Patents

Literature

138 results about "Stress range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The stress range considered for the specimens is 627 MPa, 1. The effects of increased stress range from family conflicts and alcohol misuse to increasing mental health difficulties and even domestic violence.

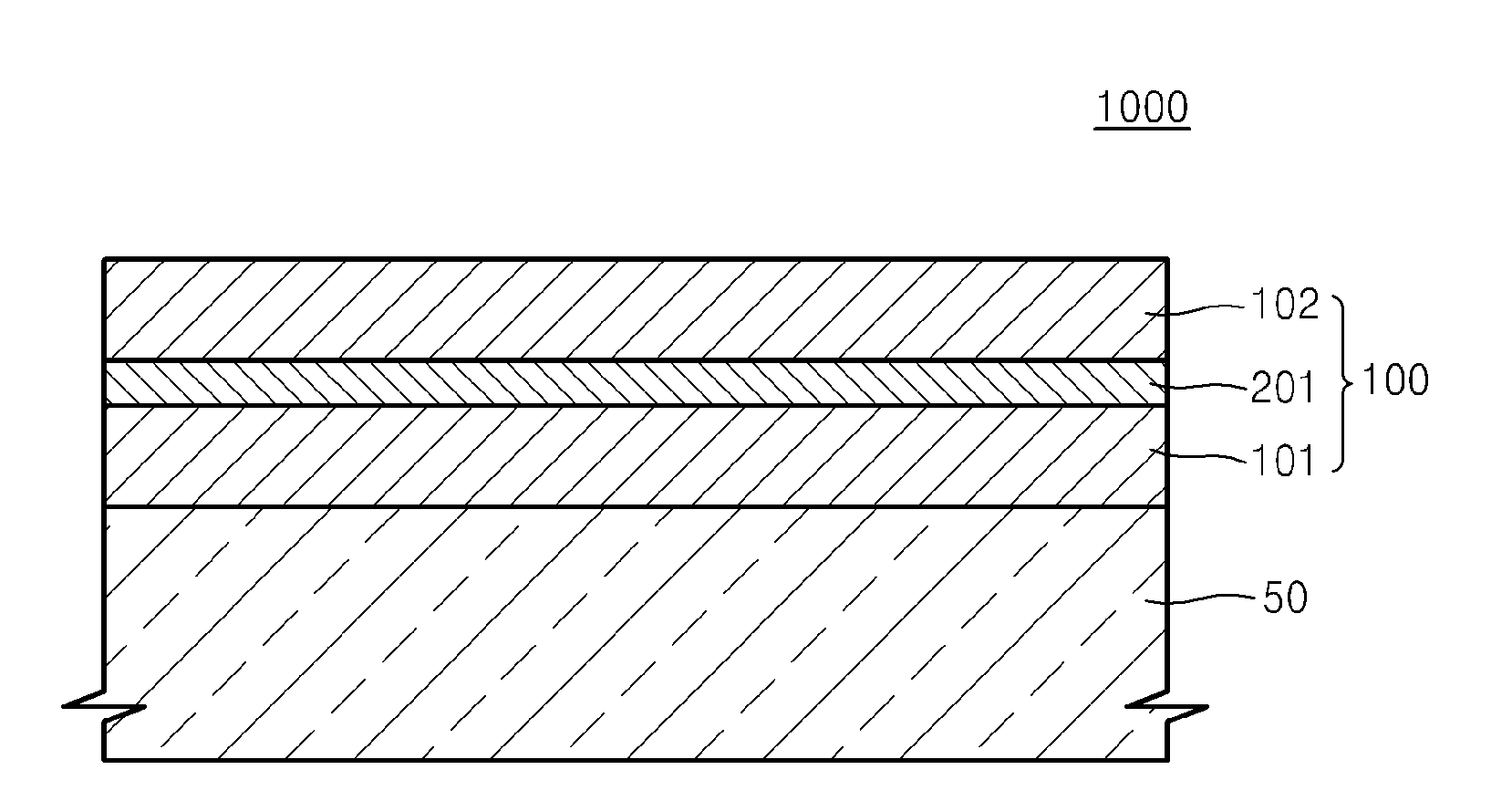

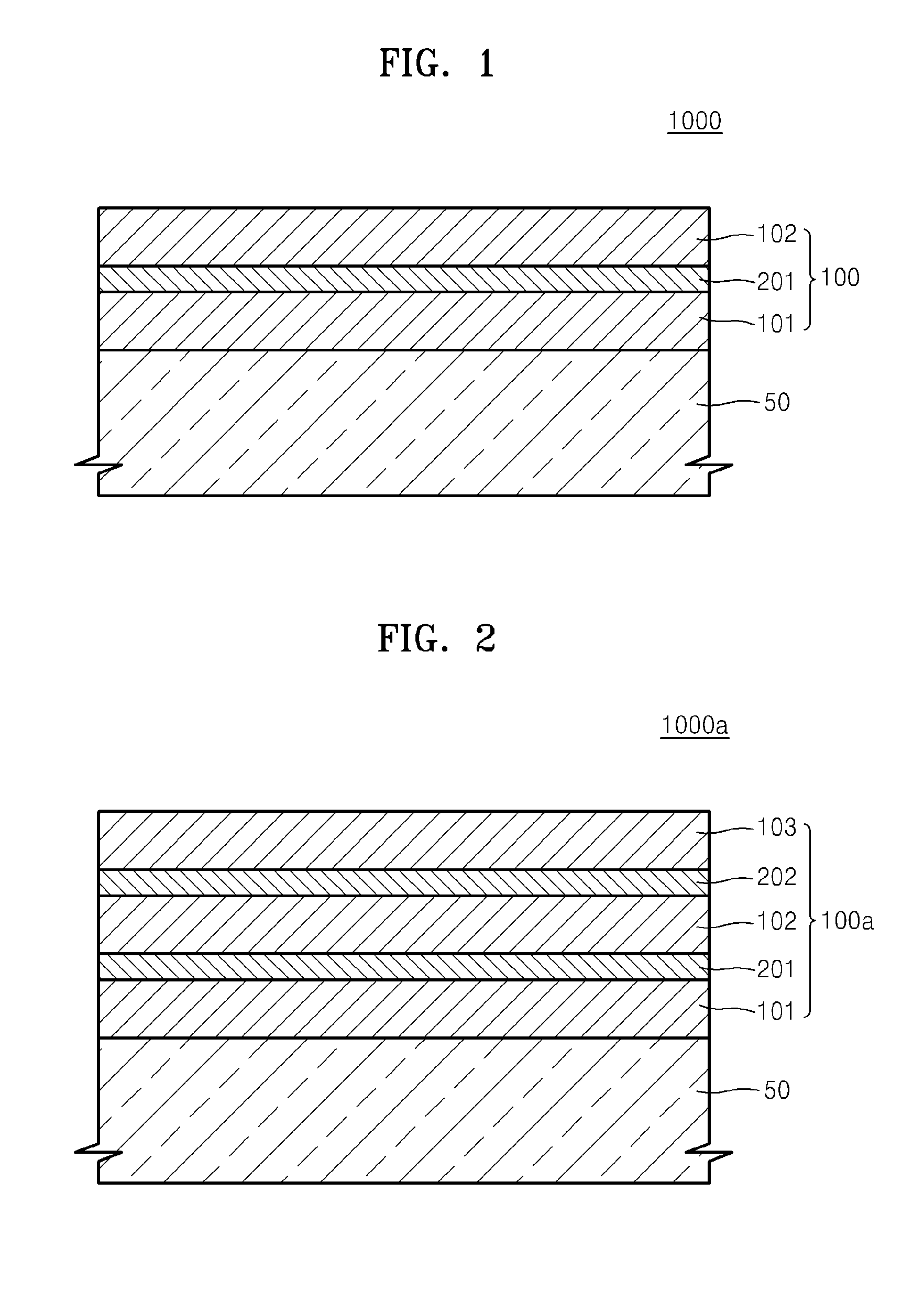

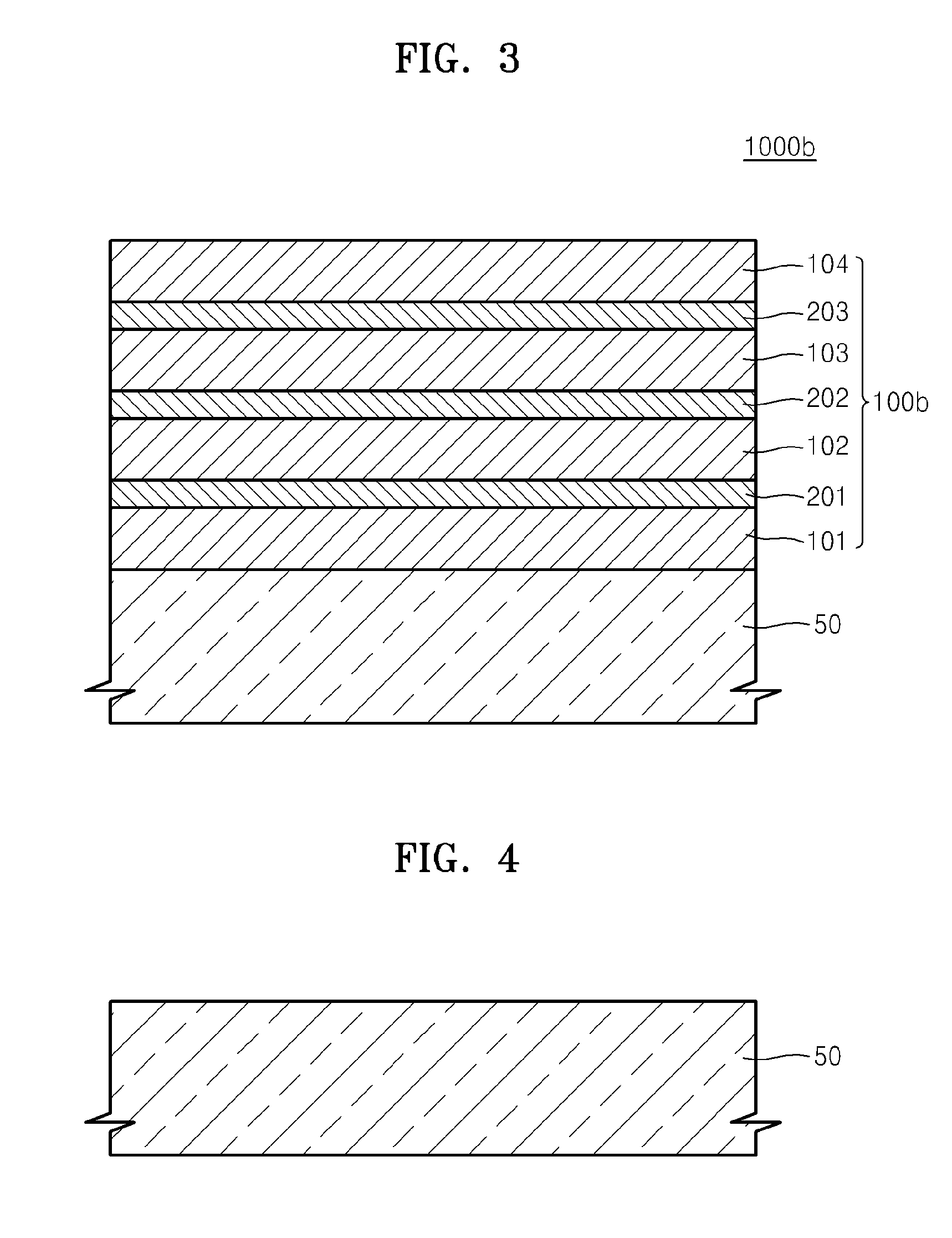

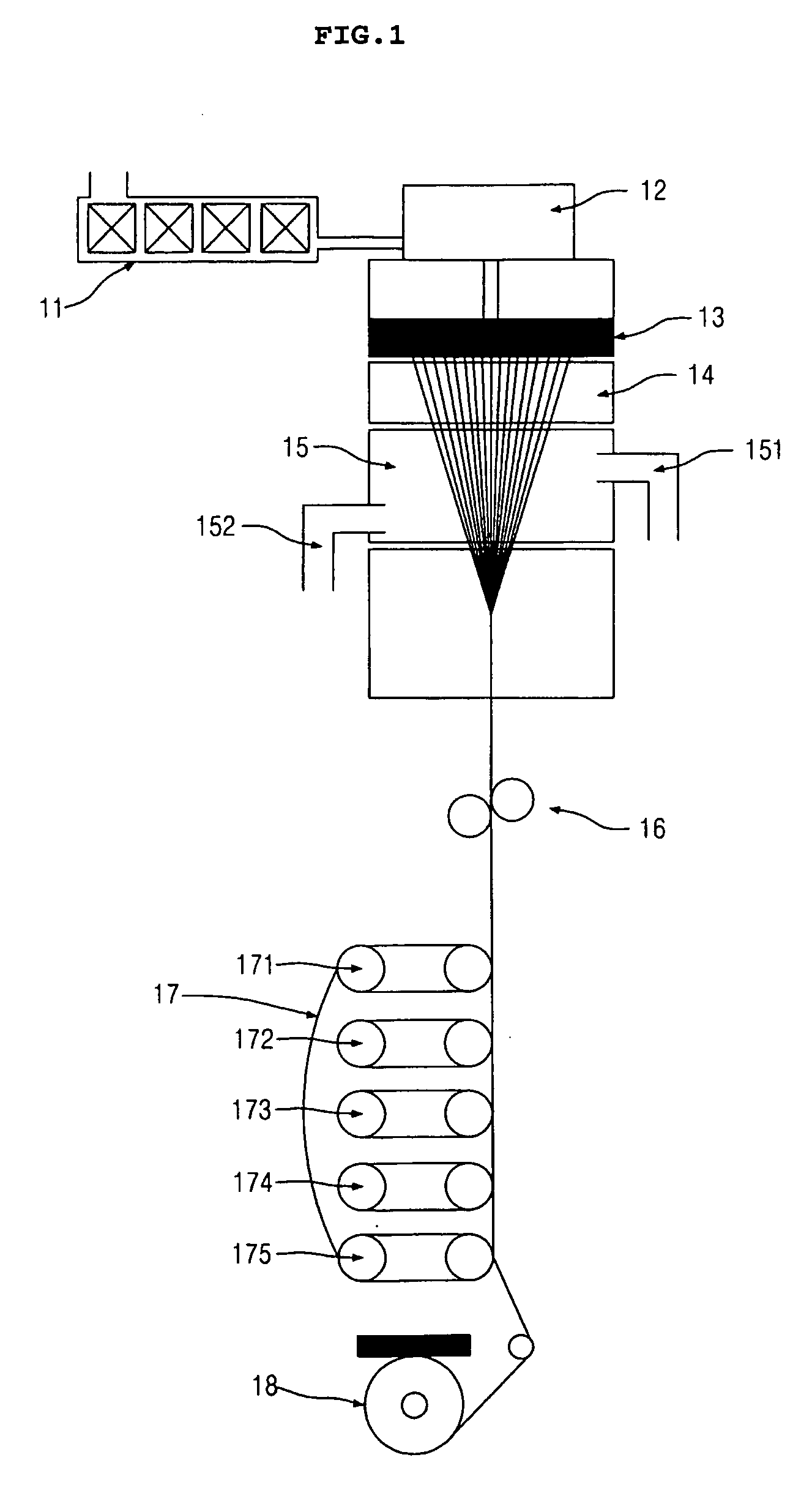

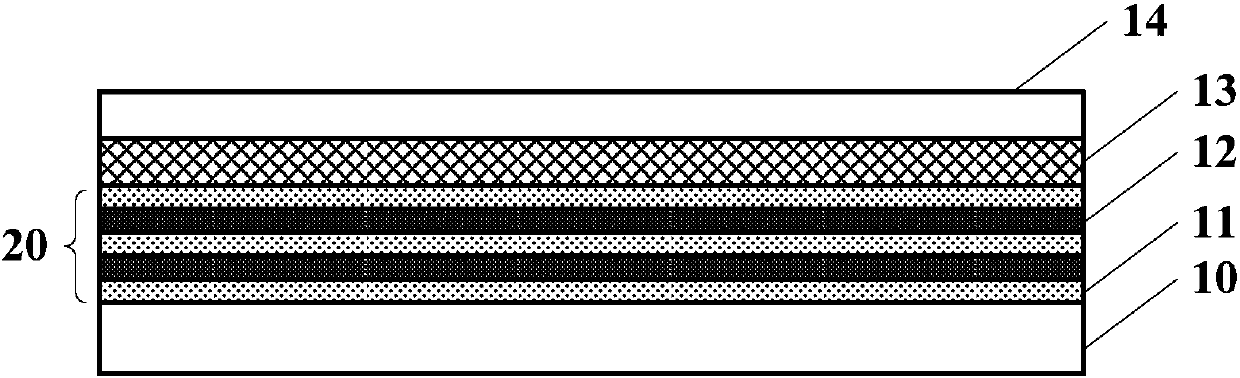

Substrate for flexible display and method of manufacturing the substrate

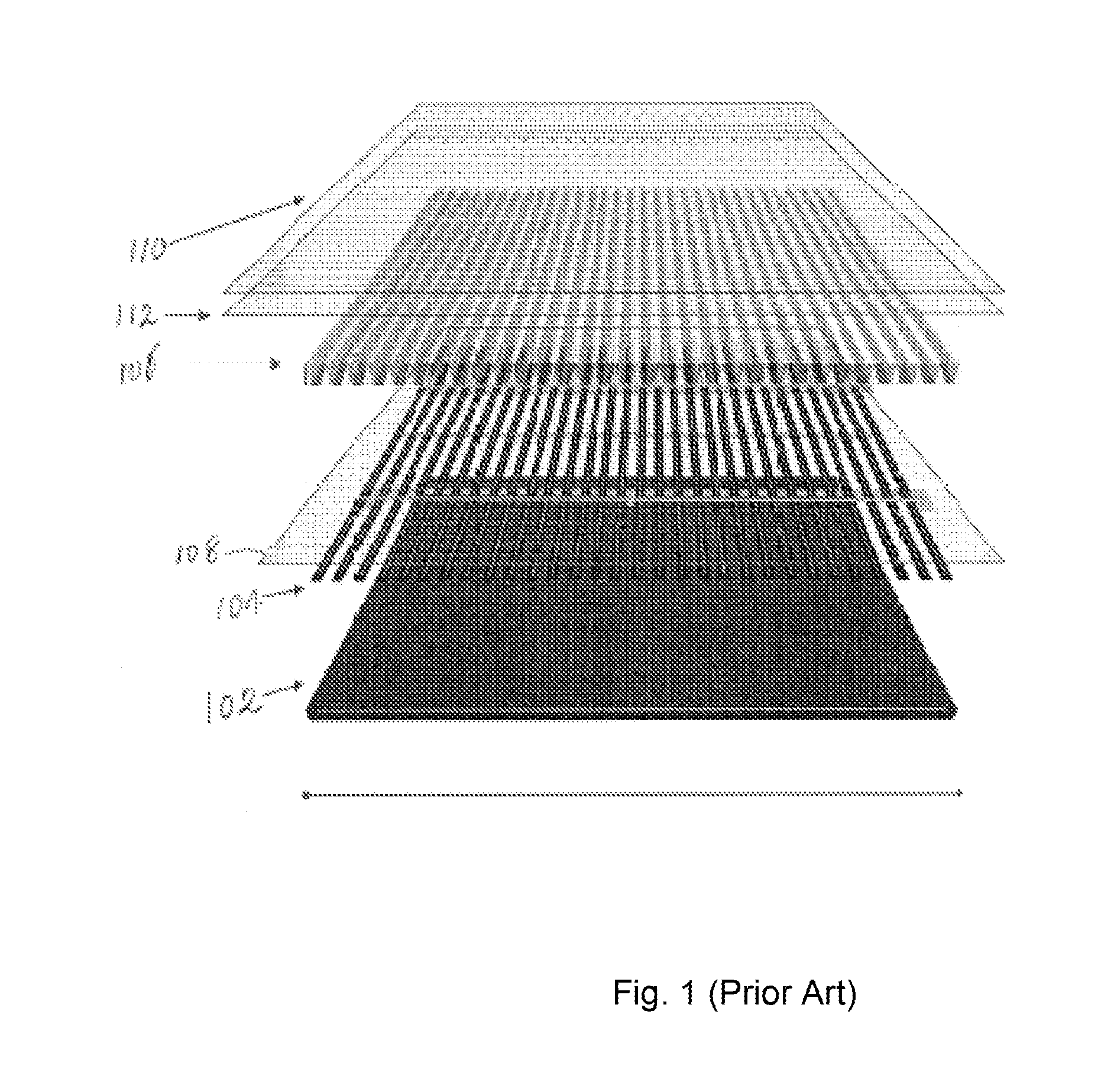

InactiveUS20120034451A1Good oxygenExcellent moisture blocking characteristicTransistorLiquid surface applicatorsVitrificationDisplay device

A substrate for a flexible display is disclosed. The substrate has a film stress range that does not affect an electronic device such as a thin film transistor, and includes a barrier layer having excellent oxygen and moisture blocking characteristics, and a method of manufacturing the substrate. The substrate includes: a plastic substrate having a glass transition temperature from about 350° C. to about 500° C.; and a barrier layer disposed on the plastic substrate, having a multi-layer structure, wherein at least one silicon oxide layer and at least one silicon nitride layer are alternately stacked on each other, and having a film stress from about −200 MPa to about 200 MPa due to the at least one silicon oxide layer and the at least one silicon nitride layer.

Owner:SAMSUNG DISPLAY CO LTD

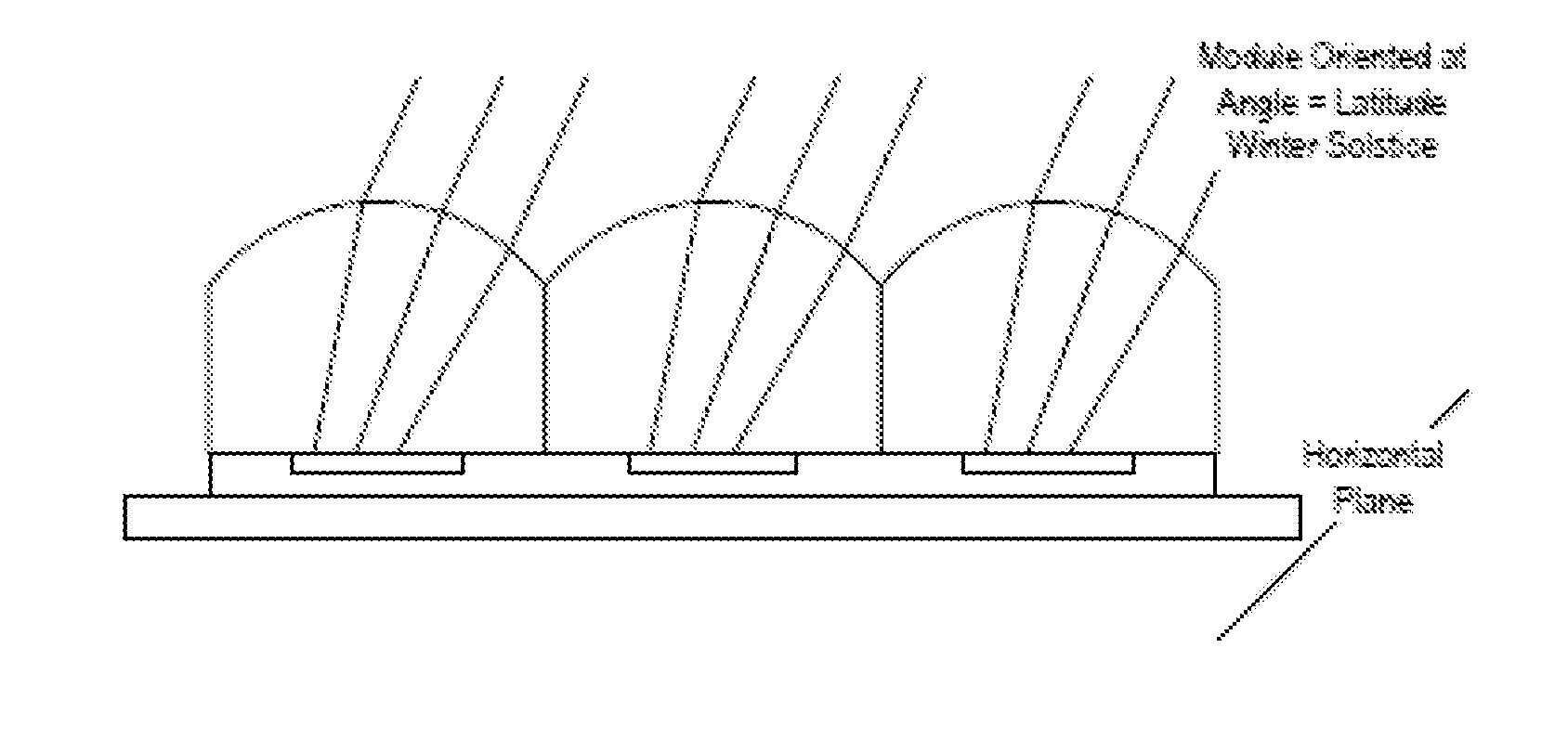

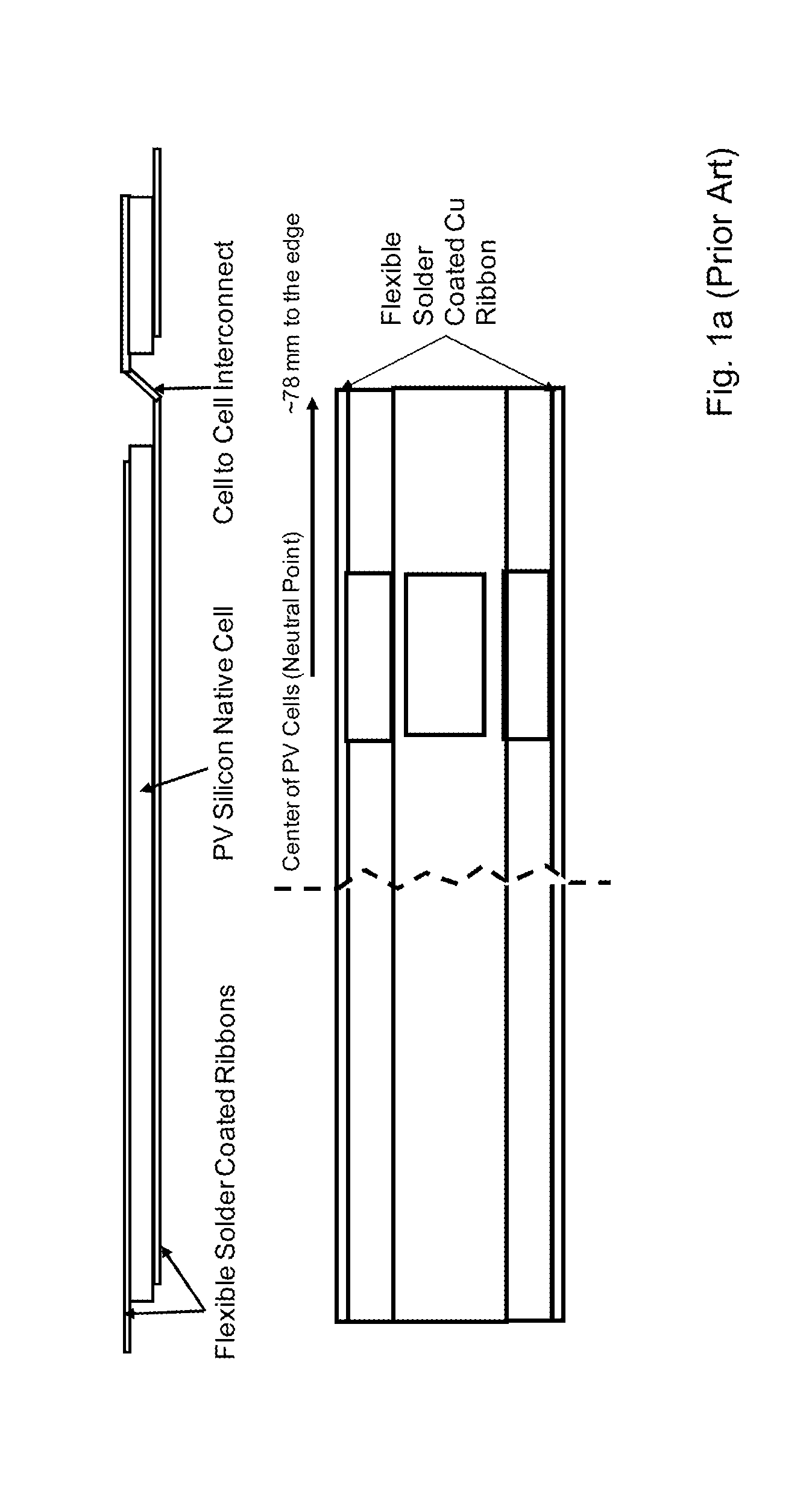

Large area concentrator lens structure and method configured for stress relief

InactiveUS20110240096A1Simple structureEliminate usePV power plantsSemiconductor/solid-state device manufacturingStress reliefConcentrator

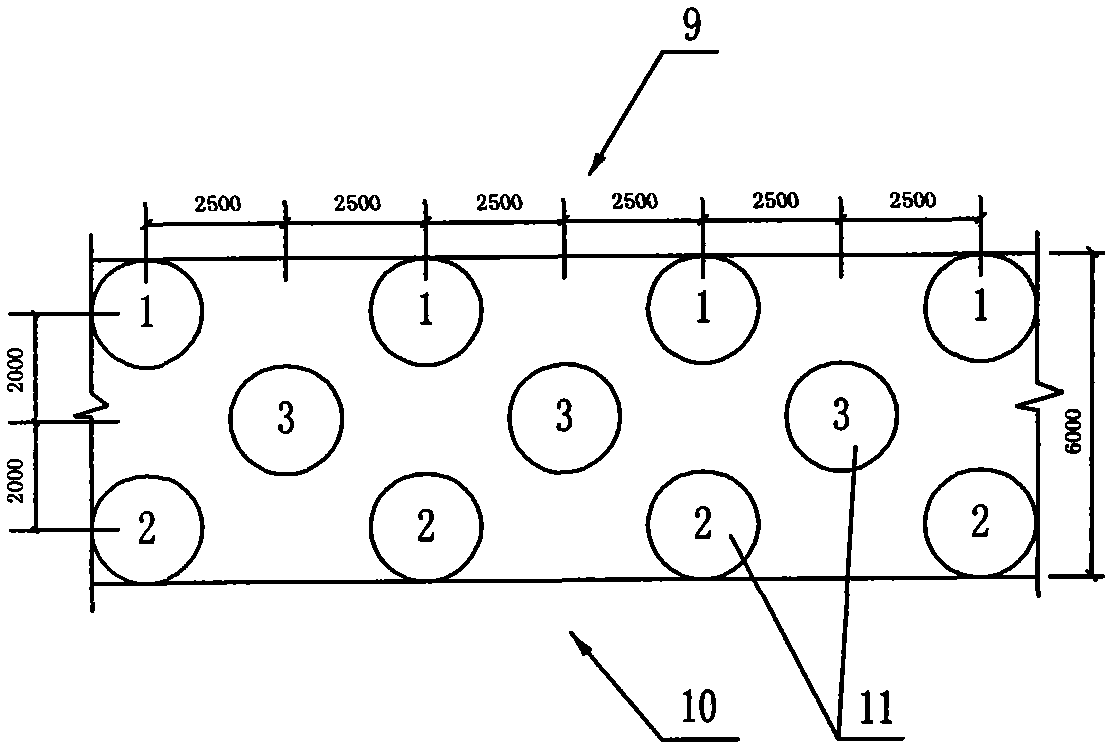

A solar module. The solar module includes a substrate member. a plurality of photovoltaic strips arranged in an array configuration overlying the substrate member. In a specific embodiment, the solar module includes a concentrator structure comprising extruded glass material operably coupled to the plurality of photovoltaic strips. A plurality of elongated annular regions are configured within the concentrator structure. The plurality of elongated annular regions are respectively coupled to the plurality of photovoltaic strips, which are configured to one or more bus bars to maintain a desired stress range.

Owner:SOLARIA CORP

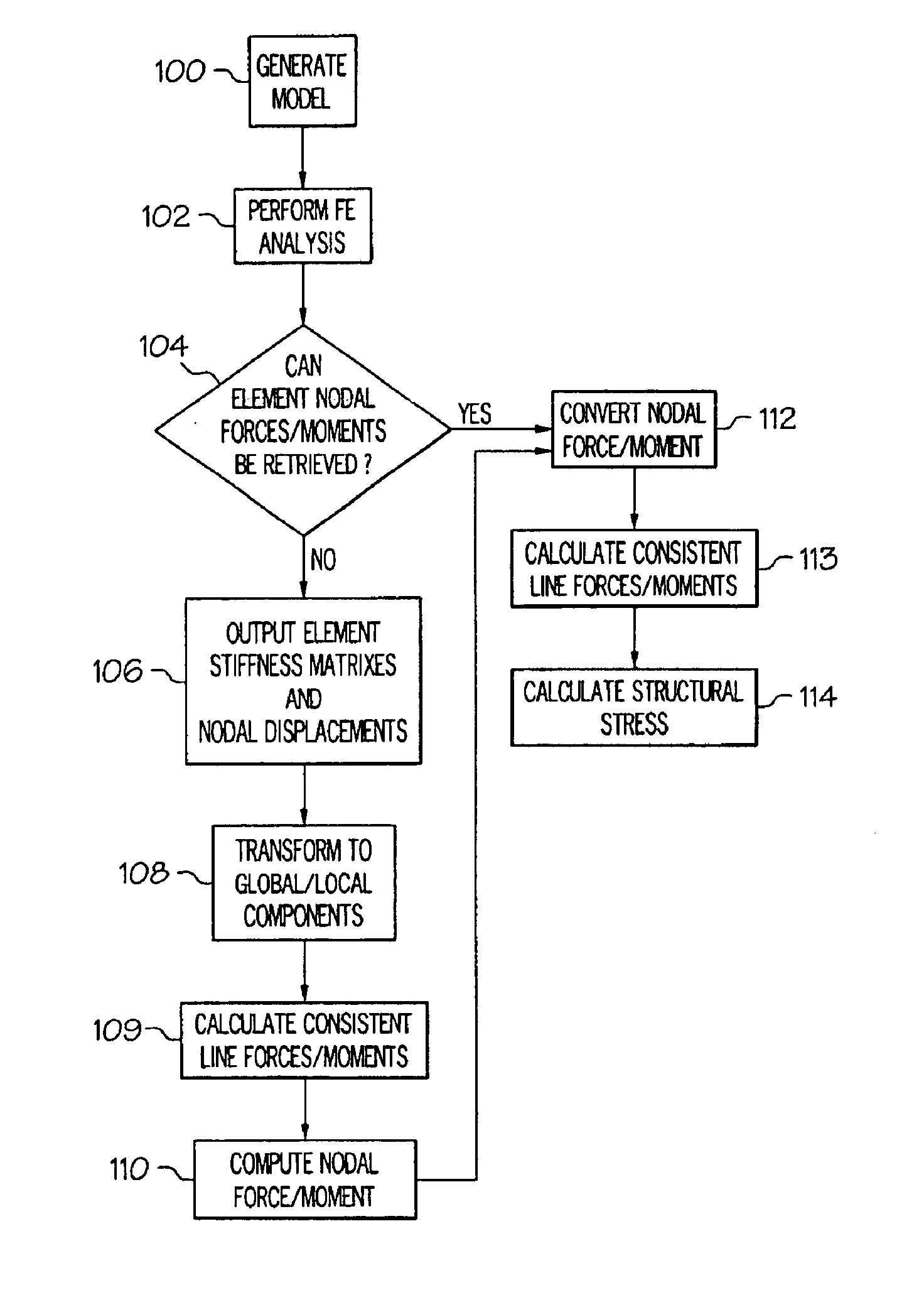

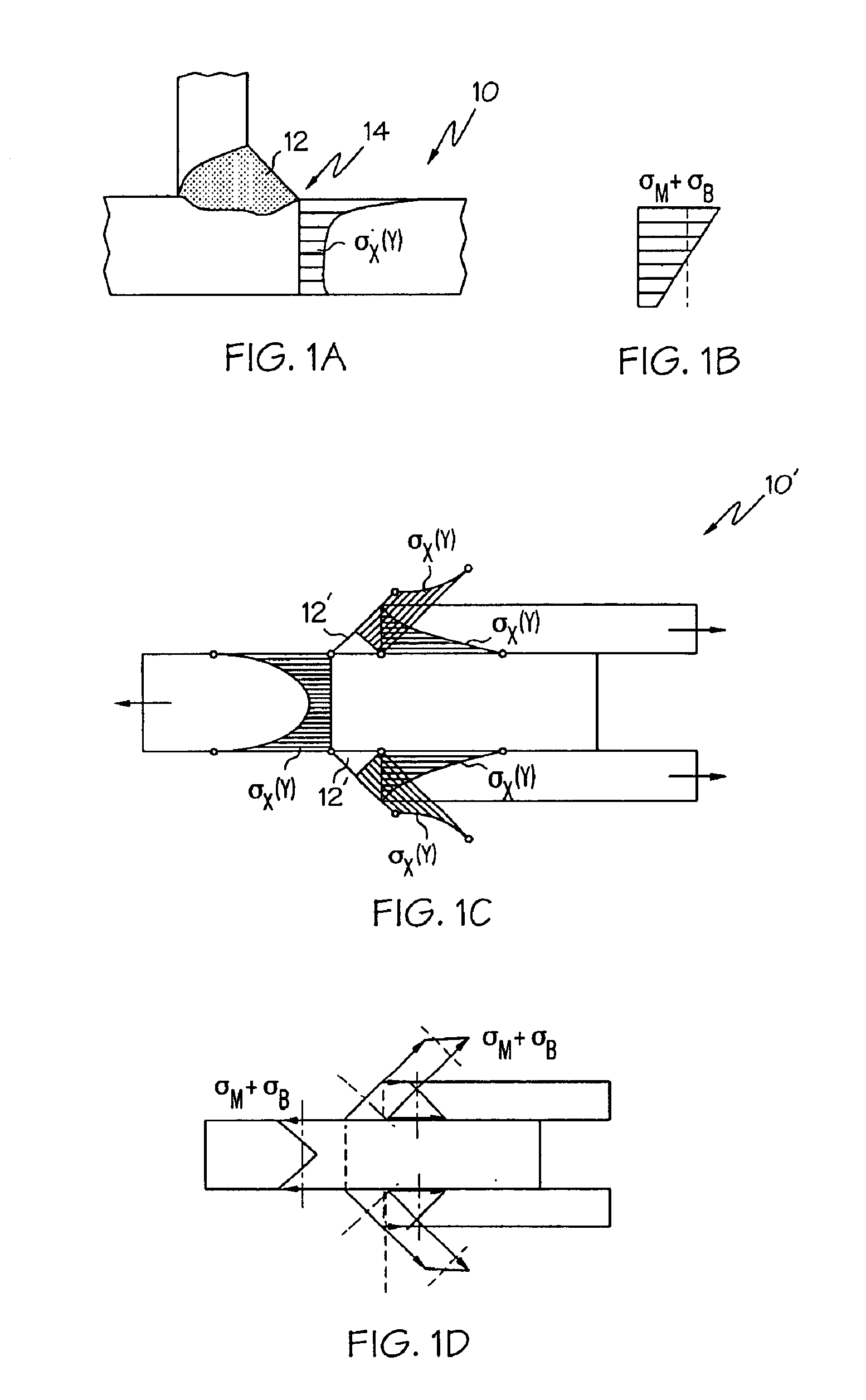

Structural stress analysis

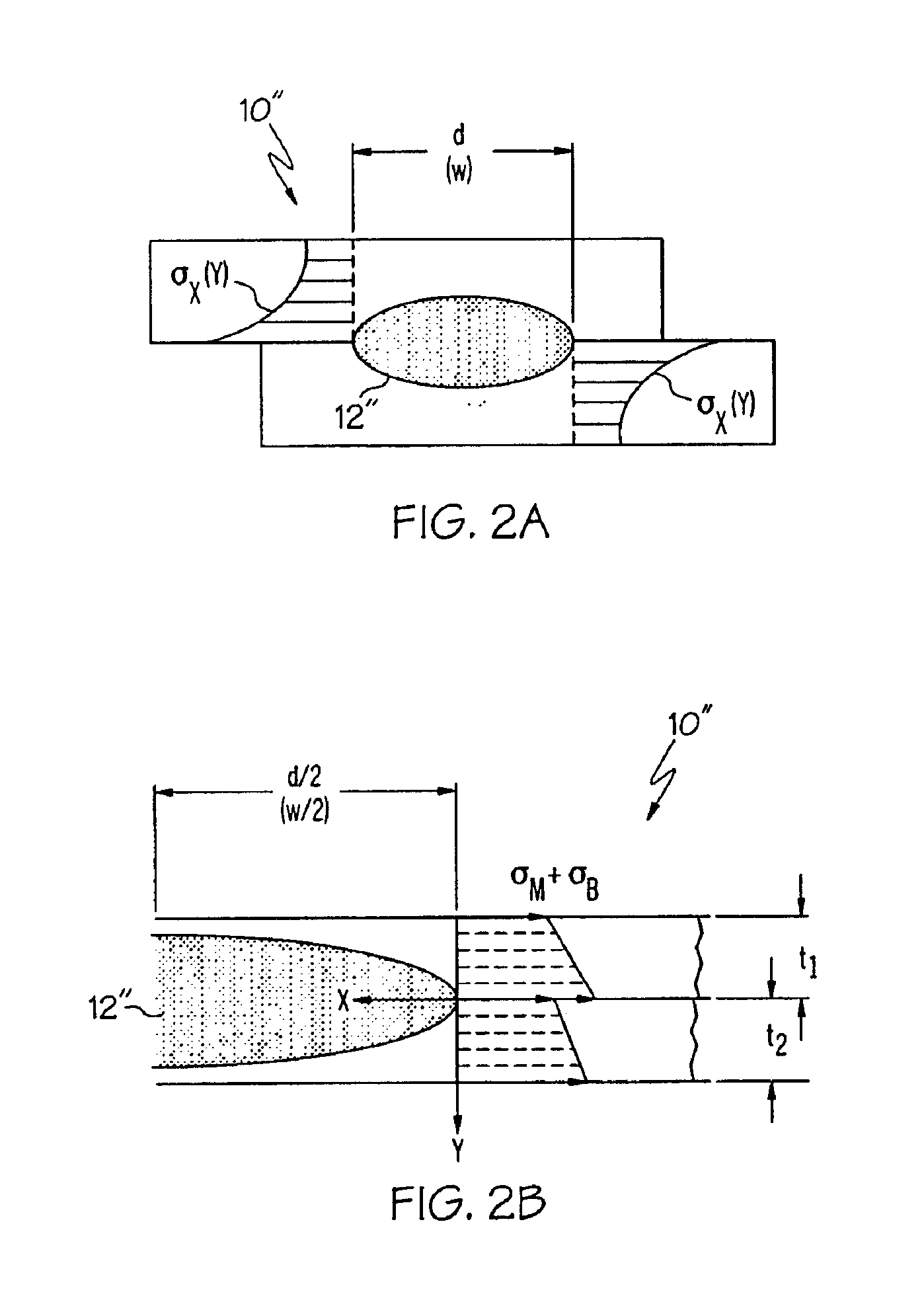

InactiveUS6901809B2Measurement arrangements for variableMaterial strength using steady bending forcesNODALEngineering

This need is met by the present invention wherein structural stress in a fatigue-prone region of a structure is determined by using the nodal forces and displacement values in the fatigue-prone region, or equilibrium-equivalent simple stress states consistent with elementary structural mechanics in the fatigue-prone region. The determination is substantially independent of mesh size and is particularly well-suited for applications where S-N curves are used in weld fatigue design and evaluation, where S represents nominal stress or stress range and N represents the number of cycles to failure. The present invention is directed to structural stress analysis through various combinations of modeling, calculation, and direct measurement schemes.

Owner:BATTELLE MEMORIAL INST

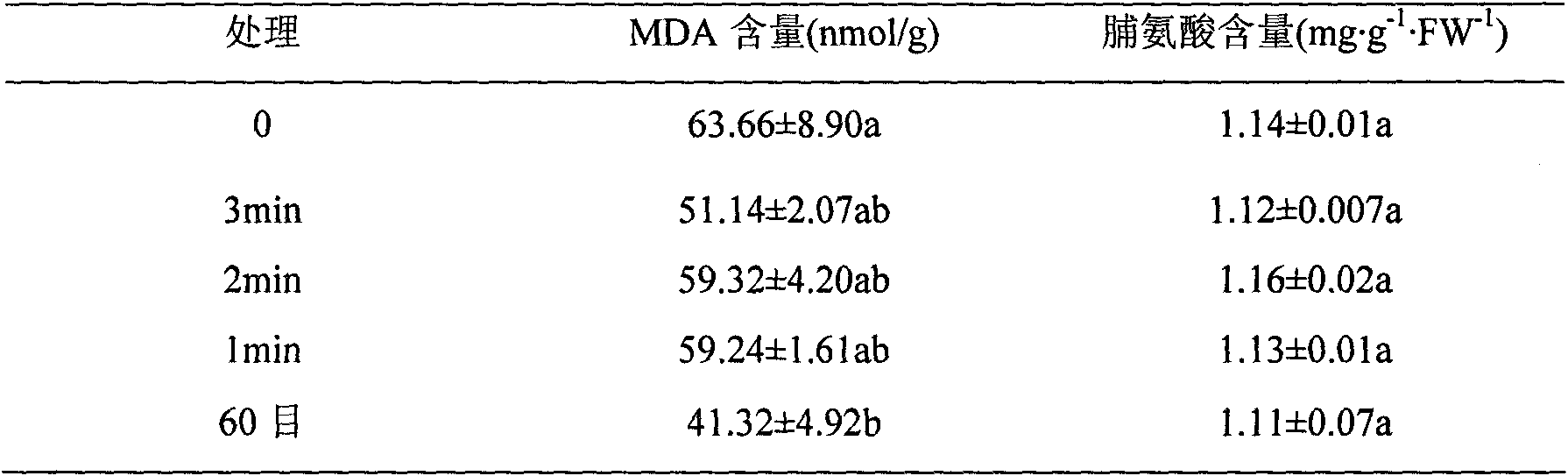

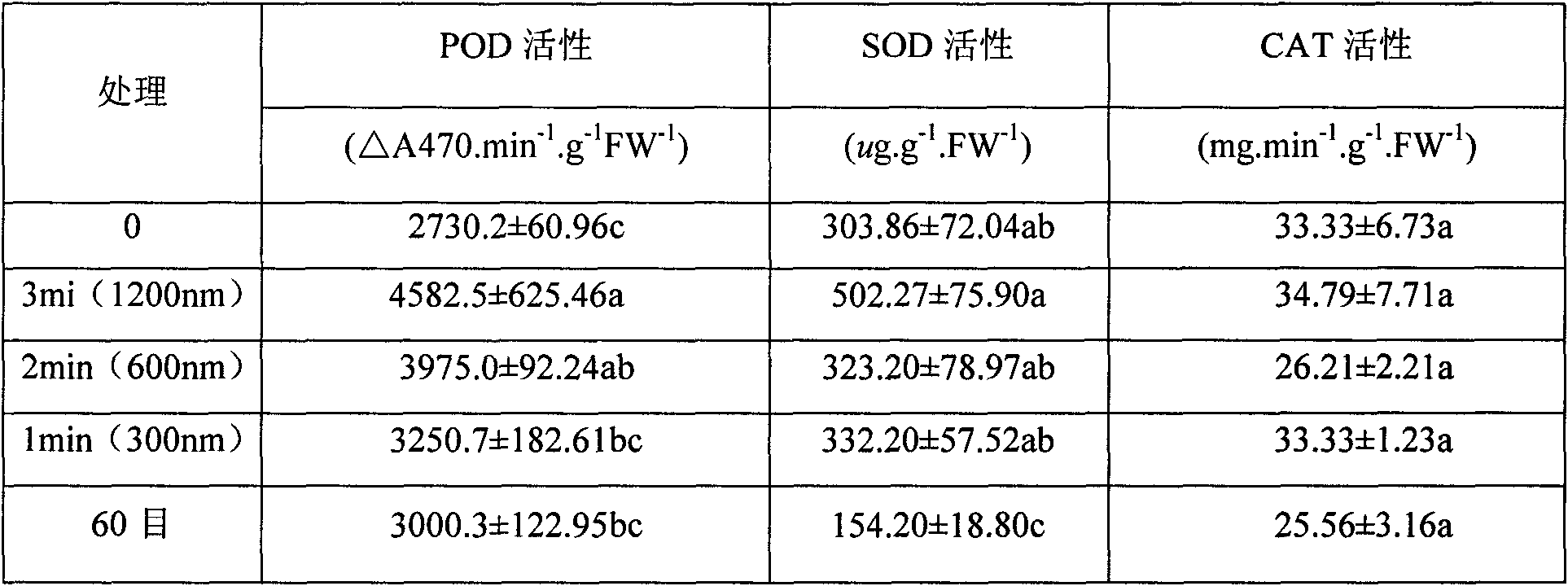

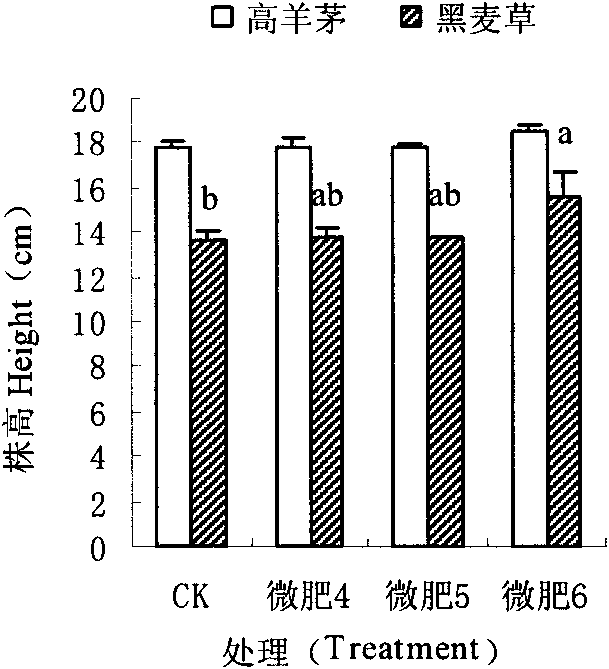

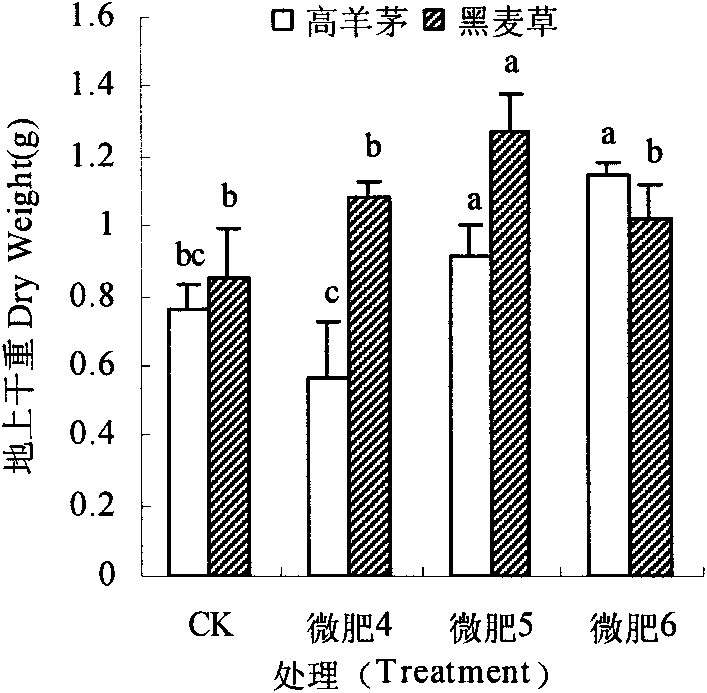

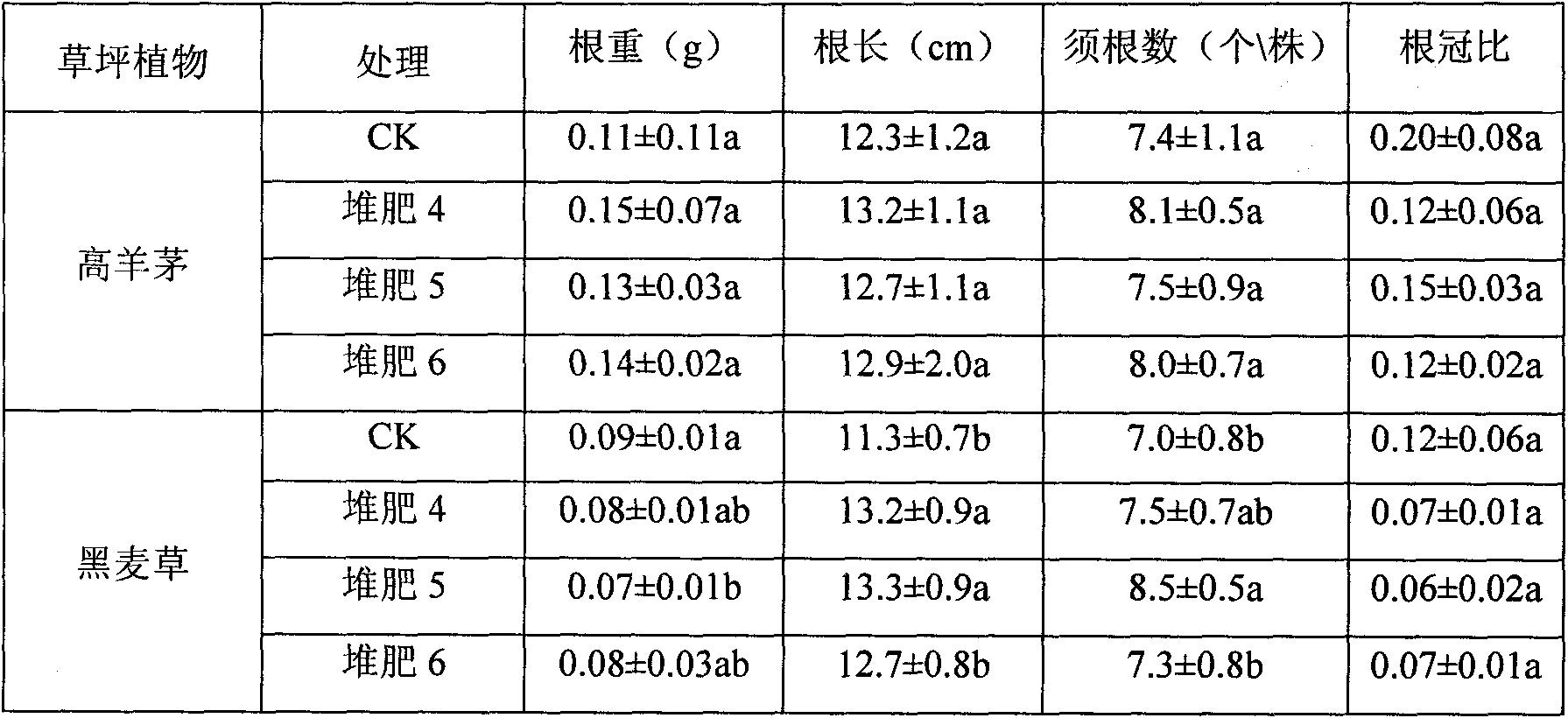

Method for improving activity of protective enzyme of festuca arundinacea under drought conditions

InactiveCN101884278AReduce contentAlleviate adversity stressHorticultureFertilizer mixturesReactive oxygen radicalsOxygenase activity

The invention relates to a method for improving activity of antioxidant enzyme of festuca arundinacea by using fine domestic garbage compost under drought conditions. In the method, a plastic pot with diameter of 7cm and height of 10cm is used through a pot experiment; and the method comprises the steps of: putting 150g of soil into each pot; sowing 0.5g of lawn plants in each pot; uniformly spreading 3g of municipal domestic garbage fine compost with particle sizes of 1,200nm, 600nm and 300nm on the surface of the soil; uniformly covering 20g of soil on the surface of the soil; controlling the temperature to be between 20 and 26 DEG C, wherein the relative humidity is between 40 and 60 percent, and illumination is natural light transmitting indoors; fully watering the plants in the initial stage of sowing, and watering by weighing every day to every two days according to 55 to 65 percent of water-holding capacity in fields after two weeks so as to maintain the capacity within a stress range; and measuring all the indexes on the 44th day. A result shows that the fine compost protects the festuca arundinacea plant from being damaged by active oxygen radicals, and reduces adverse environmental stresses to the plant caused by drought stresses.

Owner:TIANJIN NORMAL UNIVERSITY

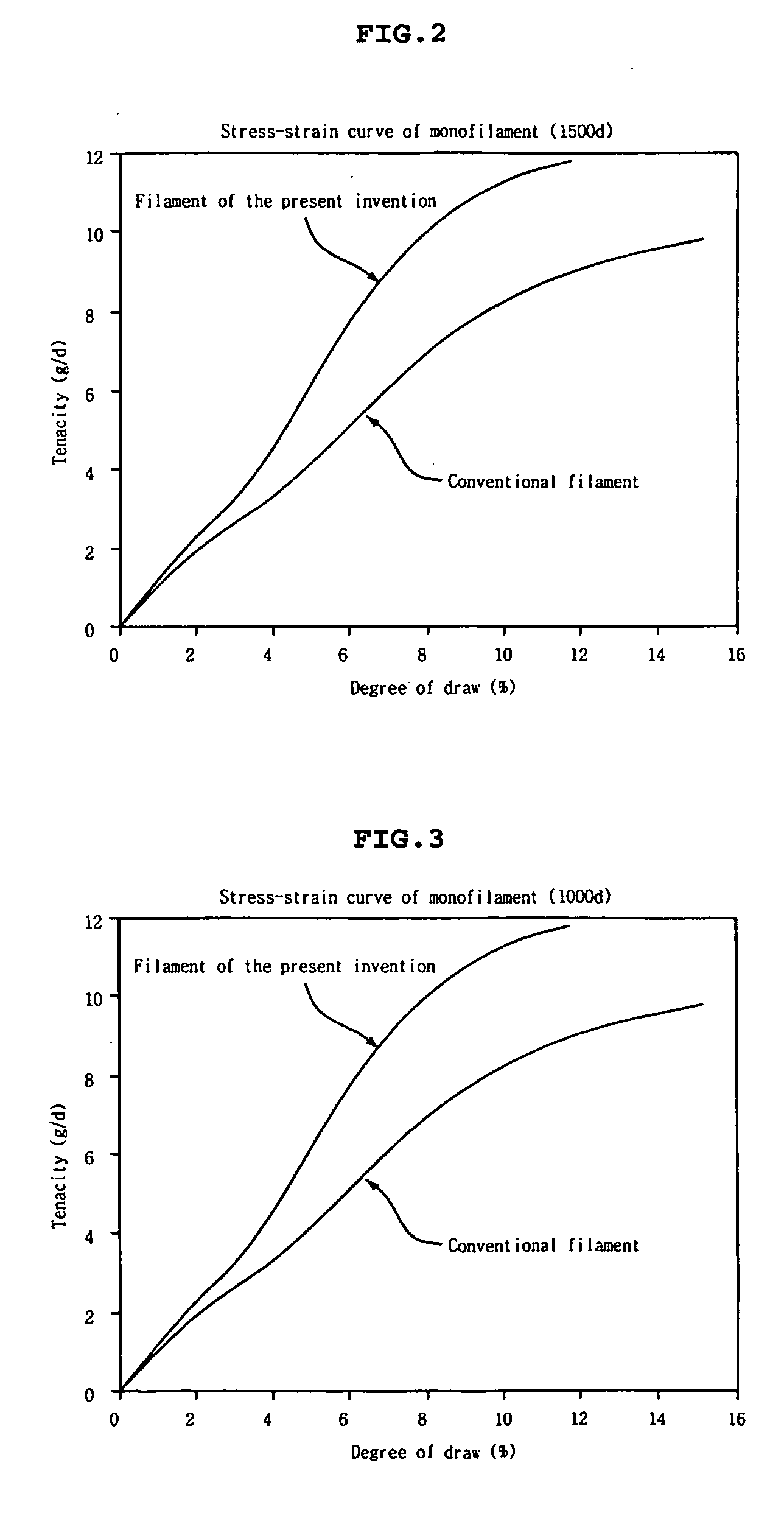

Polyethylene terephthalate filament having high tenacity for industrial use

InactiveUS20070243378A1Raise the draw ratioGeotextilesYarnPolyethylene terephthalateStress–strain curve

A polyethylene terephthalate monofilament obtained by spinning a polyethylene terephthalate chip having an intrinsic viscosity of 0.8 to 1.3, which gives a stress-strain curve exhibiting an elongation of less than 2.5% at an initial stress of 2.0 g / d, with an initial modulus value of 80 to 160 g / d, an elongation of 7.5% or less in a stress range of from 2.0 g / d to 9.0 g / d, and an elongation of at least 2.0% or more in a stress range of from 10.0 g / d to the point of break, is provided.

Owner:HYOSUNG CORP

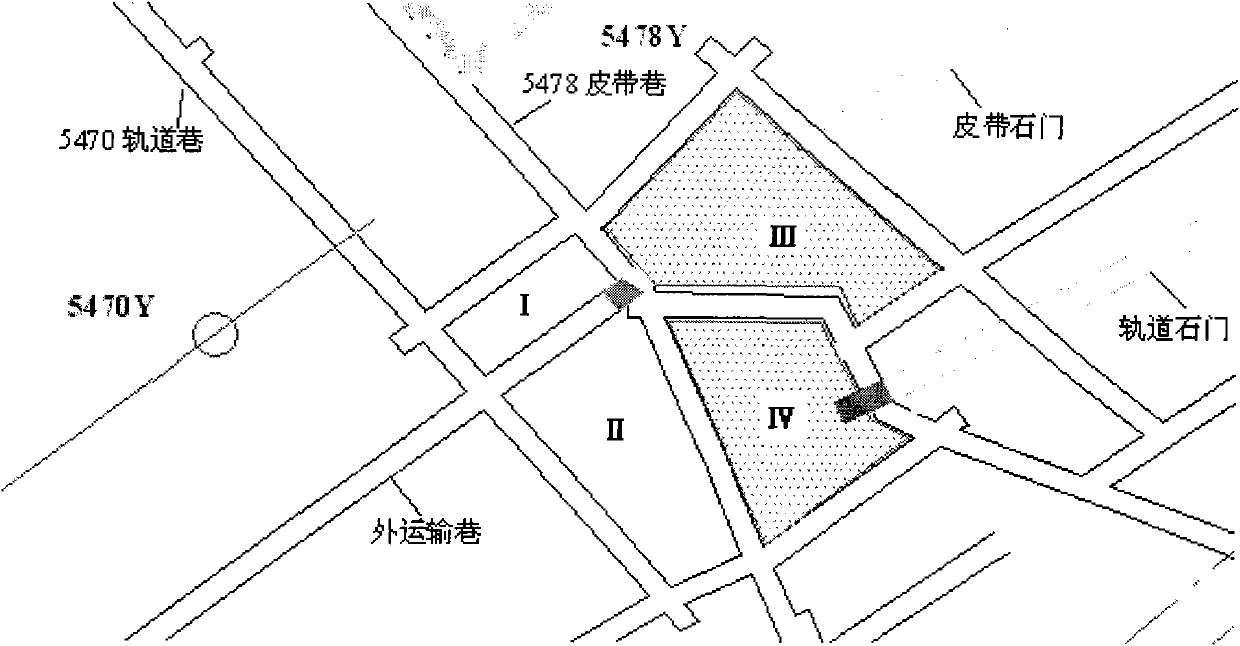

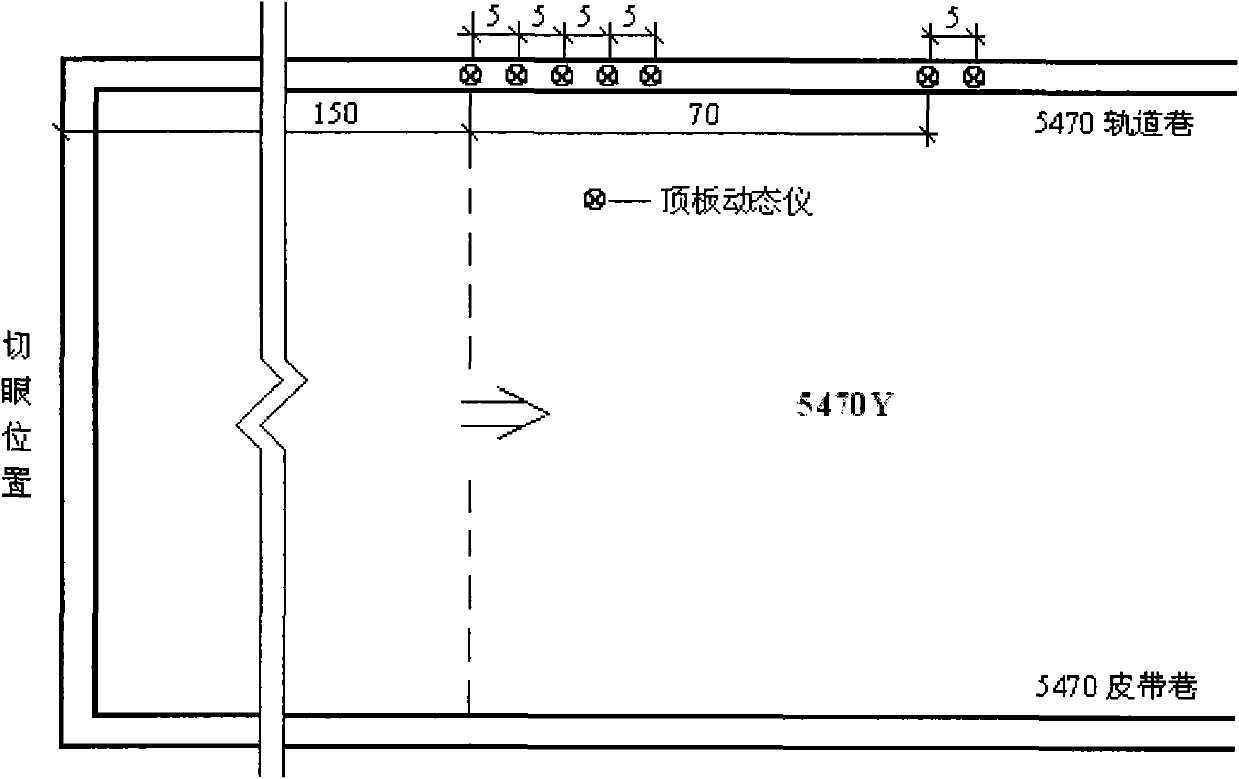

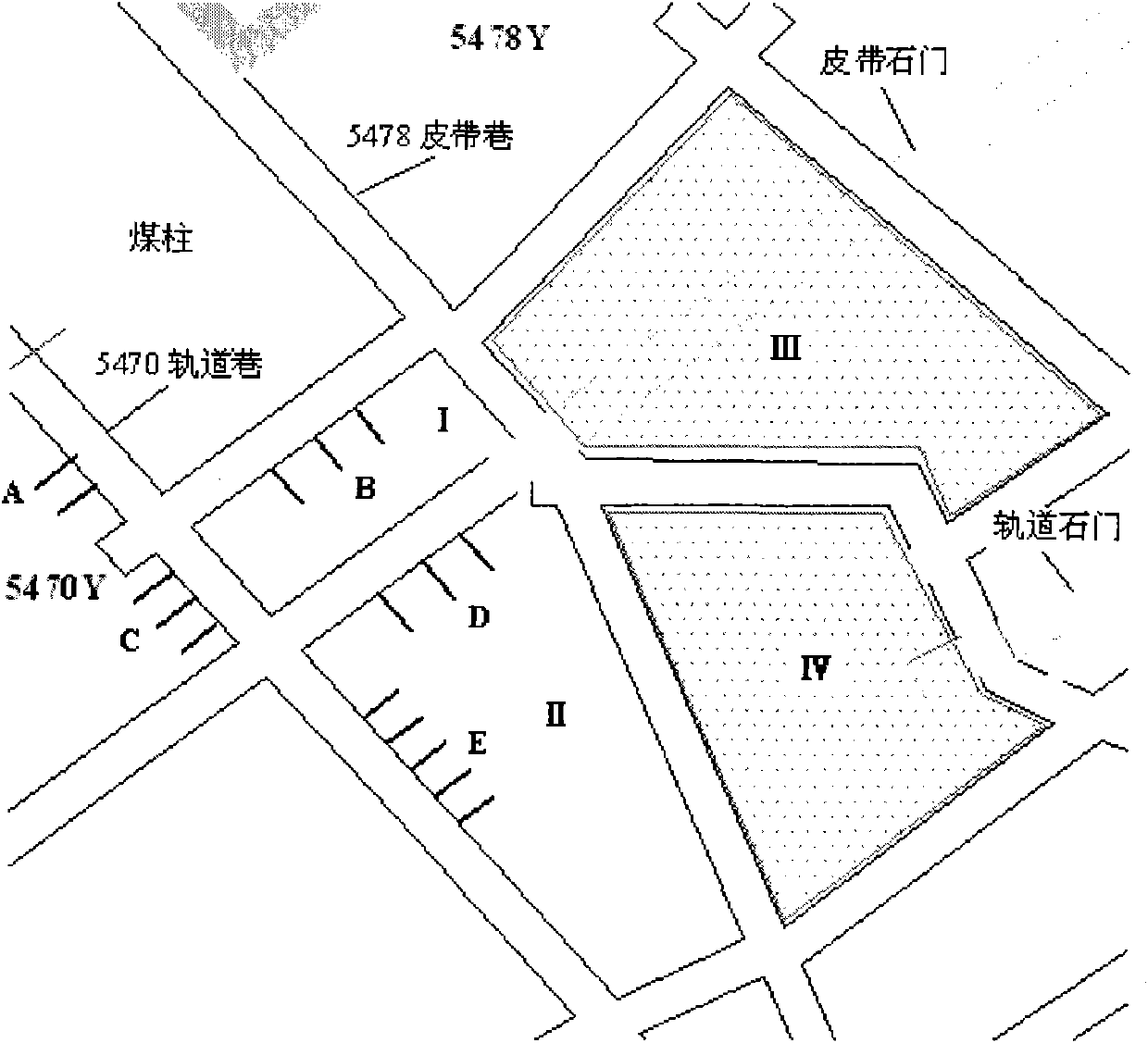

Dense roadway group rock burst hazard prediction method

InactiveCN102392685ATimely determination of early disturbance responseMining devicesDynamic methodHigh energy

The invention discloses a dense roadway group rock burst hazard prediction method. The method includes the following steps: first acquiring the dynamic sensitive area of a coal bed in a dense roadway group area; then mounting roof dynamics monitors along a direction leading to a dense roadway group to carry out roof dynamics observation; before a dynamic area stress range related to coal mining gets close to the dense roadway group, mounting highly sensitive stressmeters in the sensitive area to observe stress change, and when the stress increment is abruptly changed, carrying out rock burst hazard monitoring. By means of an artificial blasting technique in the dense roadway group, the method acquires the coal-rock stratum disturbance-sensitive area, finding a vulnerable area; the roof dynamics method is adopted to acquire the tendency characteristics and range of dynamic stress and quantitatively describe the distribution rule of the dynamic stress; delicate physical quantity observation timely judges the early disturbance response of the dense roadway group, rock burst hazard process monitoring is carried out before high energy is released, and the hazard level is judged by means of indexes.

Owner:SHANDONG UNIV OF SCI & TECH

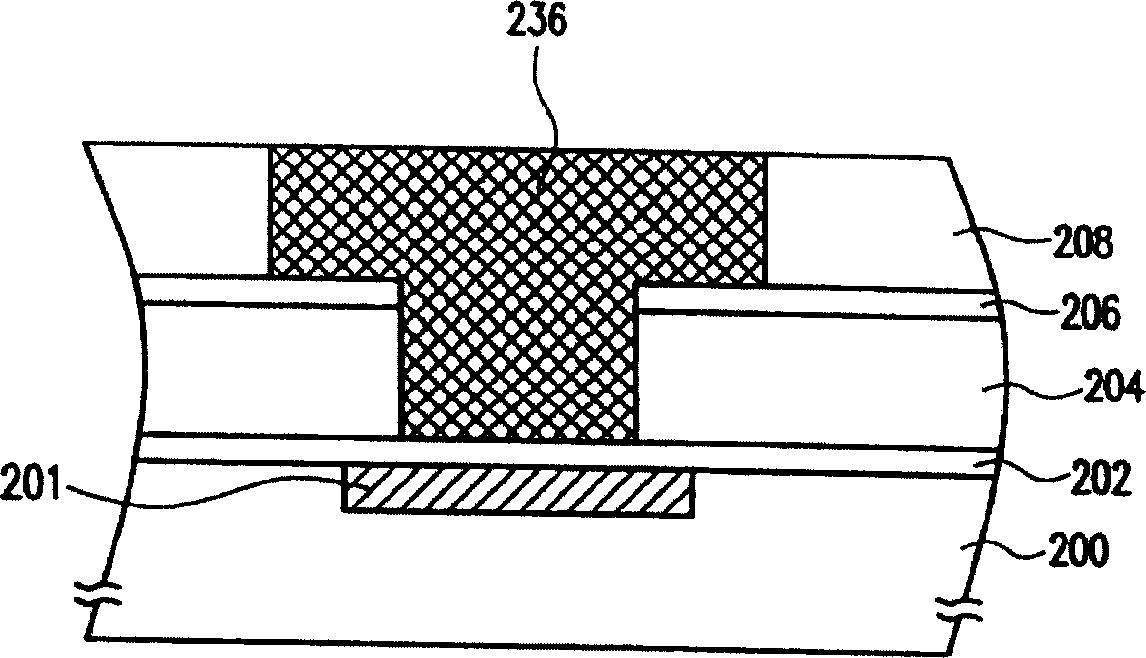

Etch stop layer and its forming method

ActiveCN101192533AImprove compactnessImprove interface propertiesSemiconductor/solid-state device detailsSolid-state devicesHigh stressDielectric layer

The invention relates to a method for forming an etch stop layer, which comprises an etch stop layer formed on a substrate; the etch stop layer is silicon nitride, the stress range of which is from -1, 600 to -2, 000MPa and the stress of which is compressive stress. The invention further provides a structure of a semiconductor device and a manufacturing method thereof. The invention adopts the silicon nitride with a high stress as the etch stop layer. As the silicon nitride has a relative high compactness, and at the same time, the compressive stress of the silicon nitride with a high stress can neutralize a tensile stress of a dielectric layer with a low specific inductive capacity, interface characteristics between the dielectric layer and the dielectric layer, Cu and the dielectric layer are changed, thus realizing the object of increasing the breakdown voltage between layers of the dielectric layer and the reliability of the device.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

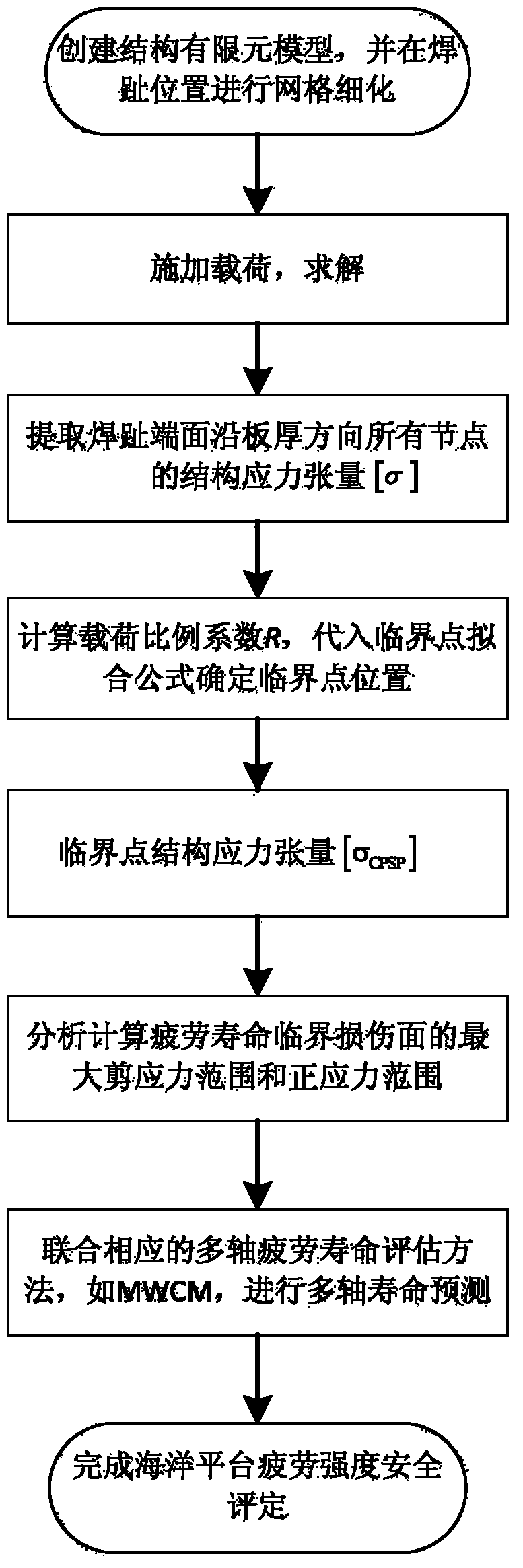

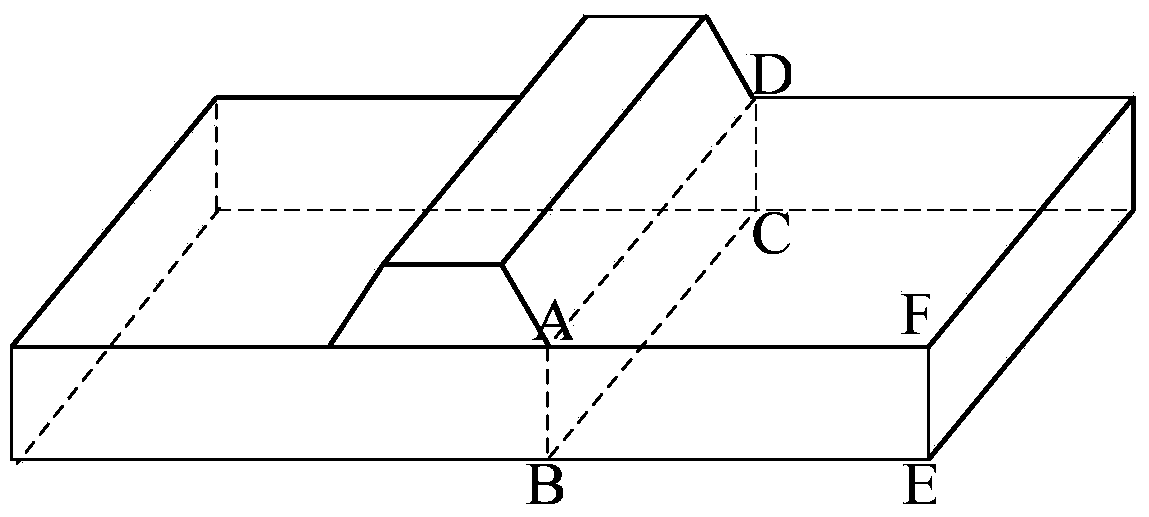

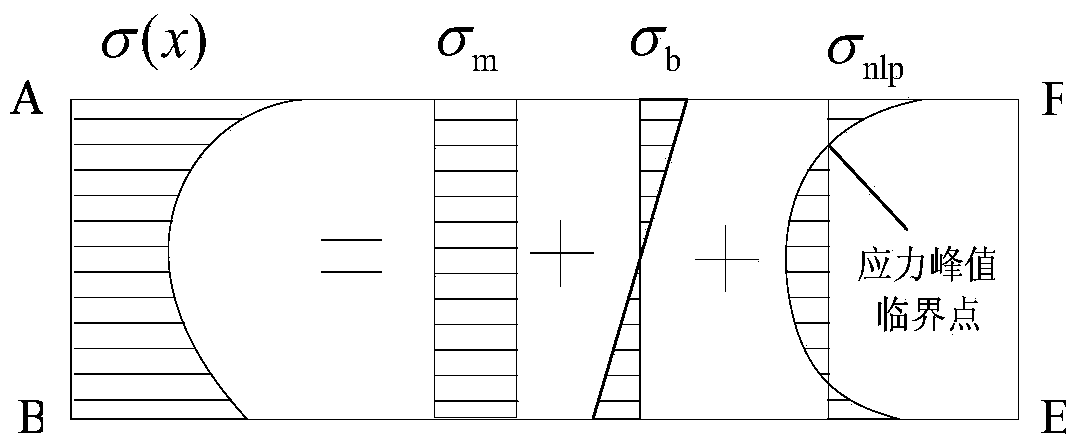

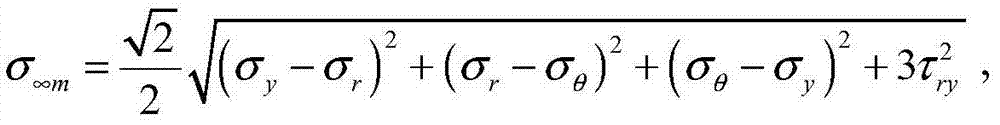

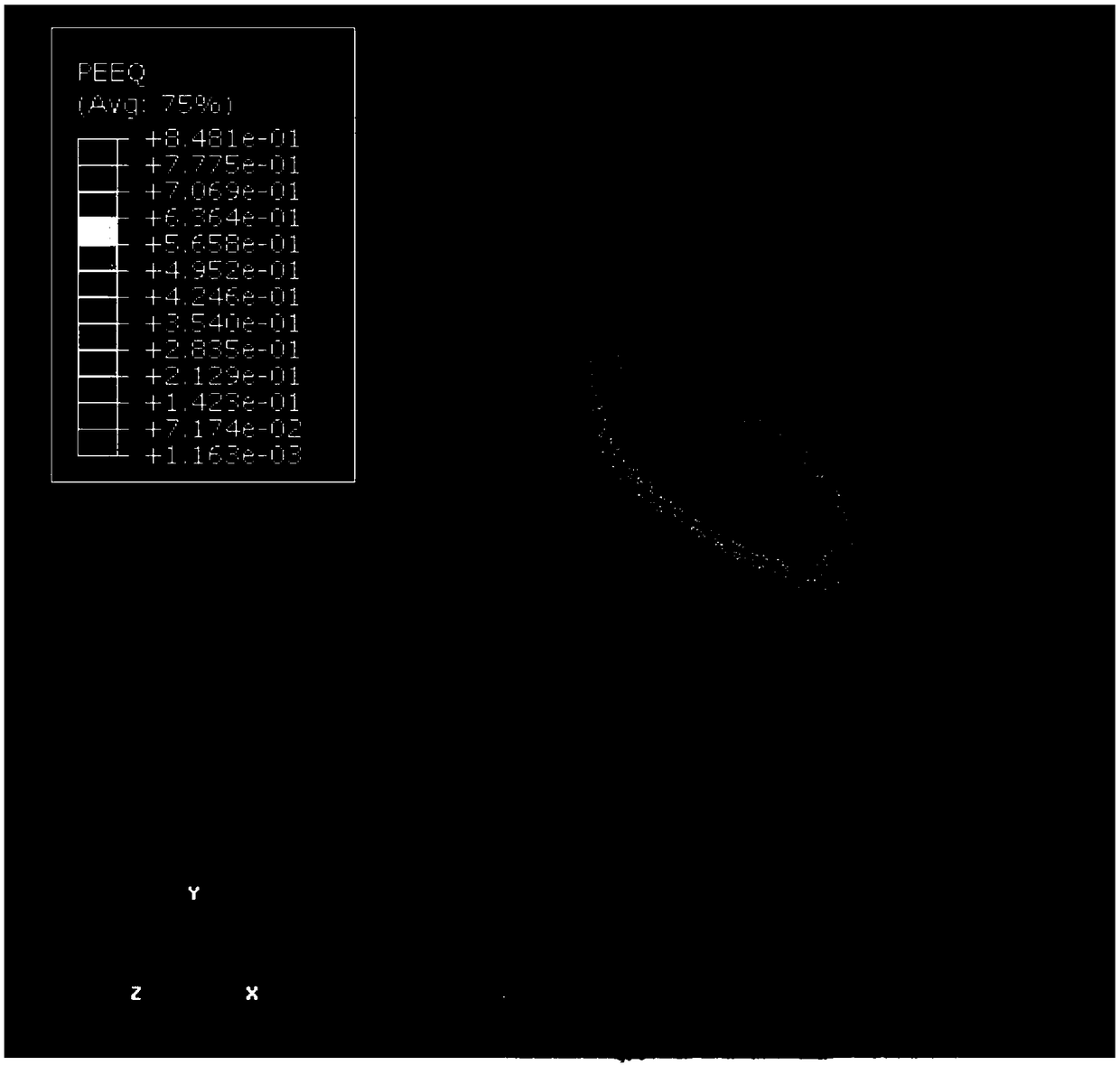

Welding structure multi-axial fatigue life evaluation method

The invention discloses a welding structure multi-axial fatigue life evaluation method. The method includes the following steps that a finite element model of a welding structure to be measured is established; multiple test loads are applied to the welding structure, and structural stress tensors [sigma] of all joints of the end face of a weld toe in the board thickness direction are obtained through solving; corresponding load proportionality coefficients R of the joints are worked out according to the structural stress tensors [sigma] of the joints, and then the position of a stress peak critical point is determined; the structural stress tensor [sigma CPSP] of the stress peak critical point is obtained through the interpolation method; the maximum shear stress and normal stress range of a fatigue life critical damage plane are worked out according to the structural stress tensor [sigma CPSP] of the stress peak critical point, and multi-axial fatigue life evaluation is carried out through the union multi-axial fatigue life evaluation method MWCM.

Owner:DALIAN UNIV OF TECH

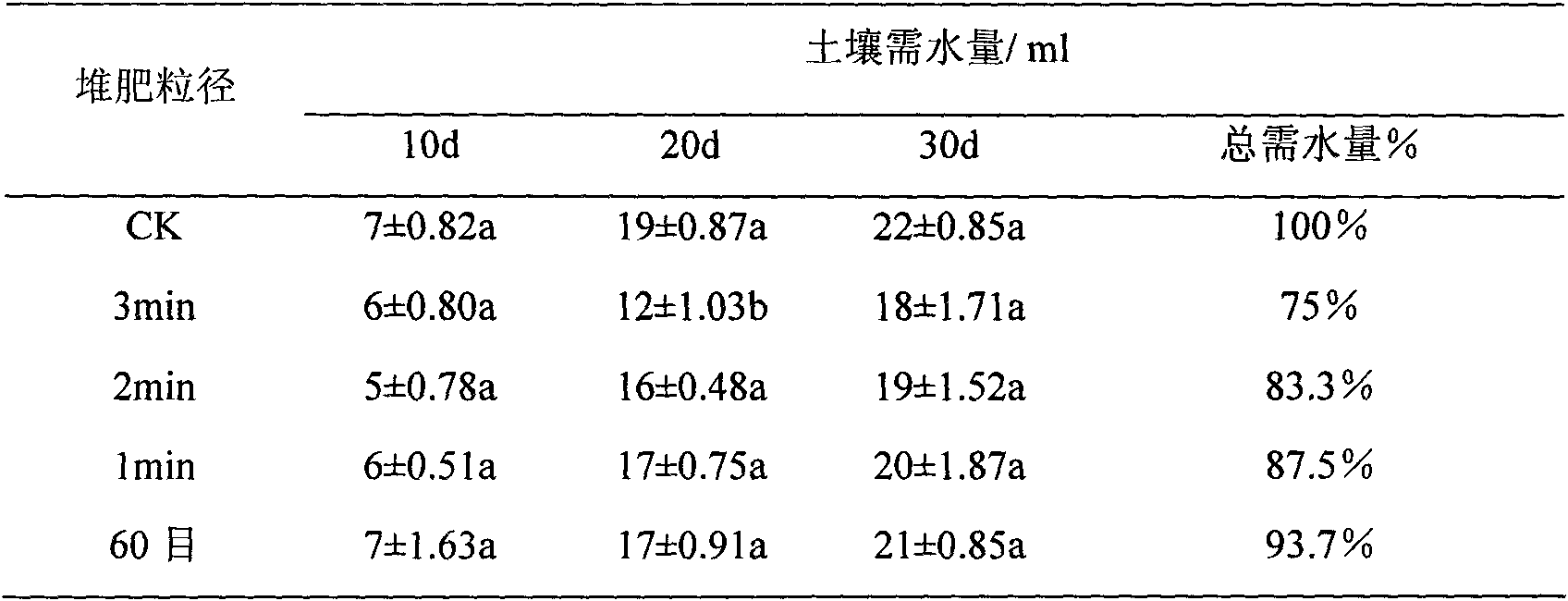

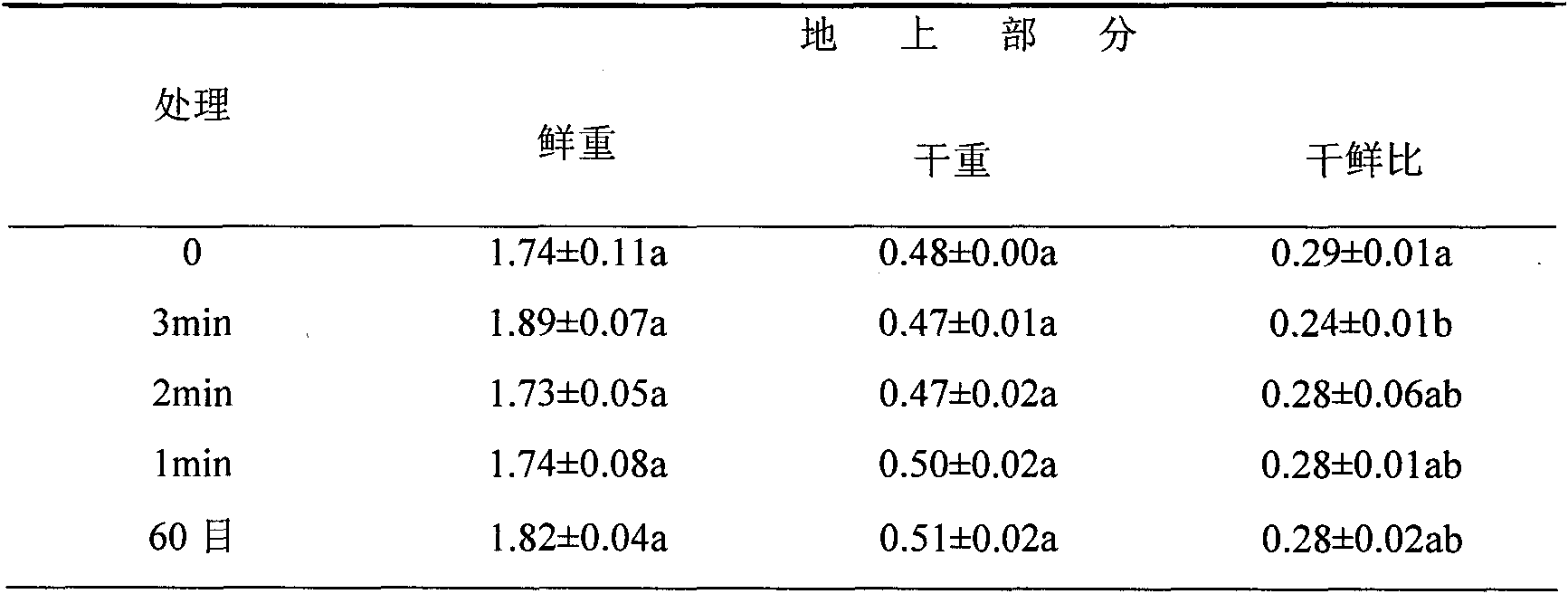

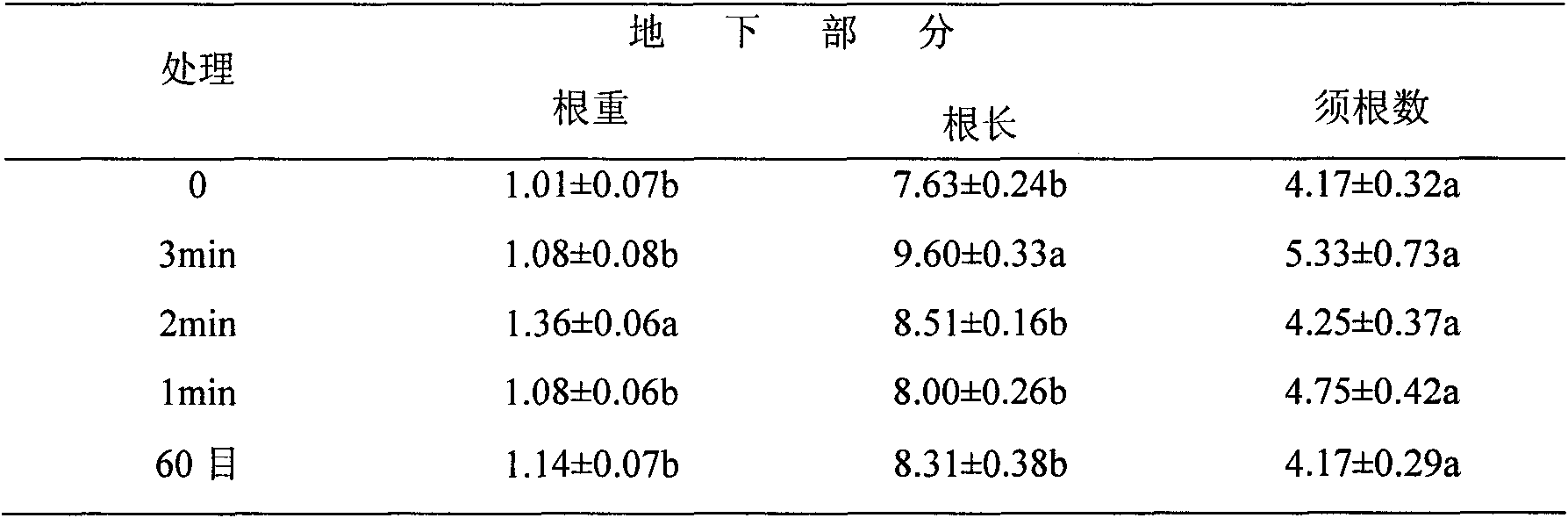

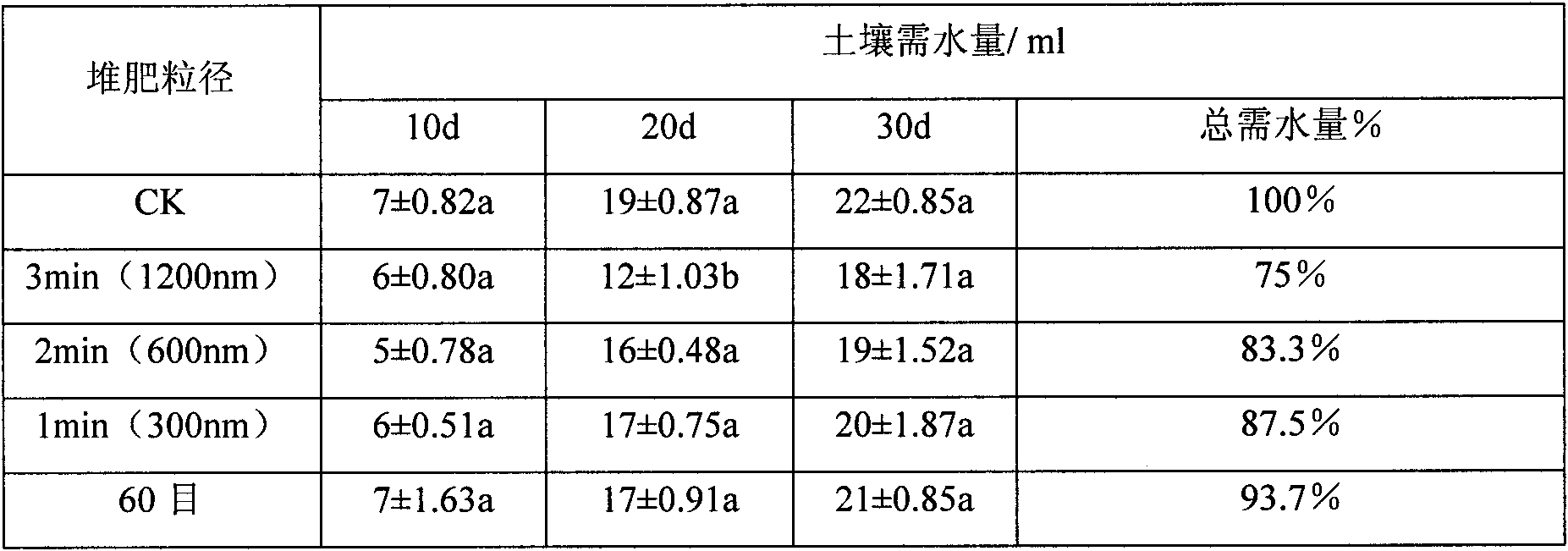

Method for improving drought resistance of drought substrate tall fescue by adopting fine garbage compost

InactiveCN101869031ALarge biomassMeet growthClimate change adaptationFertiliser formsMoisture capacityCompost

The invention relates to a method for improving the drought resistance of drought substrate tall fescue by adopting urban household fine garbage compost, which comprises the following steps of: respectively scattering fine garbage compost of which the particle diameter is respectively 1200nm, 600nm and 300nm uniformly on the surface of soil, wherein the ratio of the particle diameter to parts by weight of the soil is 1:60-80, the temperature is controlled at 20-26 DEG C, the relative humidity is controlled at 40-60%, and natural light permeating a room is used for illuminating; fully watering at the initial stage of seeding; weighing and watering every one or two days according to 55-65% of field moisture capacity after two weeks to maintain the field moisture capacity in the stress range; and measuring each index from the 44th day. The result shows that under the drought stress, the fine compost increases the biomass of the tall fescue to a certain extent, and the research result of growth of root systems of lawn plants can be basically met by matching the compost with the substrate for cultivating turf.

Owner:TIANJIN NORMAL UNIVERSITY

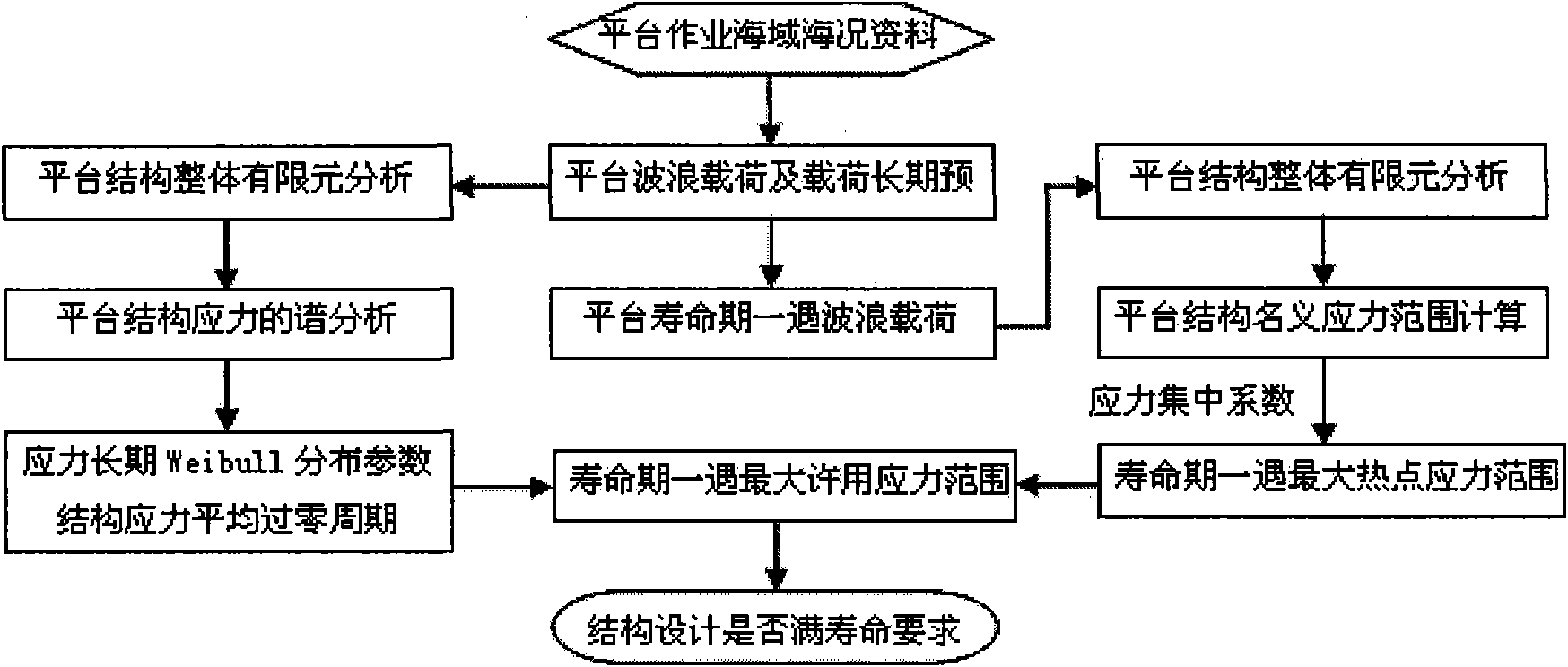

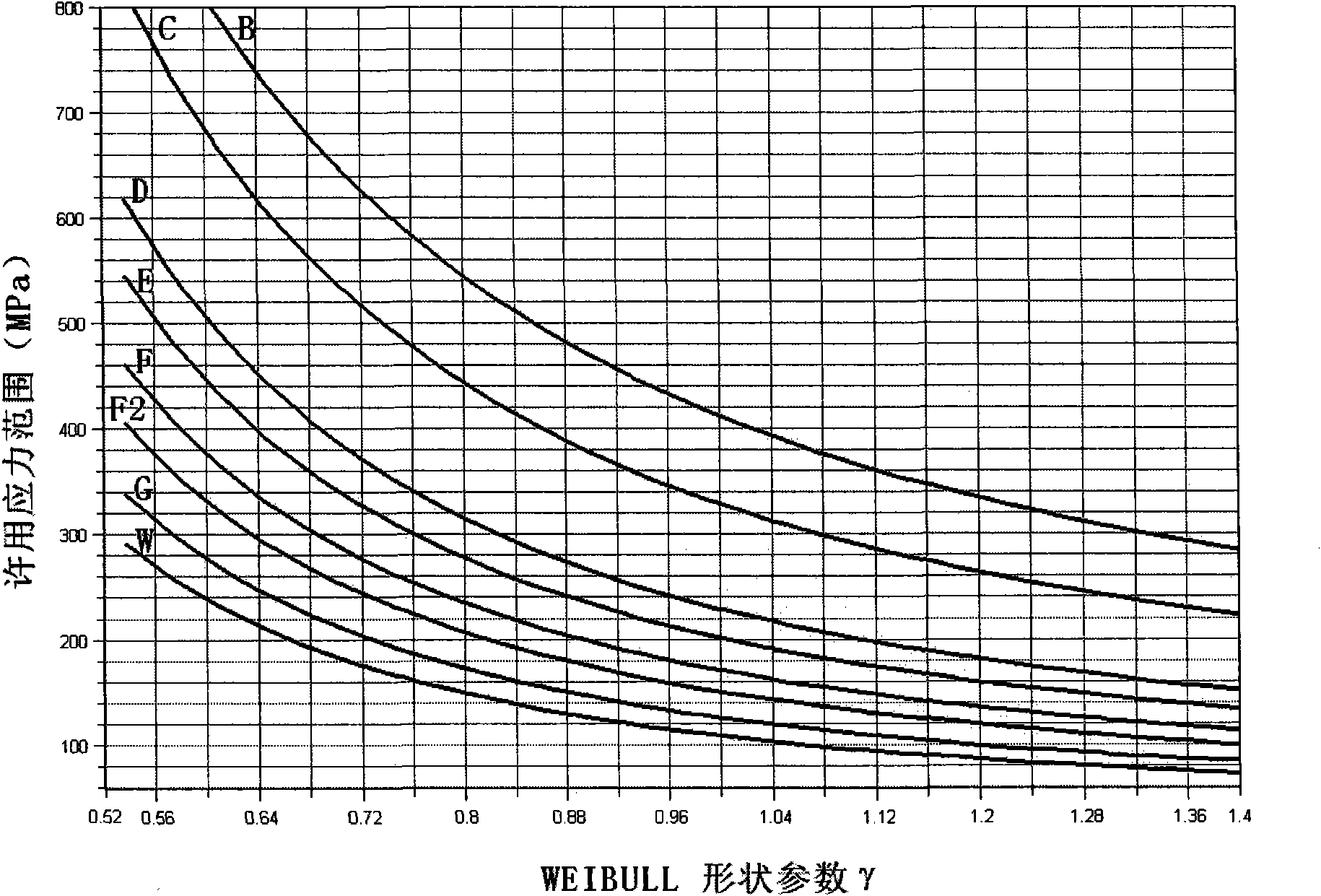

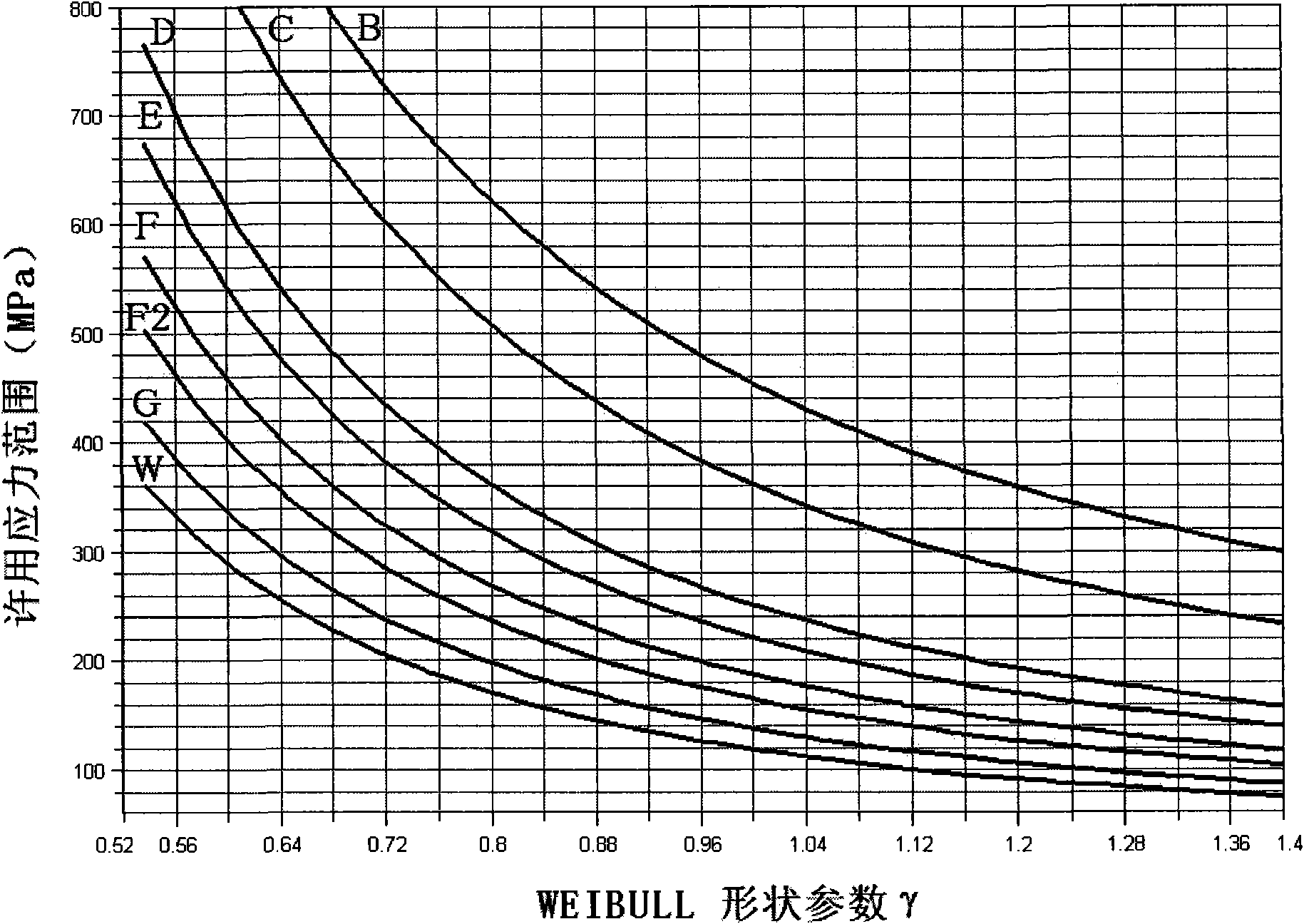

Design method for simplifying fatigue for semi-submersible type platform structure

ActiveCN101615215AThe analysis result is accurateAnalytical results are reliableSpecial data processing applicationsWorkloadSouth china

The invention relates to a design method for simplifying fatigue for a semi-submersible type platform structure, comprising the following steps: (1) a semi-submersible type platform wave loading long-term forecast is carried out; (2) semi-submersible type platform structure stress long-term Weibull distribution shape parameter is determined; (3) the return-period maximum permissible stress range curve of the semi-submersible type platform structure life period is determined; (4) the return-period hotspot stress range of the semi-submersible type platform structure life period is calculated; (5) the fatigue life of the semi-submersible type platform structure is estimated. Compared with the existing fatigue design method of the platform structure, the design method for simplifying fatigue for semi-submersible type platform structure provided by the invention has the advantages of small workload and accurate calculation result, and can be used in the structure fatigue design of the semi-submersible type platform in the South China Sea.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Repairing process for surface defect of magnesium alloy casting

ActiveCN103056586ASolving Organizational Transformation ProblemsSolve the cooling effectWelding deformationThermal cycle

The invention discloses repairing process for a surface defect of magnesium alloy casting. The process includes steps of cleaning and machining the defect, cleaning welding wires, pre-heating, repairing welding, preserving heat and the like. The process has the advantage that by means of the pre-heating, fast welding, heat preservation and the like, a thermal stress range is small, magnesium casting is basically not deformed, a base material texture of repaired magnesium casting basically keeps original texture and performance, and a problem of conversion of metal magnesium casting texture in thermal cycle of welding repairing and a problem that a welding repairing area is cooled fast and uneven in contraction are solved. The repaired metal magnesium casting base material texture basically keeps the original texture and performance, cracks and a new welding regenerated defect are prevented, and welding deformation is effectively controlled. The repairing process is applicable to repairing of the surface defect of the magnesium casting and the repairing of surface allowance insufficiency, widens an application range, and has the advantages of being simple to operate, low in cost, easy to master and high in welding repairing efficiency.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

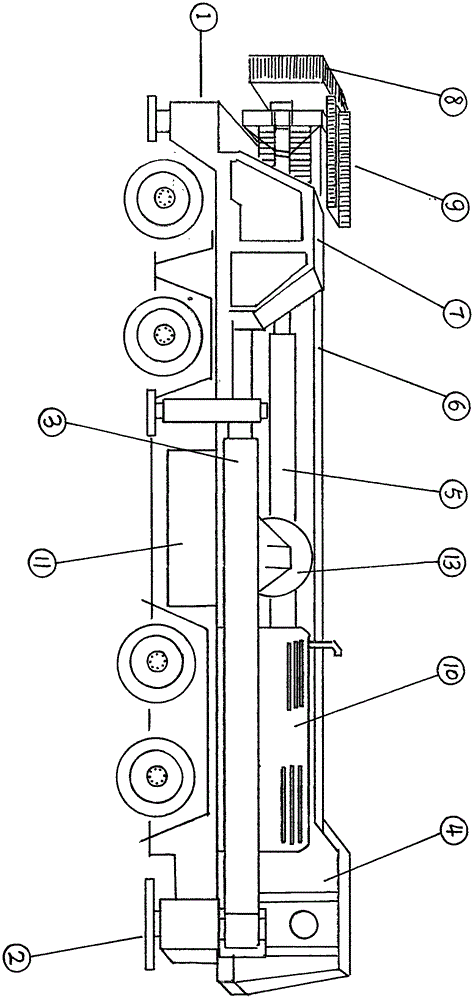

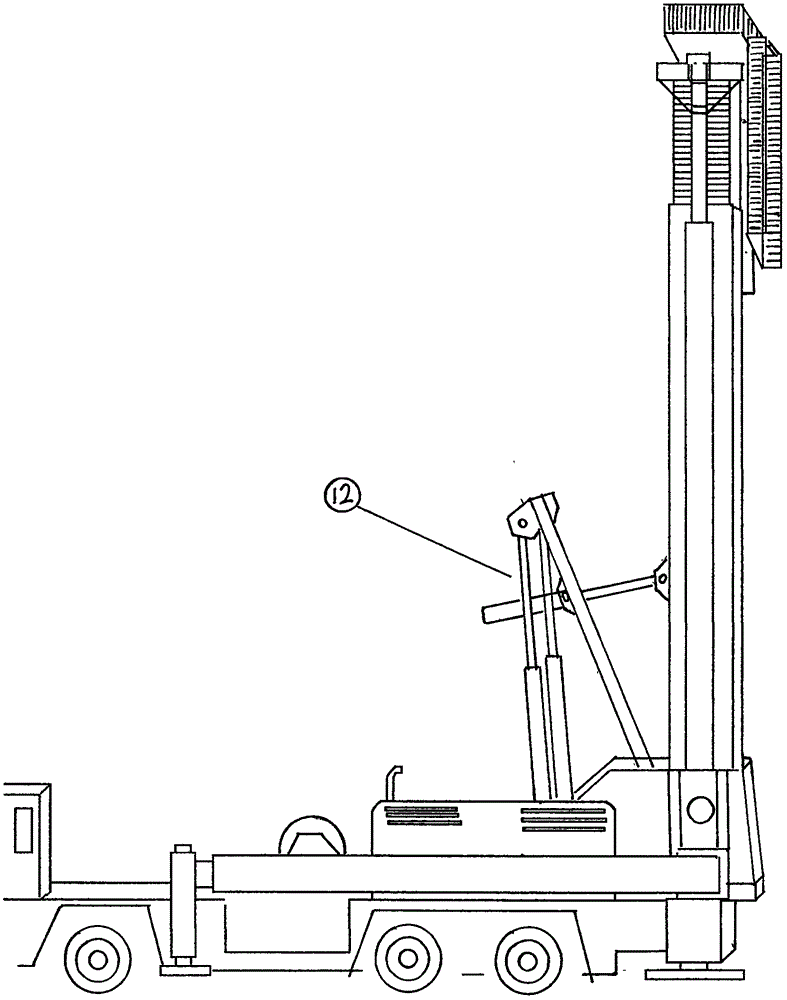

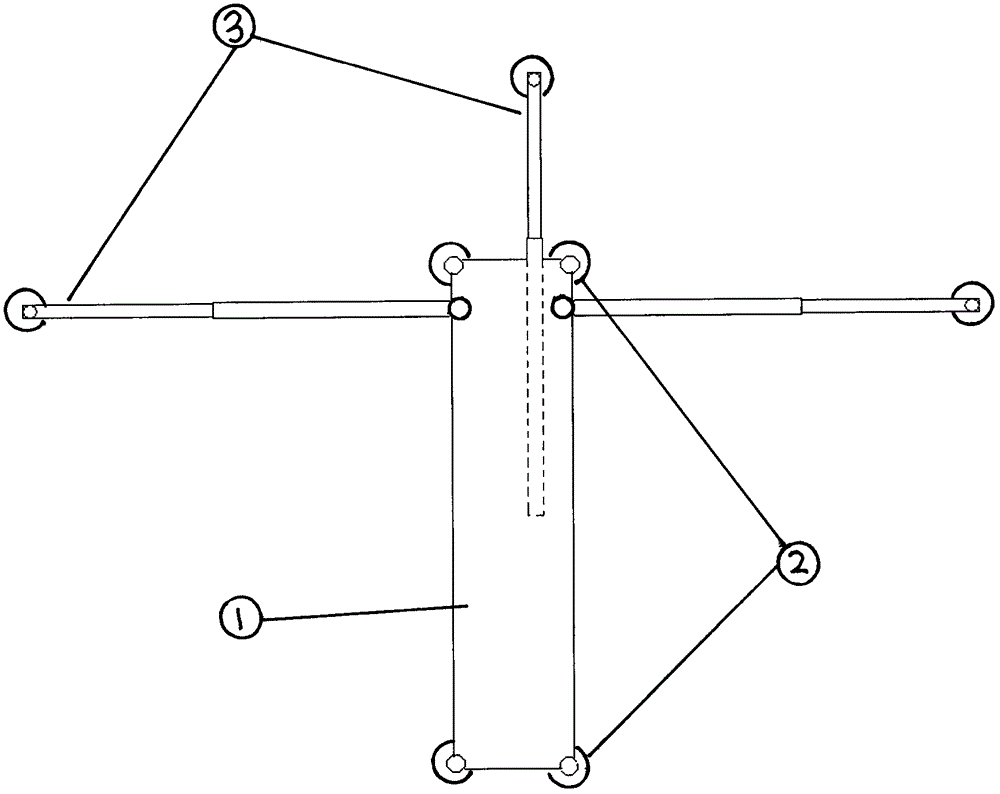

Telescopic boom system of ultrahigh aerial ladder fire truck lifting stage by stage

The invention relates to the field of fire-fighting machinery, and particularly relates to a telescopic boom of an aerial ladder fire truck. The telescopic boom of a telescopic boom system of an ultrahigh aerial ladder fire truck lifting stage by stage can be drawn out as an antenna; two groups of multi-stage oil cylinders with ultralong strokes are arranged at the two ends of the telescopic boom; an electric movable pin pushing device is arranged at the top end of each oil cylinder; the telescopic boom is pushed out upwards by the multi-stage oil cylinders with the ultralong strokes and stops at a corresponding position under the stroke limiting action of an induction switch during working of equipment; the second stage of the telescopic boom and one section of ascending telescopic boom are located through location pins; and at this moment, the two sections of the telescopic boom are connected into one piece; a movable pin is retreated by the electric movable pin pushing device; the multi-stage oil cylinders with the ultralong strokes are descended to the position of the second stage of the telescopic boom; and the telescopic boom can be sequentially pushed out through repeating the abovementioned action. More telescopic booms can be accommodated in the main telescopic boom in a stress range of the strength of the telescopic boom because the telescopic boom uses an external thrust device, and therefore, a high lifting height can be achieved.

Owner:王明中

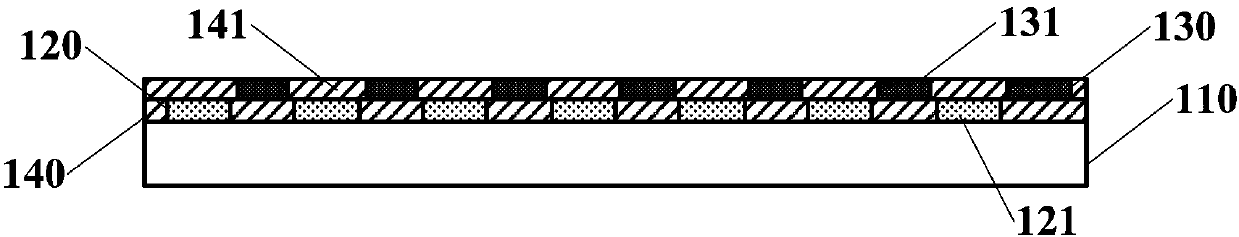

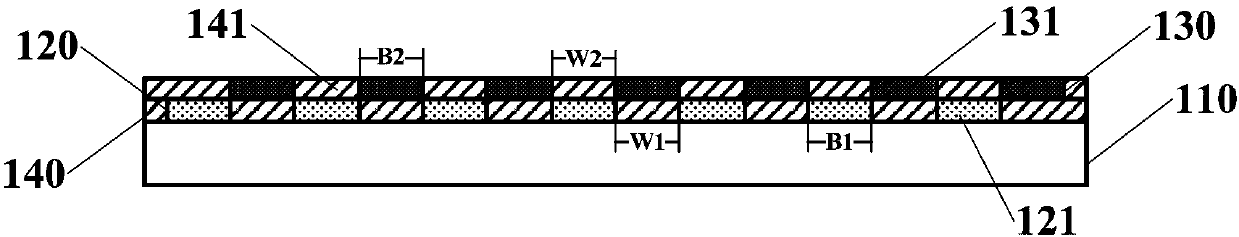

Array substrate and flexible display panel

ActiveCN108022944AIncrease internal stressReduce the chance of crackingSolid-state devicesSemiconductor/solid-state device manufacturingTotal thicknessFlexible display

The embodiment of the invention discloses an array substrate and a flexible display panel. The array substrate comprises a flexible substrate, a first buffer layer located on the flexible substrate and a second buffer layer, wherein the first buffer layer comprises a plurality of first protrusions, and any two adjacent first protrusions are filled with a flat layer therebetween; the second bufferlayer is located at the side, which is away from the flexible substrate, of the first buffer layer, the second buffer layer comprises a plurality of second protrusions, any two adjacent second protrusions are filled with a flat layer therebetween, and the projection of each second protrusion at least covers part of the clearance between the two adjacent first protrusions in the direction perpendicular to the flexible substrate. According to the array substrate provided by the embodiment of the invention, the internal stress of each buffer layer is optimized through interrupted lamination of each buffer layer under the condition that the total thickness of the buffer layers is slightly changed, so that the bending stress range of a product in a corresponding bending area when being bent isenabled to be restricted within a certain area, the buffer layers are enabled to be stressed in a staggered manner, and the cracking probability of the buffer layers is reduced.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

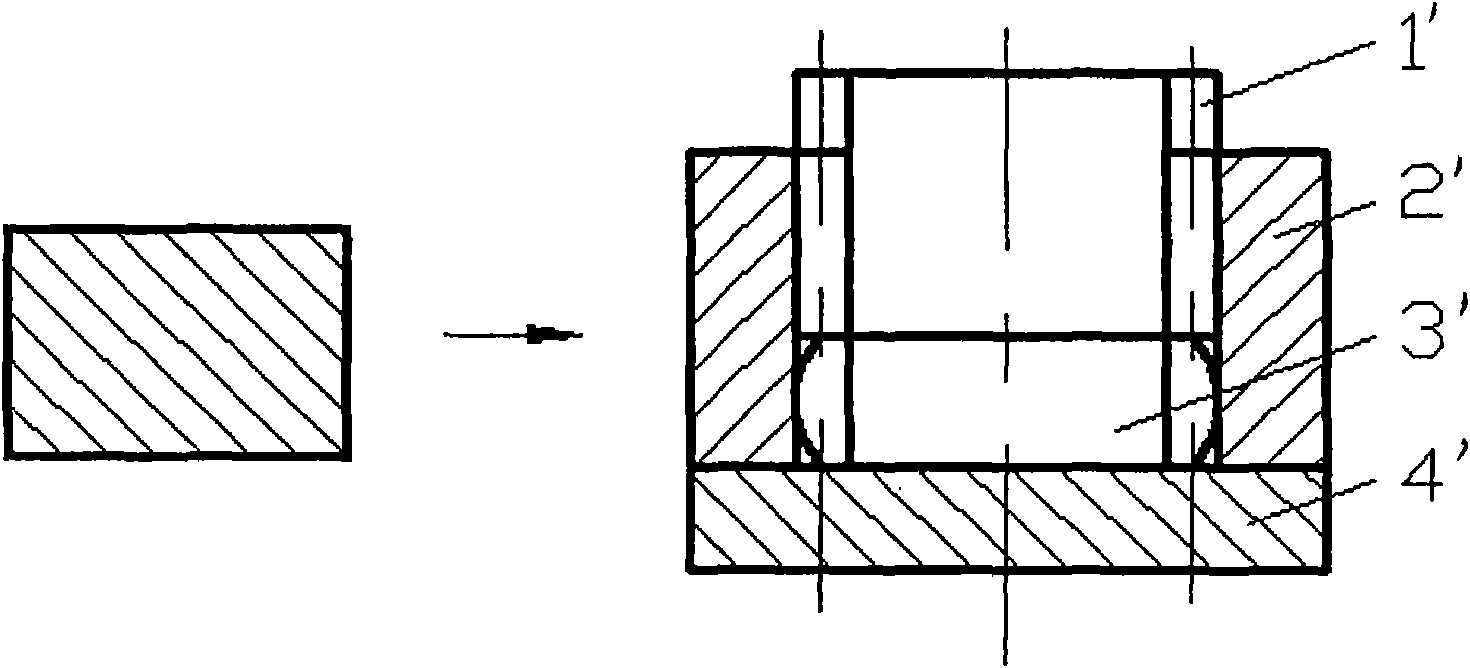

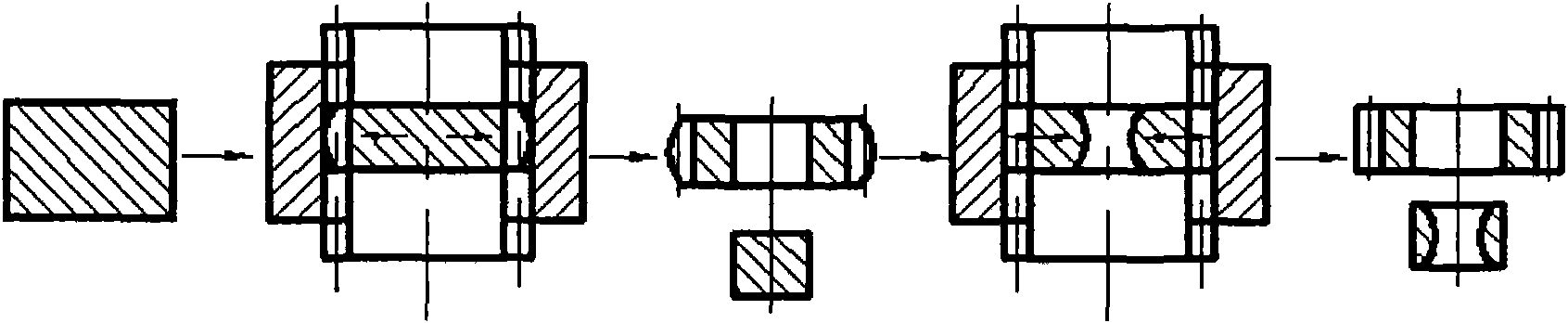

Cold precision forming technique of helical-spur gear and device thereof

The present invention provides a cold precision forming technique of helical-spur gear and a device thereof. The invention is characterized by adopting a cold precision forming technique that the inner punch pin and the outer punch pin are controllable and are upset-extruded bidirectionally so that the helical-spur gear can be formed to the gear with full tooth profile in one-step in the stress range allowable for the strength of the cold-forming mold material. The mould base of the special device is divided into an upper part and a lower part. The upper part is provided with an inner cylinder and an outer cylinder, a slider, an inner upper punch pin, an outer upper punch pin and an upper press plate. The lower part is provided with an inner cylinder and an outer cylinder, a cavity die, an inner punch pin, an outer punch pin and a lower press plate. When a pressing machine operates downwards, the upper press plate, the upper inner punch pin and the upper outer punch pin move downwards, the lower outer punch pin is fixed and the cavity die moves downwards. The upper inner punch pin and the lower inner punch pin are held by the pressures of the upper inner cylinder and the lower inner cylinder for squeezing out openings on the blank. After the openings are extruded to a preset depth, the upper inner punch pin and the lower inner punch pin stops the squeezing. Then the pressing machine continuously operates downwards, the upper outer punch pin and the lower outer punch pin with tooth shape start upset-extrude the blank until the final forming. The cold precision forming technique of the invention has the characteristics of one-step forming, simple technique and short flow path. The purposes of high efficiency, energy saving and material saving in cold precision forming are obtained.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

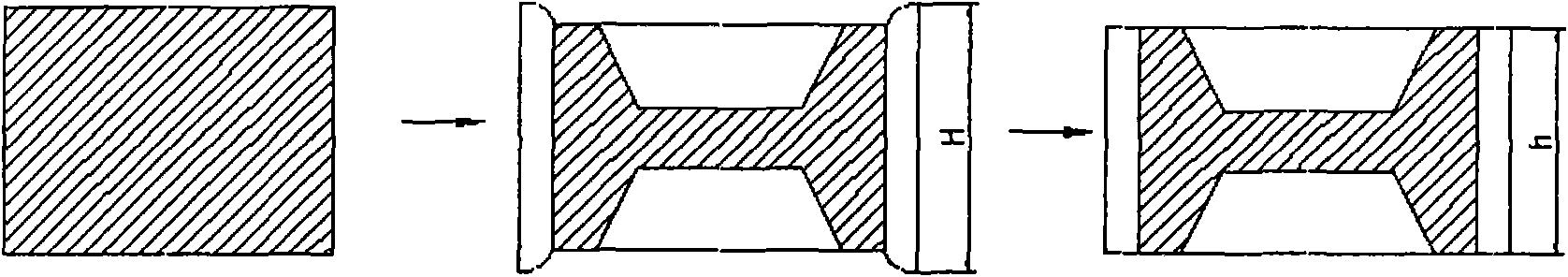

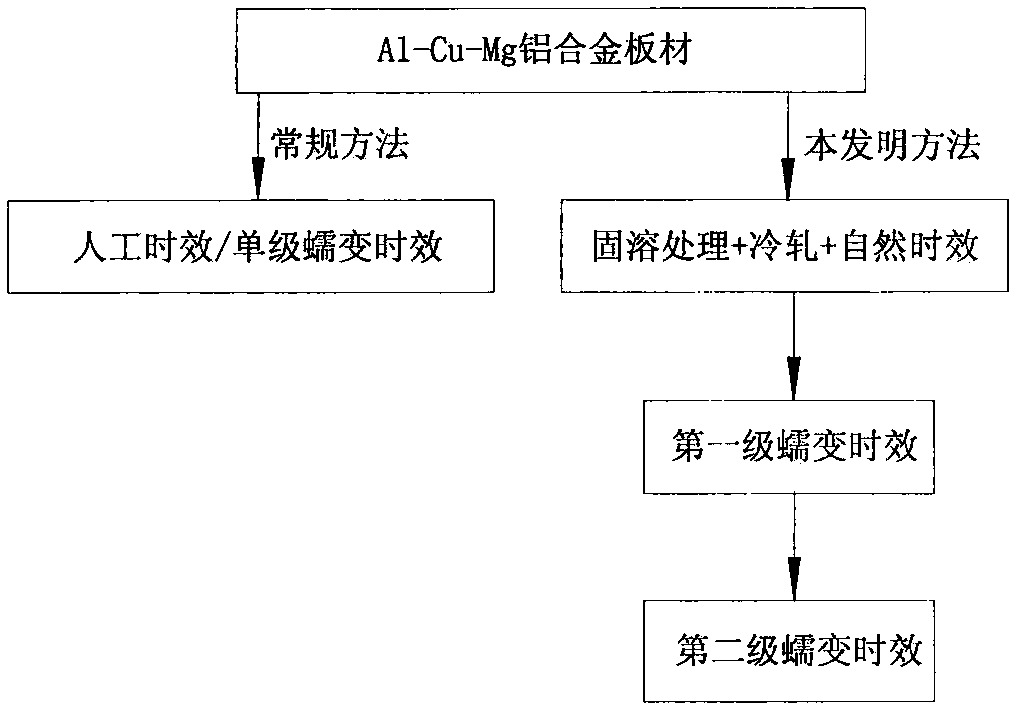

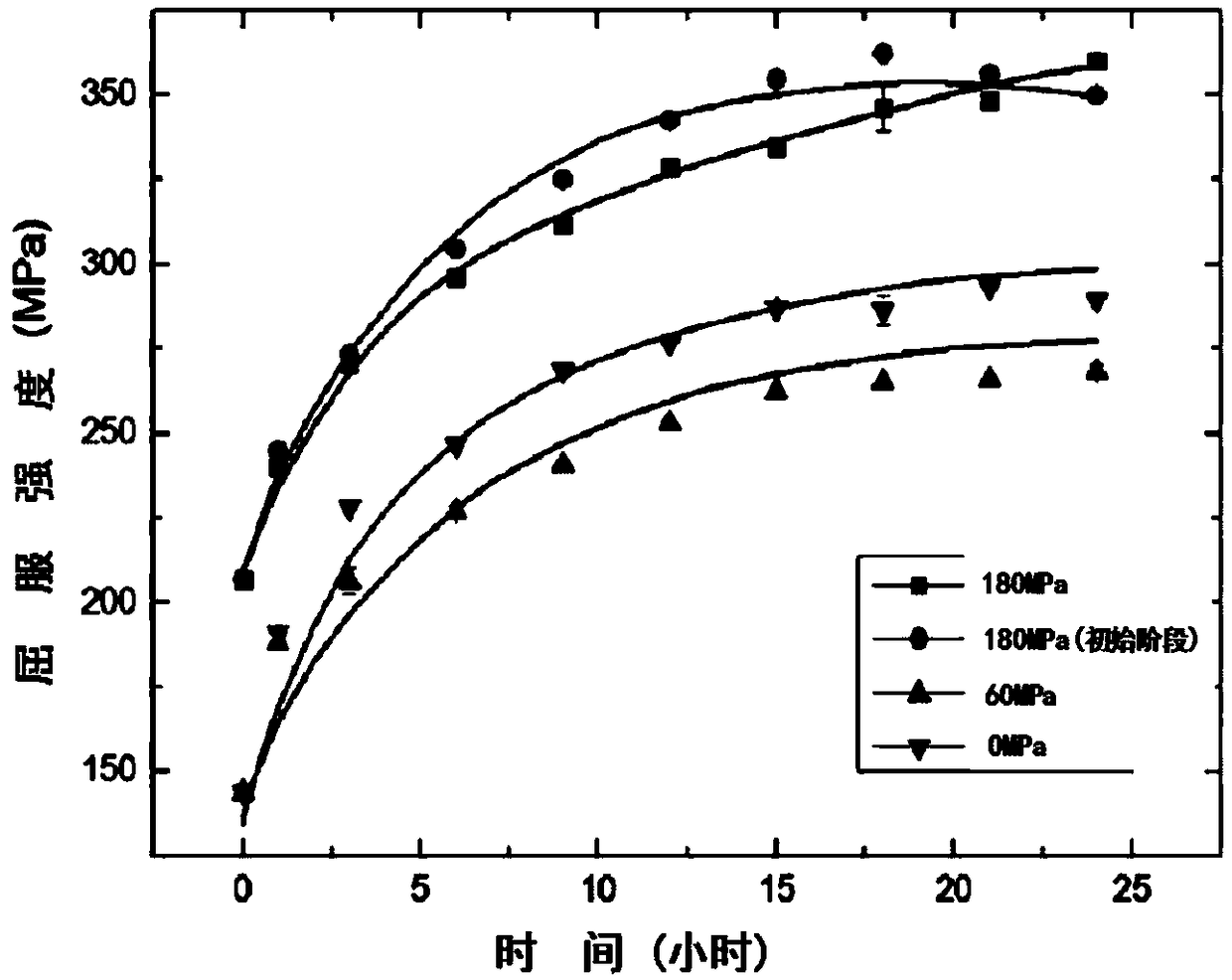

Multistage creep age forming method for Al-Cu-Mg series aluminum alloy panel

The invention discloses a multistage creep age forming method for an Al-Cu-Mg series aluminum alloy panel. The method includes the steps that firstly, water quenching is conducted on the Al-Cu-Mg series aluminum alloy panel with the thickness ranging from 2 mm to 35 mm after solid solution processing is conducted on the Al-Cu-Mg series aluminum alloy panel at the temperature ranging from 490 DEG C to 505 DEG C for 30 minutes to 90 minutes, 1 percent to 5 percent of cold rolling is conducted, and then natural aging processing is conducted for 100 hours to 200 hours; secondly, the first stage of creep age forming is conducted, wherein the creep age temperature ranges from 140 DEG C to 160 DEG C, the applied stress ranges from 170 MPa to 230 MPa, and the time ranges from 10 hours to 14 hours; thirdly, the second stage of creep age forming is conducted, wherein the creep age temperature ranges from 160 DEG C to 200 DEG C, the applied stress ranges from 170 MPa to 230 MPa, and the time ranges from 10 hours to 14 hours; fourthly, the panel is unloaded from a die. When the Al-Cu-Mg series aluminum alloy panel is processed through the method, the mechanical property and the corrosion resistance of the aluminum alloy panel can be effectively improved.

Owner:CENT SOUTH UNIV

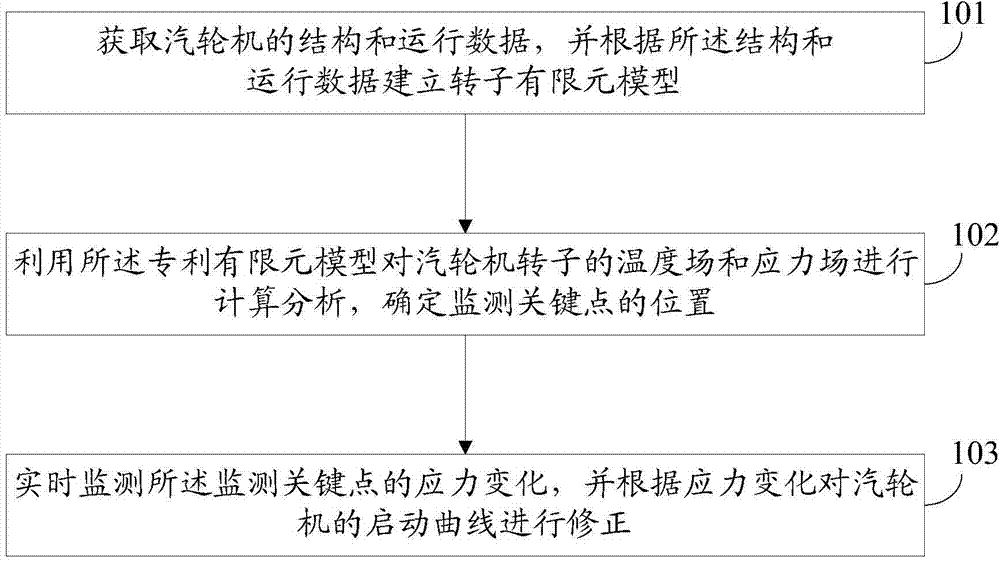

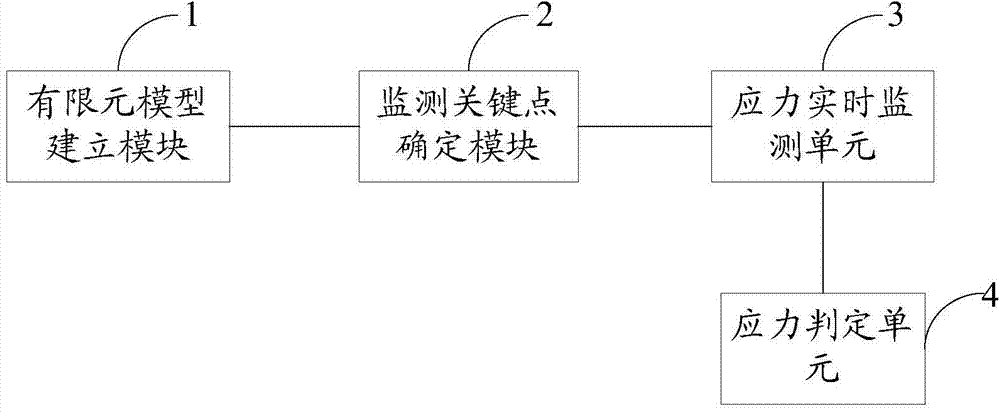

Rapid starting control method and rapid starting control system for steam turbine of combined cycle generating unit

InactiveCN104775856AStart fastShorten warm-up timeMachines/enginesEngine startersElectricityHeating time

The application discloses a rapid starting control method and a rapid starting control system for a steam turbine of a combined cycle generating unit. Because the starting speed of the steam turbine is constrained by the stress level of a rotor of the steam turbine, under the condition that the stress of the rotor does not exceed a maximum stress range, the starting curve of the steam turbine is adjusted according to real-time stress received by the rotor, the heating time of the steam turbine is shortened, moreover, the steam turbine is heated under low load, consequently, the steam turbine is started rapidly, and the purpose of generating more electricity and saving energy in the process of starting is achieved.

Owner:STATE GRID CORP OF CHINA +2

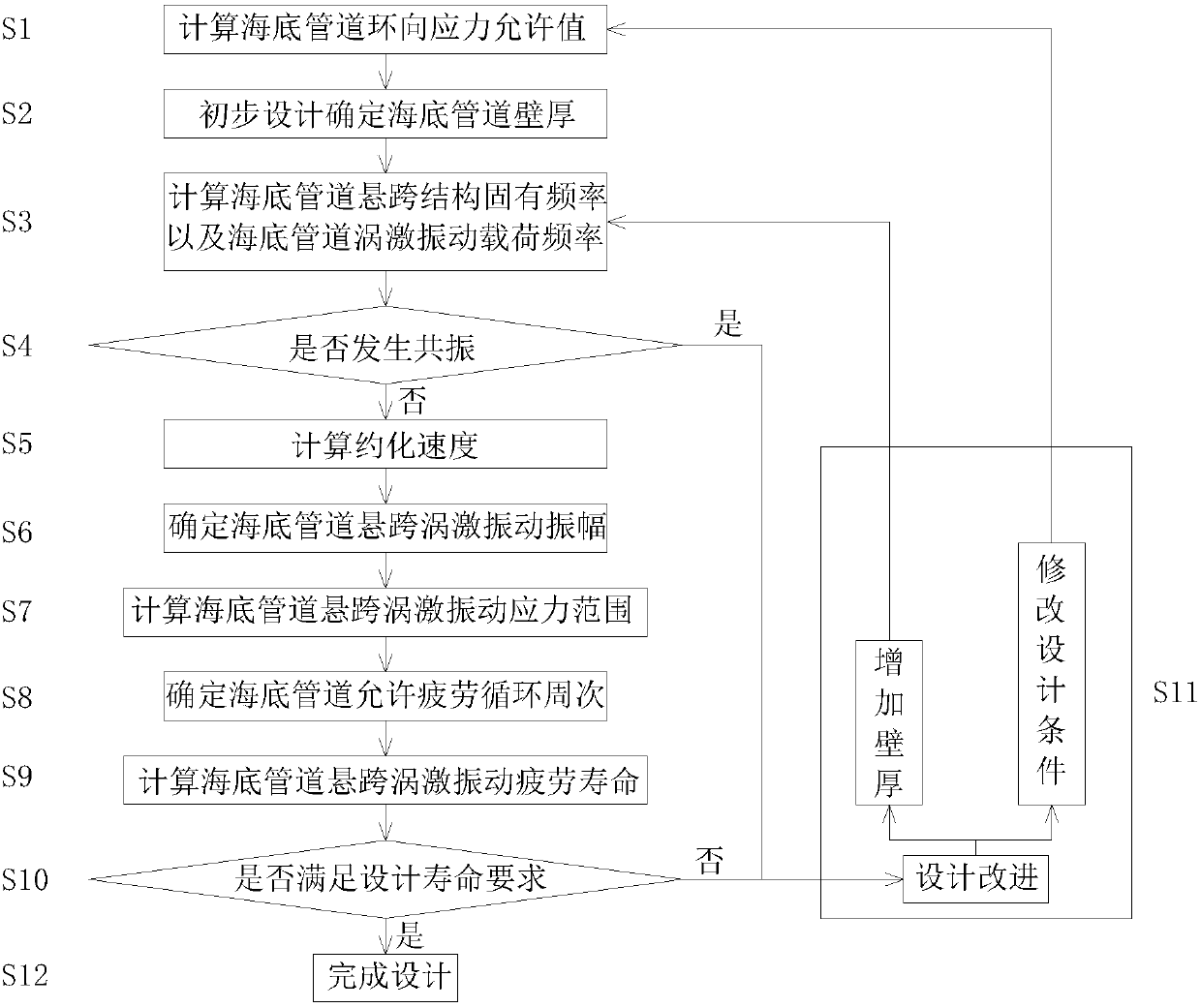

Submarine pipeline design method based on suspended-span vortex-induced vibration fatigue life

ActiveCN107742039AOvercoming too conservativeOvercoming complexityGeometric CADSpecial data processing applicationsTechnical supportStress range

The invention discloses a submarine pipeline design method based on the suspended-span vortex-induced vibration fatigue life. The submarine pipeline design method comprises the following steps that firstly, the permissible value of the pipeline hoop stress is calculated; secondly, primary design is conducted to determine the pipeline wall thickness; thirdly, the inherent frequency of a suspended-span structure of a submarine pipeline and the vortex-induced vibration load frequency of the submarine pipeline are calculated; fourthly, it is judged whether the suspended-span structure of the submarine pipeline resonates or not; fifthly, the reduced velocity is calculated; sixthly, the suspended-span vortex-induced vibration amplitude of the submarine pipeline is determined; seventhly, the suspended-span vortex-induced vibration stress range of the submarine pipeline is calculated; eighthly, the number of the permissible fatigue cycle times of the submarine pipeline is determined; ninthly,the suspended-span vortex-induced vibration fatigue life of the submarine pipeline is calculated; tenthly, it is judged whether the designed life requirements of the submarine pipeline are met or not;eleventhly, design improvement is conducted; twelfthly, the submarine pipeline design based on the suspended-span vortex-induced vibration fatigue life is completed. The submarine pipeline design method provides a technical support for China to establish submarine pipeline design standards based on the life.

Owner:HEFEI GENERAL MACHINERY RES INST +1

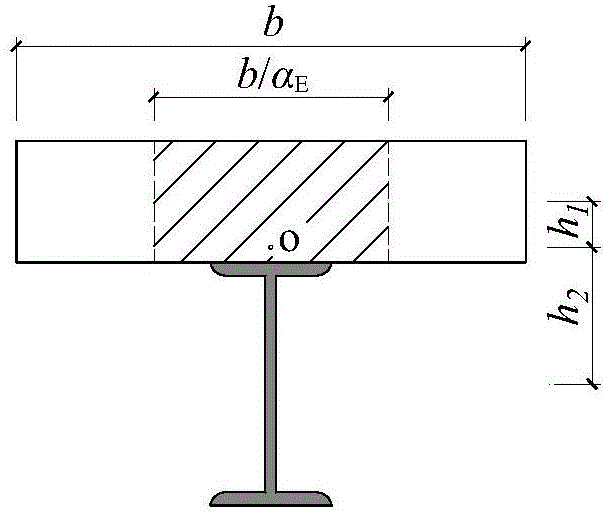

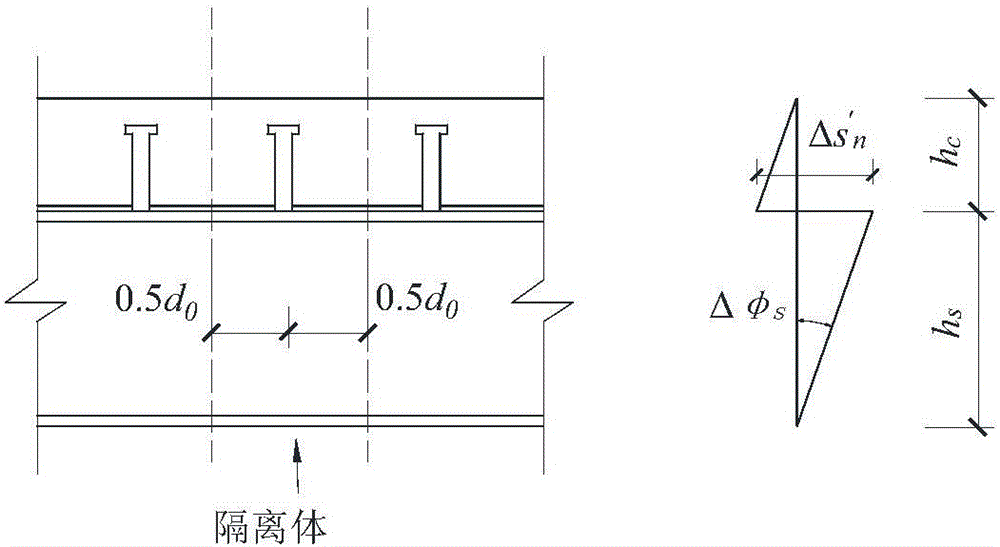

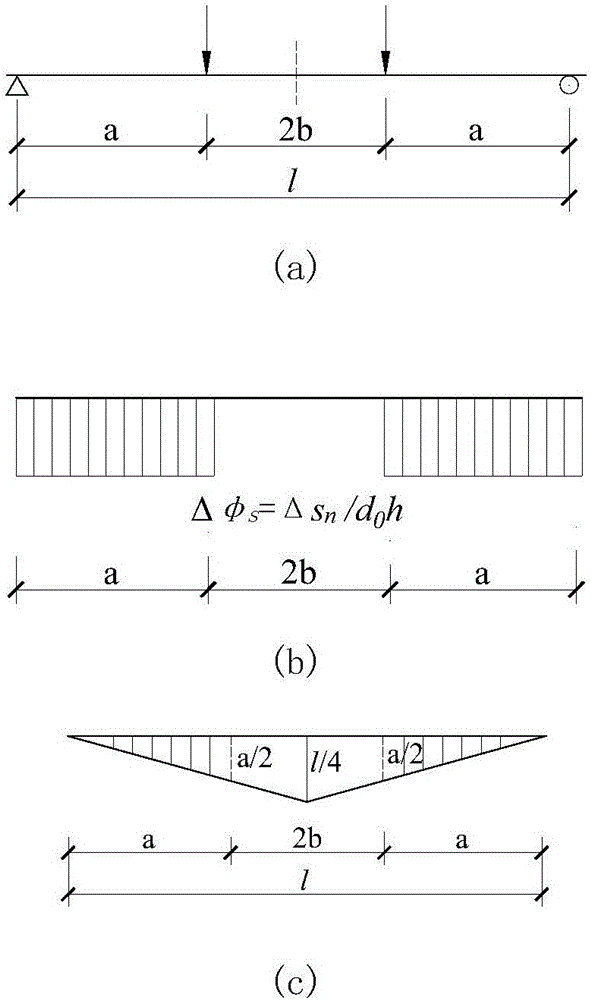

Evaluation method of fatigue additional deformation of steel-concrete composite beam applying stud connector

The invention discloses an evaluation method of fatigue additional deformation of a steel-concrete composite beam applying a stud connector; the method determines a stress state of the most unfavorable section in a combined beam according to a fatigue design load, and accordingly acquires a stress range of the concrete and the stud; respectively calculates the degeneration degree of concrete elasticity modulus and slippage gain of the stud connector, and calculates the fatigue additional deformation of the steel-concrete combined beam caused by the both. The method considers about the influence of the degeneration of concrete elasticity modulus and slippage gain of the stud anti-shearing connector on the fatigue additional deformation of the steel-concrete composite beam at the same time, exactly predicts the fatigue additional deformation of the steel-concrete composite beam applying the stud anti-shearing connector under the equal fatigue load function; thus the method is good for guaranteeing that the combined beam structure is under a good technology state; meanwhile, the method can effectively control the risk of disastrous fatigue damage of the steel-concrete composite beam applying the stud connector.

Owner:GUANGXI UNIV +1

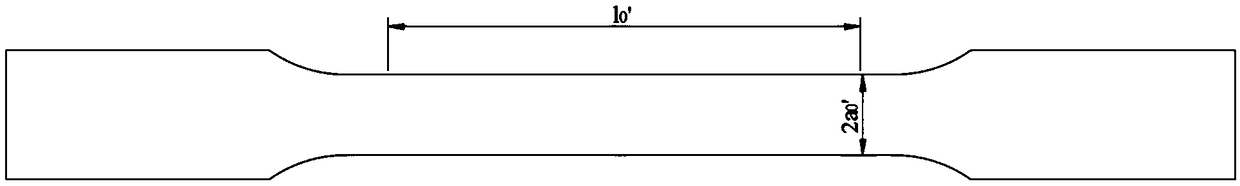

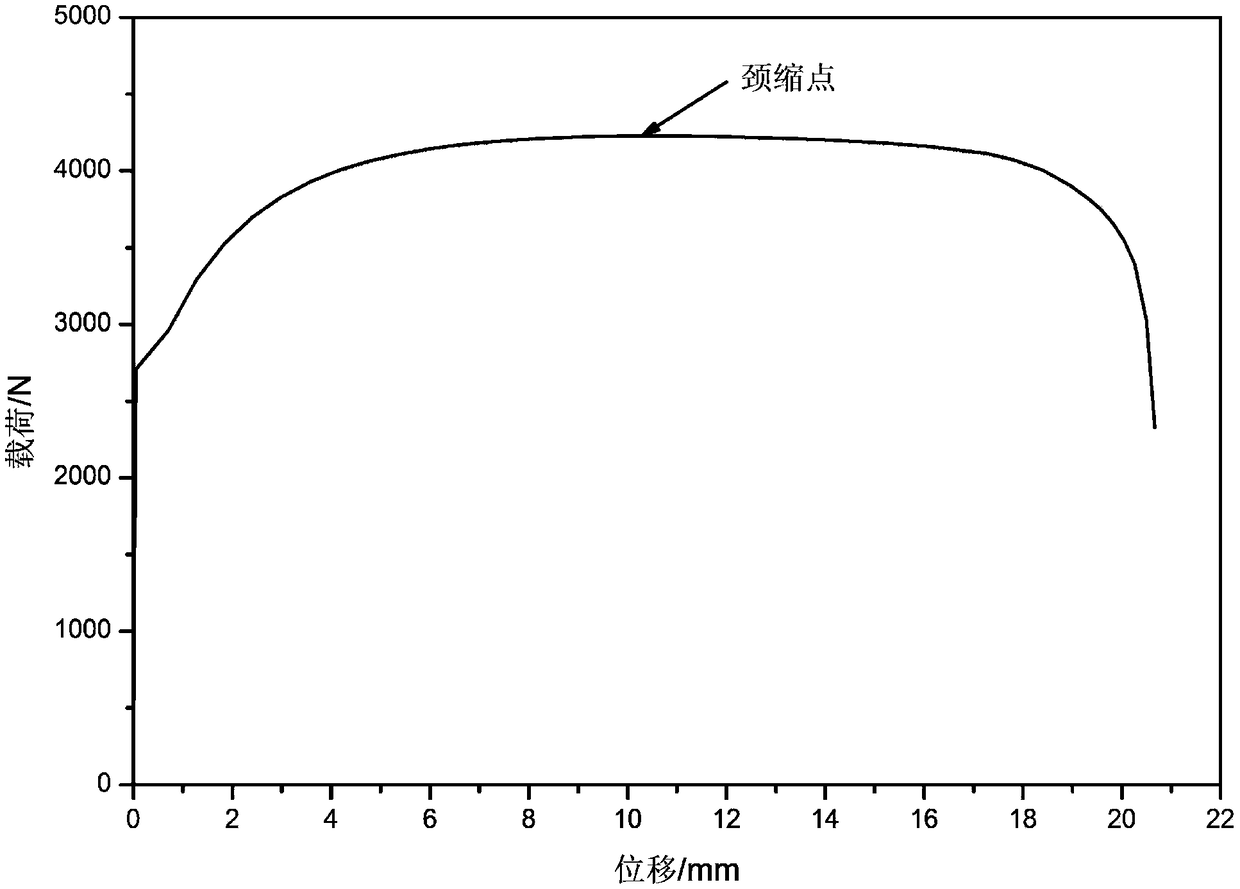

Method for measuring large-stress range stress strain in uniaxial tensile test of metal plate sample

InactiveCN108982222AEliminate cumbersome measurement linksSave time and costMaterial strength using tensile/compressive forcesBridgman methodStress–strain curve

The invention relates to a method for measuring the large-stress range stress strain in a uniaxial tensile test of a metal plate sample. The method comprises the following steps: building a step modelfor gradual expansion of unstable necking of uniaxial tension of the metal plate sample; measuring the instant gauge length and the minimum sectional width at a necking position of the plate sample after extension instability; building an interpolation curve expression of the necking profile on the basis of necking step coordinates of the necking step model at each moment; solving the parametersof the necking step model according to the mechanical relationship of necking in the width direction and the thickness direction and the principle of volume conservation; finally calculating the actual stress and actual strain at the moment through a Bridgman method. By adopting the method, the test measuring link for the necking outer profile curvature radius in the existing method is omitted, and the measuring accuracy of a large-strain range stress-strain curve is improved, so that the method has important significance to the mechanical performance test of metal materials.

Owner:JILIN UNIV

HPLC frit filter assembly

InactiveUS20140021116A1High melting pointObstruct passageFurnaces without endless coreIon-exchange process apparatusUltra high pressureFrit

An apparatus and method for creating a high pressure chromatography frit filter assembly is described. The frit is positioned in bondable contact with a polymer ring and then the frit is subject to inductive or targeted heating to cause the frit material to heat the adjacent polymer ring from the inside out. The polymer to liquefies and flow into and past one or more narrowing locations in the pore passageway extending from the surface of the frit to an infusion depth, which provides previously unachieved secure mechanical engagement and adherence and resistance to pressure blow by (break through) and prevents the flow of contaminants between the edge of the frit and the facing edge of the polymer ring in a high pressure or ultra-high pressure chromatography system, where inlet pressures in the range of pressures up to 18,000 PSI are expected.

Owner:FORD POLYMET +1

Method for improving antioxidant enzyme activity of ryegrass under drought conditions

InactiveCN101869032AImprove drought resistanceEliminate or reduce harmClimate change adaptationOrganic fertilisersOxygenase activityAntioxidative enzyme

The invention relates to a method for improving antioxidant enzyme activity of ryegrass by adopting fine domestic garbage compost under drought conditions. The method comprises the following steps of: uniformly scattering garbage trace fertilizers with grain diameters of 1,200 nanometers, 600 nanometers and 300 nanometers respectively on the surface of soil, wherein the weight part ratio of the grain diameter to the soil is 1: 60-80; then, sowing 0.5 gram of tall fescue, controlling the temperature to be between 20 and 26 DEG C and relative humidity to be between 40 and 60 percent, and illuminating the tall fescue with indoor natural light; and fully watering the tall fescue at the initial sowing stage, weighing the water in an amount which is 55 to 65 percent of the field holding amount every day or every two days after two weeks to maintain the water in a stress range, and measuring each index on the 44th day. The method provides technical support for applying the fine-grain urban domestic garbage compost to a lawn planting system.

Owner:TIANJIN NORMAL UNIVERSITY

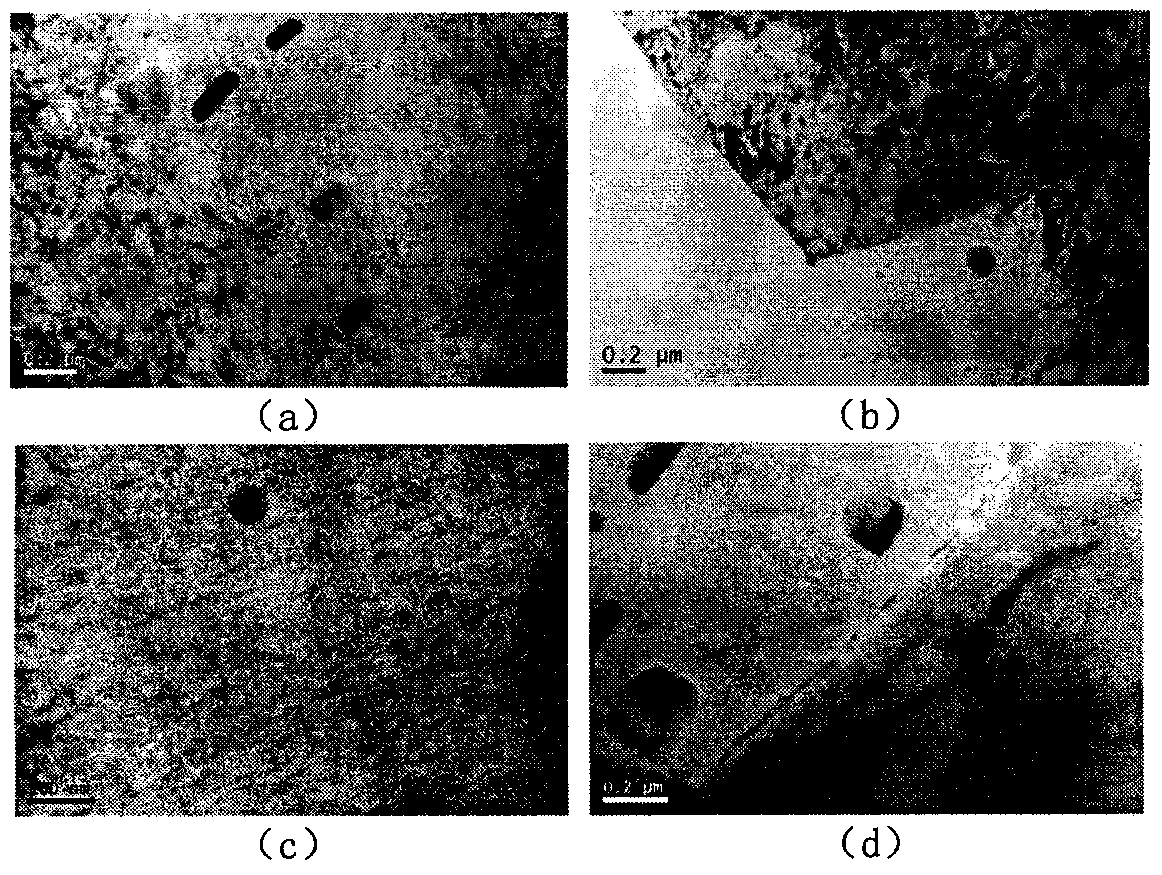

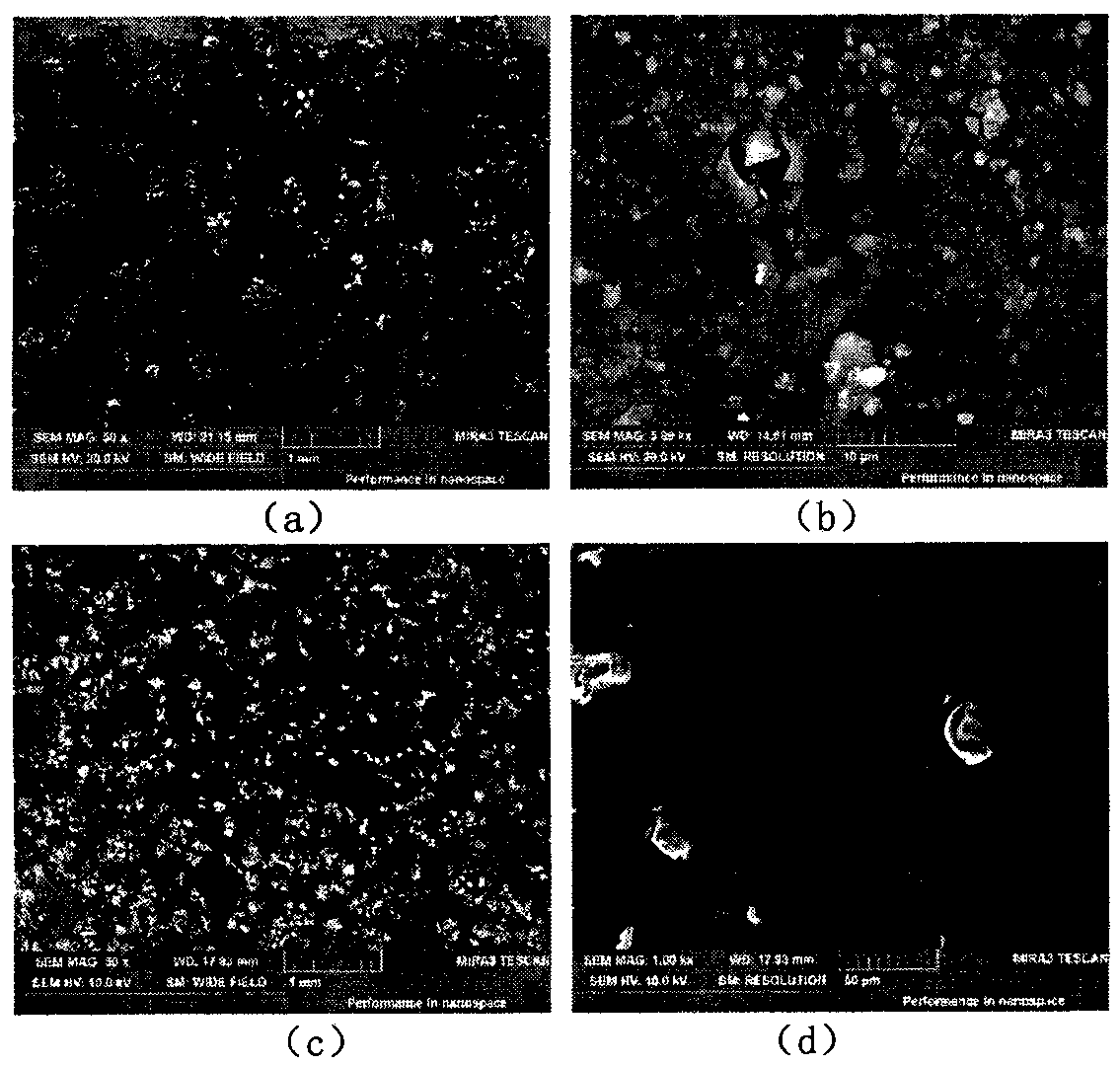

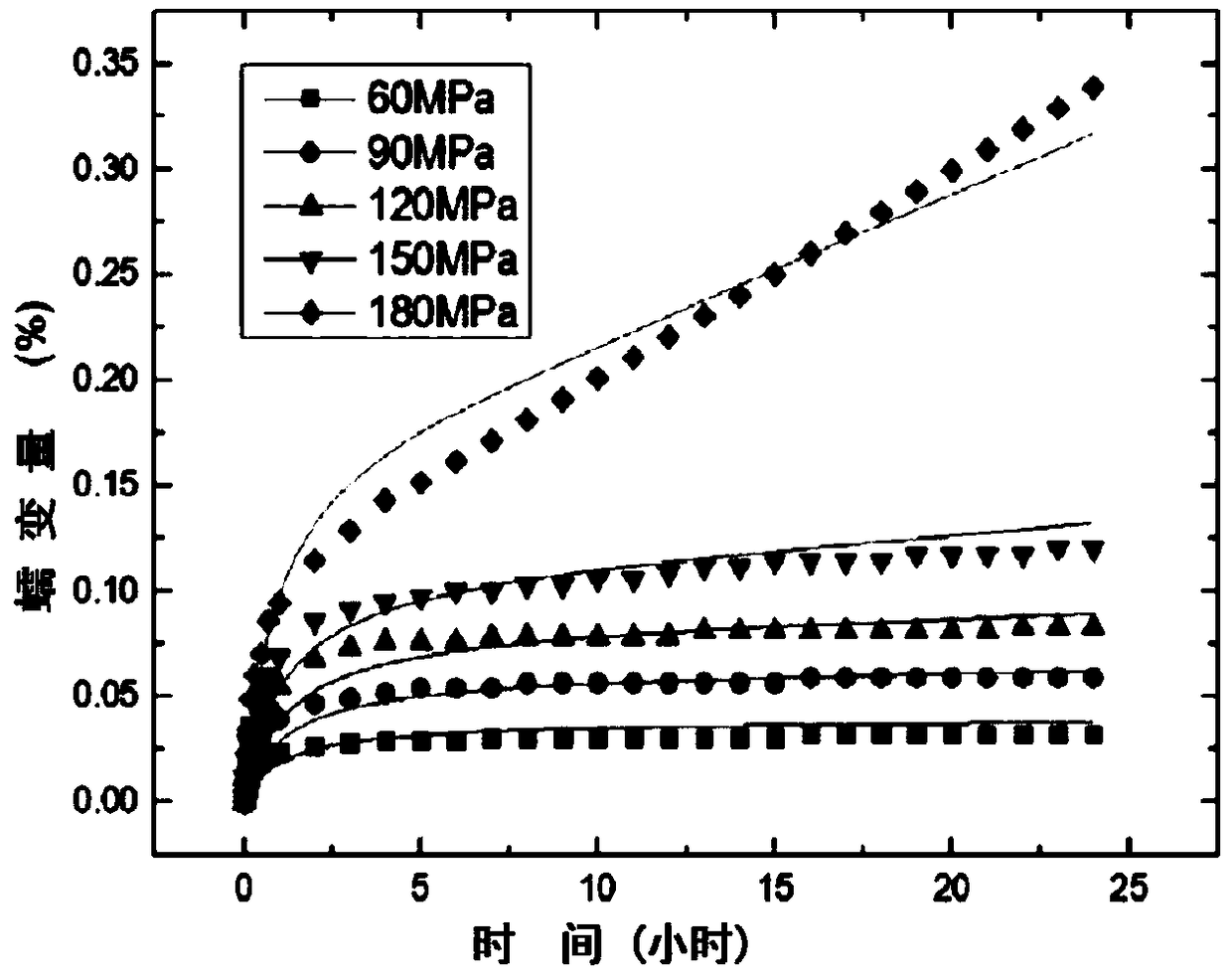

A method for predicting creep ageing behavior of aluminum-copper alloys under variable stress

A method for predicting creep aging behavior of Al-Cu alloy unde variable stress is provided. The uniaxial tensile stress aging treatment was carried out on a creep tester, and the creep curves were obtained under different stress levels at specific temperatures. Then the tensile tests were carried out after air cooling to room temperature, and the yield strength changes under different stress aging were obtained. The evolution of dislocation density in step one creep process was calculated by X-ray diffraction method. The changes of theta 'and theta size and volume fraction of main strengthening phases in creep process were observed by transmission electron microscope. A unified macroscopic and microscopic constitutive model for predicting creep and age hardening of Al-Cu alloys under strain stress was established. The material constants are determined and the parameters in the model are obtained by particle swarm optimization algorithm. The invention solves the drawback that the prior method can only be used in a narrow stress range, has important guiding significance for accurately predicting creep deformation and property evolution under complex stress of practical materials and components, and can be applied to numerical simulation of component manufacturing.

Owner:CENT SOUTH UNIV

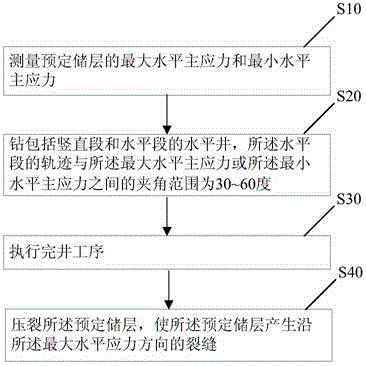

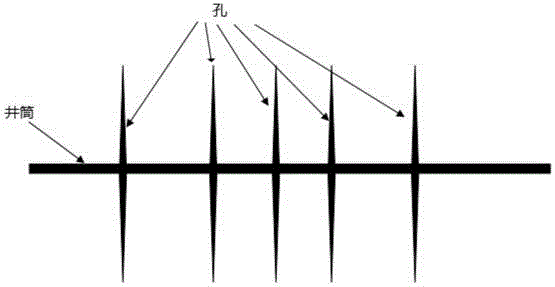

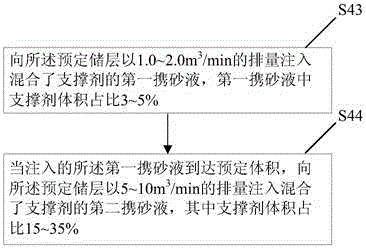

Reservoir reforming method

InactiveCN104594869ABest empirical completenessGood fracture oil conduction effectFluid removalDirectional drillingHorizontal stressDesign stage

The invention provides a reservoir reforming method. The reservoir reforming method includes the steps that the maximum horizontal principle stress and the minimum horizontal principle stress of a predetermined reservoir are measured; a horizontal well comprising a vertical section and a horizontal section is drilled, wherein the included angle between the track of the horizontal section and the maximum horizontal principle stress or the minimum horizontal principle stress ranges from 30 degrees to 60 degrees; a well completion procedure is executed; the predetermined reservoir is cracked so that a crack can be formed in the predetermined reservoir in the direction of the maximum horizontal stress. At the initial design stage, in consideration of the possible extension direction of the crack when the reservoir is cracked, the included angle between the extension direction of the horizontal section and the maximum horizontal principle stress or the minimum horizontal principle stress of the predetermined reservoir is made to range from 30 degrees to 60 degrees, so that the horizontal well has good experience completeness and a good oil-guiding effect of the crack, and then the oil and gas production rate is easily increased.

Owner:PETROCHINA CO LTD

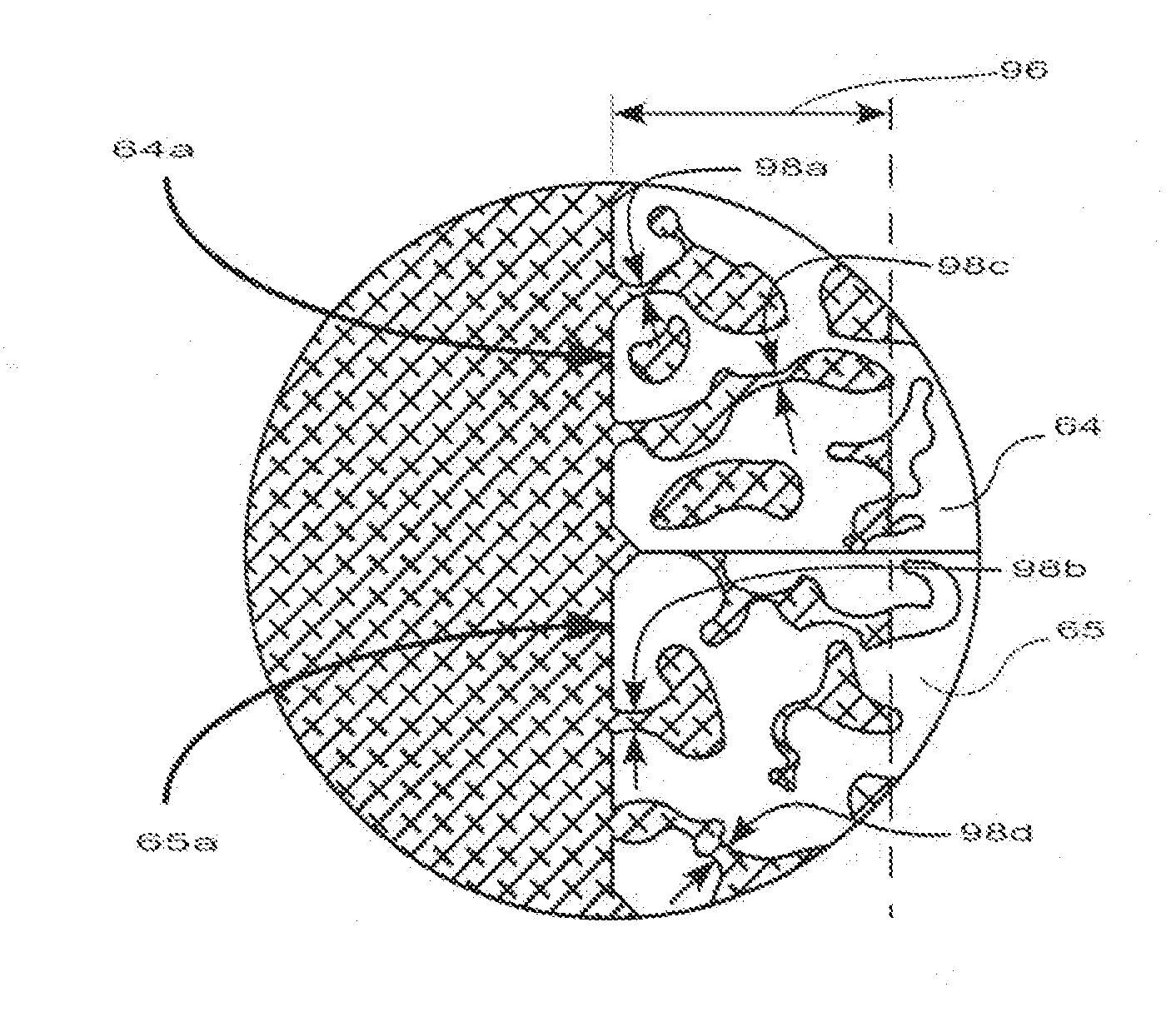

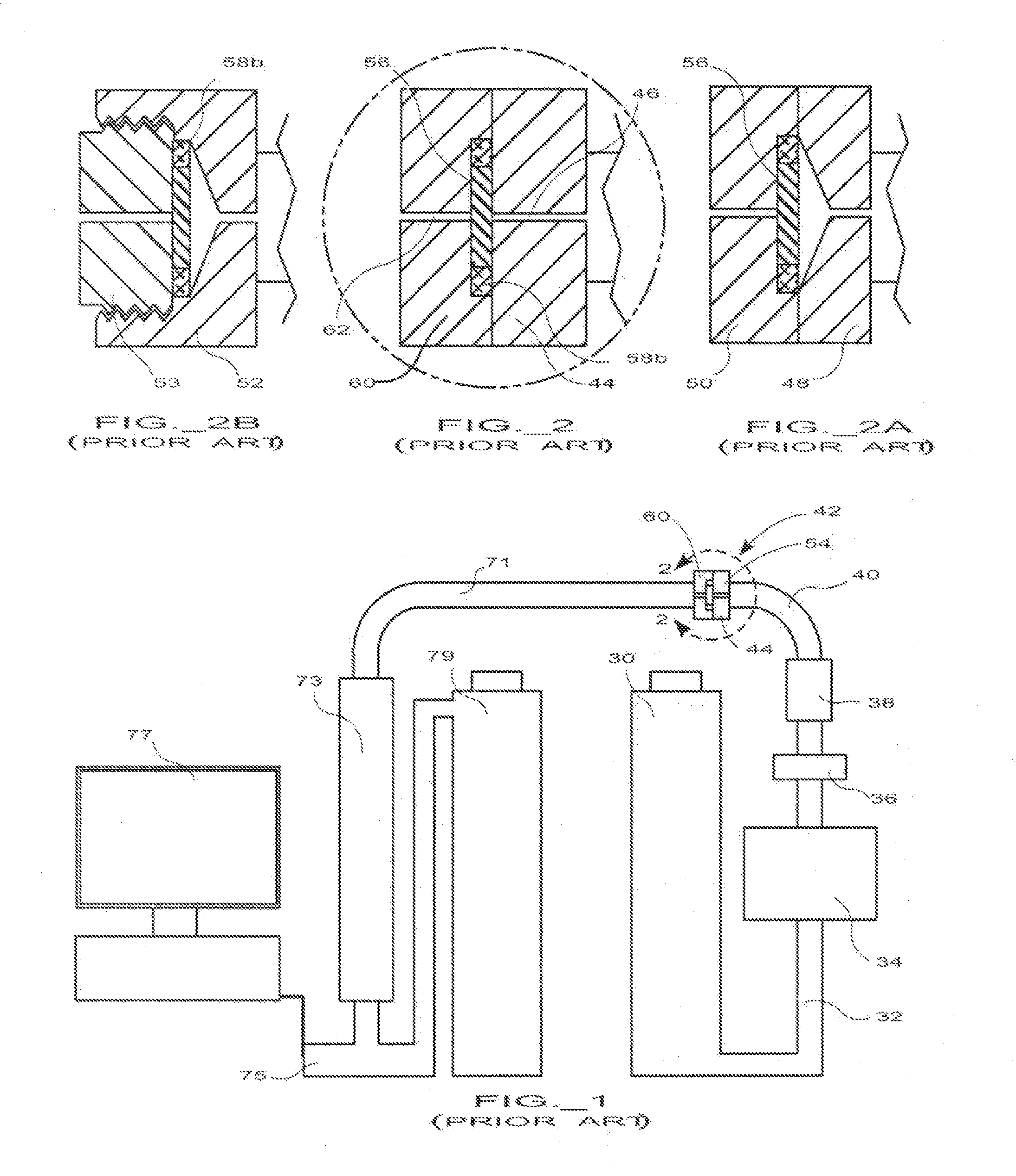

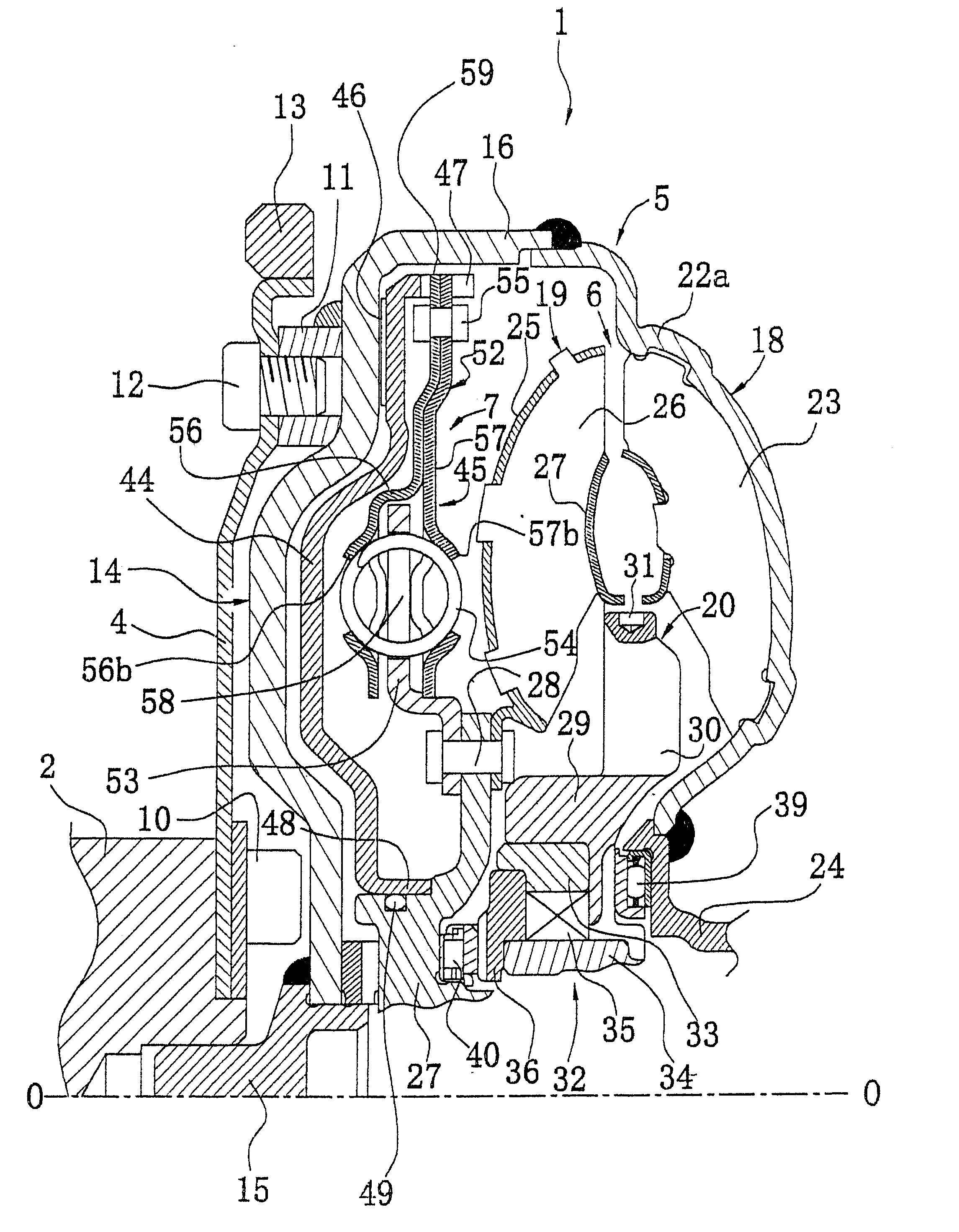

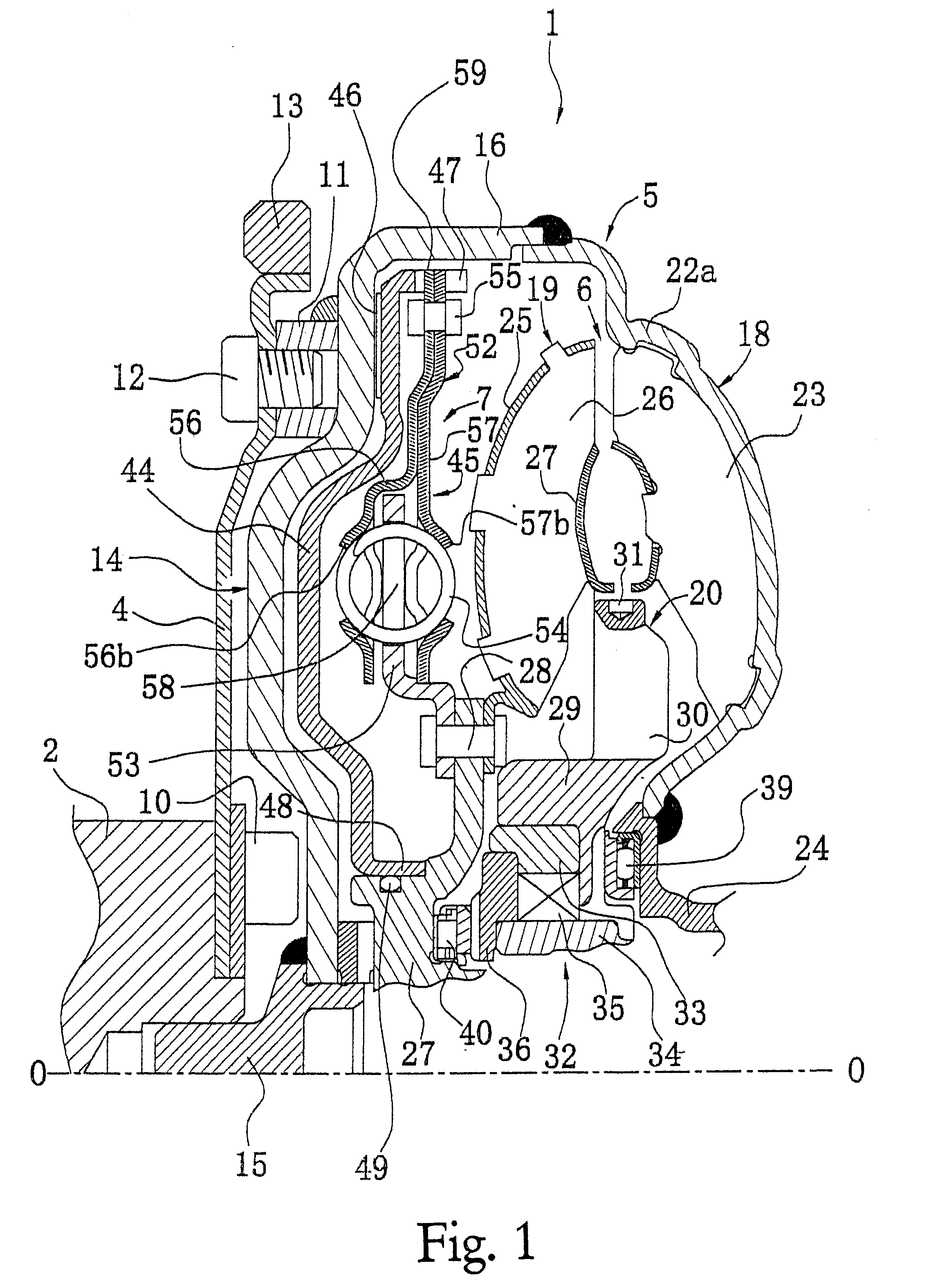

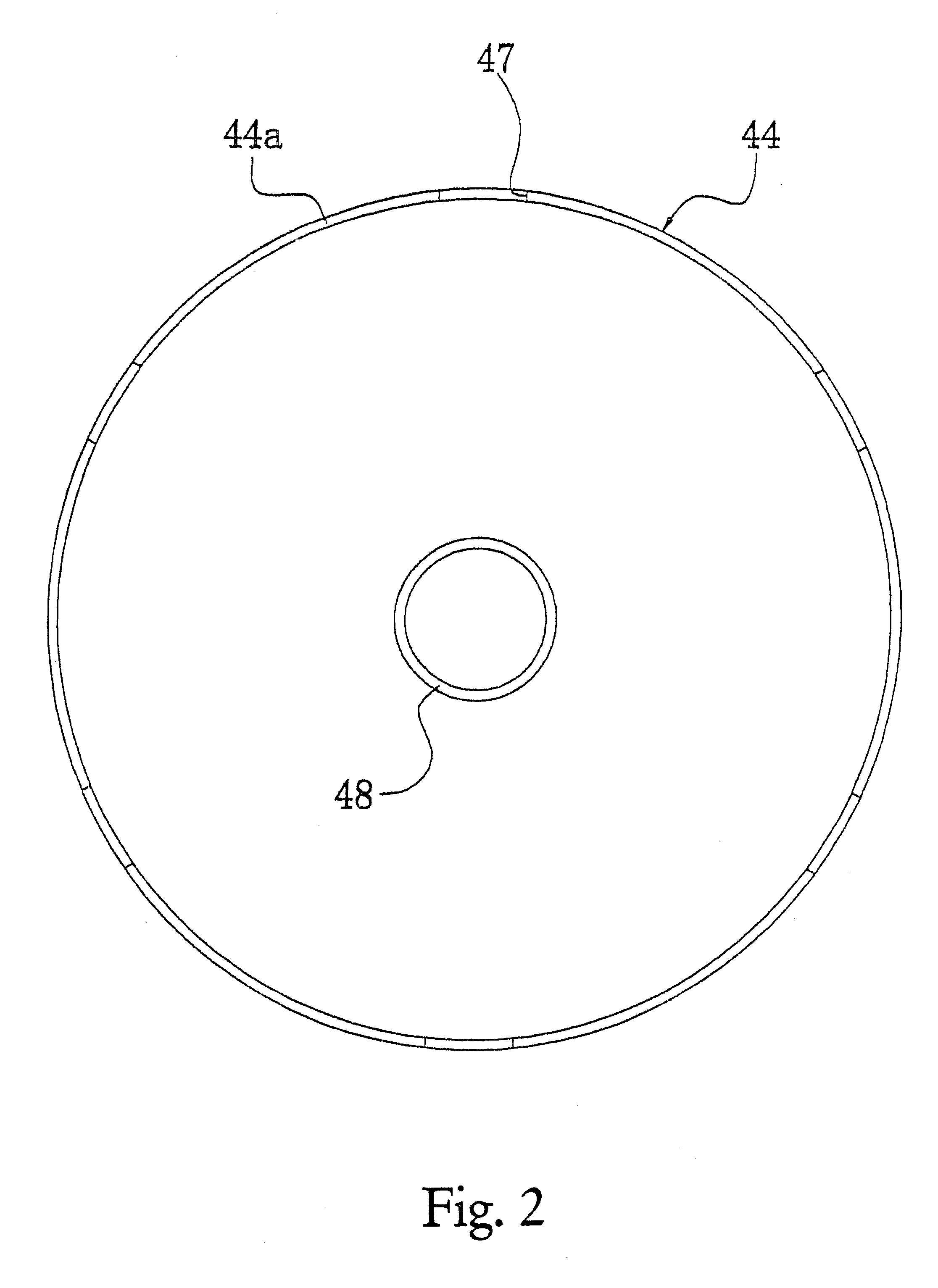

Lock-up damper of torque converter

InactiveUS6267213B1Reduce weightReduce thicknessYielding couplingRotary clutchesEngineeringTorsion spring

A lock-up mechanism 7 of a torque converter 1 has a piston 44 with a lock-up damper 45. The lock-up damper 45 includes a drive member and a hub flange 53 with the elastic members or torsion springs 54 operatively coupled therebetween to dampen vibrations in the torque converter 1. The drive member and the hub flange 53 both have a plurality of window holes 56d, 57d and 58 that are arranged circumferentially for receiving the corresponding torsion springs 54. The drive member includes a clutch plate 56 and a retaining plate 57. The clutch plate 56 of the drive member has a plurality of holes or cutouts 56e arranged radially outward of the window holes 56d. These holes or cutouts 56e are arranged to reduce the weight of the clutch plate 56, while maintaining the stresses around the window holes 56d of the clutch plate 56 within an allowable stress range. The retaining plate 57 of the drive member also has a plurality of holes or cutouts 57e that are arranged radially outward of the window holes 57d. These holes or cutouts 57e are arranged to reduce the weight of a retaining plate 57, while maintaining the stresses around the window holes 57d of the retaining plate 57 within an allowable stress range. The hub flange 53 of the lock-up damper 45 also include a plurality of holes or cutouts 59 that are circumferentially arranged between the window holes 58 in the hub flange 53. These holes or cutouts 59 are arranged to reduce the weight of a hub flange 53, while maintaining the stresses around the window holes 58 of the hub flange 53 within an allowable stress range.

Owner:EXEDY CORP

Method for preparing pressure-sensitive material based on carbonized sponge

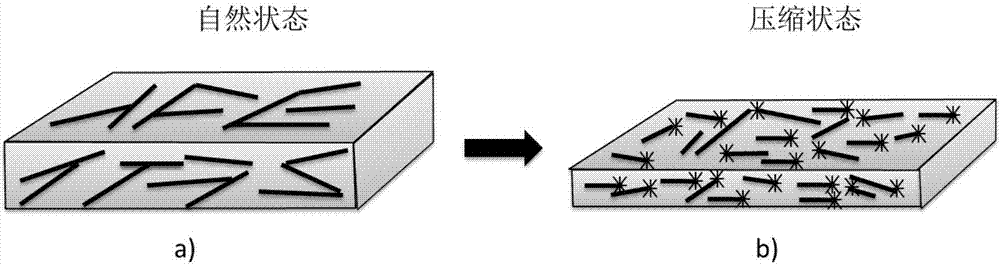

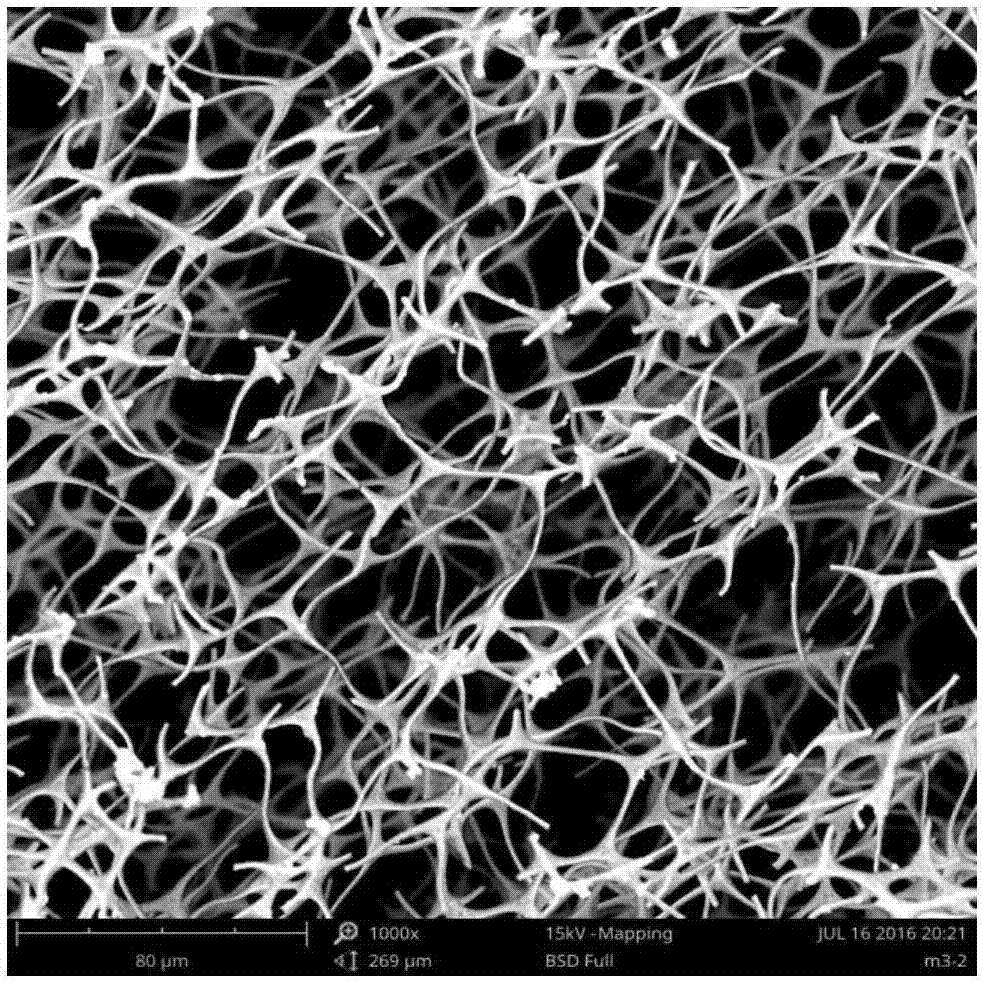

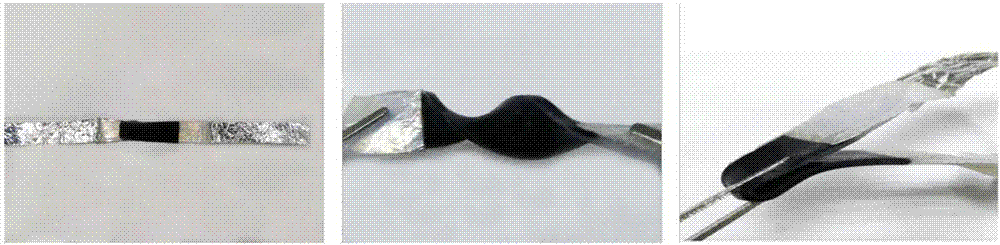

InactiveCN106852687ASimple preparation processLow costCatheterRespiratory organ evaluationStructure health monitoringRepeatability

The invention provides a method for preparing a pressure-sensitive material based on a carbonized sponge. The method comprises the following steps that 1, a melamine sponge is subjected to thermal decomposition treatment for 0.5-5 hours at the high temperature of 700 DEG C to 1,000 DEG C under vacuum or inert atmosphere protection, and the carbonized sponge is prepared; 2, resin materials with the volume 0.2-1 time that of the carbonized sponge are poured into the carbonized sponge, vacuum defoaming is carried out, and after resin is cured, the pressure-sensitive material with high sensitivity is obtained. The method has the advantages that raw material sources are cheap, high repeatability is achieved, the preparation process is simple and controllable, the prepared pressure-sensitive material is wide in stress range and high in sensitivity, and the method has good application prospects on the aspects of structure health monitoring, electronic skin, biological medicine, wearable electronic products and the like.

Owner:CHONGQING UNIV

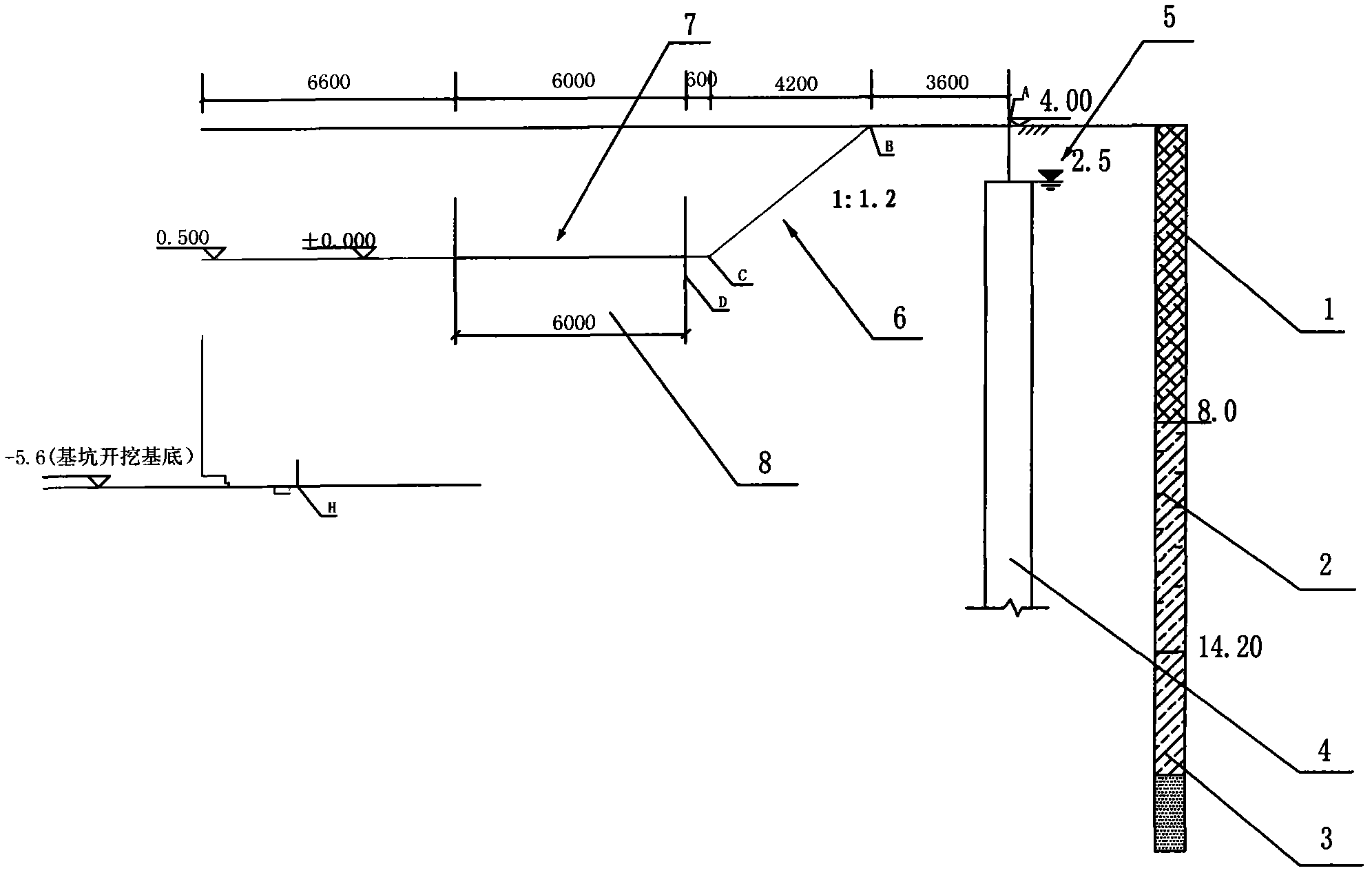

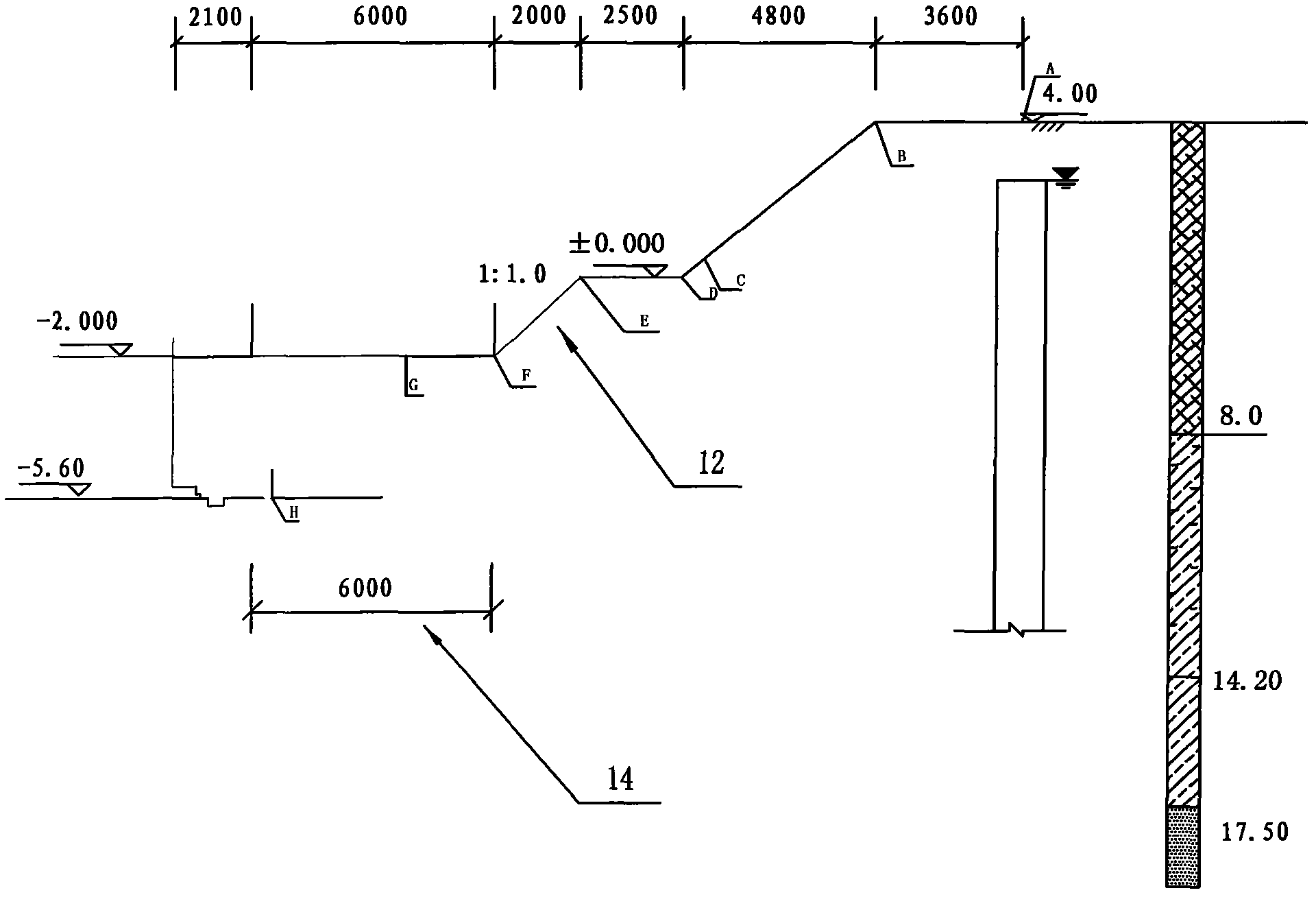

Construction method for foundation pit supporting by dynamic compaction replacement of muddy soil

InactiveCN102561362AImprove support efficiencyEasy constructionExcavationsDynamic compactionSoil horizon

The invention discloses a construction method for foundation pit supporting by dynamic compaction replacement of muddy soil, which includes the steps: performing pre-dewatering in a pit before excavation of the foundation pit according to a designed elevation; performing natural sloping according to a certain proportion, excavating to a first preset elevation, confirming tamping settlement and area of tamped corrected land, and locating and paying off a line according to the design requirements; distributing spots one or two times of the rammer base diameter in a foundation base stress range to confirm compacting spots, and controlling spot distribution among foundation bases in the range of land reinforcement and expanded compaction according to land photometric conditions and structural design requirements, eight to twelve times of the rammer base diameter. The construction method is suitable for coastal shoals with upper backfill soil and lower muddy soil poor in stability. By the construction method, supporting efficiency is improved greatly, construction is simpler, operation is easy, construction cost is saved, procedures of the method compared with the traditional supporting process are reduced, construction period is shortened, and cost is reduced.

Owner:青建集团股份公司

Method for enhancing drought resistance of lawn by adopting fine garbage compost leaching solution

ActiveCN101869033AHarm mitigationThe effect of spraying compost 6 is goodClimate change adaptationFertiliser formsLitterDistilled water

The invention relates to a method for enhancing the drought resistance of a lawn by adopting fine garbage compost, which comprises the following steps of: preprocessing urban domestic garbage compost, pulverizing the compost with the grain diameter of 1700nm at 24000 revolutions / minute and preparing garbage micro-compost with different grain diameters of 300nm, 240nm and 100nm; leaching the compost with the grain diameters by using distilled water according to the proportion of 15:1 in parts by weight and collecting leacheate as spraying liquid for the leaf surfaces of plants; adopting plastic pots with the diameter of 7cm and the height of 10cm for a pot culture experiment, filling 150g of soil into each pot, sowing lawn plants according to 0.5g / pot, ensuring that seeds can germinate successfully and seedlings grow at an initial stage, spraying the leaf surfaces after two weeks according to 55 to 65 percent of the stress degree of the field moisture capacity and afterwards weighing every one to two days so as to maintain the water content within a stress range; and carrying out an experiment for 60d continuously, then cutting up the lawn plants and measuring various indexes. An experimental result shows that compost leaching solutions with different grain diameters, which are sprayed to the leaf surfaces, can relieve the injury of drought stress to the lawn plants and act as the functions of drought defying and moisture retention.

Owner:TIANJIN NORMAL UNIVERSITY

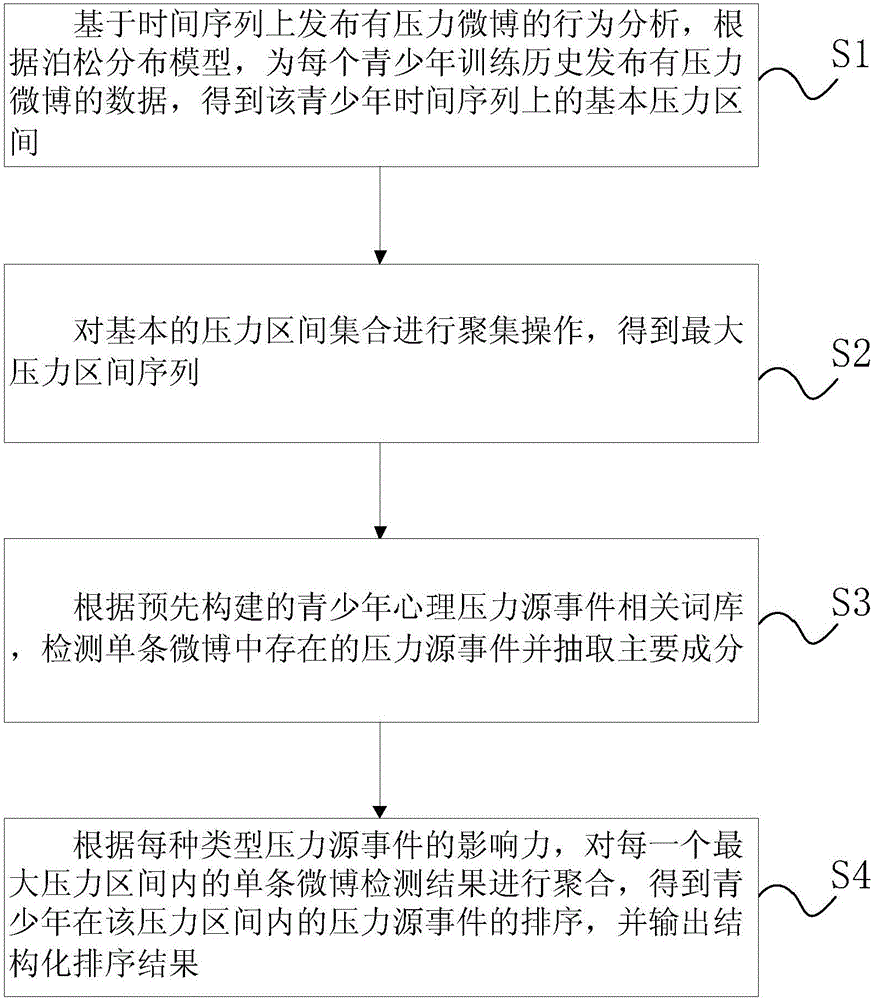

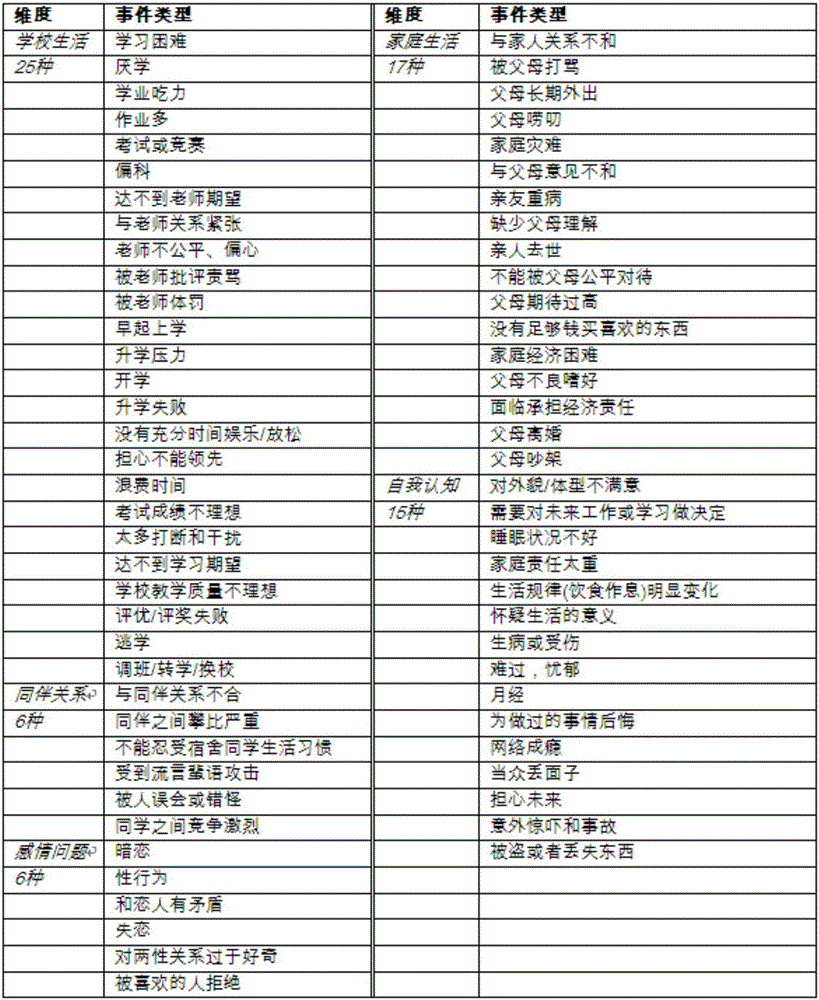

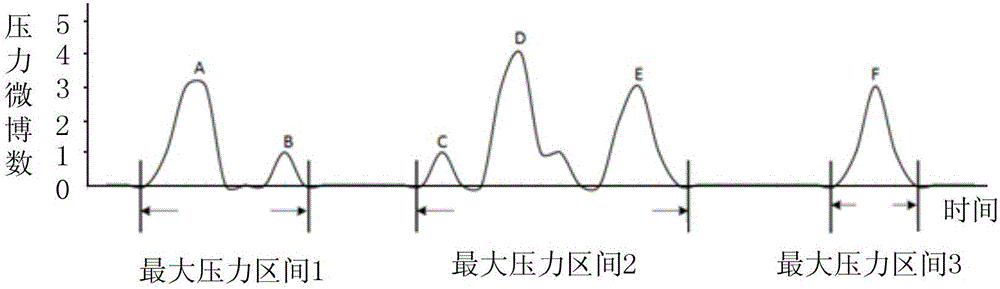

Method and device for sensing adolescent psychological stress range and stress source event

InactiveCN106202052AEasy to understandHelps deal with uncertaintyNatural language data processingSpecial data processing applicationsStressorMaximum pressure

Owner:TSINGHUA UNIV

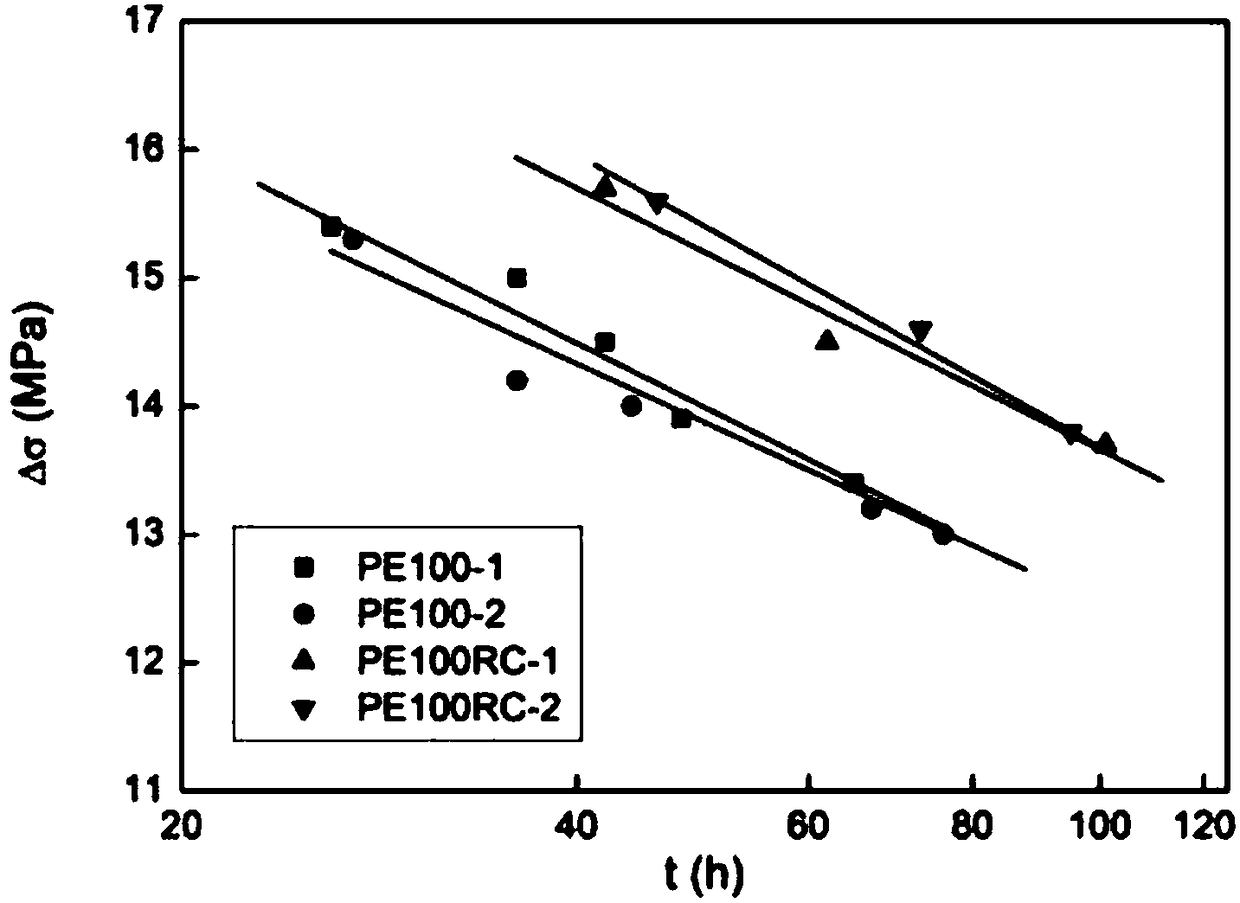

Method for rapidly evaluating slow crack growth resistance of plastic pipe material

PendingCN108318336AShorten test timeSimple test timePreparing sample for investigationMaterial strength using tensile/compressive forcesCrack growth resistance curveTest sample

The invention relates to a method for rapidly evaluating the slow crack growth resistance of a plastic pipe material. The method comprises two steps of preparing a test sample and performing tensile test, wherein a cylindrical test sample is obtained by performing injection molding and presetting notch crack, the cylindrical test sample is subjected to cyclic tensile test by a tensile force changed in sinusoidally, and a relation function of failure time and stress range is obtained and is used for evaluating the slow crack growth resistance of the cylindrical test sample. The method providedby the invention has the advantages of short test time, low cost and high result reproducibility.

Owner:GUANGZHOU SPECIAL PRESSURE EQUIP INSPECTION & RES INST

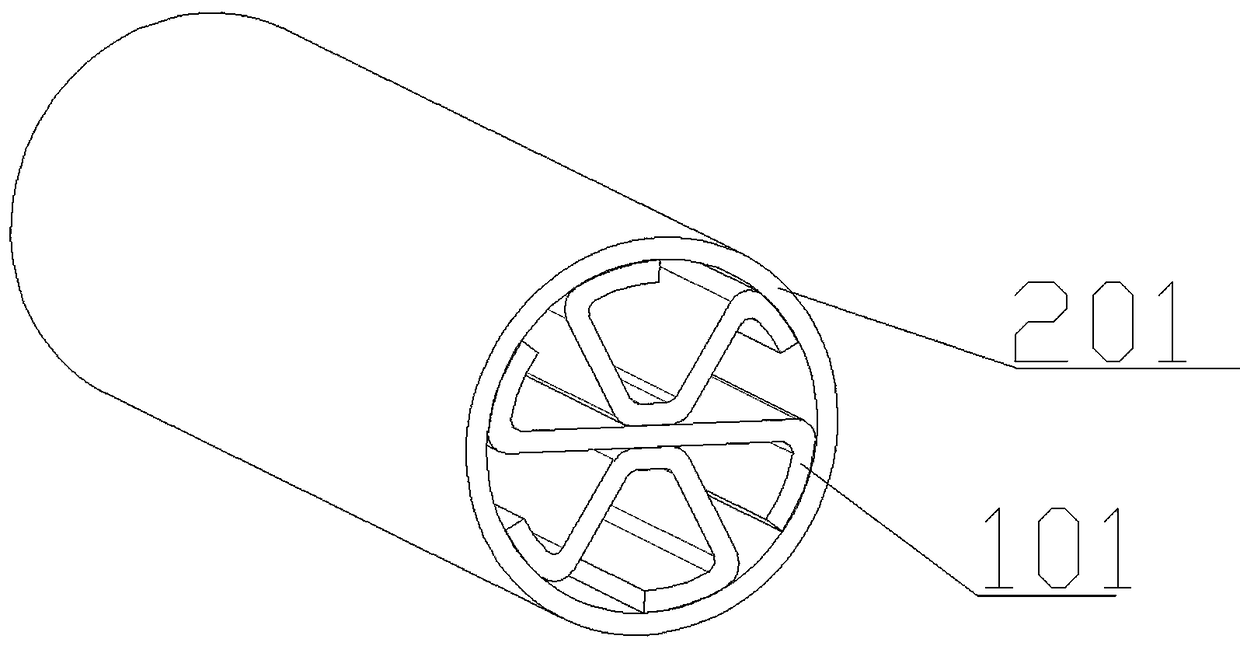

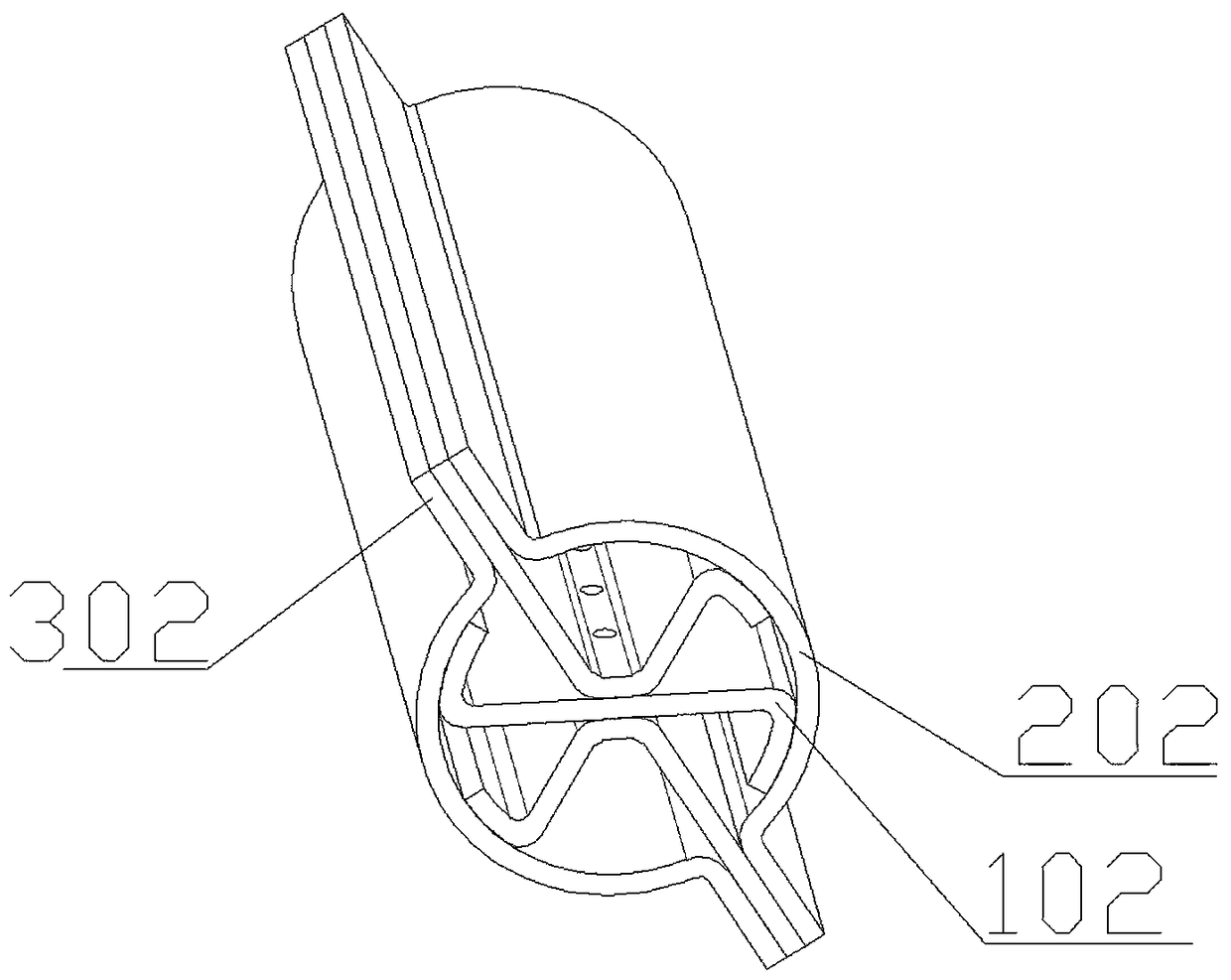

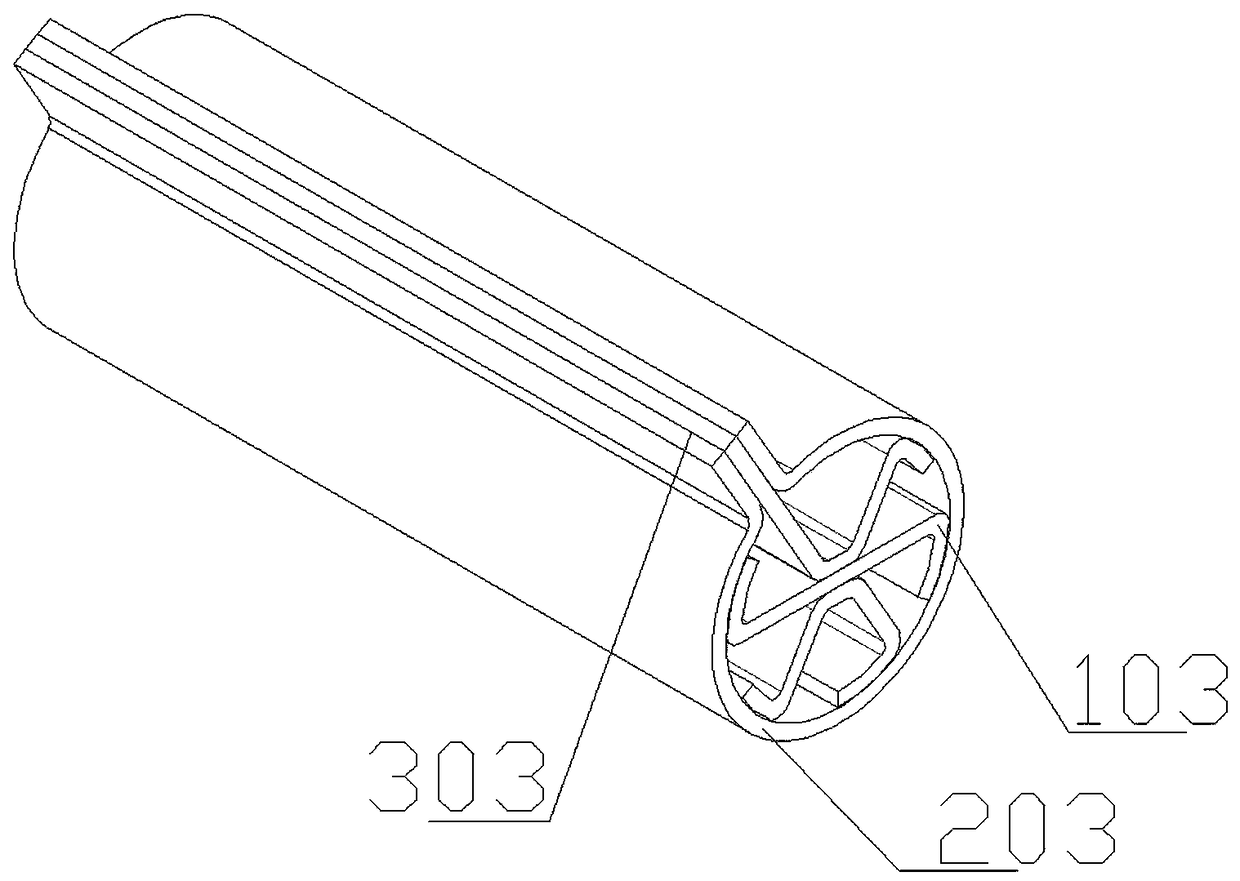

Fiber-fabric-composite-material structural piece and preparing method thereof

InactiveCN108262984AIncrease the degree of stressExpand the scope ofDomestic articlesTubular articlesFiberHoneycomb

The invention discloses a fiber-fabric-composite-material structural piece. The shape of the structural piece is tubular, and the tubular structural piece is a fiber-fabric-composite-material honeycomb tube supported by a fiber-fabric composite material. The fiber-fabric composite material is prepared into the honeycomb-shaped-support tubular structural piece, when the structural piece prepared with a method is stressed, bearing force can be distributed all honeycomb-shaped branches and are evenly distributed on the structural piece, and the whole stress degree of the structural piece is enhanced; a common carbon fiber composite material can bear high pressure, but the pressing bearing capacity is low, an in-tube support of the structural piece is achieved through the honeycomb-shaped carbon fiber fabric composite material, the structural piece can bear pressure to a certain degree, and the stress range and the stress direction of the structural piece are widened. According to the fiber-fabric-composite-material structural piece, the structural piece is prepared into a honeycomb shape, compared with a solid structural piece, in the fiber-fabric-composite-material structural piece,materials and the weight are reduced, the cost is saved, and meanwhile compared with a hollow structural piece, the fiber-fabric-composite-material structural piece has the higher stress capacity.

Owner:河南吉地专利运营有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com