Hydraulic jack

A technology of hydraulic jacks and hydraulic cylinders, applied in the field of hydraulic jacks, can solve the problems of limited lifting height, low stability of the jack, laborious use, etc., and achieve the effects of increased lifting height, difficult to lift off, and large area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

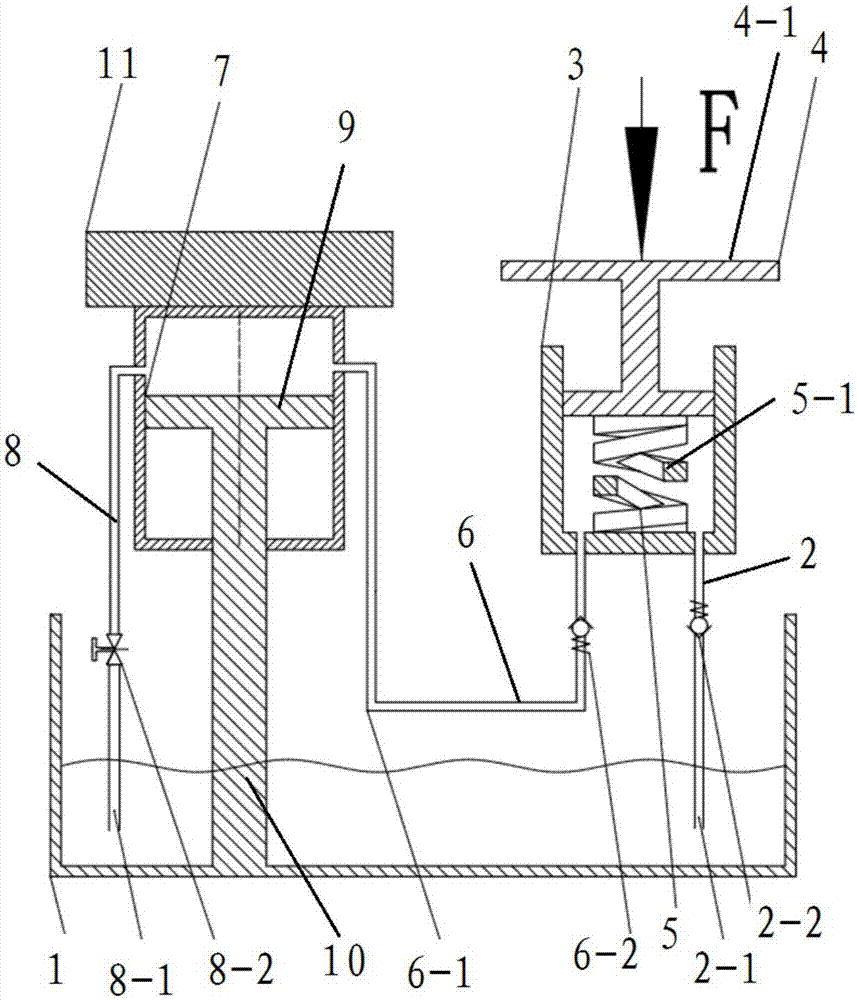

[0017] see figure 1 , a hydraulic jack provided by an embodiment of the present invention includes: a fuel tank 1, a first conveying device 2, an auxiliary hydraulic cylinder 3, a pressing device 4, a restoring device 5, a second conveying device 6, a main hydraulic cylinder 7, a third conveying Device 8, piston rod 10 and piston 9.

[0018] The first end of the first conveying device 2 communicates with the oil tank 1 , and the second end communicates with the rodless cavity of the auxiliary hydraulic cylinder 3 .

[0019] The pressing device 4 is movably arranged in the auxiliary hydraulic cylinder 3 .

[0020] The return device 5 is arranged in the auxiliary hydraulic cylinder 3 , and the return device 5 is arranged between the pressing device 4 and the first end of the auxiliary hydraulic cylinder 3 .

[0021] The first end of the second conveying device 6 communicates with the rodless chamber of the auxiliary hydraulic cylinder 3 , and the second end communicates with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com