Method for rapidly evaluating slow crack growth resistance of plastic pipe material

A slow-crack-resistant, plastic-pipe technology, applied in strength characteristics, analysis materials, preparation of test samples, etc., can solve the problems of long test time, harsh experimental conditions, high cost, etc., and achieve low test cost and good reproducibility , high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

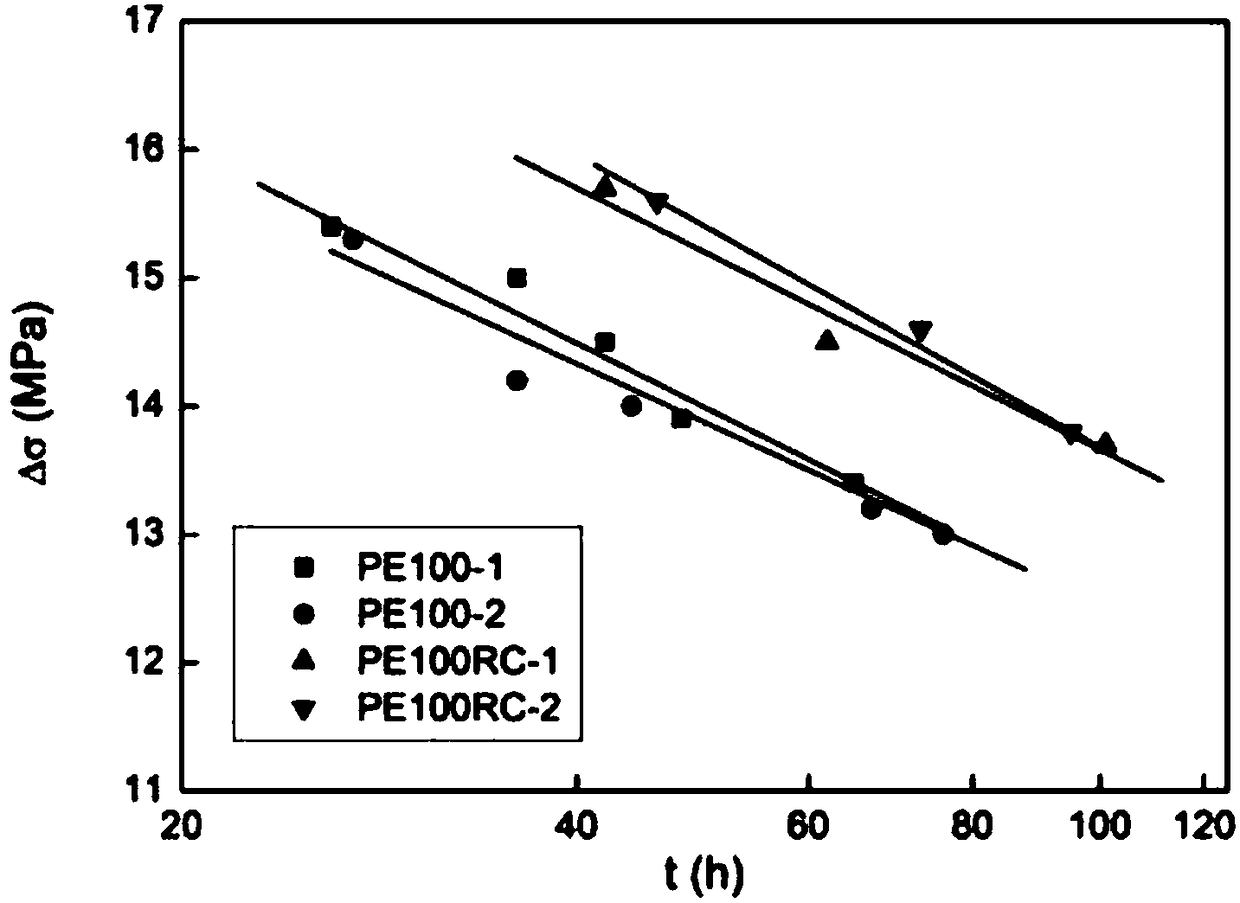

Image

Examples

Embodiment Construction

[0029] The method for quickly evaluating the slow crack growth resistance of plastic pipes in this embodiment includes two steps of sample preparation and tensile testing.

[0030] The equipment used in the sample preparation process includes plastic injection molding machines, slicers, and crack presetting machines. The specific preparation process is as follows:

[0031] (1) Put the raw material of the plastic pipe into the plastic injection molding machine, and inject to make a cylindrical rod.

[0032] (2) Use a slicer to cut the cylindrical rod. The size of the cut cylindrical rod is: 12-20mm in diameter and 80-130mm in length. The preferred size is: 13-15mm in diameter and 95-110mm in length .

[0033] (3) Utilize the crack presetting machine to preset notch cracks on the cylindrical rod, the speed of the blade feed is 0.05~0.06mm / circle, preferably, the direction of the notch crack is perpendicular to the axial direction of the cylindrical rod, and the depth is 1.3 ~ ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com