A method for predicting creep ageing behavior of aluminum-copper alloys under variable stress

An aluminum-copper alloy, creep aging technology, used in special data processing applications, computational models, biological models, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

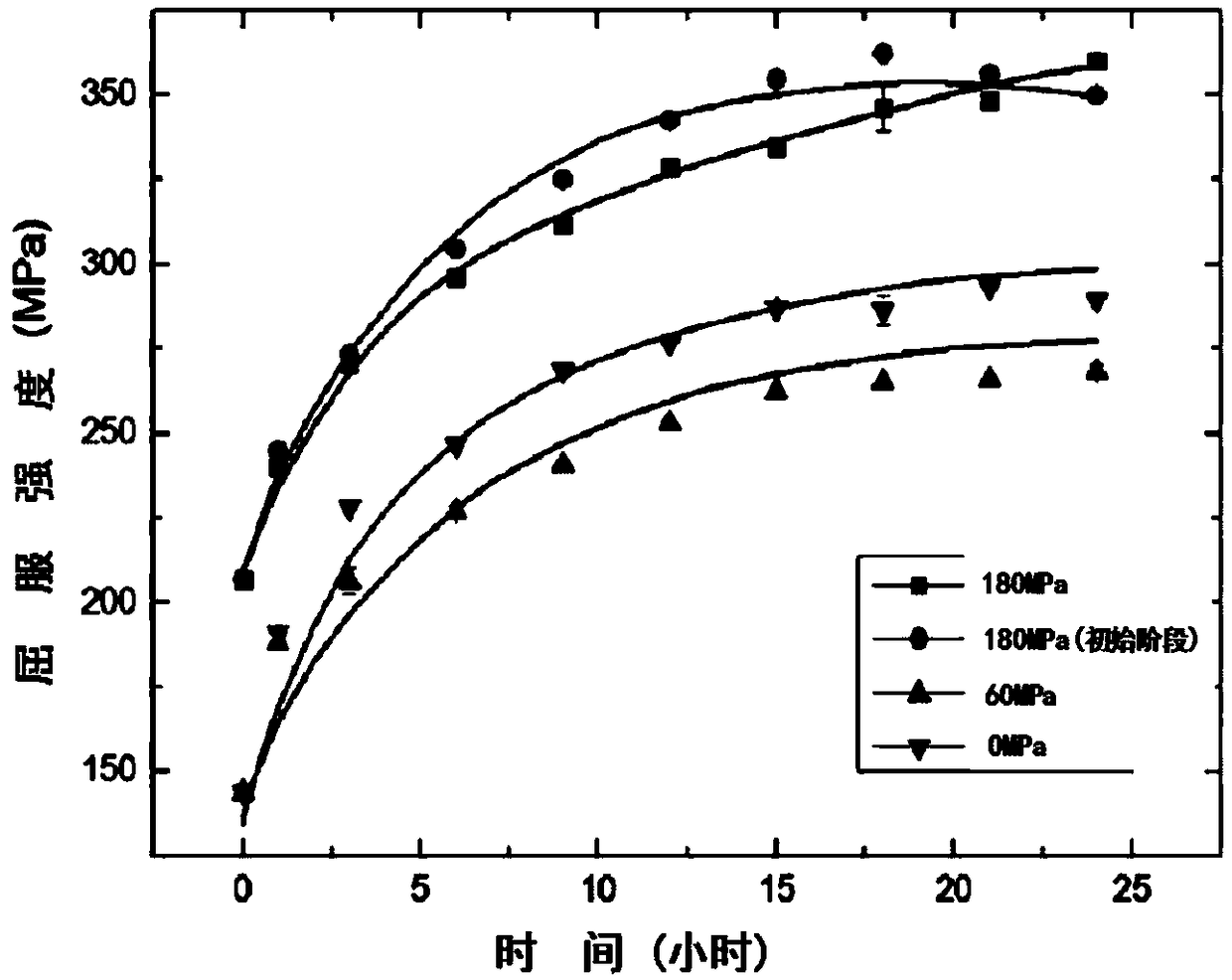

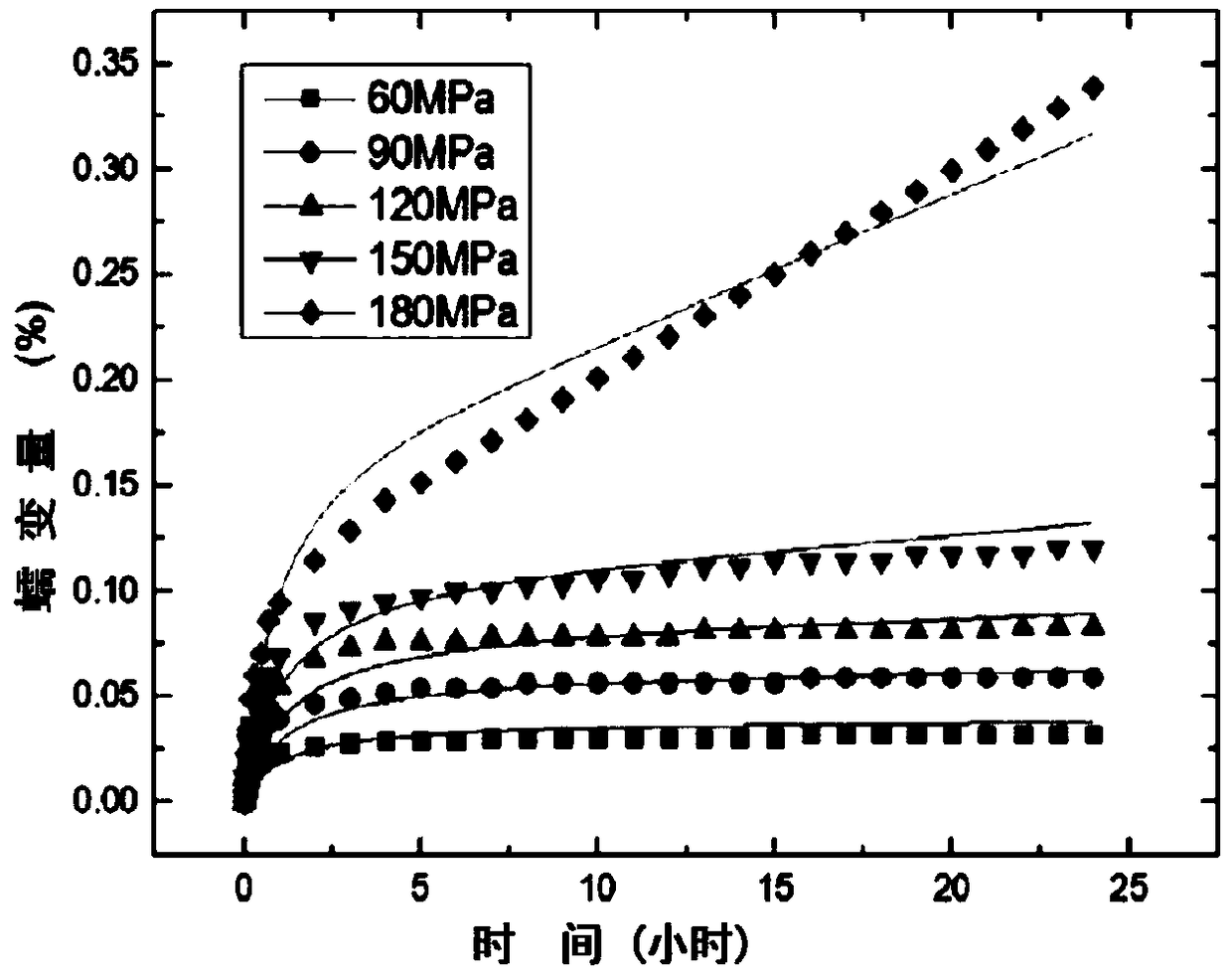

[0057] In the following, the method of the present invention will be further explained and the data will be illustrated in conjunction with the accompanying drawings and specific embodiments. The samples used in the examples are commercial 2219 aluminum alloys. Tensile test adopts the standard: GB / T 228-2002. The high-temperature creep aging test is carried out on the RMT-D10 electronic high-temperature creep durability tester produced by Sansi Taijie Company. The temperature control accuracy of the tester is ±2°C, and the load accuracy is ±3N.

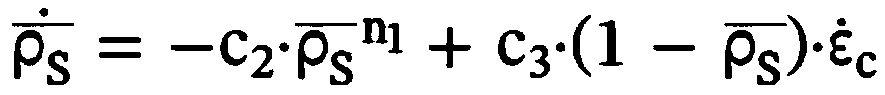

[0058] The present invention provides a method for accurately predicting the creep aging behavior of an aluminum-copper alloy under variable stress. The following takes the prediction of the creep and aging strengthening behavior of a 2219 alloy (a typical aluminum-copper alloy) as an example to introduce the prediction method provided by the present invention in detail. And specific implementation details, the methods involved are a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com