High-altitude lifter and lifting method

A technology for elevators and walking mechanisms, which is applied to elevators, lifting devices, balloon vehicles, etc., can solve problems such as decreased stability, reduced operator work efficiency, and inability to meet the requirements at the same time, so as to improve lifting height, improve safety performance, reduce shaking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

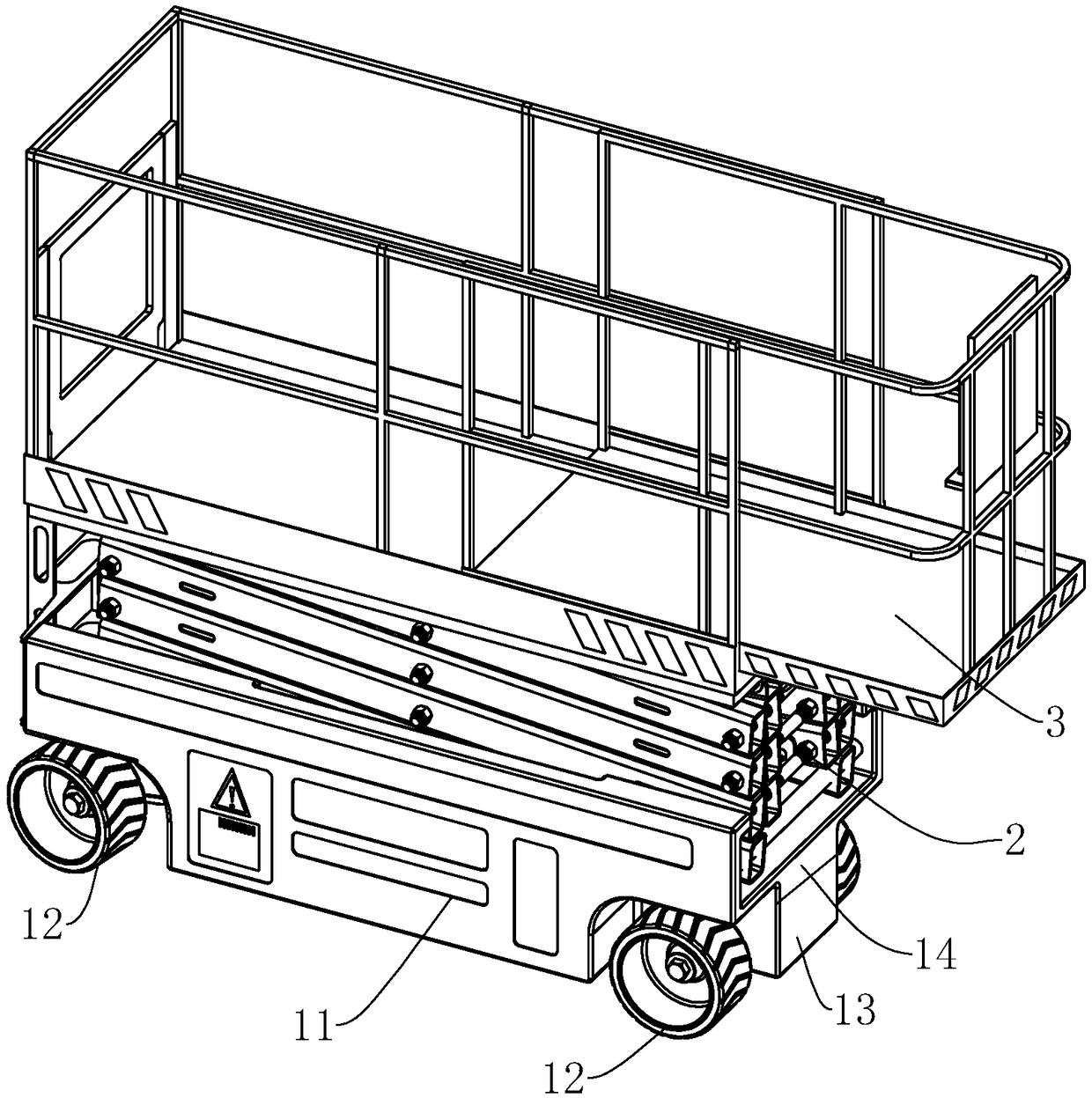

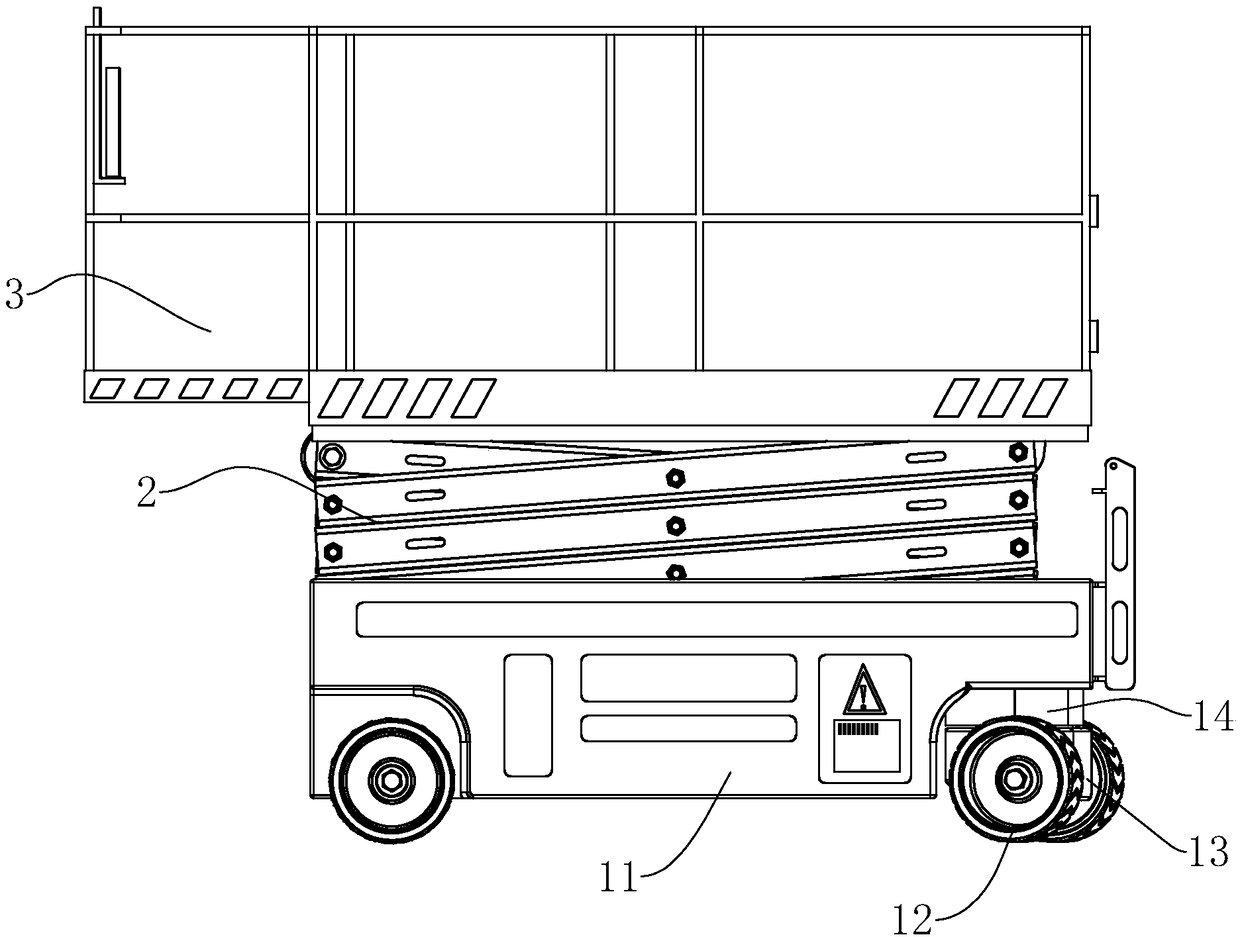

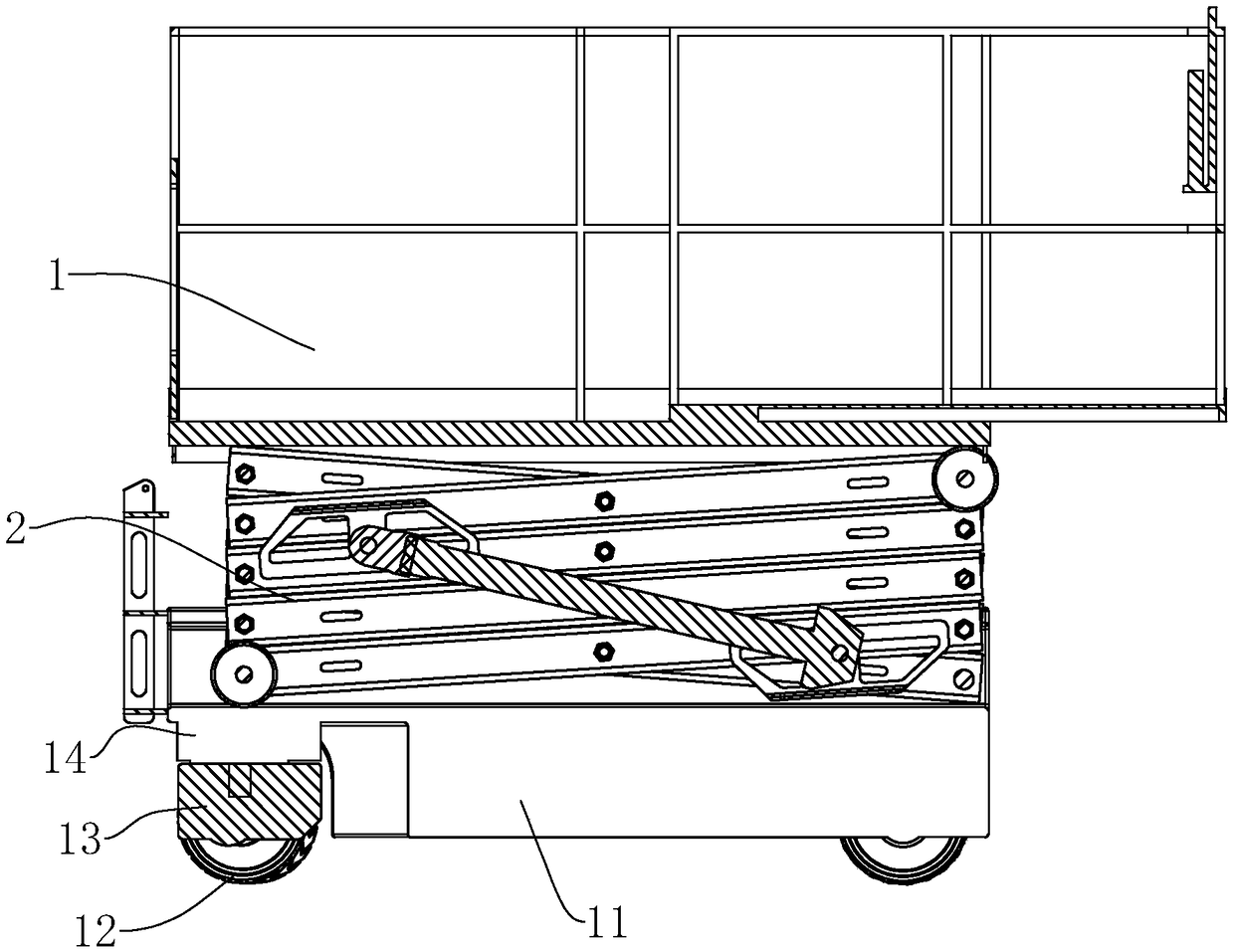

[0035] A kind of aerial lift, refer to figure 1 As shown, it includes a traveling mechanism 1 , a scissor link structure 2 installed on the traveling mechanism 1 , and a loading platform 3 installed on the scissor link structure 2 .

[0036] combine figure 1 , figure 2 and image 3 As shown, the traveling mechanism 1 includes a base 11, four rollers 12 installed on the base 11, each pair of rollers 12 front and rear, the two rollers 12 are connected by a rotating shaft, the rotating shaft is connected with a shaft seat 13, and the shaft seat 13 is rotatably connected to the base 11, a first oil cylinder 14 for changing the distance between the shaft seat 13 and the base 11 is arranged between the shaft seat 13 and the base 11. Wherein, in the initial state of the first oil cylinder 14 , the bottom surface of the base 11 is lower than the lower level where the four rollers 12 are located. The roller 12 is for a wheel or a universal wheel, and the first oil cylinder 14 can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com