Patents

Literature

1291 results about "Pallet fork" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The pallet fork is a component of the lever escapement of a mechanical watch. The pallet fork and the lever form one component that sits between the escape wheel and the balance wheel. Its purpose is to lock the escape wheel, and release it one tooth at a time at each swing of the balance wheel, and also give the balance wheel small pushes to keep it going.

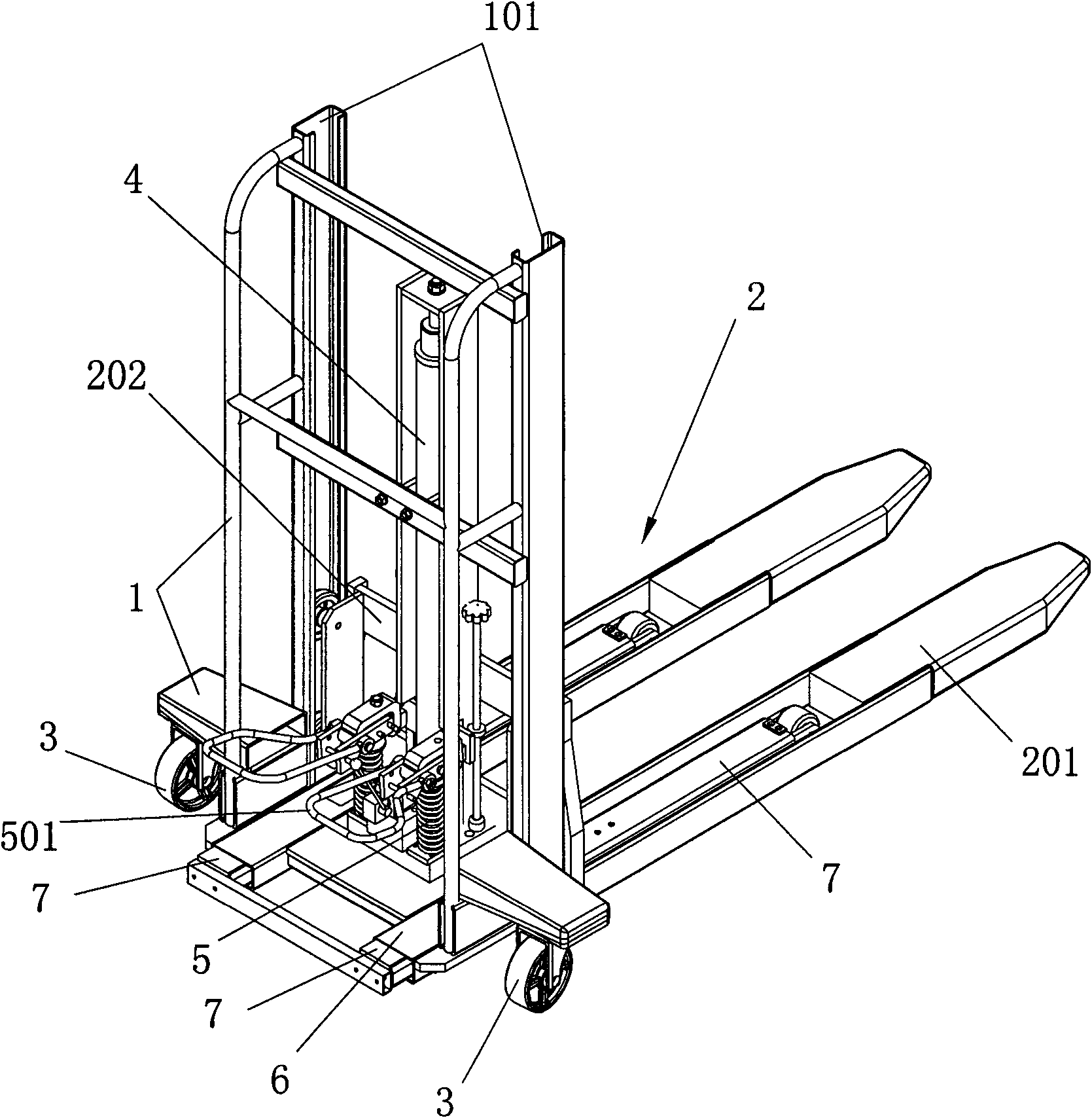

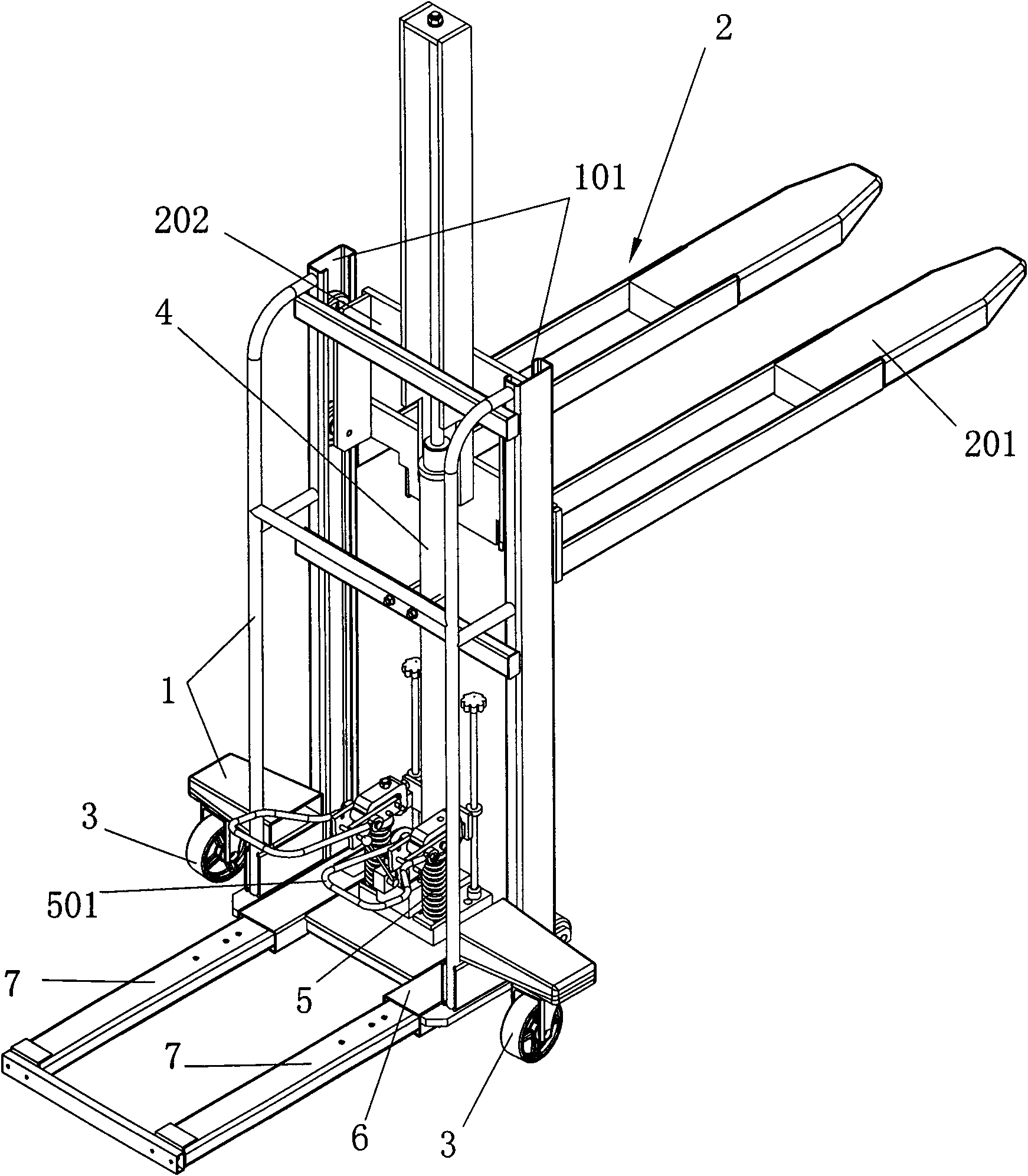

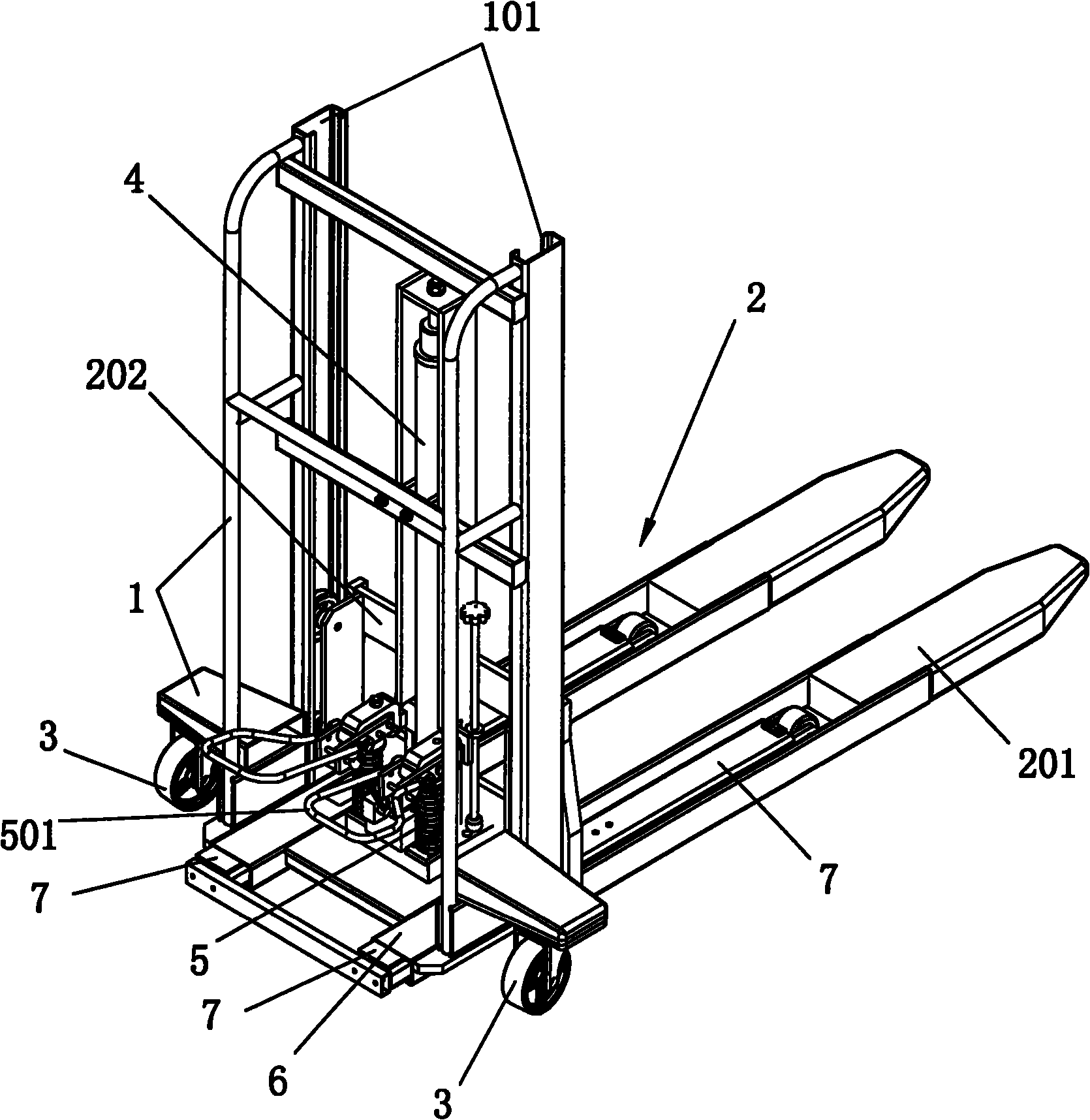

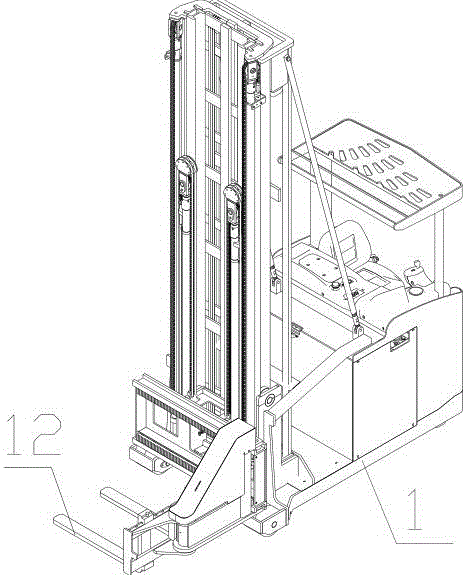

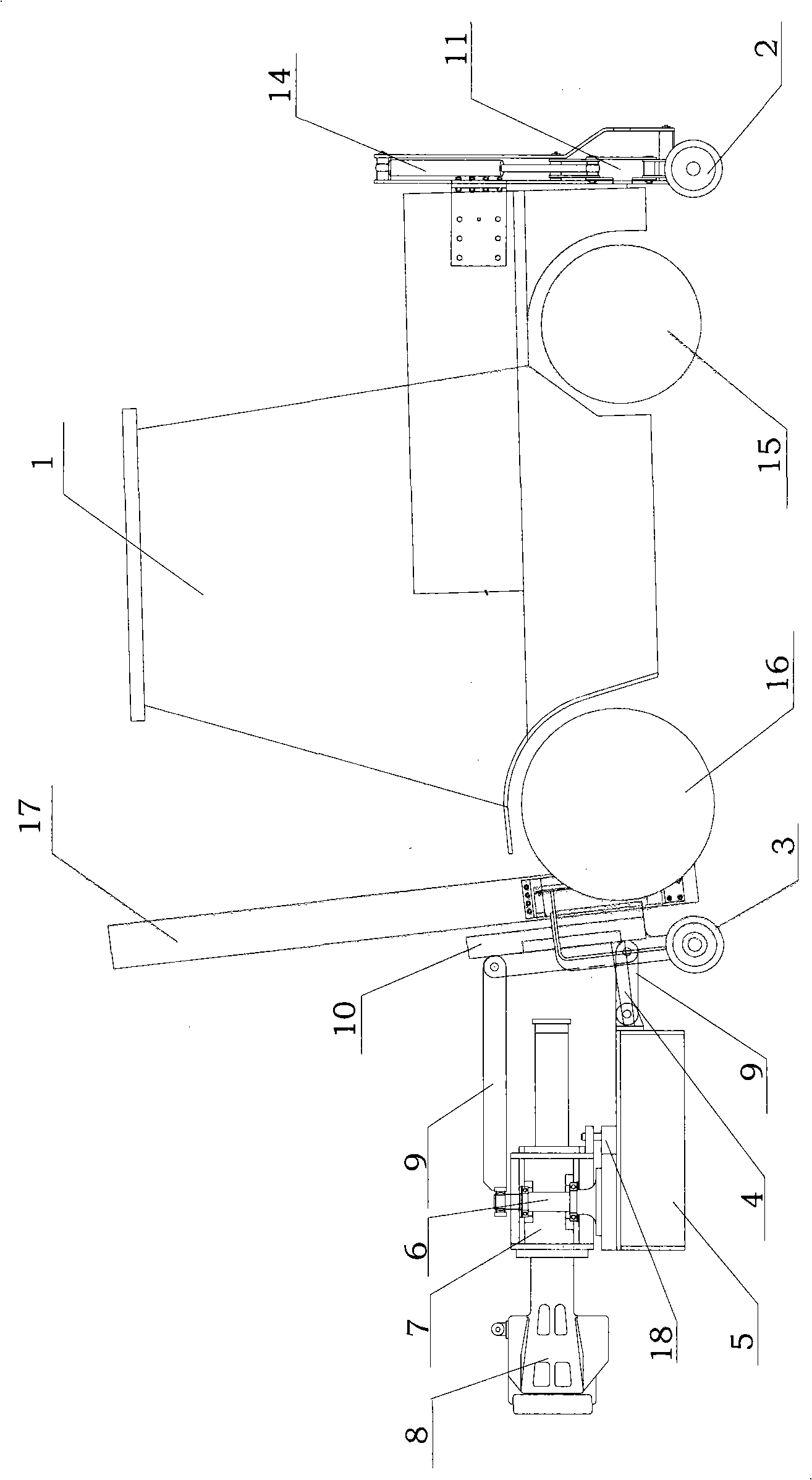

Manual self-elevating pallet truck

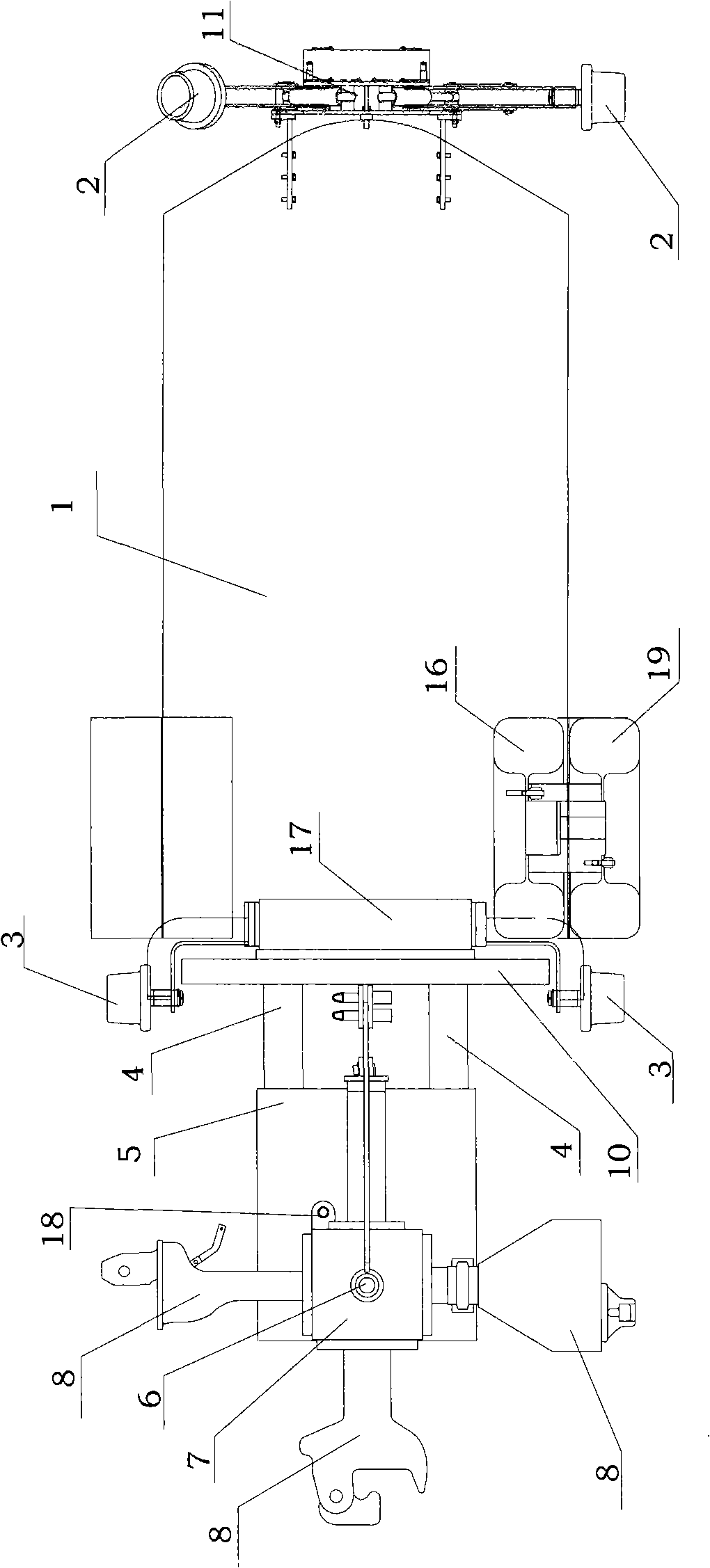

The invention discloses a manual self-elevating pallet truck, which comprises an upright post bracket and an elevating pallet fork. A manual hydraulic drive device is arranged on the upright post bracket, and comprises a hydraulic oil cylinder and a hydraulic oil pump, wherein the hydraulic oil pump is a manual oil pump and is provided with a drive handle which can be pressed by hands or pedaled; and one of a hydraulic cylinder body and a piston rod of a difunctional hydraulic cylinder which is the hydraulic oil cylinder is fixedly connected with the upright post bracket, and the other of the hydraulic cylinder body and the piston rod is in drive connection with a pallet fork sliding bracket. Caster stand sliding chutes are formed at the lower end of the upright post bracket, and telescopic caster stands are arranged in a matching way in the caster stand sliding chutes. Front and rear support casters are arranged at the front and rear ends of each telescopic caster stand. The manual self-elevating pallet truck provided by the invention has a simple structure and a small volume, works stably, and is well designed and easy to operate and maintain and difficult to fail when working.

Owner:上海海资国际贸易有限公司

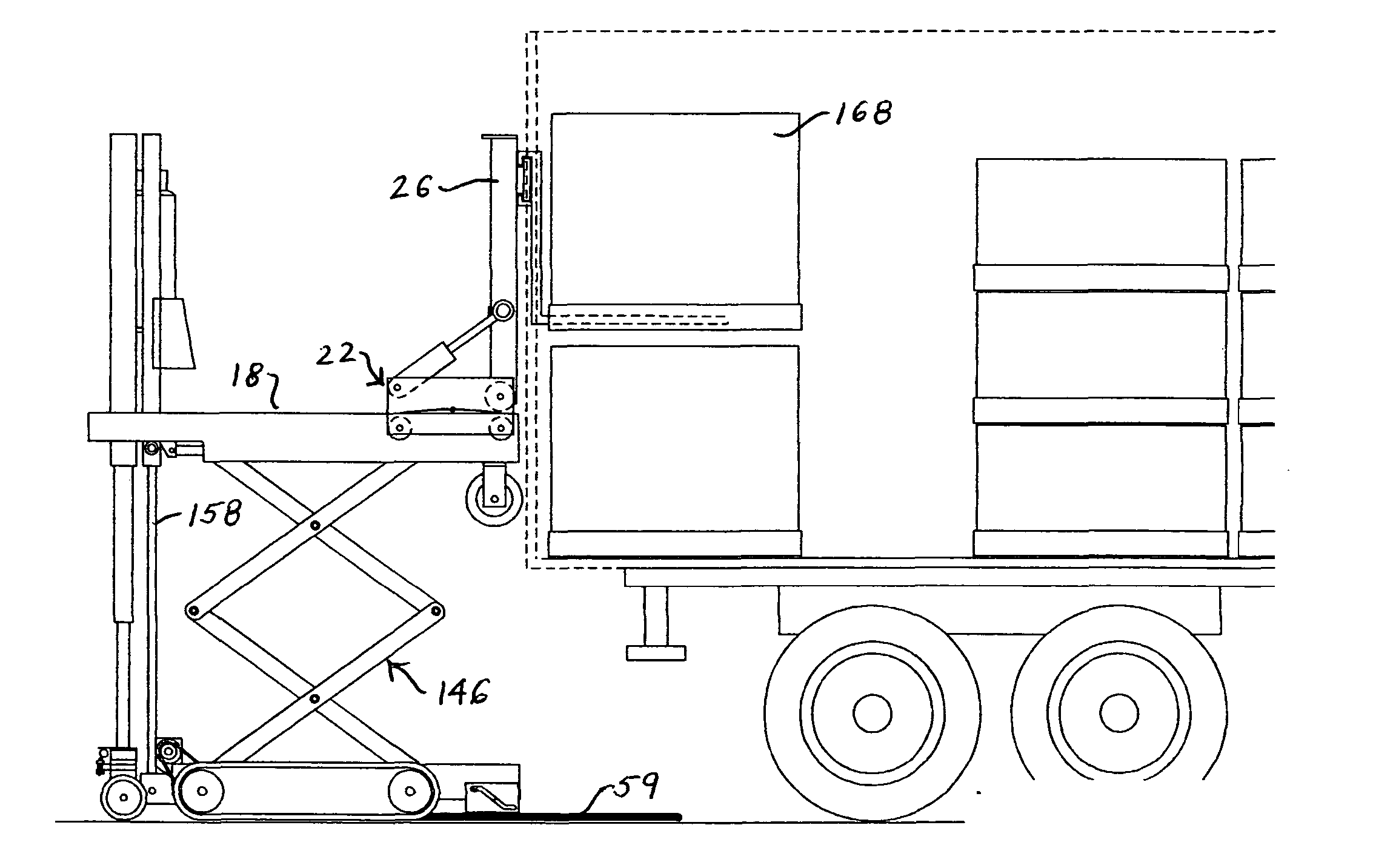

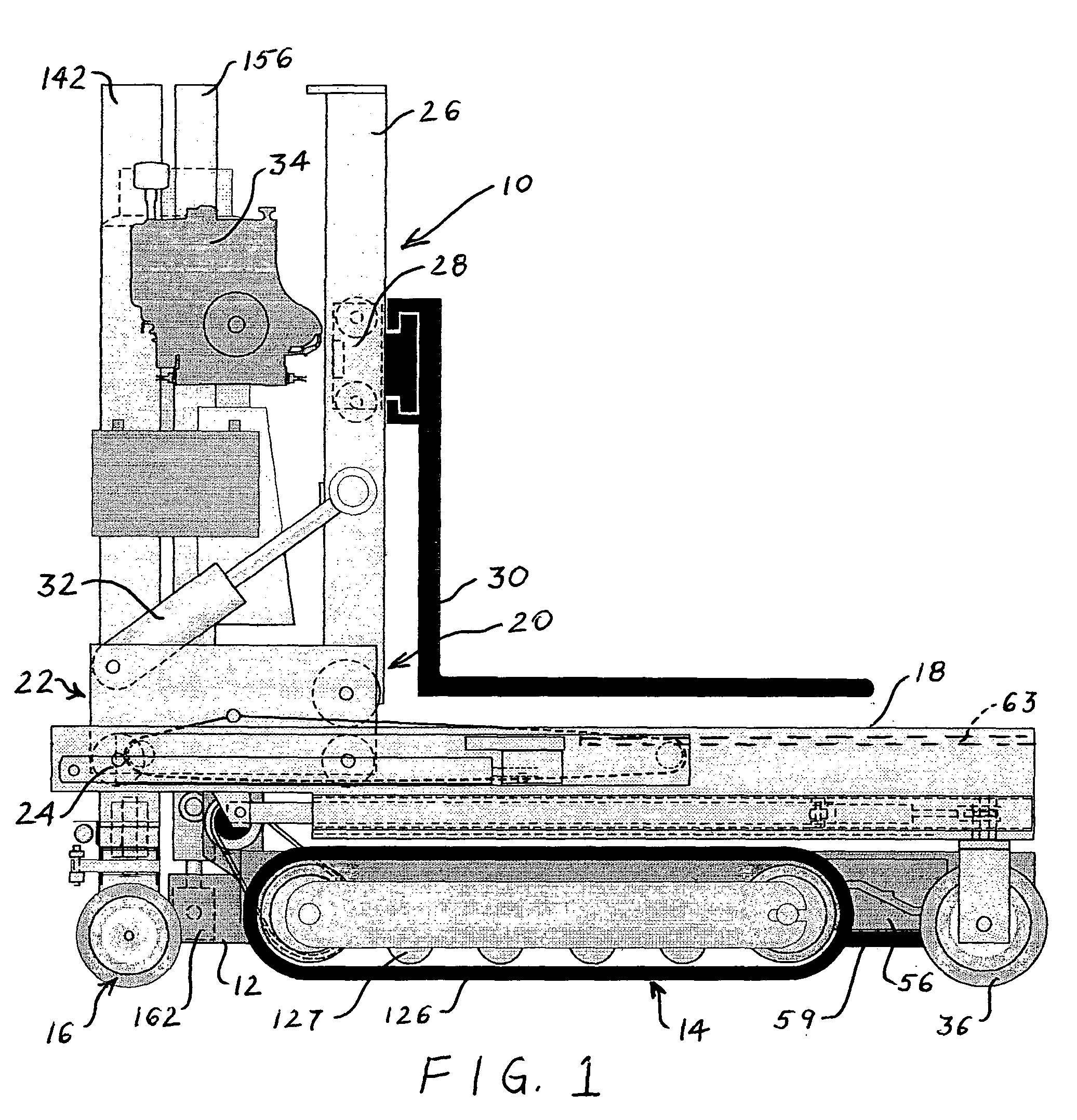

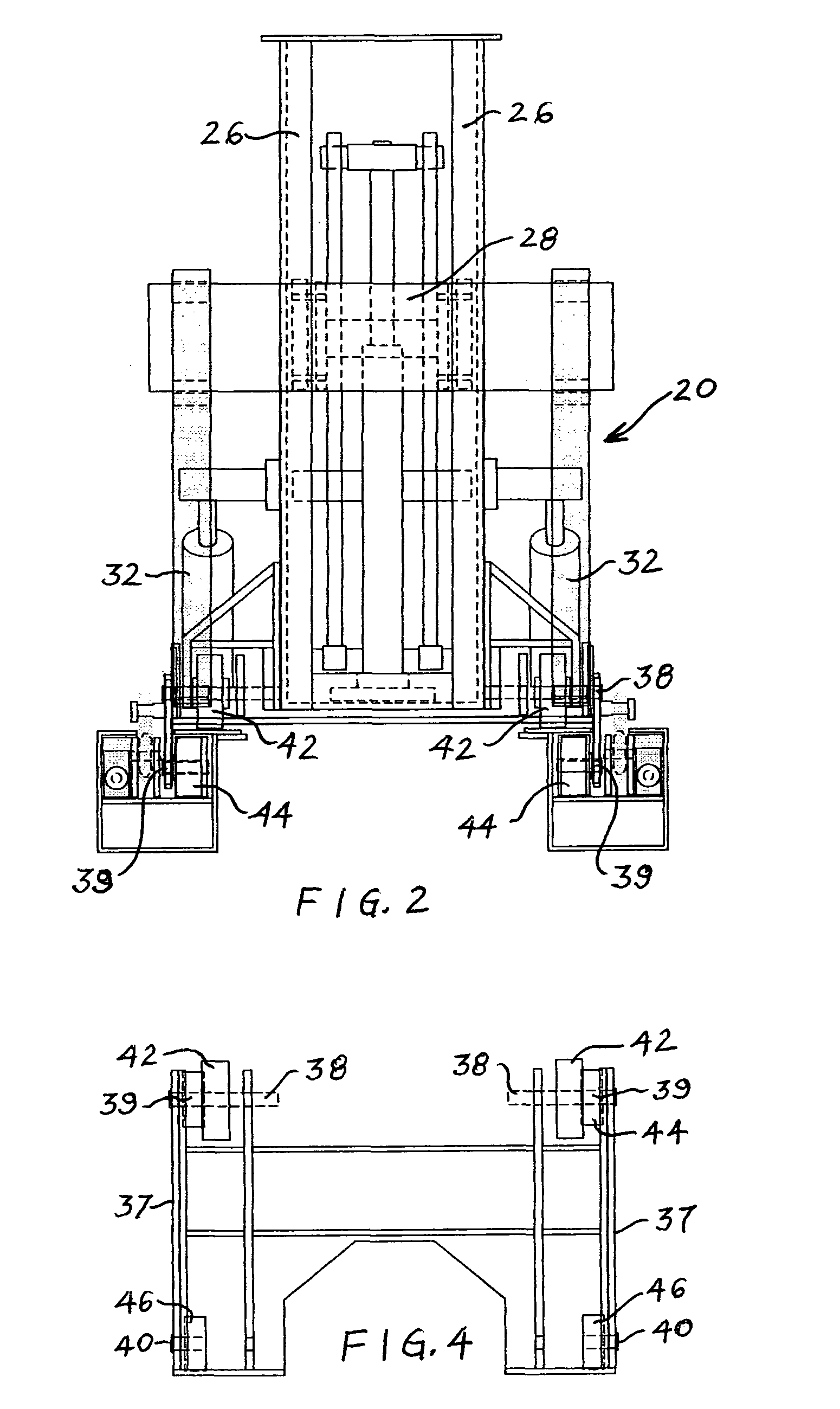

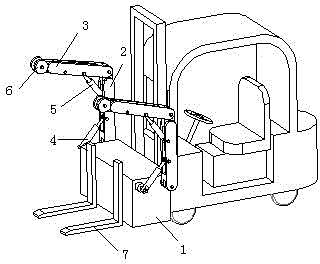

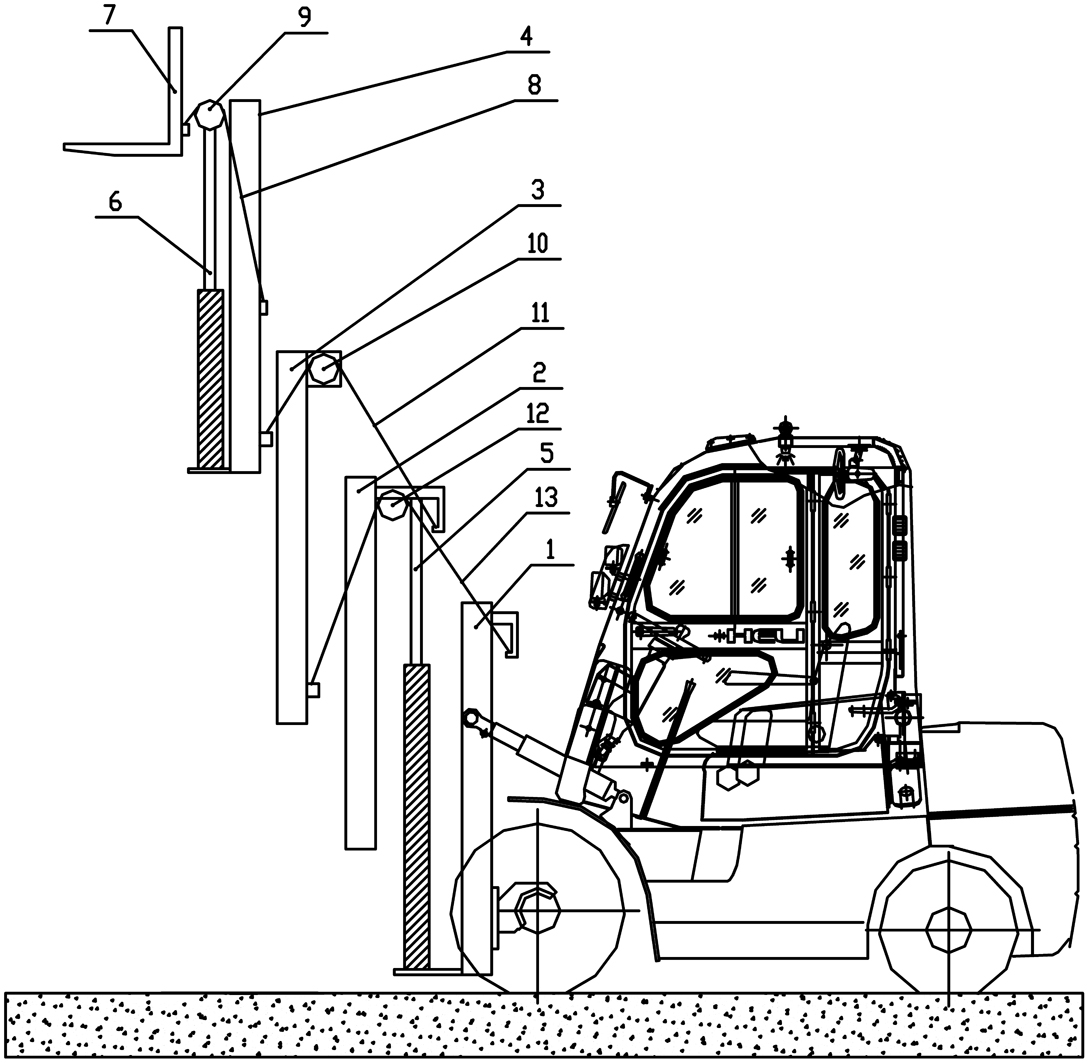

Forklift with stabilizing forks

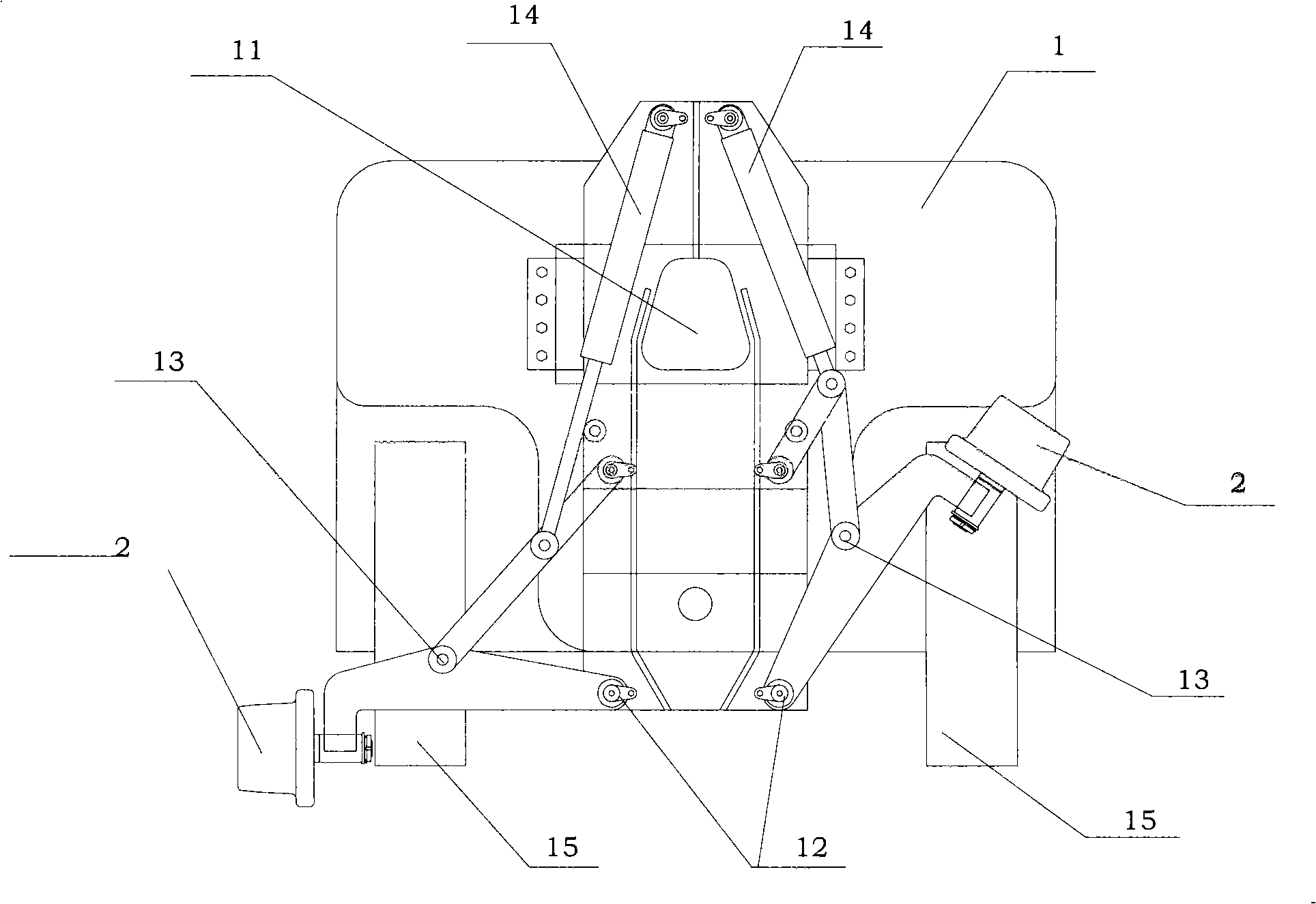

A forklift that can move itself and loads between two heights uses multiple sets of forks to stabilize the forklift while raising and lowering loads. A conventional set of pallet forks is mounted on a forward and rearward horizontally moveable chassis. Upper stabilizing forks are selectively extended forward from the forklift chassis to rest on a surface located below the load being moved. Lower stabilizing forks extend downward and forward from the bottom of the forklift for additional stability. A set of extendable front wheels extends forward to stabilize the forklift when moving the forklift between two heights. The pallet forks are mounted on a deck that can be raised and lowered. There are two independent drive systems that move the forklift depending on whether the main drive system is on the ground or elevated. The entire forklift can be remote controlled.

Owner:EHMEN RONALD

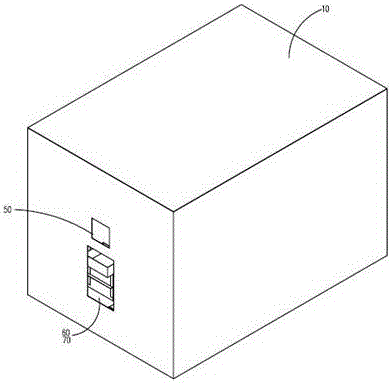

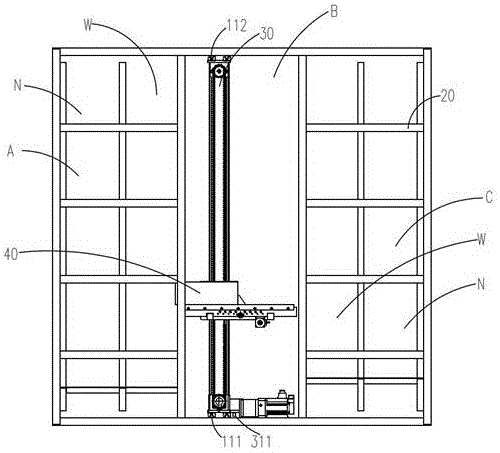

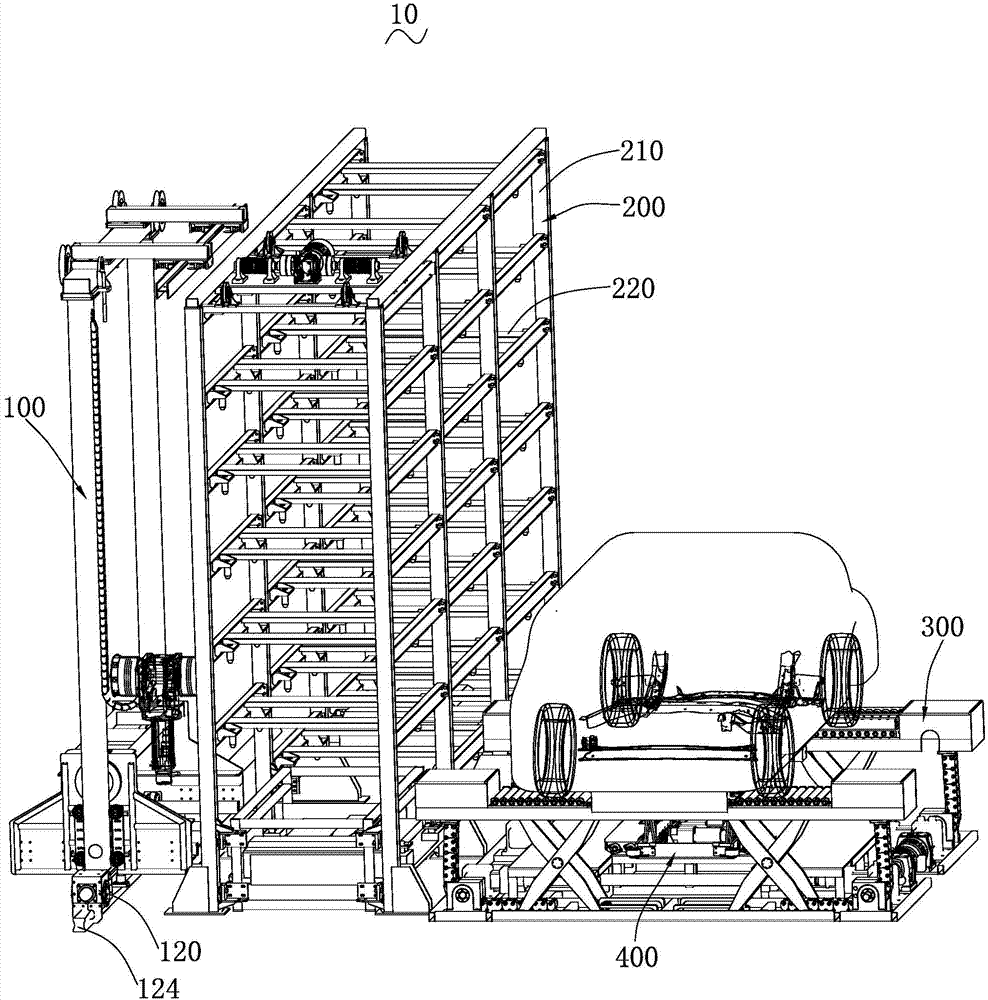

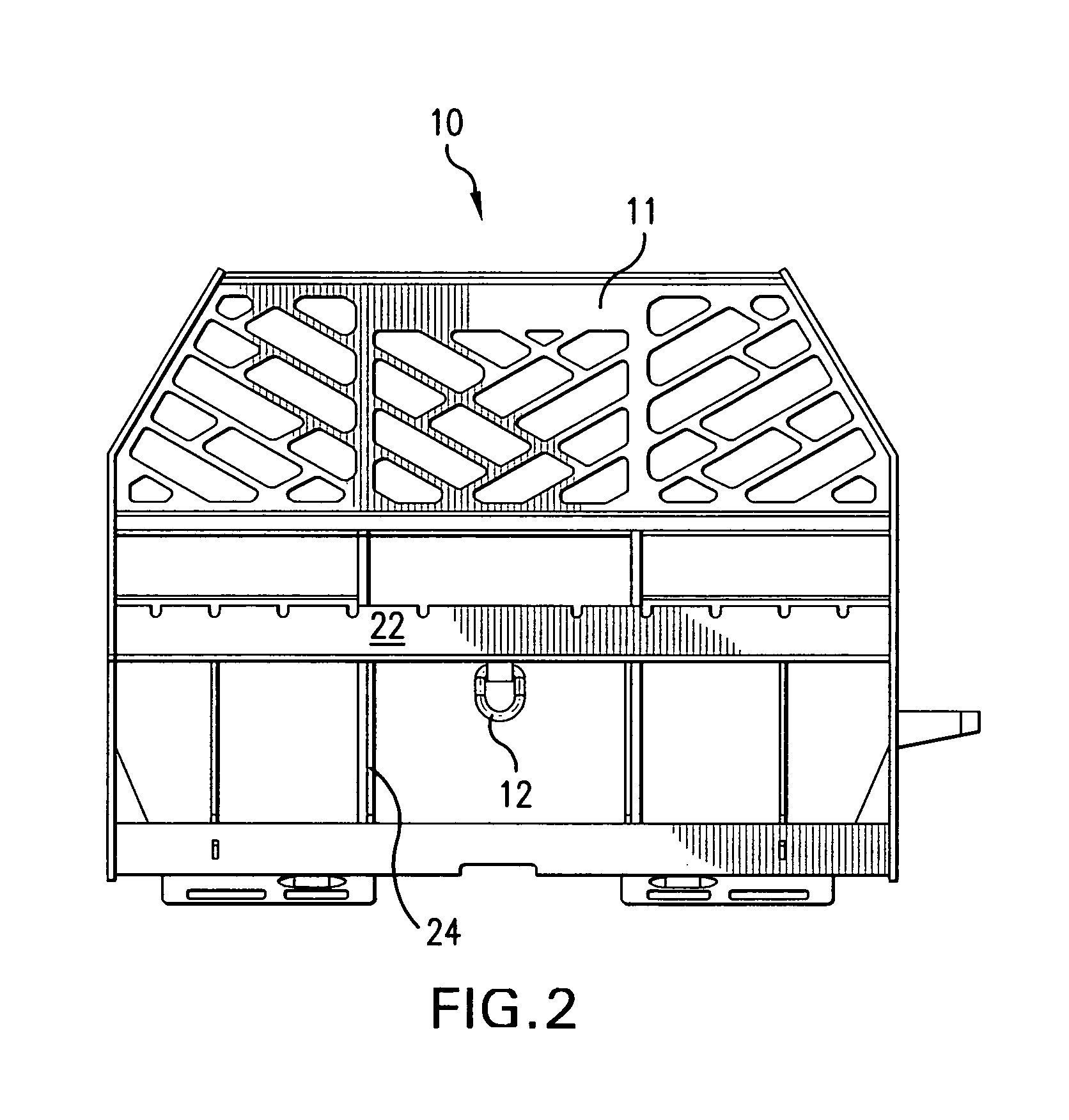

Three-dimensional goods storage equipment with flexible storage function

PendingCN106829299AWith automatic identification and automatic accessHigh degree of automationStorage devicesStack machineEngineering

The invention relates to a three-dimensional cargo storage and retrieval device with a flexible storage function, which includes a box body, a shelf and a stacker. A track is installed in the roadway in the middle of the box body, and a stacker machine is arranged on the track. A cargo identification mechanism is installed on the inner side of the pick-up port on the front face; the stacker includes a traveling mechanism, a lifting mechanism, a loading platform and a column. A pair of telescopic forks are symmetrically arranged on both sides of the cargo platform. The traveling mechanism includes gears and driving drive system. The lifting mechanism includes chains, sprockets and lifting drive system. The sprocket at the lower end is connected with the lifting drive system. The invention can store goods of various sizes, has the function of automatic identification and automatic storage, realizes fast storage and storage, and rationally utilizes the space of the shelf.

Owner:深圳市丰巢电商物流科技有限公司

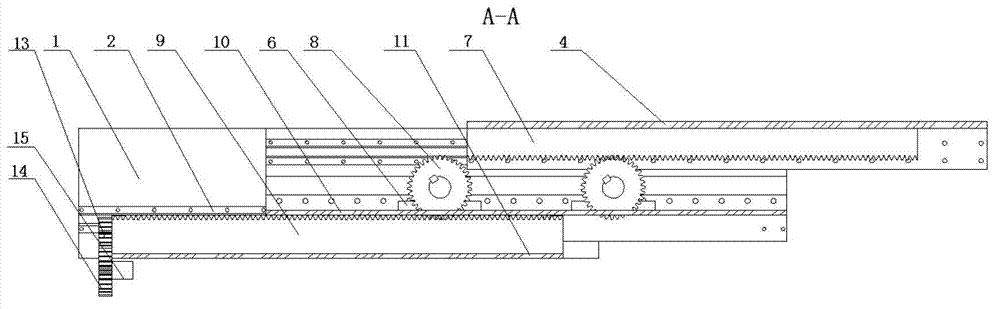

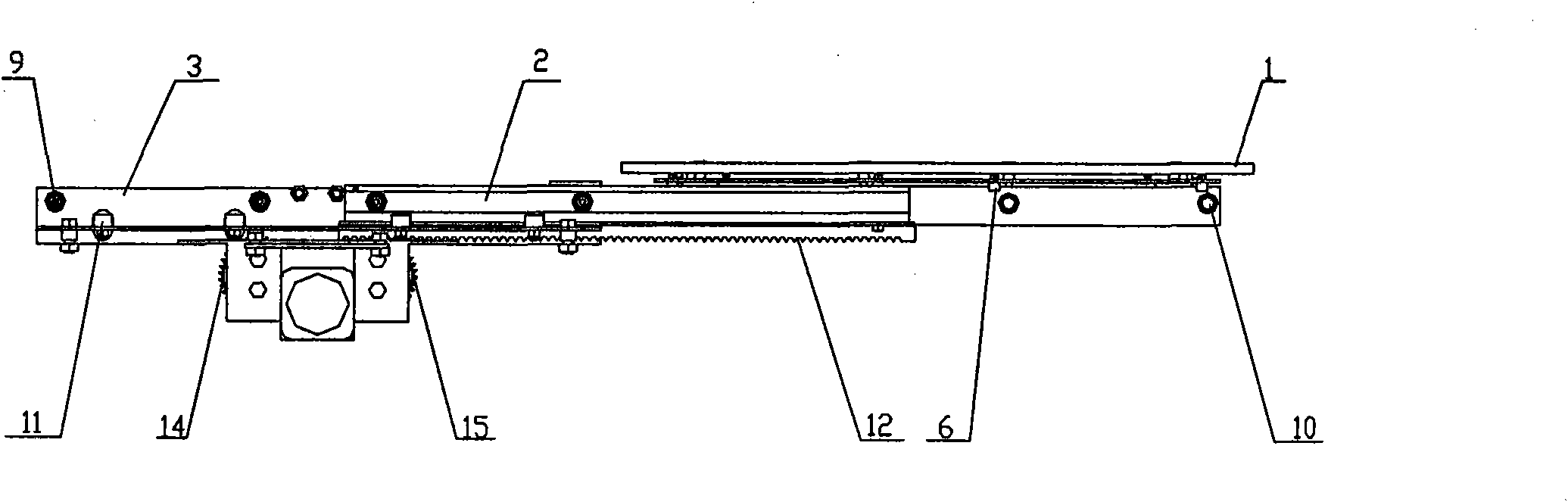

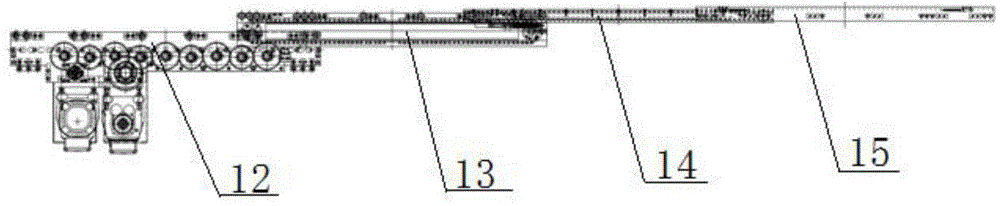

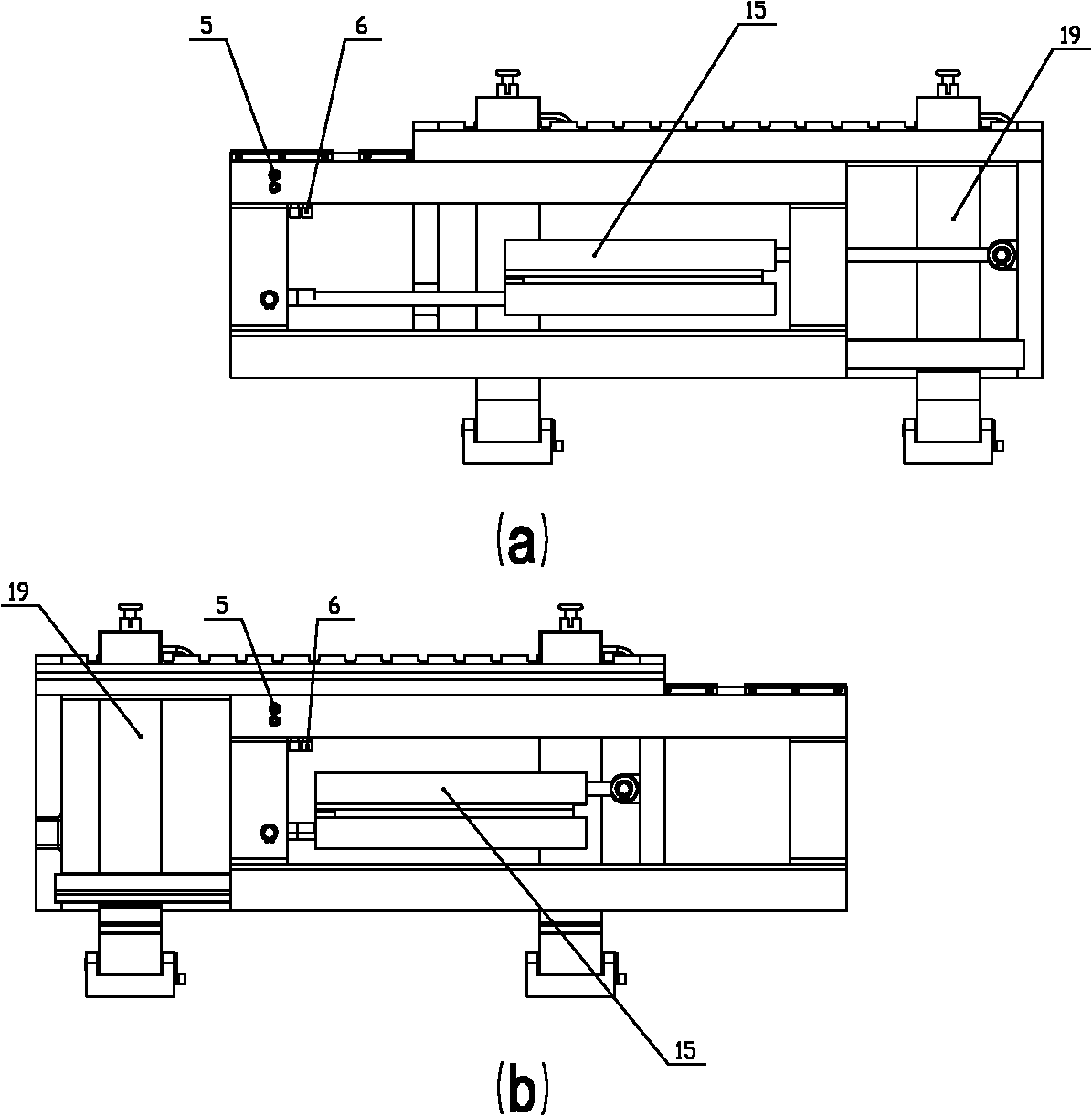

Telescopic fork

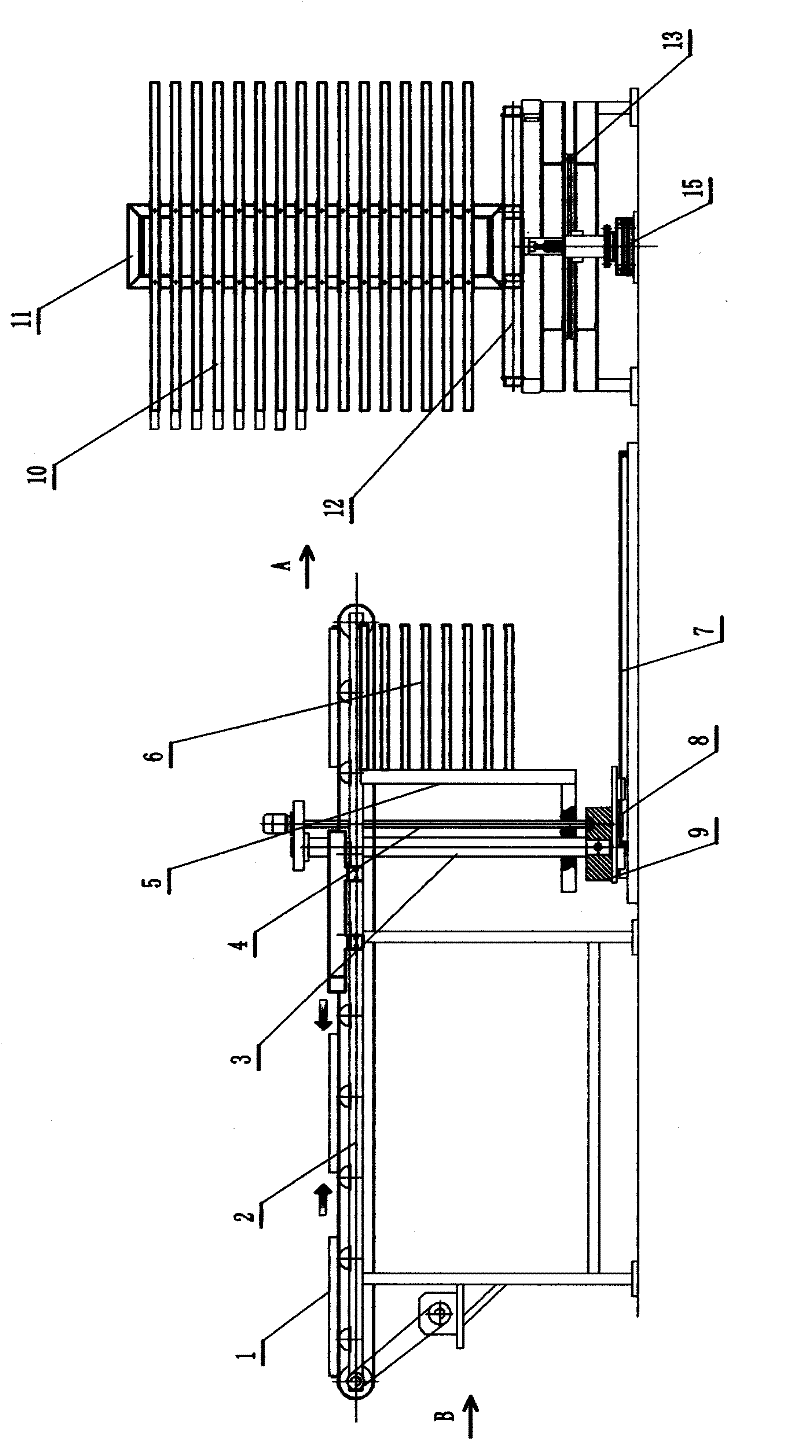

InactiveCN101885456AFree accessCorrect access convenienceLifting devicesDrive shaftElectric machinery

The invention discloses a telescopic fork. Lower roll bearings of two groups of middle forks slide freely in fixed guide rails; upper roll bearings of two middle forks are positioned in movable guide rails of upper forks; and the two groups of middle forks are positioned at the middle parts of the fixed guide rails on a lower fork respectively. Two main chain wheels of a transmission system are positioned at the two ends of a first step of a transmission shaft respectively; the central line of one main chain wheel overlaps with that of a group of end chain wheel sets on the lower fork; the central line of the other main chain wheel overlaps with that of the other group of end chain wheel sets on the lower fork; and two bearings with seats are arranged at the lower parts of two U-shaped plates of a motor retaining plate respectively. An end retaining plate and a retaining plate are provided with limiters respectively. Through the roll bearings and the rails, the entire telescopic fork is light, convenient and flexible to move; and the travel of the fork is controlled by the limiters, so that the fork has the characteristics of compact structure, high working efficiency, safety and practicability.

Owner:XIAN AEROSPACEMOTOR MACHINE FACTORY

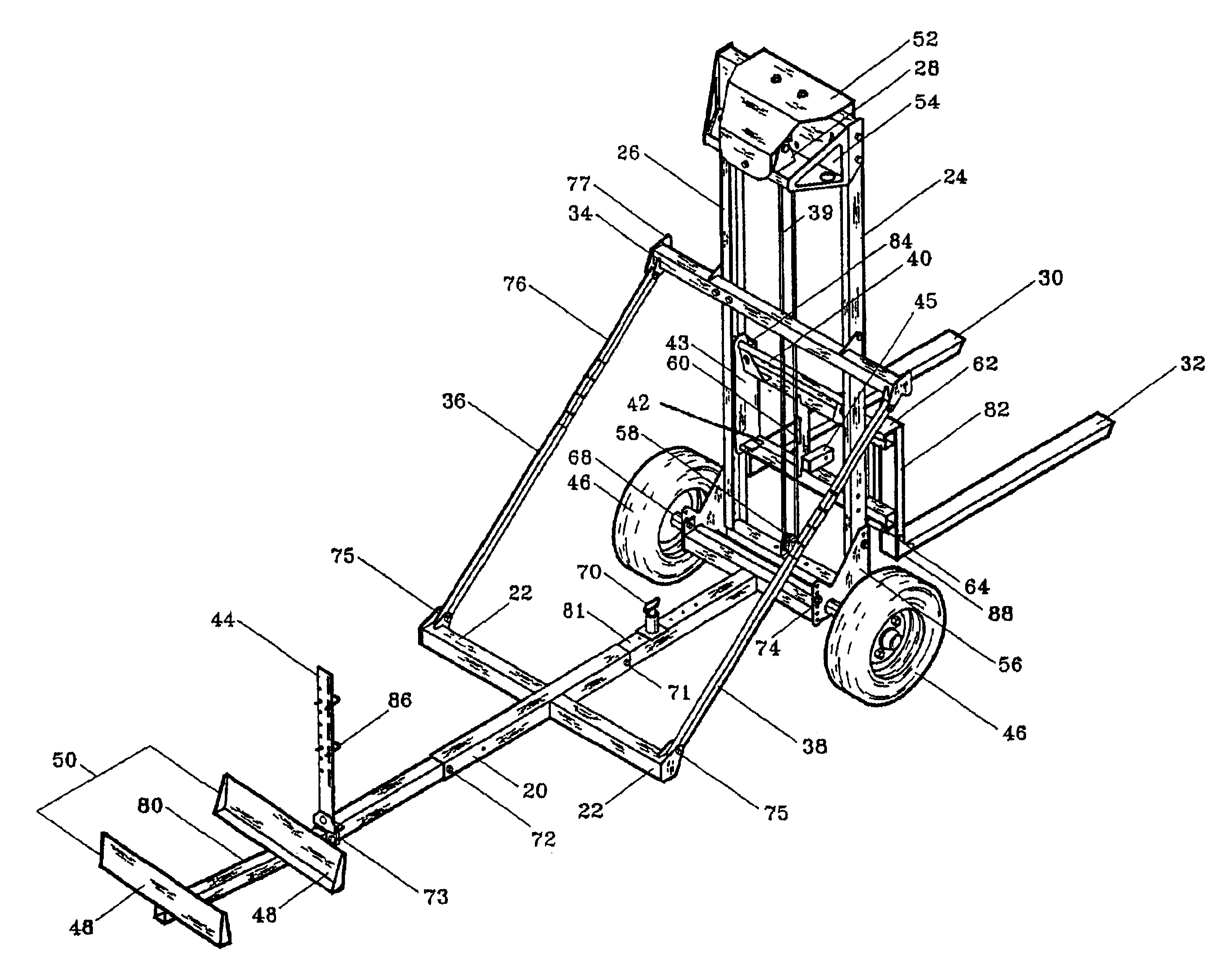

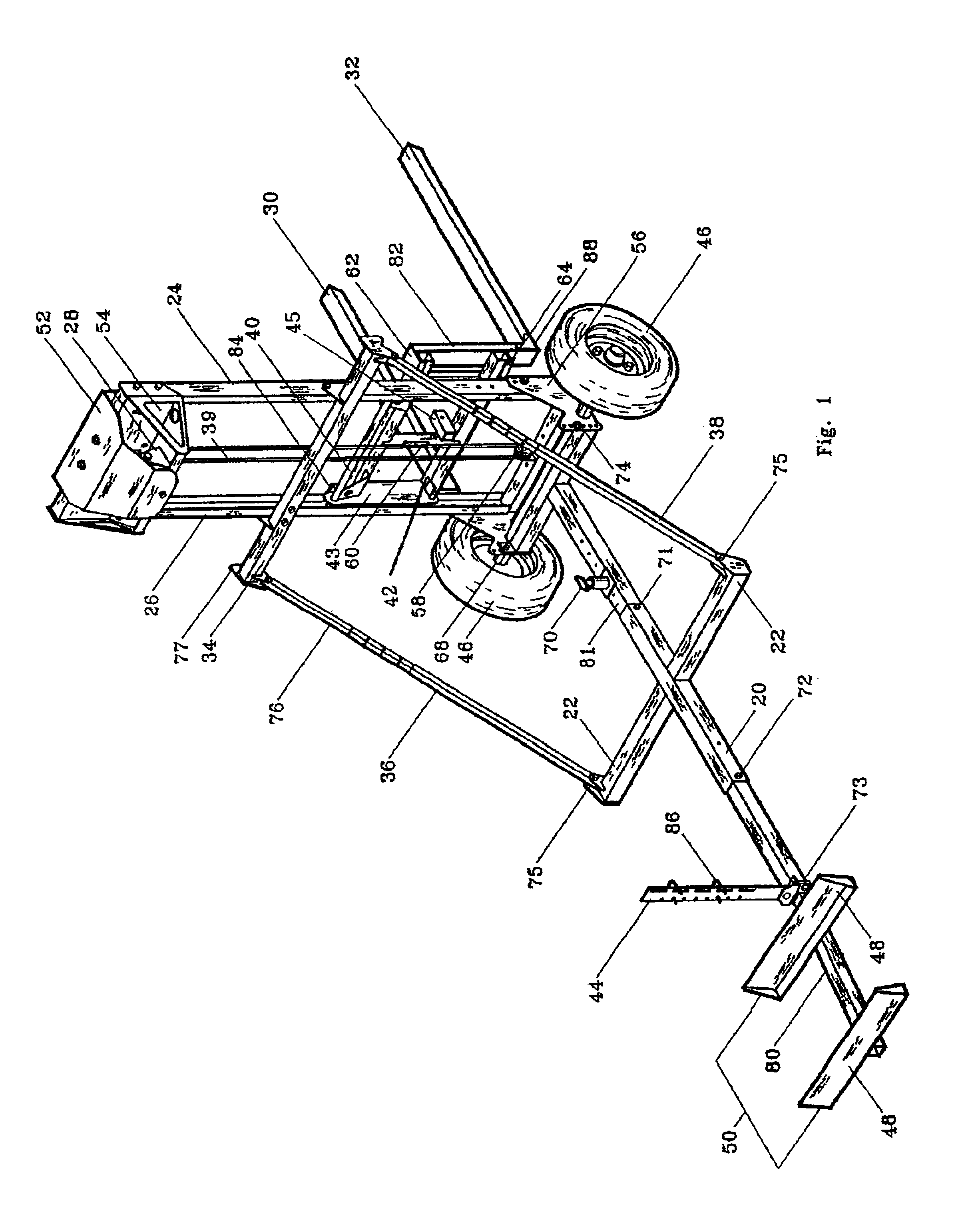

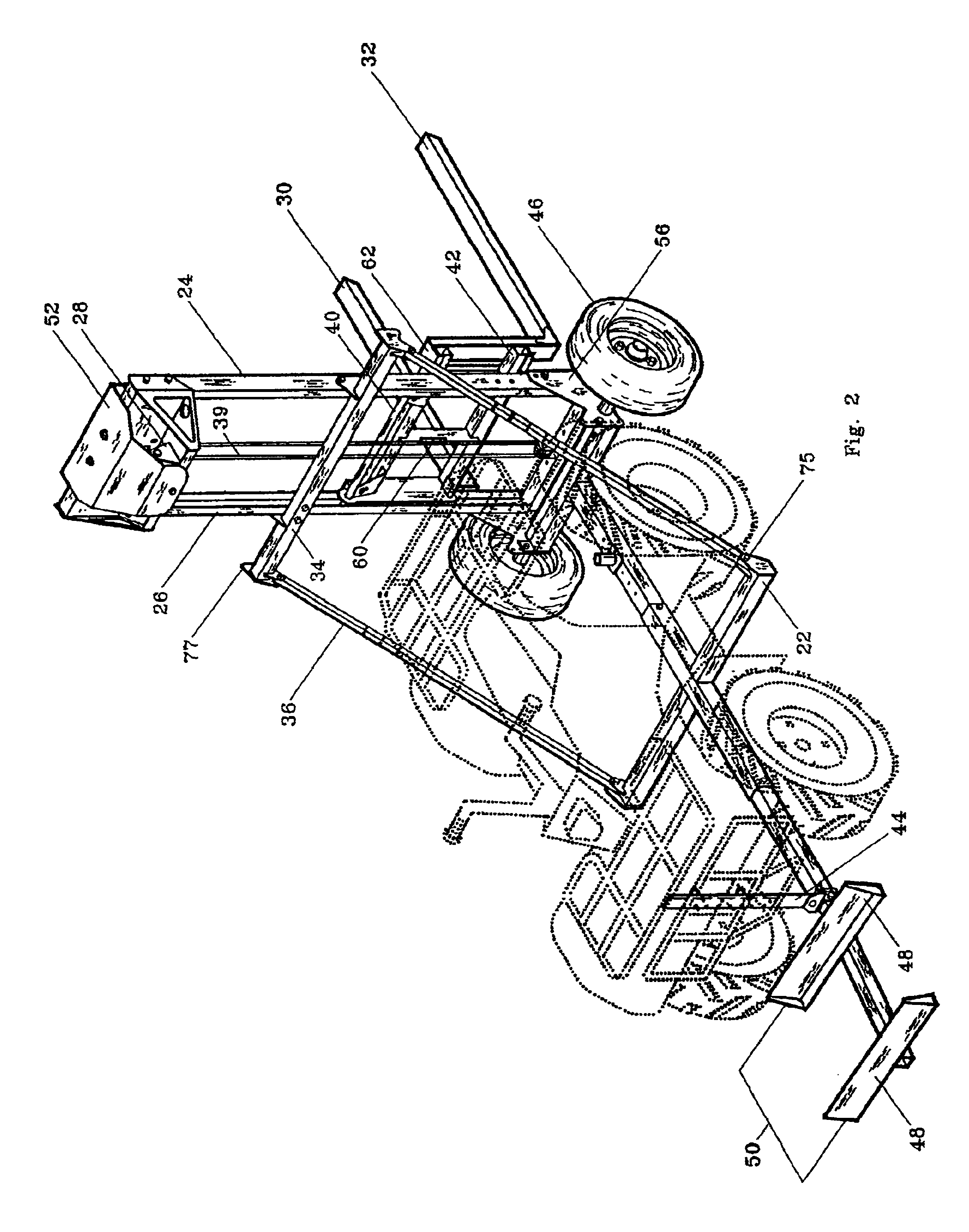

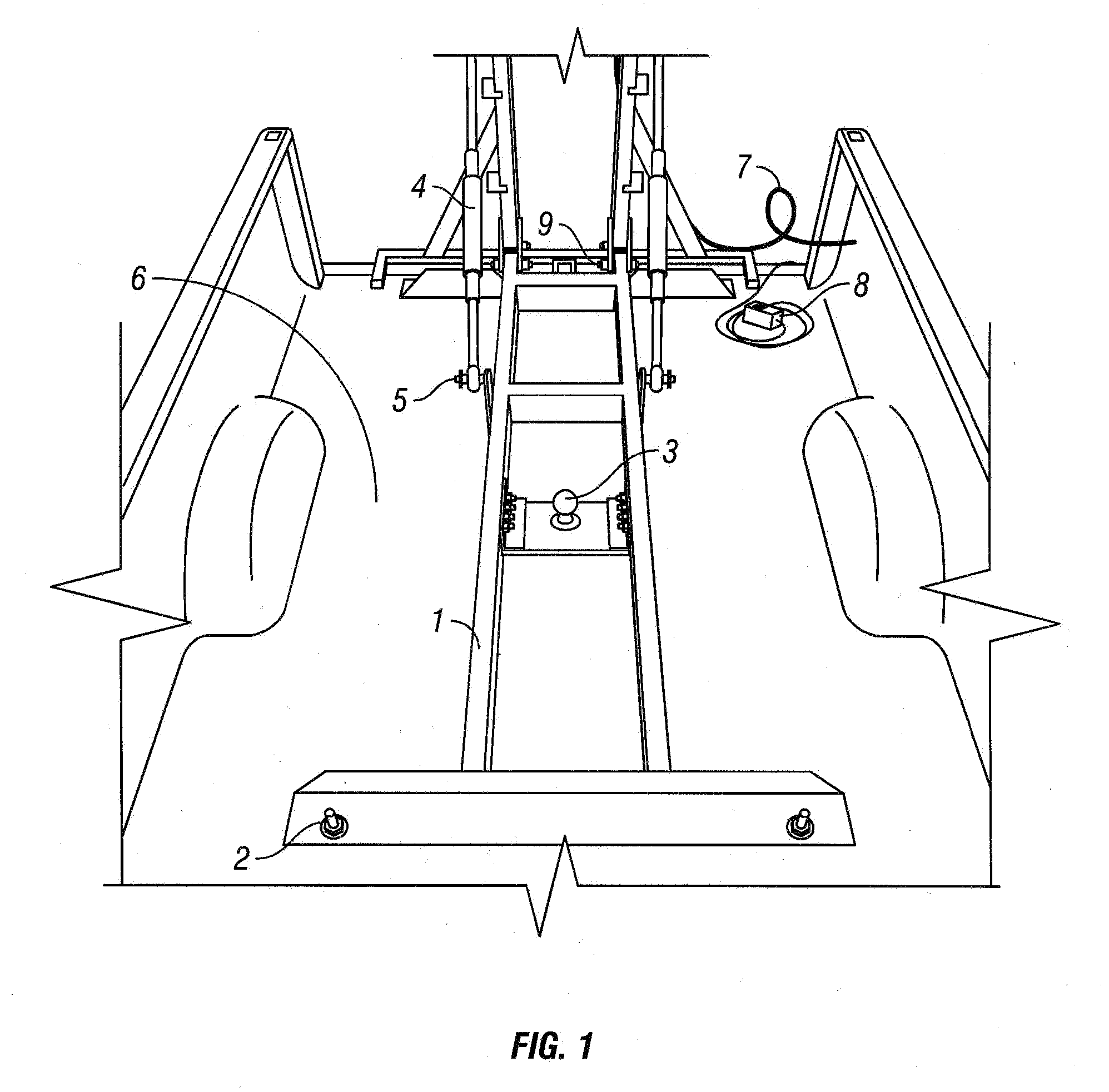

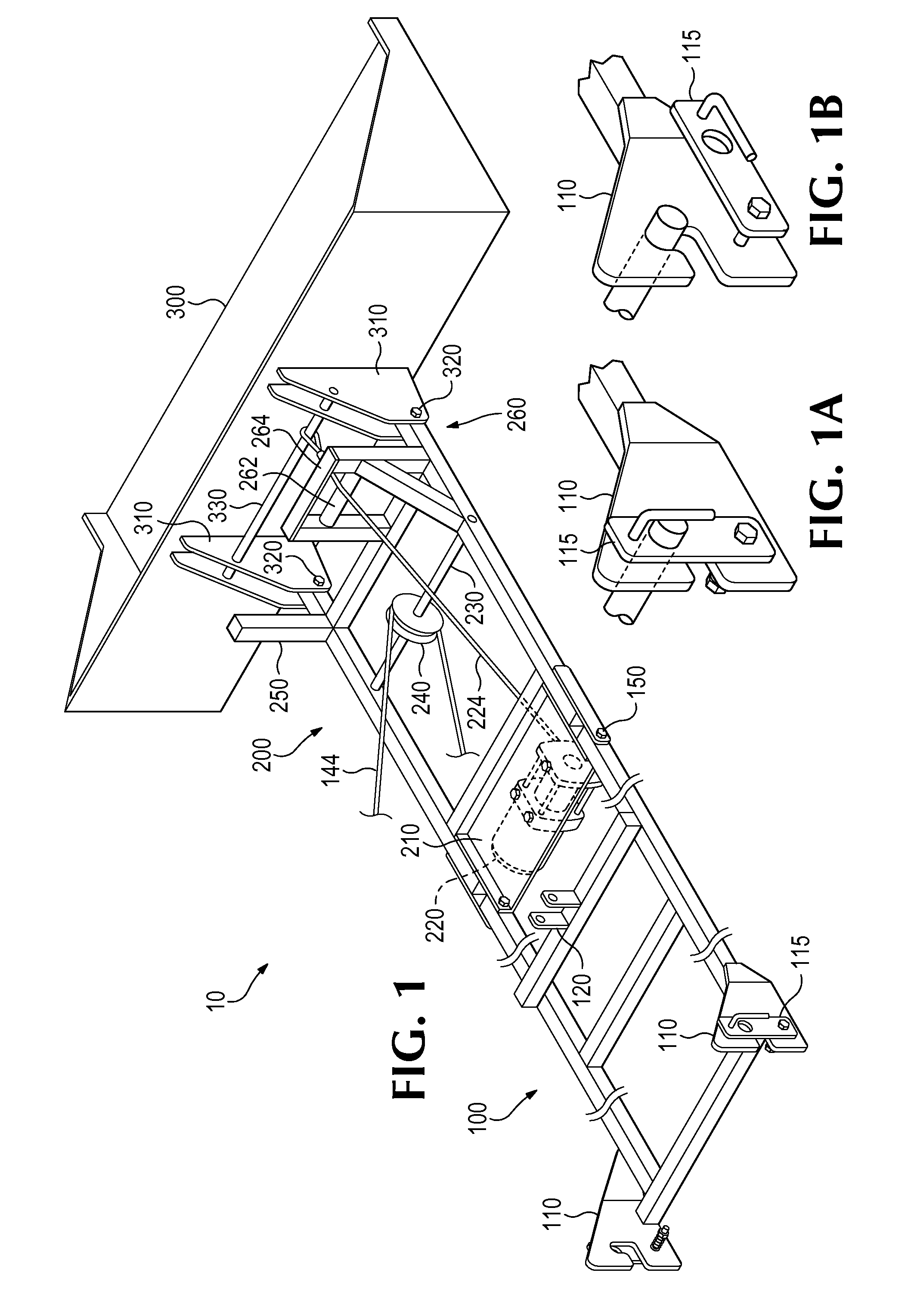

Multi-purpose load bearing assembly for all terrain vehicle (ATV)

An support structure is provided comprising: (a) a mast extending upwards; (b) a center bar extending horizontally from the mast, the center bar configured to extend along the bottom of the light vehicle; (c) a T bar extending from the center bar, along the bottom of the light vehicle to a T bar end at a lateral side of the light vehicle; and (d) a first truss member extending upwards on an incline from the first T bar end to a truss position on the mast. A counter load bearing mount may be attached to the center bar at the second end of the vehicle. Also taught is a load bearing apparatus comprising a support structure of the invention and at least one load bearing member selected from the group consisting of a dump box, 3-point hitch, hitch, dump bucket, log skidder, pallet forks, backhoe, agricultural plow, folding forks, tiller, scraper, disk harrow, disk harrow, hydraulic hammer, auger, grinder, and grapples.

Owner:1326033 ONTARIO

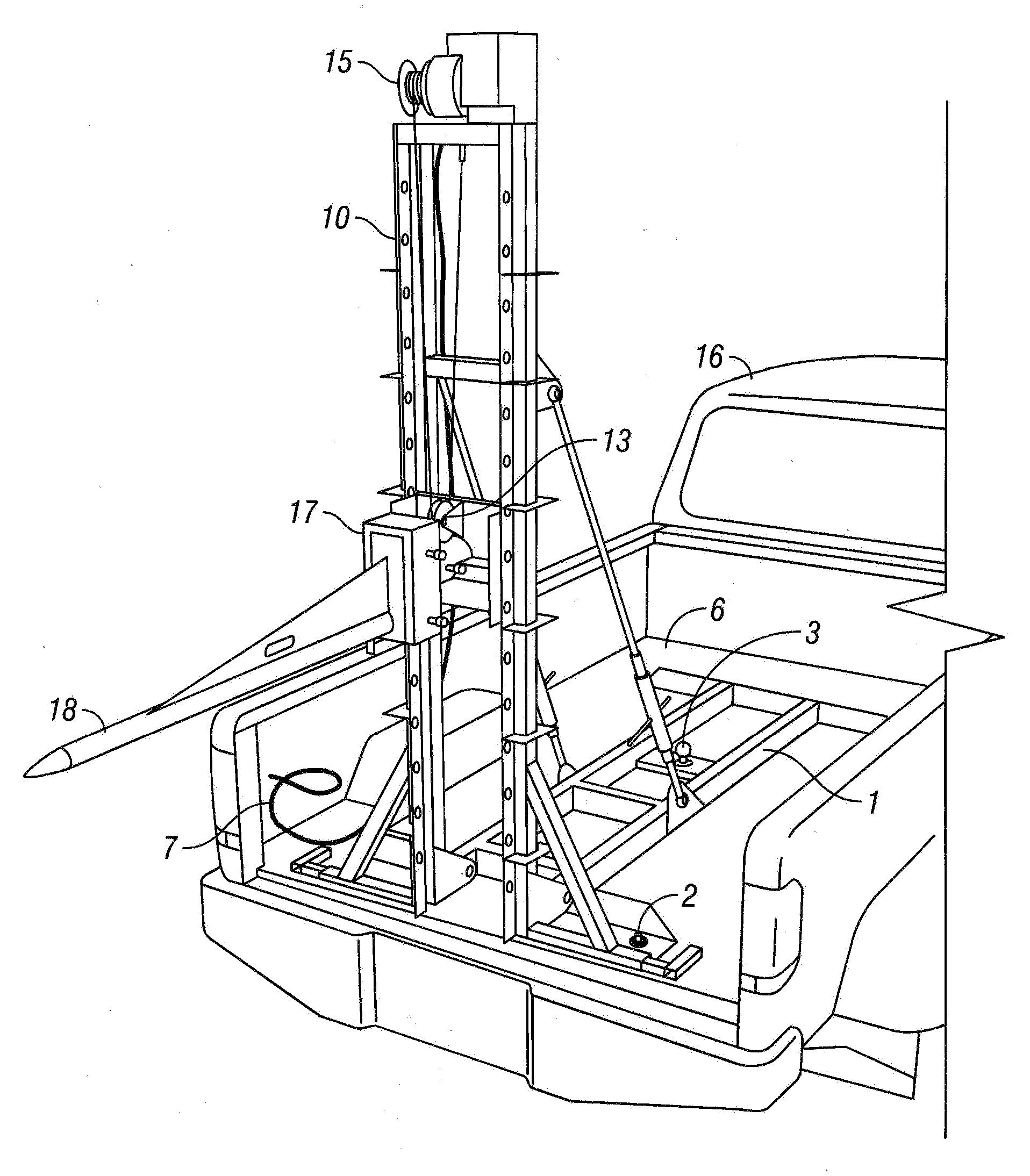

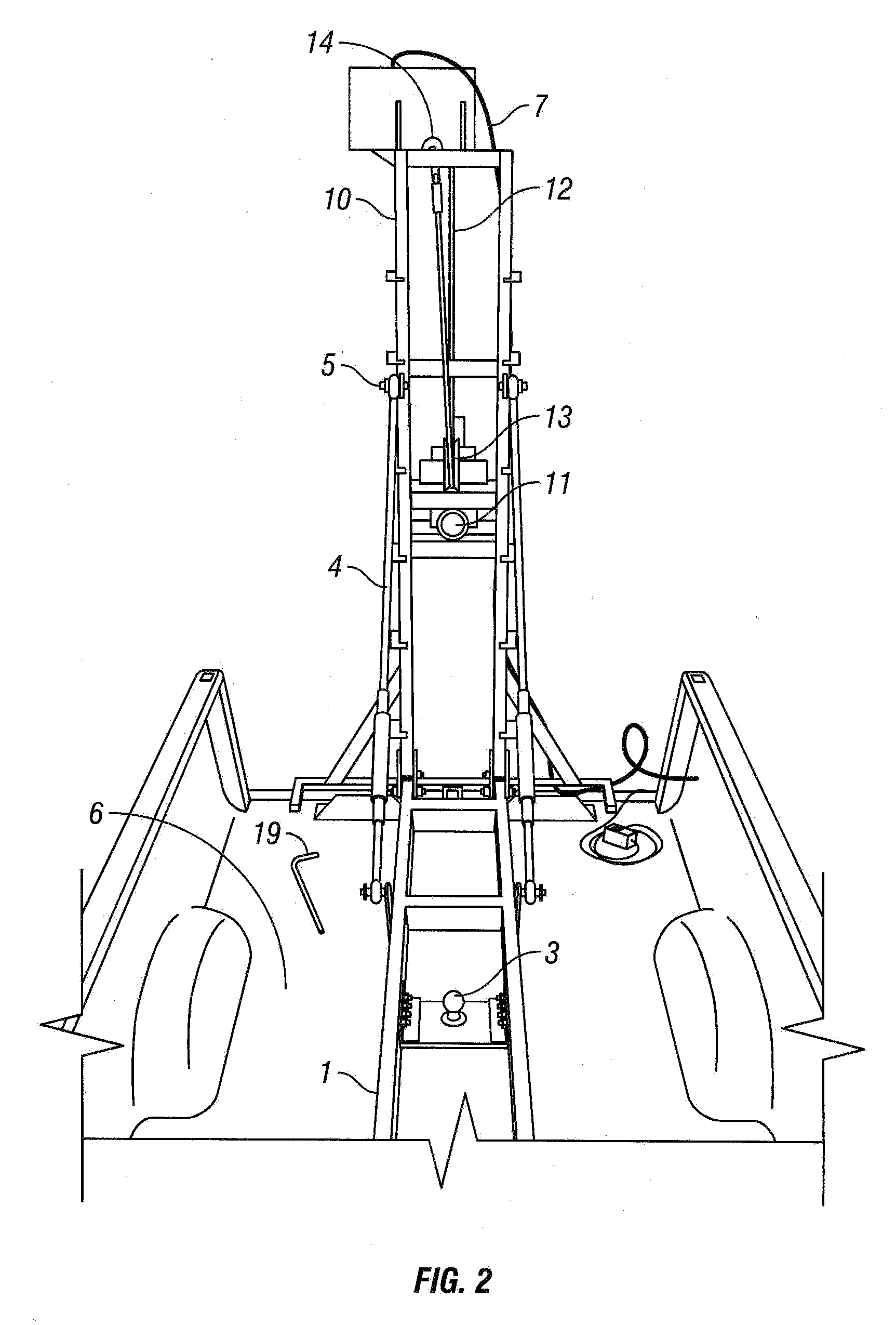

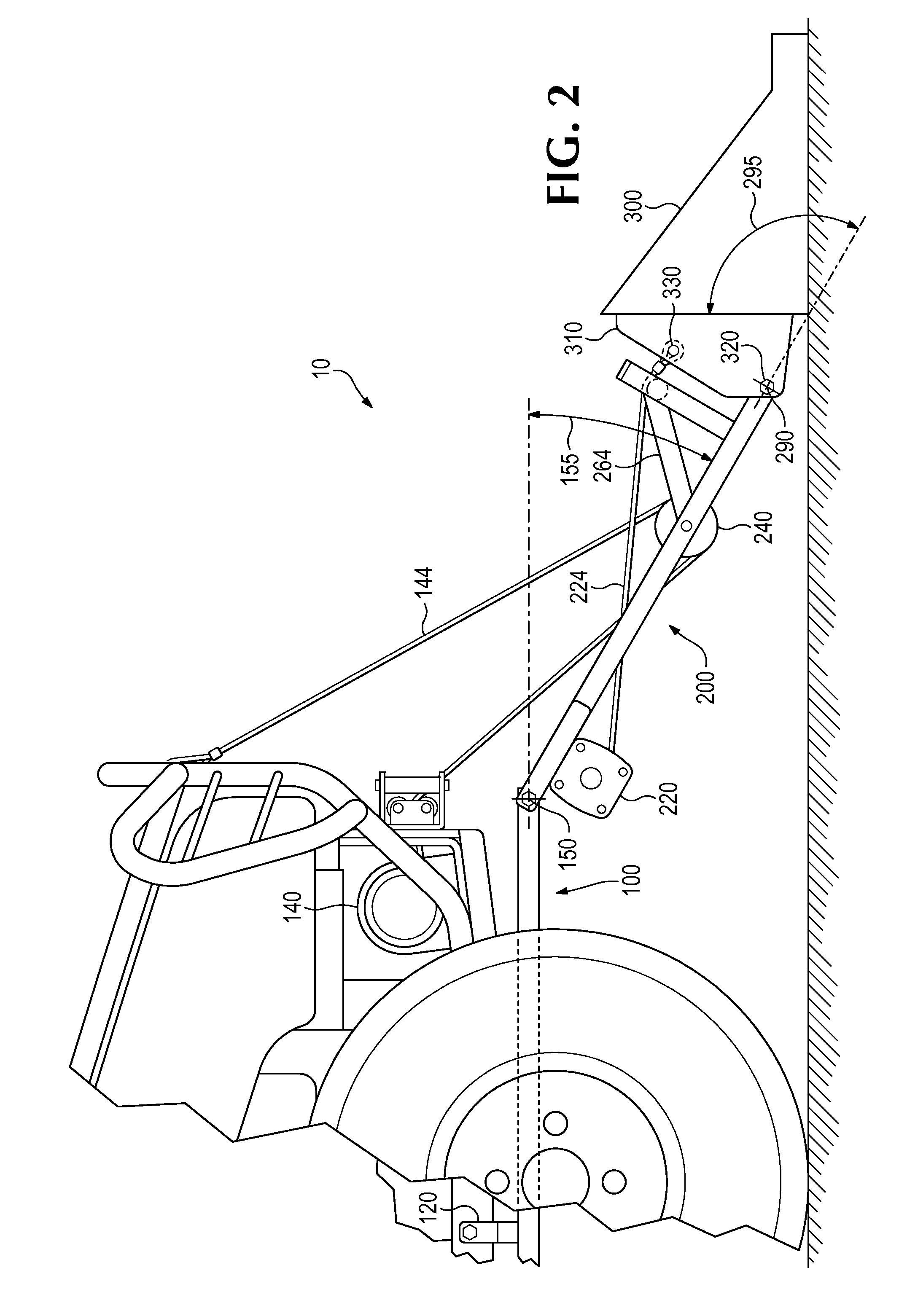

Truck Mounted Multifunction Lifting System and Method

A collapsible electrical or hydraulic system mountable in the rear of a truck for lifting and other functions. The system is compatible with other common uses of pick-up trucks. It is operated from within the cab of the truck, standing outside the pick-up truck bed, or remotely. The system operates in various modes and with various tools. The lifting system is collapsible to a low-profile and allows the use of the pick-up truck for towing a “gooseneck” trailer. Multiple attachments include, but are not limited to, a fork lift, hay bale spear, hay bale unroller, pallet forks, man-lift cages, dump bucket, drilling attachment, and / or a vehicle recovery platform, such as the towing / lifting functions of a tow truck.

Owner:BROOKS BRADY B

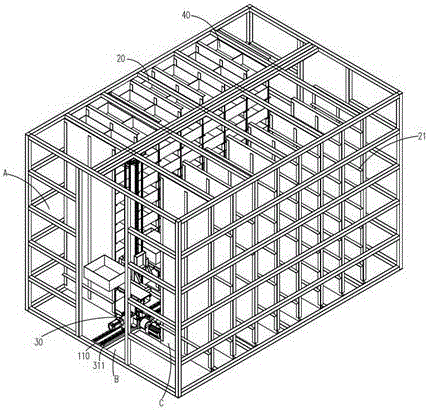

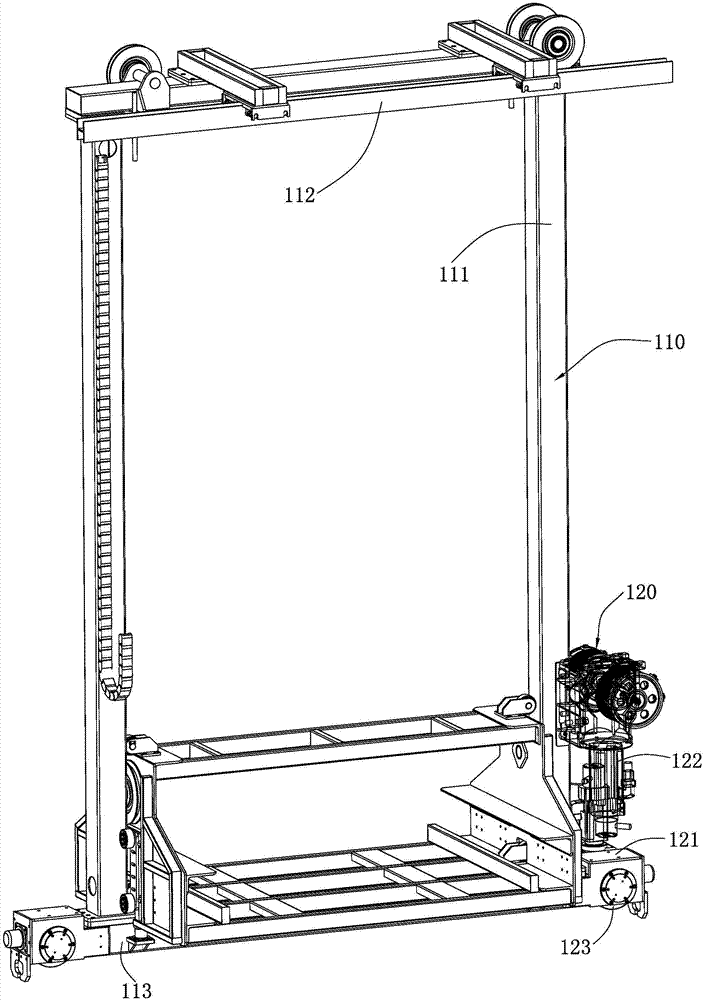

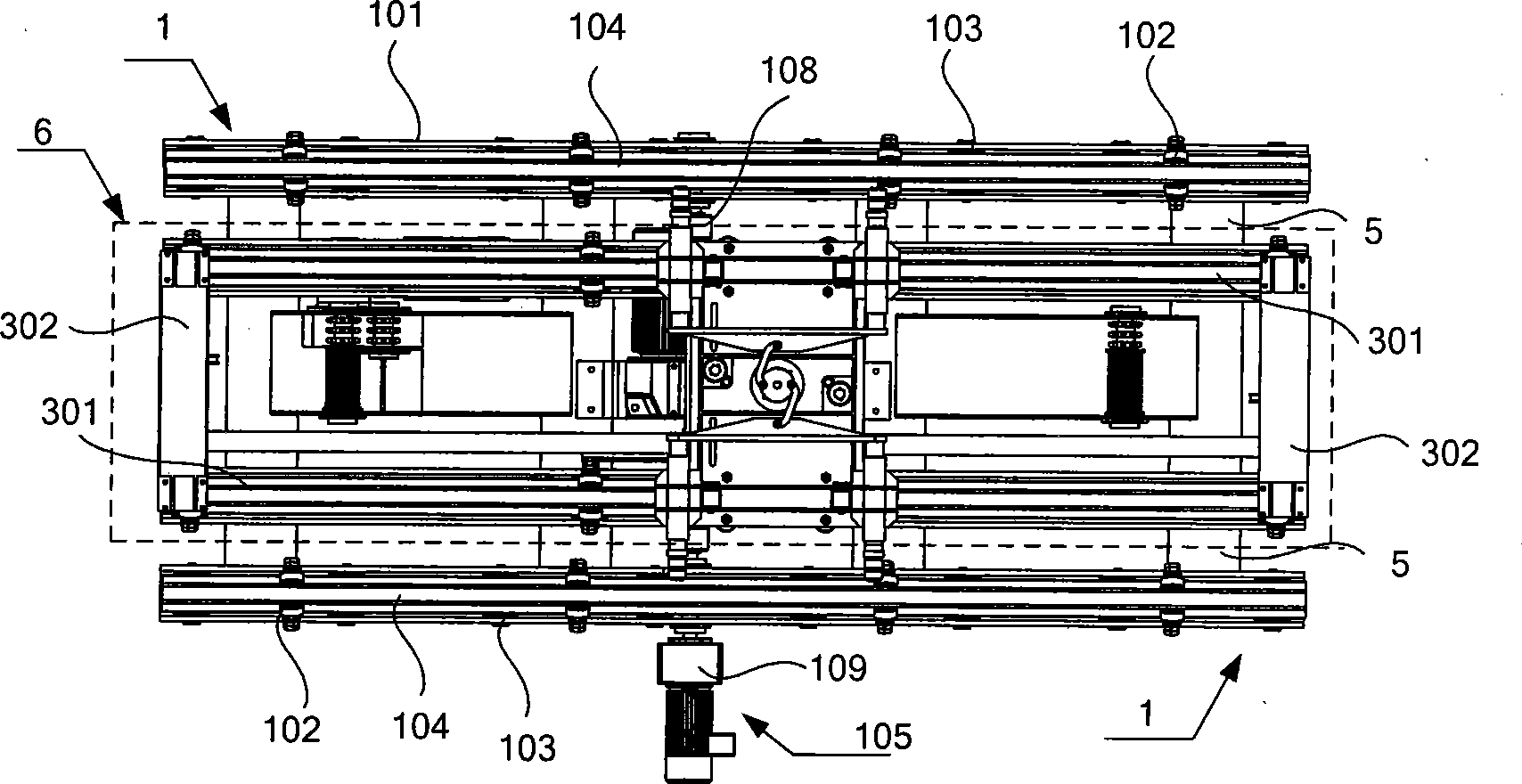

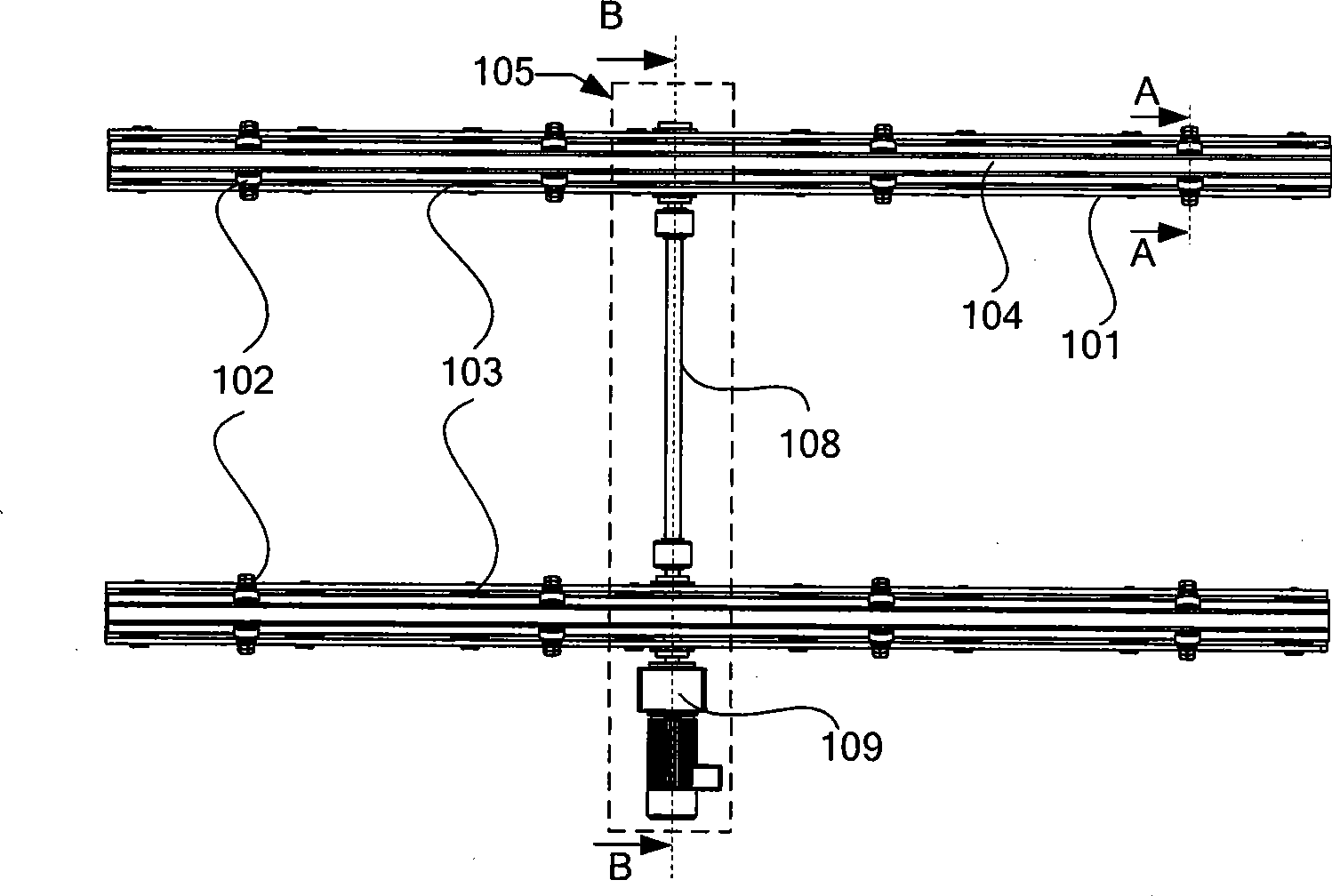

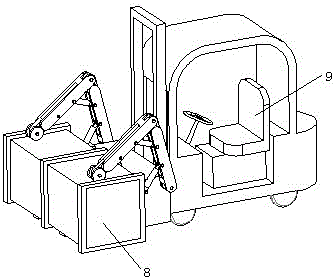

Stacking machine structure for stereoscopic warehouse

InactiveCN105253507AReduce weightReduce volumeStacking articlesDe-stacking articlesStack machineEngineering

The invention relates to the technical field of stacking machines and discloses a stacking machine structure for a stereoscopic warehouse. The stacking machine structure for the stereoscopic warehouse comprises a lower rail and an upper rail parallel to the lower rail. A horizontal sliding base is arranged on the lower rail. A vertical lifting rail is arranged on the horizontal sliding base. The upper end of the lifting rail is in connected with the upper rail in a sliding mode. A vertical sliding base is arranged on the lifting rail. A pallet fork fixing base is arranged on the side face of the vertical sliding base. A telescopic pallet fork is arranged on the pallet fork fixing base. A horizontal driving mechanism used for driving the horizontal sliding base to slide along the lower rail is arranged on the horizontal sliding base. A lifting driving mechanism used for driving the vertical sliding base to rise and fall is arranged on the horizontal sliding base and located at the lower end of the lifting rail. The stacking machine structure for the stereoscopic warehouse has the beneficial effects that flexibility is achieved, goods can be put into and out of the warehouse more conveniently, and the efficiency is high; the stacking machine structure is particularly suitable for transferring light and small-sized goods into or out of the warehouse.

Owner:HANGZHOU DC ENERGY EQUIP

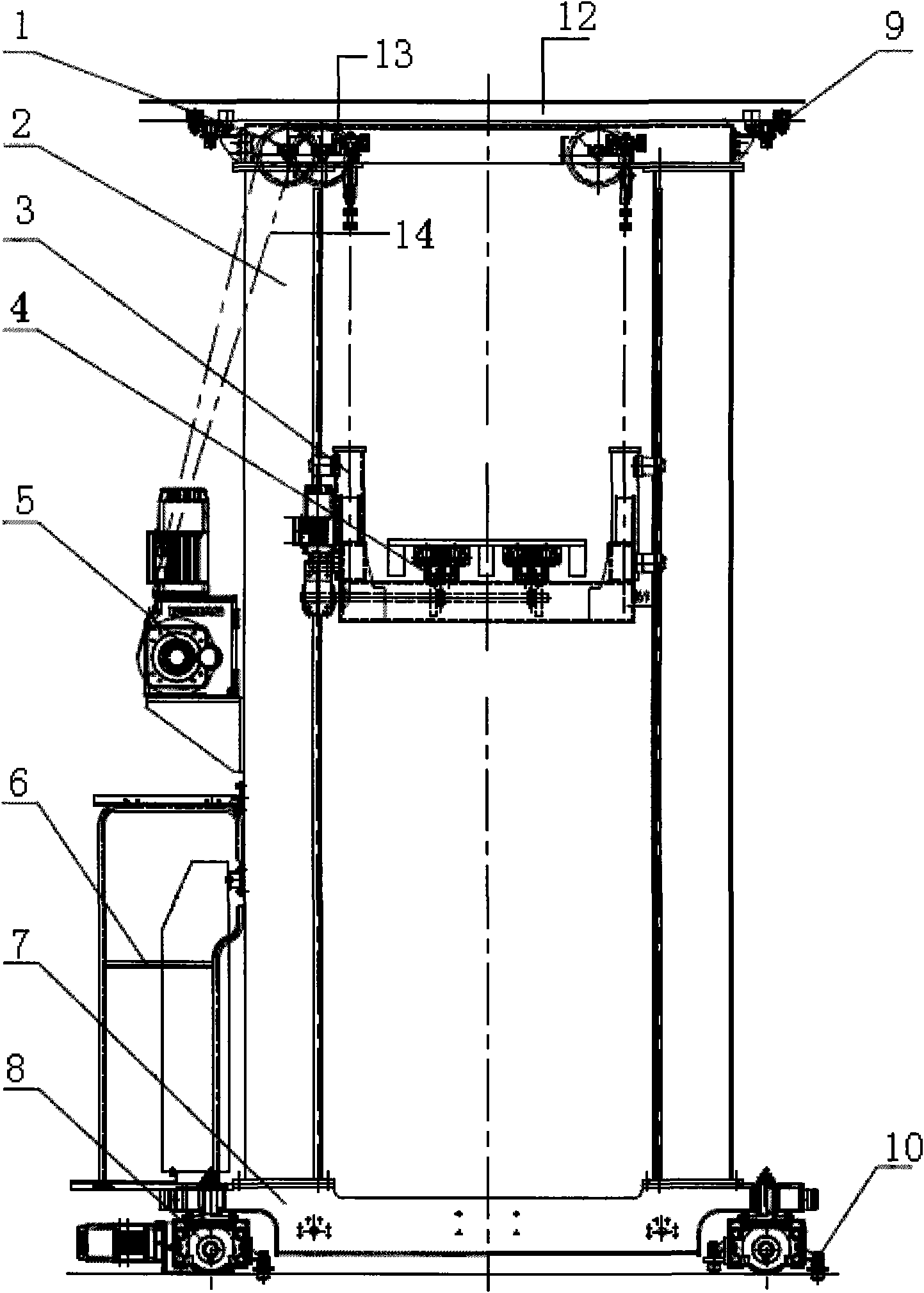

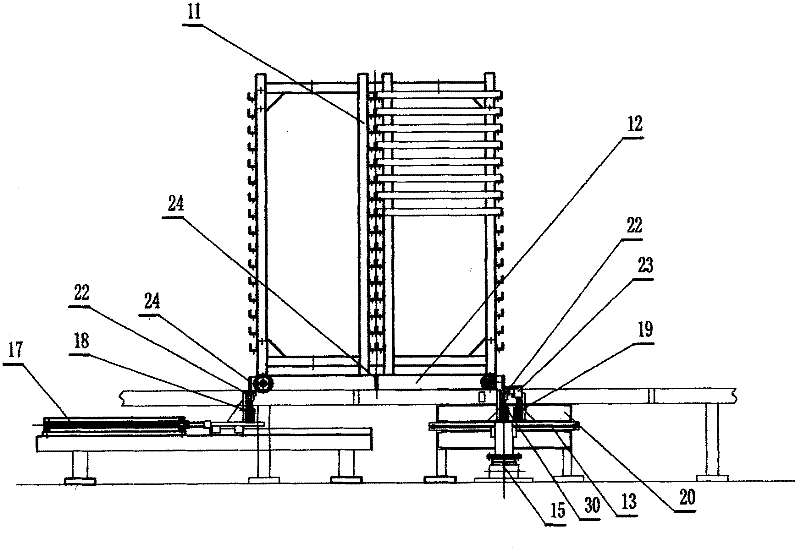

Tunnel double-column piler

ActiveCN101648688ANo need to change the structure layoutReduce consumptionLifting devicesEngineeringPallet fork

The invention provides a tunnel double-column piler which is characterized in that the tunnel double-column piler comprises a lower guide rail. The upper side of the lower guide rail is provided withtwo travelling wheel boxes; the upper side of the travelling wheel box is connected with a lower beam; the upper side of the lower beam is provided with two stand columns, and the upper side of the stand column is provided with an upper beam; the upper side of the upper beam is provided with an upper guide rail; a freight carrying table is arranged between stand columns, the upper side of the freight carrying table is provided with a pallet fork, and the freight carrying table is connected with a hauling cable; the hauling cable is connected with a hoisting mechanism arranged at one side of the stand column via a fixed pulley arranged on the upper beam, and the hoisting mechanism and the travelling wheel boxes are respectively connected with an electric cabinet. The invention is characterized in that two sides of the upper beam are respectively connected with an upper beam guide pulley, and the travelling wheel boxes are connected with lower beam guide pulleys. The invention has the advantages that the invention can automatically turn a corner, a piler device can be operated among various tunnels, can effectively improve device efficiency and reasonable goods arrangement and lowerthe consumption of power resources and realizes the goal of energy saving and emission reduction for enterprises.

Owner:上海精星仓储设备工程有限公司 +1

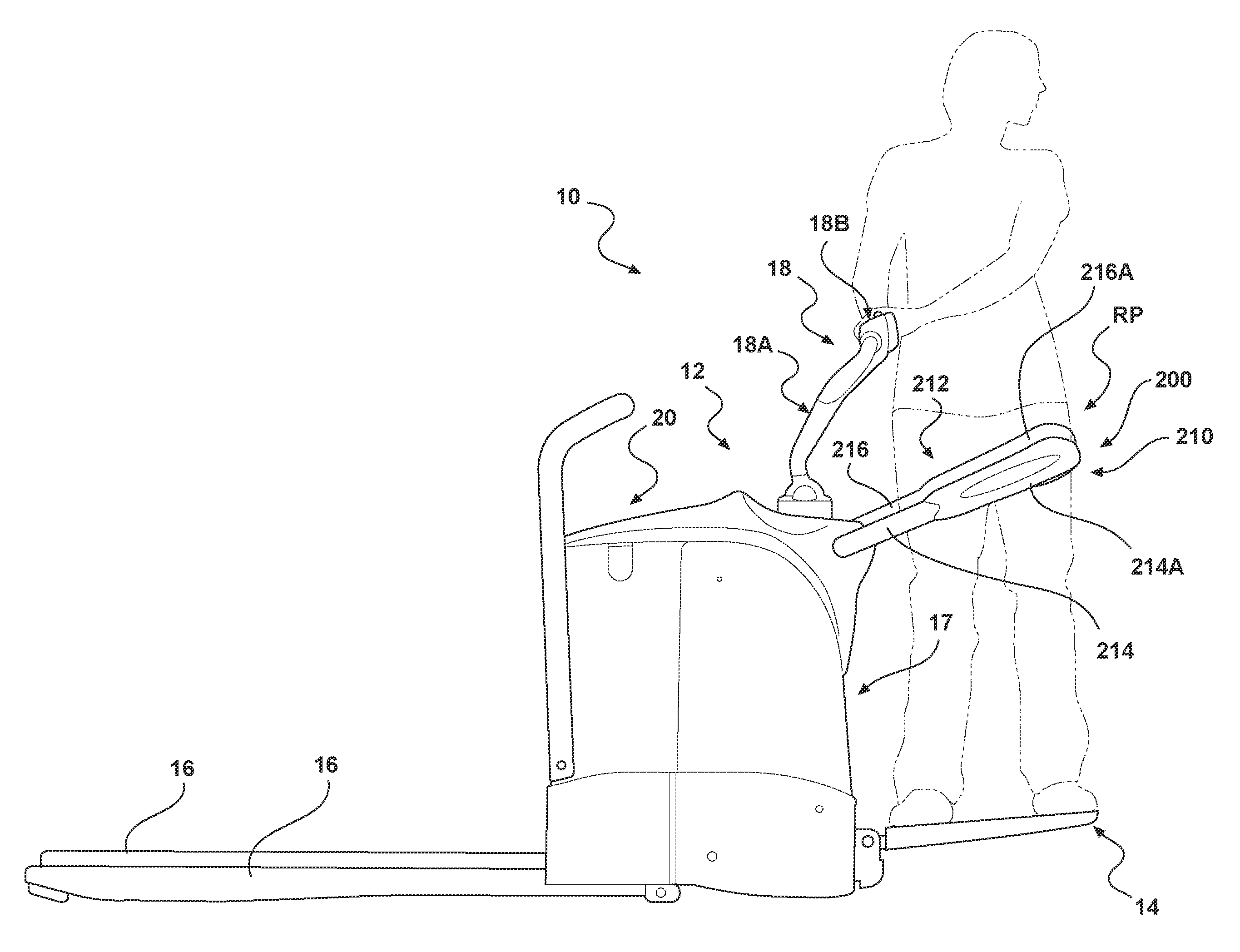

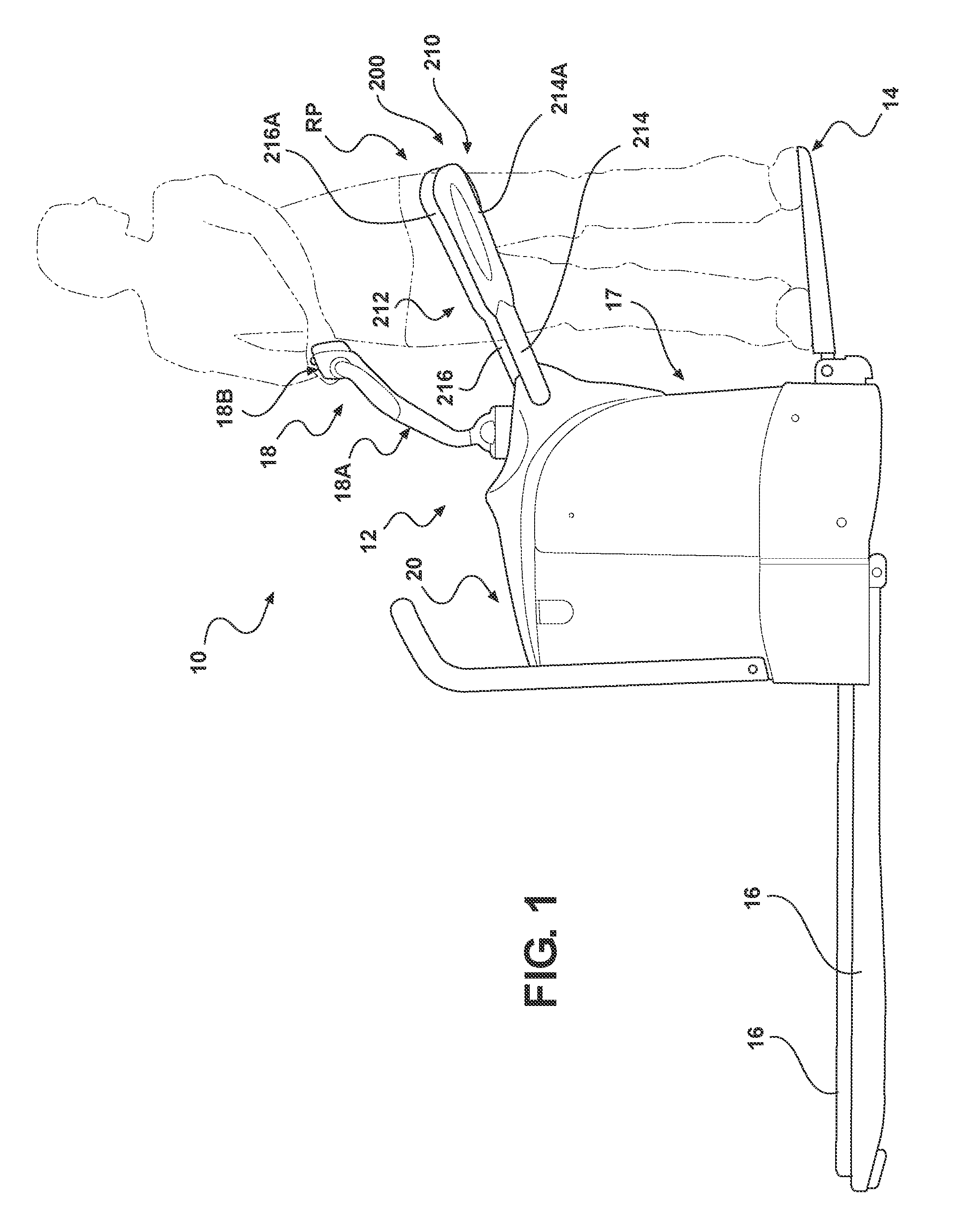

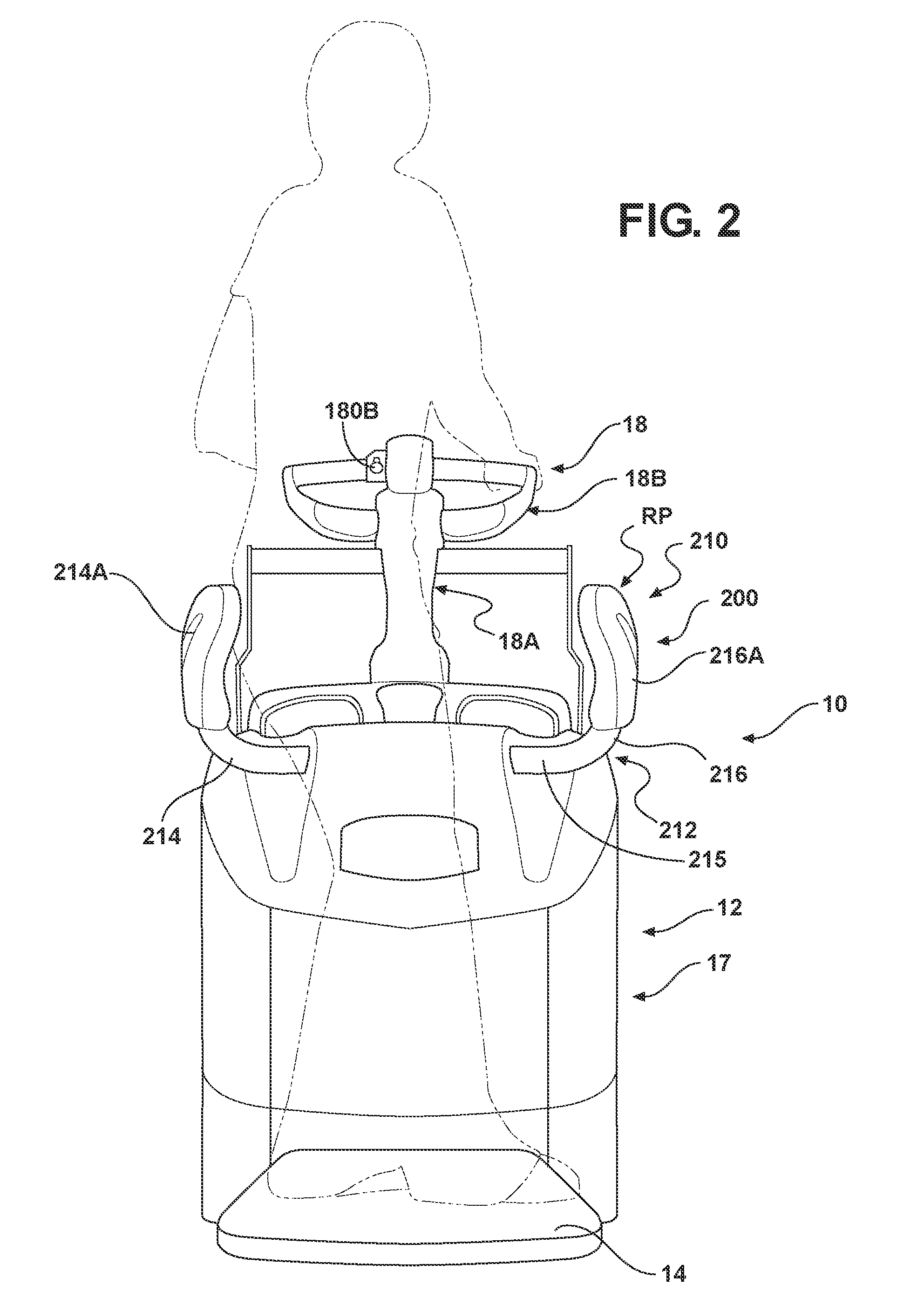

Restraint system for walkie/rider pallet truck

A walkie / rider pallet truck is provided comprising a power unit; a set of forks associated with the power unit; a platform associated with the power unit and defining a location upon which an operator may stand; and a restraint system comprising a pivotable restraint structure. The restraint structure is movable to one of a walkie position, a rider-driving position and a quick-exit position.

Owner:CROWN EQUIP CORP

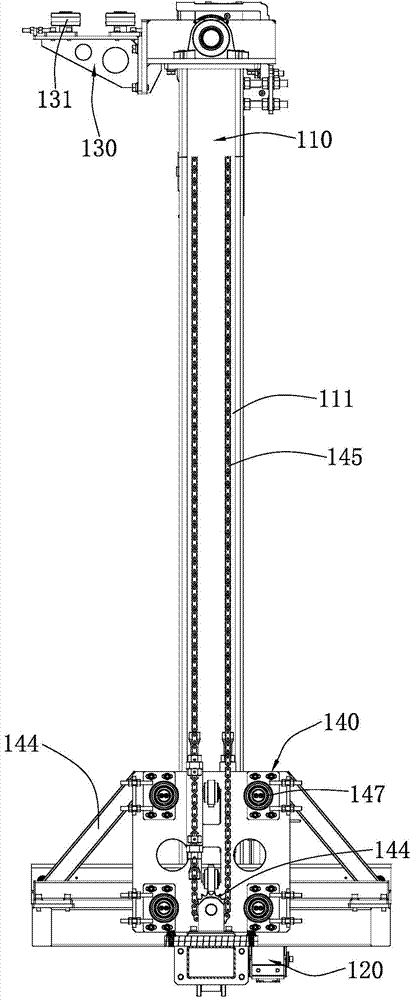

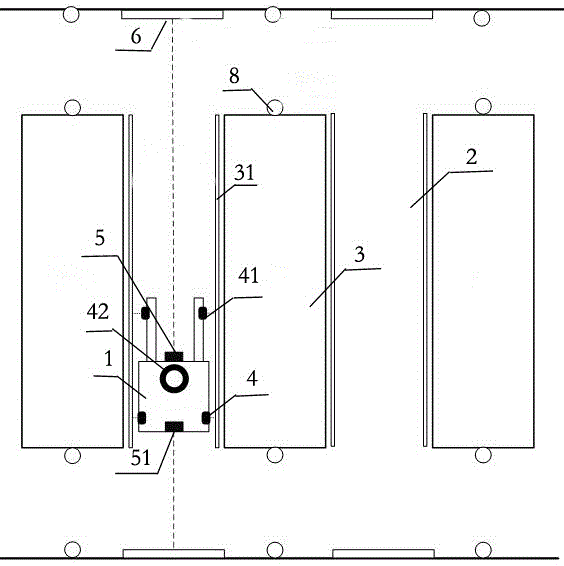

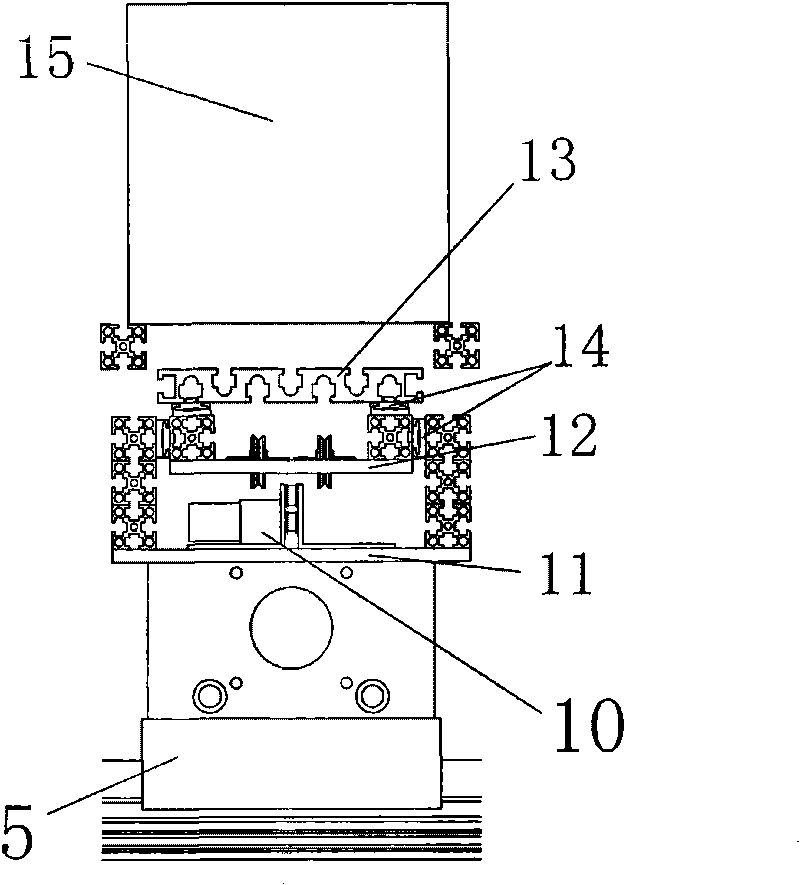

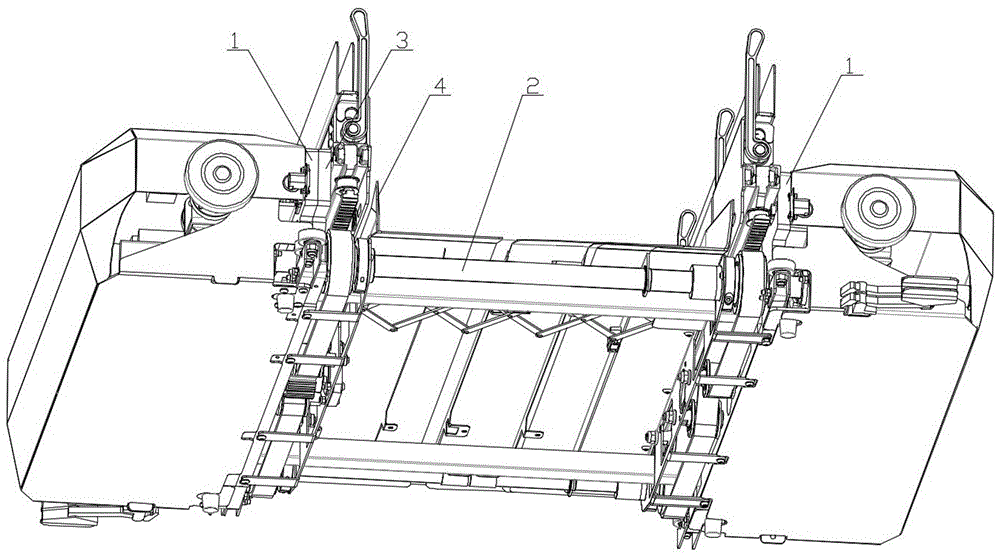

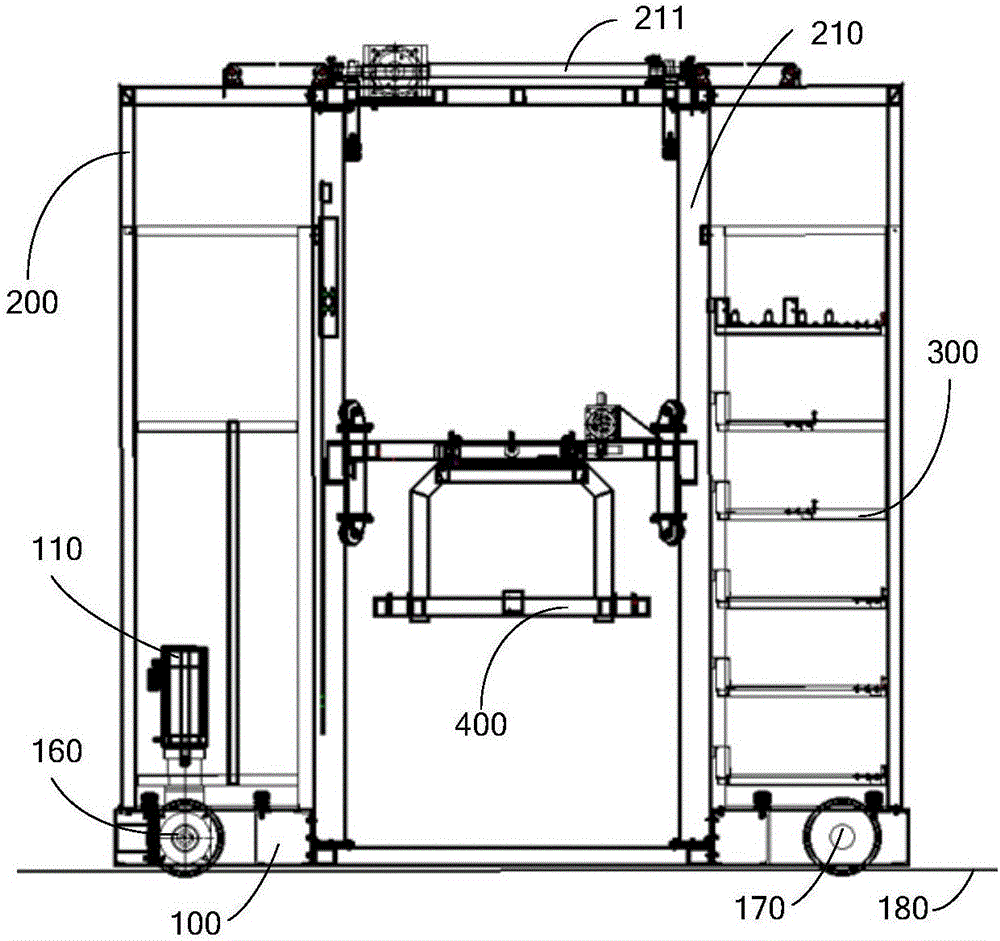

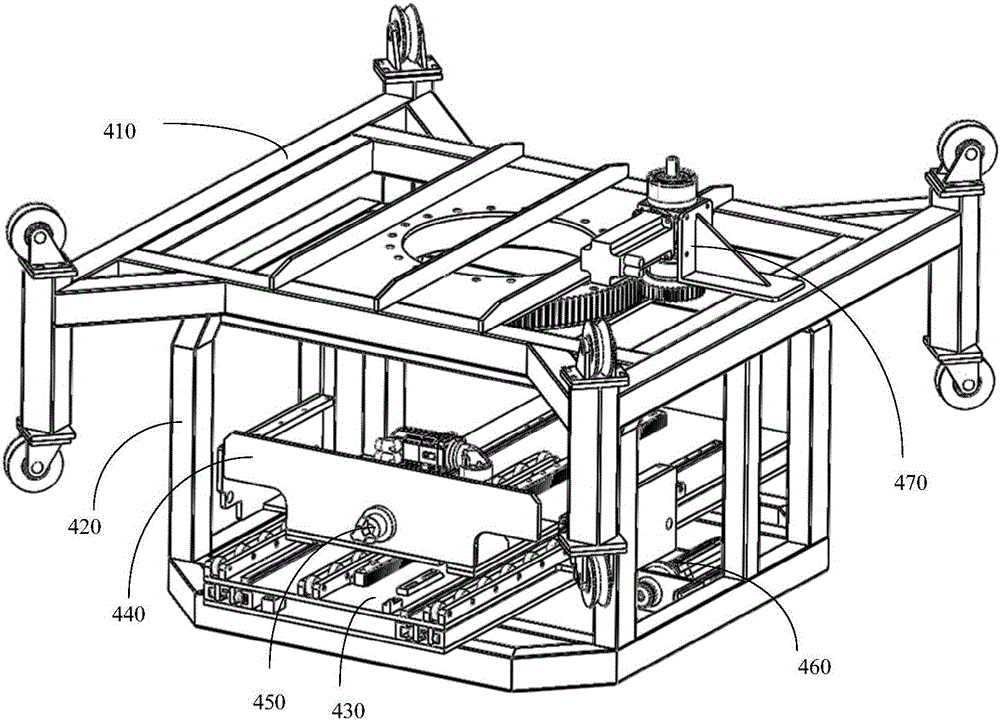

Stacking device and battery replacement apparatus

ActiveCN104773139ASmooth liftSafe and reliableElectric propulsion mountingVehicle servicing/repairingEngineeringSprocket

The invention relates to a stacking device and a battery replacement apparatus. The stacking device comprises a frame, a stacking walking mechanism, a hoisting mechanism and a fork mechanism, wherein the stacking walking mechanism comprises a walking motor and walking wheels; the hoisting mechanism comprises a hoisting motor, a hoisting drive sprocket wheel, a hoisting tensioning sprocket wheel, a hoisting chain and a tray assembly; the hoisting motor is mounted on the frame; the hoisting drive sprocket wheel is connected with the hoisting motor; the hoisting tensioning sprocket wheel is arranged on the frame; the hoisting chain is arranged on the hoisting drive sprocket wheel and the hoisting tensioning sprocket wheel in drive and sleeving manners; the tray assembly is fixed with the hoisting chain; the fork mechanism comprises a fork motor, a fork gear, a fork gear rack and a fork plate; the fork gear rack is meshed with the fork gear; the fork plate is fixed with the fork gear rack. By arranging the stacking walking mechanism, the hoisting mechanism and the fork mechanism, which cooperate with one another, the stacking device can be used for realizing picking and placing operations carried out on an object, and is compacter in structure. In addition, compared with a conventional drive structure, the hoisting mechanism is smoother in going up and down and more reliable in safety performance.

Owner:SHENZHEN JINGZHI MACHINE

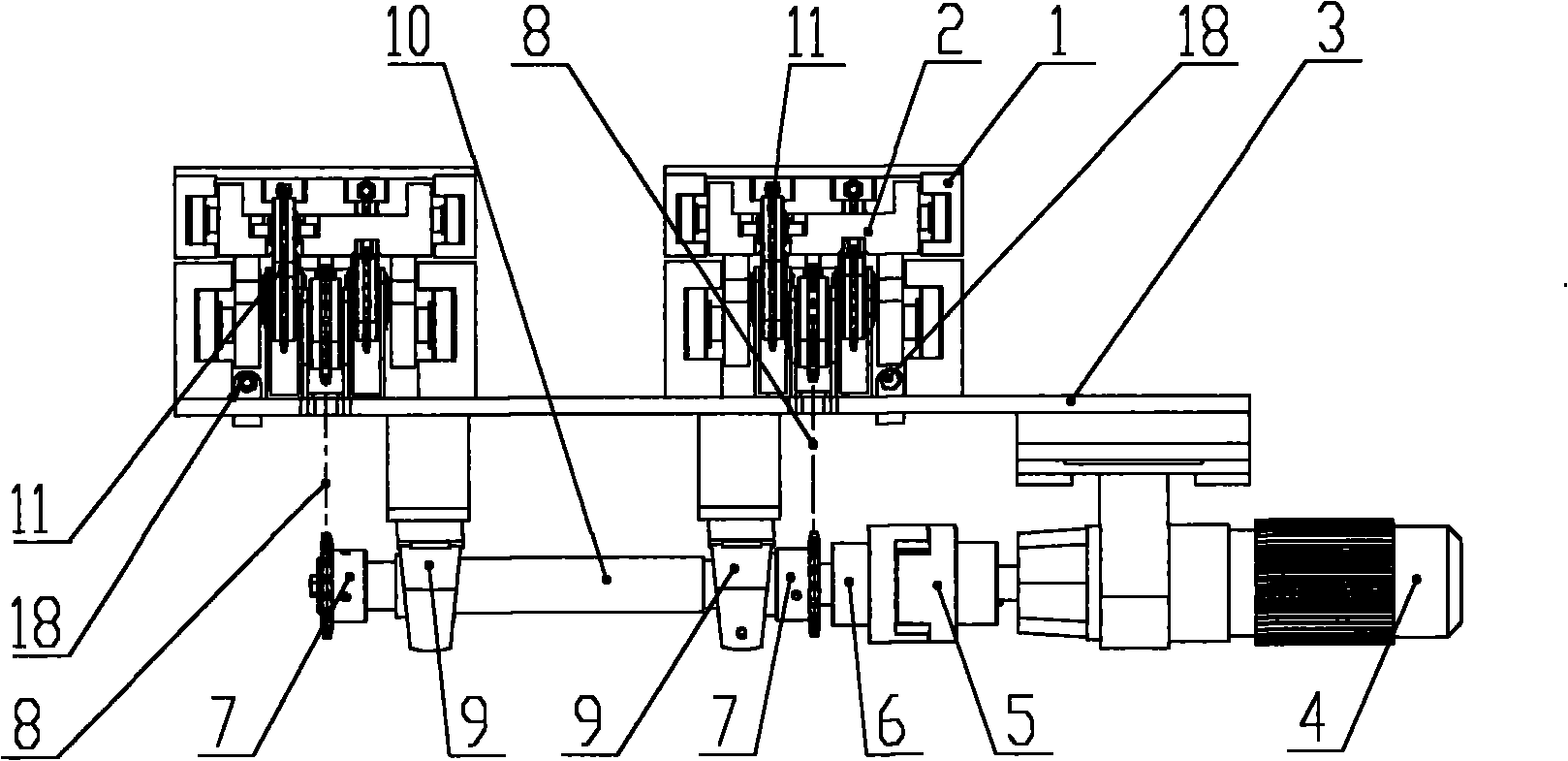

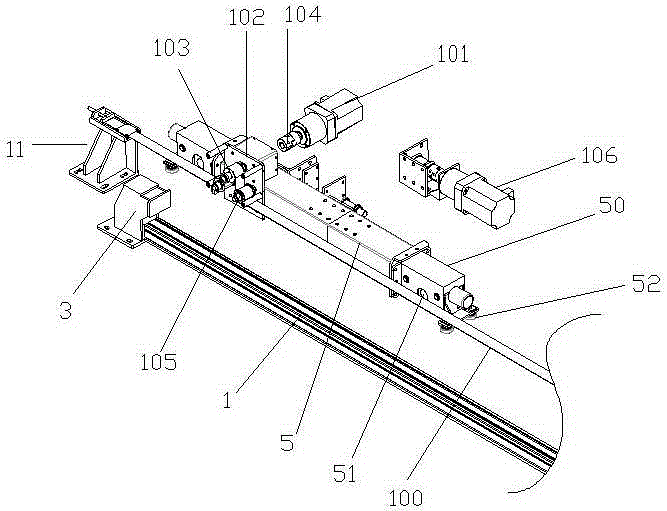

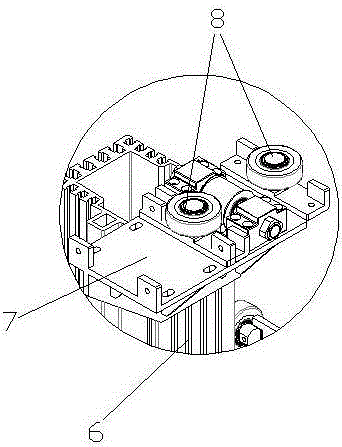

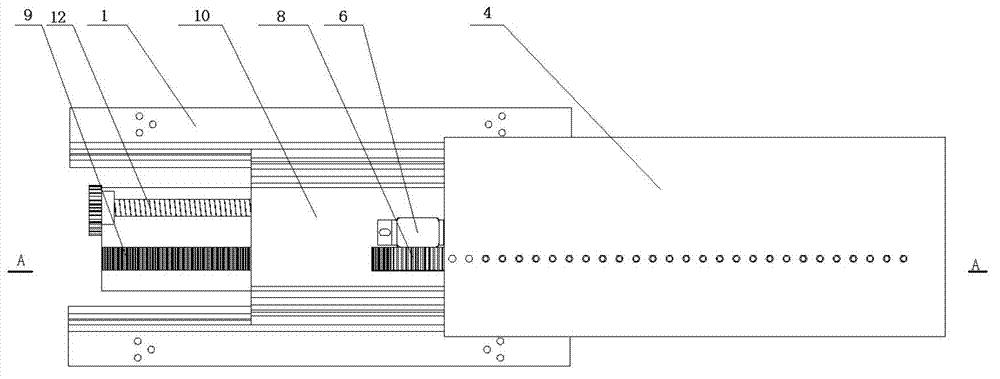

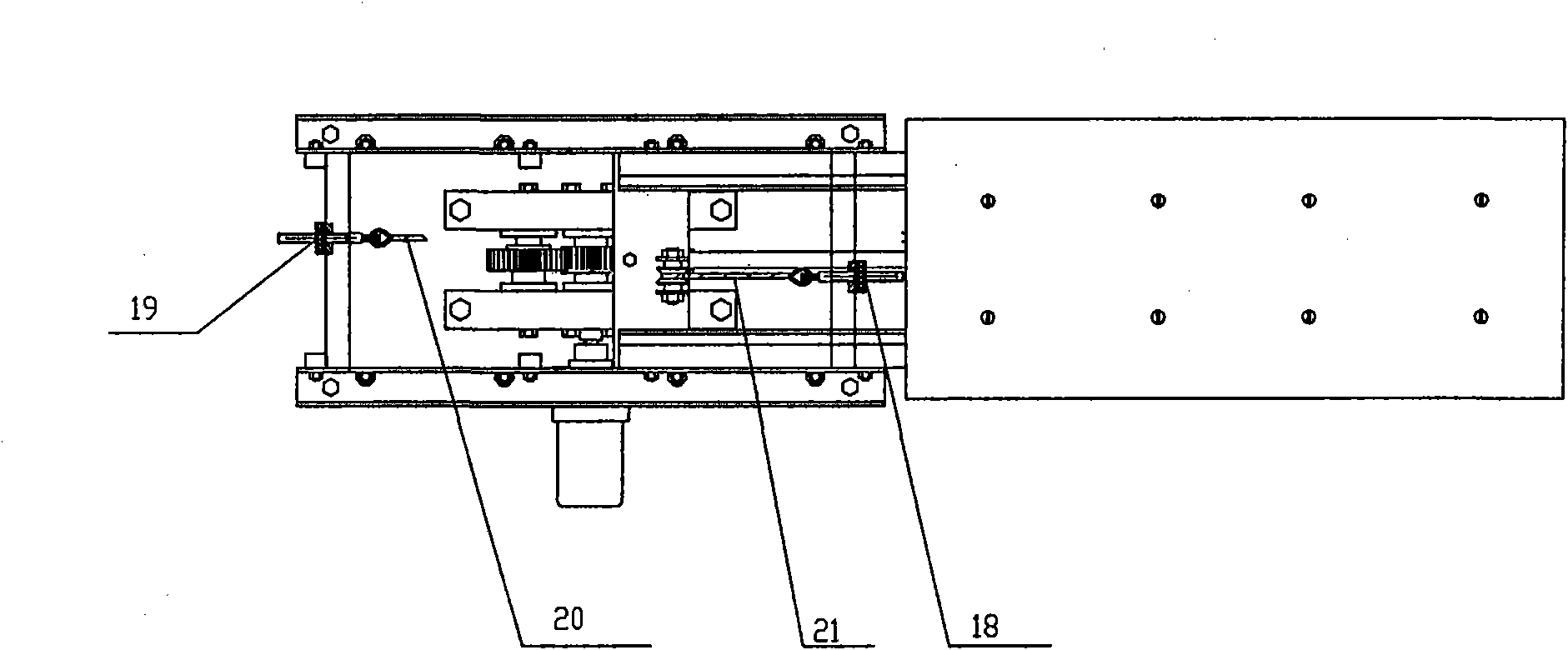

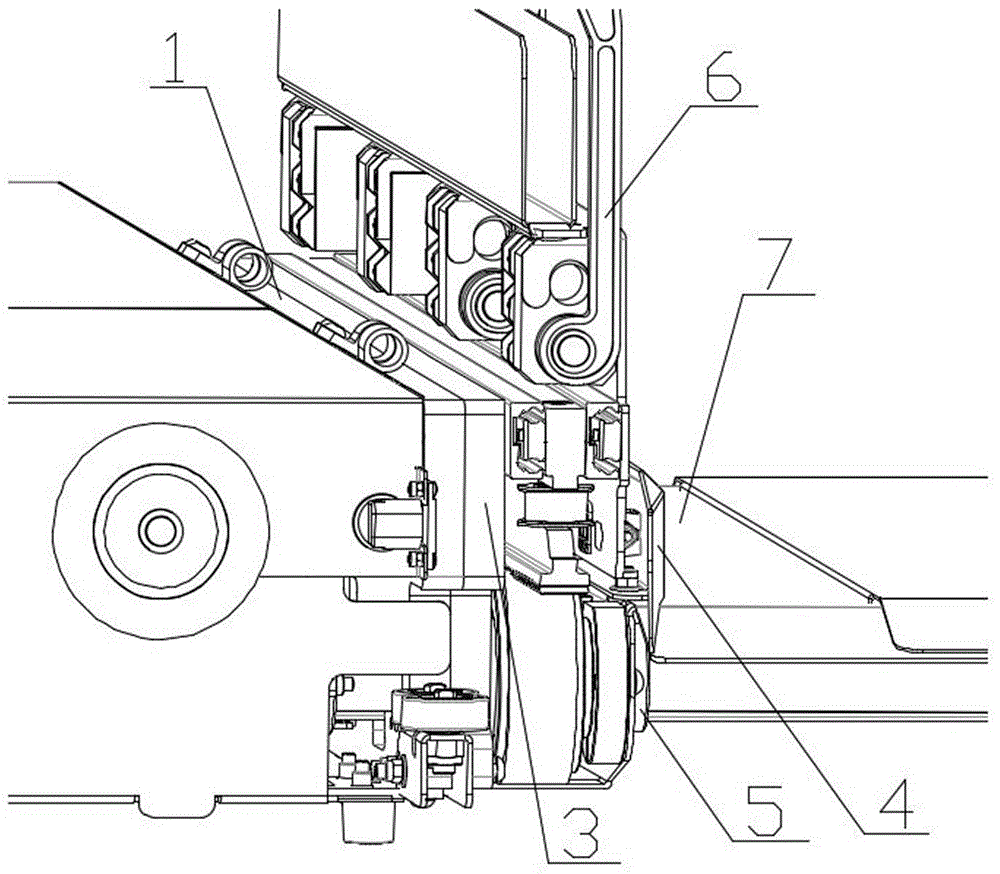

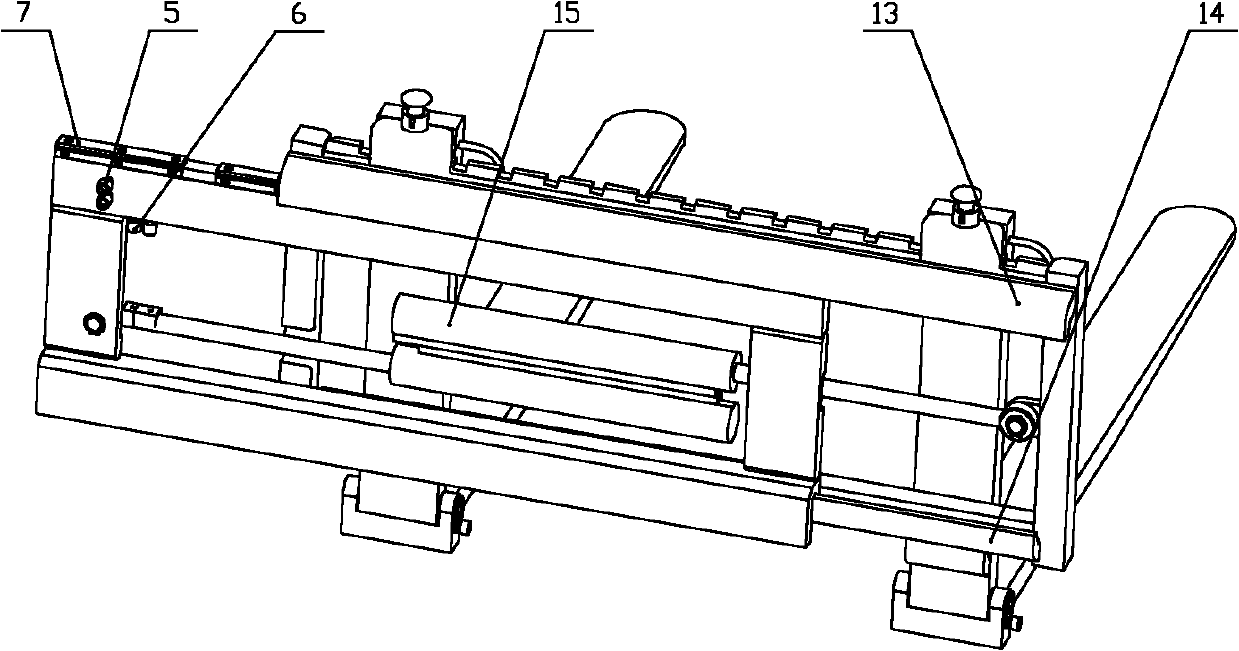

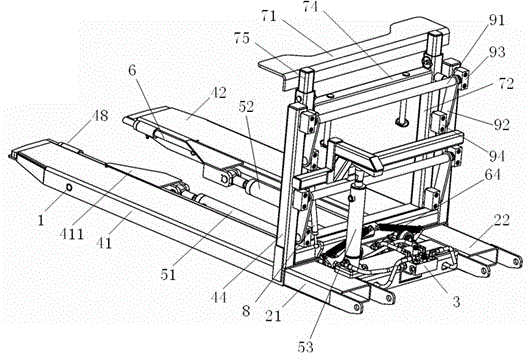

Light stacking robot pallet fork device

A light stacking robot pallet fork device comprises two middle forks connected through a middle fork connecting plate, lower portions of the two middle forks are respectively connected with a lower fork through a sliding rail structure, upper portions of the two middle forks are respectively connected with an upper fork through a sliding rail structure, and therefore the lower forks, the middle forks and the upper forks can slide in the same direction in a reciprocating mode. According to the light stacking robot pallet fork device, the upper forks, the middle forks and the lower forks are connected through linear sliding rails, therefore positioning precision of the pallet fork device is greatly improved, and meanwhile noise caused by gaps of rolling connection is effectively reduced. The light stacking robot pallet fork device ensures the fact that the extending length of the upper forks meets forking and conveying requirements, achieves differential connection of the pallet fork device, guarantees transmission stability, moving precision and the positioning precision, further reduces noise brought by transmission adopting a chain wheel device, reduces the structural size of the pallet fork device, reduces the weight of the pallet fork device, saves resources and energy, reduces noise pollution, and meanwhile improves working stability and production efficiency.

Owner:SHAANXI UNIV OF SCI & TECH

Tunnel automatic guide vehicle, guide system, and operating method for guide system

ActiveCN105974922AMinor changesImprove construction efficiencyPosition/course control in two dimensionsVehiclesAutomated guided vehicleLogistics automation

The invention relates to the field of logistics automation, and specifically relates to a tunnel automatic guide vehicle, a guide system, and an operating method for the guide system. The invention is implemented through the following technical scheme that the guide vehicle comprises a vehicle body and a pallet fork disposed on the vehicle body; the pallet fork is a bidirectional pallet fork which can stretch out in two directions along the width of the vehicle body or is a three-direction pallet fork which can stretch out in two directions along the width of the vehicle body and also can stretch out towards the front of the vehicle body. The vehicle body is provided with a path guide device which is used for guaranteeing the traveling path of the vehicle, and a positioning device which is used for the positioning of the vehicle. The objective of the invention lies in providing the vehicle, the guide system and the operating method for the guide system. Parallel guide rails in a tunnel are used for achieving the linear traveling in the tunnel, and the reconstruction cost of a cabin is low. The vehicle comprises the positioning device, so the positioning is precise.

Owner:上海诺力智能科技有限公司 +1

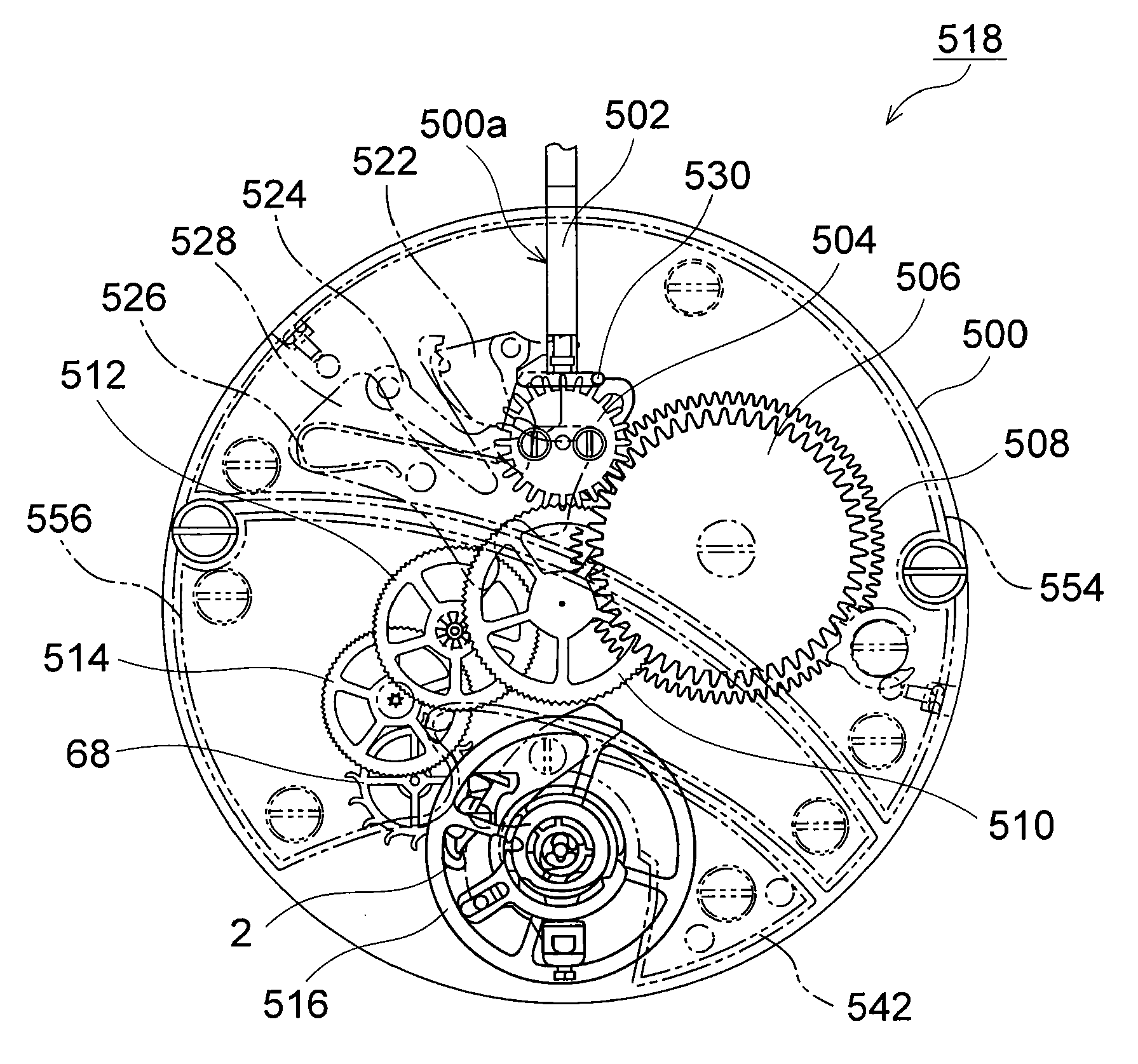

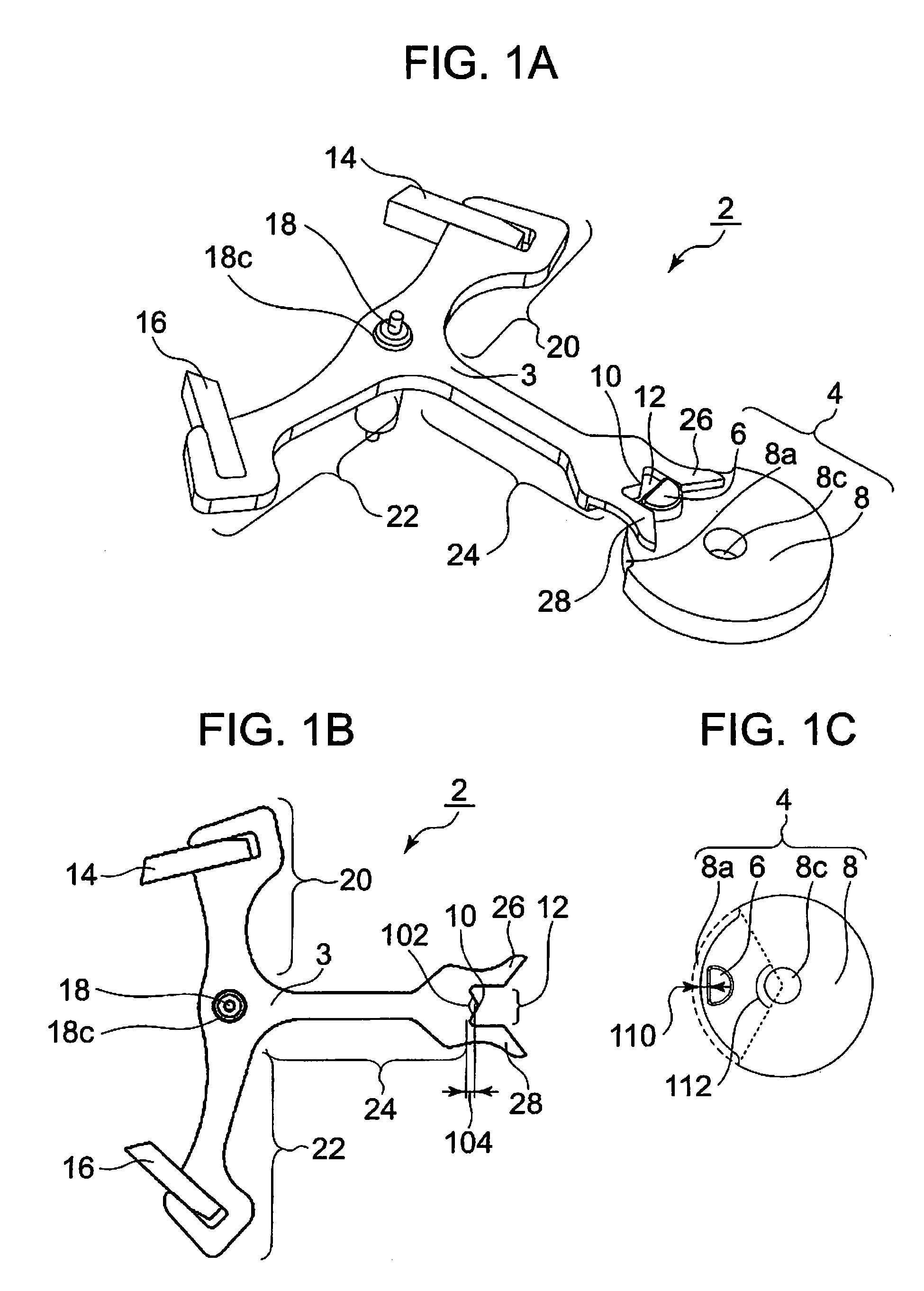

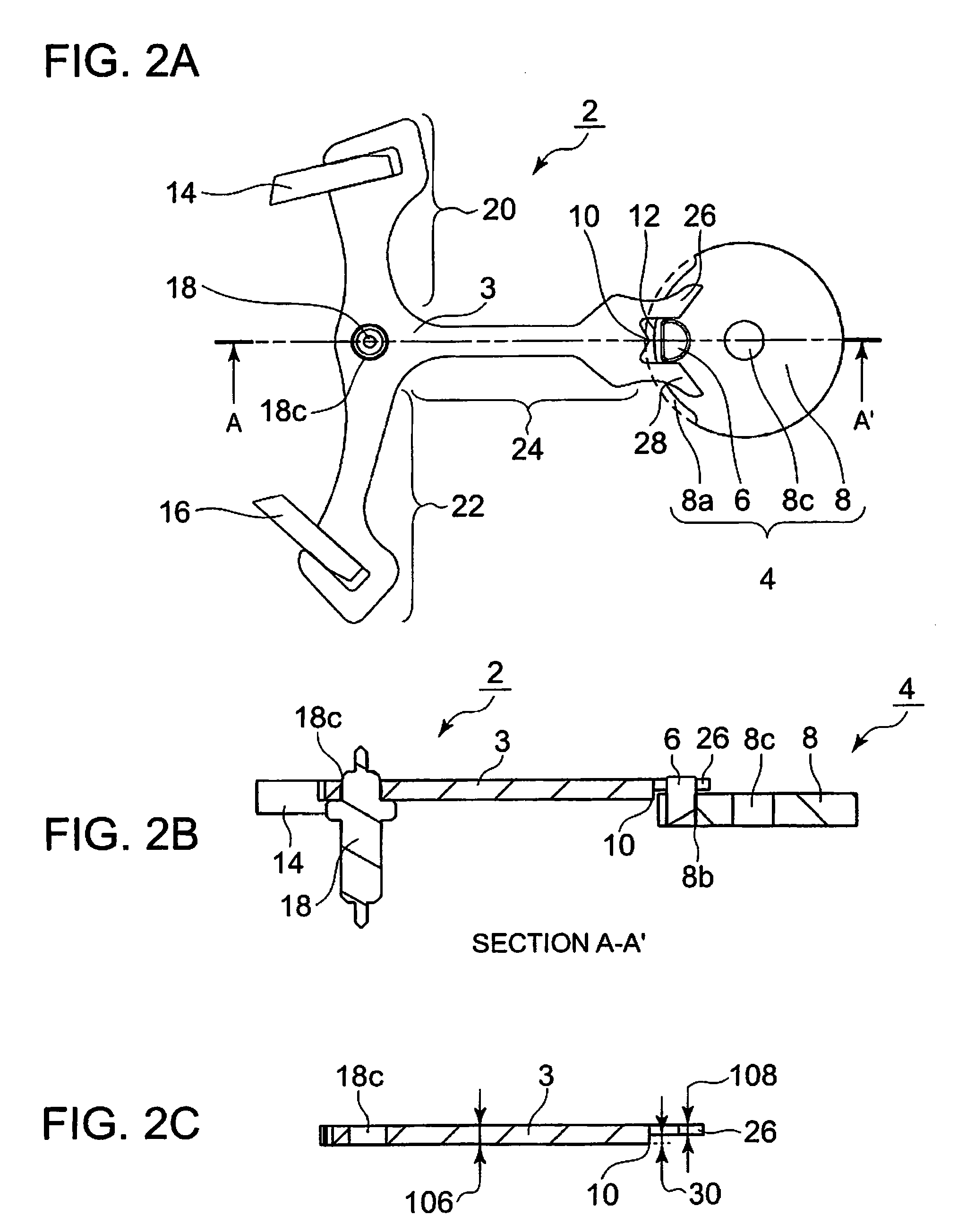

Escapement governor, mechanical watch, pallet fork (incomplete) manufacturing method, and roller manufacturing method

ActiveUS20100208555A1Improve accuracyReduce thicknessEscapementsPhotomechanical exposure apparatusMechanical watchCounter rotation

Disclosed are an integrally molded type pallet fork (incomplete) with a safety pin and a roller table that are formed with high precision by a simple process, a thin escapement governor including the pallet fork (complete) and the roller table, and a method of manufacturing the pallet fork (complete) and the roller table. The pallet fork (complete) of the escapement governor includes a pair of entry horn and exit horn extending from the rotation axis of the pallet fork (complete) toward the rotation axis of a balance with hairspring and adapted to transmit the power of an escape wheel to an impulse pin; and a safety pin which is provided in a side surface of the pallet fork (complete) between the pair of entry horn and exit horn, which extends from the rotation axis of the pallet fork (complete) toward the rotation axis of the balance with hairspring, which is situated at a position nearer to the rotation axis of the pallet fork (complete) than the pair of entry horn and exit horn, which enters a passing hollow to thereby cause the pallet fork (complete) to make normal rotation or reverse rotation with respect to the rotation axis of the pallet fork (complete), and which abuts a portion of a roller other than the passing hollow to thereby prevent erroneous rotation of the pallet fork (complete); and the roller is formed in a single layer.

Owner:SEIKO INSTR INC

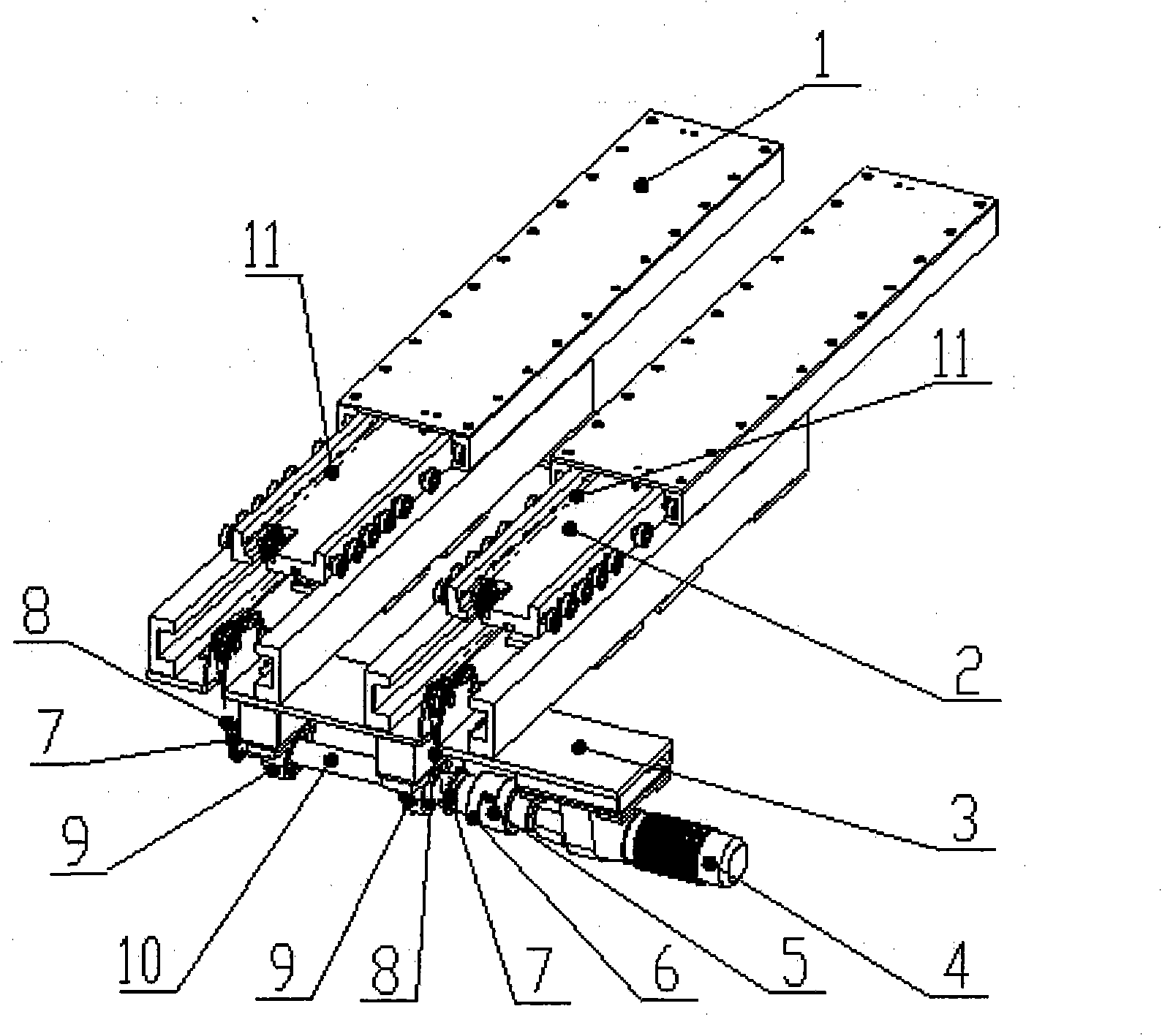

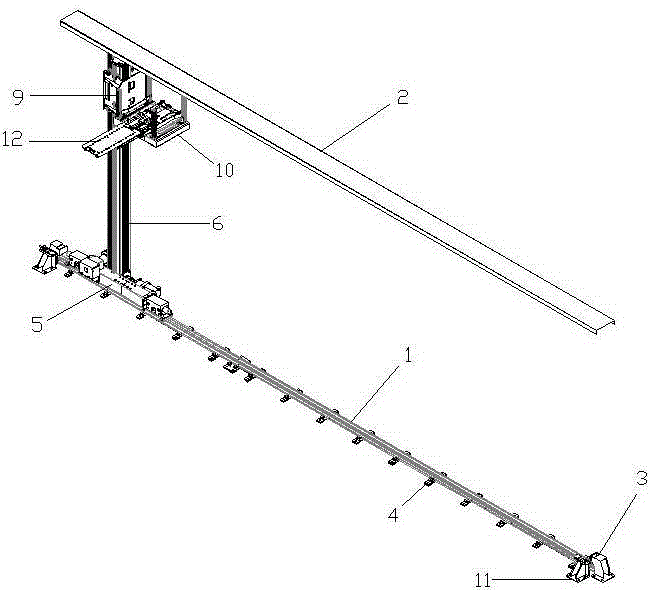

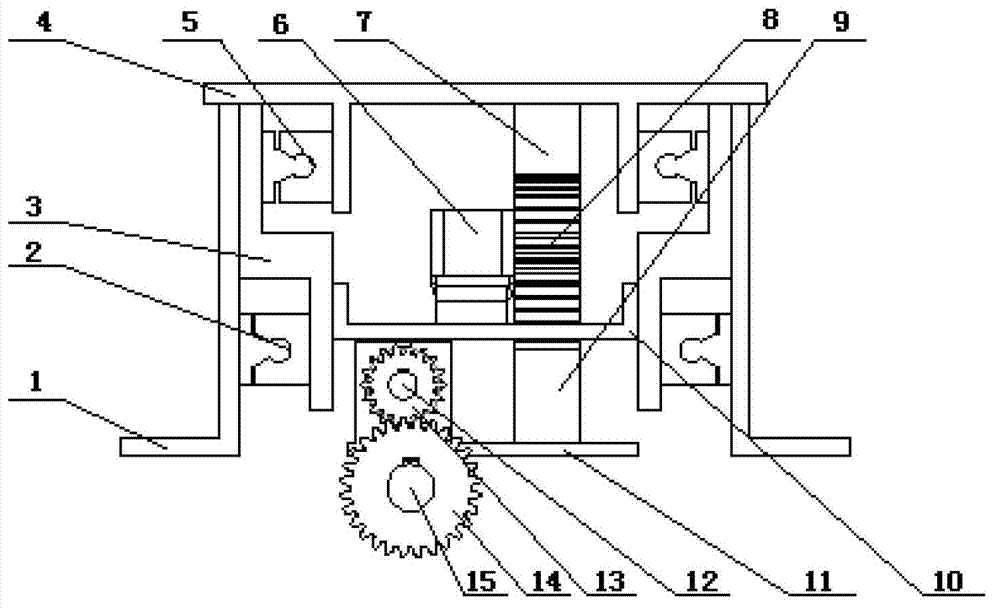

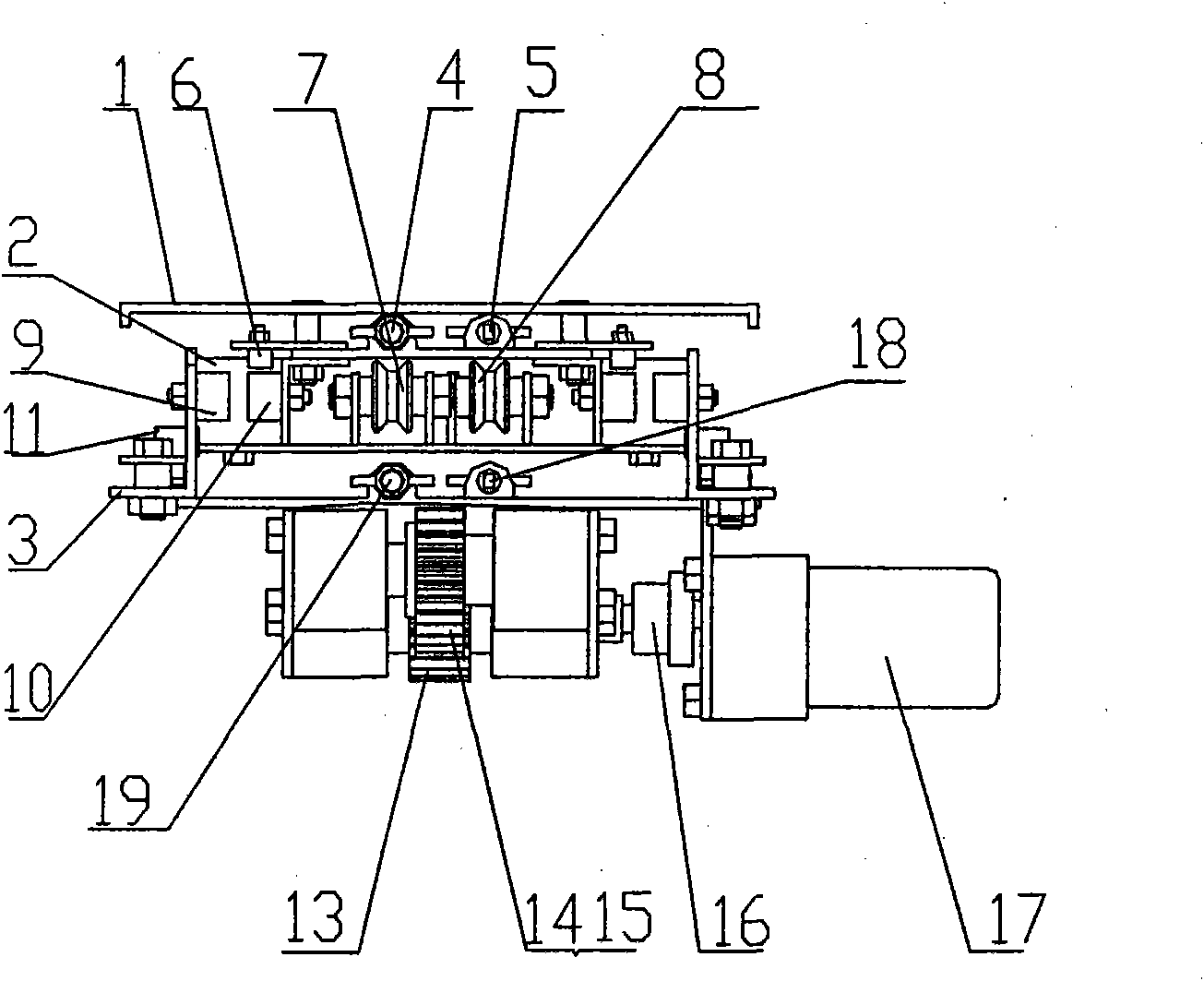

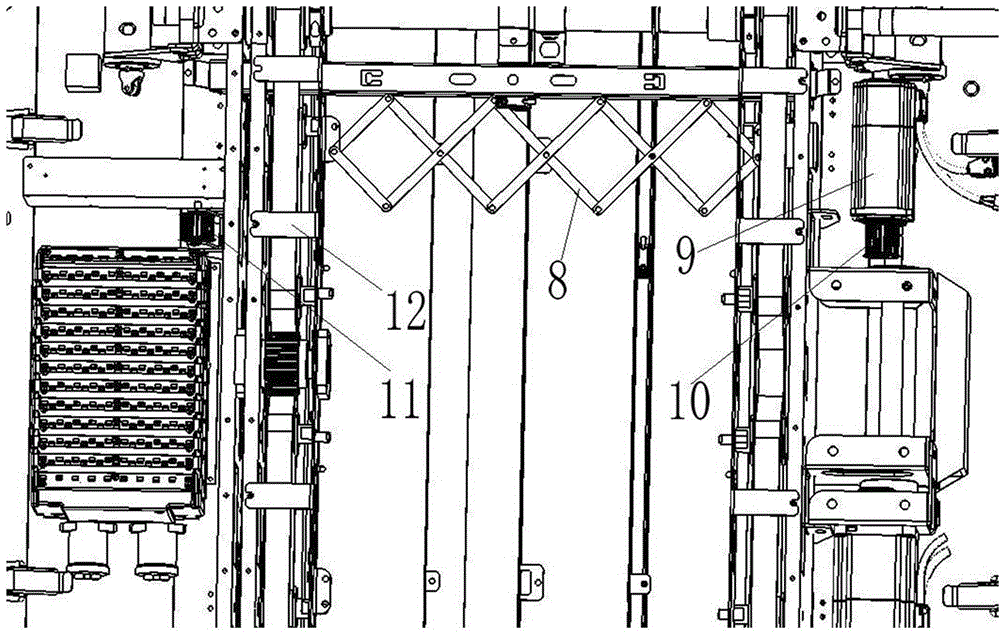

Light bidirectional fork for stacker

The invention relates to a light bidirectional fork for a stacker, and belongs to an laminated-structure stacker fork. The invention mainly solves the technical problem that the conventional stacker fork is unreasonable in structure, heavy in self weight, large in occupied space, inconvenient to install and regulate, and difficult to machine and manufacture. In order to solve the technical problem, the invention adopts the following technical scheme: the light bidirectional fork for the stacker comprises an upper fork, a middle fork, a lower fork, a steel wire rope, a steel wire rope regulator, a middle fork roller, an upper fork guiding bolt bearing, a middle fork guide bolt bearing, a middle fork transmission rack, a lower fork transmission gear, a coupler, and a motor. The upper fork, the middle fork and the lower fork form a three-layer laminated structure, the motor is connected with a gear shaft through the coupler and drives the lower fork gear, the lower fork gear makes the middle fork move leftwards and rightwards through the middle fork transmission rack, and the leftward and rightward movement of the middle fork drives the upper fork to move leftwards and rightwards through the middle fork roller and the steel wire rope.

Owner:GUANGXI UNIV

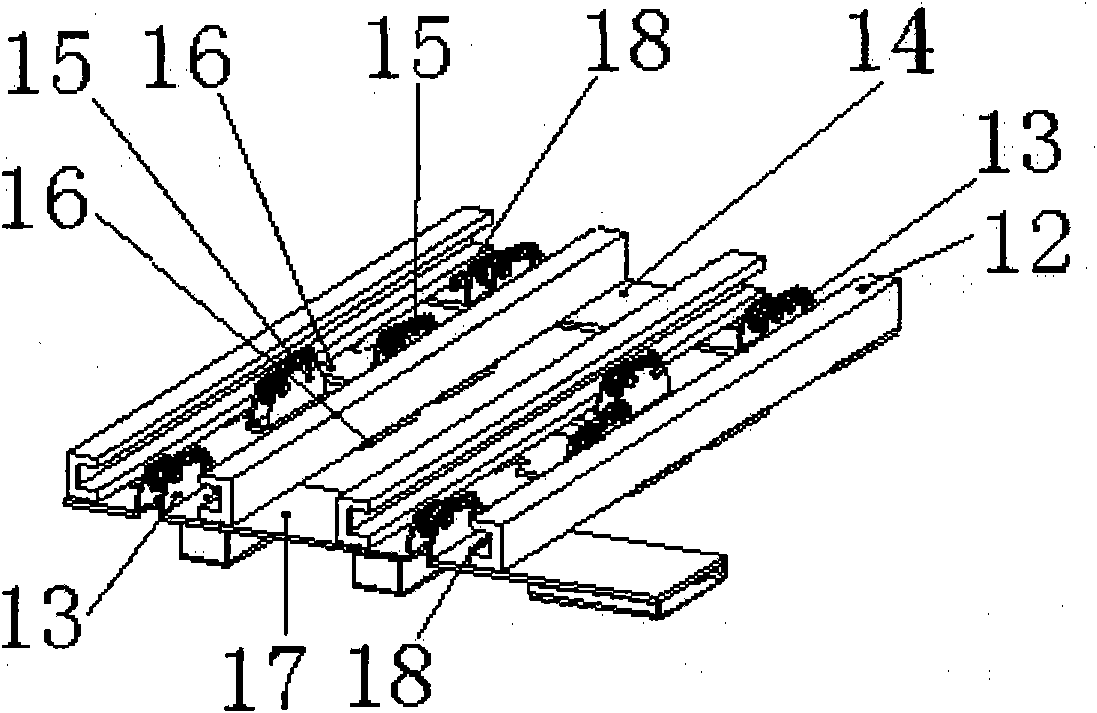

Fork mechanism of stacker

The invention discloses a stacker fork mechanism which comprises a bearing mechanism and a fork mechanism. The fork mechanism further comprises a lower fork, a middle fork and an upper fork, wherein the bearing mechanism and the lower fork are both fixed on a beam of a stacker. When the stacker runs to a designated goods location, bearing steel rails are driven by a reducing motor A to translate toward a shelf to be accurately abutted with the steel rails on the shelf. Then the middle fork moves on the steel rail of the lower fork; a telescopic shaft of the upper fork is extended out to seize the flanges of the wheels of a bogie and push the bogie toward the shelf so as to complete the storage operation. When the operation is completed, the bearing steel rails on a loading platform translate inversely to an original position on the loading platform. The fork mechanism pushes the bogie to move and bears the gravity load of the bogie through the bearing steel rails, thereby bringing about a simple structure and light mass for telescopic forks. The motion and storage is realized through the running of the wheels of the bogie, thereby saving the cost for a special-purpose pallet.

Owner:BEIJING CTROWELL INFRARED TECHN

Clamping device for forklift

The invention discloses a clamping device for a forklift. The clamping device comprises a fork bracket, wherein the two sides of the fork bracket are movably connected with clamping devices; the clamping device comprises a first mechanical arm, a second mechanical arm, a first cylinder, a second cylinder and a PLC; one end of the first mechanical arm is movably connected with the fork bracket, and the other end of the first mechanical arm is movably connected with one end of the second mechanical arm; the other end of the second mechanical arm is movably connected with a pressing wheel; the fixed end of the first cylinder is movably connected with the fork bracket; the movable end of the first cylinder is movably connected with the first mechanical arm; the fixed end of the second cylinder is movably connected with the first mechanical arm; the movable end of the second cylinder is movably connected with the second mechanical arm; and the first cylinder and the second cylinder are both in signal connection with the PLC. The clamping device can realize the goods clamping in the use of the forklift to prevent goods from dropping in carrying to cause the damage, so that the potential safety hazard of hurting persons is reduced.

Owner:铜陵市精品工具模具有限责任公司

Positioning method of pallet fork

The invention discloses a positioning method of a pallet fork, and belongs to the field of logistic device control methods. According to the positioning method, at least one linear positioning device is arranged on a forklift, the bottom of a tray is positioned through linear waves emitted by the linear positioning devices, and therefore the position and the posture of the tray relative to the forklift are determined. By means of the positioning method, fork holes can be rapidly positioned, misoperation can be effectively eliminated, and the safety of the tray lifting process and the tray transport process can be improved.

Owner:上海诺力智能科技有限公司 +1

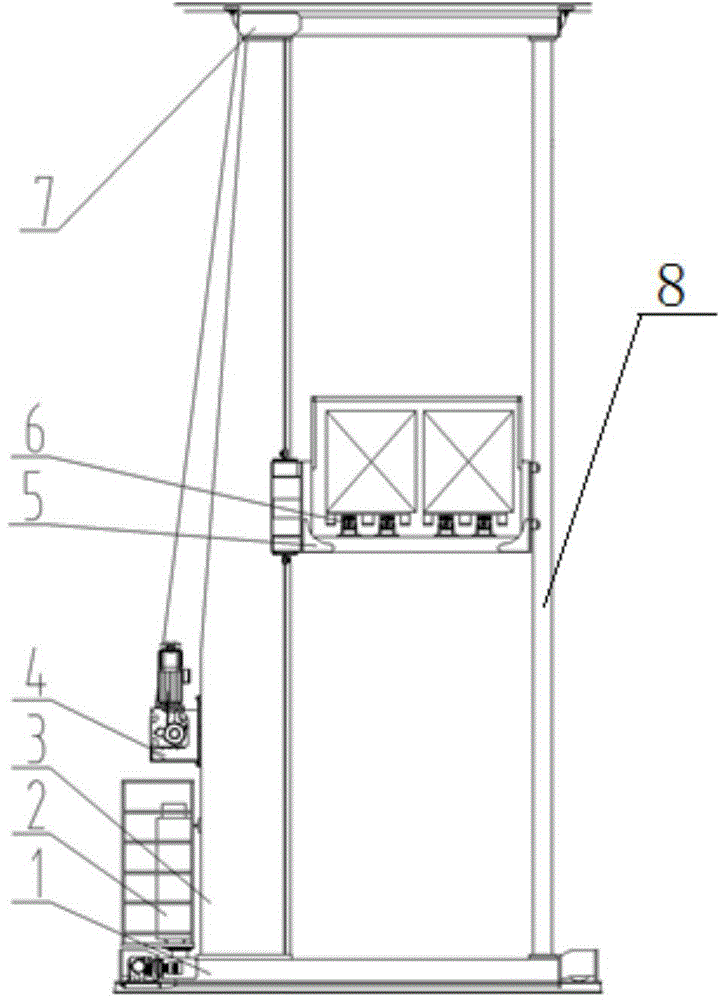

Double pallet fork rectangular coordinate robot stereoscopic warehouse

InactiveCN101712404AImprove operational efficiencyLots of homeworkLifting devicesStorage devicesKinematicsRectangular coordinates

The invention discloses a double pallet fork rectangular coordinate robot stereoscopic warehouse. The warehouse comprises multilayer goods shelves, a stacking crane kinematic system and a stock in / out mechanism, wherein the goods shelves are arranged in a single-roadway double-row goods shelves manner, the stacking crane kinematic system comprises vertical beams arranged on the two ends of the roadway, cross beams arranged between the vertical beams and a stacking crane, the two ends of each cross beam are separately latched on the vertical beams and slide vertically along the axial direction of the vertical beams, the cross beams are provided with over two stacking cranes and a crane driving mechanism, and the crane driving mechanism drives the stacking cranes to slide along the cross beams. The invention is also characterized in that the MCS structure in the current automatic stereoscopic warehouse can be changed and the number of the stacking cranes can be increased to significantly increase the overall operating efficiency of the warehouse and ensure the stability of the system in higher operating condition, thus the increase of the height of the stereoscopic warehouse can be realized.

Owner:于皓瑜

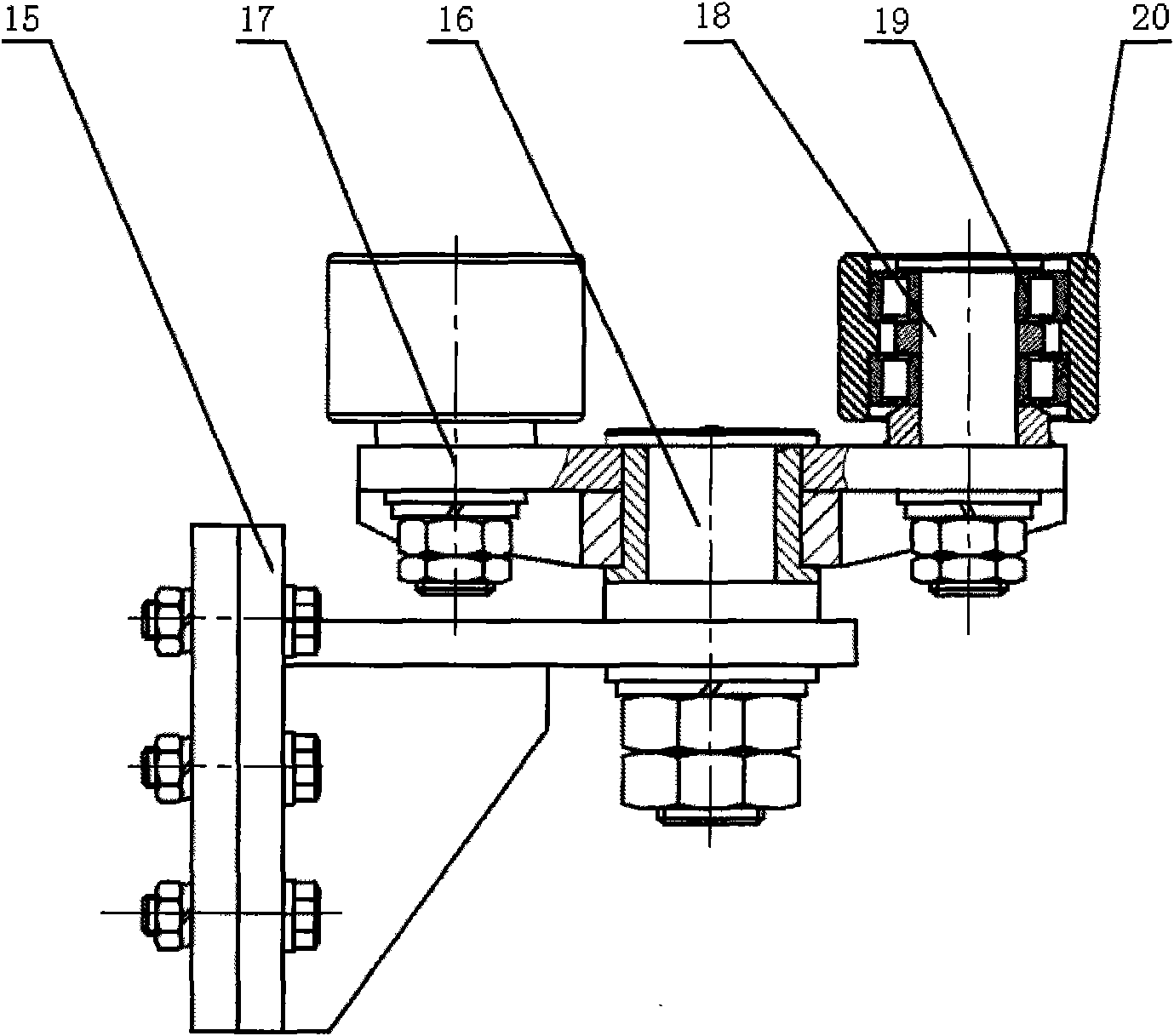

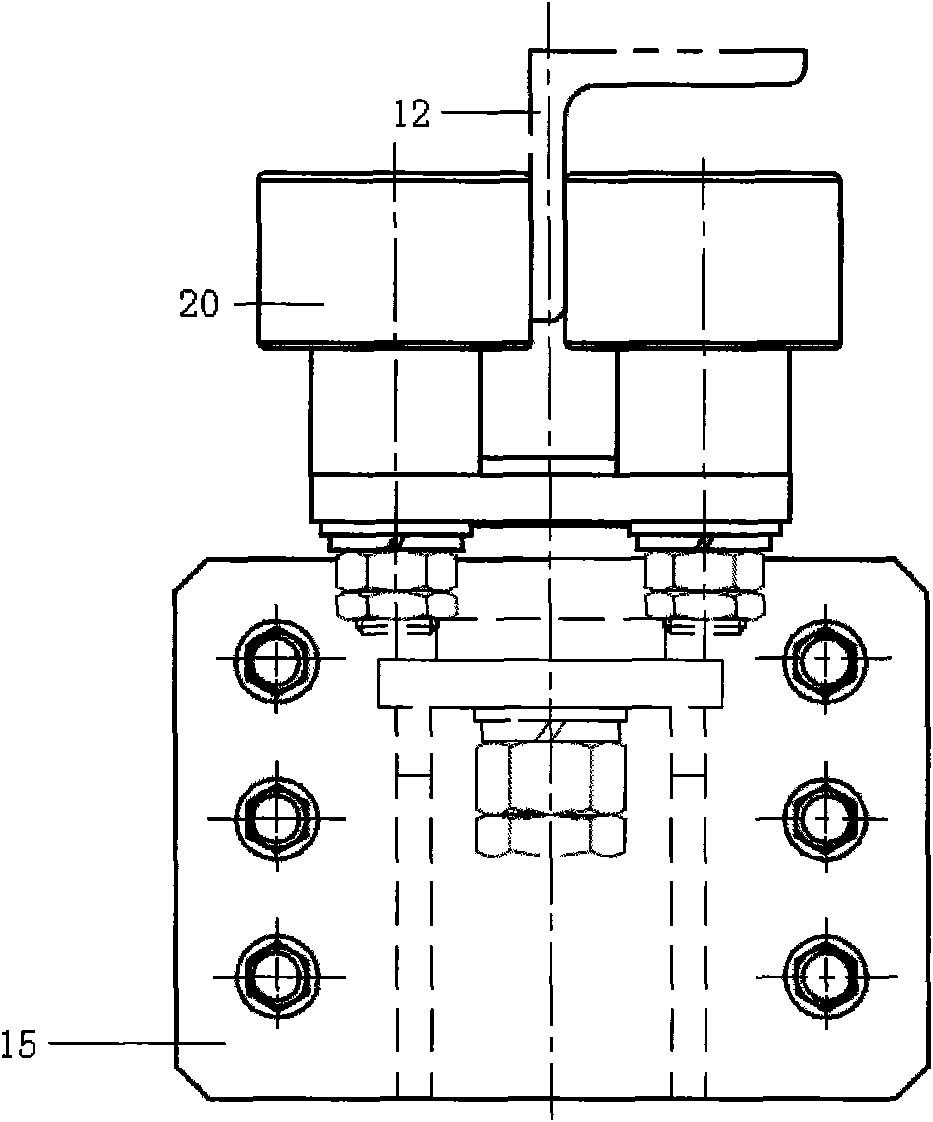

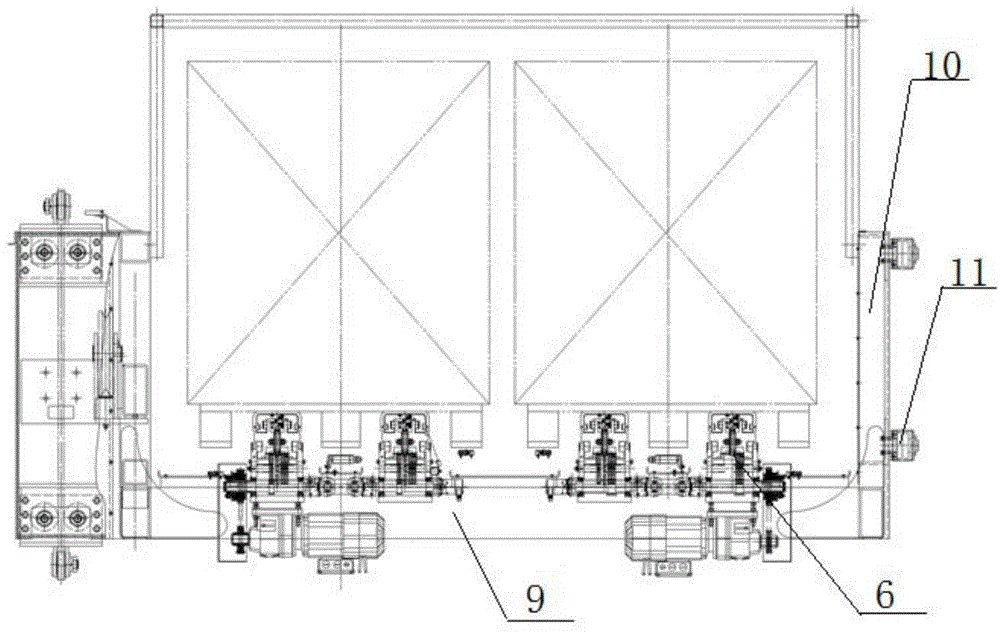

Railroad aisle stacking crane

ActiveCN104973540AImprove the efficiency of inbound and outboundImprove space utilizationLifting devicesWork cycleTransportation technology

The invention relates to the technical field of material storage and transportation, in particular to a railroad aisle stacking crane. The railroad aisle stacking crane comprises a traveling mechanism and a hoisting mechanism and a post mechanism which are arranged at the top of the traveling mechanism, and the traveling mechanism can drive the hoisting mechanism and the post mechanism to move in the horizontal direction; a double-goods-allocation carrying platform is horizontally arranged on the post mechanism and connected with the hoisting mechanism, and the hoisting mechanism can drive the double-goods-allocation carrying platform to move up and down along the post mechanism; two pairs of double deep forks are arranged on the double-goods-allocation carrying platform, and the double deep forks can do telescopic movement on the double-goods-allocation carrying platform. According to the railroad aisle stacking crane, the problems that in the prior art, the space utilization ratio is low due to the structure, one pallet of goods can only be fetched in one working cycle, and the efficiency is low are solved.

Owner:BEIJING MATERIALS HANDLING TECH INST CO LTD

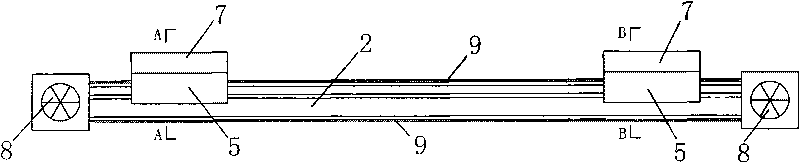

Width-adjustable shuttle vehicle

InactiveCN106628781AImprove versatilityImprove storage efficiencyPackagingStorage devicesEngineeringMechanical engineering

A width-adjustable shuttle vehicle comprises two outer fork plates which are located on the left side and the right side correspondingly and are parallel to each other, two parallel connecting rods, a walking mechanism, a movable outer fork plate and two parallel goods fork assemblies, wherein the two ends of each connecting rod are connected with the corresponding outer fork plate on the same side, and the two outer fork plates and the two connecting rods form a shuttle vehicle body of a rectangular structure; the walking mechanism is installed on the shuttle vehicle body, and is used for driving the shuttle vehicle body to move in the transverse direction; the movable outer fork plate is installed on the two connecting rods in a sliding manner through a sliding bearing; and one of the two parallel goods fork assemblies is installed on the movable outer fork plate, and the other one of the two parallel goods fork assemblies is installed on the corresponding outer fork plate on the other side. A movable outer fork plate driving mechanism drives the movable outer fork plate to move in the axial direction of the connecting rods, thus, the distance between the corresponding goods fork assembly fixed to the movable outer fork plate and the corresponding goods fork assembly fixed to the outer fork plate on the other side is adjustable, a goods fork of the shuttle vehicle is made to be applicable to goods cells in different specifications for taking and placing goods to be used, the universality of the shuttle vehicle is improved, and the commodity logistics storage and placement efficiency is improved.

Owner:SHANDONG LOGISTIC TECH CO LTD

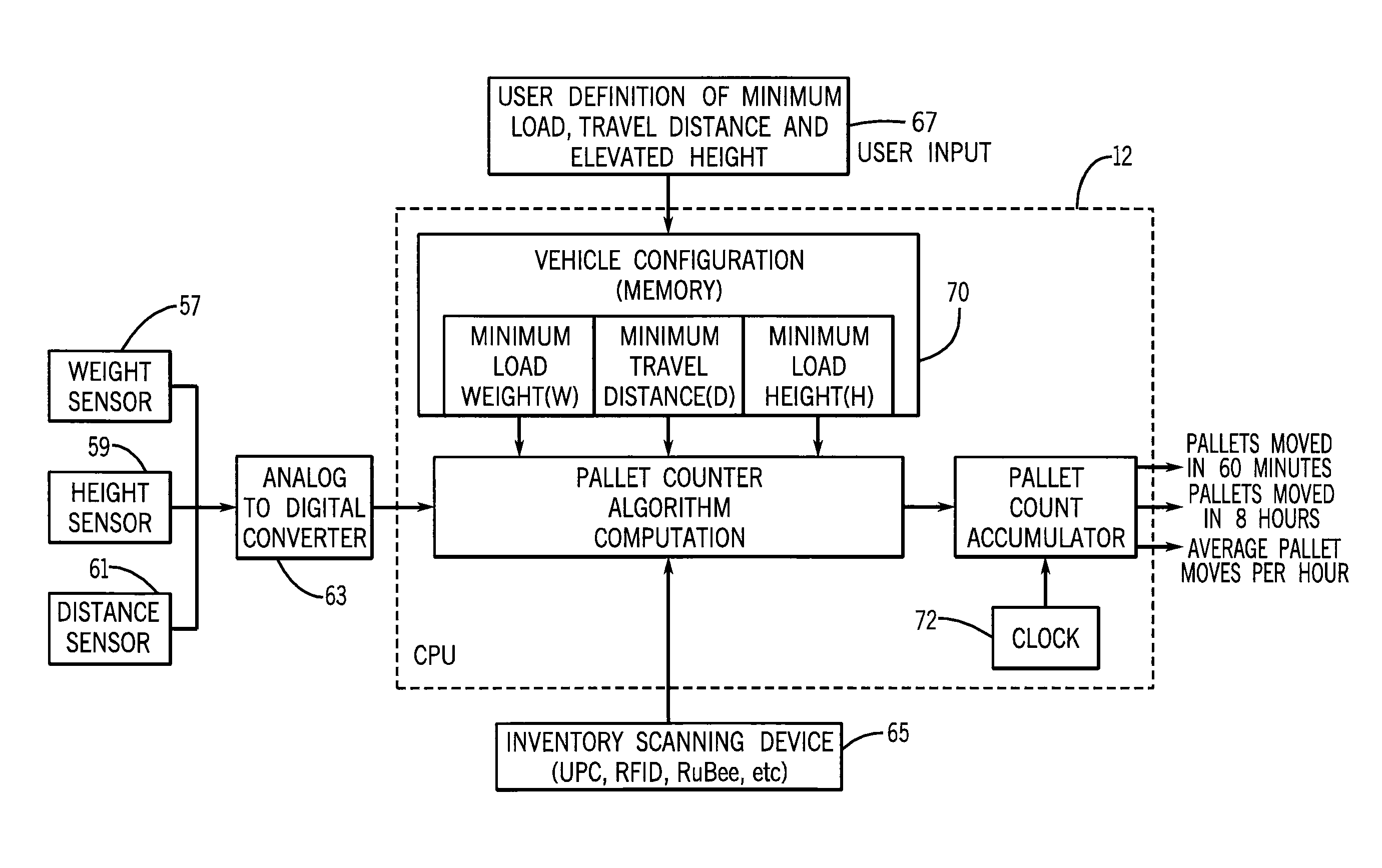

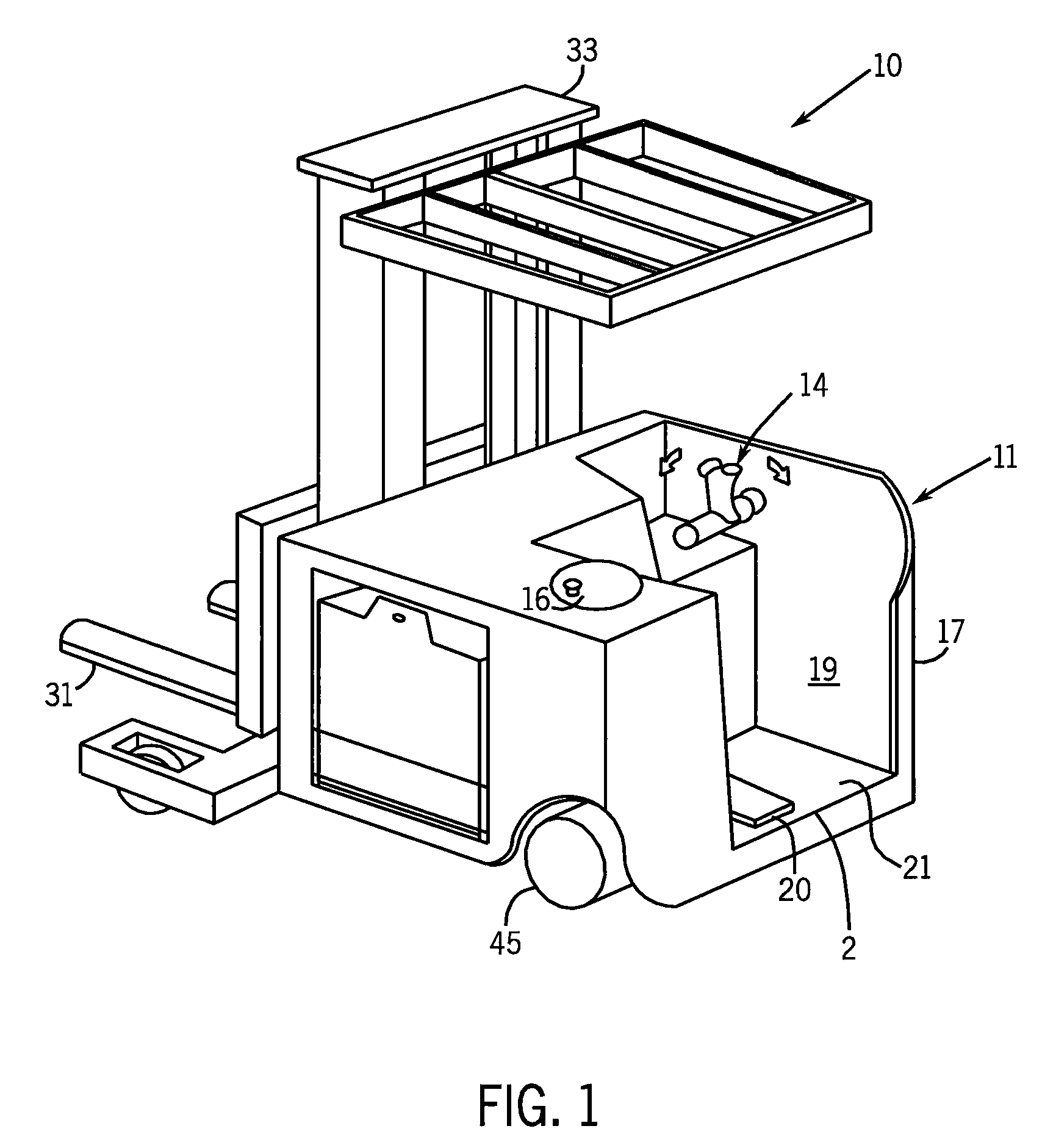

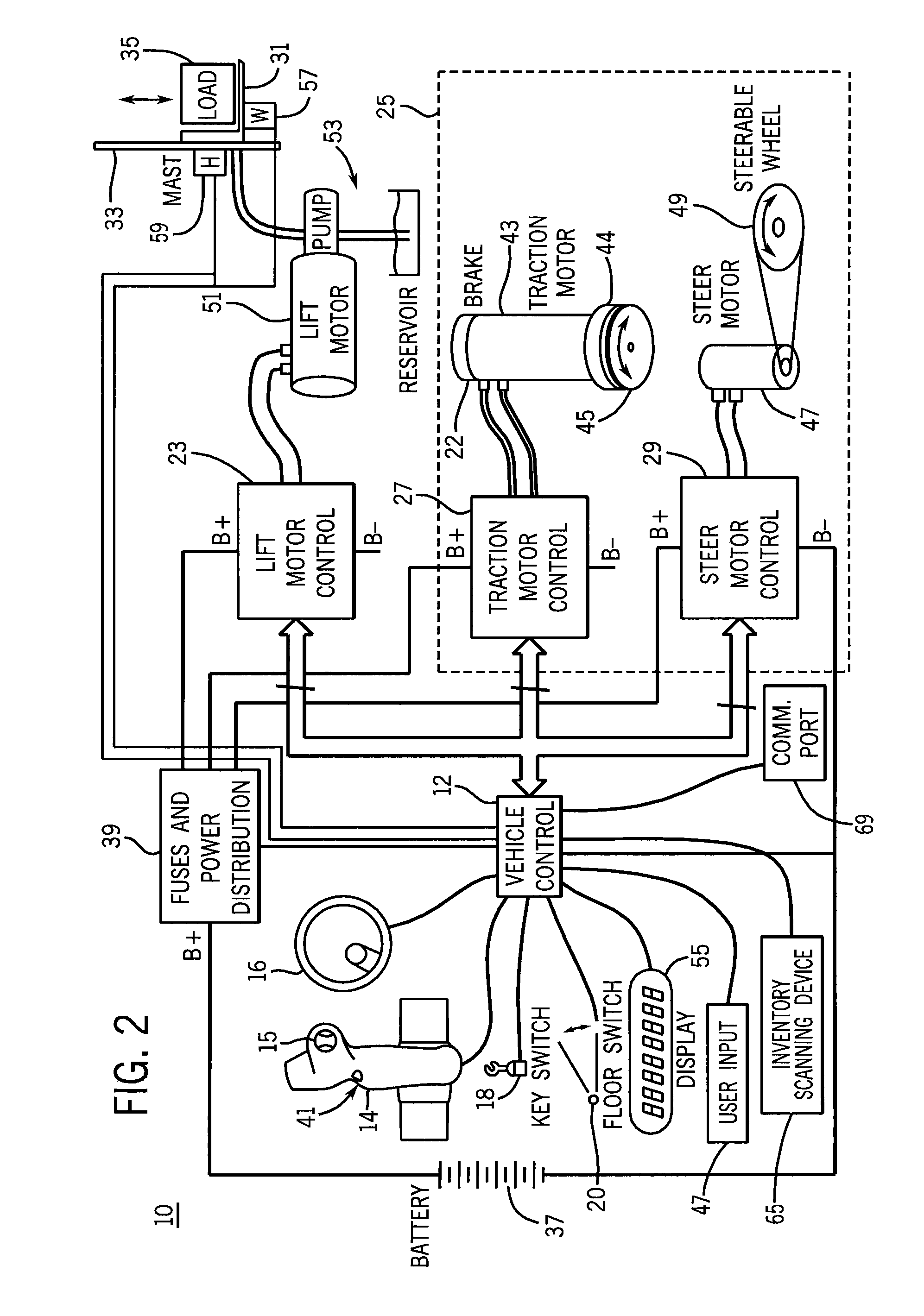

Pallet counter for lift truck

ActiveUS7992686B2Analogue computers for trafficSoil-shifting machines/dredgersControl systemEngineering

A method for counting the pallets or loads moved by a lift truck using internal sensors is disclosed. The lift truck includes a weight sensor for weighing a load, a height sensor, for measuring a height of the forks, and a distance sensor for determining whether the vehicle has moved. When the data from each of these sensors exceeds a corresponding minimum value, a vehicle control system increments a pallet counter. A count of the number of pallets moved is therefore maintained without the need for tracking specific pallets of for adding expensive components and devices.

Owner:RAYMOND LTD

Dual-purpose traction forklift for road and railway and driving method thereof

ActiveCN101327902AReduce labor intensitySimple structureLifting devicesRail and road vehiclesDrive wheelRoad surface

The invention relates to a towing fork truck for a highway and a railway and a driving method thereof. The towing fork truck comprises a fork truck body, the rear part of a tail directive wheel of the fork truck body is provided with a pair of liftable rear rail wheels controlled by a hydraulic transmission mechanism, the front part of a front driving wheel of the fork truck body is provided with a pair of front rail wheels which are fixed on a main frame and can lift with the swing of the main frame, a fork in the front of the fork truck is fixed with a base, the base is provided with a permanent seat which rotates around a vertical shaft fixed on the base, a shackle bar is fixed on the base, and the base and the top end of the vertical shaft respectively extend a supporting rod which is fixed with a fork lifter in the front of the fork body. The workers can realize the converting drive between on the road surface and the rail by simple operation, and the fork truck is particularly operated on trench platform position; when the fork truck draws different vehicles, the shackle bar does not need to be detached, the permanent seat is only rotated, and the needed shackle bar can be selected; and the fork truck has the advantages of simple structure, convenient operation, safe and reliable use, and the reduction of labor intensity of workers.

Owner:CRRC QINGDAO SIFANG CO LTD

An automatic loading and unloading machine

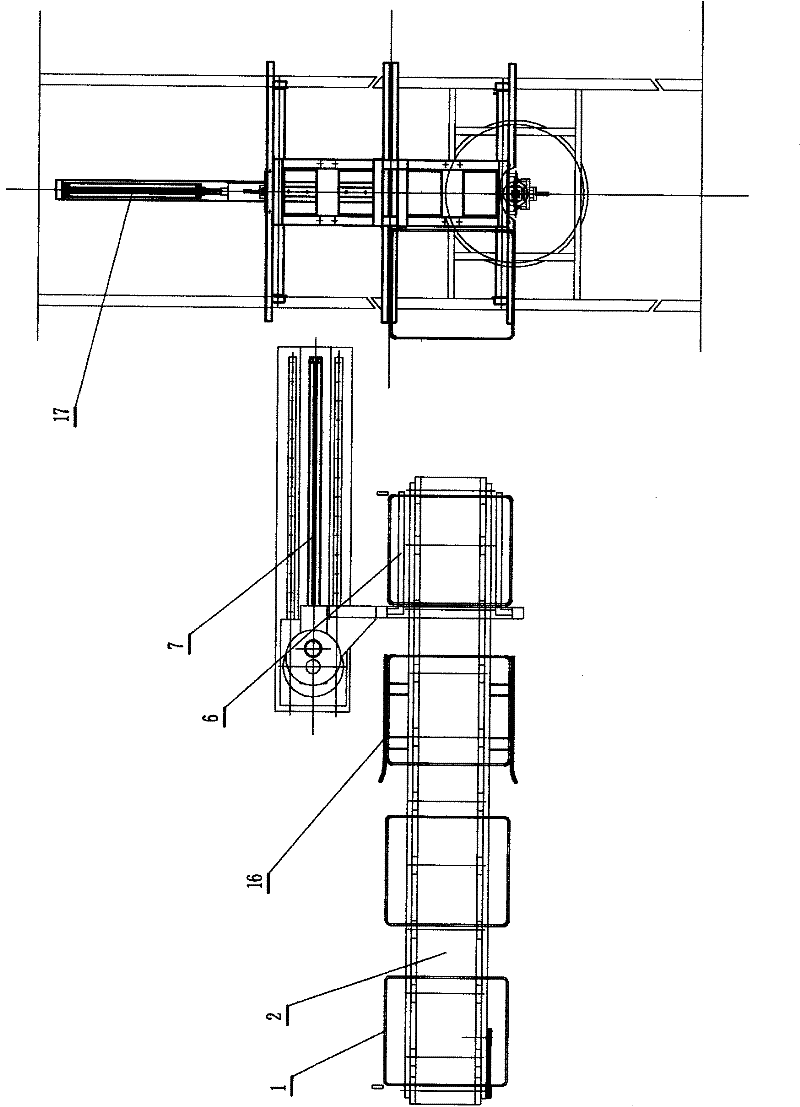

ActiveCN102275744ASimple structureEasy to operateLoading/unloadingAutomatic controlProgrammable logic controller

The invention discloses an automatic pallet loading and unloading machine comprising pallets for holding materials, a conveyor for conveying the pallets and a material trolley, wherein the material trolley is provided with a pallet support for holding the pallets and a PLC (Programmable Logic Controller), the material trolley is arranged at an end of the conveyor and is arranged vertical to the conveyor, a pallet forking device is arranged at the end of the conveyor and is provided with a base, a stand column and a screw rod are arranged on the base, a liftable pallet yoke is arranged on the lead screw, a forking rod is arranged at the front end of the pallet yoke, the base is arranged on a moving block, and the moving block is connected with a linear driver. According to the invention, the problems on automatic transfer and loading of the empty pallets are solved, the automatic transfer and loading of the pallets can be realized, and the automatic pallet loading and unloading machine has the advantages of time-saving and labor-saving performances, high efficiency and convenience for operation, can realize full-automatic control and can be widely applied to the fields such as foot, sanitation, medicines and the like to serve as equipment for automatically transferring, loading and unloading the pallets.

Owner:北京创思佳信息技术有限责任公司

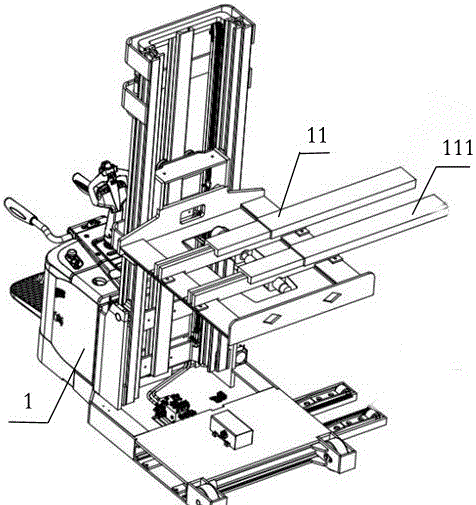

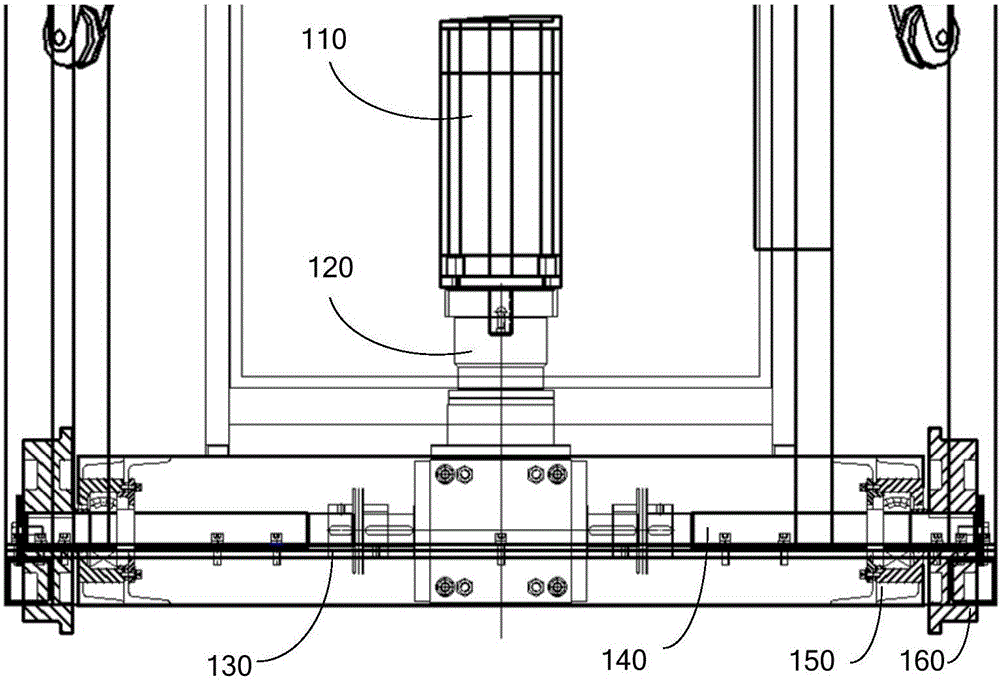

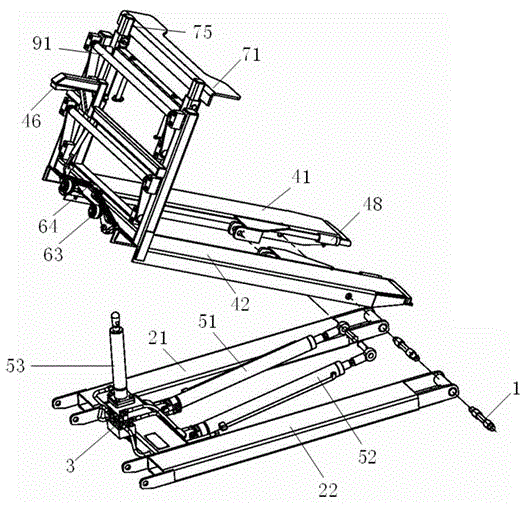

Full-automatic battery changing robot for electric automobile

InactiveCN106627512AQuick and fully automatic replacementImprove power exchange efficiencyElectric propulsion mountingVehicle servicing/repairingPush and pullElectricity

The invention belongs to the field of electric automobile battery changing and relates to a full-automatic battery changing robot for an electric automobile. The battery changing robot comprises a movable chassis, wherein a main robot body is installed on the chassis, a battery changing jig is installed in the main robot body, the main robot body comprises a main frame and a lifting device. The bottom end of the main frame is fixed to the chassis, and the lifting device is installed at the top end of the main frame. The lifting device is connected with the battery changing jig. The battery changing jig comprises a jig lifting frame, a jig body, a pallet fork and a push-and-pull mechanism. The jig lifting frame is connected with the lifting device. The jig body is connected with the jig lifting frame through a direction turning mechanism. The pallet fork is connected with the jig body through a pitching mechanism. The push-and-pull mechanism is installed on the pallet fork, and a battery unlocking mechanism is arranged on the push-and-pull mechanism. The full-automatic battery changing robot achieves rapid and full-automatic change of batteries on two sides of the electric automobile, the battery changing efficiency is greatly improved compared with traditional semi-automatic change or single-shaft one-by-one motion, and the battery changing success rate is high.

Owner:XIAN AEROSPACE PRECISION ELECTROMECHANICAL INST

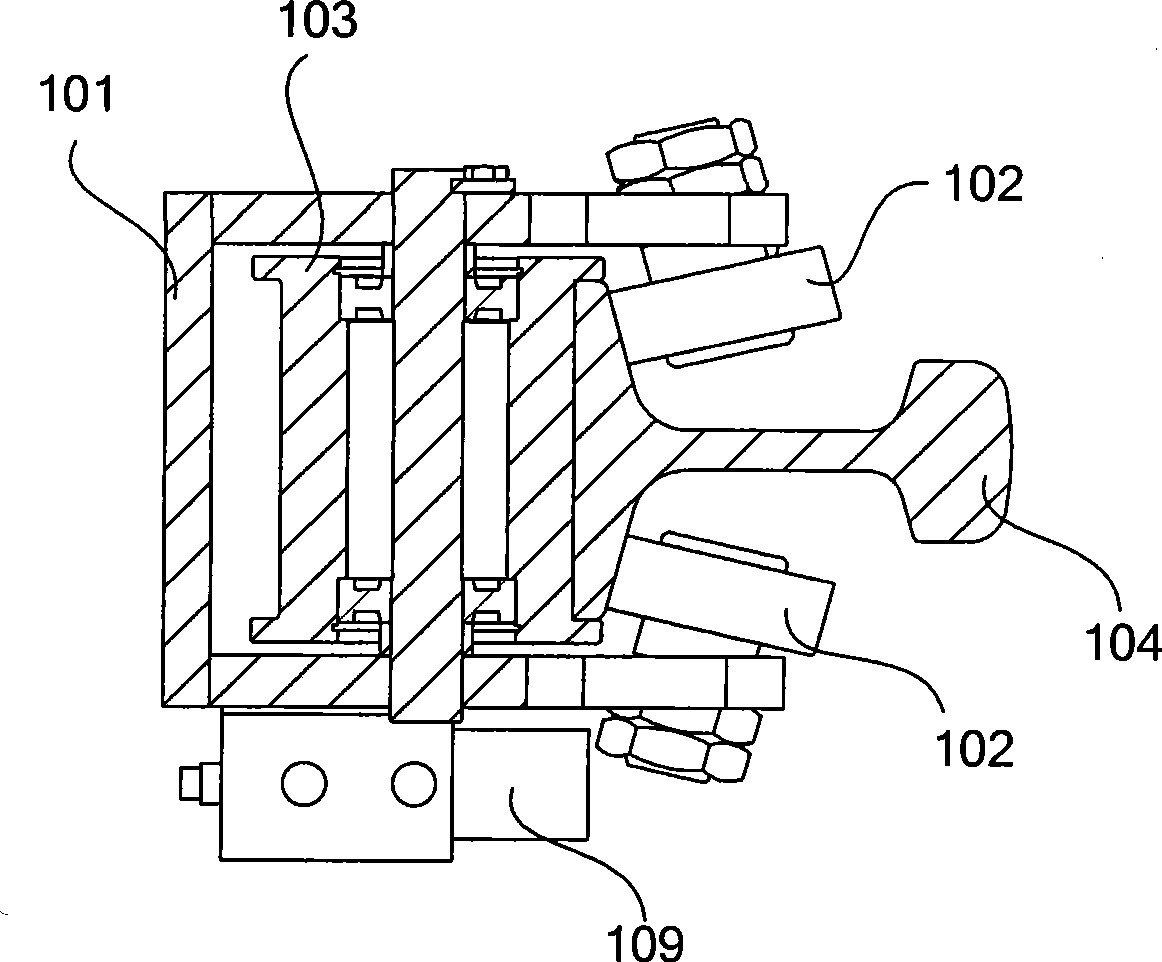

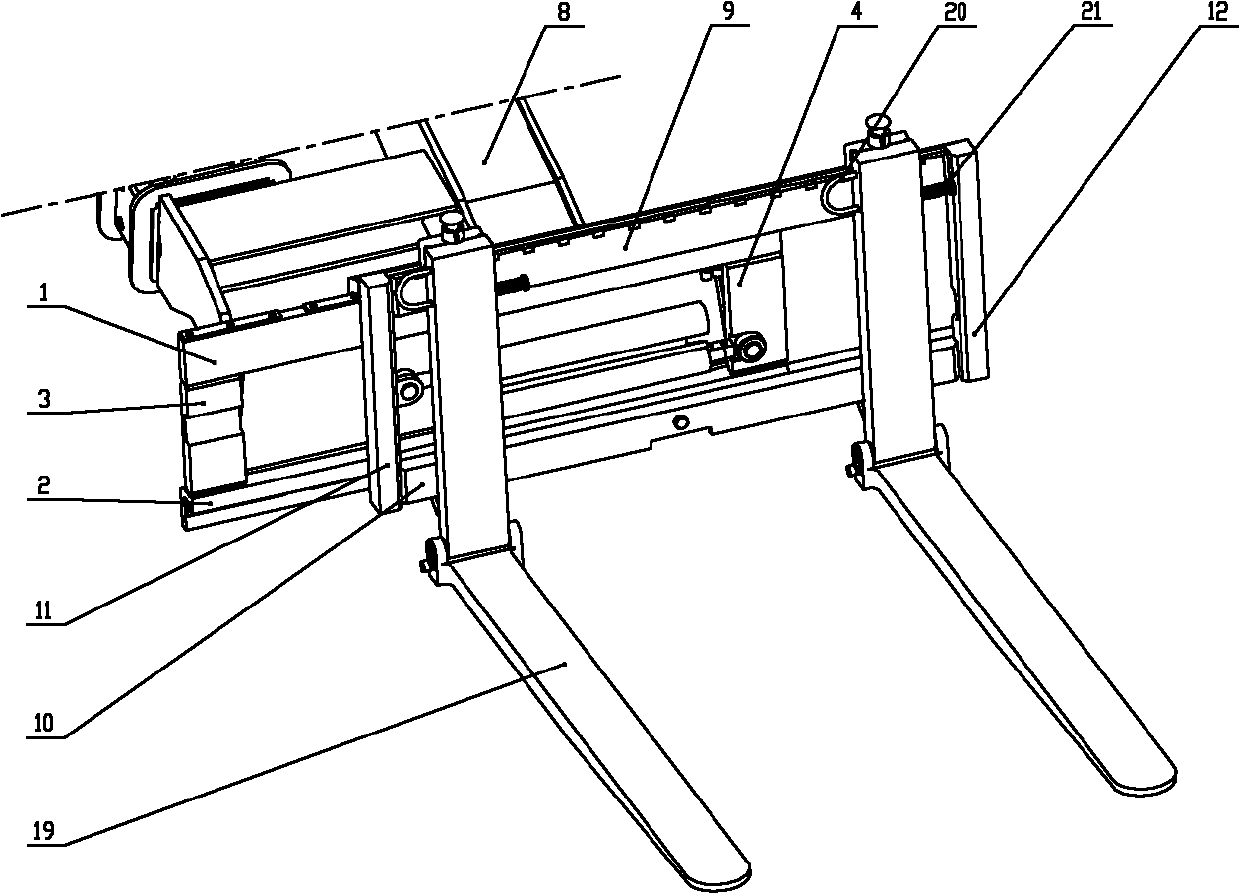

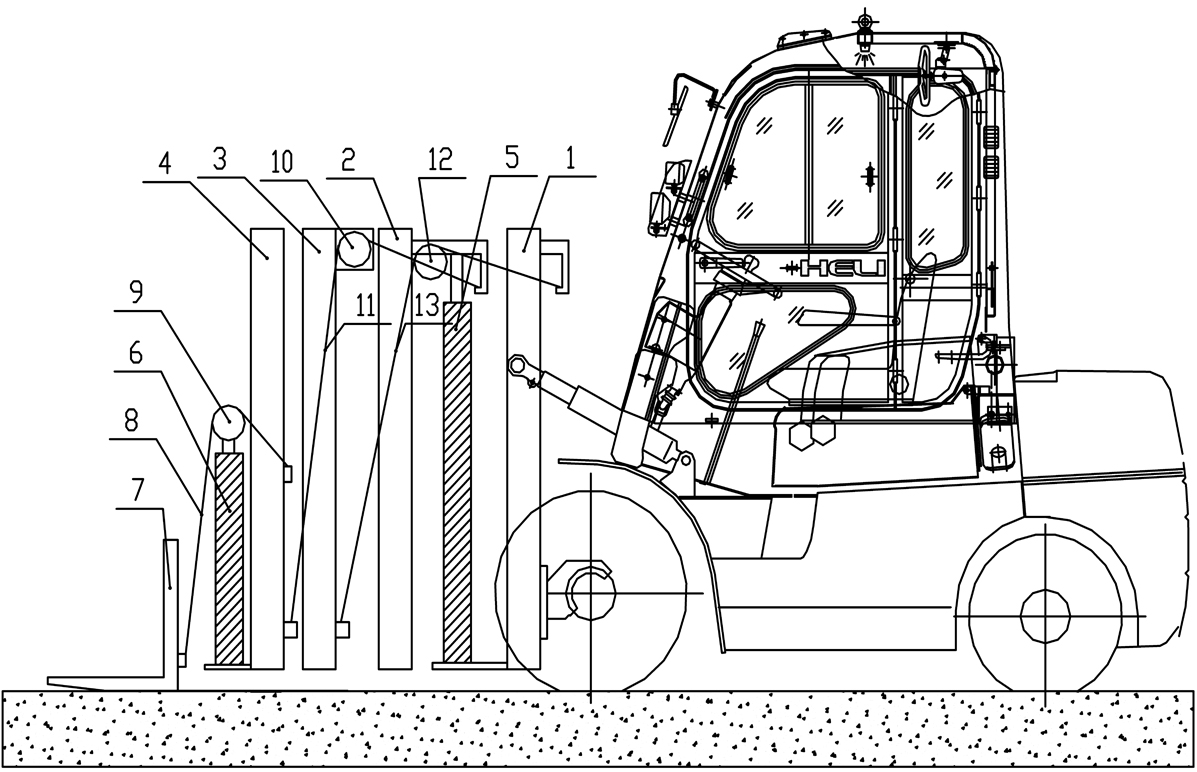

Integrated type forklift sidesway mechanism with internally-installed di-oil cylinder

The invention discloses an integrated type forklift sidesway mechanism with an internally-installed di-oil cylinder. The mechanism comprises a fixed sliding frame, a moving sliding frame, a bi-sidesway oil cylinder, a folded pallet fork and the like. The fixed sliding frame is fixed on a work mechanism; the moving sliding frame is fixed on the fixed sliding frame by the upper chute and the lower chute of the moving sliding frame and can transversely move; the bi-sidesway oil cylinder is arranged in a space between the moving sliding frame and the fixed sliding frame, so that a plurality of levers are fixed and distributed in an overlapping way, the levers are under the oil-charging state, and a cylinder barrel is under the moving state; and a greater oil cylinder stroke is realized withina smaller cylinder barrel range. The mechanism has the characteristics of being great in sidesway distance, simple in structure, small in volume, flexible in operation, high in movement reliability and the like, so that the lost carrying distance of the forklift caused by an external sidesway device can be reduced. A hydraulic oil way is integrated with a plurality of equipment parts, so that a plurality of connecting pipelines are reduced, and the visual field of the forklift is improved; and the forklift can be fixed in a folding way, thereby being convenient to transport.

Owner:ARCHITECTURAL ENG INST GENERAL LOGISTICS DEPT P L A

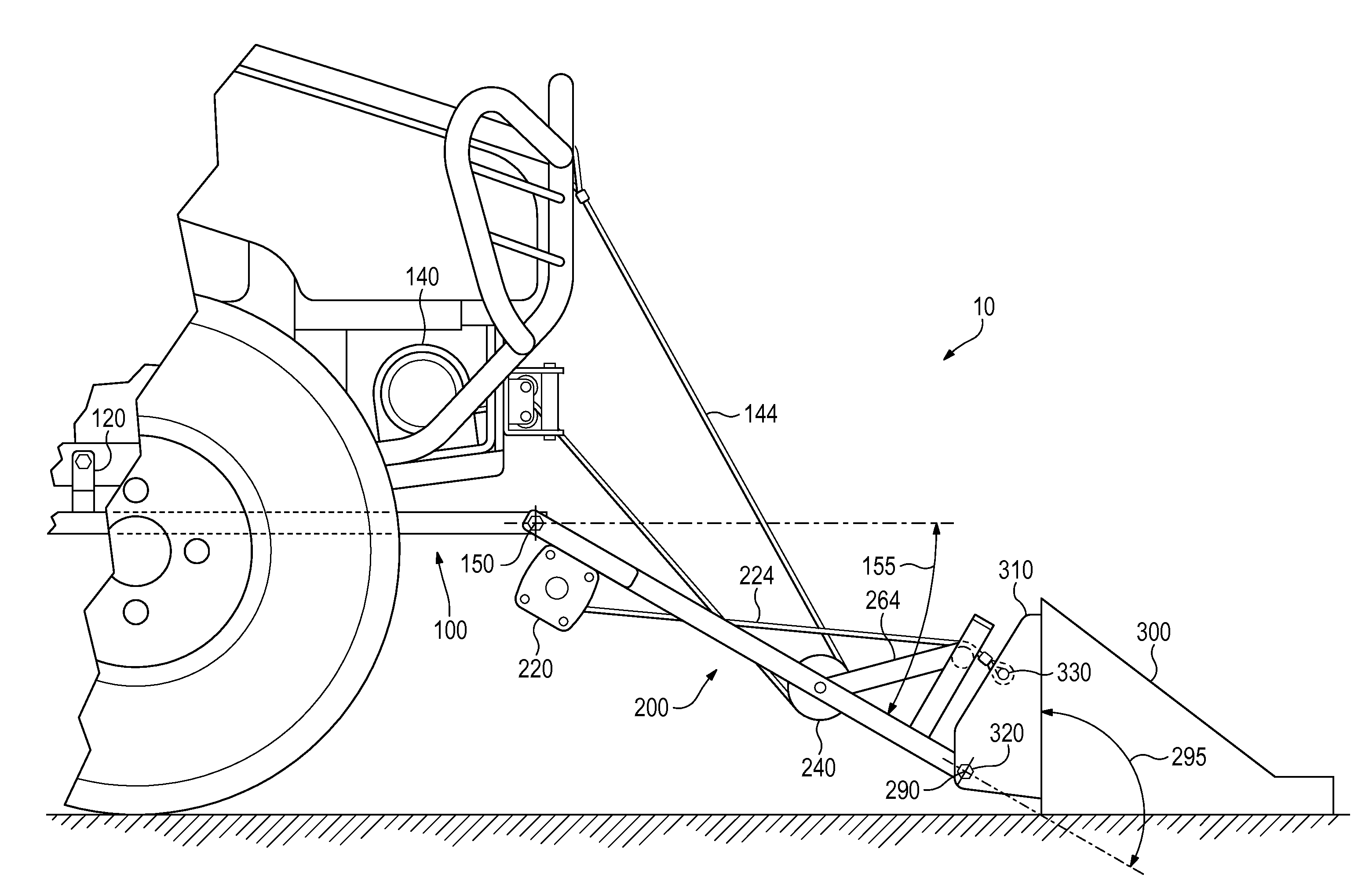

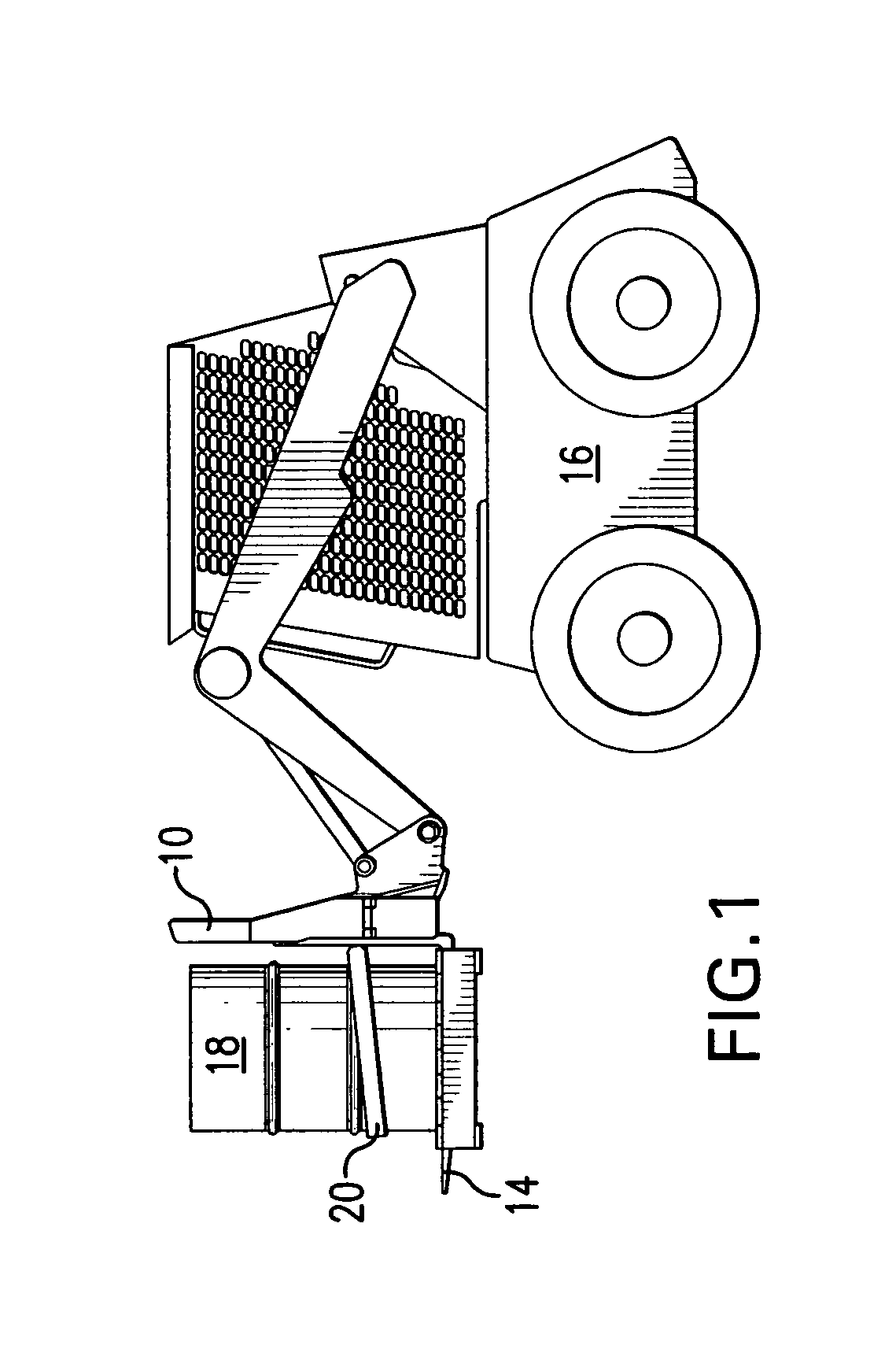

Removable loader for all-terrain and utility-terrain vehicles

Disclosed is multi-use attachment device that is easily attached to and removed from an all-terrain vehicle (ATV) or a utility-terrain vehicle (UTV). The device comprises a lift frame including an inner lift frame, an outer lift frame, a first pivotal axis and a second pivotal axis, and is configured to pivot about the first pivotal axis with a first electrical device, and has a second electrical device mounted on the lift frame to pivot the outer lift frame with respect to the inner lift frame. One end of the multi-use attachment is attached to the ATV / UTV, and the other end is attached to an implement such as a loader bucket, a pallet fork, or a plow blade. Some embodiments of the multi-use attachment use tension devices both for pivoting the lift frame about the first pivotal axis and for pivoting the outer lift frame with respect to the inner lift frame about the second pivotal axis.

Owner:BENESCH BRIAN ANTHONY

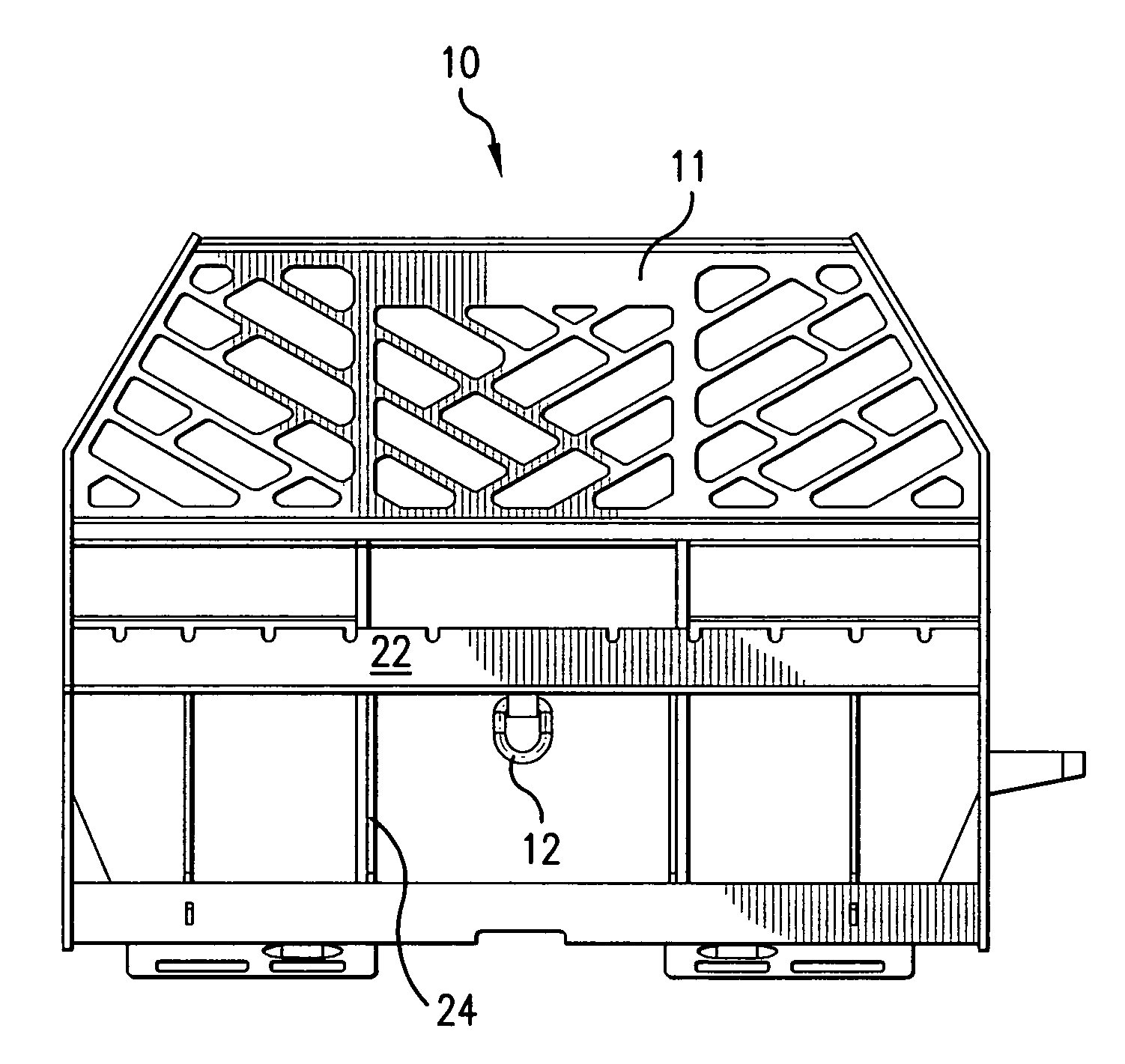

Pallet fork carriage with a load securing D-ring and method of using

The present invention is a skid-steer attachment device with a load bearing D-ring for securing loads to the attachment device. A number of different attachment devices can be attached to a skid-steer loader, however, the preferred attachment device in this invention is a pallet fork carriage. The load securing D-ring is attached to the pallet fork carriage of the skid-steer so that loads can be secured to the D-ring by tying, strapping, or otherwise attaching the load to the D-ring. The D-ring on the pallet fork carriage functions to prevent a skid-steer loader's load from becoming dislodged prematurely.

Owner:PALADIN BRANDS GROUP

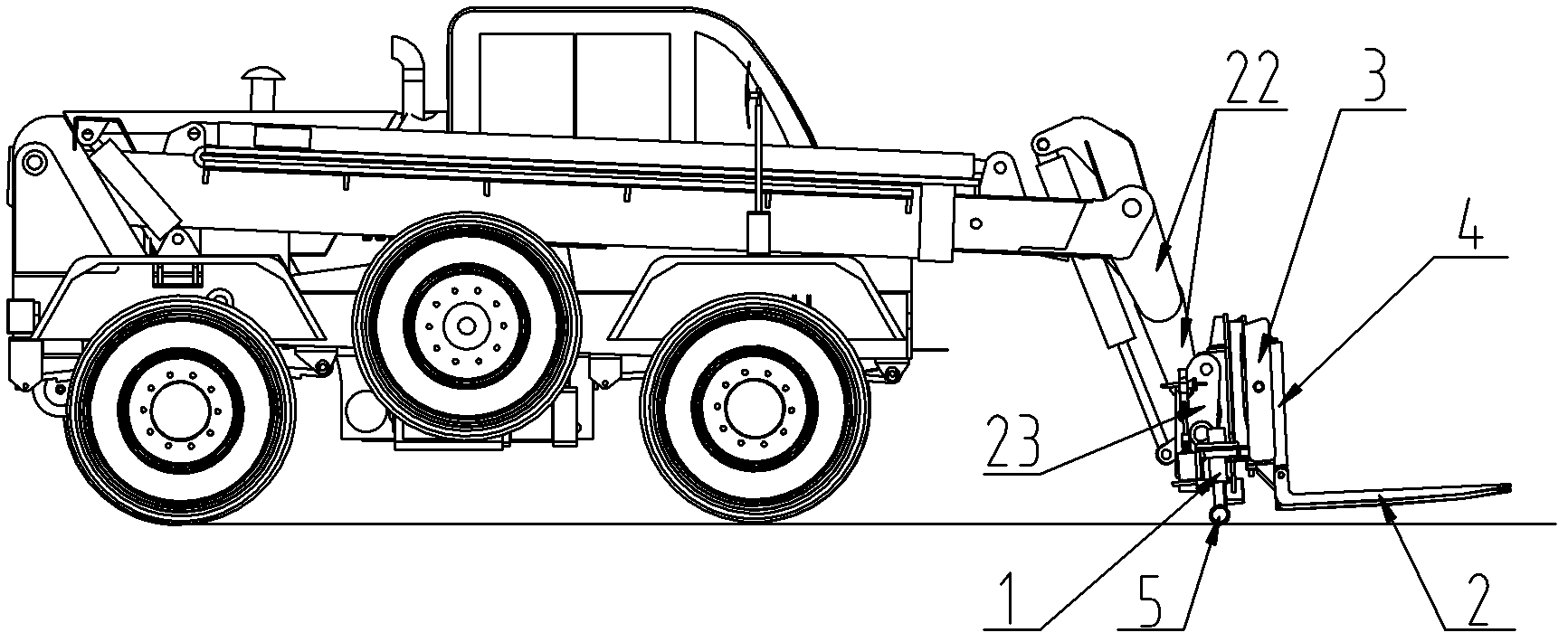

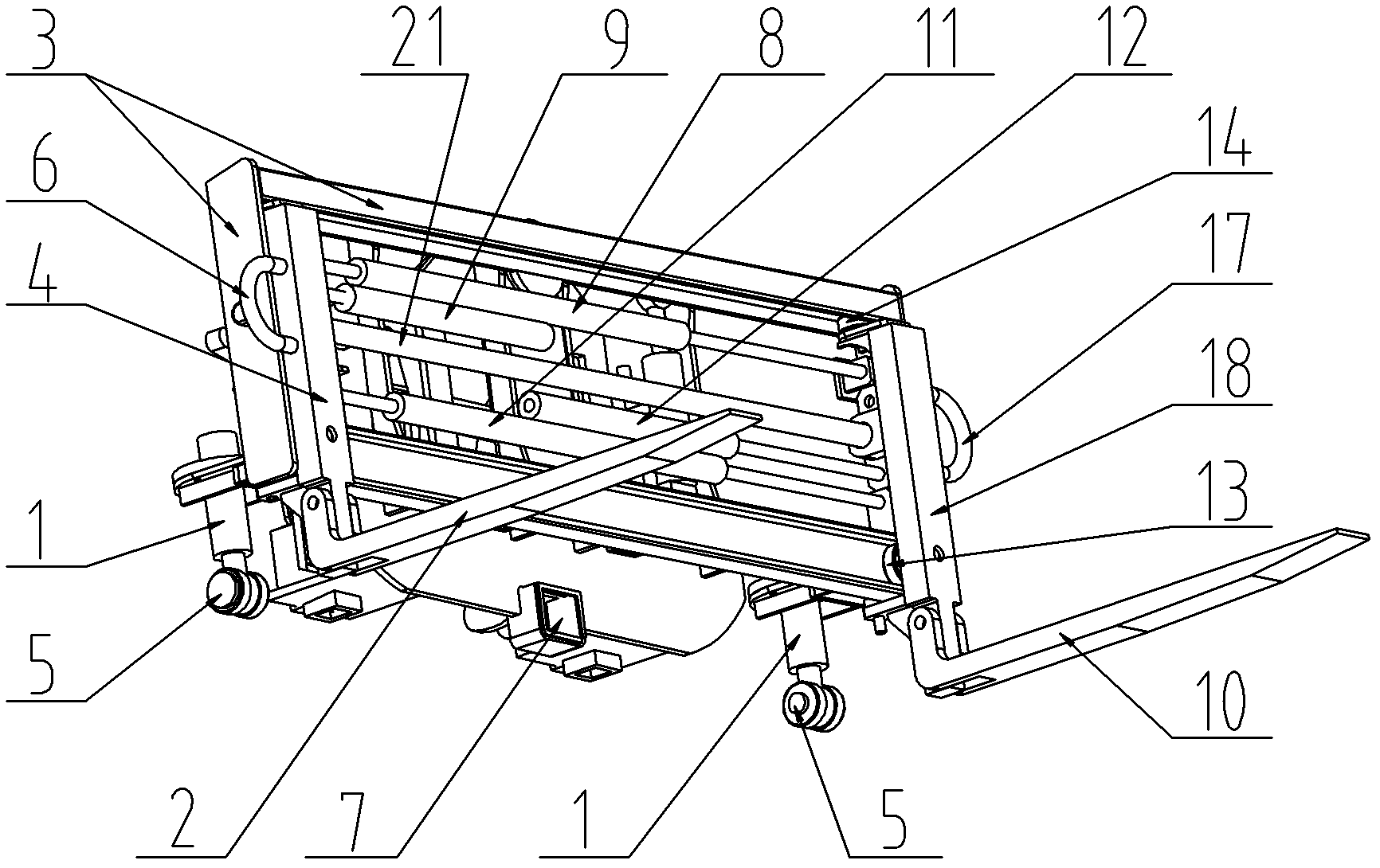

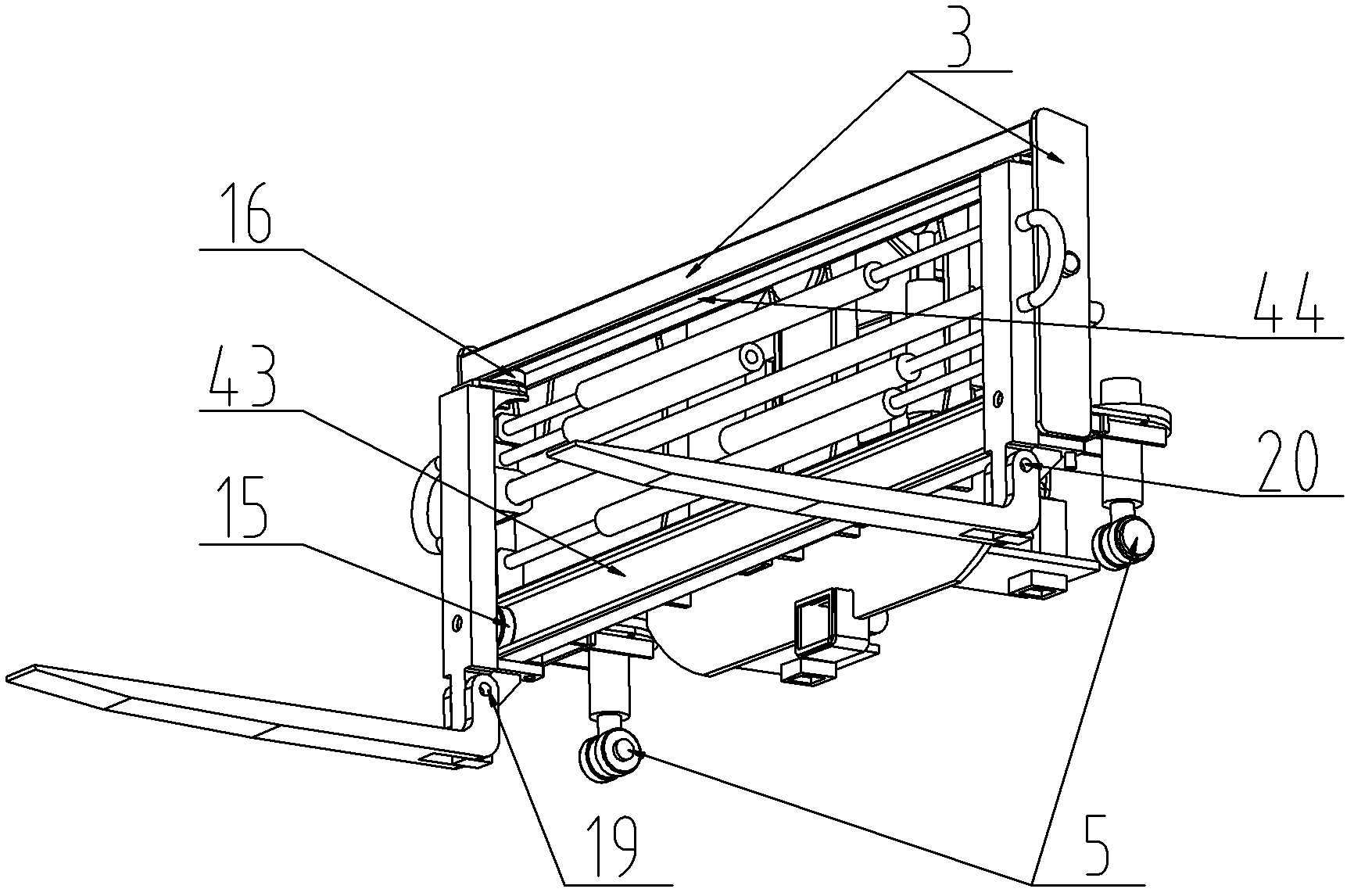

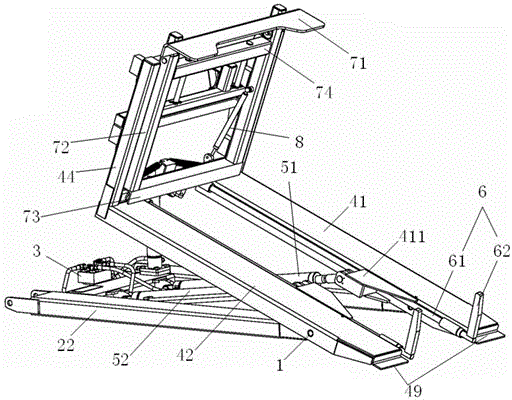

Pallet fork mechanism with quick change function

ActiveCN102583195ASatisfy the horizontal movement functionSatisfy the left and right leveling functionLifting devicesDual mechanismEngineering

The invention discloses a pallet fork mechanism with a quick change function. The pallet fork is characterized in that a baffle mechanism is connected with a folding arm mechanism and rotates around the folding arm mechanism; the baffle mechanism is provided with two quick change handles and two limiting blocks; the two quick change handles lift the two limiting blocks by pin shafts; a hanging plate mechanism is provided with a camera mounting hole and two limiting holes; the baffle mechanism is inserted in the two limiting holes of the hanging plate mechanism by the two limiting blocks and is connected with the hanging plate mechanism; the hanging plate mechanism is connected with a pallet fork frame through a rotary shaft; a leveling cylinder is arranged between the pallet fork frame and the hanging plate mechanism; one end of the leveling cylinder is connected with the hanging plate mechanism, and the other end of the leveling cylinder is connected with the pallet fork frame by the pin shaft; and the leveling cylinder pushes the pallet fork frame to rotate around the rotary shaft of the hanging plate mechanism by the pin shaft. The quick change function of the pallet fork mechanism of a handler with a high-speed telescopic arm can be realized to meet the left-and-right transverse movement function of the pallet fork mechanism, and a cylinder and a cylinder roller can be supported to realize rolling and moving in the case that the transported materials are overloaded.

Owner:ARCHITECTURAL ENG INST GENERAL LOGISTICS DEPT P L A

Container turnover device for forklift

InactiveCN104986698AReduce labor intensityImprove labor efficiencyLifting devicesRolloverMechanical engineering

The invention relates to a container turnover device for a forklift. The device comprises a fork cover base assembly for inserting in a fork of the forklift, and a tipping frame assembly clamped above the fork cover base assembly, wherein the front part of the tipping frame assembly and the fork cover base assembly are hinged through a pin shaft; the fork cover base assembly is provided with a power oil cylinder for driving the tipping frame assembly to rotate along the pin shaft to realize the rollover; and the tipping frame assembly is provided with a limiting pressing device for preventing containers from falling. Known from the technical scheme, as the fork cover base assembly is connected with the fork of the forklift, and a hydraulic oil pipe is connected with a power system of the forklift, the device operates goods required to be separated through overturning the containers so as to reduce the labor intensity of operators and to improve the labor efficiency.

Owner:ANHUI ZHIZAO LOGISTICS EQUIP TECH

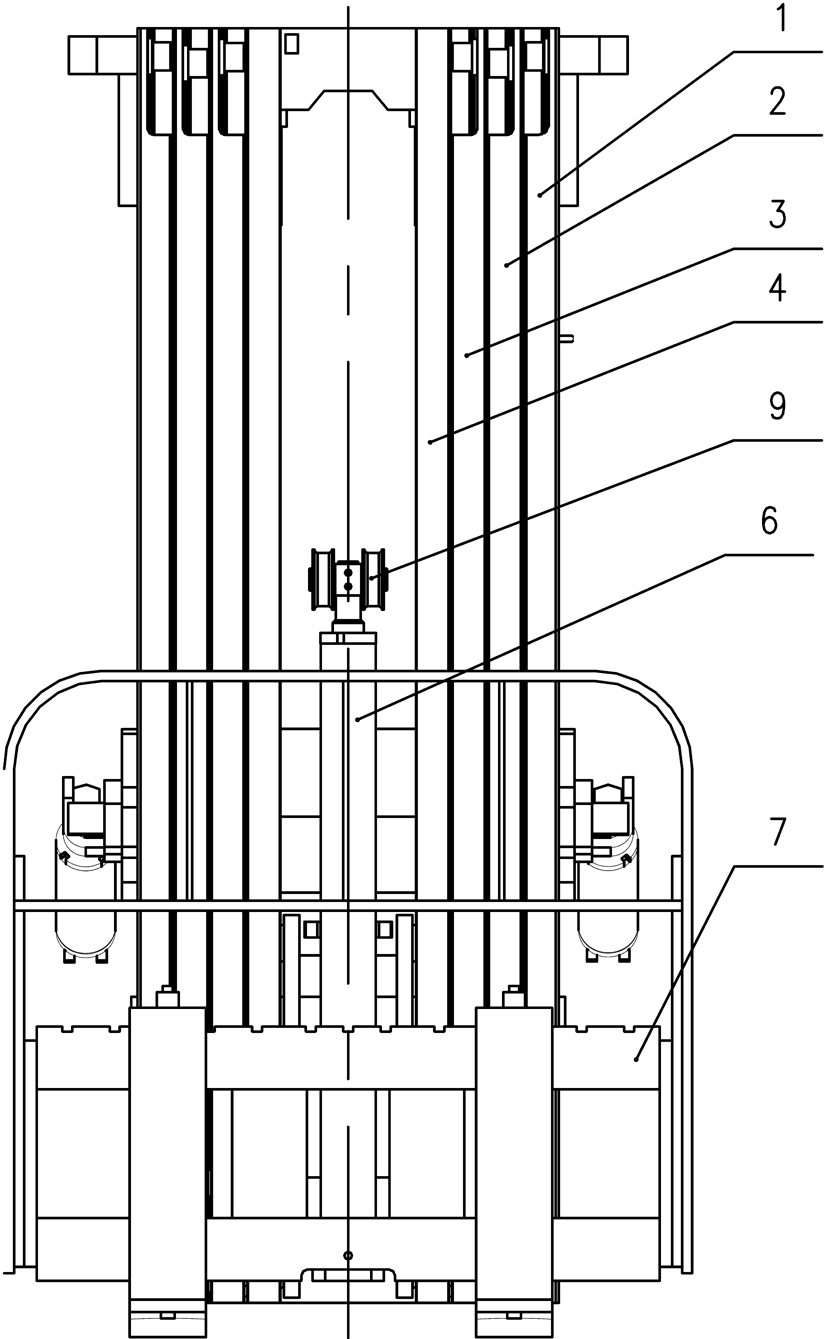

Forklift gantry

The invention relates to a forklift gantry which comprises four classes of gantries and a goods fork frame, wherein two rear lifting oil cylinders are uniformly distributed on a connecting plate of the first class gantry, and the piston rod ends of the rear lifting oil cylinders are connected with the second class gantry; a second class chain wheel, a second class chain, the second class gantry and the first class gantry form a moving chain wheel group; the third class chain wheel, the third class chain, the second class gantry and the highest class gantry form a moving chain wheel group; andthe third class gantry and the highest class gantry are pulled by the chains to move relative to the first class gantry under the interaction of the rear lifting oil cylinders and the chains. Front lifting oil cylinders are uniformly distributed on the highest class gantry; the piston rod ends of the front lifting oil cylinders are provided with two chain wheels; and one ends of the two chains matched with the chain wheels are connected with the highest class gantry, and the other ends are connected with the rear part of the goods fork frame. The chain wheels, the chains, the highest class gantry and the goods fork frame form a moving chain wheel group; and the goods fork frame can move relative to the highest class gantry. The four groups of gantries are compactly distributed and are basically distributed in parallel, thereby ensuring minimal front suspension and favorable visual field.

Owner:ANHUI HELI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com