Telescopic boom system of ultrahigh aerial ladder fire truck lifting stage by stage

A technology of a ladder fire truck and telescopic boom, which is applied in the direction of lifting device, fire rescue, etc., can solve the problems of untimely firefighting, which will bring serious consequences, limited capacity of fire hydrants, and difficulty in firefighting and rescue.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

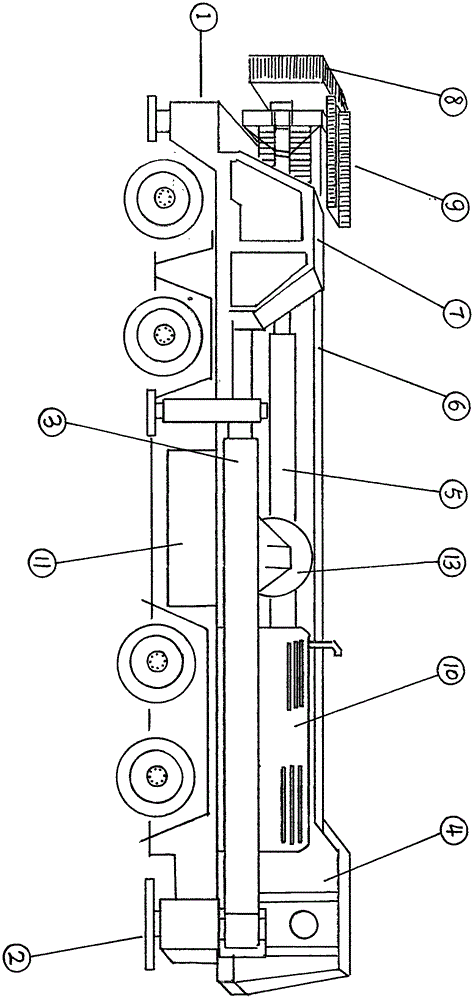

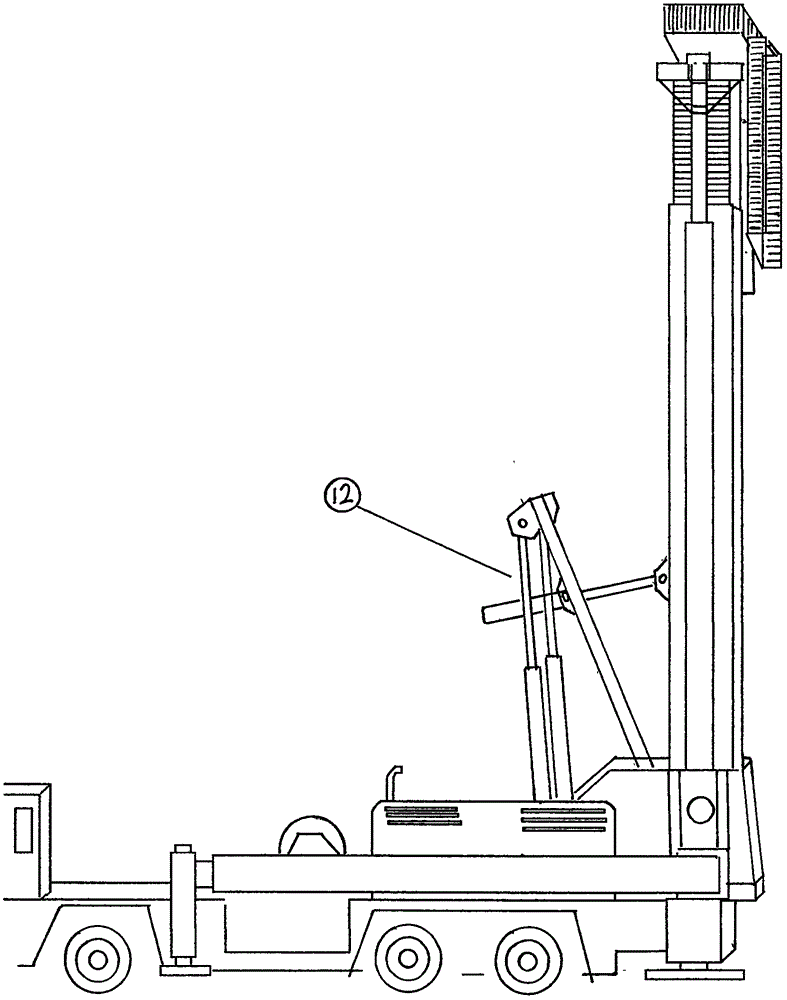

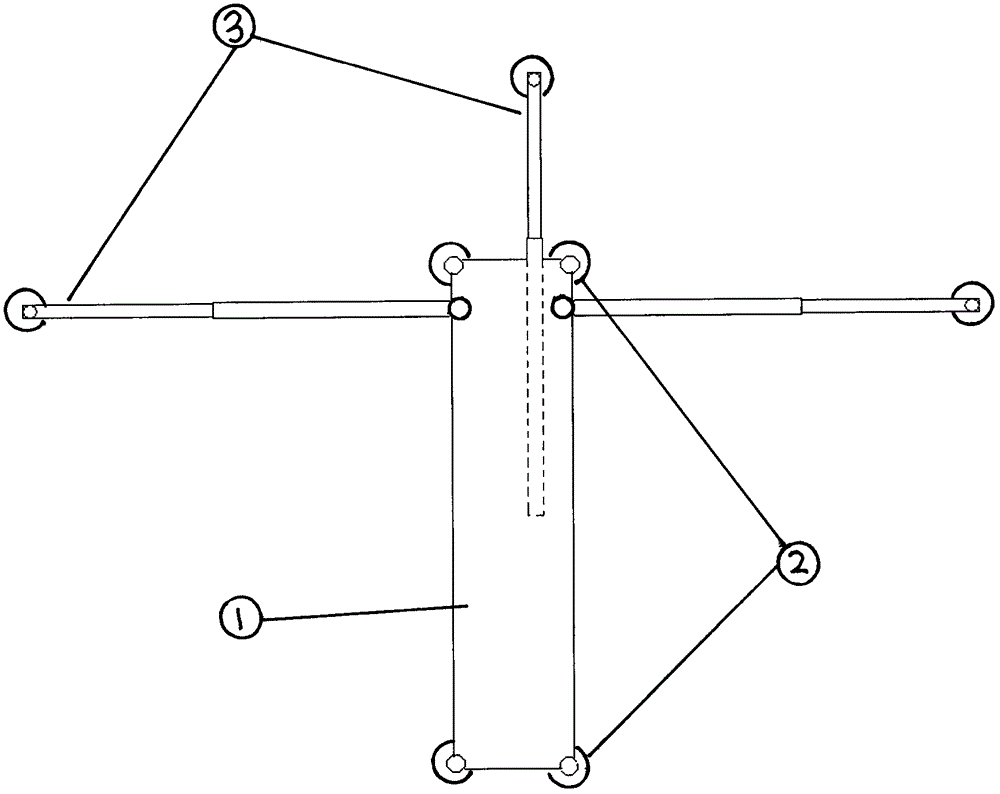

[0027] according to figure 1 , figure 2 , image 3 It can be seen that the fire truck consists of a car body (1), a base main support (2), a base auxiliary support (3), a base (4), an ultra-long stroke multi-stage oil cylinder (5), a free telescopic arm (6), A two-way cab (7), an operating platform (8), an electric telescopic ladder (9), a power system (10), and a hydraulic oil tank (11) etc., and the base main support (2) is installed on both sides and The lower part of the cab at the front end of the vehicle is directly pushed to the ground by the oil cylinder to form the main force supporting the vehicle body. The sub-support (3) of the base is installed on the base (4), and is supported by the rotating support arms on both sides and the telescopic support at the rear. The rotating support arms on both sides are close to the car body when contracted, and are swung out to both sides by the motor rotation mode when in use. The telescopic length can be freely controlled acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com