Spray gun lifting mechanism for casting pipe

A technology of lifting mechanism and spray gun, which is applied in the direction of spraying device, liquid spraying device, pressure inorganic powder coating, etc. It can solve problems such as safety accidents, affecting production efficiency, interrupting production, etc., and achieves large maintenance space, saving production time, and high efficiency. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

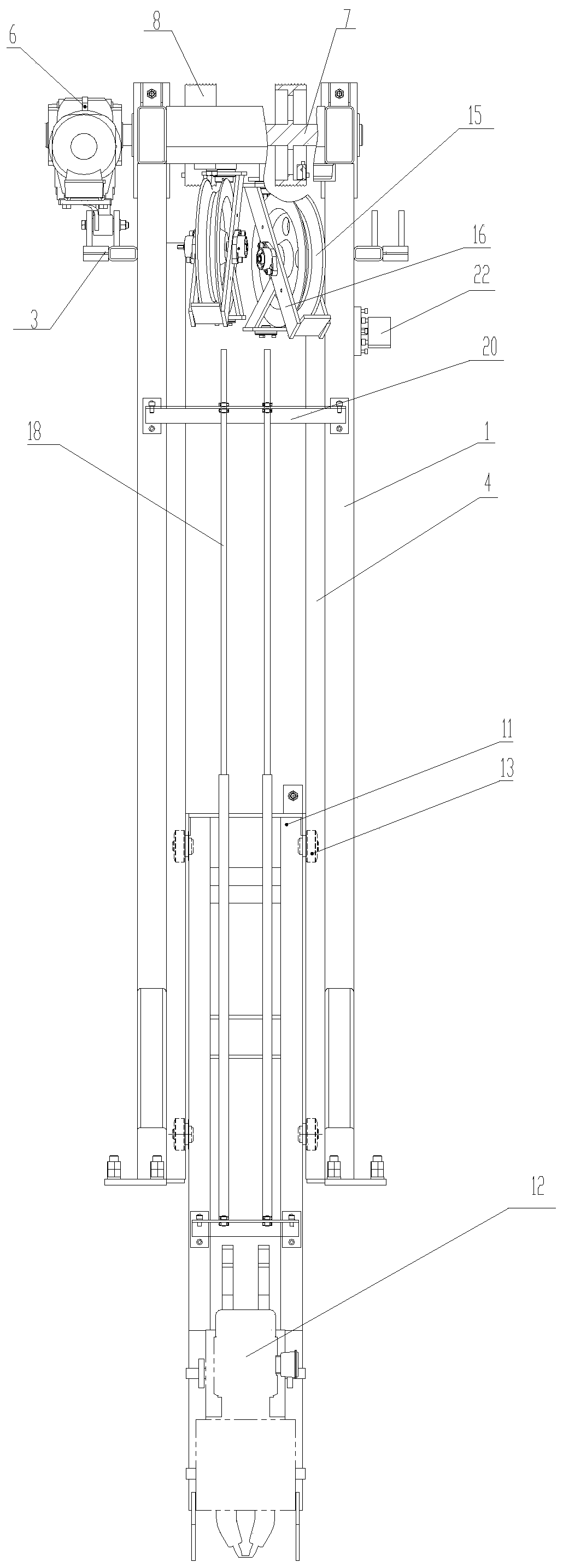

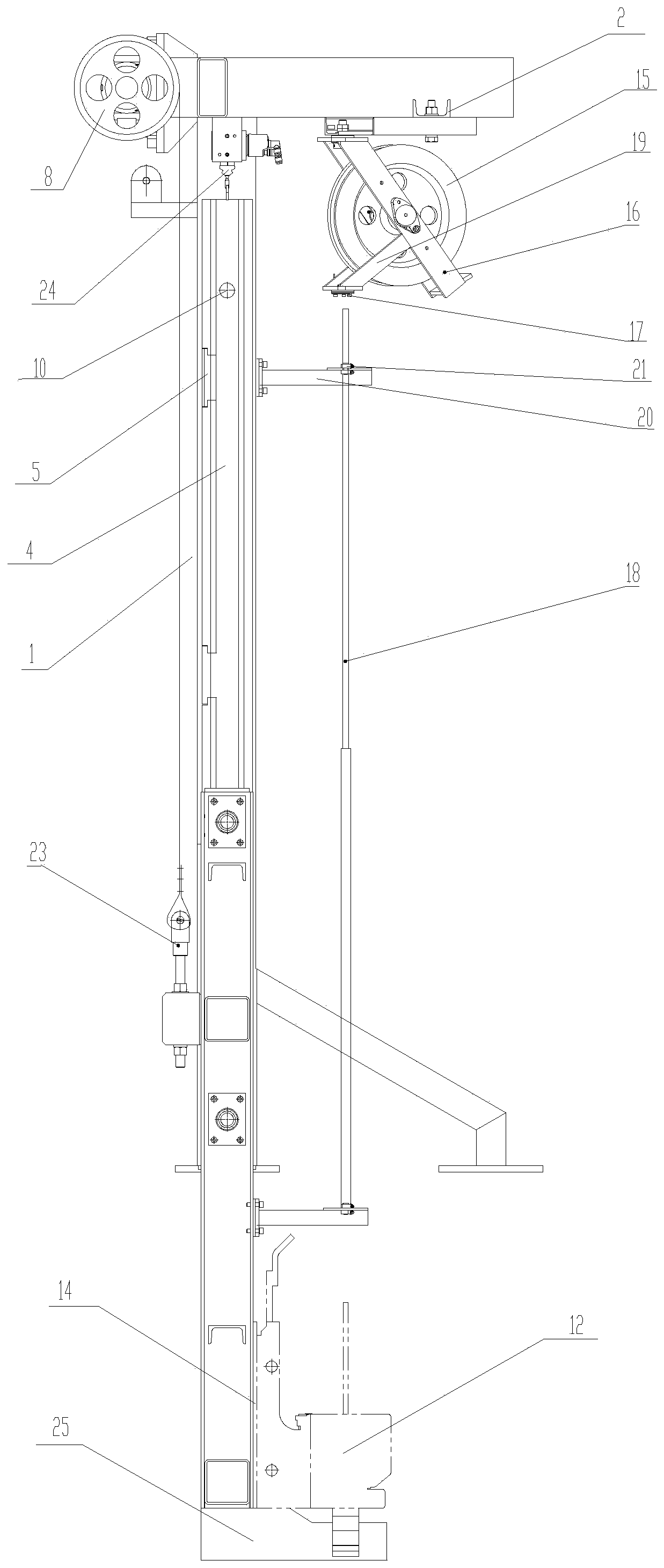

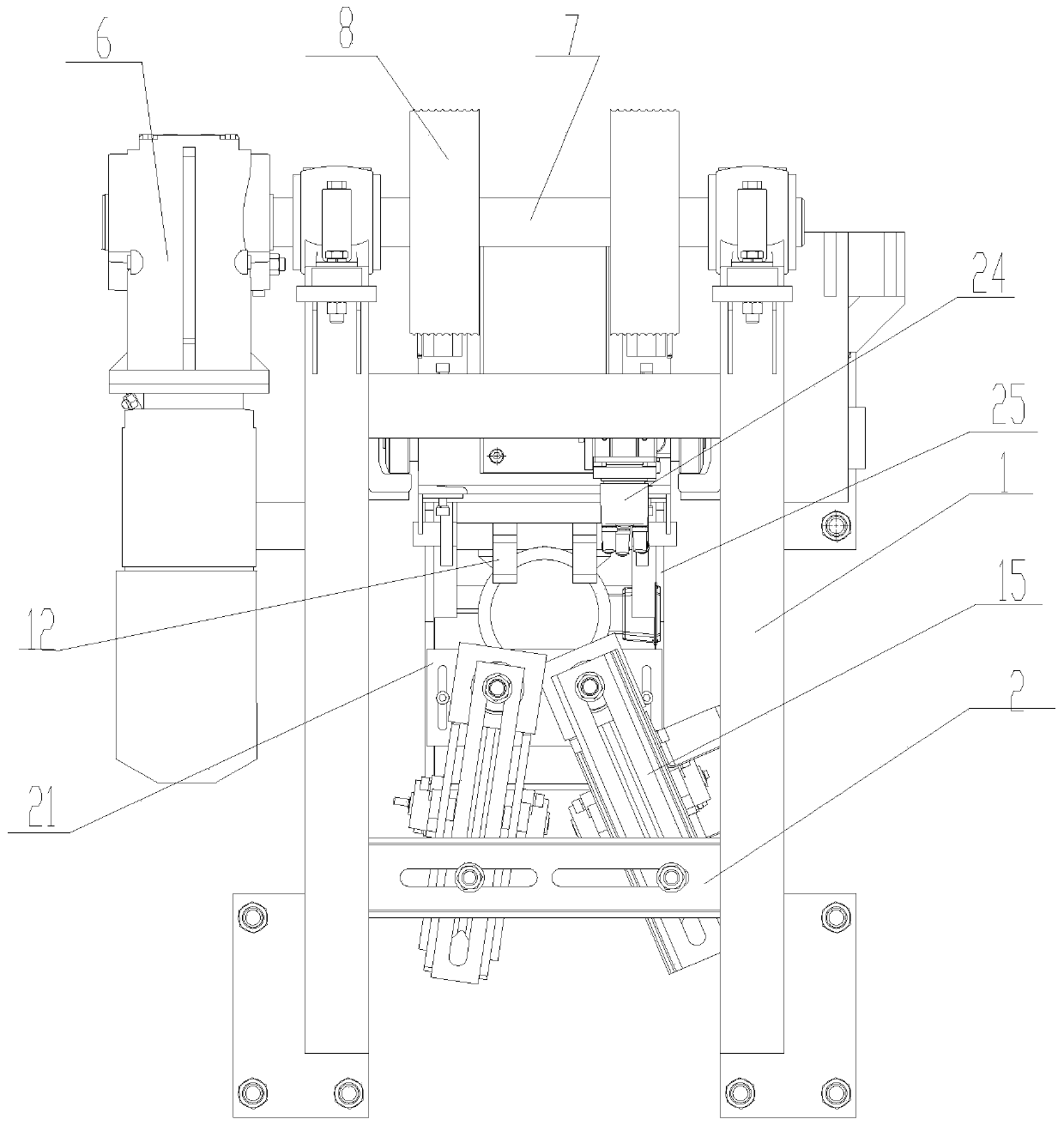

[0020] Such as Figure 1-3 As shown, a spray gun lifting mechanism for cast pipe is characterized in that it includes a fixing device, a driving mechanism, a moving device and a guide wire system; the fixing device includes three horizontal rectangular hollow steels and two longitudinal rectangular hollow steels The portal frame 1, the transverse channel steel 2 and the motor reducer fixing seat 3; the two ends of the transverse channel steel 2 are respectively fixed on the transverse rectangular hollow section steel, and the inner sides of the two longitudinal rectangular hollow section steel 1 are fixed with C-shaped guide rail 4, the motor reducer fixing seat 3 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com