Patents

Literature

67results about How to "High lifting height" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

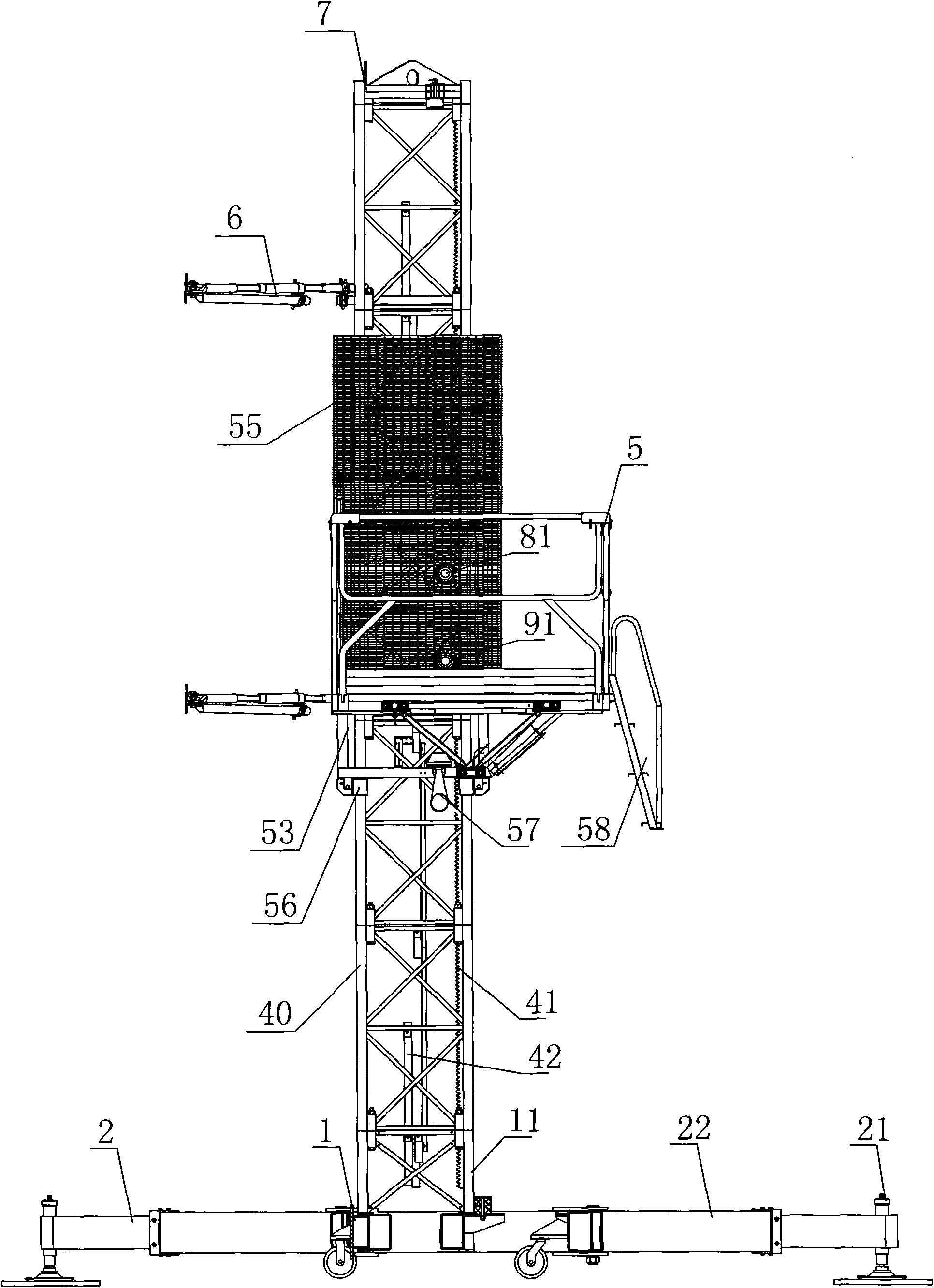

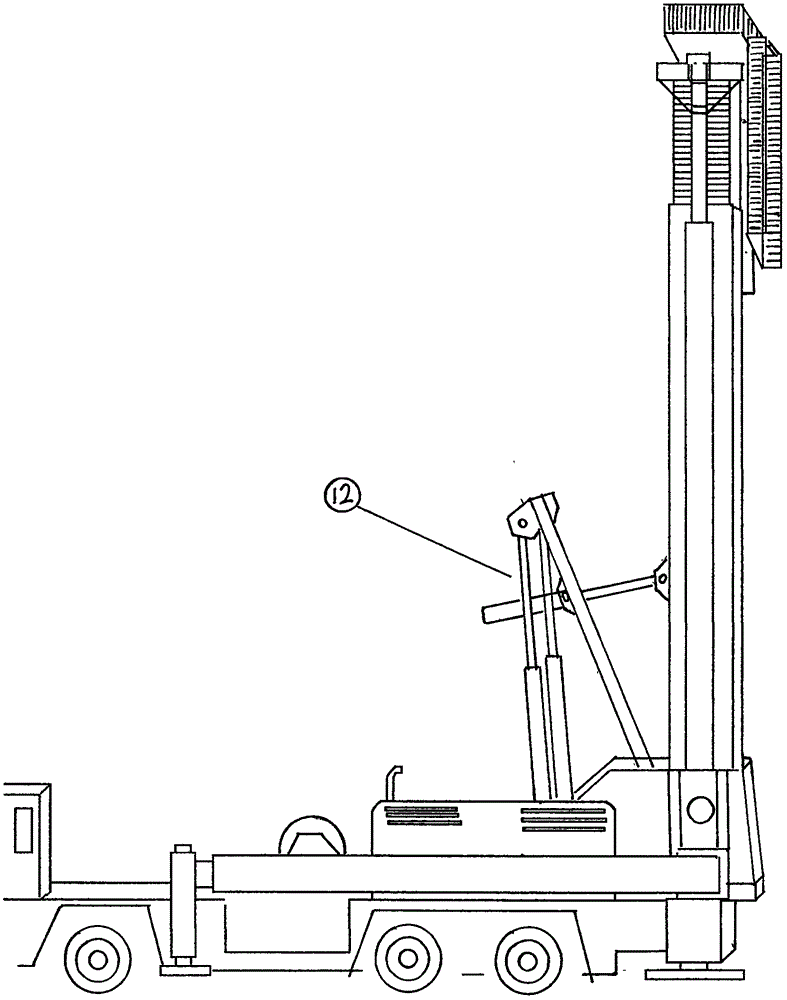

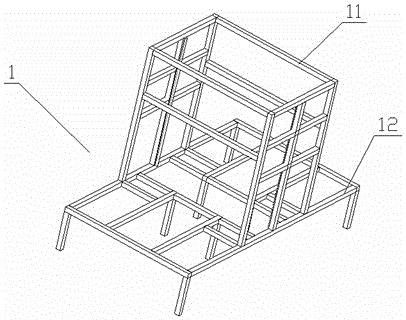

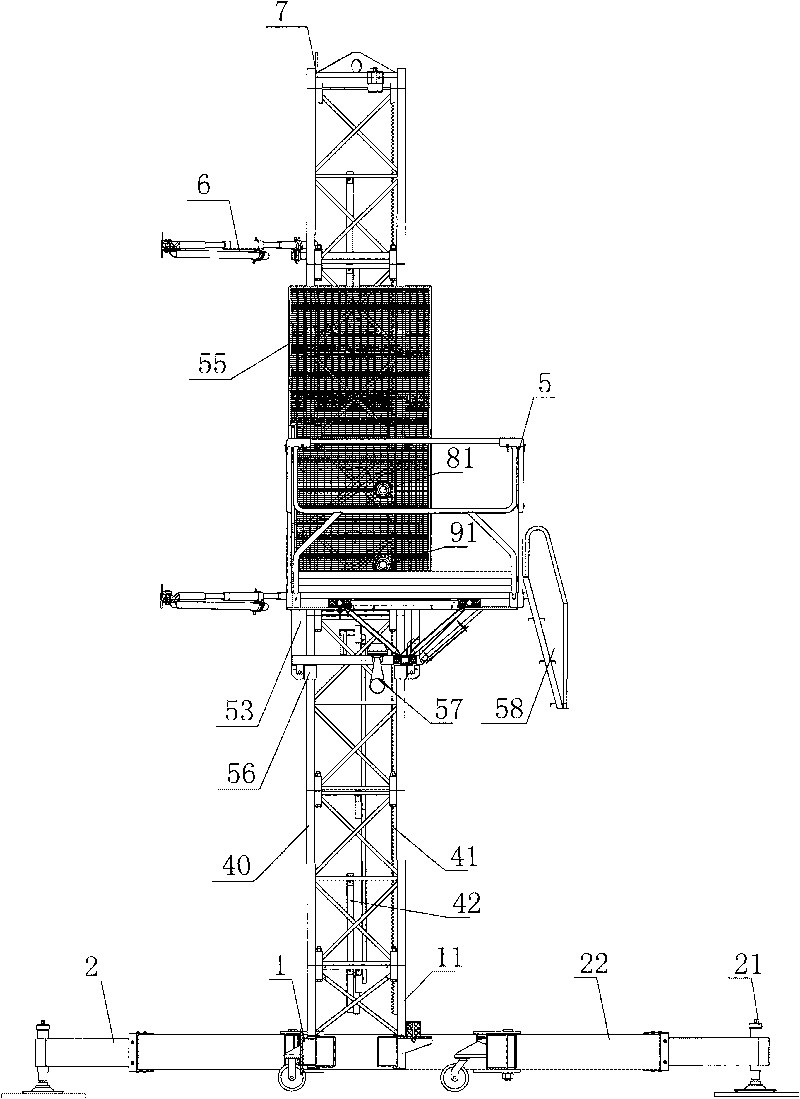

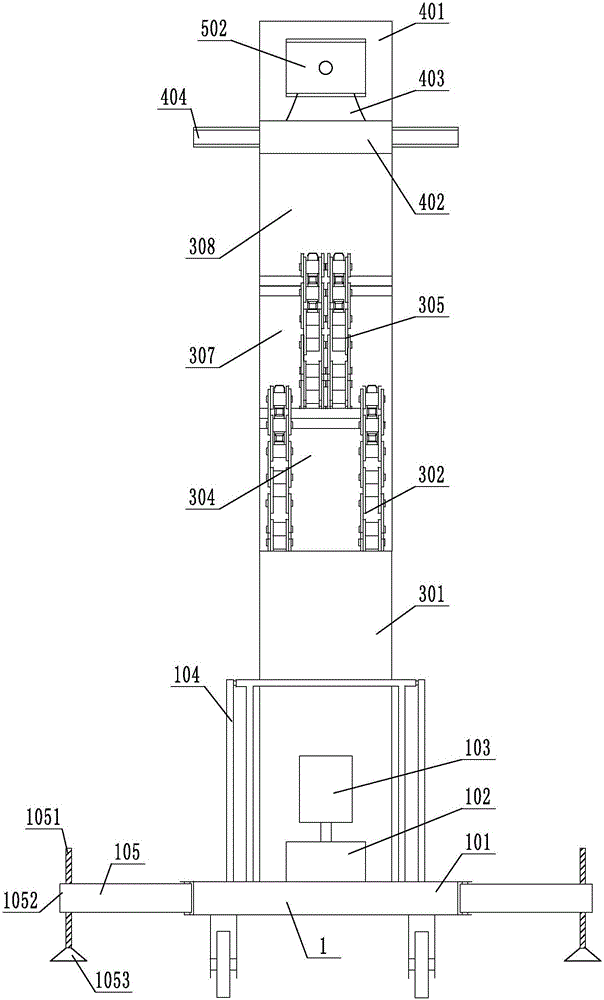

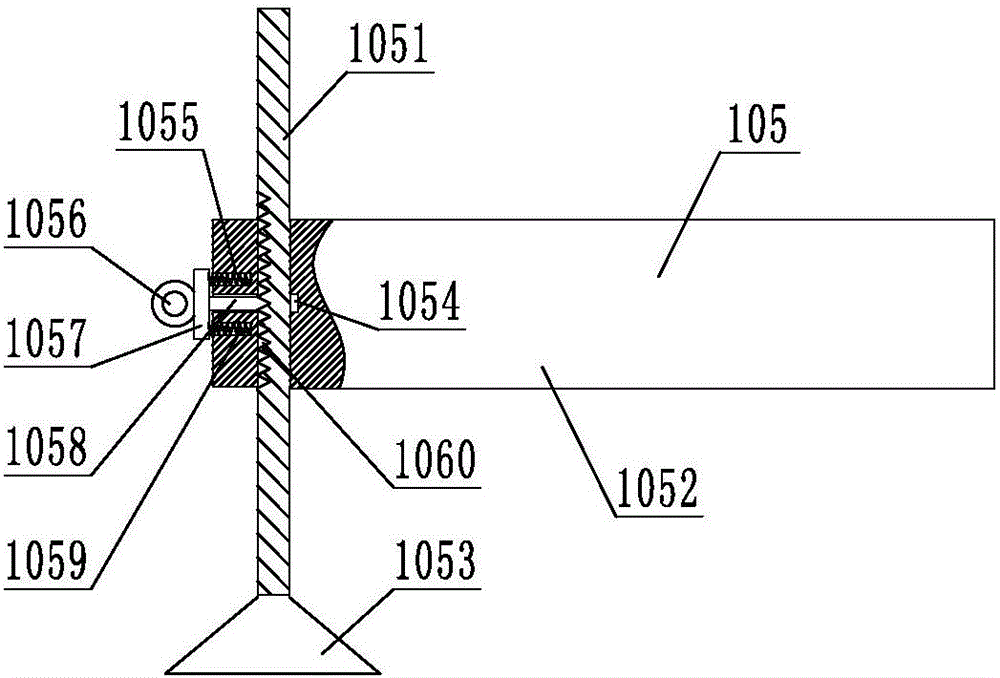

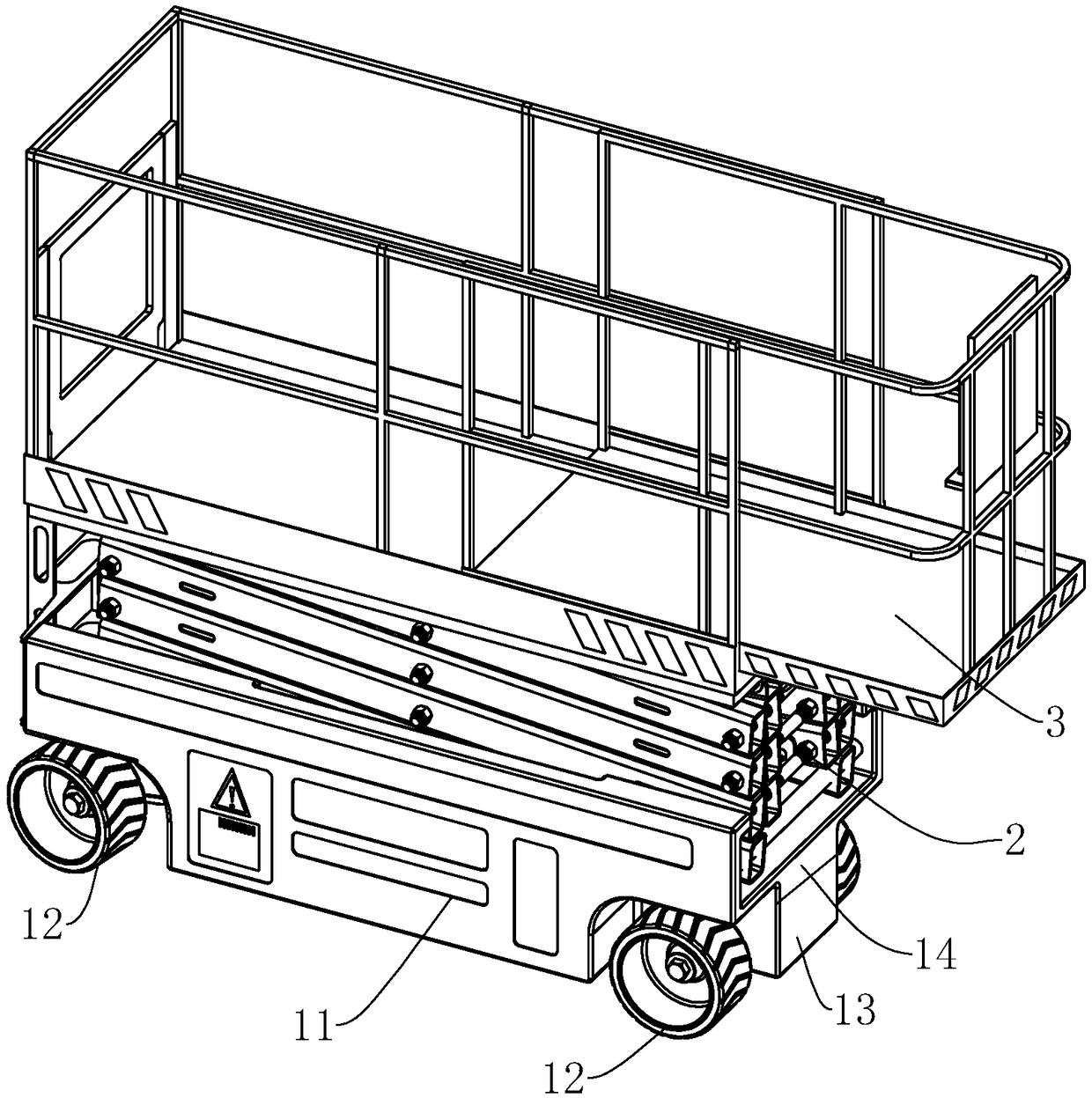

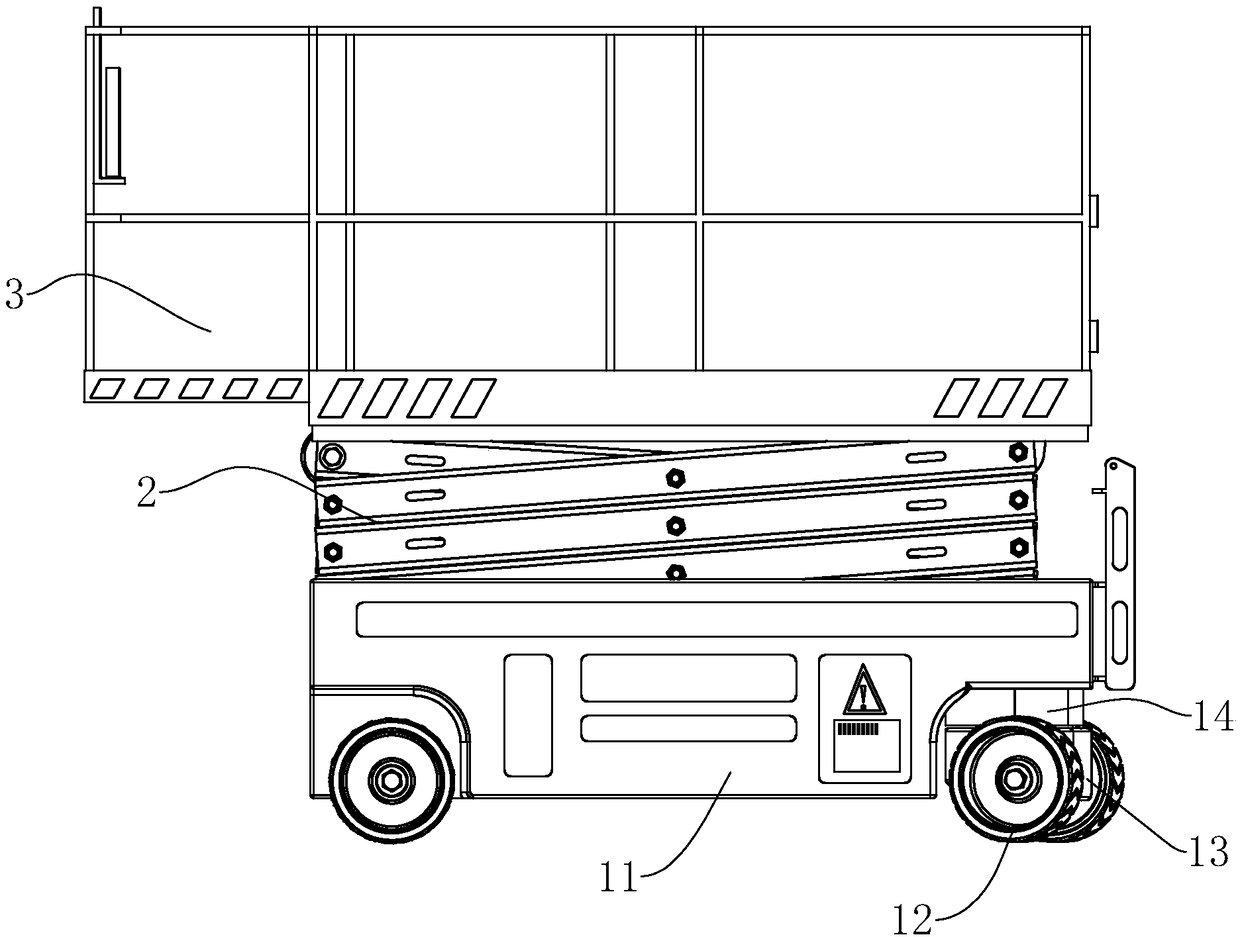

Mast climbing type aerial working platform

The invention relates to an aerial working device. A mast climbing type aerial working platform comprises a vertical tower assembly and a platform assembly, the vertical tower assembly is composed of a top cap and a plurality of standard knots of frame structures, the standard knots are in fixed connection, the standard knots are fixedly and detachably connected with a connection frame and the top cap, sides of the connection frame and the standard knot are respectively provided with teeth bars, the teeth bars are connected with each other to compose a tooth-shaped rail; a mounting rack is mounted on the platform assembly, the vertical tower is arranged through the mounting rack, rolling wheels are arranged on the mounting rack, the rolling wheels and the standard knots are pasted rollingly, a fixed plate is fixedly arranged on the mounting rack, a motor and an anti-drop gear are respectively engaged with the teeth bars. The invention extends the range of the platform surface, the standard knots can be added unlimitedly, the lifting height of the platform surface can be extended, the invention has characteristics of large working range, high lifting height, safety and reliability.

Owner:ZHEJIANG DINGLI MACHINERY CO LTD

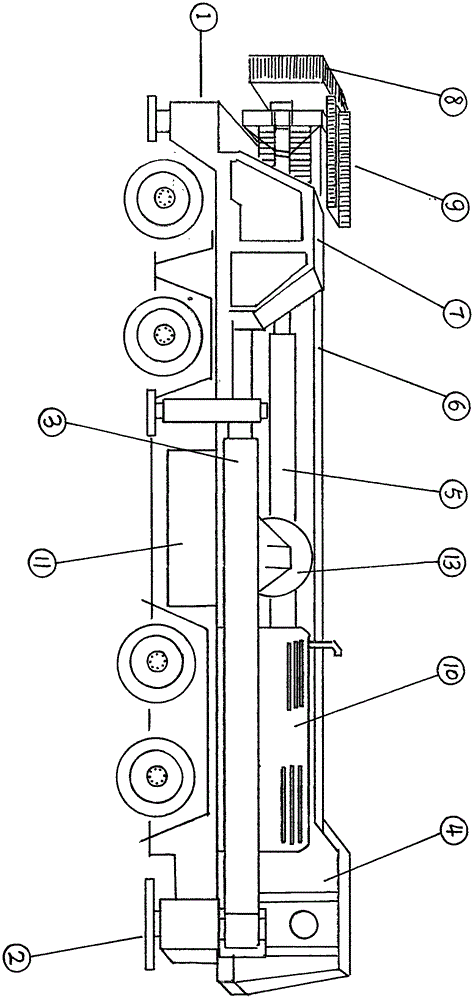

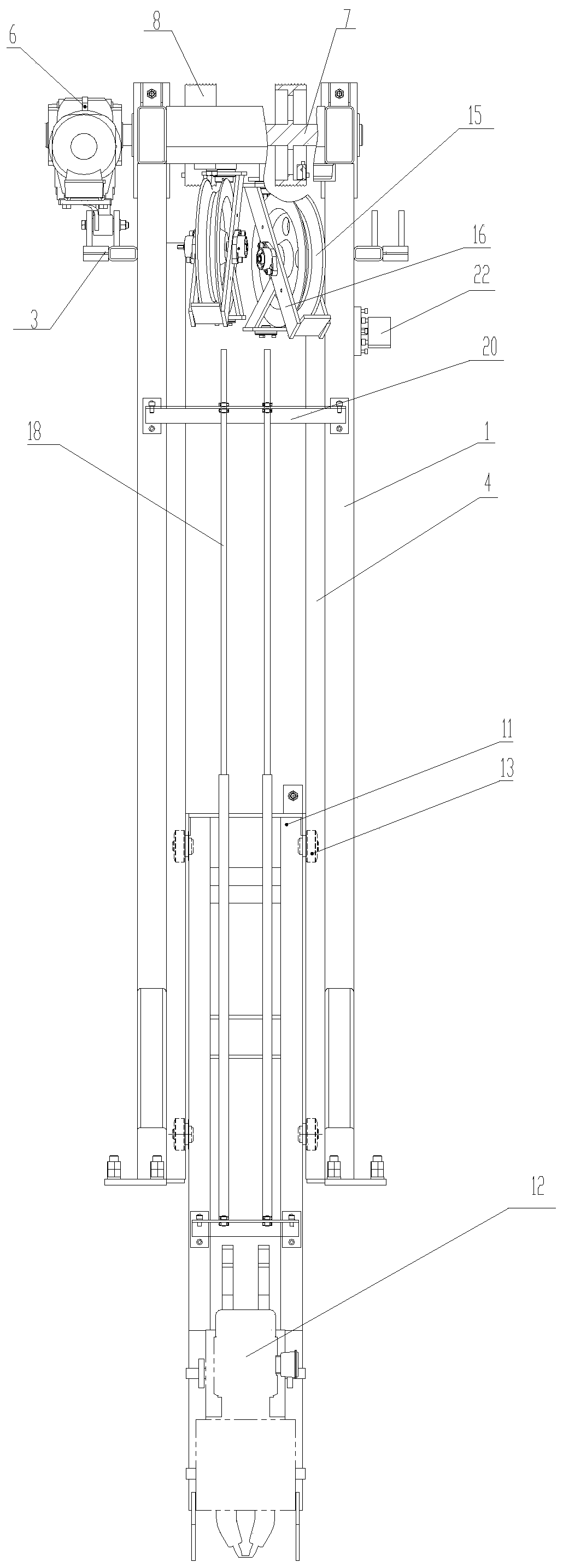

Telescopic boom system of ultrahigh aerial ladder fire truck lifting stage by stage

The invention relates to the field of fire-fighting machinery, and particularly relates to a telescopic boom of an aerial ladder fire truck. The telescopic boom of a telescopic boom system of an ultrahigh aerial ladder fire truck lifting stage by stage can be drawn out as an antenna; two groups of multi-stage oil cylinders with ultralong strokes are arranged at the two ends of the telescopic boom; an electric movable pin pushing device is arranged at the top end of each oil cylinder; the telescopic boom is pushed out upwards by the multi-stage oil cylinders with the ultralong strokes and stops at a corresponding position under the stroke limiting action of an induction switch during working of equipment; the second stage of the telescopic boom and one section of ascending telescopic boom are located through location pins; and at this moment, the two sections of the telescopic boom are connected into one piece; a movable pin is retreated by the electric movable pin pushing device; the multi-stage oil cylinders with the ultralong strokes are descended to the position of the second stage of the telescopic boom; and the telescopic boom can be sequentially pushed out through repeating the abovementioned action. More telescopic booms can be accommodated in the main telescopic boom in a stress range of the strength of the telescopic boom because the telescopic boom uses an external thrust device, and therefore, a high lifting height can be achieved.

Owner:王明中

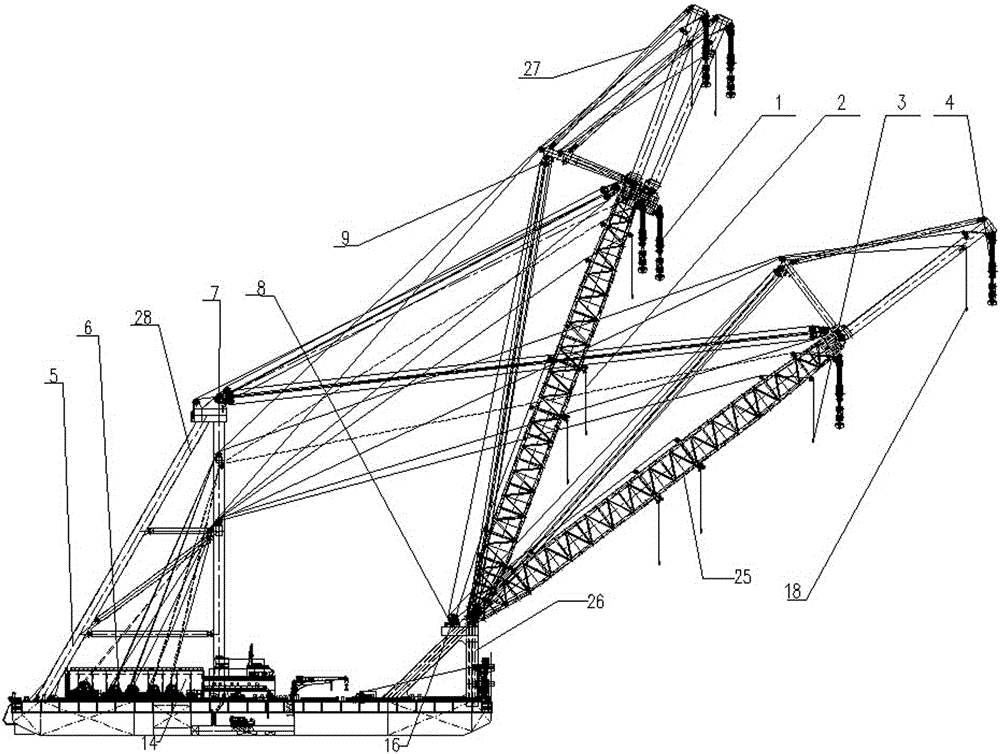

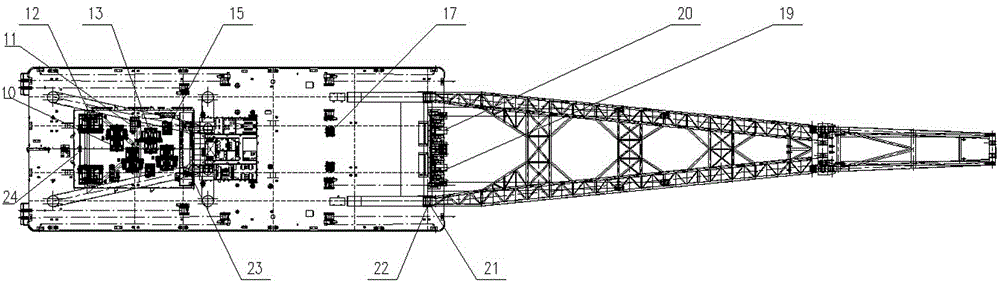

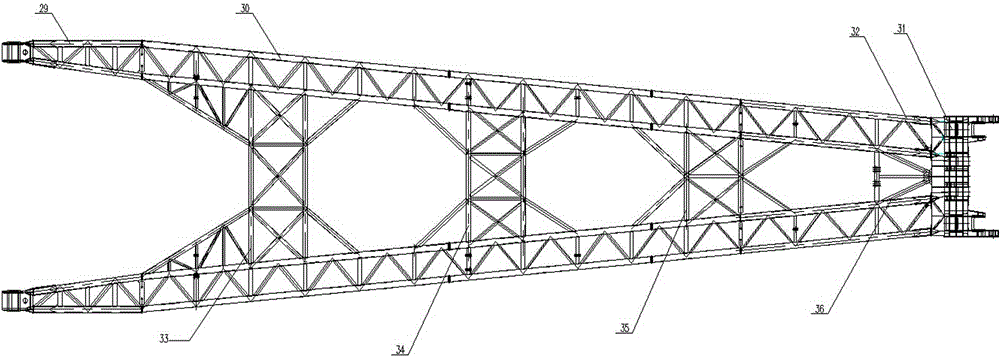

Large-scale ultrahigh lift height floating crane

The invention discloses a large-scale ultrahigh lift height floating crane. The large-scale ultrahigh lift height floating crane comprises an arm support bracket, an arm support, a small arm support and an A-bracket which are connected in sequence, wherein a main hook pulley system, a dead rope pulley system and a main rigging hook pulley system are arranged on the arm support; an arm support head adjusting mechanism, a dead rope mechanism and an auxiliary winch mechanism are arranged at the root part of the arm support; an assistant hook pulley system, an assistant rigging hook pulley system and an arm support head adjusting pulley system for connecting the arm support and the small arm support are arranged on the small arm support; the arm support bracket is arranged at the bottom of the arm support; a limiting system and a lubricating system are arranged at the connecting part of the arm support and the arm support bracket; a metal structure and a luffing pulley system are arranged on the A-bracket; a ladder platform and a machine room are arranged at the lower part of the A-bracket. The floating crane is high in lifting height and huge in weight, can lift a maximal 3000 ton object to the height of 165 m at a time, and is high in mounting efficiency and low in cost; the original mounting is changed, spud legs of the floating crane are successfully mounted at a time, the cost is lower, and the mounting efficiency is improved.

Owner:CHINA MERCHANTS HEAVY IND JIANGSU +1

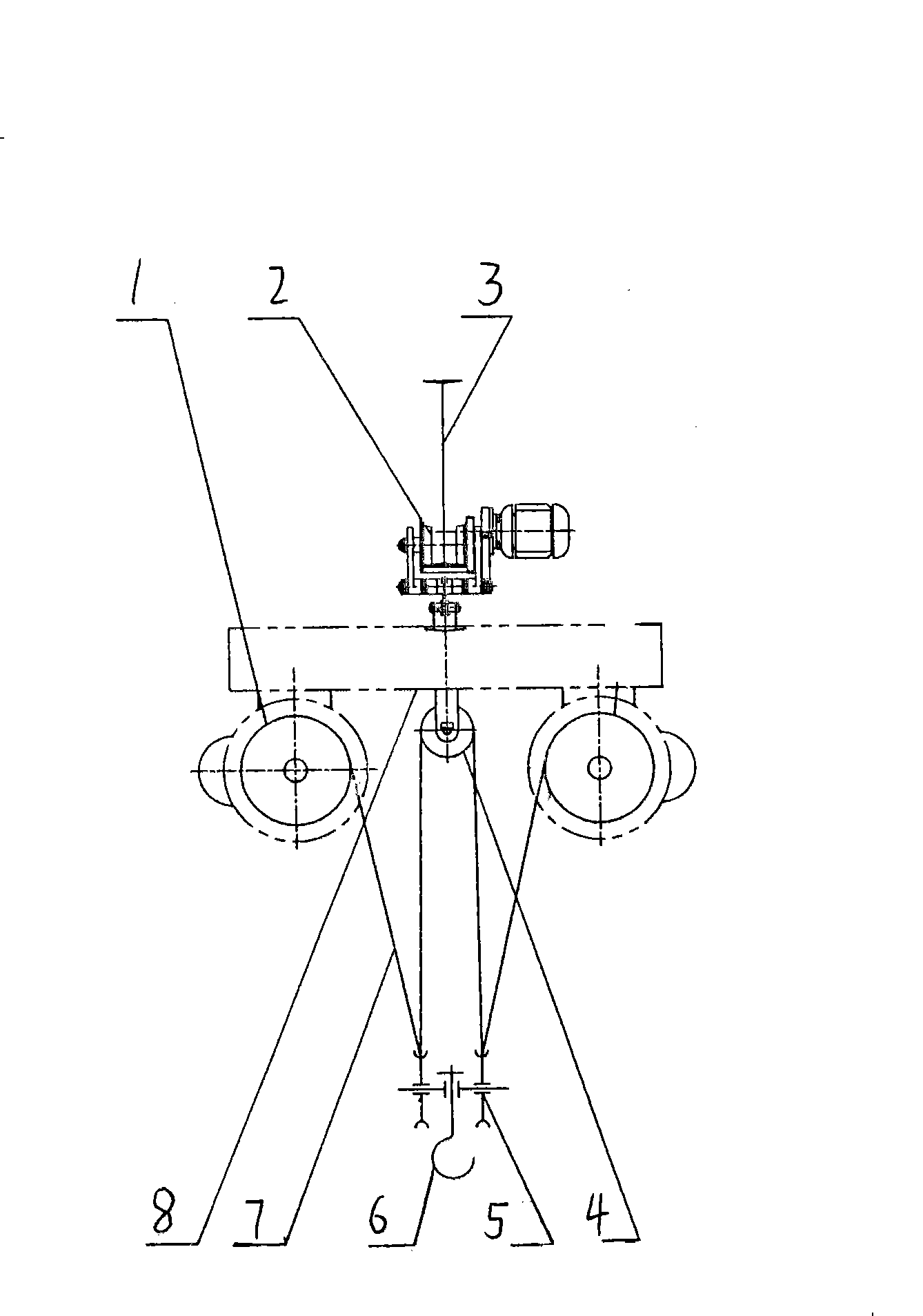

Ultra-long electric block

The invention discloses an overlong motor hoist, which comprises two reels and a pulley group; wherein, two reels are reversely mounted and parallel arrayed; wire ropes are respectively connected with two reels through the pulley group; the pulley group comprises a fixed pulley and a movable pulley; the pulley group at least comprises a static pulley and two movable pulleys; hooks are arranged on the lower part of the two movable pulleys of the pulley group; and the reel can be mounted above a bracket or under a bracket. The invention has the advantages of convenient use, safety and reliability, and increases the hoisting height of the motor hoist.

Owner:河南省新乡市矿山起重机有限公司

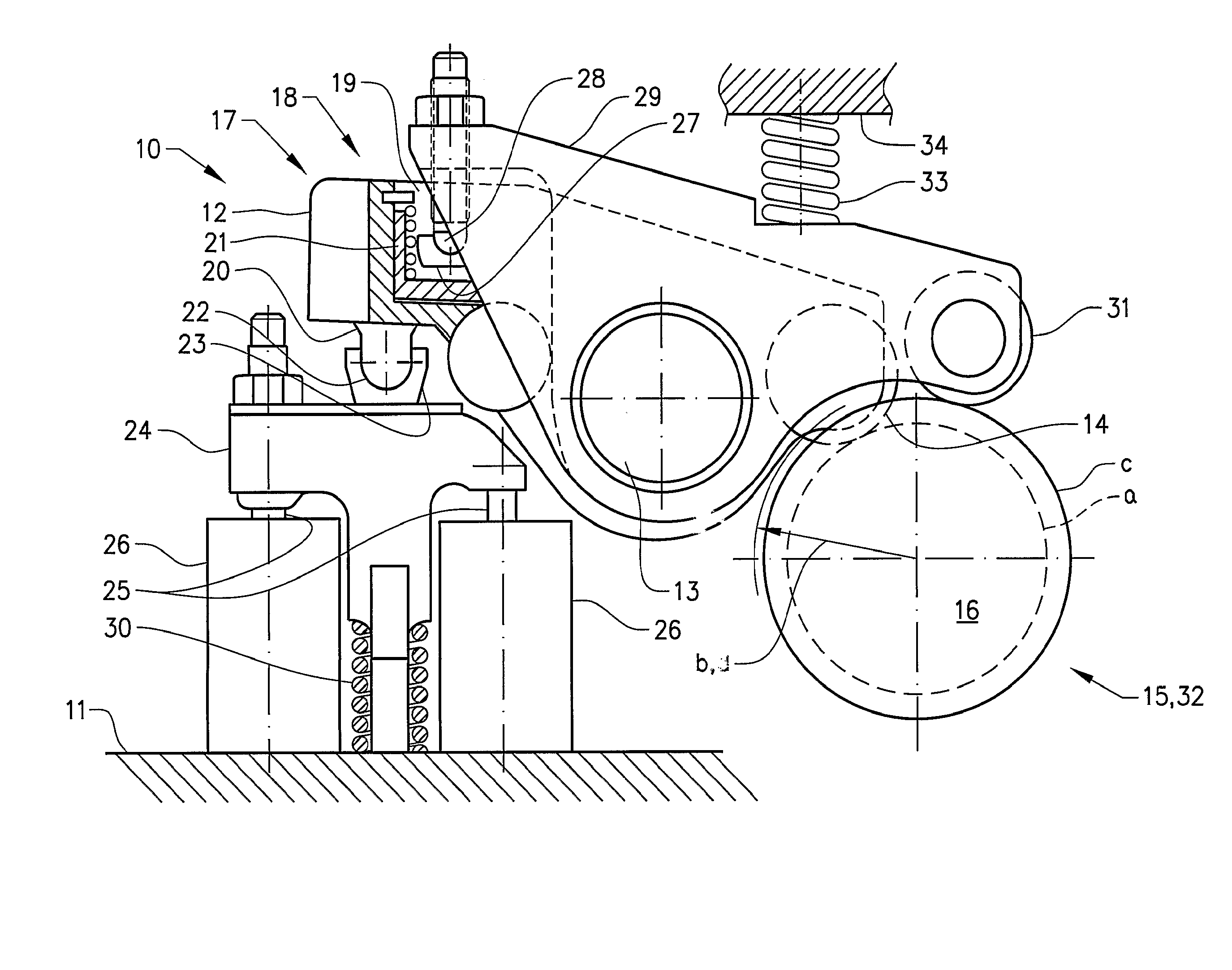

Exhaust valve mechanism for internal combustion engine

ActiveUS20070028878A1Increase oil film thicknessImprove braking effectValve drivesOutput powerExhaust valveSpring force

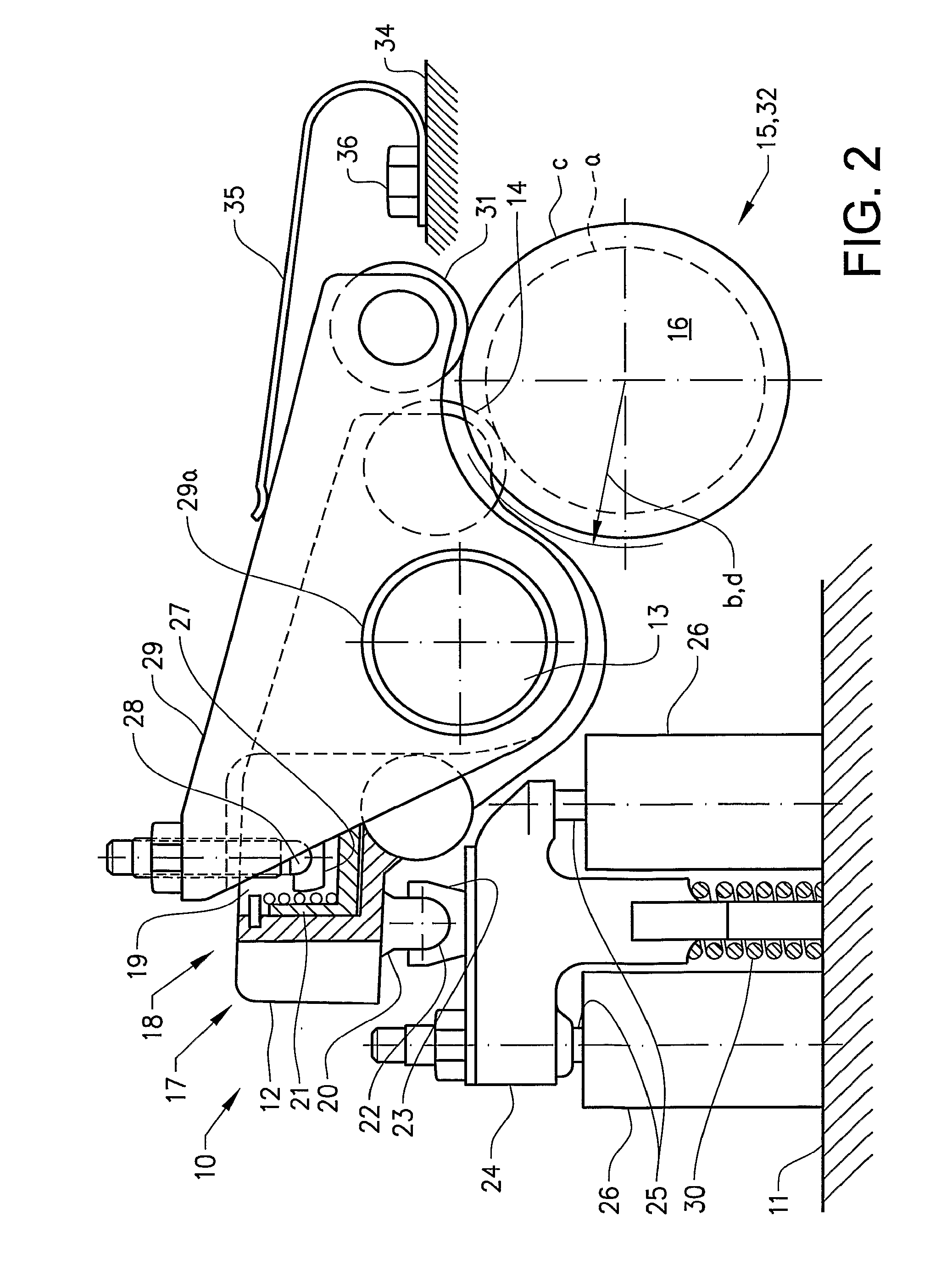

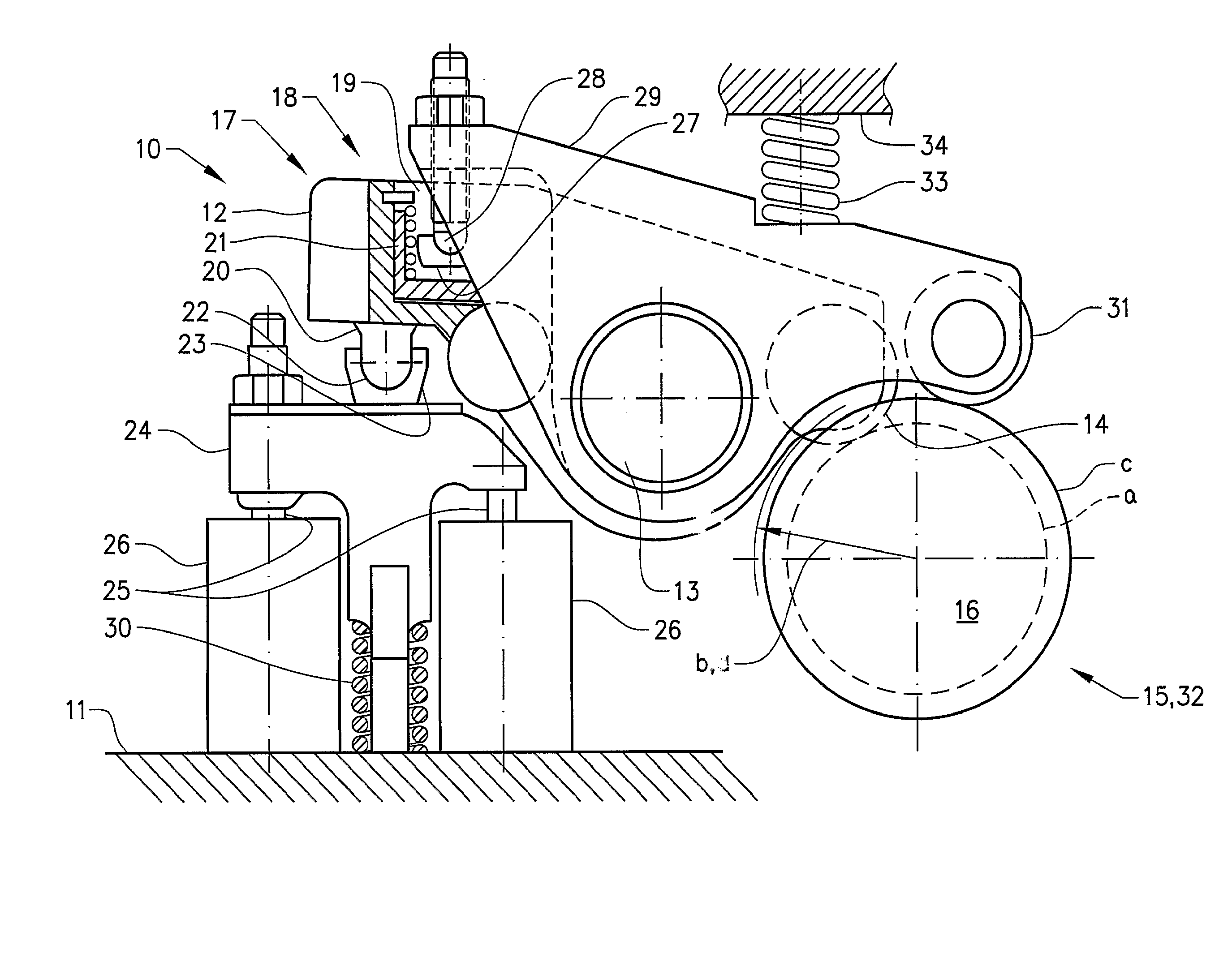

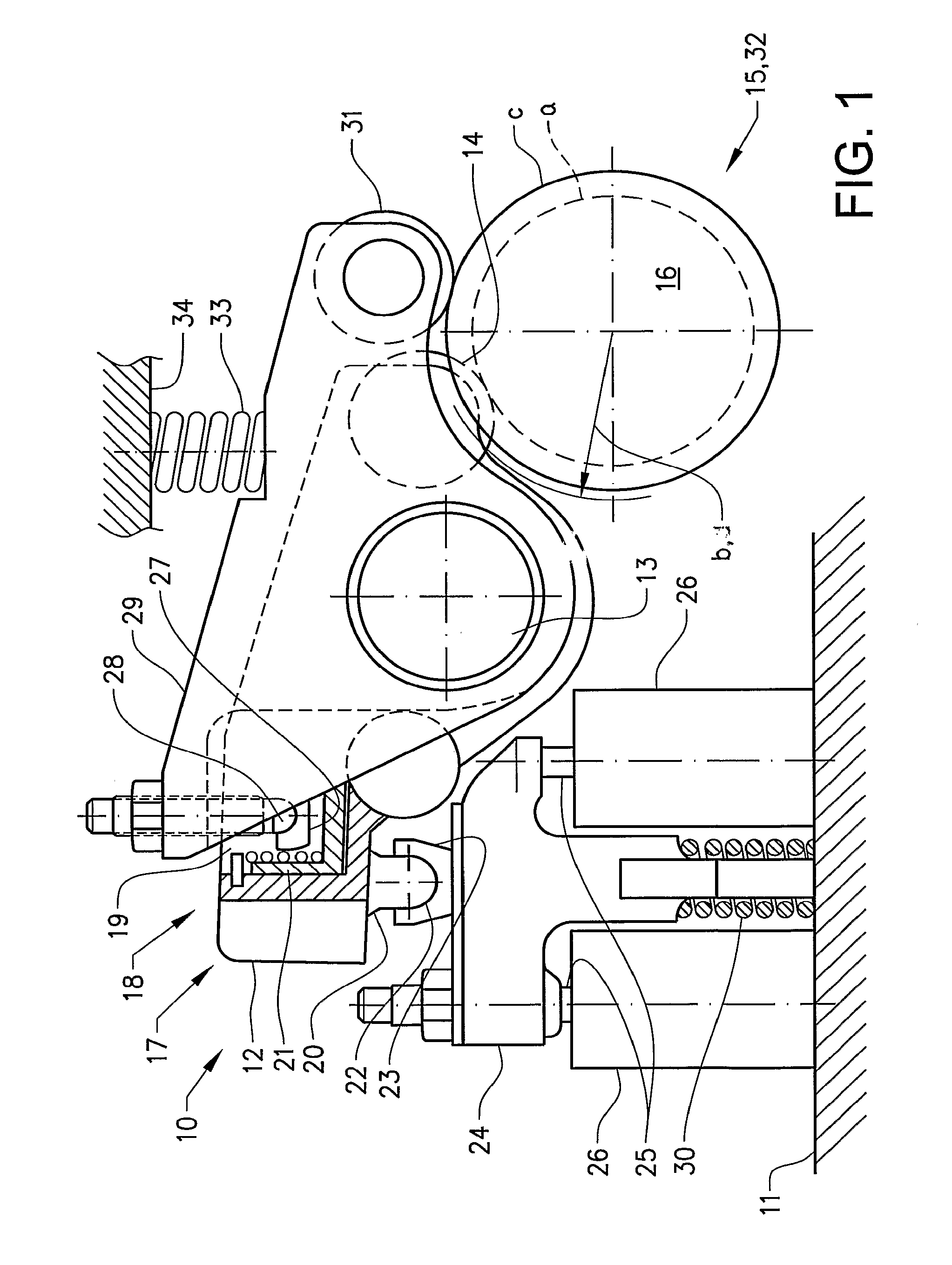

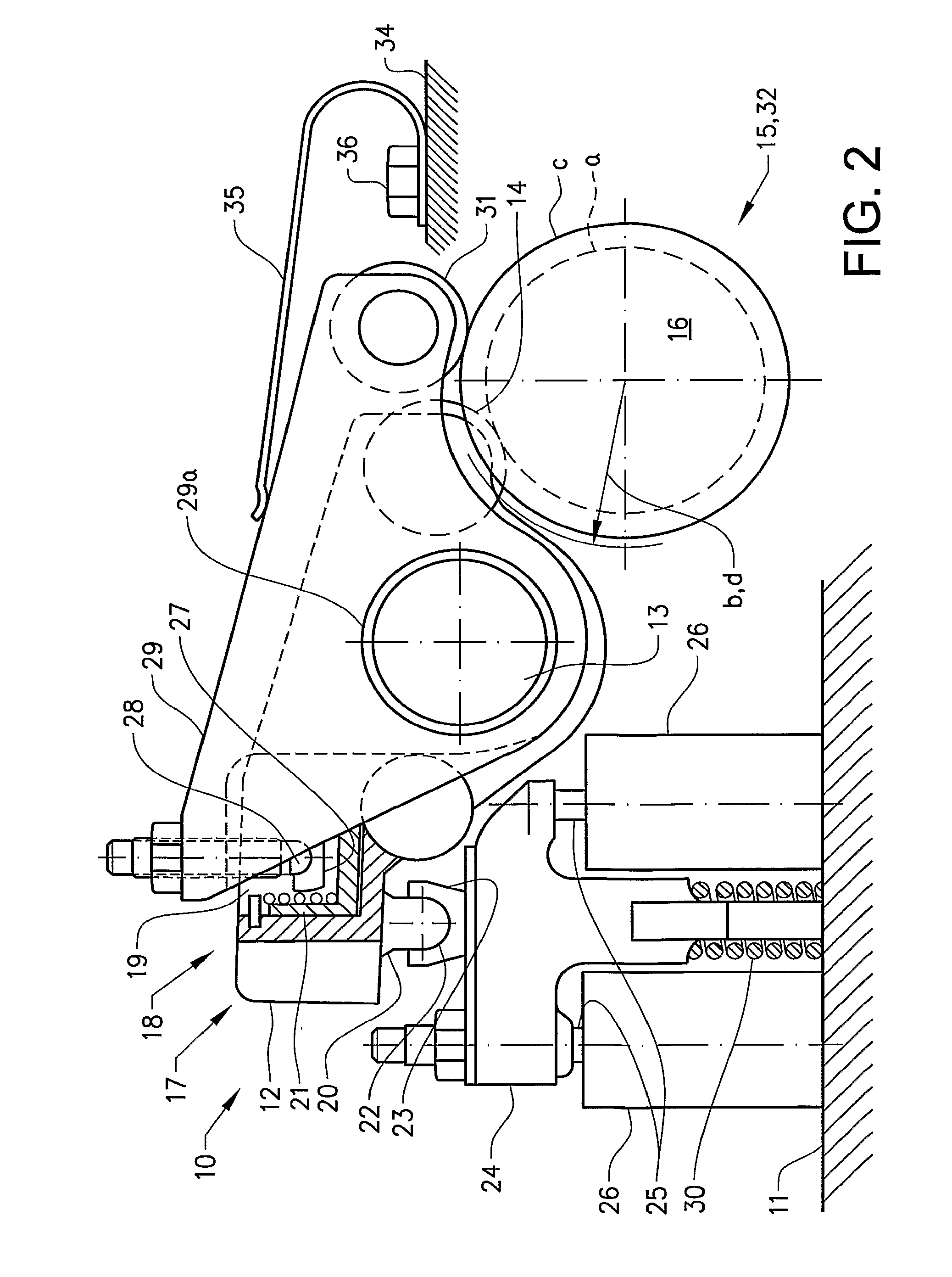

An exhaust valve mechanism for an internal combustion engine with at least one exhaust valve in every engine cylinder includes a main rocker arm mounted on a rocker arm shaft and a secondary rocker arm arranged on the main rocker arm and mounted on the rocker arm shaft for the activation of an exhaust brake function. A spring device is so arranged as to act between a fixed point on the engine and the secondary rocker arm, in such a way that the latter rocker arm is caused by the spring force to engage with the cam element of the camshaft.

Owner:VOLVO LASTVAGNAR AB

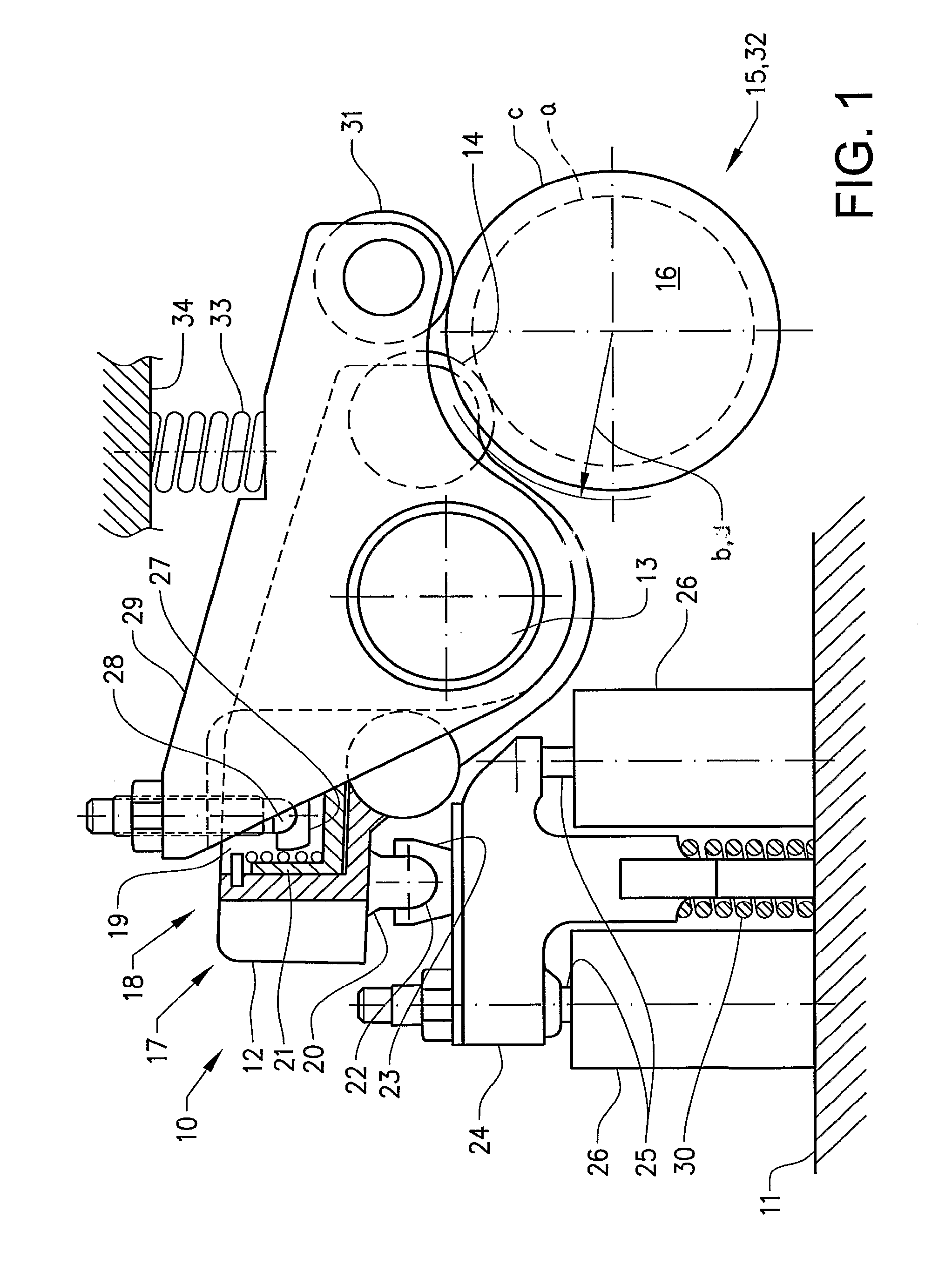

Exhaust valve mechanism for internal combustion engine

ActiveUS8230831B2Improve braking effectEfficient exchangeValve arrangementsOutput powerExhaust valveSpring force

An exhaust valve mechanism for an internal combustion engine with at least one exhaust valve in every engine cylinder includes a main rocker arm mounted on a rocker arm shaft and a secondary rocker arm arranged on the main rocker arm and mounted on the rocker arm shaft for the activation of an exhaust brake function. A spring device is so arranged as to act between a fixed point on the engine and the secondary rocker arm, in such a way that the latter rocker arm is caused by the spring force to engage with the cam element of the camshaft.

Owner:VOLVO LASTVAGNAR AB

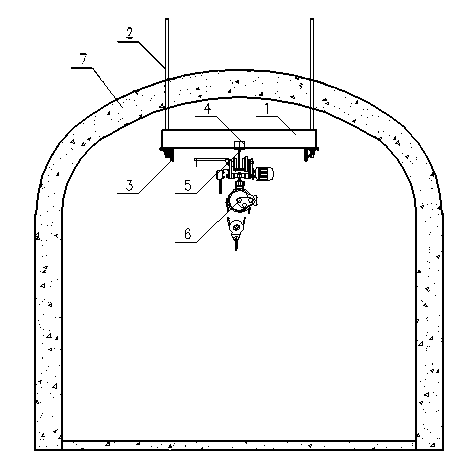

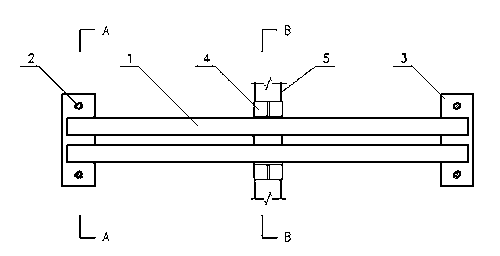

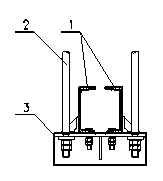

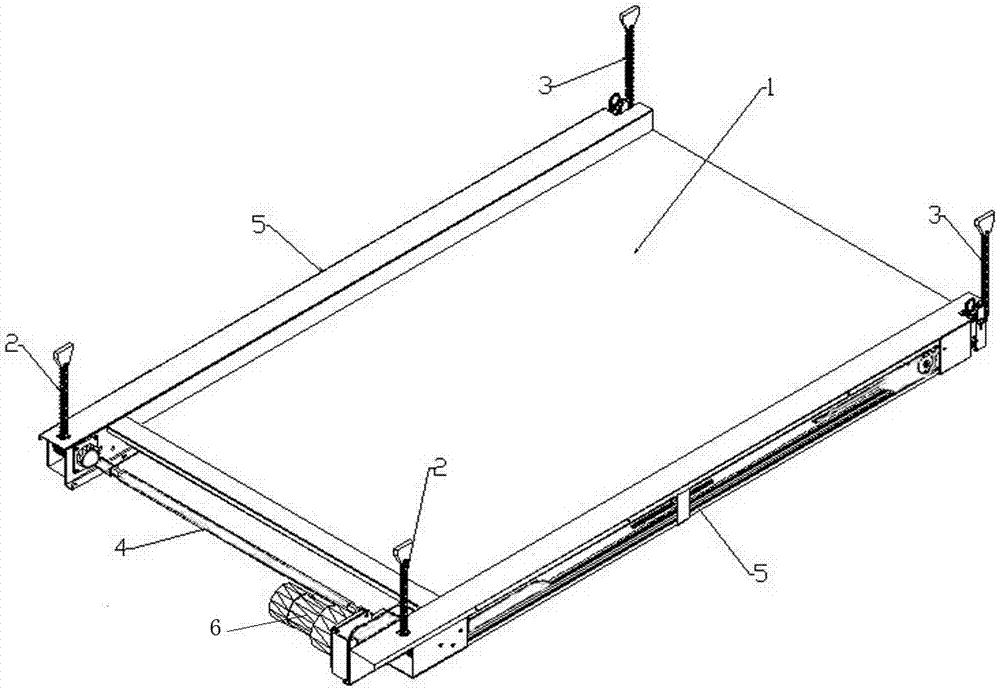

Lifting device suitable for underground ally and chamber

InactiveCN103130103AIncrease the installation heightIncrease lift heightLoad-engaging girdersBase supporting structuresMachine maintenanceBottle

The invention discloses a lifting device suitable for an underground ally and a chamber. The lifting device consists of two main beams (1), four fixed anchoring rods (2), bearing angle steel (3), connection angle steel (4), an I-shaped steel rail (5) and an electric bottle guard (6), wherein the four anchoring rods (2) are perpendicularly anchored in an alley arch supporting and protecting body (7), and an upper rock body of the alley arch supporting and protecting body (7); the bearing angle steel (3) is arranged at the lower ends of the anchoring rods (2) through bolts; the two main beams are parallel to each other and are horizontally arranged on the bearing angle steel (3) side by side through bolts; the I-shaped steel rail (5) is horizontally arranged on the main beams (1) through the connection angle steel (4) and are distributed along the direction of the alley or the chamber; a roller of the electric bottle guard (6) is arranged on the I-shaped steel rail (5); and the main beams (1) adopt groove steel structures. The lifting device has the advantages of simple structure, convenience in use and dismounting, wide application range, light structural weight and high bearing capacity and is very suitable for facilities such as underground machine maintenance chambers and water pumps; and the span of the main beams is small.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +2

Bin packing equipment for solar cells

Owner:浙江巨力宝纺织科技有限公司

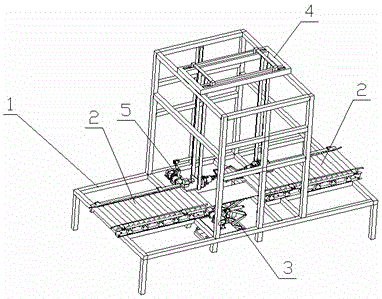

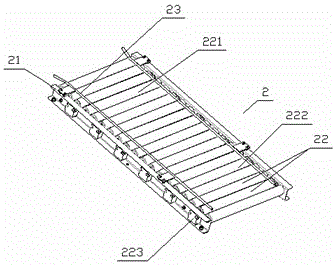

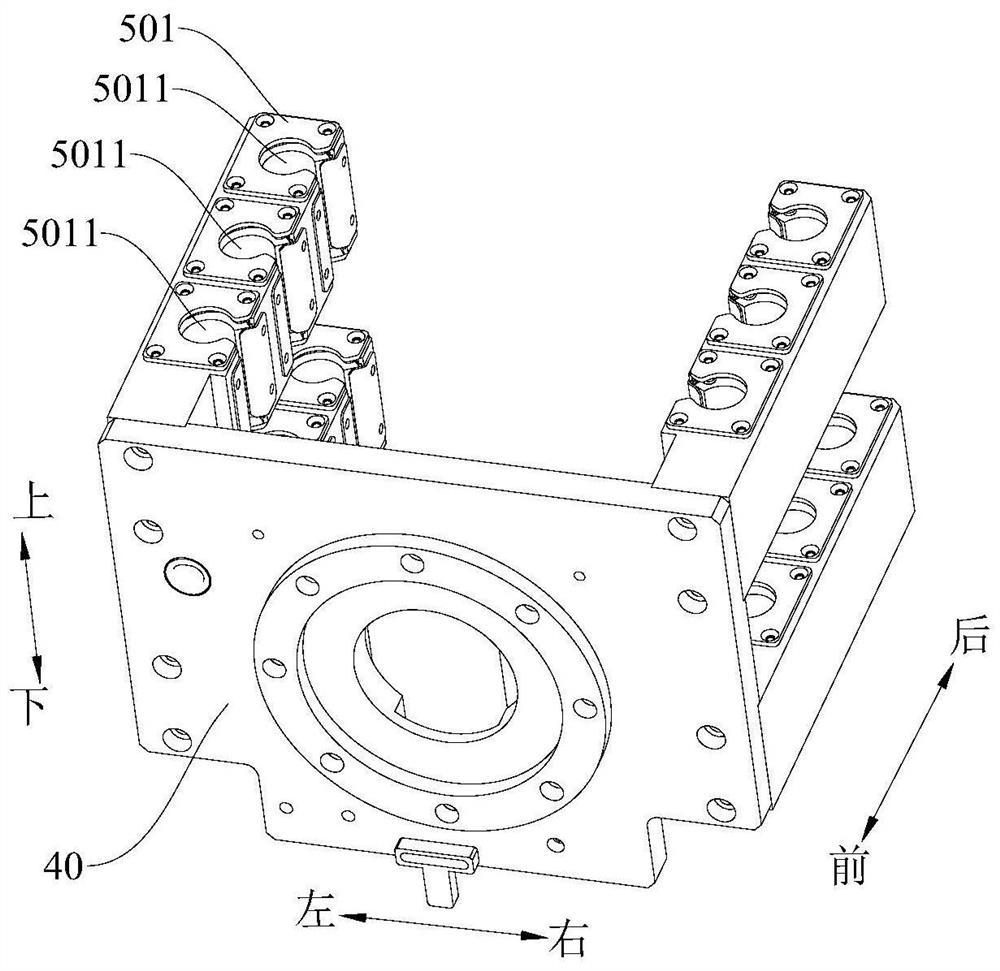

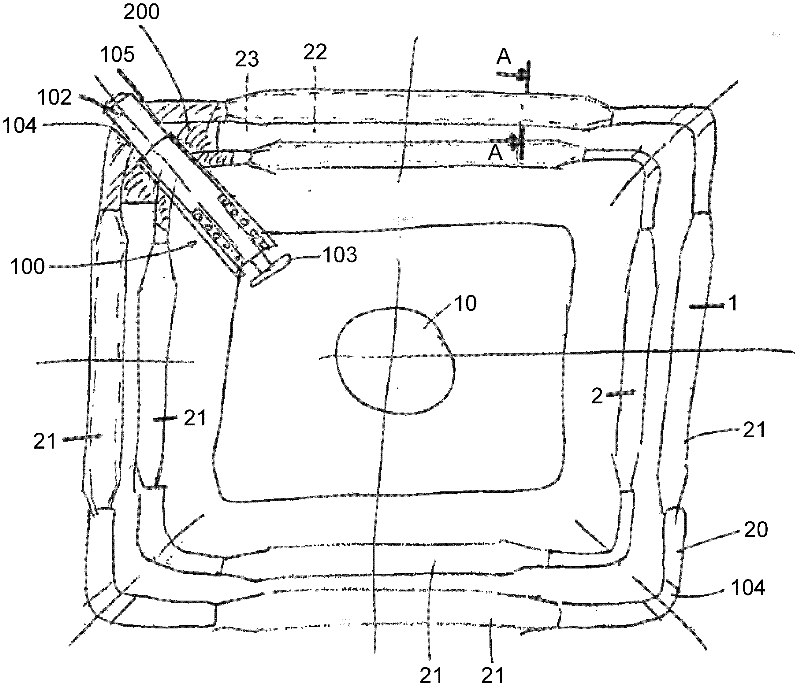

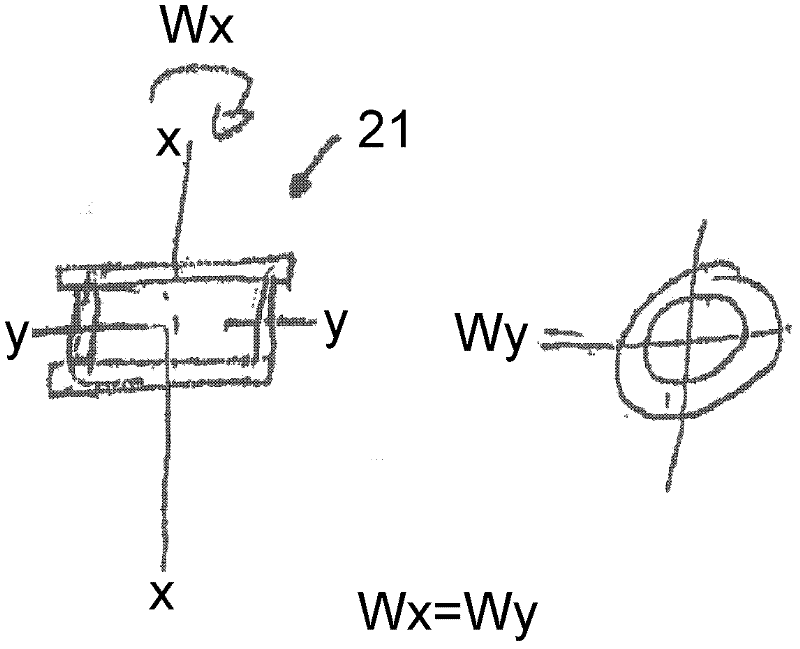

Lift platform with rate-based withdrawing of tail ends of chains by adopting multiplying wheel

The invention discloses a lift platform with rate-based withdrawing of tail ends of chains by adopting a multiplying wheel. The lift platform comprises a holding plate, two first chains, two second chains, a transmission shaft, two transmission assemblies, a power device and a support table. One transmission assembly is arranged on each side of the holding plate and comprises a beam body, a driving assembly, a chain tail end fixing pin shaft, a multiplying sliding assembly and a chain hanging assembly. One ends of the first chains are fixed to the support table, and the other ends of the first chains extend into the beam bodies from left and sequentially wind around the driving assemblies and the multiplying sliding assemblies to be fixed to the chain tail end fixing pin shafts. One ends of the second chains are fixed to the support table, and the other ends of the second chains extend into the beam bodies from right and sequentially wind around the chain hanging assemblies, the driving assemblies and the multiplying sliding assemblies to be fixed to the chain tail end fixing pin shafts. The lift range of the lift platform can be expanded by times. According to the invention, the structure is compact, lifting is stable, automatic operation is achieved and the cost is low.

Owner:山东东方华宸智能停车设备有限公司

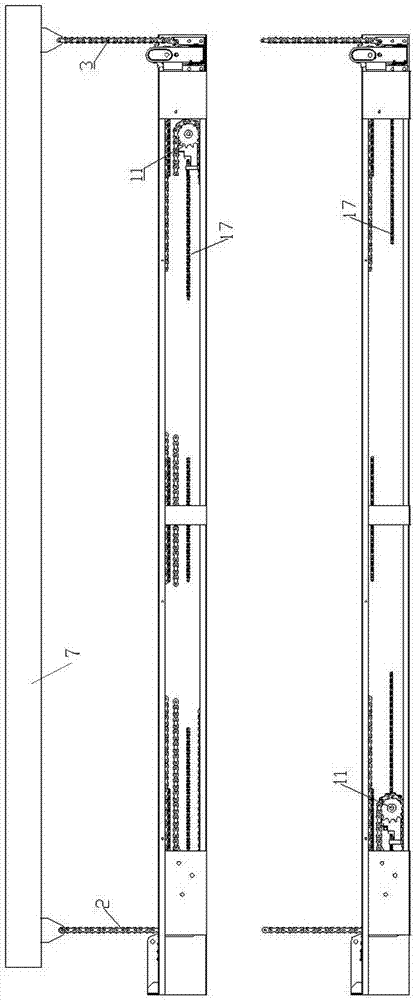

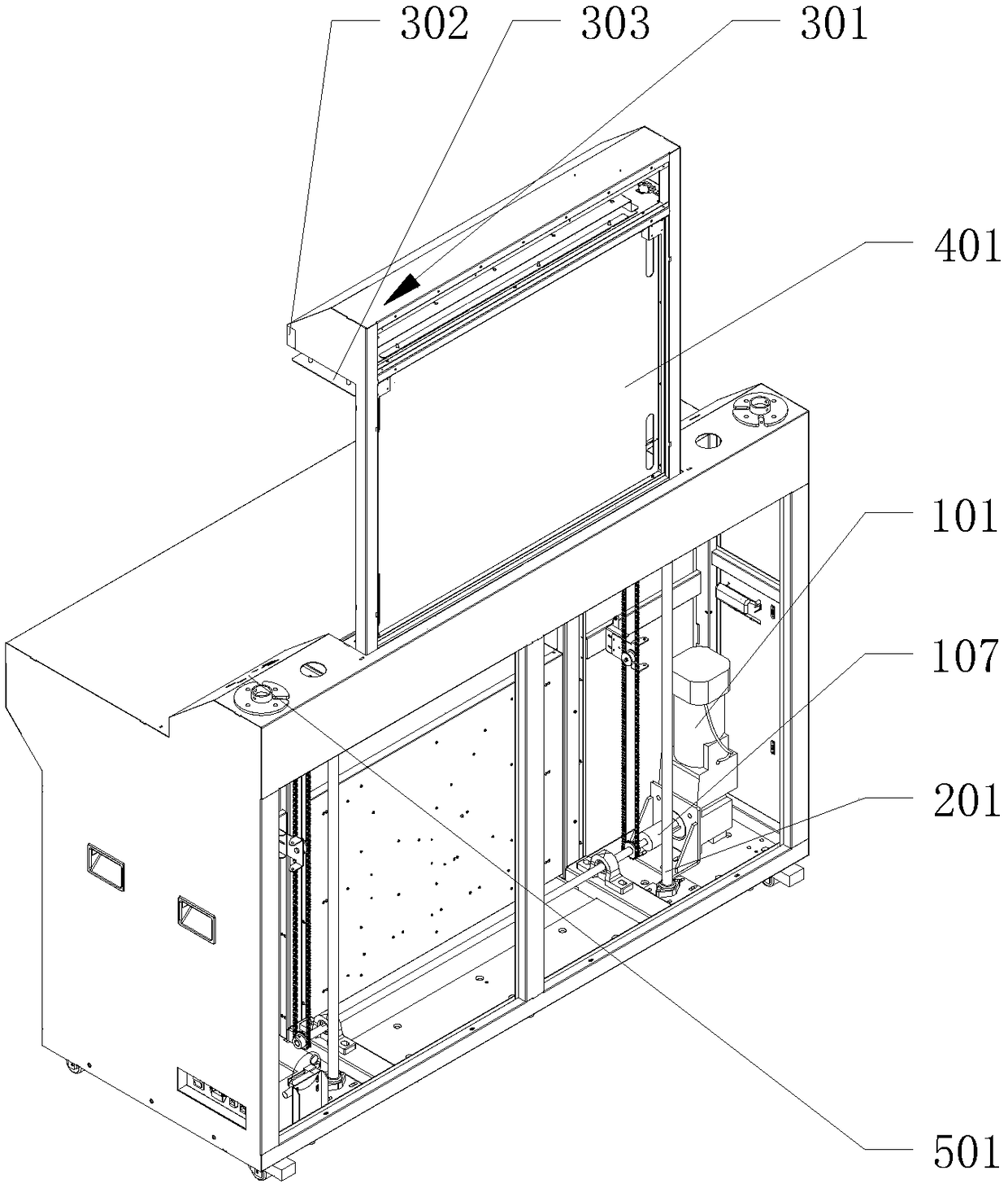

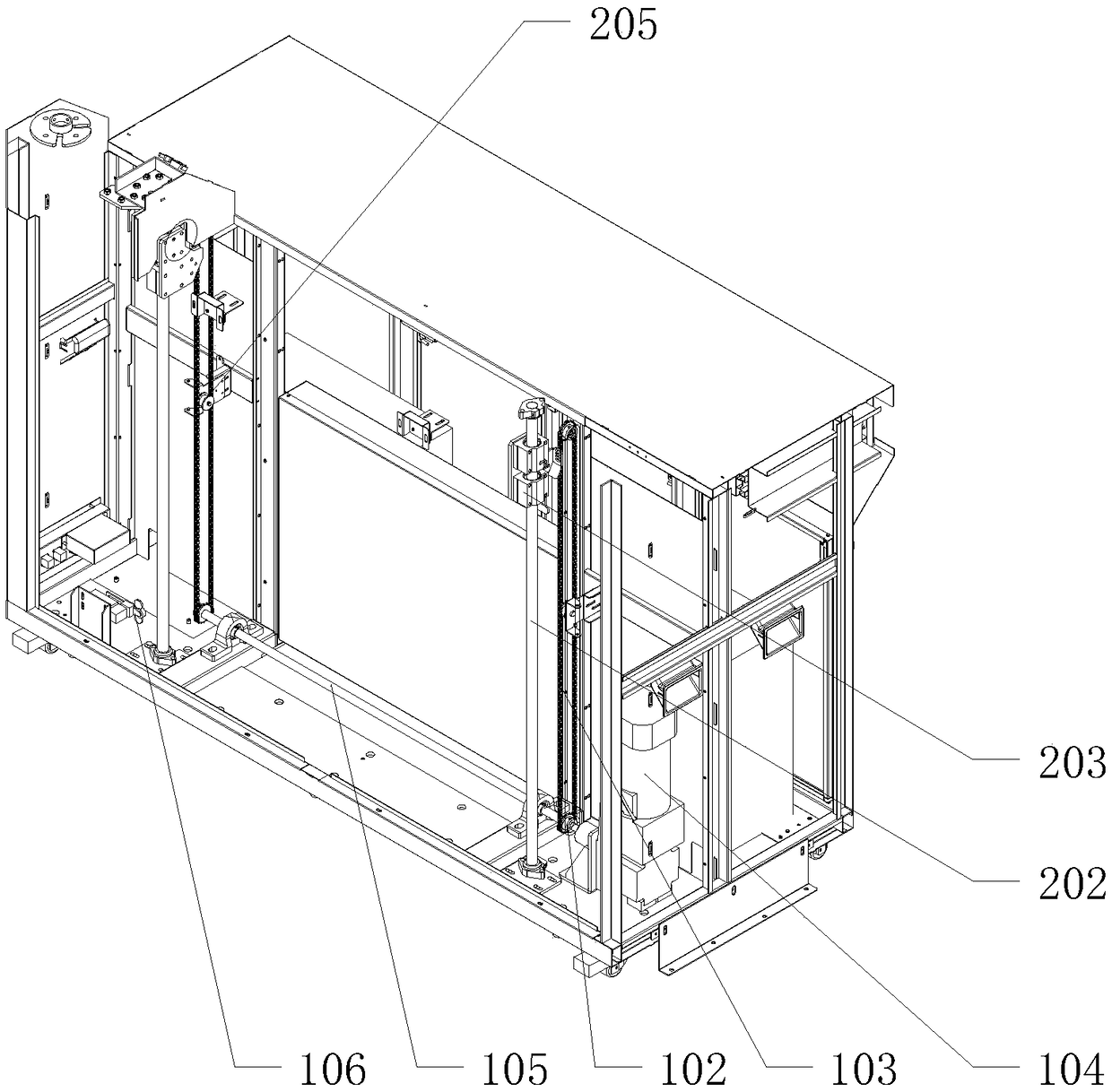

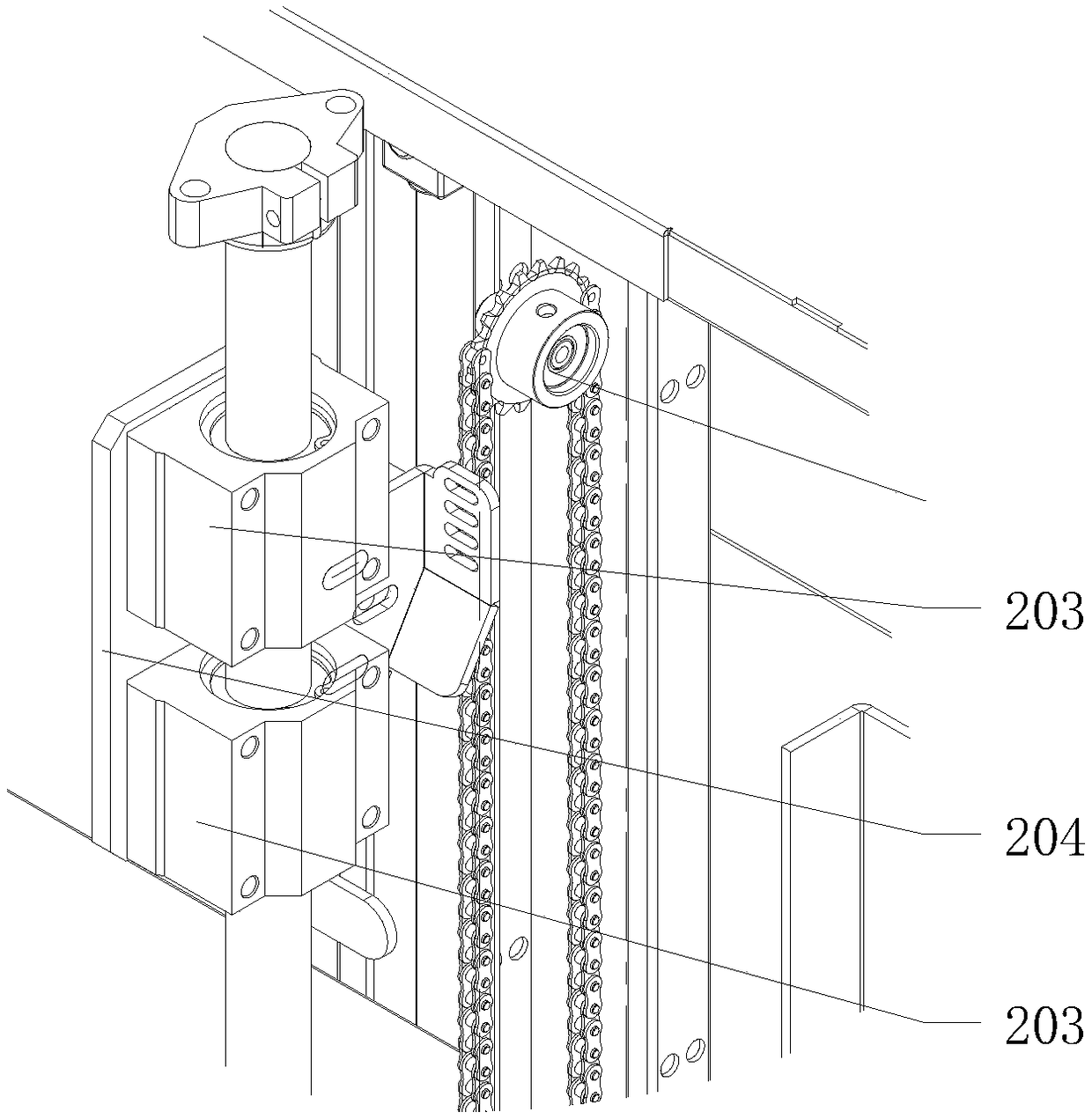

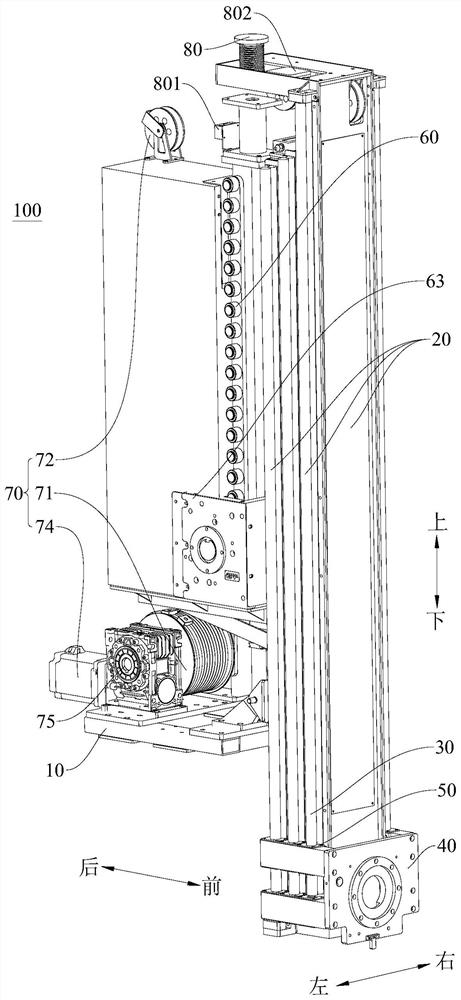

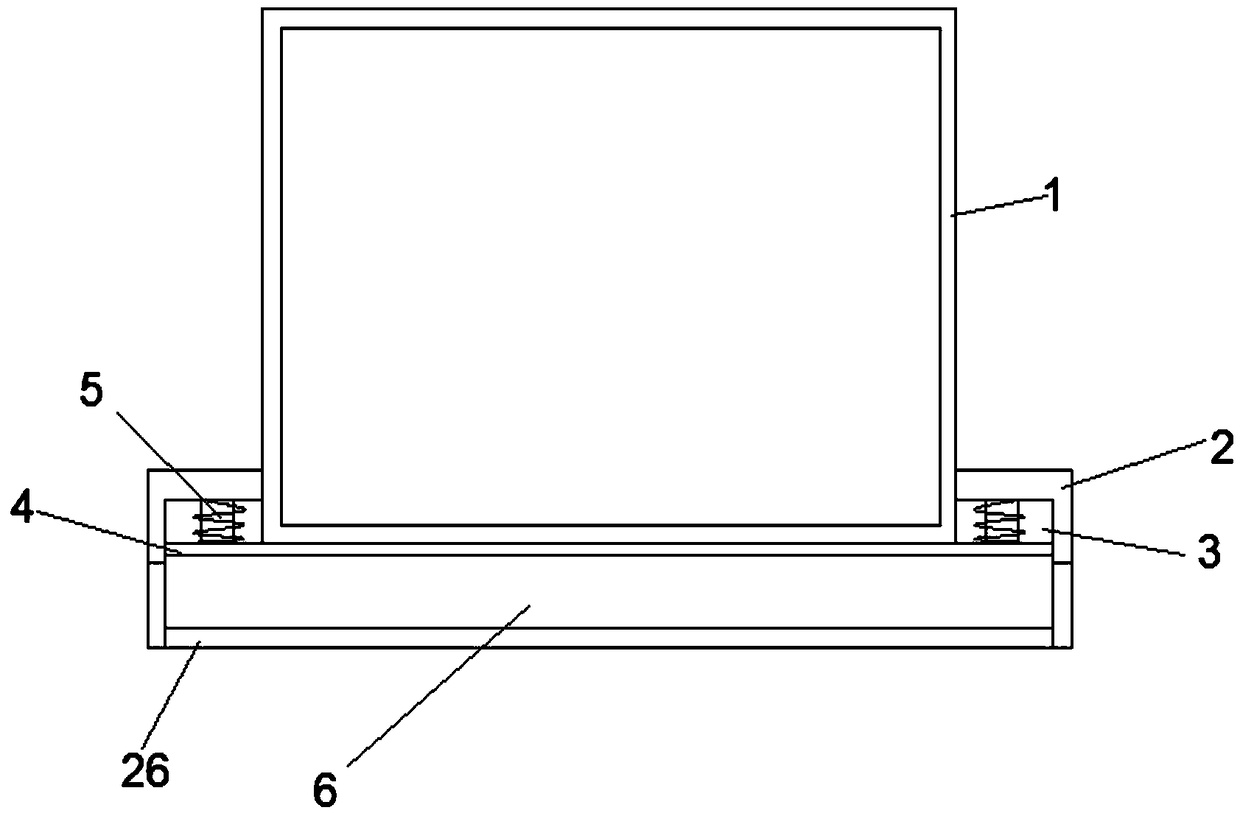

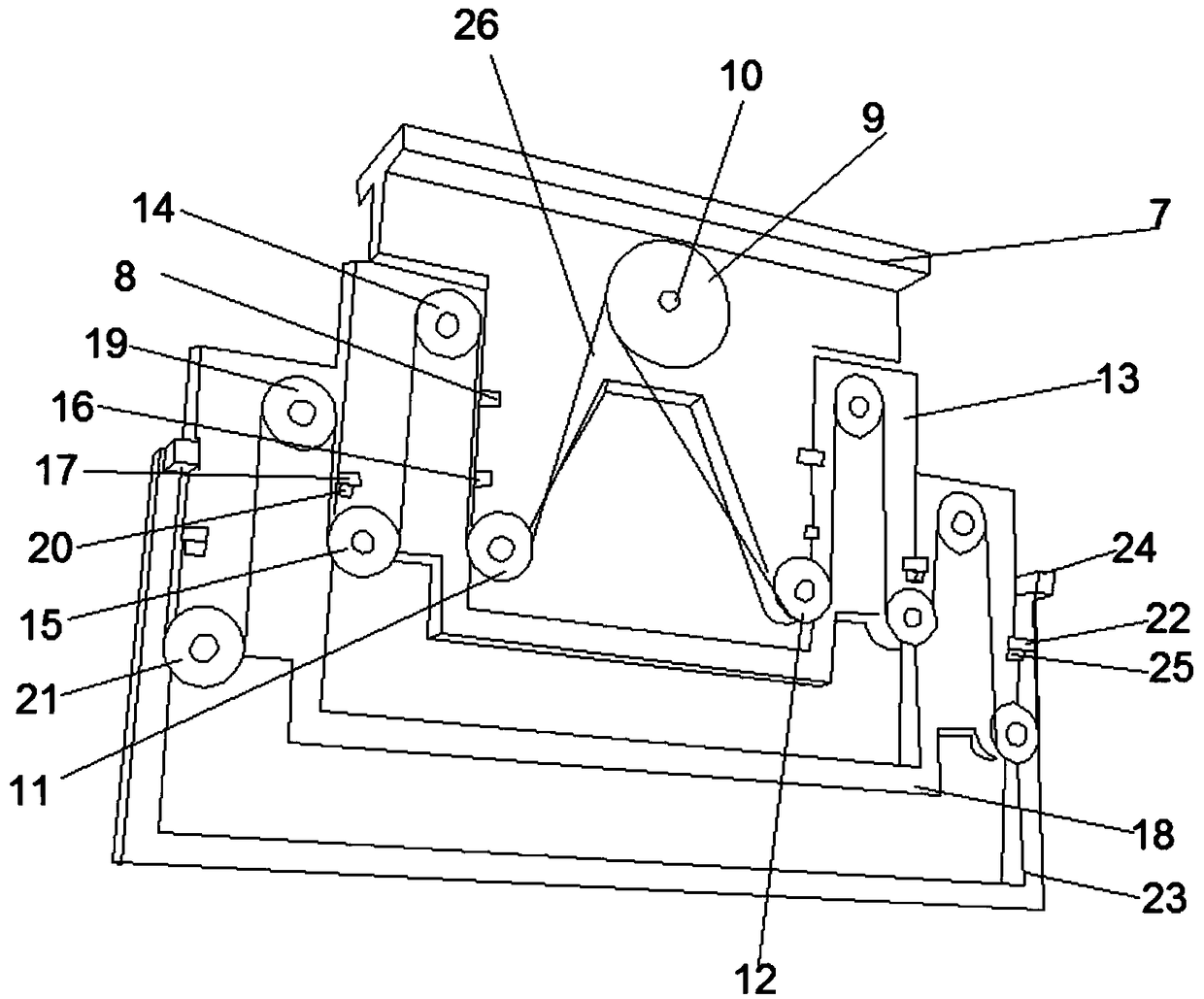

Panel lifting device and multimedia terminal

PendingCN108825952ASmall sizeSmall footprintStands/trestlesIdentification meansMiniaturizationSprocket

The invention discloses a panel lifting device and a multimedia terminal. The device comprises a driving assembly and a guide assembly, the driving assembly comprises sprockets, chains and a motor, the number of the sprockets is two, the sprockets are arranged in the height direction, the chains are arranged around the sprockets, the motor is arranged on one side of the chains, a power output shaft of the motor is in transmission connection with the sprockets, and the sprockets are used to drive the chains to move in the height direction; and a guide assembly comprises a guide rod and slidingblocks, and the sliding blocks are arranged on the guide rod in a sleeved mode and connected with the chains and a panel. According to the device, the position where the driving assembly is arranged is changed from the upper part or the lower part of a lifting device to one side of the lifting device, the occupied space of the lifting device in the whole device is reduced, the structure where theguide rod is driven by the chains to get on the sliding blocks is adopted to ensure that the lifting process moves along the straight line all the time, the lifting height in the height direction is increased, and solutions for the increase of the size of the panel and the miniaturization of the multimedia terminal while the lifting height is the same are provided.

Owner:FUJIAN XIN LIAN DA INTELLIGENT TECH

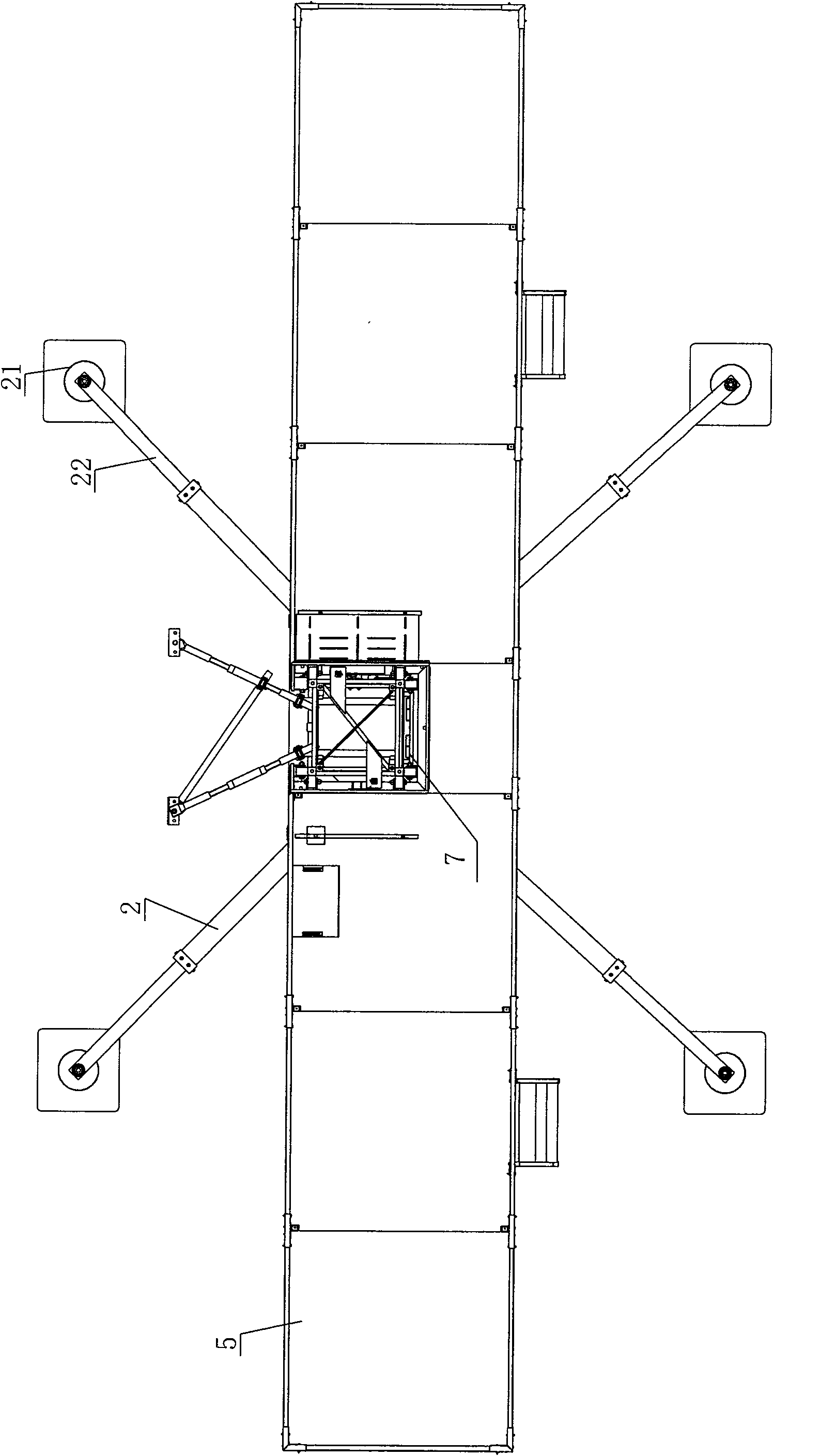

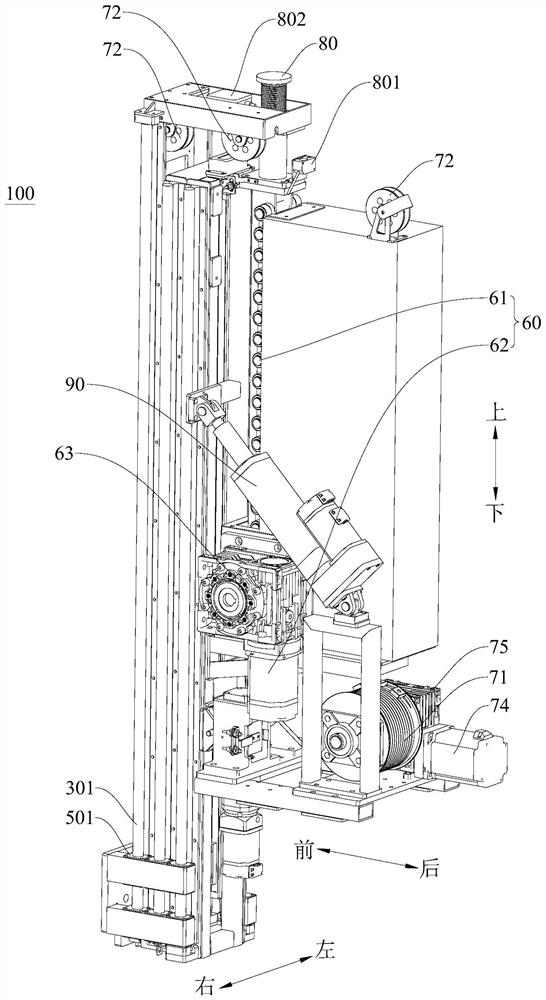

Lifting device and plastering equipment

ActiveCN111891967AImprove reliabilityReduce replacement usageLifting framesBuilding constructionsVertical planeMechanical engineering

The invention discloses a lifting device and plastering equipment. The lifting device comprises a fixed base, at least two lifting supports, a mounting base, a first driving mechanism and a second driving mechanism, wherein the first lifting support is liftably connected to the fixed base, the latter lifting support is liftably connected to the former lifting support, and the side portion of eachlifting support is provided with a first guide part; the side portion of the mounting base is provided with at least two first matching parts; the first driving mechanism is used for driving the lastlifting support among the multiple lifting supports to rise and drop, so that the last lifting support drives the other lifting supports to rise and drop relative to the fixed base; and the second driving mechanism is used for driving the mounting base to go up and down along the at least two lifting supports in sequence. The lifting device has the large lifting height, is wider in coverage area,suitable for processing of vertical planes with different heights and capable of improving the adaptability and realizing full coverage and has the high stability.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

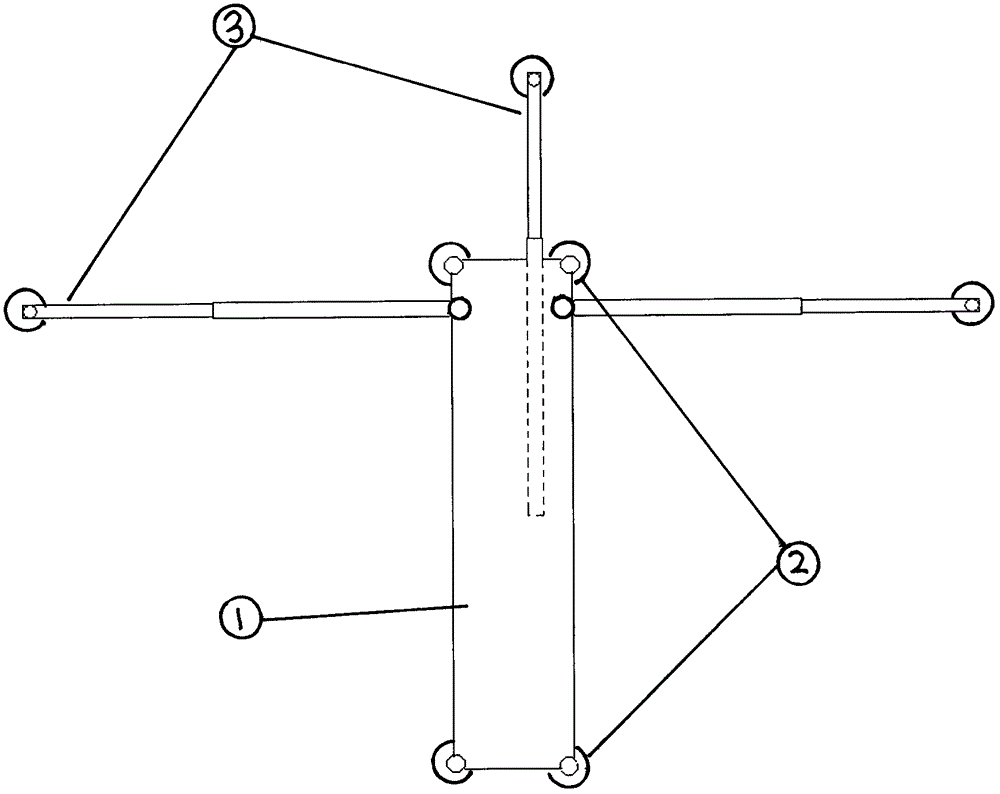

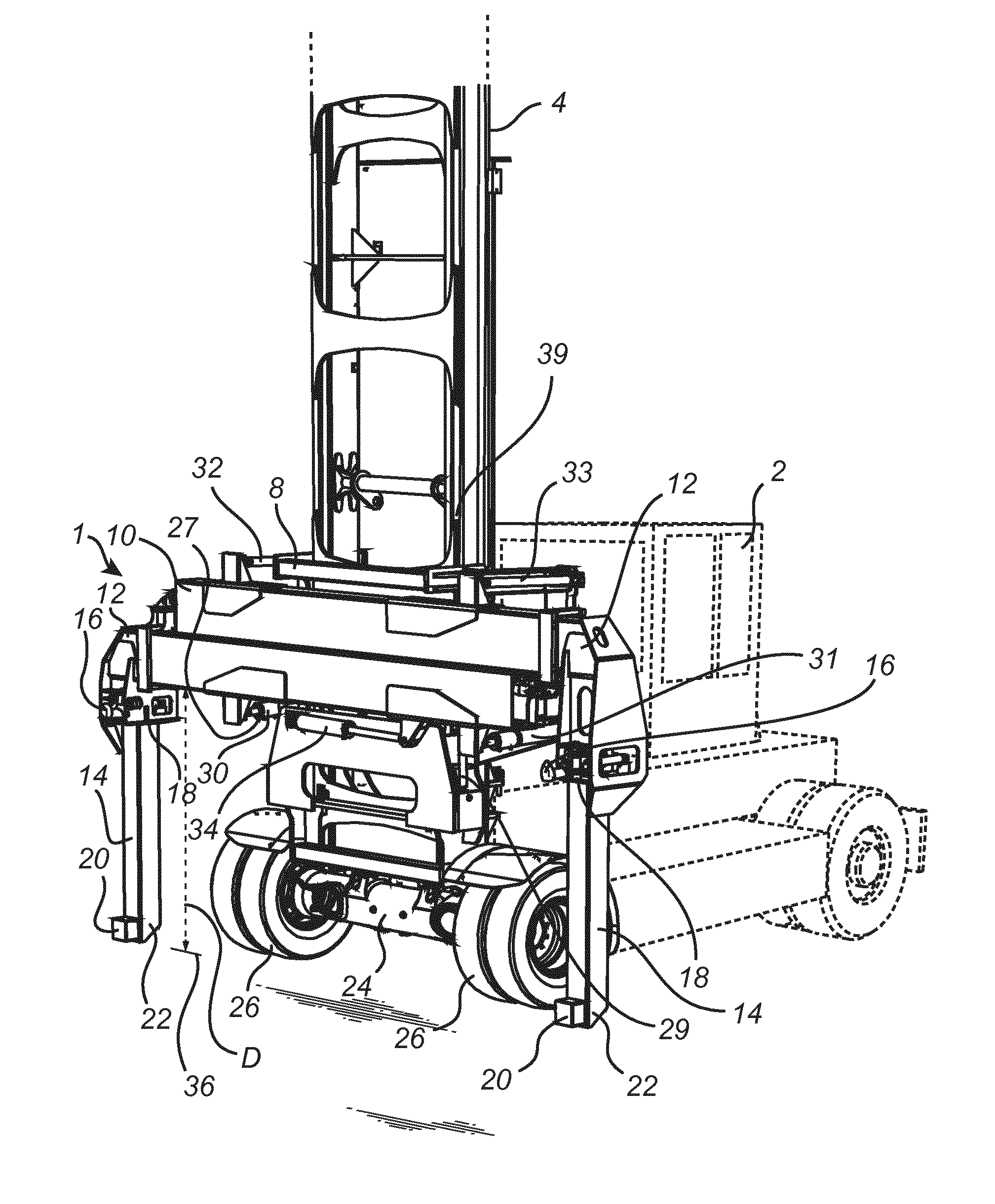

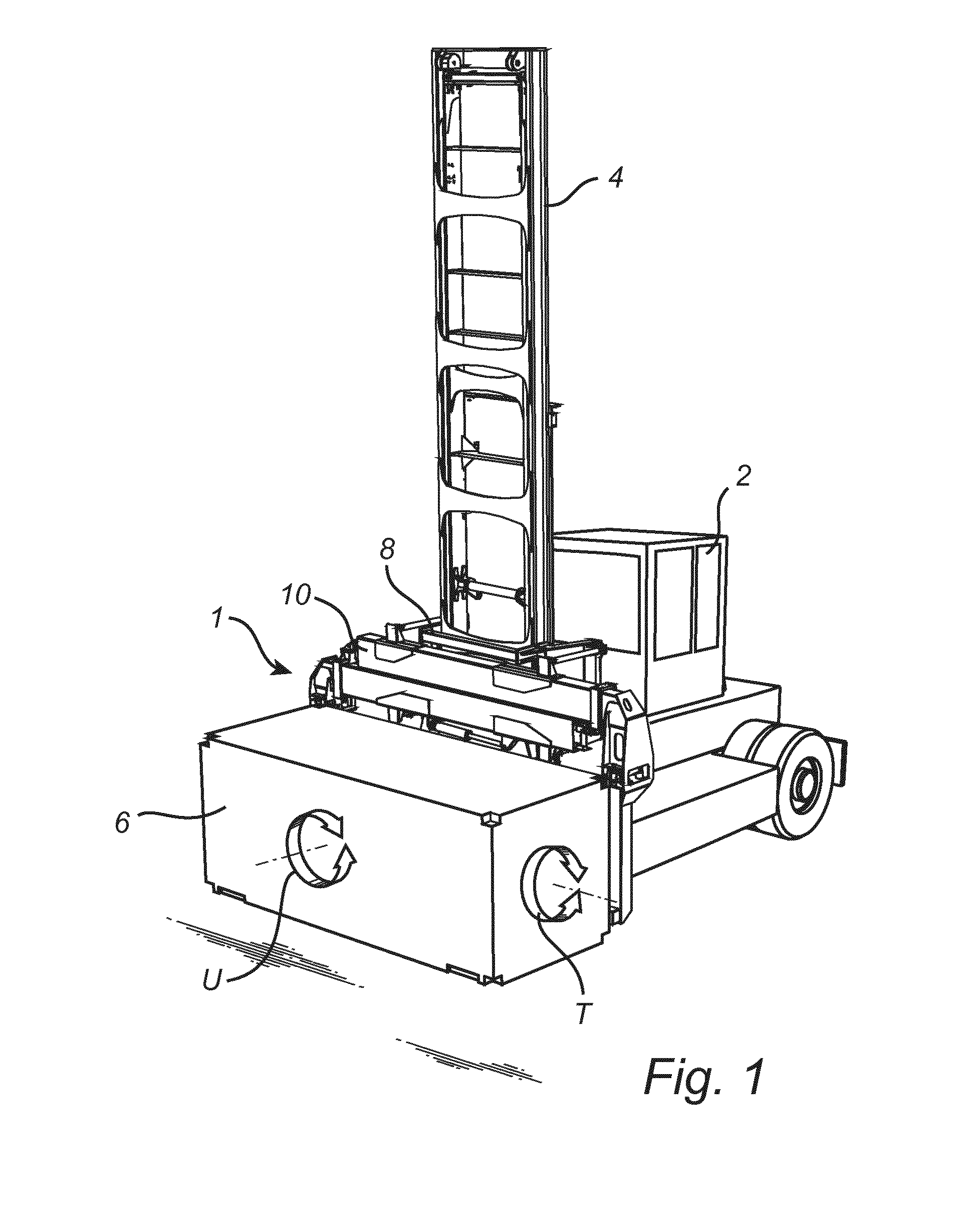

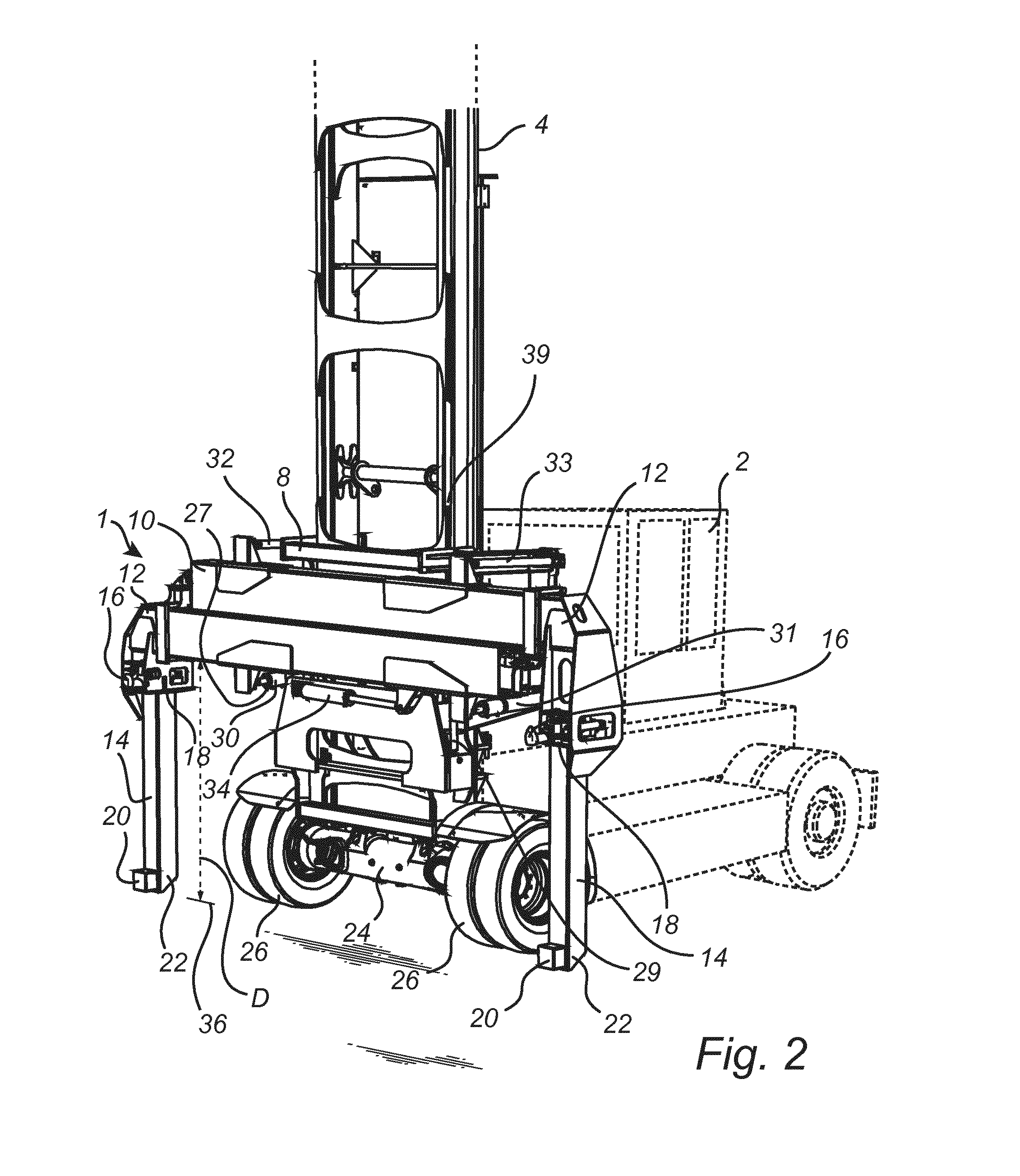

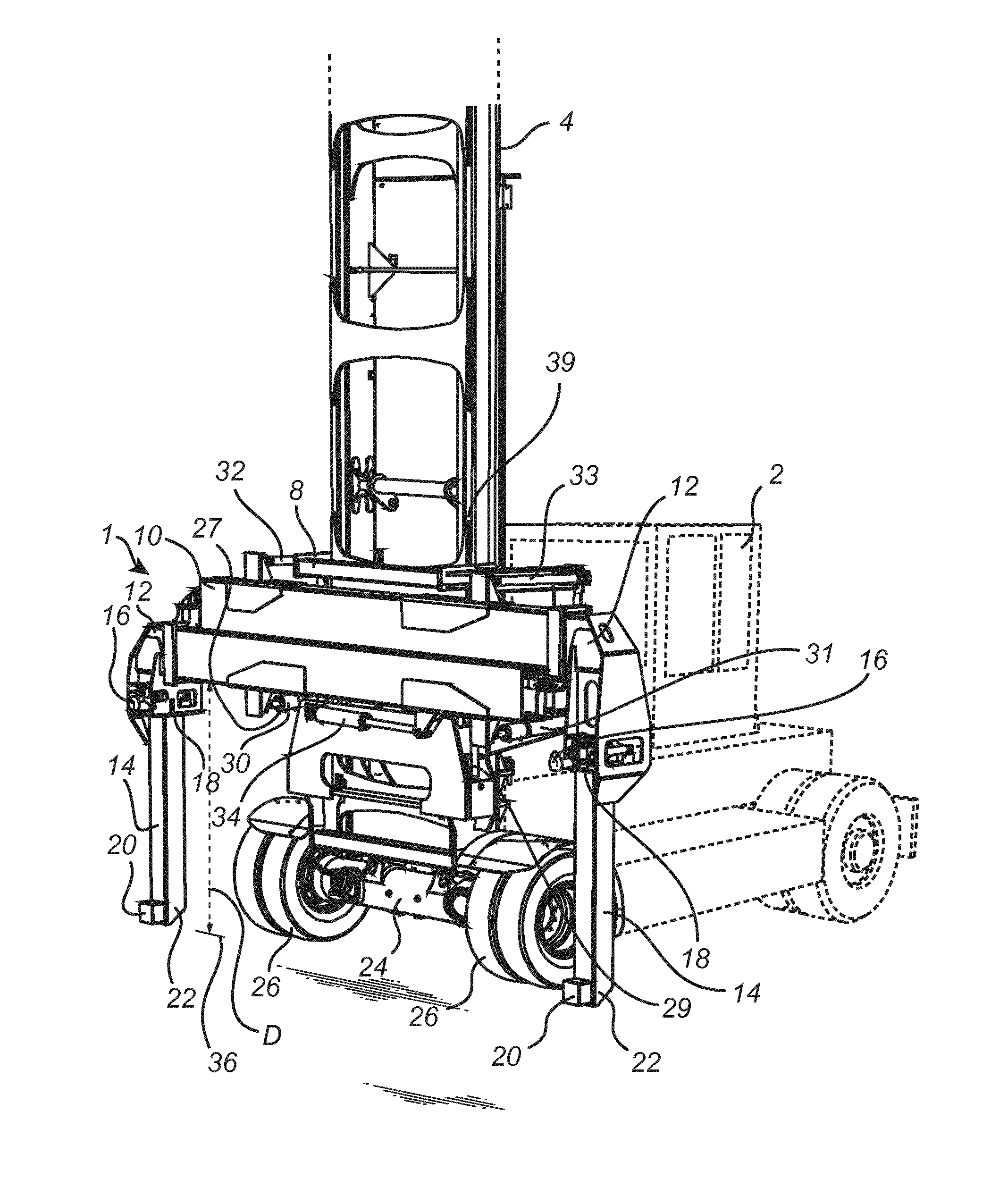

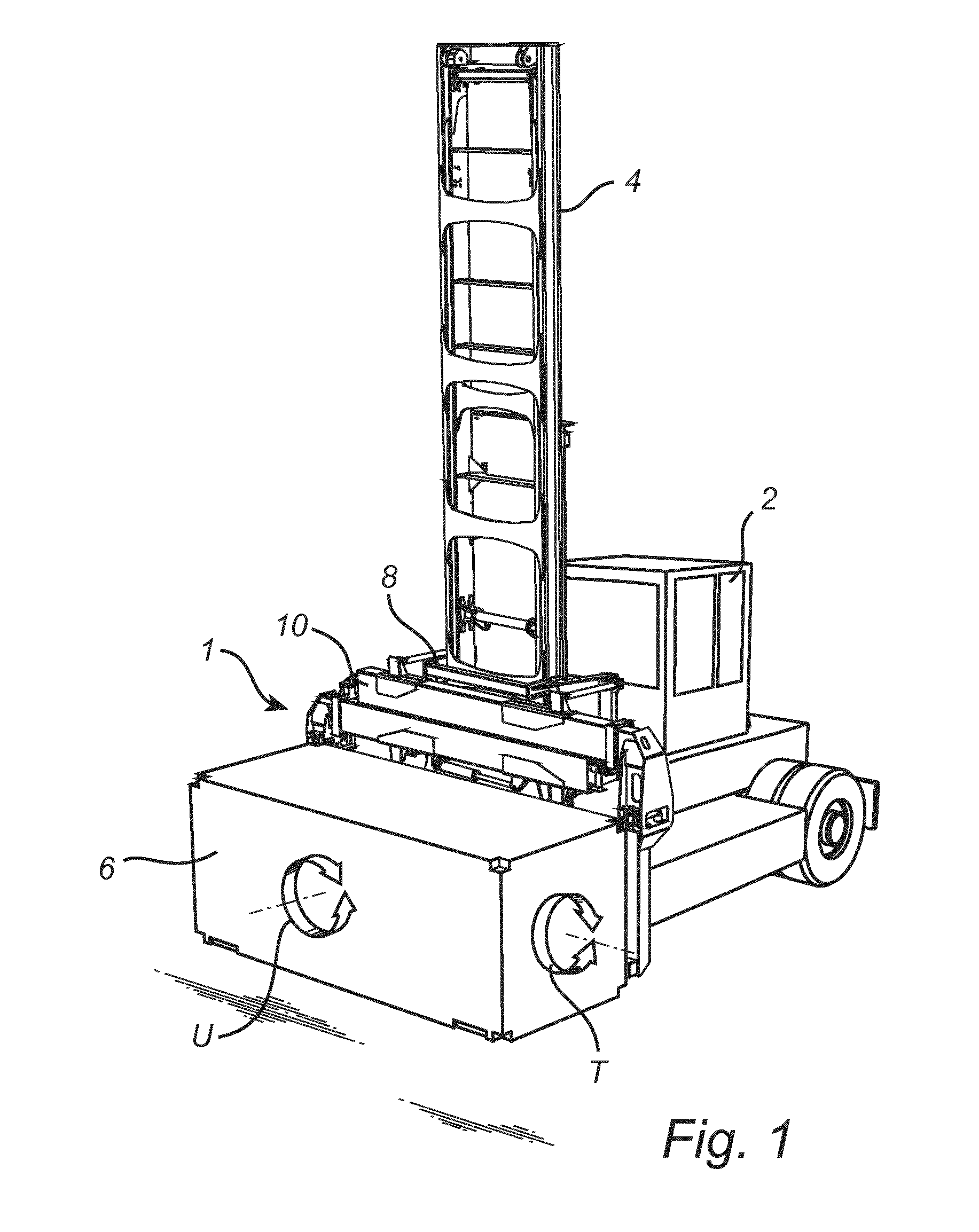

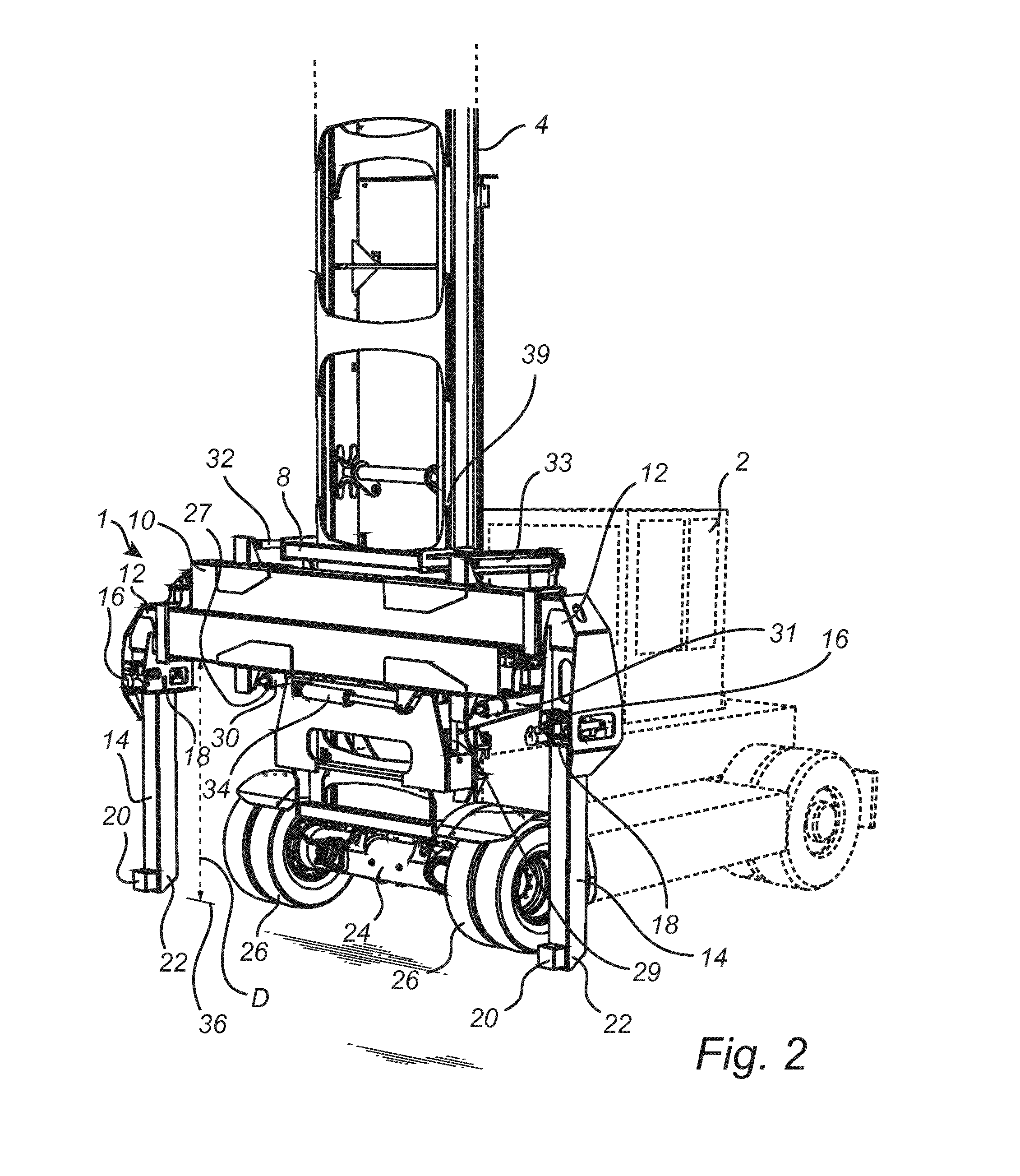

Side lift spreader

ActiveUS20150030422A1Reduce weightAffect stabilityLifting devicesLoad-engaging elementsEngineeringEMPTY CONTAINER

A side lift spreader for handling empty containers, and method for adjusting a main frame of an inverted side lift spreader. The inverted side lift spreader comprises a main carriage connectable to a lifting device, movable along a front side of a mast of the lifting device, the main frame being carried by and sideways movable with respect to the main carriage, and main frame guiding means for guiding movement of the main frame with respect to the main carriage. The main frame guiding means comprises at least two links, one first portion of each link connected to the main frame and one second portion of each link connected to the main carriage. The second portions of the links are arranged at the main carriage at respective points of attachment which are located, in use of the spreader, at an opposite side of the mast compared to the front side.

Owner:ELME SPREADER

Side lift spreader

ActiveUS9394149B2Reduce weightAffect stabilityLifting devicesLoad-engaging elementsEngineeringEMPTY CONTAINER

A side lift spreader for handling empty containers, and method for adjusting a main frame of an inverted side lift spreader. The inverted side lift spreader comprises a main carriage connectable to a lifting device, movable along a front side of a mast of the lifting device, the main frame being carried by and sideways movable with respect to the main carriage, and main frame guiding means for guiding movement of the main frame with respect to the main carriage. The main frame guiding means comprises at least two links, one first portion of each link connected to the main frame and one second portion of each link connected to the main carriage. The second portions of the links are arranged at the main carriage at respective points of attachment which are located, in use of the spreader, at an opposite side of the mast compared to the front side.

Owner:ELME SPREADER

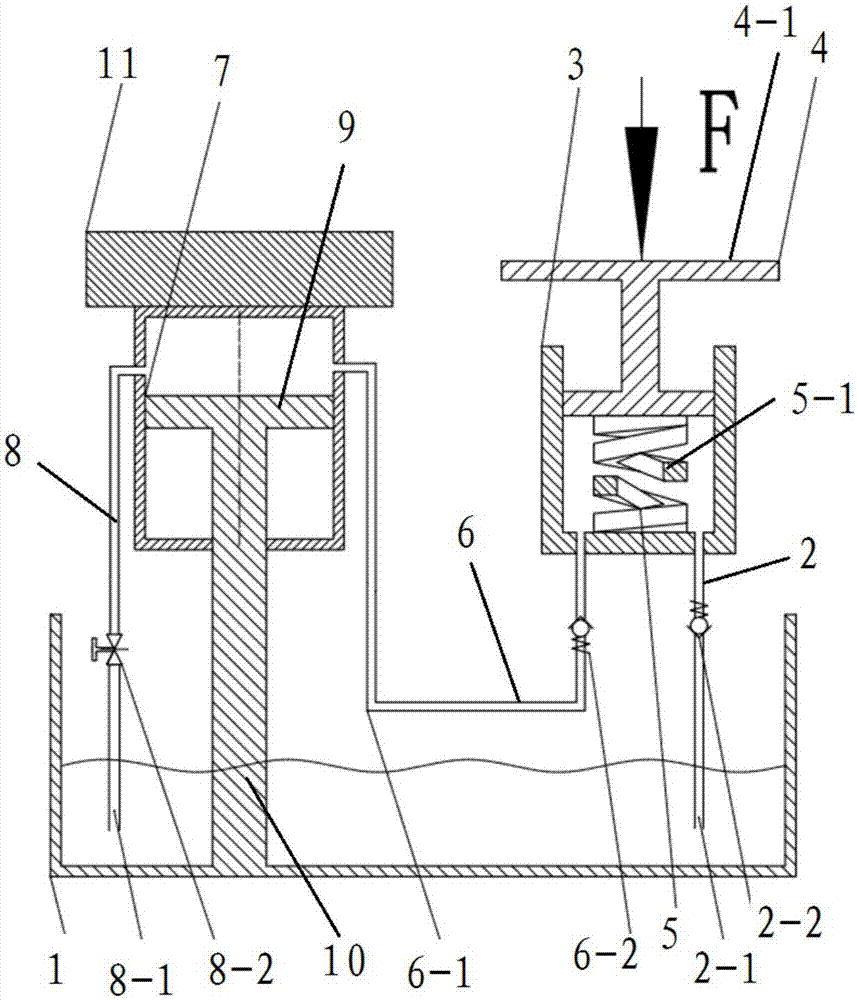

Hydraulic jack

InactiveCN107963569AIncrease the areaNot easy to take off the topLifting devicesHydraulic cylinderFuel tank

The invention discloses a hydraulic jack, and belongs to the technical field of hoisting equipment. The hydraulic jack comprises an oil tank, a first conveying device, a press-down device, a return device, a second conveying device, a third conveying device, a piston rod and a piston. The first end of the first conveying device communicates with the oil tank, and the second end of the first conveying device communicates with a rodless cavity of an auxiliary hydraulic cylinder. The press-down device is movably arranged in the auxiliary hydraulic cylinder. The return device is arranged in the auxiliary hydraulic cylinder and arranged between the press-down device and the first end of the auxiliary hydraulic cylinder. The first end of the second conveying device communicates with the rodlesscavity of the auxiliary hydraulic cylinder, and the second end of the second conveying device communicates with a rodless cavity of a main hydraulic cylinder. The first end of the third conveying device communicates with the rodless cavity of the main hydraulic cylinder, and the second end of the third conveying device communicates with the oil tank. The first end of the piston rod is arranged inthe oil tank, and the second end of the piston rod is movably arranged in the main hydraulic cylinder. The piston is arranged at the second end of the piston rod. By means of the hydraulic jack, a hydraulic cylinder barrel can stretch out and contract, the output force of the jack can be improved, space can be saved, and the hoisting height of the jack can be increased.

Owner:WUHAN UNIV OF SCI & TECH

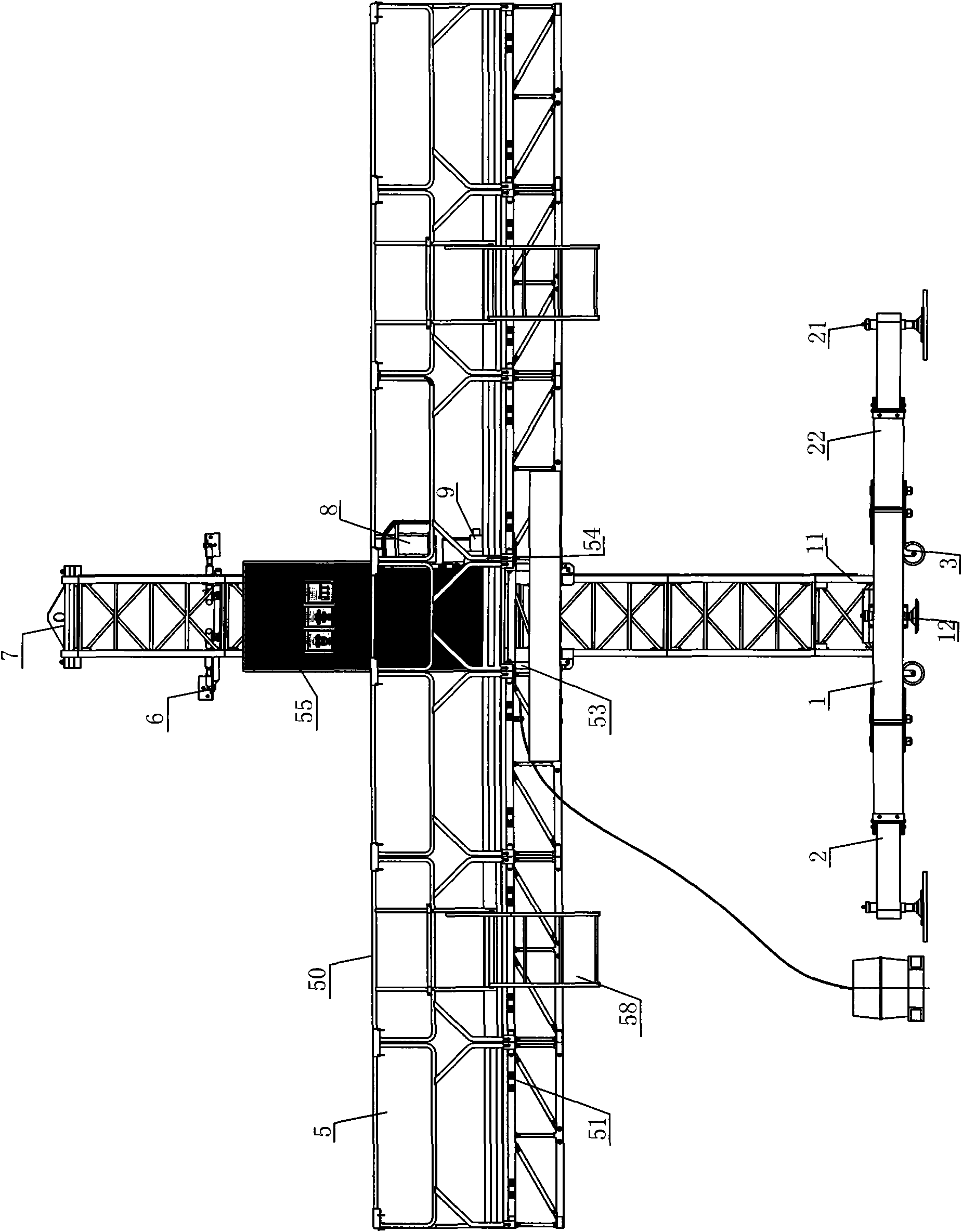

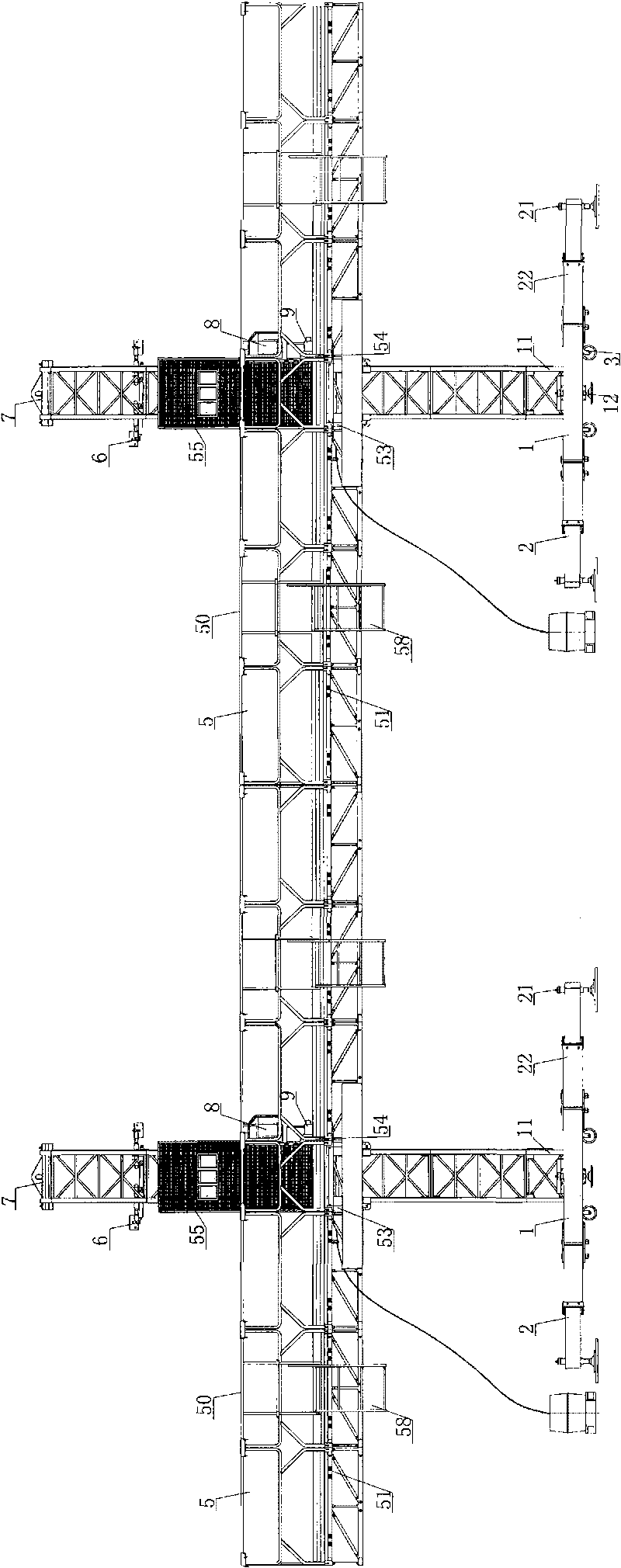

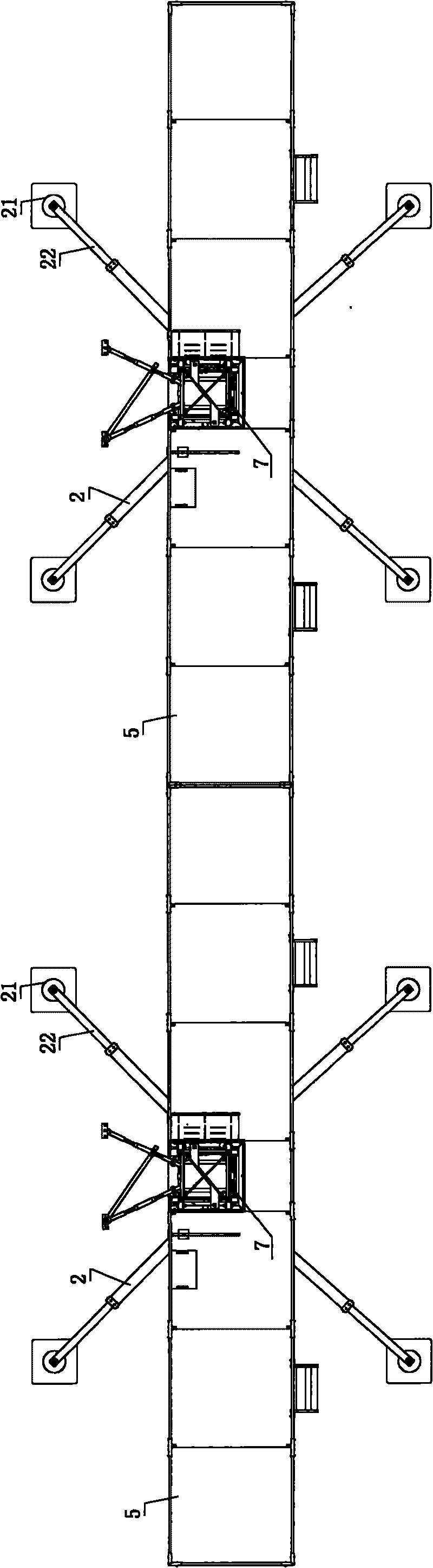

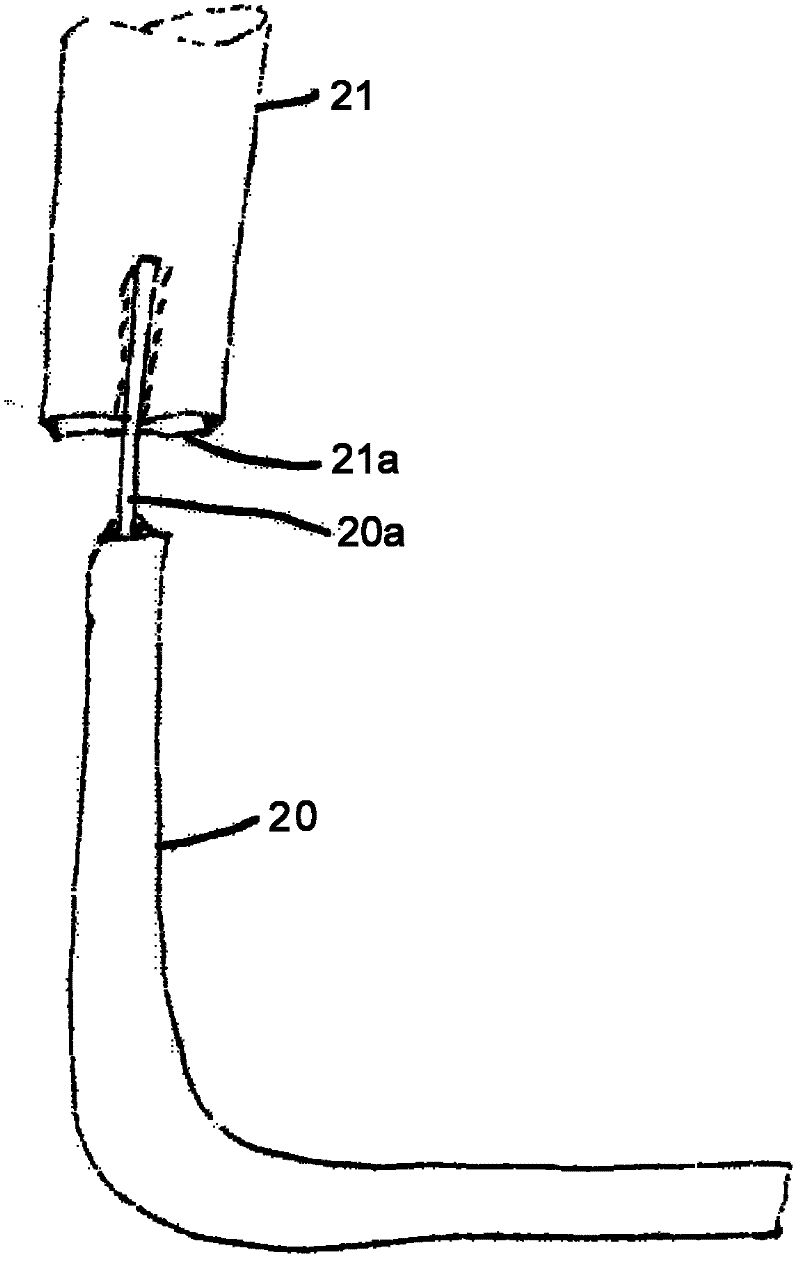

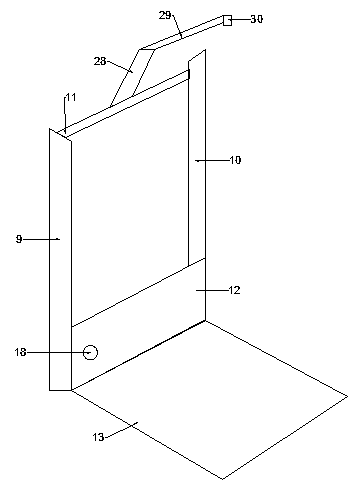

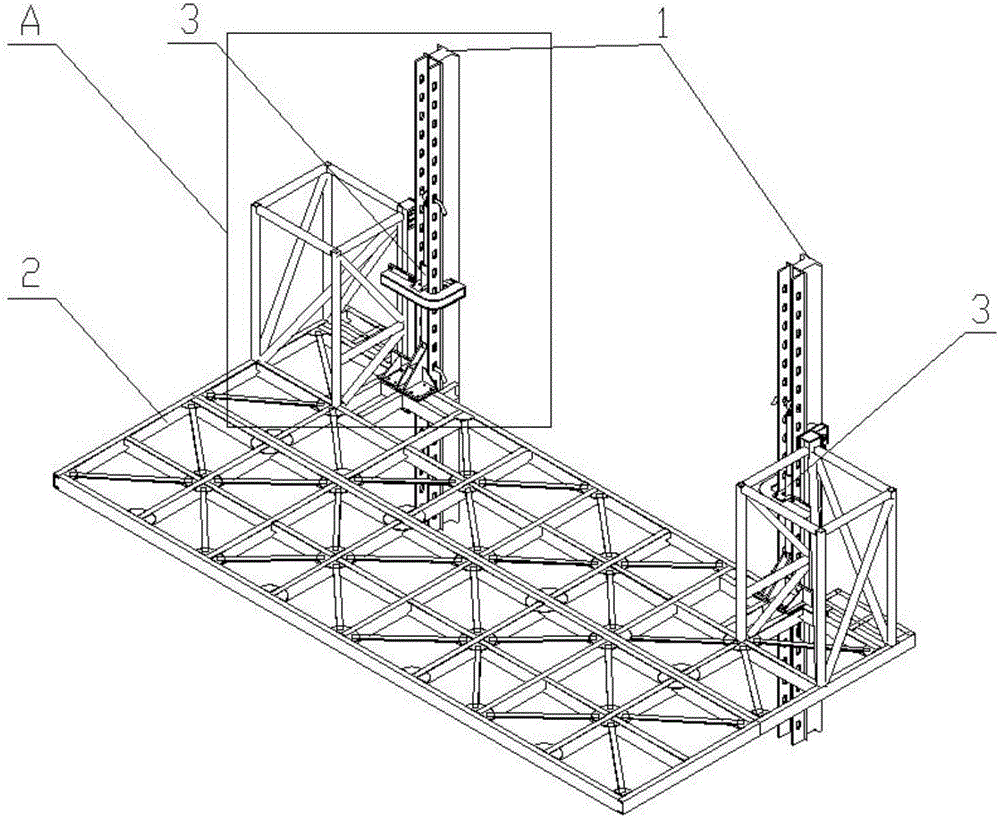

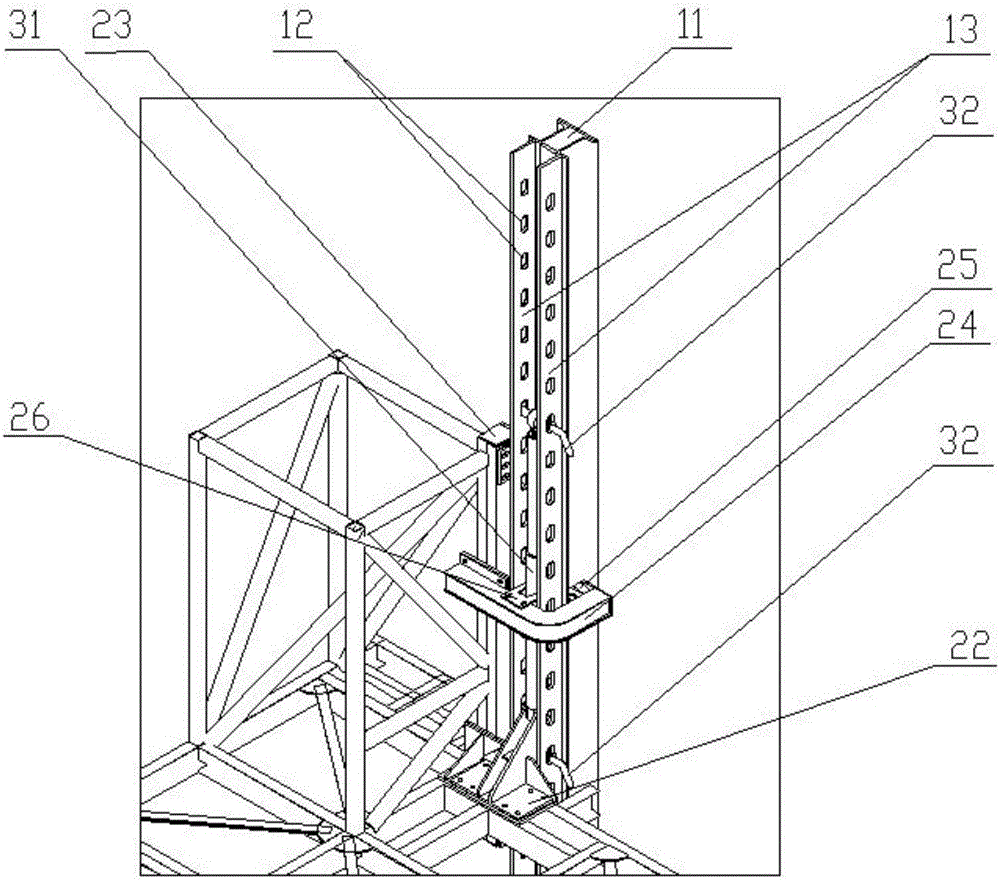

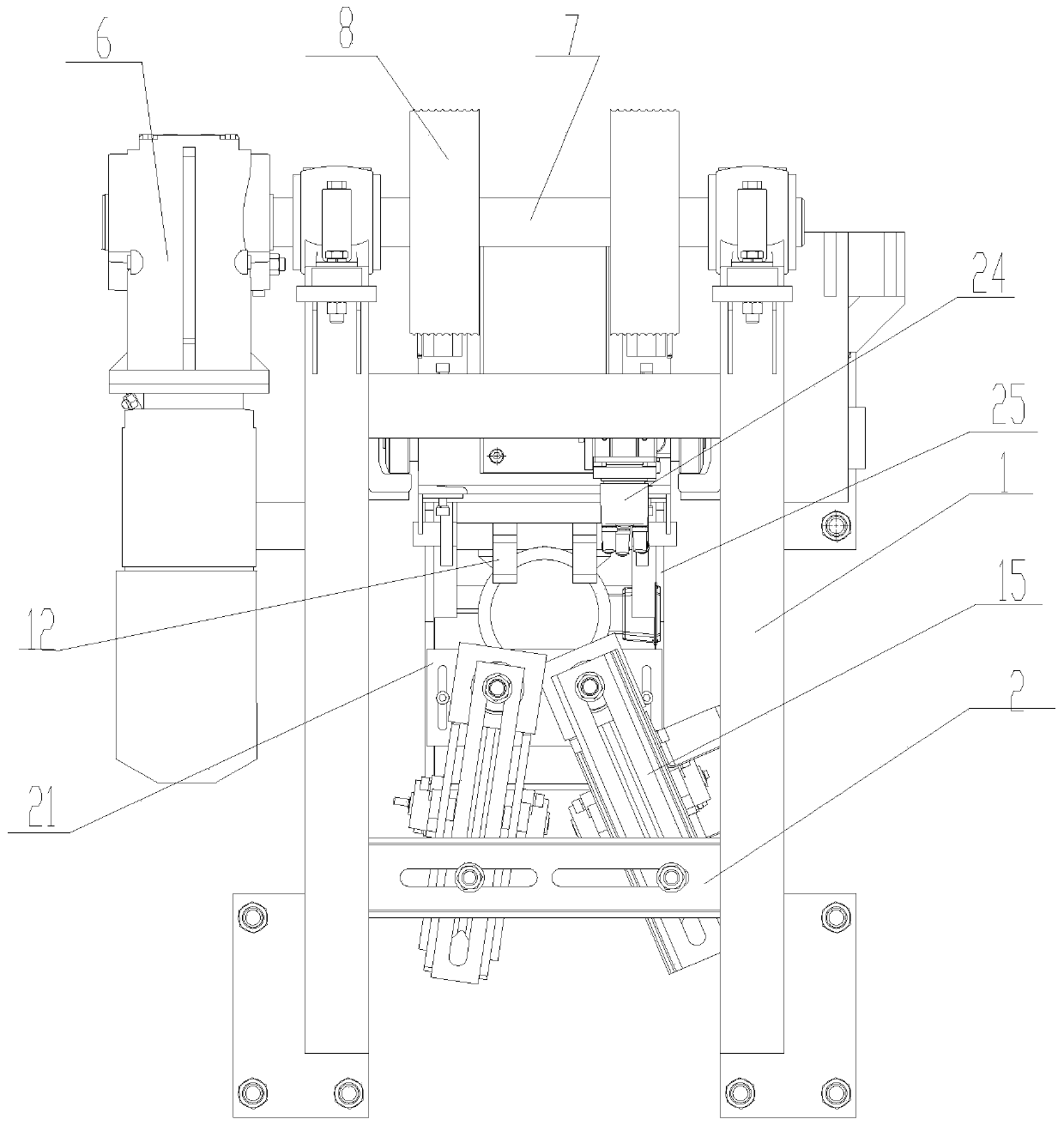

Double-pole climbing aerial working platform

The invention relates to an aerial working device. The double-pole climbing aerial working platform comprises two sets of vertical tower assemblies and platform assemblies, wherein two sets of vertical tower assemblies are respectively composed of a top cap and a plurality of standard knots with frame structure; standard knots are in demountable fixed connection, and the standard knots, a connection frame and the top cap are also in demountable fixed connection; one side of the connection frame and one side of the standard knot are respectively provided with racks which are mutually connected to form a tooth-shaped rail; the platform assembly is fixedly provided with an installation rack; the vertical tower passes through the installation rack which is provided with a roller; the roller sticks to the standard know in a rolling mode; the installation rack is also fixedly provided with a fixed plate; a motor and an anti-dropping safety device are both fixed on the fixed plate; the motor is connected with a drive gear; and the drive gear and the anti-dropping gear of the anti-dropping safety device are respectively meshed with the rack. The invention enlarges the range of the working table surface, can add the standard knots without limitation and has the advantages of wider operation range, high lifting height and reliable stability and safety.

Owner:ZHEJIANG DINGLI MACHINERY CO LTD

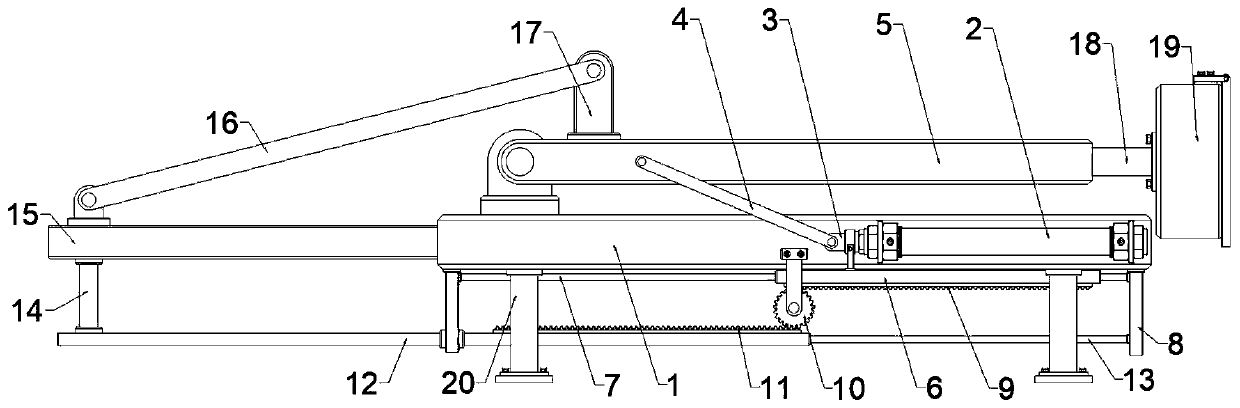

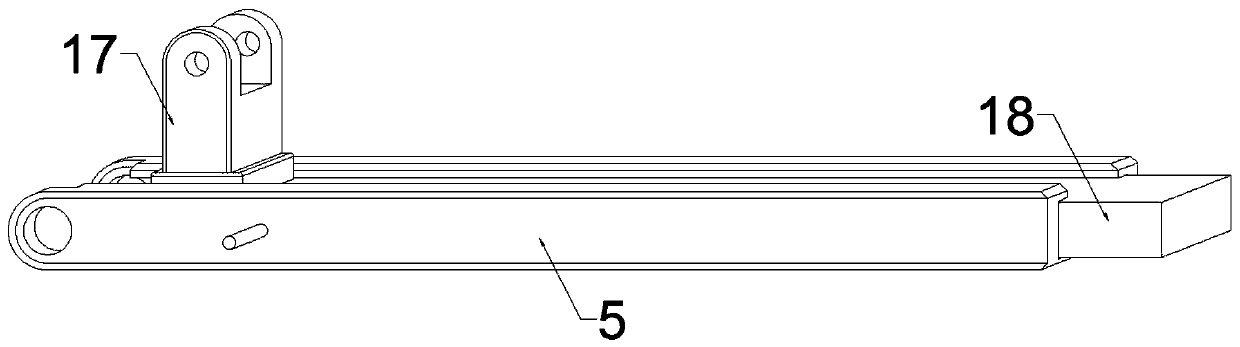

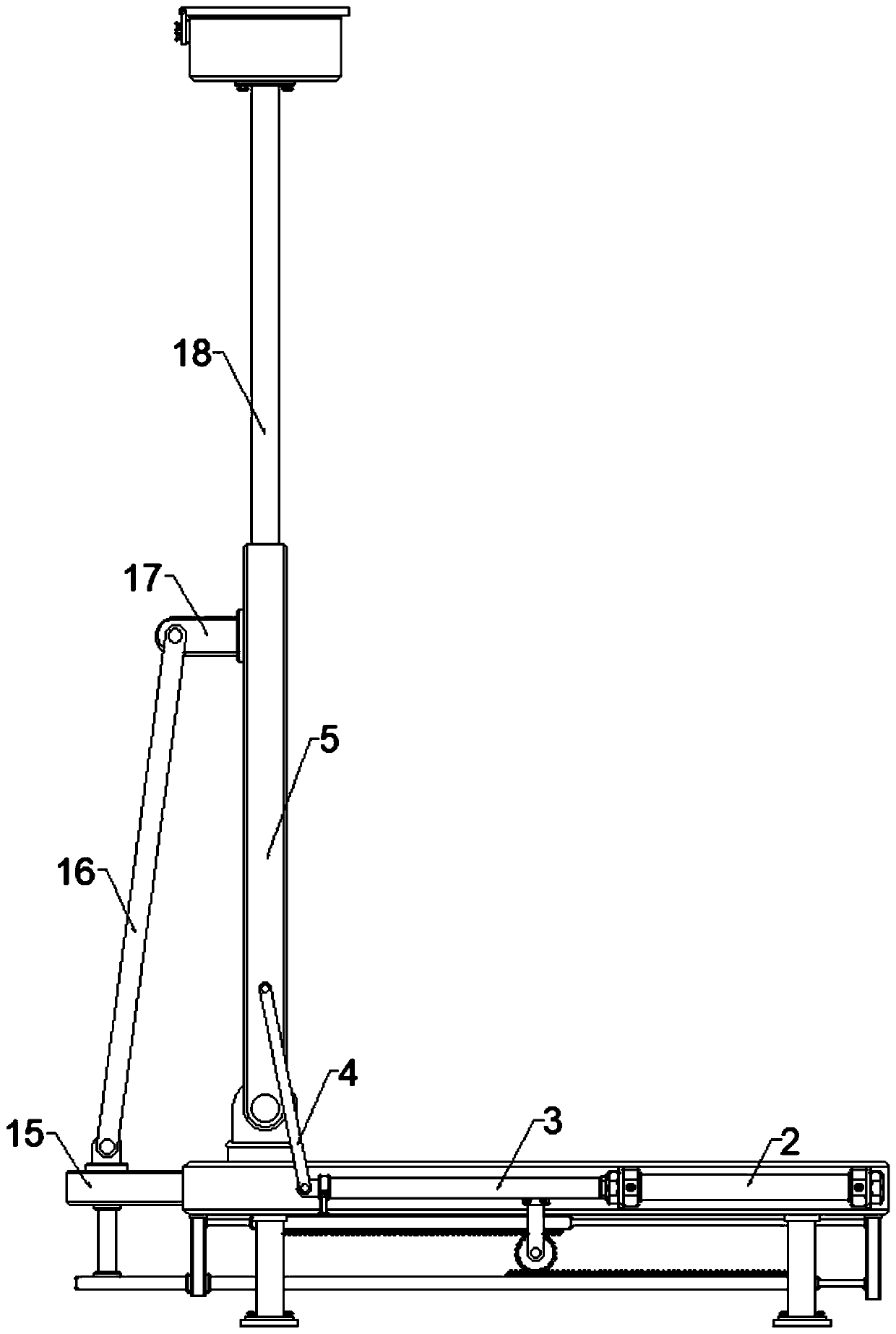

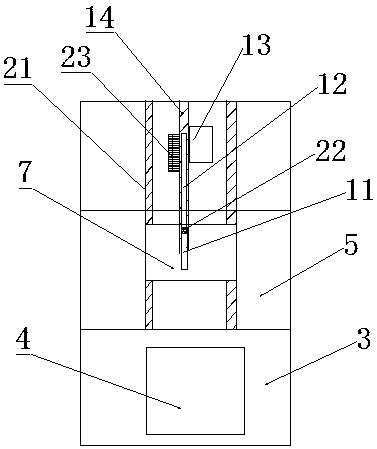

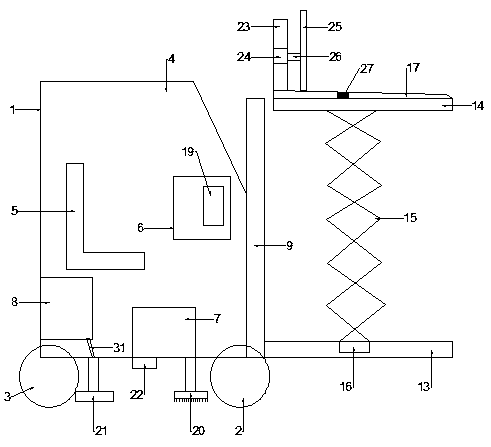

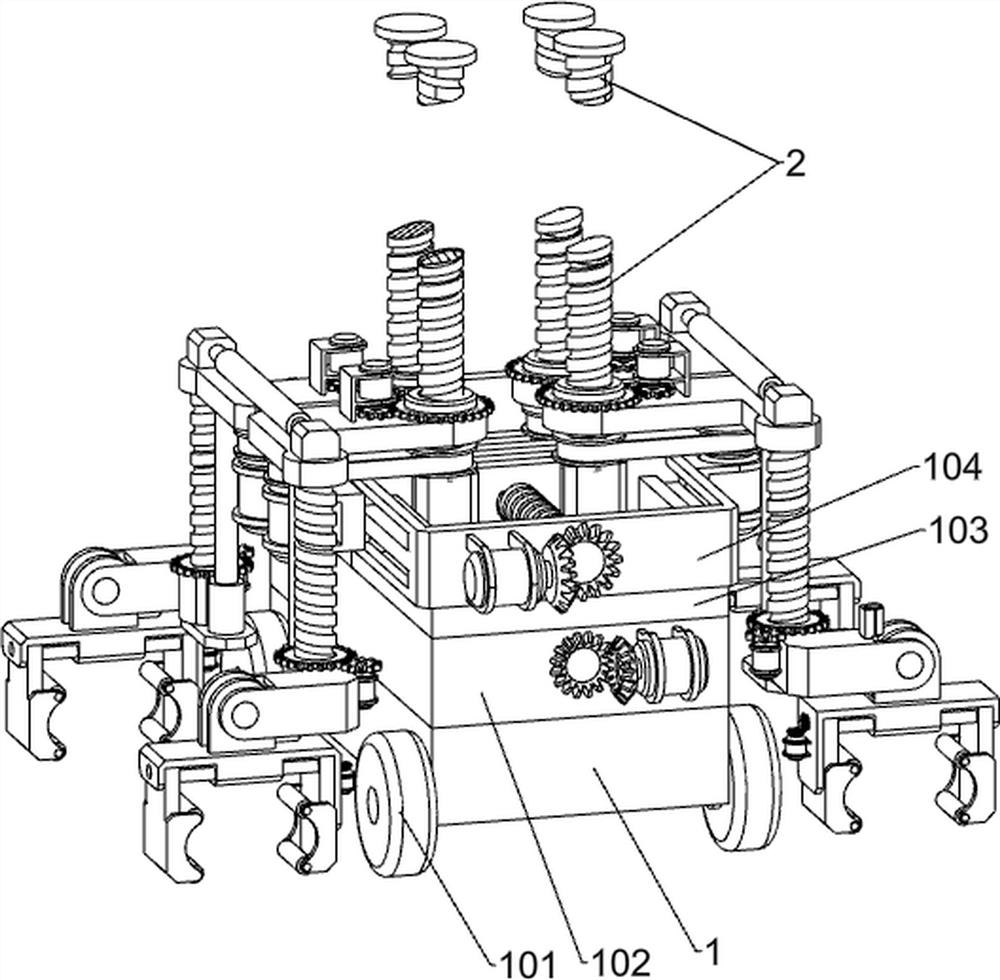

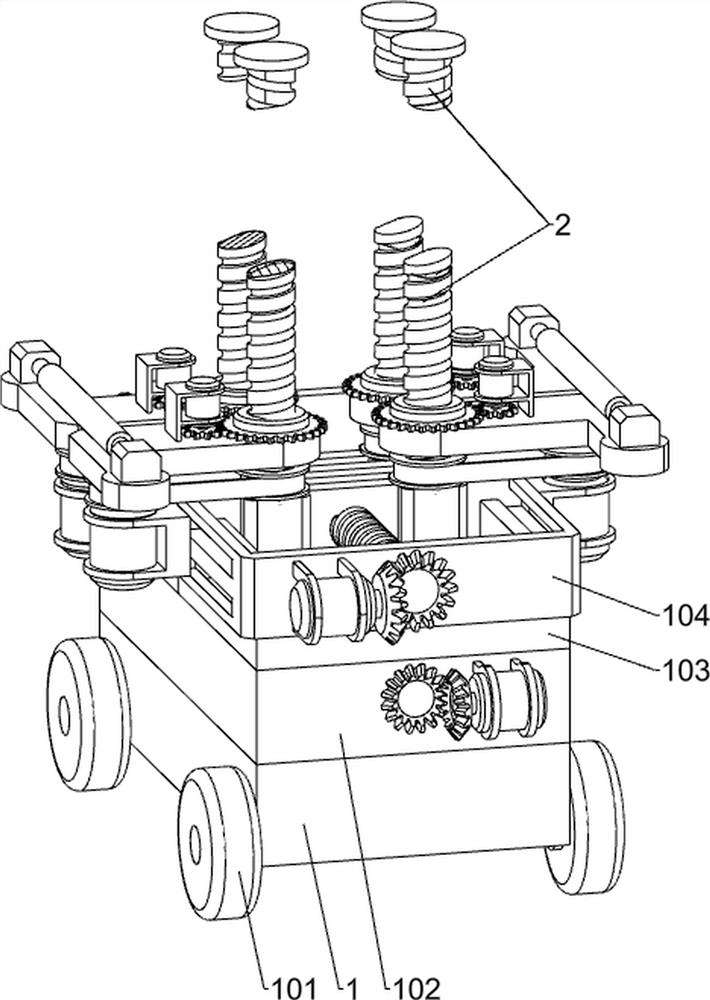

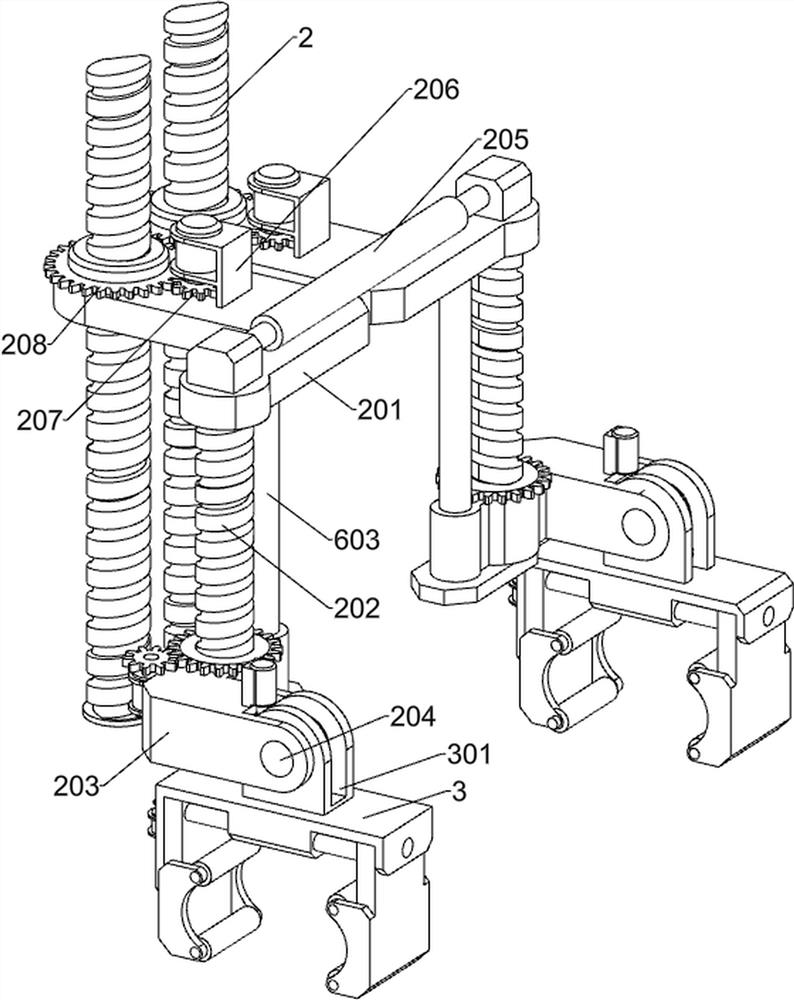

Remote control type mechanical and electrical installation lifting system and lifting driving structure

PendingCN111268592AHigh lifting heightThe overall structure is compactLifting framesMoving partsLift system

The invention discloses a remote control type mechanical and electrical installation lifting system and a lifting driving structure. A rising part is rotatably mounted on a workable, the rising part is connected with the worktable through a driving mechanism, a telescopic part is slidingly mounted in the rising part in a parallel manner, one end of the telescopic part is fixedly provided with a box body used for placing electrical equipment, the telescopic part is connected with the driving mechanism through a transmission mechanism, through the structure, an air cylinder or hydraulic cylinderor screw drives a piston rod to do horizontal movement, a driving arm can be further driven to enable the rising part to swing and rise, the piston rod drives two sets of transverse moving parts to do reverse horizontal moving under the effect of an engaging structure while the rising part rises, an expansion part can be driven to stretch into the worktable, a supporting arm is used for driving the telescopic part and the box body mounted at the end of the telescopic part to further rise along a through hole formed in the rising part, and the dual-stroke rising and falling function is achieved.

Owner:CHINA CONSTR FOURTH ENG DIV INSTALLATION ENG

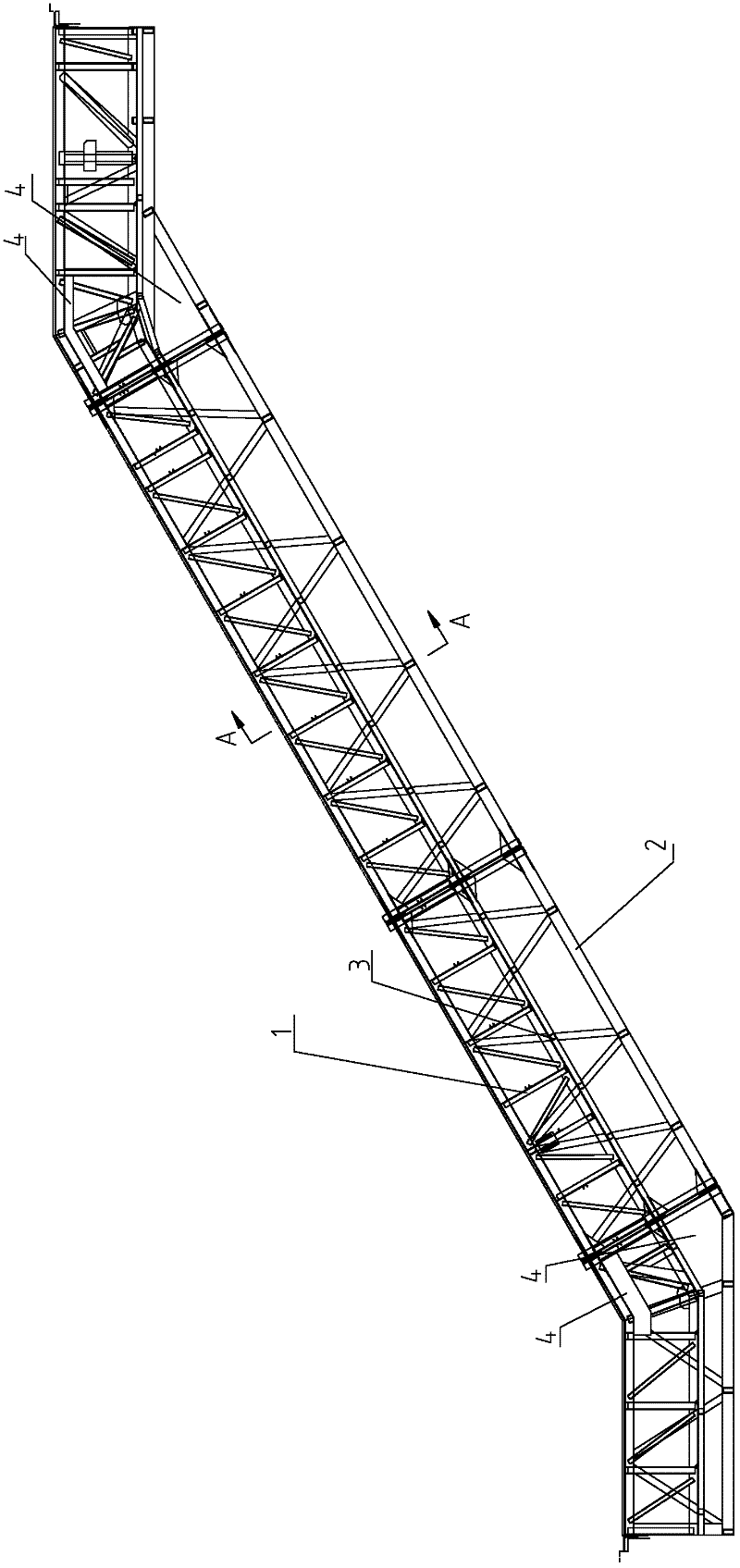

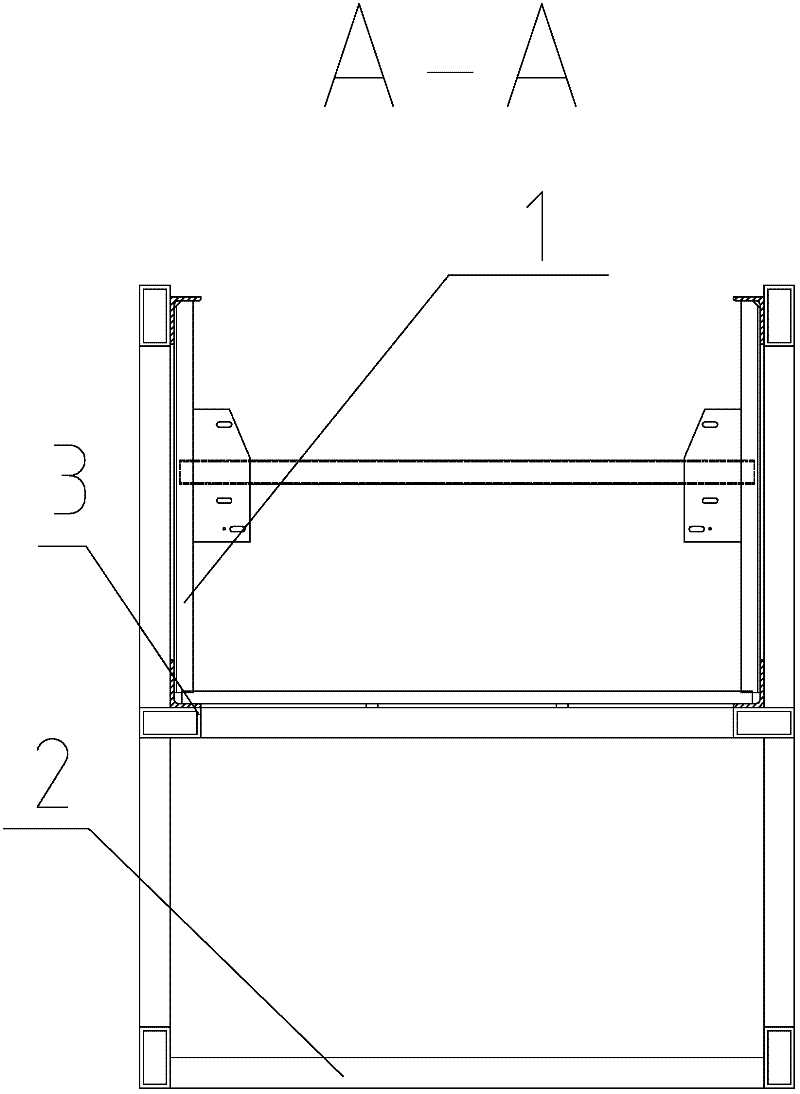

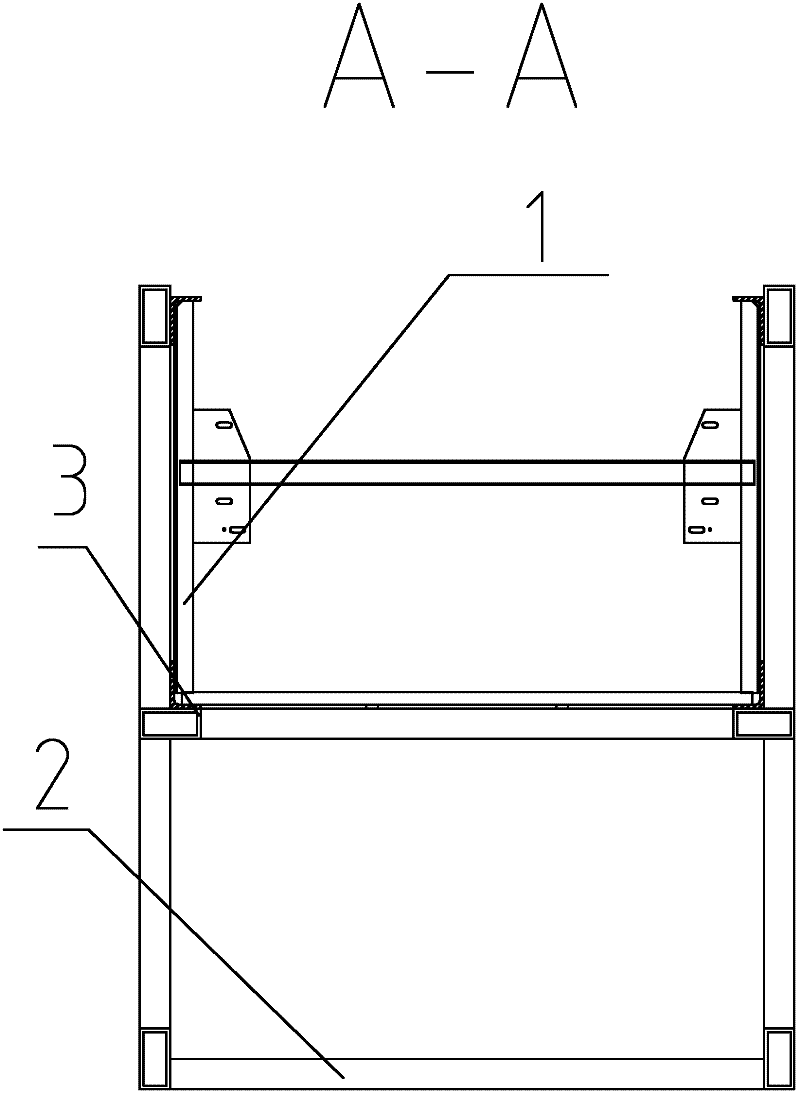

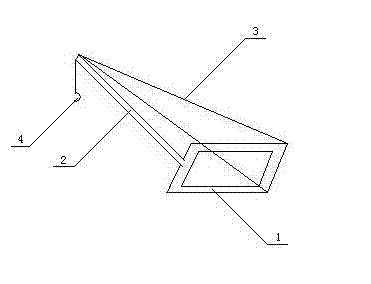

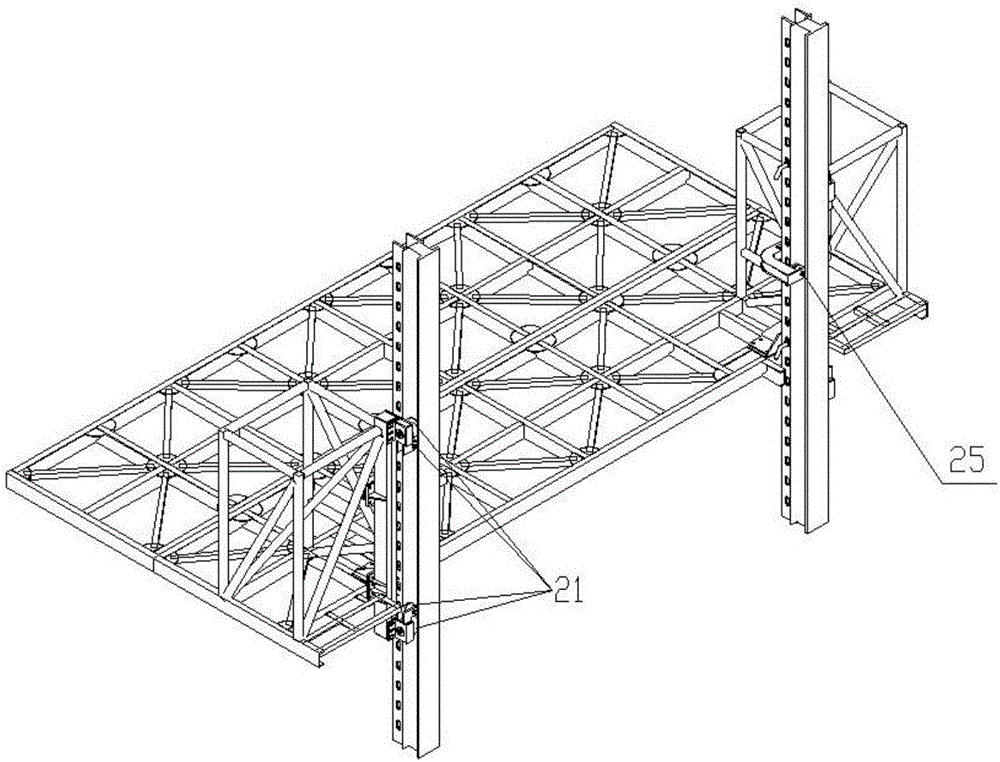

Metal framework structure for escalator

InactiveCN102398840AHigh strengthLarge lifting heightEscalatorsMetal frameworkStructural engineering

The invention discloses a metal framework structure for an escalator. A second metal framework is embedded outside a first metal framework, so a double-truss metal framework structure is realized; the double-truss metal framework structure has the advantages of high intensity and large lifting height and is applicable to a large-span escalator; a middle support is not required; the span can reach about 30 meters; by the double-truss metal framework structure, the requirement on civil engineering is reduced; and the structure has higher usability.

Owner:三六零安全科技股份有限公司

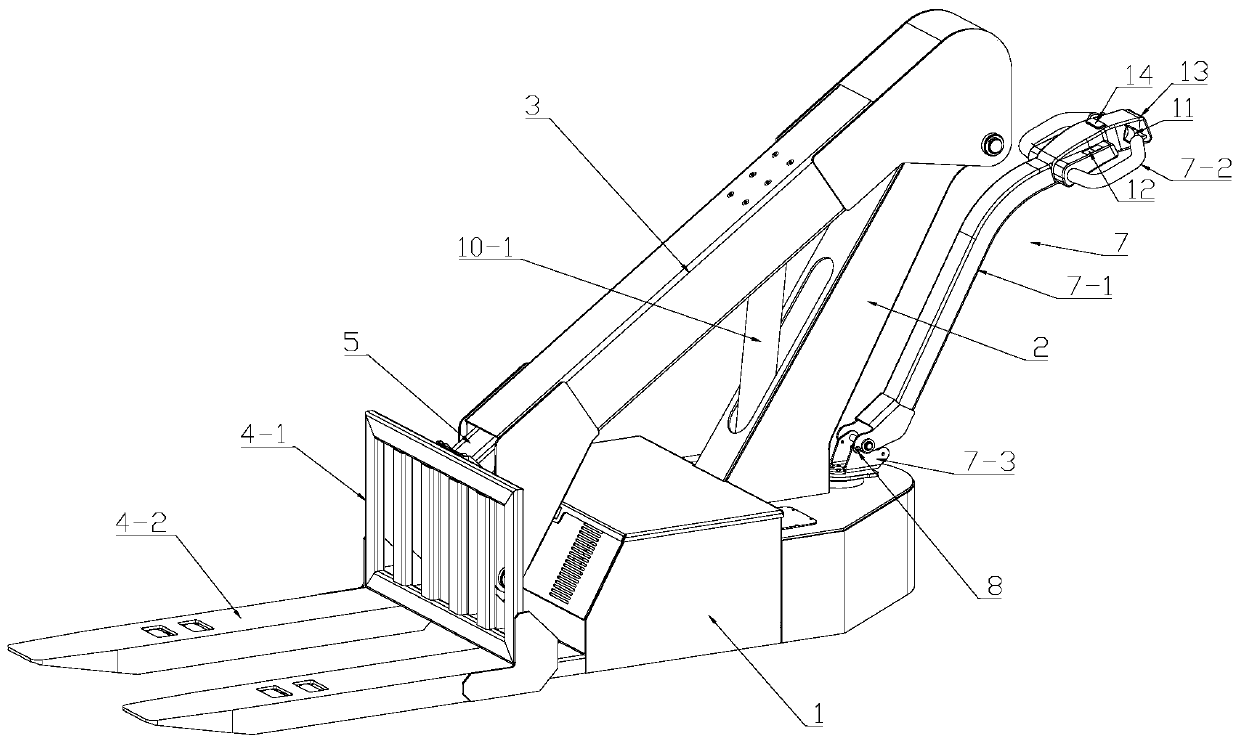

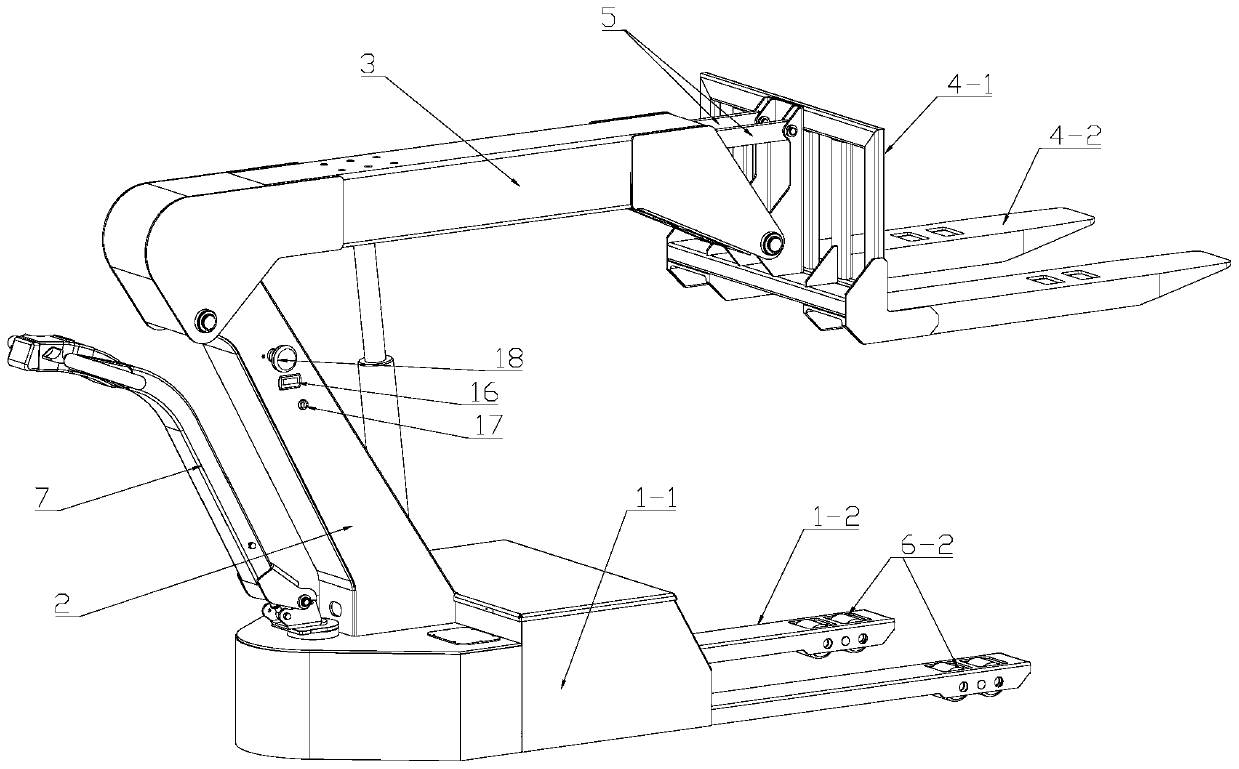

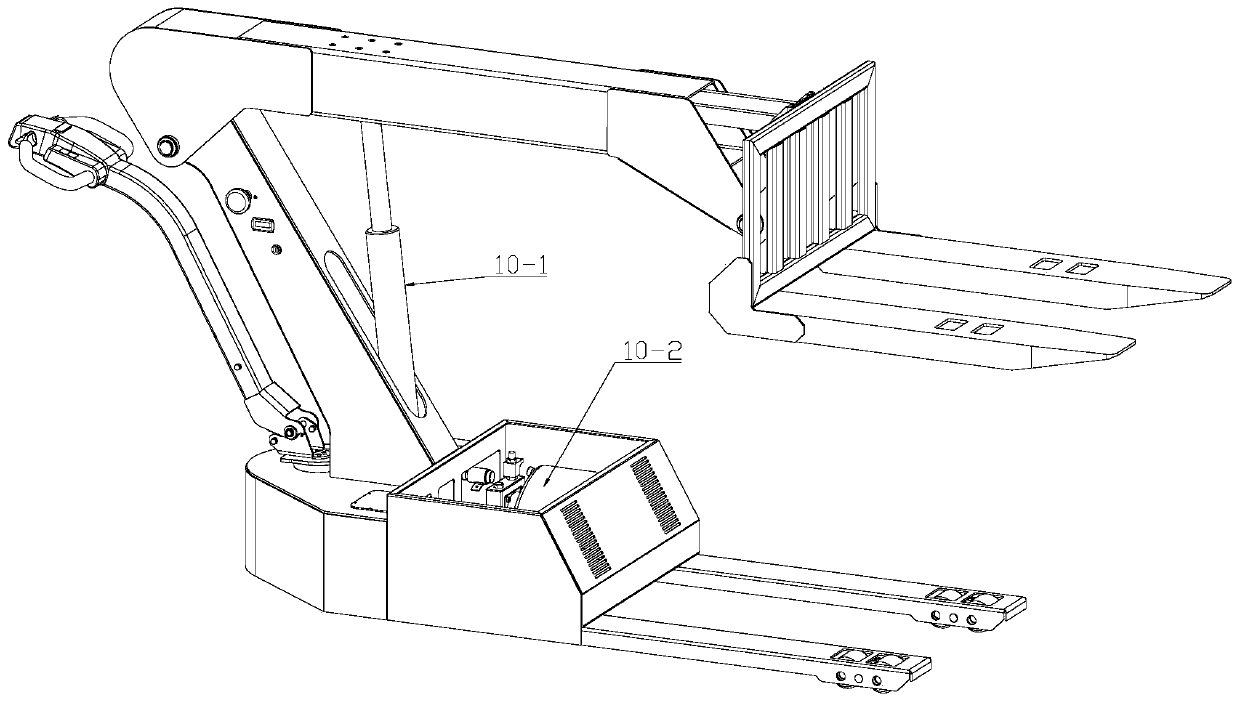

Walking type forklift

The invention relates to a walking type forklift. The forklift comprises a waking chassis device, a lifting device and an operating device. The lifting device comprises a supporting arm, a lifting arm, a fork device and a lifting driving device, the lower end of the supporting arm is fixed to a walking chassis, the upper end of the supporting arm is hinged to the rear end of the lifting arm, the lifting arm extends in the direction in front of the forklift, the lifting driving device drives the lifting arm to rotate around the hinge point to ascend or descend, the front end of the lifting armis provided with the fork device, the walking chassis is of an n structure and comprises an equipment bin on the rear portion and two cross leg frames on the front portion, the two cross leg frames are arranged on the left side and the right side, the rear ends of the cross leg frames are connected with the front end of the equipment bin, and the descending fork device is placed on the two cross leg frames. The forklift has the beneficial effects that the forklift body is low and is suitable for cargo carrying in narrow low spaces such as cargo cabinets and containers, mounting is convenient,the fork lifting height is large, the appearance is simple and novel, operation is easy and convenient, and comfort and safety are achieved.

Owner:江苏盛誉动力科技有限公司

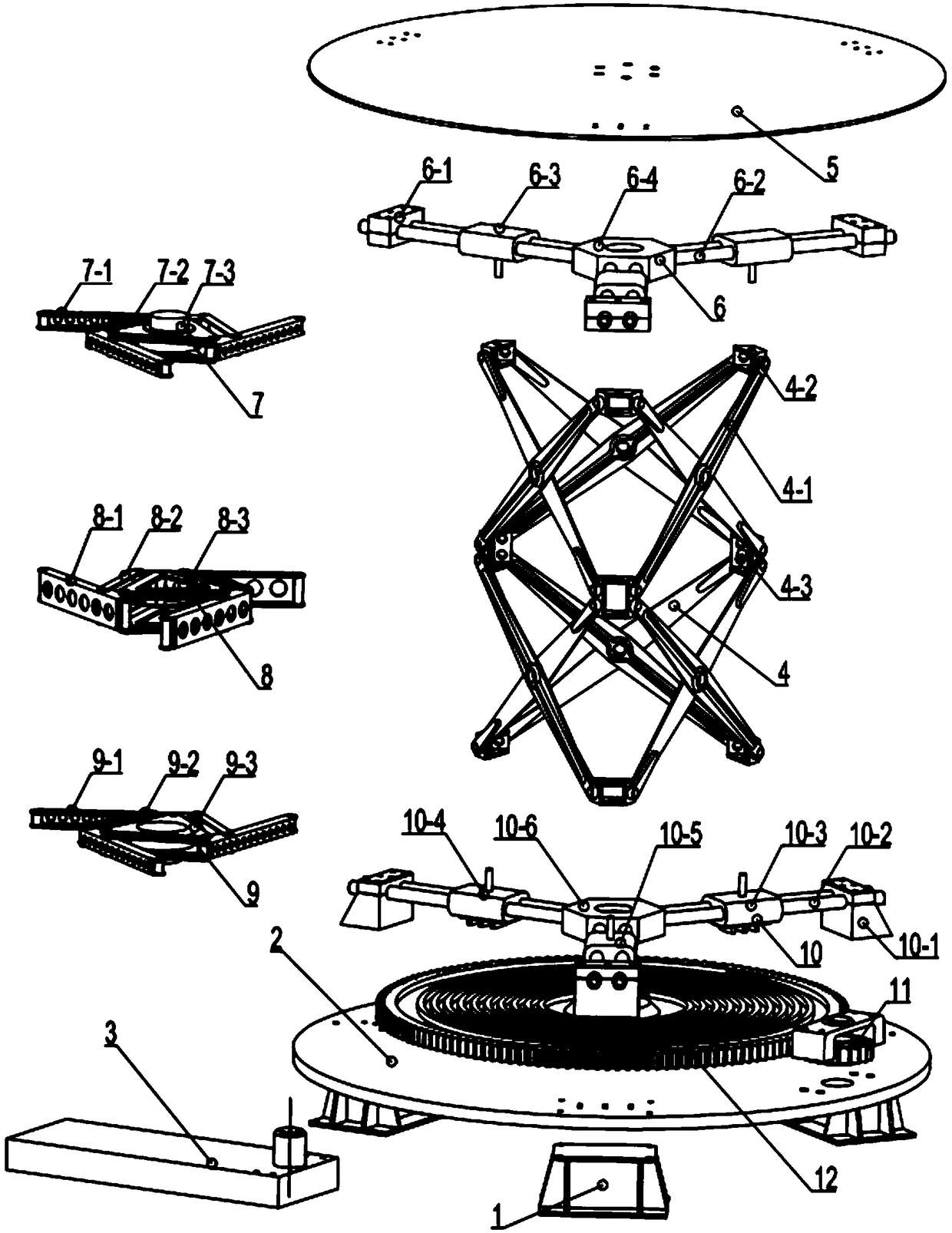

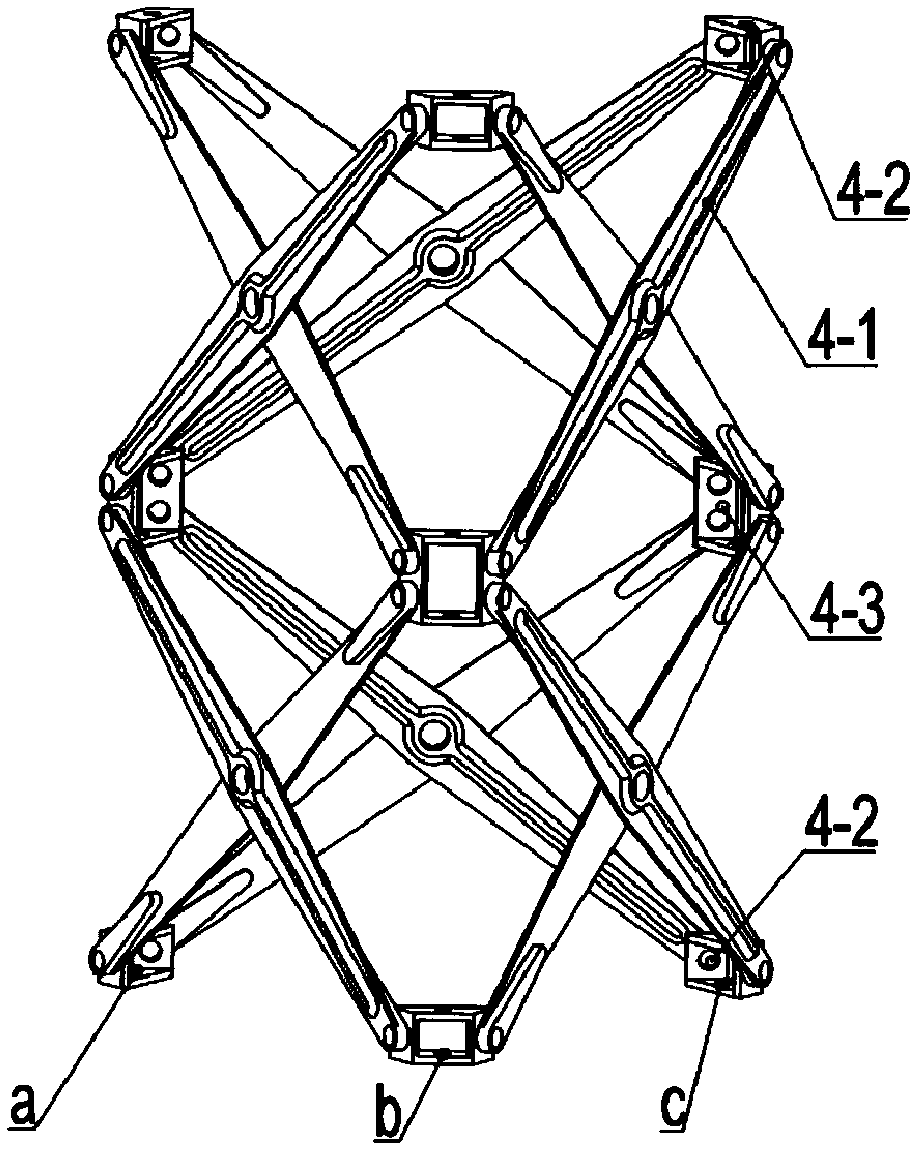

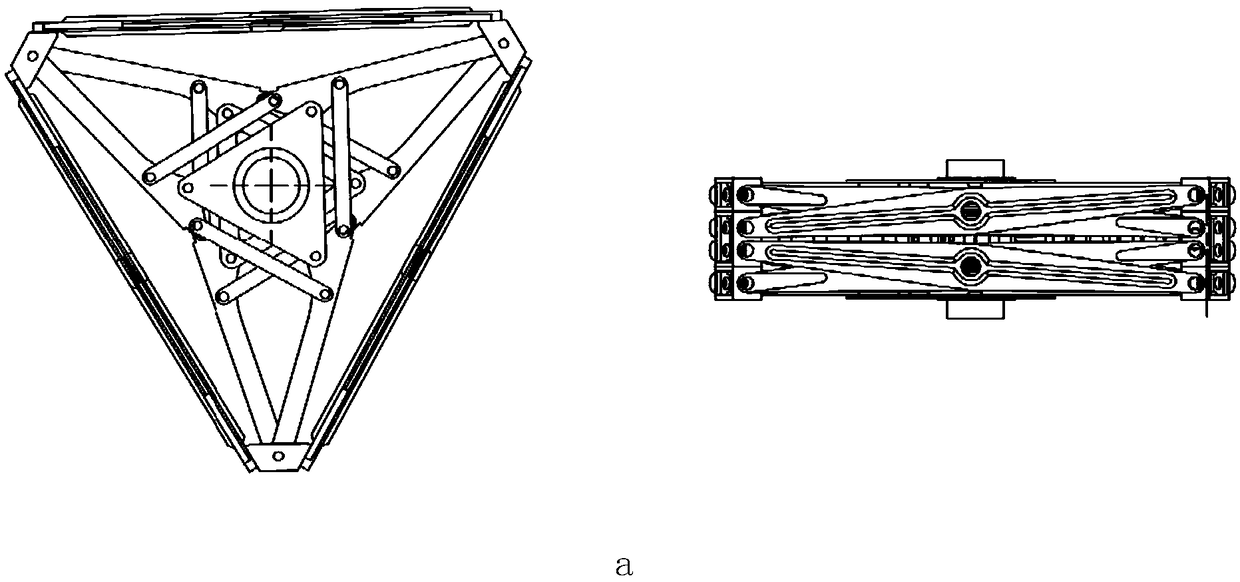

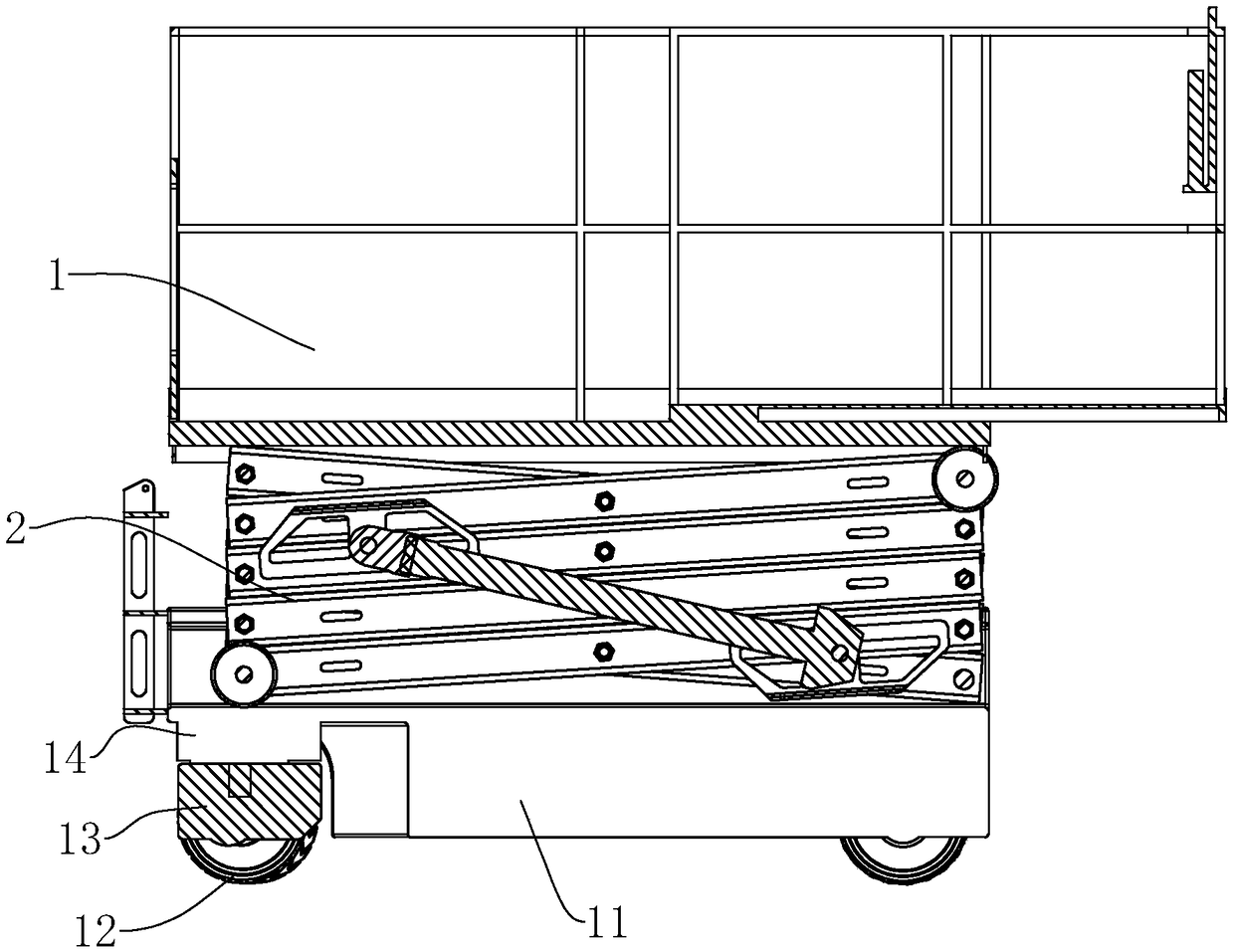

Shearing fork lifting assembly and shearing fork lifting system

The invention relates to a shearing fork lifting assembly and a shearing fork lifting system, and belongs to the field of lifting platforms. The shearing fork lifting assembly comprises three sets ofshearing fork structures, and each set of shearing fork structure comprises two shearing fork ribs arranged in a crossed manner, wherein the two shearing fork ribs are rotatably connected at the intersection position; and the three sets of shearing fork structures define a circle, the upper ends of the shearing fork ribs of every two adjacent shearing fork structures are rotatably connected to form three first connecting points, the lower ends of the shearing fork ribs of every two adjacent shearing fork structures are rotationally connected to form three second connection points, the three planes where the three sets of shearing fork structures are located form a triangular prism structure, the first connection points are used for being connected with a support platform assembly, and thesecond connection points are used for being connected with a lifting base. The shearing fork lifting assembly and the shearing fork lifting system guarantee stability of the support platform, are suitable for lifting and handling of large heavy-duty cargoes, and are suitable for high-precision controllable lifting of light cargoes.

Owner:航天时代(青岛)海洋装备科技发展有限公司

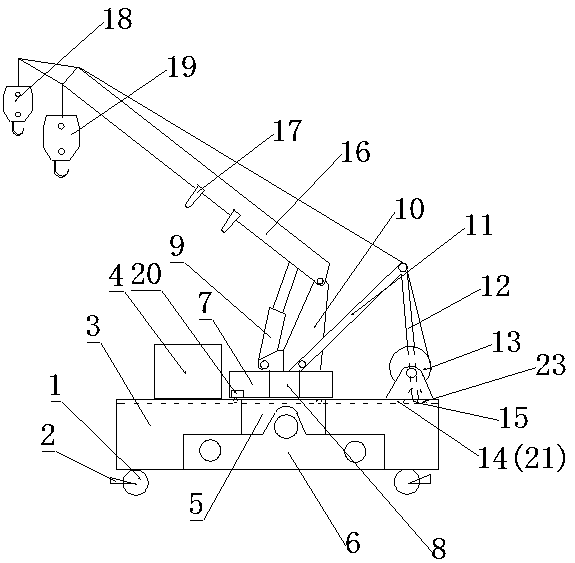

Ship crane for navigation height limit area

The invention relates to a ship crane for a navigation height limit area. The ship crane comprises a revolution driving platform, a bearer is arranged under the revolution driving platform, crossbeamsare arranged at the left side and the right side of the bearer, a revolution driving platform slide way and a rear strut slide way are arranged above the beaer and the crossbeams, the revolution driving platform is arranged on the revolution driving platform slide way, a rear strut is arranged on the rear strut slide way, a hinge seat is arranged at the side part of the rear strut slide way, therear strut is fixed on the hinge seat through a nut, rollers are arranged under the revolution driving platform and the rear strut, a boom and a boom cylinder are arranged above the revolution drivingplatform, a lifting arm is hinged to the top of the boom, the cylinder body of the boom cylinder is hinged to the bottom of the boom, the end part of the piston rod of the boom cylinder is hinged tothe lifting arm, a front strut is hinged to the side part of the boom, and a hoist is arranged at the side part of the rear strut. The ship crane has the advantages of simplified structure, high reliability, excellent performances, and suitableness for the navigation height limit area.

Owner:德马科起重机械有限公司

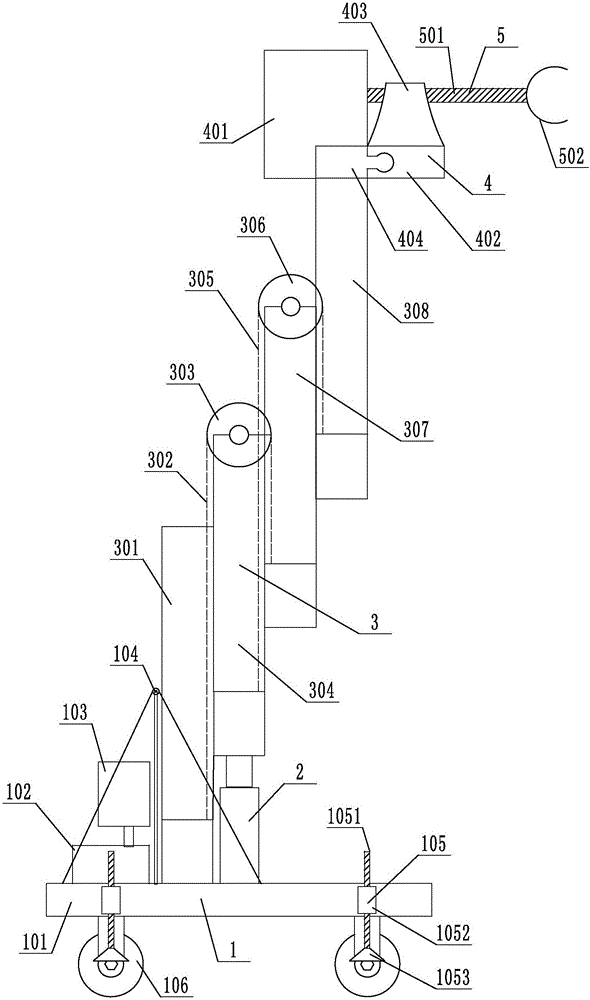

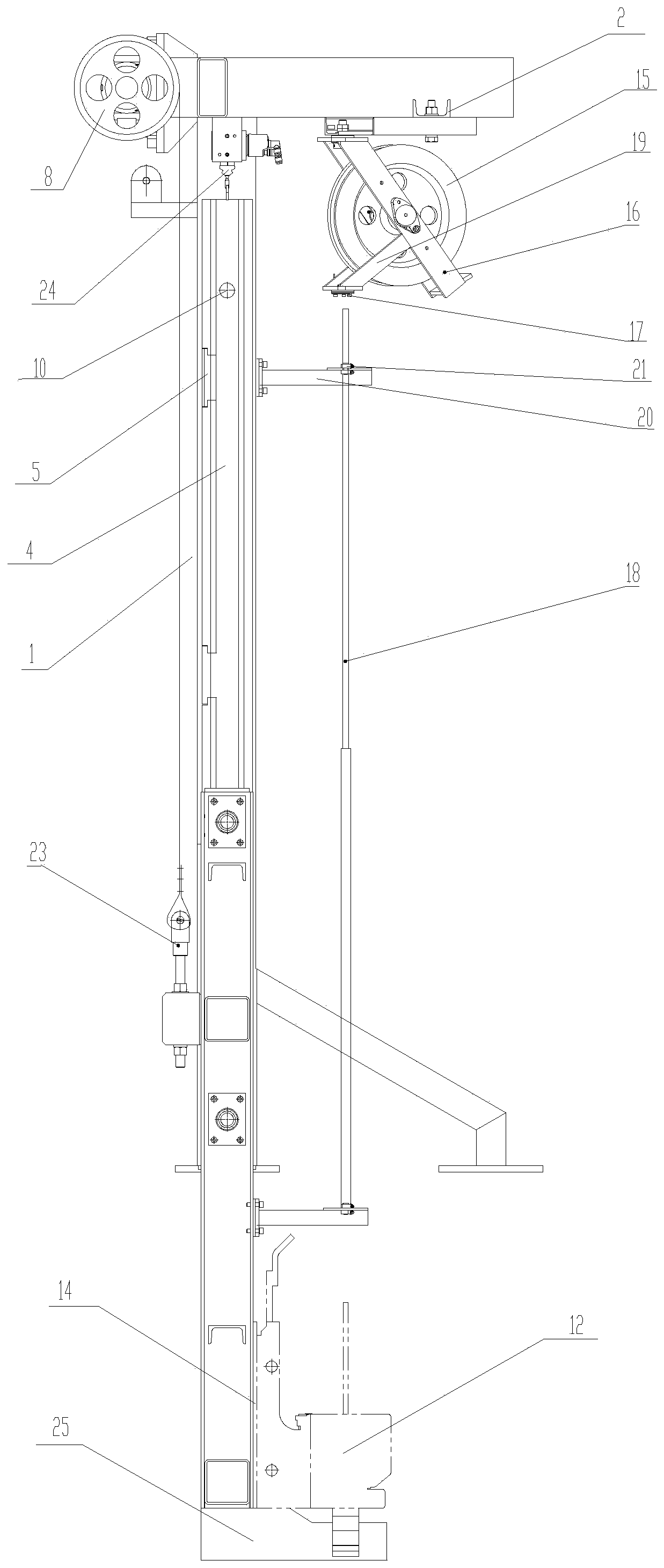

Lifting support for X-ray flaw detection machine

ActiveCN106645233AReduce the number of movesIncrease the number ofMaterial analysis by transmitting radiationX-rayEngineering

The invention discloses a lifting support for an X-ray flaw detection machine, and relates to the field of industrial X-ray flaw detection. The lifting support comprises a base, a driving piece, a lifting assembly, a sliding assembly and a rotating assembly. The driving piece and the lifting assembly are arranged on the base, the lifting assembly is connected to the driving piece, a working hopper is arranged on the lifting assembly, the sliding assembly is arranged on the working hopper, the rotating assembly is connected to the sliding assembly, and the X-ray flaw detection machine is arranged at the tail end of the rotating assembly. The lifting support can replace a scaffold, working procedures are saved, and the working requirements of X-ray flaw detection are simplified; application is flexible, an X-ray machine can move in a transverse-U shape, the space occupied rate is small, the number of moving times is small, and the working efficiency is high; the larger lifting height can be obtained when manufacturing is carried out with different materials or the number of masts is increased.

Owner:SHANDONG MECHANICAL ENG TESTING CO LTD

Boom element, telescopic boom and construction vehicle

Owner:LIEBHERR WERK EHINGEN

High-pressure homogenizer

InactiveCN108993289AEasy to adjust fixationEasy to adjust mobilityTransportation and packagingMixer accessoriesEngineeringHigh pressure

The invention discloses a high-pressure homogenizer which comprises a high-pressure homogenizer body, wherein a base is arranged at the bottom of the high-pressure homogenizer body; the base is of a cavity structure of which the bottom is opened; a fixing tank matched with the high-pressure homogenizer body is arranged at the top of the base; a cushion plate is arranged inside the base and at thebottom of the high-pressure homogenizer body; a buffer spring is arranged between the top of the cushion plate and the base; a lifting mechanism is arranged at the bottom of the cushion plate; the lifting mechanism comprises bottom plates which are positioned in symmetry; at the bottom of the cushion plate the bottom plates are of W-shaped structures; limiting blocks I are symmetrically arranged on both sides of the bottom plates; guide wheels I are arranged in the middles of one sides of the bottom plates; the axis centers of the guide wheels I are connected with rotating motor output shaftsinside the bottom plates; guide wheels II and guide wheels III are respectively arranged on both sides of the bottom ends of the bottom plate. The high-pressure homogenizer has the beneficial effectsthat the cooperation relationship of the high-pressure homogenizer body and the base can be conveniently adjusted, the high-pressure homogenizer body can be conveniently fixedly placed and moved, in addition, the height position of an ultrahigh-pressure homogenizer body can be conveniently adjusted, and the high-pressure homogenizer is simple in structure and convenient to use.

Owner:贵州泛亚实业(集团)有限公司

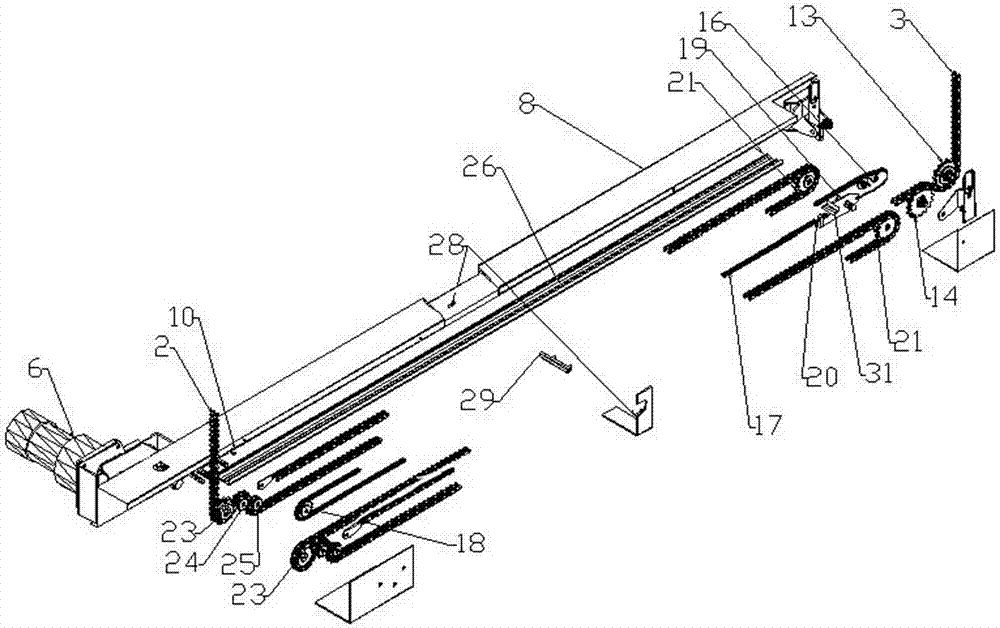

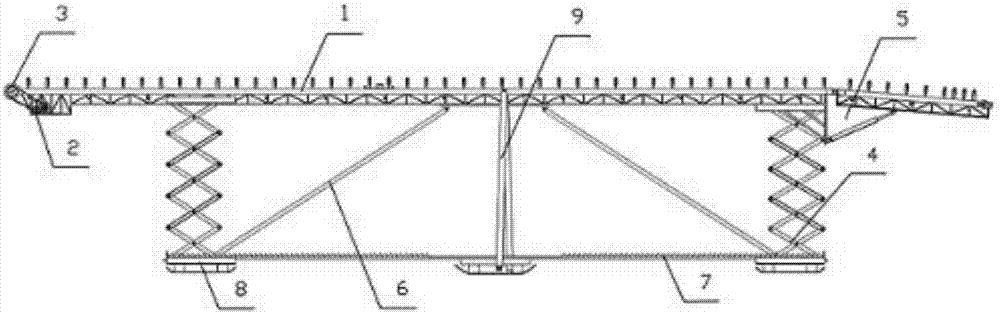

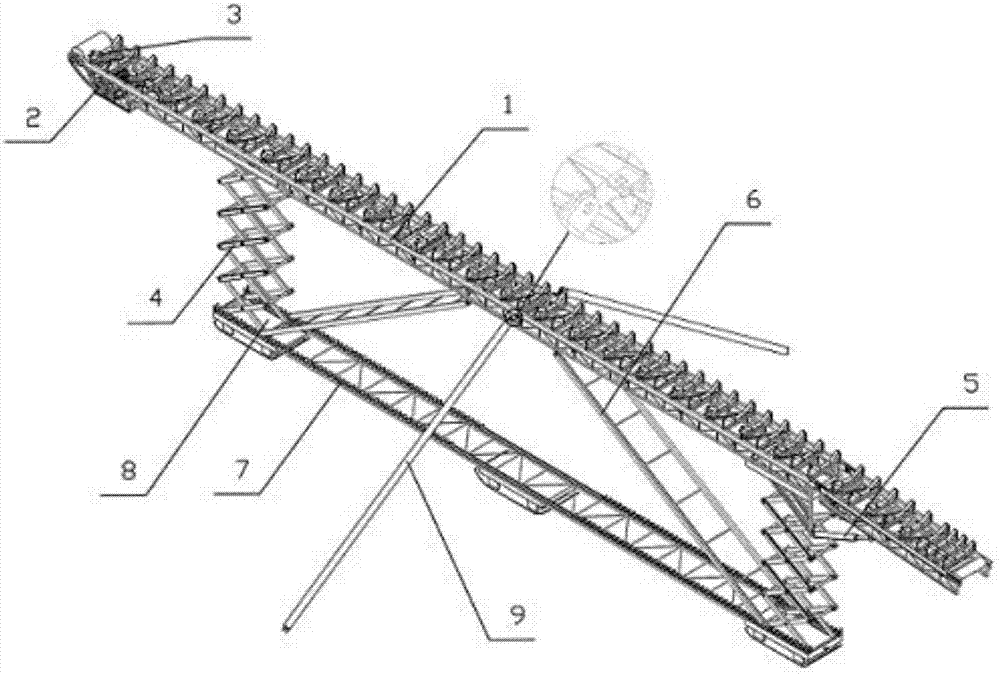

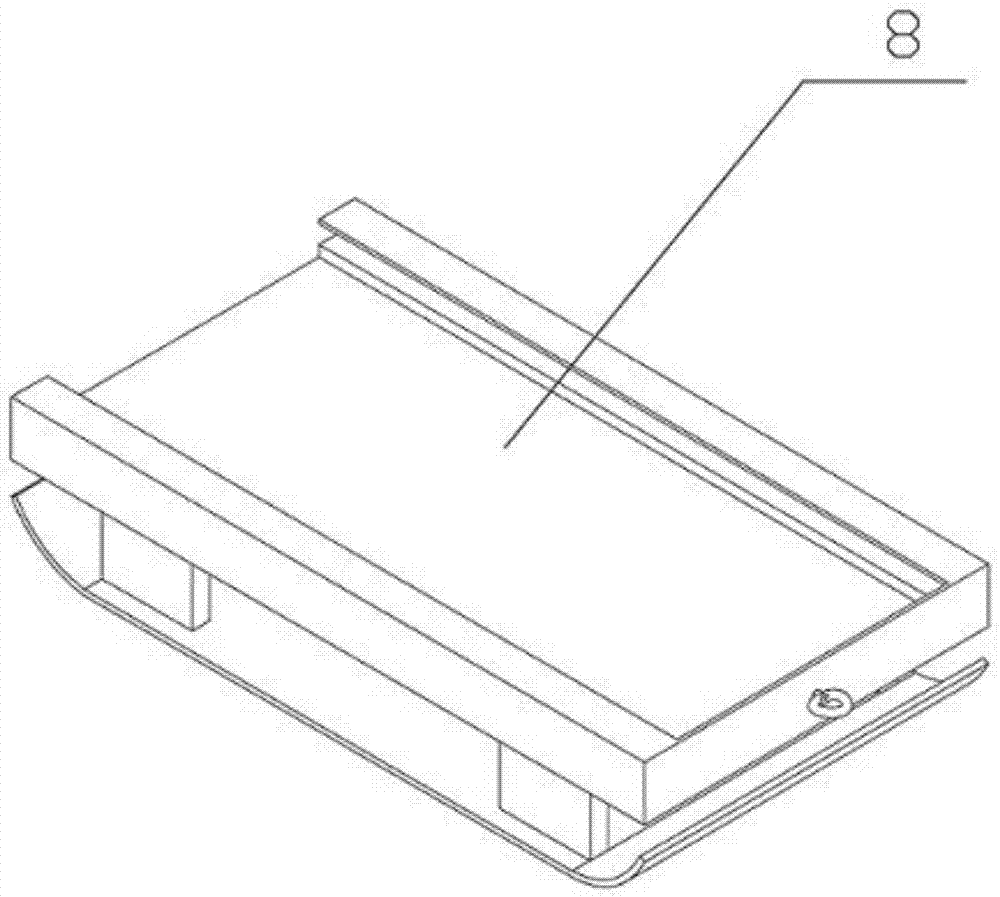

Ultralong multifunctional movable conveyer

An ultralong multifunctional movable conveyer comprises a conveying cantilever crane, a power system, a driving roller, lifting mechanisms, an amplitude varying mechanism, supporting rods, a groove strip, slide plates, a stabilizing rod and rolling wheels. The conveying cantilever crane is formed through hinge of two sections of cantilever crane bodies with different lengths. The lifting mechanisms are driven by adopting a hydraulic oil cylinder, a shear-fork mechanism is mounted below a main beam of the conveying cantilever crane, and the slide plates are mounted below the lifting mechanisms.The amplitude varying mechanism is arranged at the position where the two sections of cantilever crane bodies are hinged to each other. The supporting rods are symmetrically arranged in the left andright, one ends of the supporting rods are hinged to the middle section of the cantilever crane, the rolling wheels are mounted at the other ends of the supporting rods and roll along an inner grooveof the groove strip, and a rolling wheel shaft is matched with a side edge groove of the groove strip. One end of the stabilizing rod is hinged to a main beam on the side face in the middle of the conveying cantilever crane, and the other end of the stabilizing rod can move freely. The ultralong multifunctional movable conveyer has the characteristics that the conveying distance is long, the lifting structure is simple, the amplitude of variation is large, the lifting height is high, the angle of a conveying cantilever is adjustable, the ground adaptability is high, and the using cost is low.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Forklift heightening type hoisting device

Owner:南通恒隆化工有限公司

Novel forklift

The invention discloses a novel forklift. The novel forklift comprises a car body, the car body comprises front wheels, rear wheels and a control chamber, the control chamber is internally provided with a seat and a workbench, and the car body is internally provided with a garbage can and a water tank. A supporting frame a and a supporting frame b is arranged in front of the car body, the supporting frame a and the supporting frame b are fixedly welded to the car body, a connecting frame is fixedly connected to the top end between the supporting frame a and the supporting frame b, a bearing plate is arranged at the bottom end between the supporting frame a and the supporting frame b, a base is arranged at the bottom of one side of the bearing plate, and the base is connected with a bearingplate. A supporting platform is arranged above the base, the base is connected with the supporting platform through a lifting assembly, a driving device is arranged in the base, the driving device isconnected with the lifting assembly, and a pallet fork is fixedly connected to the upper part of the supporting platform. The novel forklift can fork and load cargos directly and then lift the cargosto perform high altitude operations, the conditions of the cargos can be observed in real time, meanwhile, a workshop or the floor can be further cleaned, and the work efficiency of the forklift is improved.

Owner:高金飞

Goods lifting equipment for construction machinery

InactiveCN113086877AEasy to installSmooth and accurate liftingPortable liftingVehicle frameEngineering

The invention relates to a lifting machine, in particular to goods lifting equipment for construction machinery. The goods lifting equipment can be conveniently mounted and can be accurately butted with pipelines. The goods lifting equipment comprises a moving mechanism, wheels, a rotating frame, sliding plates, vehicle body fixing frames and the like. The number of the wheels is four, the two sides of a vehicle frame are rotationally connected with the four wheels, the rotating frame is arranged on the upper side of the vehicle frame, the number of the sliding plates is two, the two sliding plates are arranged on the upper side of the rotating frame, the number of the vehicle body fixing frames is two, and the two vehicle body fixing frames are fixedly connected to the upper sides of the two sliding plates respectively. Lifting is more stable and accurate, pipeline installation is more stable, accurate positioning can be achieved, and therefore the installation efficiency is improved; and the two-section movement of a first translation mechanism and a second translation mechanism enables the translation distance to be longer, and the folding length can be shortened during storage.

Owner:XINXIANG VOCATIONAL & TECHN COLLEGE

High-altitude lifter and lifting method

InactiveCN108640030AHigh lifting heightReduce shakingLifting framesBalloon aircraftsWind forceEngineering

The invention discloses a high-altitude lifter and a lifting method. According to the technical scheme, the high-altitude lifter is characterized by comprising a traveling mechanism, a shear type connecting rod structure installed on the traveling mechanism, and an object carrying platform installed on the shear type connecting rod structure. The high-altitude lifter is characterized in that telescoping rods are installed on the four side faces of the object carrying platform correspondingly, the ends of the telescoping rods are fixed to the object carrying platform, the other ends of the telescoping rods are free ends and are used for ground supporting, and a hot air balloon device is arranged above the object carrying platform. The aerostatic buoyancy method and the wind power and assistance power manner can be adopted, the gravity of the object carrying platform is reduced, mutual balance between the gravity and the assistance power is achieved, then the periphery telescoping rods are utilized to serve as auxiliary supports to stabilize motion of four directions, and waggling is reduced.

Owner:浙江中升建设有限公司

Hydraulic lifting working platform and platform lifting method

ActiveCN106495053AHigh lifting heightMeet lifting height requirementsLifting framesControl engineeringLifting equipment

The invention discloses a hydraulic lifting working platform and a platform lifting method and relates to the technical field of lifting equipment. The hydraulic lifting platform comprises a bracket, a platform and a hydraulic system, wherein the bracket includes at least one guide rail, a plurality of connecting holes are formed in the bracket in the length direction of the guide rail, the platform includes a plurality of guide wheels which are all abutted with the guide rail, the hydraulic system is arranged on the platform, one end of an actuating element of the hydraulic system is connected with the platform, at the same time, the two ends of the actuating element of the hydraulic system are detachably connected with different connecting holes, and the actuating element of the hydraulic system drives the platform to ascend and descend along the guide rail. The invention further discloses the platform lifting method. The hydraulic system is arranged on the platform and drives the platform to ascend and descend along the guide rail, therefore, the lifting height of the platform is greatly increased, and a relatively high lifting height requirement is met. The lifting stability of the platform is ensured, chains are not required, and the safety and reliability of the whole hydraulic lifting platform are improved.

Owner:HEAVY EQUIP ENG CO LTD OF WUCHANG SHIPBUILDING IND

Spray gun lifting mechanism for casting pipe

PendingCN111530676AHigh adsorption rateEconomicalLiquid spraying apparatusPressure inorganic powder coatingElectric machineryRoller bearing

The invention provides a spray gun lifting mechanism for a casting pipe. The spray gun lifting mechanism comprises a fixing device, a driving mechanism, a mobile device and a wire guiding system. Thefixing device comprises a door-type frame, transverse channel steel and a motor speed reducer fixing seat. The door-type frame is formed by three pieces of transverse rectangular hollow steel and twopieces of longitudinal rectangular hollow steel. The driving mechanism comprises a speed reducer, a variable frequency motor, a driving shaft, a steel wire rope wheel and a steel wire rope. The movingdevice comprises a moving frame, a spraying gun and a composite roller bearing. The moving frame is formed by moving channel steel and a square pipe. The composite roller bearing is fixed to the moving channel steel. The wire guiding system comprises a wire guiding system, a wire guiding wheel bracket, an insulating sleeve and a wire guiding pipe. The spray gun is arranged over casting pipes of each specification and is perpendicular to the surfaces of the casting pipes of each specification. The adsorption rate of zinc spraying can be beneficially improved. Automatic lifting adjusting of spray gun positions required by the casting pipes of different specifications can be realized. The automation degree is high. The adjusting speed is high. Production time is saved.

Owner:XINXING HEBEI ENG & RES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com