Full-automatic battery changing robot for electric automobile

A technology for battery swapping robots and electric vehicles, which is applied to electric power units, vehicle maintenance, power units, etc., can solve the problems of poor accuracy and low efficiency, and achieves improved battery replacement efficiency, high battery replacement success rate, and avoidance of frequent movement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

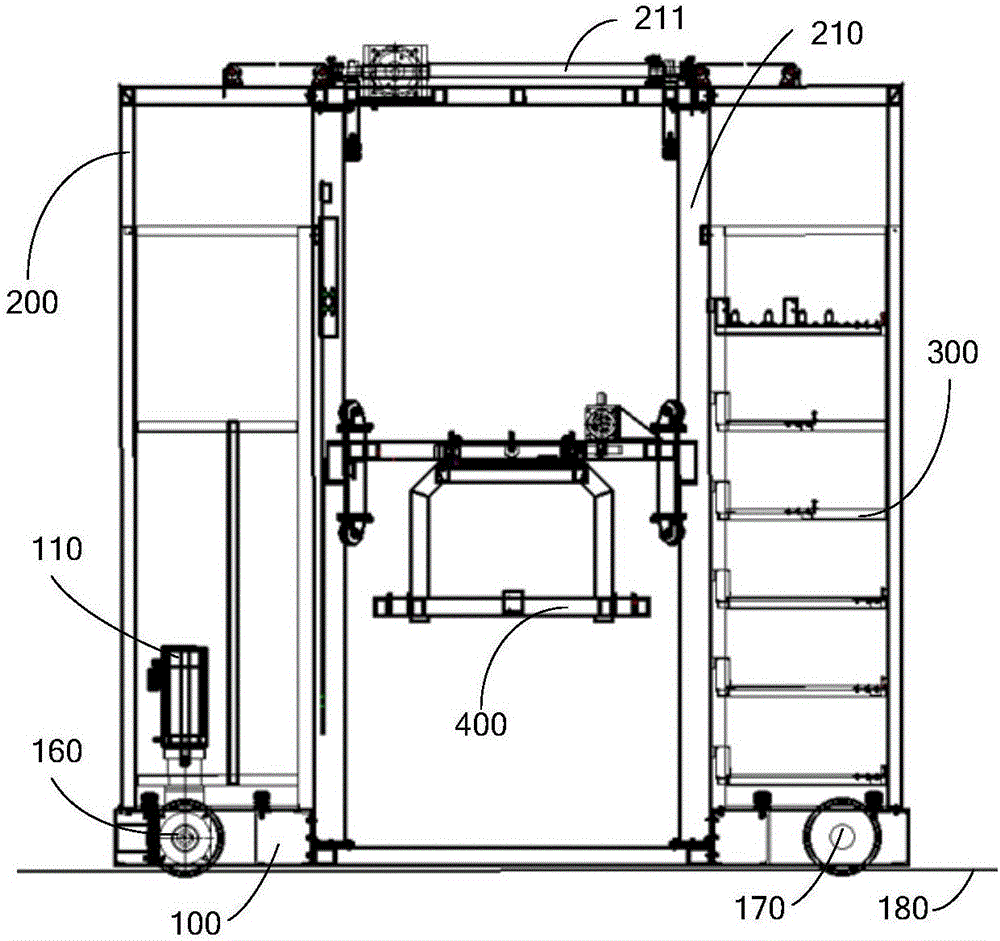

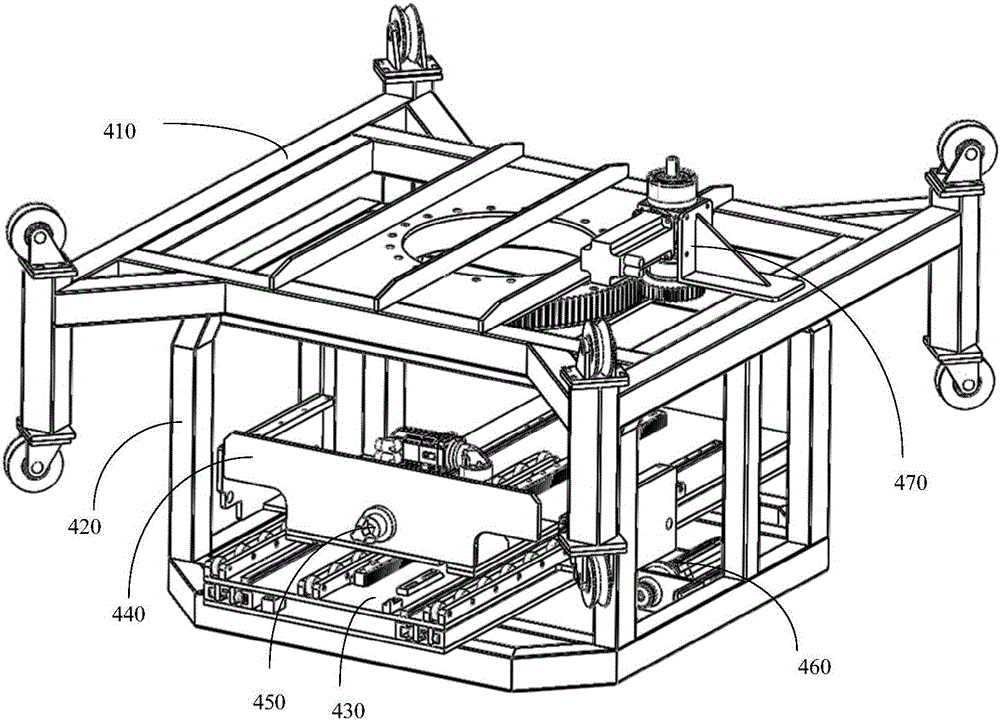

[0033] see figure 1 , the structure of the fully automatic battery-swapping robot for electric vehicles provided by the present invention mainly includes a movable chassis 100, which is used to complete the displacement walking action of the battery-swapping robot. The main body 200 is installed on the chassis, and the battery replacement jig 400 is installed in the main body to complete the pick-and-place action of the battery.

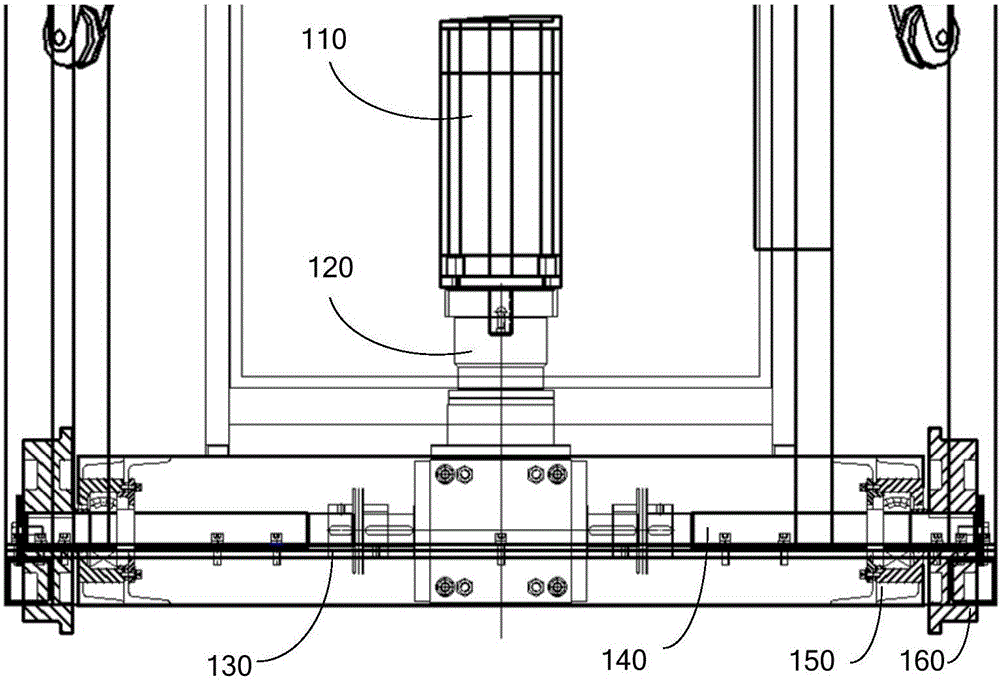

[0034] The main body 200 includes a main frame 210 and a lifting device 211; the bottom end of the main frame is fixed on the chassis, and the lifting device is installed on the top of the main frame; the main frame is the structural body of the whole battery replacement robot, which can be welded with rectangular steel, channel steel, and steel plate become. The lifting device 211 is connected with the battery replacement jig 400, and is used to complete the movement of the battery replacement robot in the up and down direction; preferably, a tempo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com