Method for monitoring and recognizing pulling rope corrosion and evaluating fatigue life on basis of computer vision

A technology of computer vision and fatigue life, applied in the direction of weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., to achieve the effect of improving automation, reducing manual participation, improving efficiency and

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

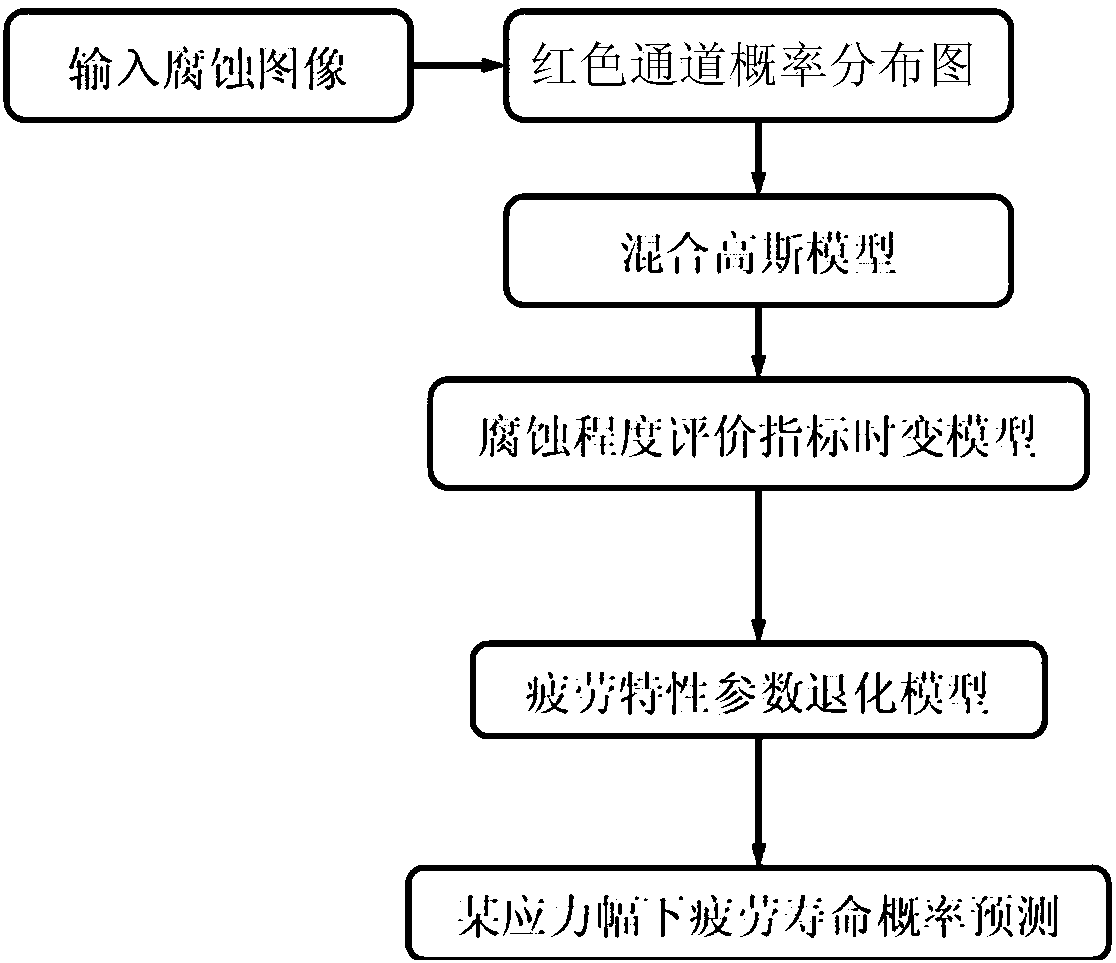

[0040] Such as figure 1 As shown, a computer vision-based cable corrosion monitoring identification and fatigue life assessment method, the steps are as follows:

[0041] Step 1, update the corrosion fatigue data set: select the area to be evaluated for the original input image, and then cut the selected area into a 64×64×3 subunit set, and the number of samples is determined according to the need; at the same time, input the uniform corrosion of the corroded steel wire degree and fatigue life information at different stress amplitudes. After completion, the newly added corrosion images will be merged into the original data set, and each corrosion image corresponds to the corresponding uniform corrosion degree and fatigue life under different stress amplitudes. So far, the corrosion fatigue data set has been updated.

[0042] Step 2, Corrosion degree evaluation model modeling: After updating the data set, draw the probability distribution diagram of the red component of the ...

Embodiment 2

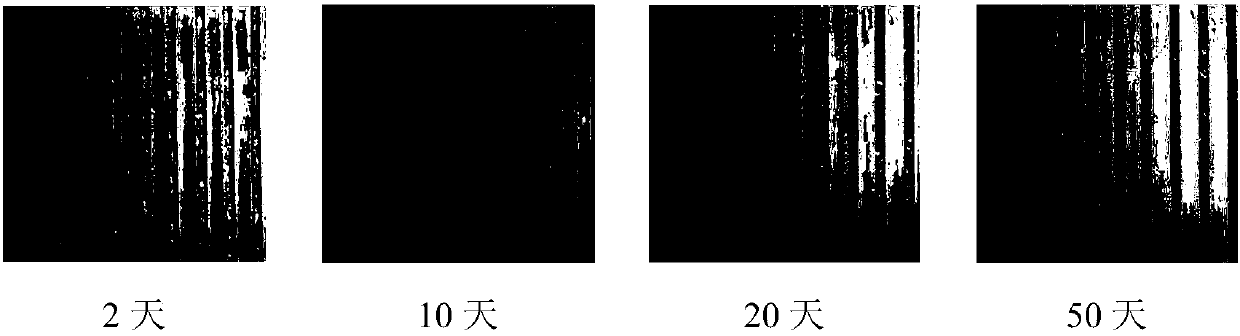

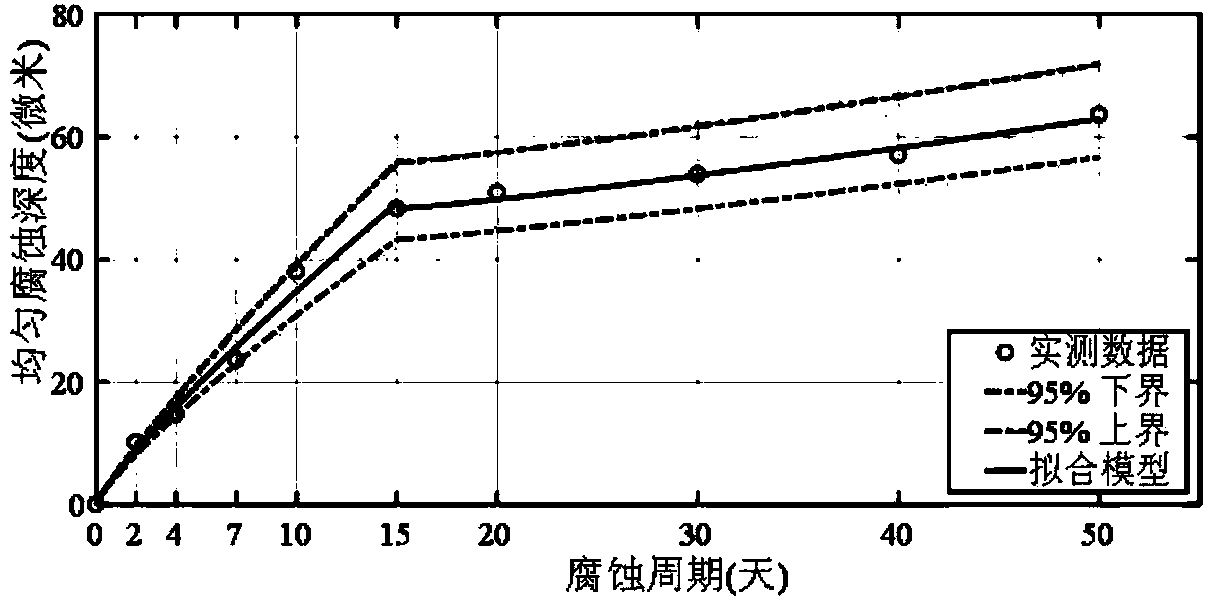

[0055] Such as Figure 3-13 Shown are the modeling results of the time-varying corrosion model, the modeling results of the fatigue life degradation model, and the corrosion fatigue evaluation results of the service cables, respectively. Compared with the fatigue life test results of steel wires in service after cable replacement, the prediction errors under each stress range are all within 15%.

[0056] Among them, the artificial accelerated corrosion test conditions are: dissolving chemically pure sodium chloride in distilled water with a conductivity not exceeding 20 μS / cm, the prepared concentration is 50g / L±5g / L, and the prepared concentration is at 25°C. At 1.05g / cm 3 , then add an appropriate amount of copper chloride dihydrate, the mass concentration reaches 0.26±0.02g / L, and add an appropriate amount of glacial acetic acid to make the pH value of the corrosion solution reach 3.0; the temperature of the salt spray box is controlled at 35±2°C. The stress ratio of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com