Multi-dimensional predicting method for strength of braided ceramic base composite material

A composite material and prediction method technology, applied in computer material science, instrumentation, computational theoretical chemistry, etc., can solve the problem of inability to analyze the microscopic failure process of woven ceramic matrix composite materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

[0049] Implementation Case: Strength Prediction of Plain Weave SiC / SiC Composites

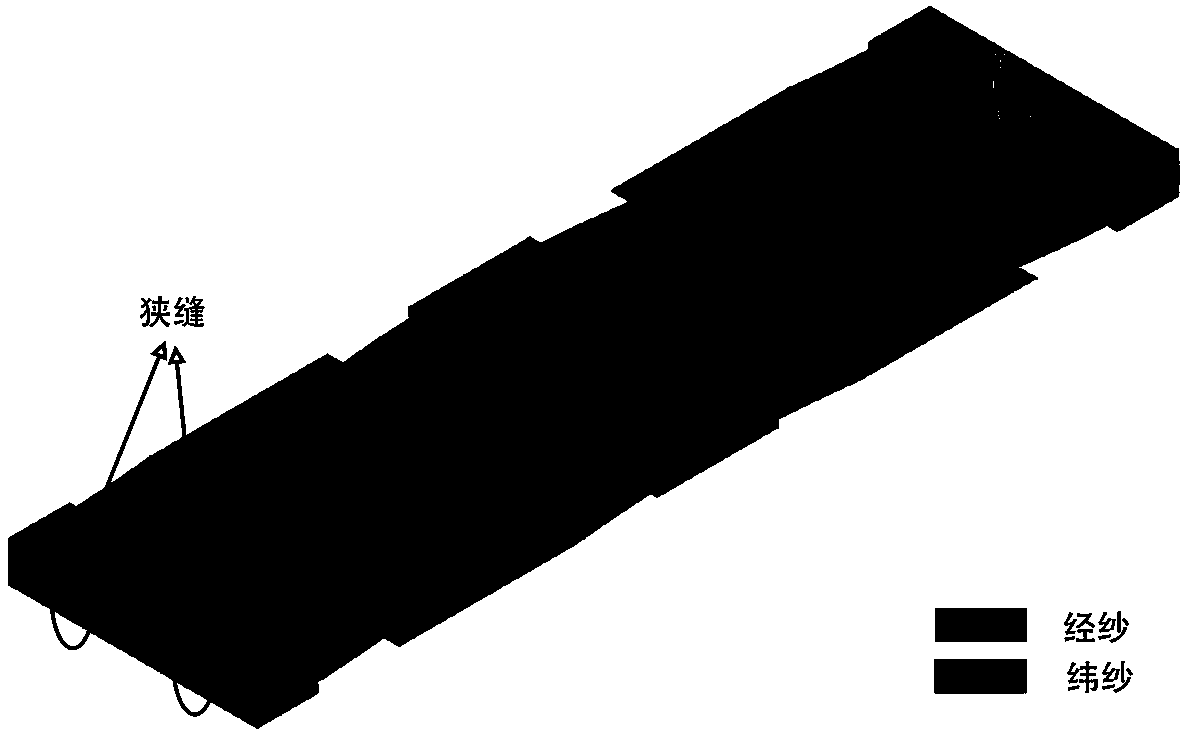

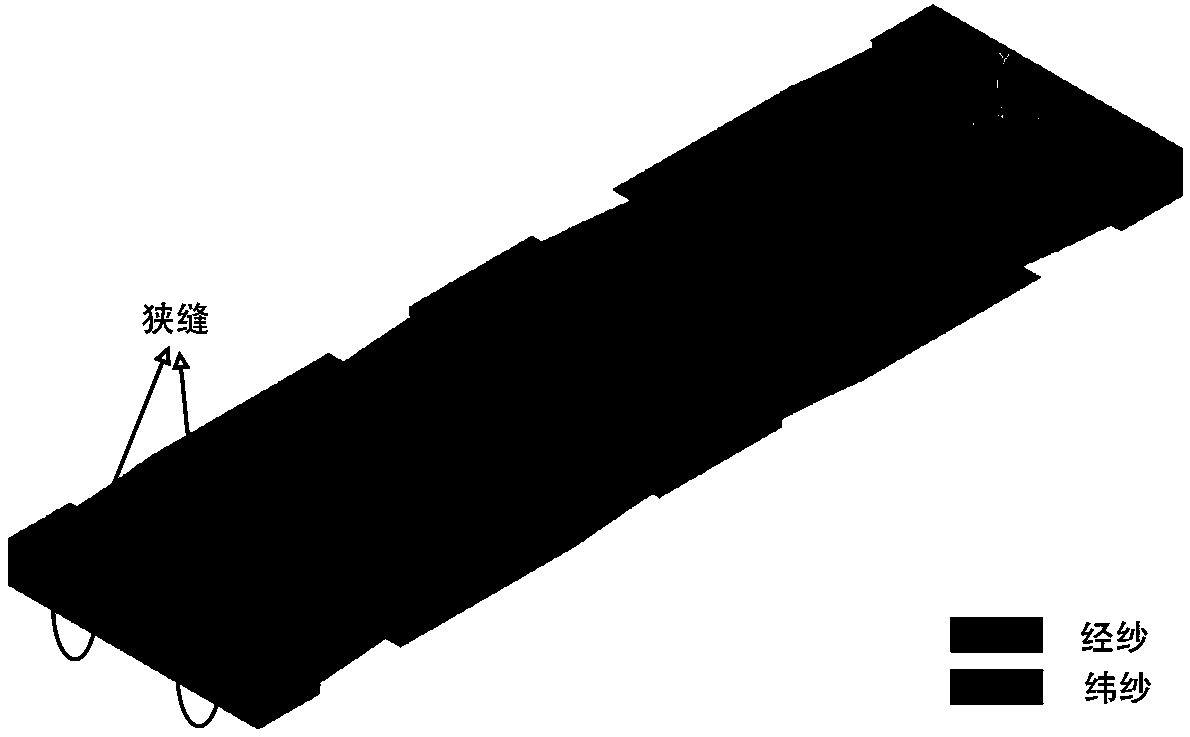

[0050] Step 1: Obtain the mesoscopic geometric parameters of braided ceramic matrix composites

[0051] The following assumptions are made on the mesoscopic geometry of woven ceramic matrix composites: a) the warp yarn direction curve satisfies the form of trigonometric functions; b) the weft yarn direction is a straight line; c) the shape of the yarn interface is rectangular. Based on the above assumptions, by observing the three-view view of the mesoscopic geometric structure of the woven ceramic matrix composite, the mesoscopic geometric parameters of the woven ceramic matrix composite are obtained, including the amplitude and wavelength of the warp curve, the width of the yarn section, and the height of the warp section. As shown in Fig. 1, it is a three-view view of the mesoscopic geometric structure of the plain weave SiC / SiC composite. The mesoscopic geometric parameters obtained accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com