Shearing fork lifting assembly and shearing fork lifting system

A technology of lifting components and lifting systems, applied in the direction of lifting devices, etc., can solve the problems of unfavorable support platform stability, support center offset, and lower stability, and achieve continuous smooth driving process, ensure stability, and ensure isotropy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

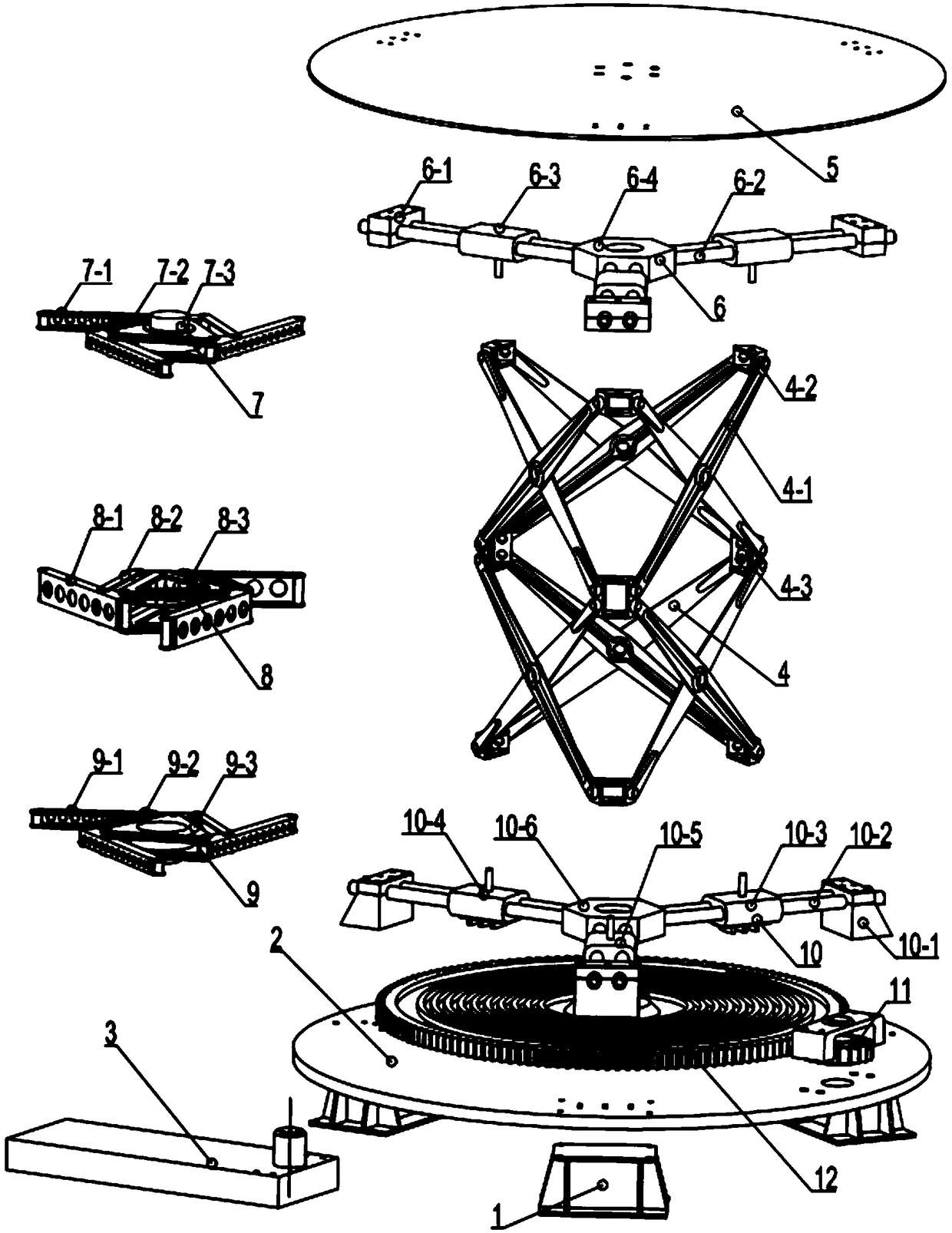

[0047] see figure 1 , the embodiment of the present invention provides a spiral three-dimensional scissors lifting platform, including a base leg 1, a lifting base 2, a drive motor 3, a scissor mechanism 4, an upper platform 5, a second sliding guide assembly 6, and an upper platform synchronization bracket 7. Central synchronous bracket 8, base synchronous bracket 9, first sliding guide assembly 10, driving gear 11, helical gear plate 12.

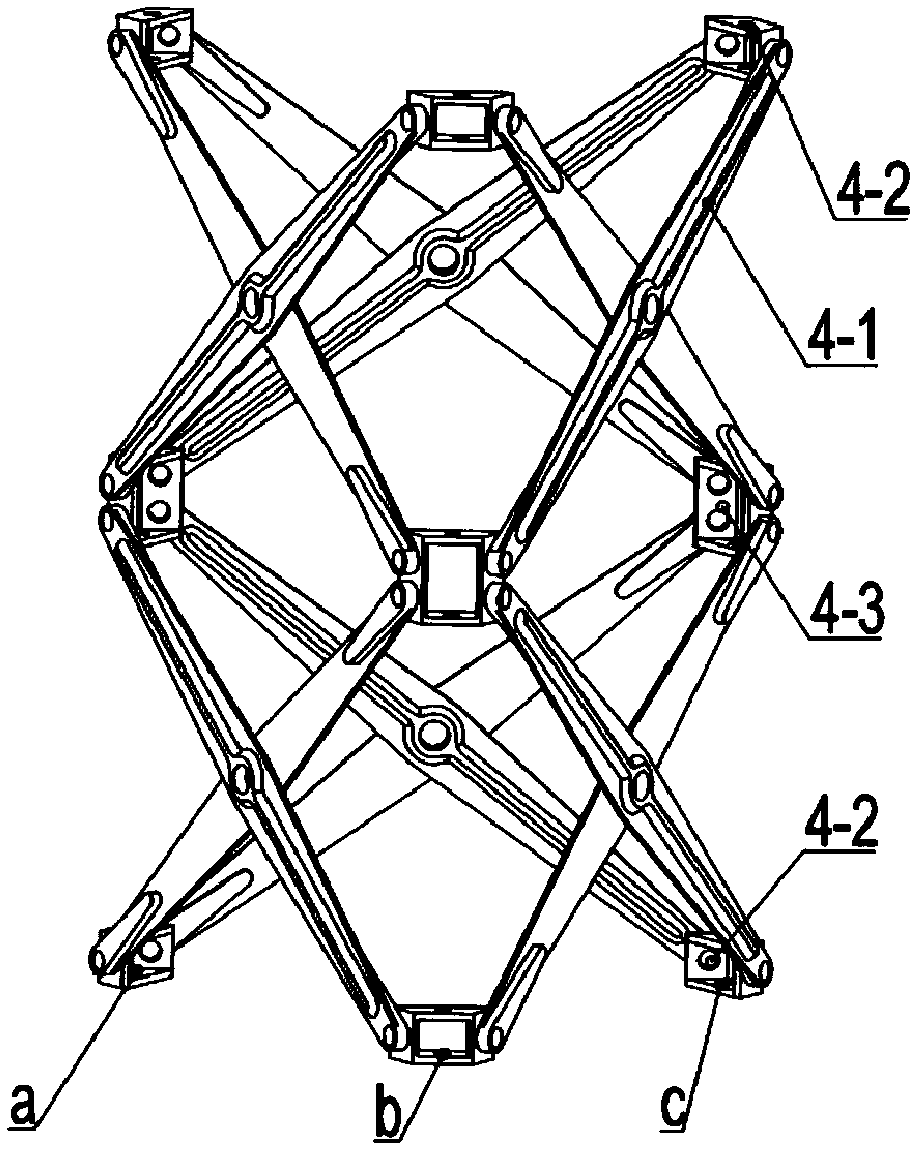

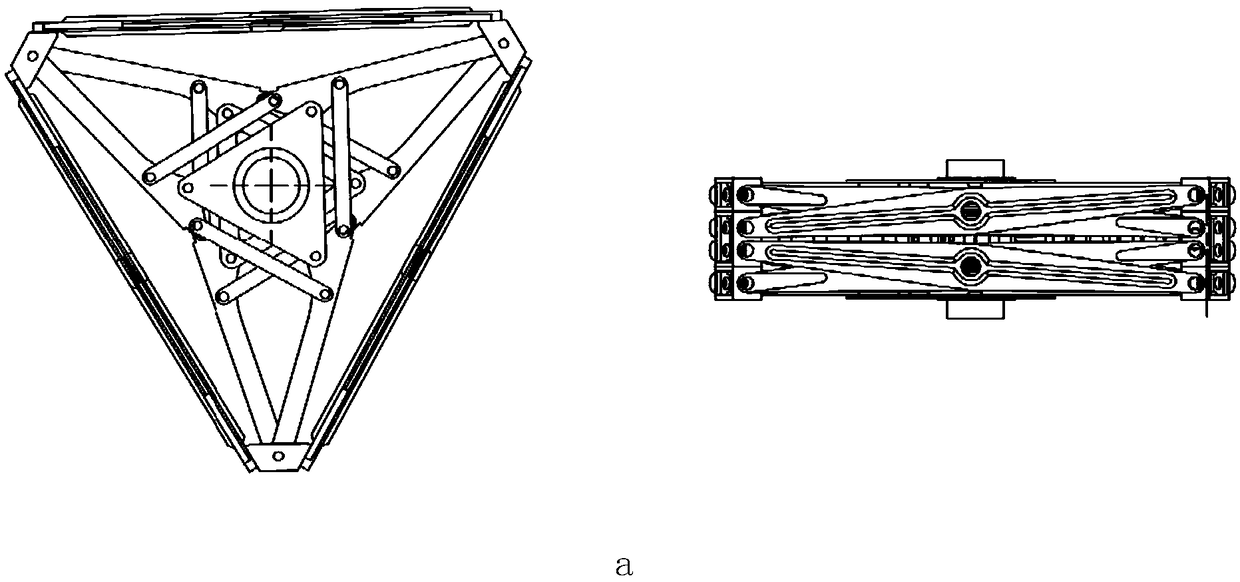

[0048] The scissor mechanism 4 is composed of multi-layer scissor lifting components, each layer of scissor lifting components is composed of 6 pieces of scissor ribs 4-1, and the scissor ribs 4-1 are in groups of two, and the ends of the scissor ribs are respectively used The rotating shaft is connected with the single-layer fin transfer corner fitting 4-2 and the double-layer fin transfer corner fitting 4-3, which can rotate freely around the shaft and form an equilateral triangle. Between each group of scissor fins 4-1 The middle part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com