Dense roadway group rock burst hazard prediction method

A technology of rock burst and prediction method, which is applied in earth square drilling, mining equipment, mining equipment, etc., and can solve problems such as little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

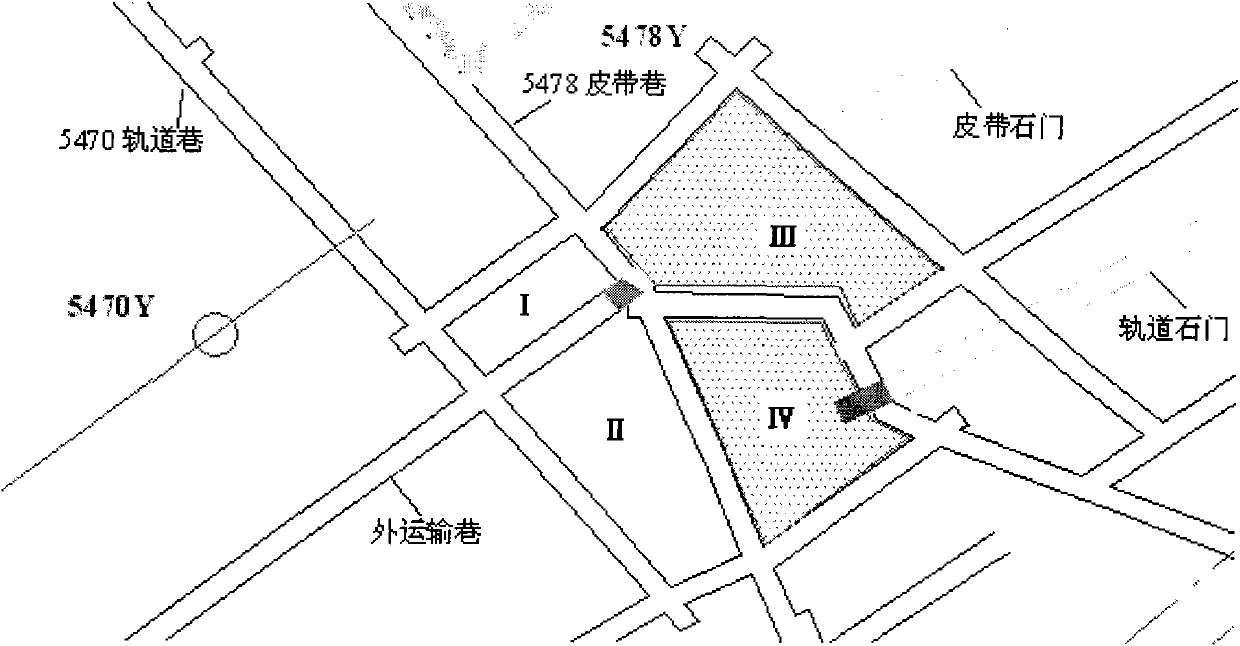

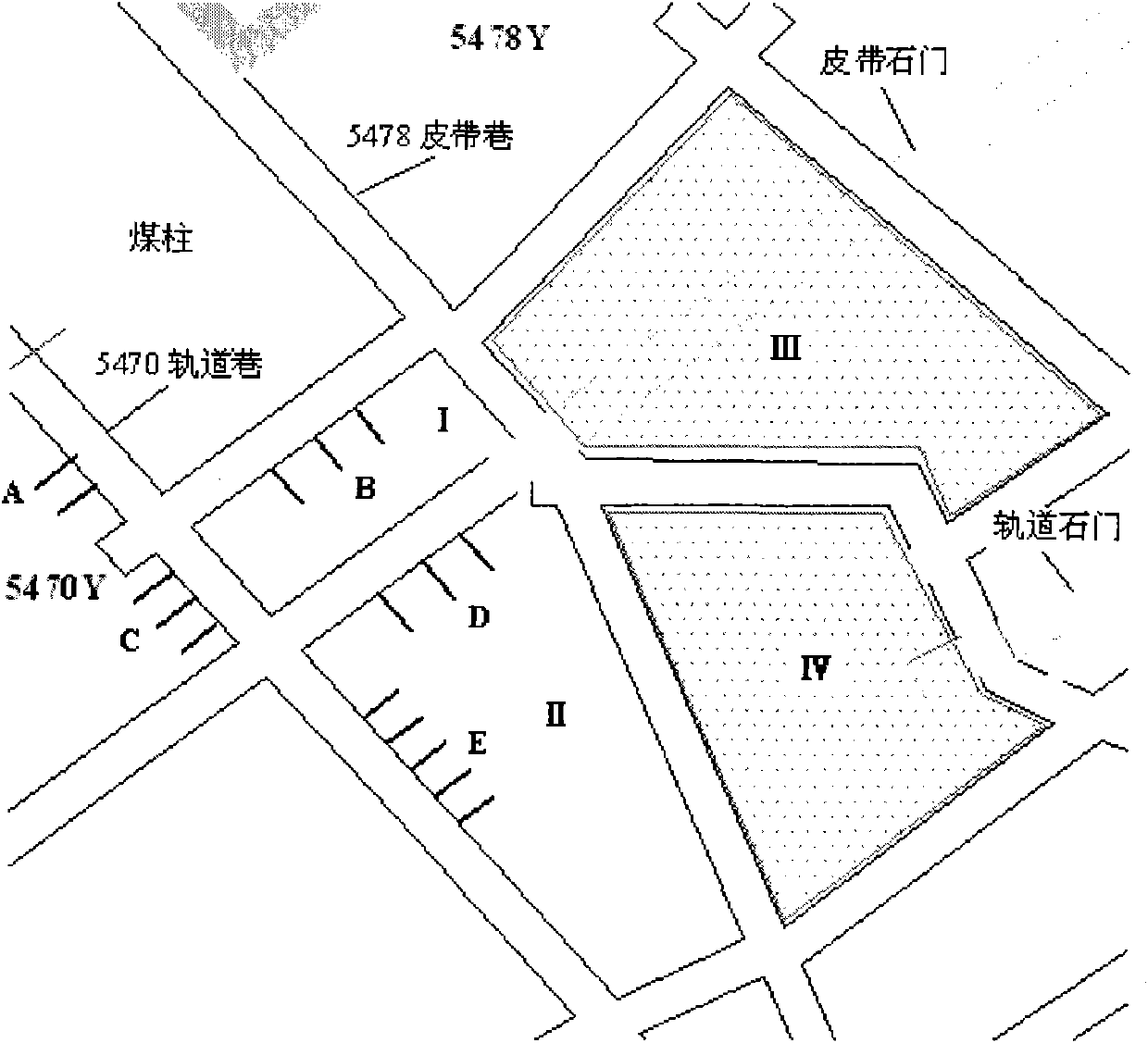

[0027] refer to figure 1 The area diagram of a dense roadway group in a certain coal mine is shown to further illustrate the prediction method of the present invention.

[0028] Step 1: Get Sensitive Areas

[0029] Before the mining of a certain working face, the preliminary delineation of the rock burst dangerous area is carried out first. In the area involved in the mining of the rock burst dangerous coal seam, especially the dense roadway group area, the characteristics of the rock burst in the adjacent stope are shown by analogy. At the same time, the drilling cuttings method is used to monitor on-site detection, and the high-stress areas of relatively dense roadway groups are divided;

[0030] Install high-sensitivity strain gauges in high-stress areas, and then carry out artificial blasting vibrations in relatively safe areas, and obtain dynamic sensitive areas of coal seams by testing blasting vibration stress waves. figure 1 The I and II areas in are dynamic sensitiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com