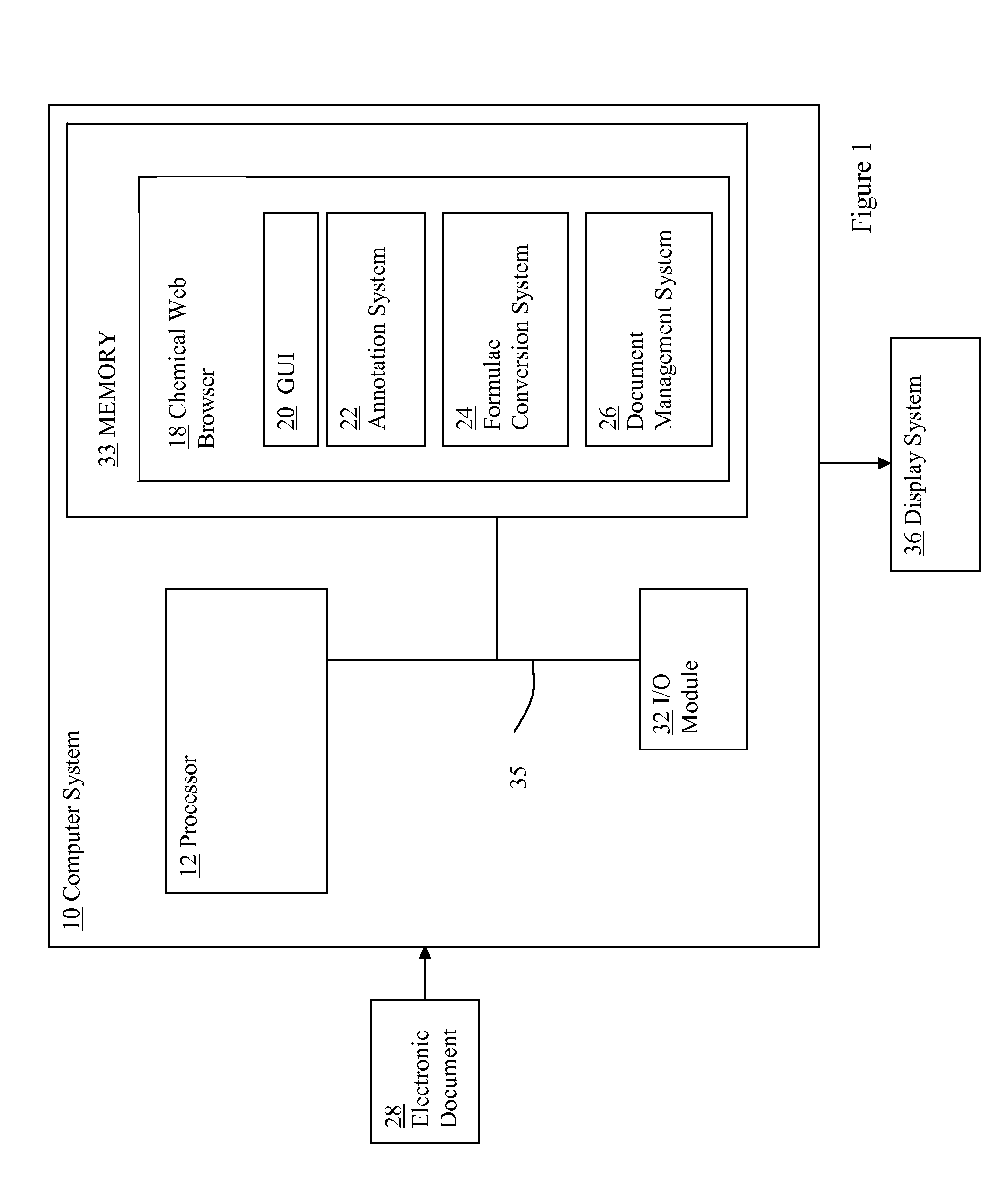

Chemical web browser

InactiveUS8407578B2Cheminformatics data warehousingNatural language data processingChemical structureWeb browser

The present invention relates to a system, method and program product for a chemical web browser. A chemical web browser including a document system for accessing a document containing at least one chemical name is provided. A chemical annotation system identifies the at least one chemical name within the document. A chemical formulae conversion system associates a chemical structure with the identified chemical name. The chemical structure is displayed.

Owner:INT BUSINESS MASCH CORP

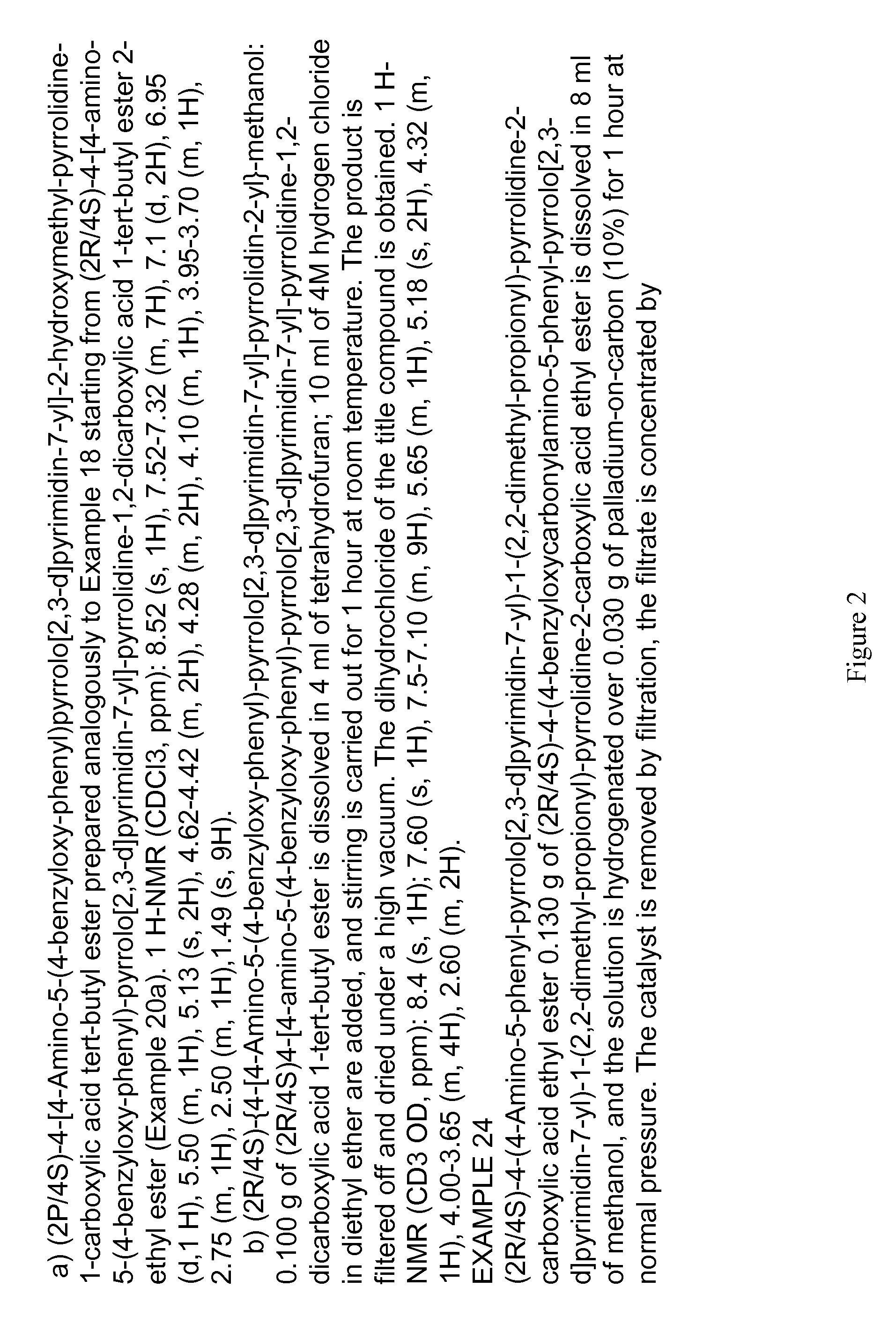

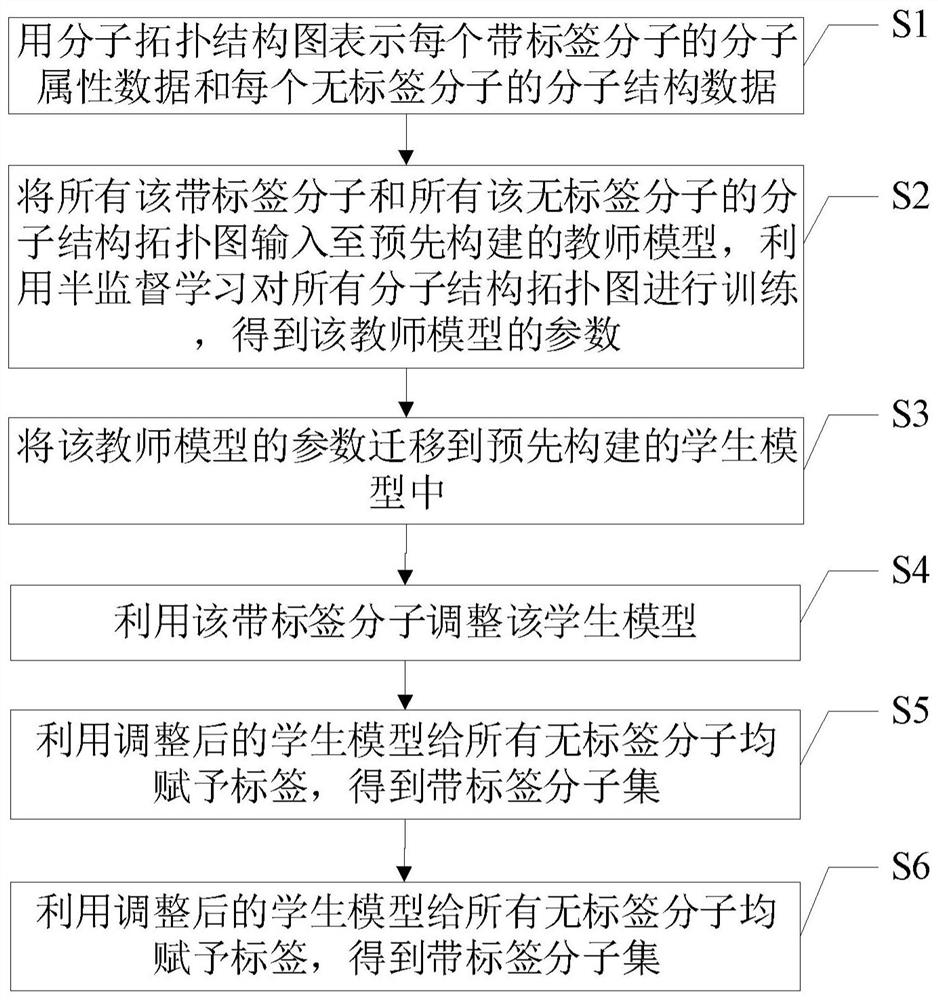

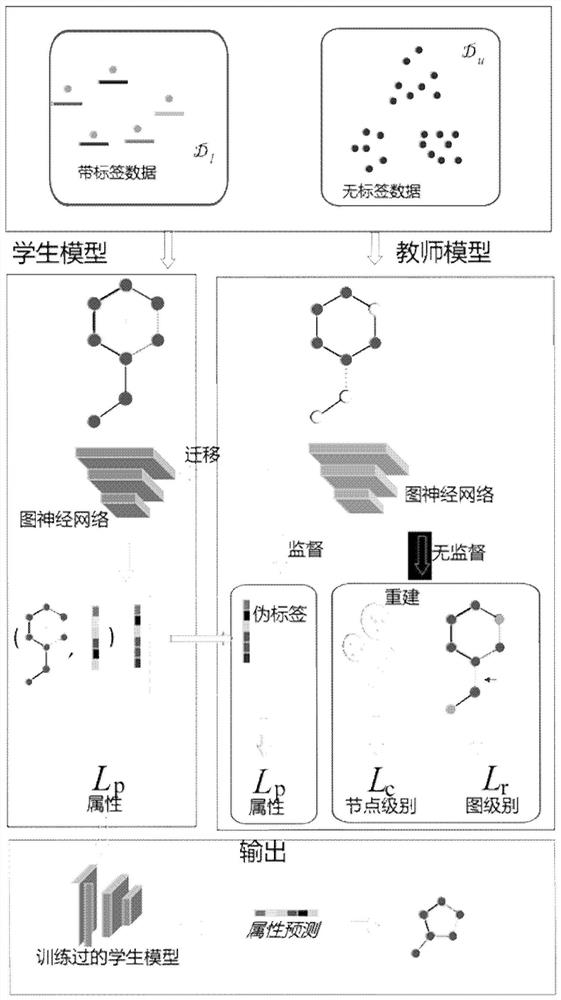

Molecular attribute determination method and device, electronic equipment and storage medium

ActiveCN111724867ASame prediction accuracyChemical property predictionChemical data visualisationAlgorithmTheoretical computer science

The invention discloses a molecular attribute determination method and device, electronic equipment and a storage medium, belonging to the technical field of molecules. The method comprise the following steps: S1, representing molecular attribute data of each labeled molecule and molecular structure data of each unlabeled molecule by using molecular topological structure diagrams; S2, inputting the molecular topological structure diagrams of all the labeled and unlabeled molecules into a pre-constructed teacher model, and training all the molecular topological structure diagrams by utilizing semi-supervised learning to obtain parameters of a teacher model; S3, migrating the parameters of the teacher model to a pre-constructed student model; S4, adjusting the student model by using labeledmolecules; S5, using the adjusted student model to assign labels to all the unlabeled molecules to obtain a labeled molecule set; S6, feeding back the labeled molecular set to the teacher model; and S7, repeatedly executing the steps S2 to S6 until the teacher model and the student model are both converged, and predicting molecular attributes by utilizing the converged student model. According tothe invention, the attributes of unknown molecules can be accurately predicted.

Owner:UNIV OF SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com