Patents

Literature

91results about How to "Universally adaptable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

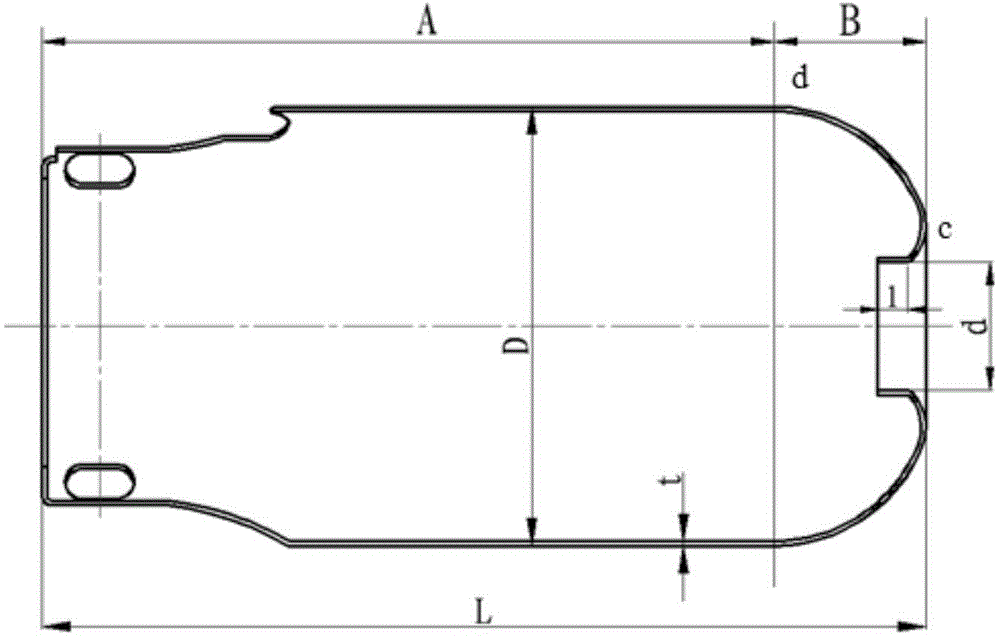

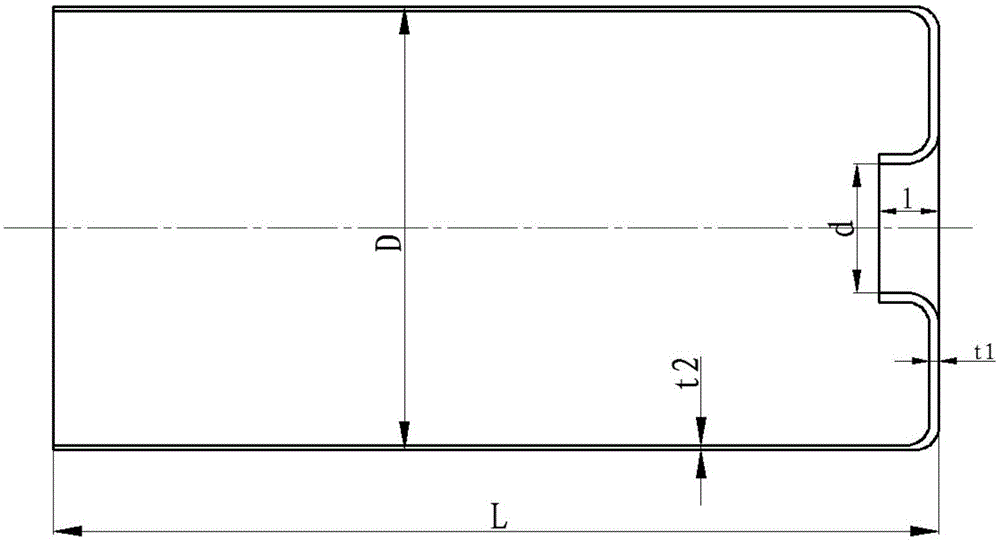

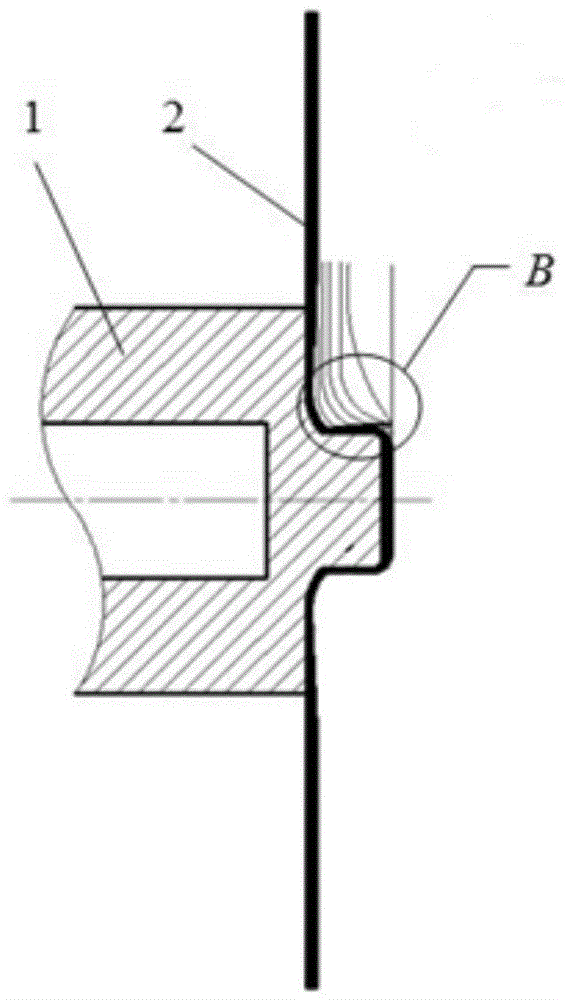

Method for precision forming of concave-bottom and thin-wall cylindrical part with large length and diameter ratio

The invention discloses a method for precision forming of a concave-bottom and thin-wall cylindrical part with large length and diameter ratio. The method comprises the following steps of firstly, calculating the size of a plate blank; then, forming the concave bottom, performing deep drawing and spinning to form a cylindrical blank, and performing spinning and thinning on the blank to reach the specified size; performing subsequent universal processing to meet the requirement of part size; in the deep drawing and spinning process of the cylindrical blank, turning the blank with the formed concave bottom, fixing between a tail jack and a code die, preparing a common spinning track by a common spinning track preparation method, enabling a main shaft to drive the blank to rotate, enabling a rotary wheel to feed according to the prepared track under the drive action of a numerical control system, using the first 6-8 passes of the spinning track as the simple reciprocating spinning, using the subsequent passes of the spinning track as the spinning track combined with the reciprocating travel, and performing the deep drawing and spinning on the blank to form the cylindrical part. The method has the advantages that by utilizing multiple times of deep drawing and spinning, the cylindrical blank is obtained, and then the spinning and thinning are performed on the blank to reach the specified size; by utilizing the characteristics of strong spinning and high accuracy, the wall thickness of the manufactured part is uniform, the surface quality is high, the compactness is good, and the number of defects is fewer.

Owner:SOUTH CHINA UNIV OF TECH

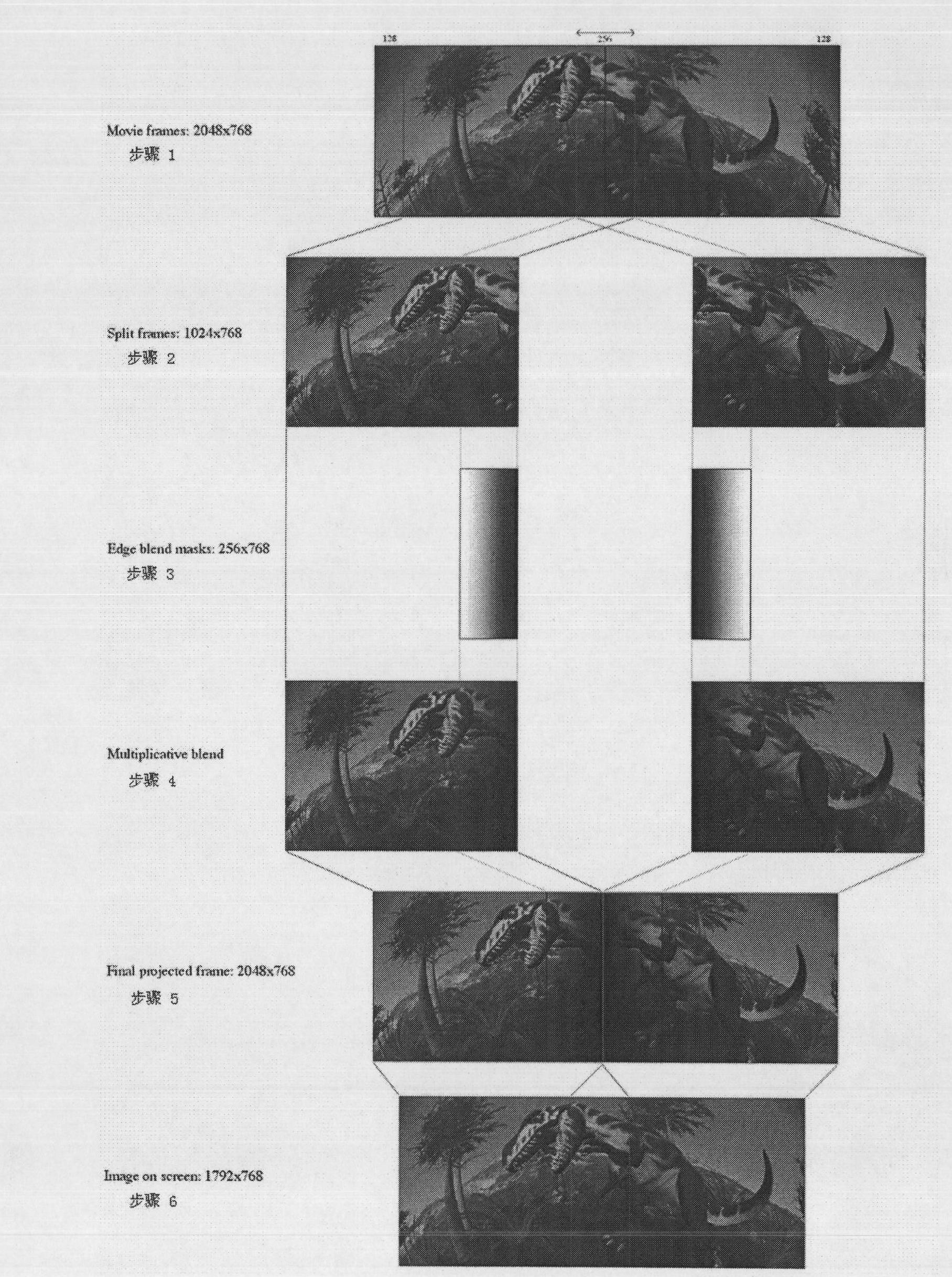

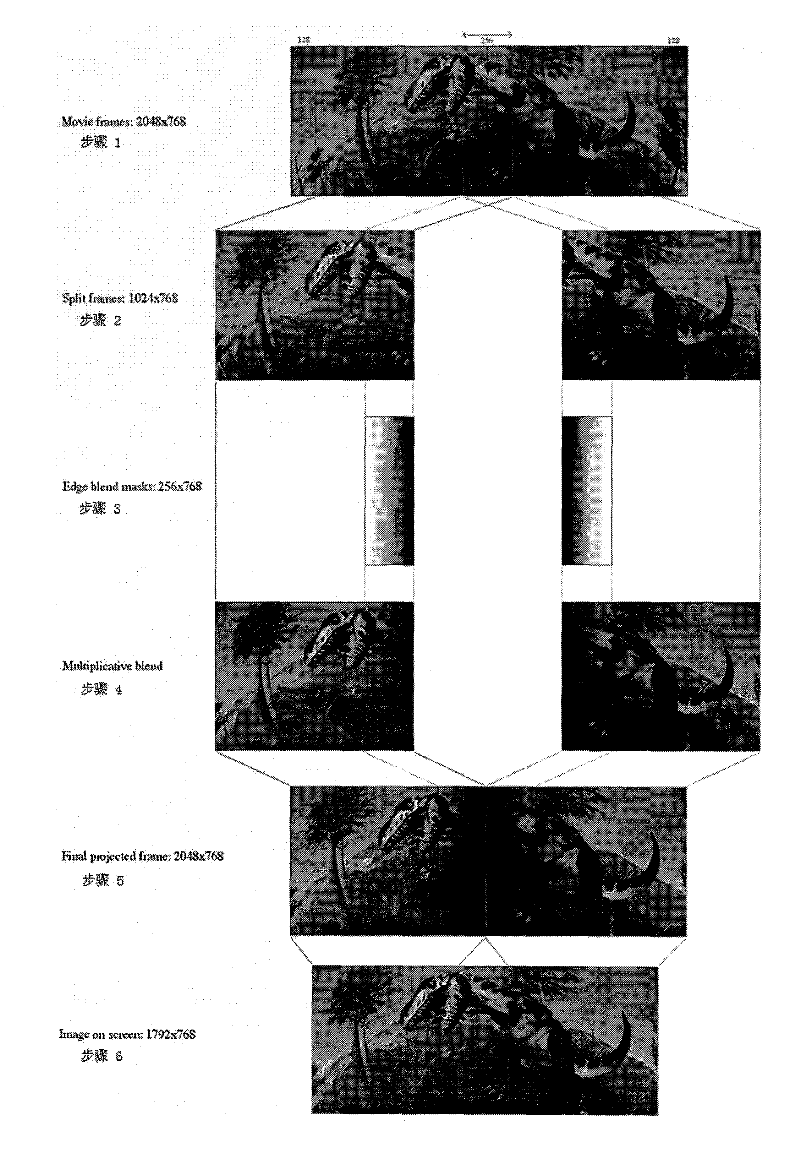

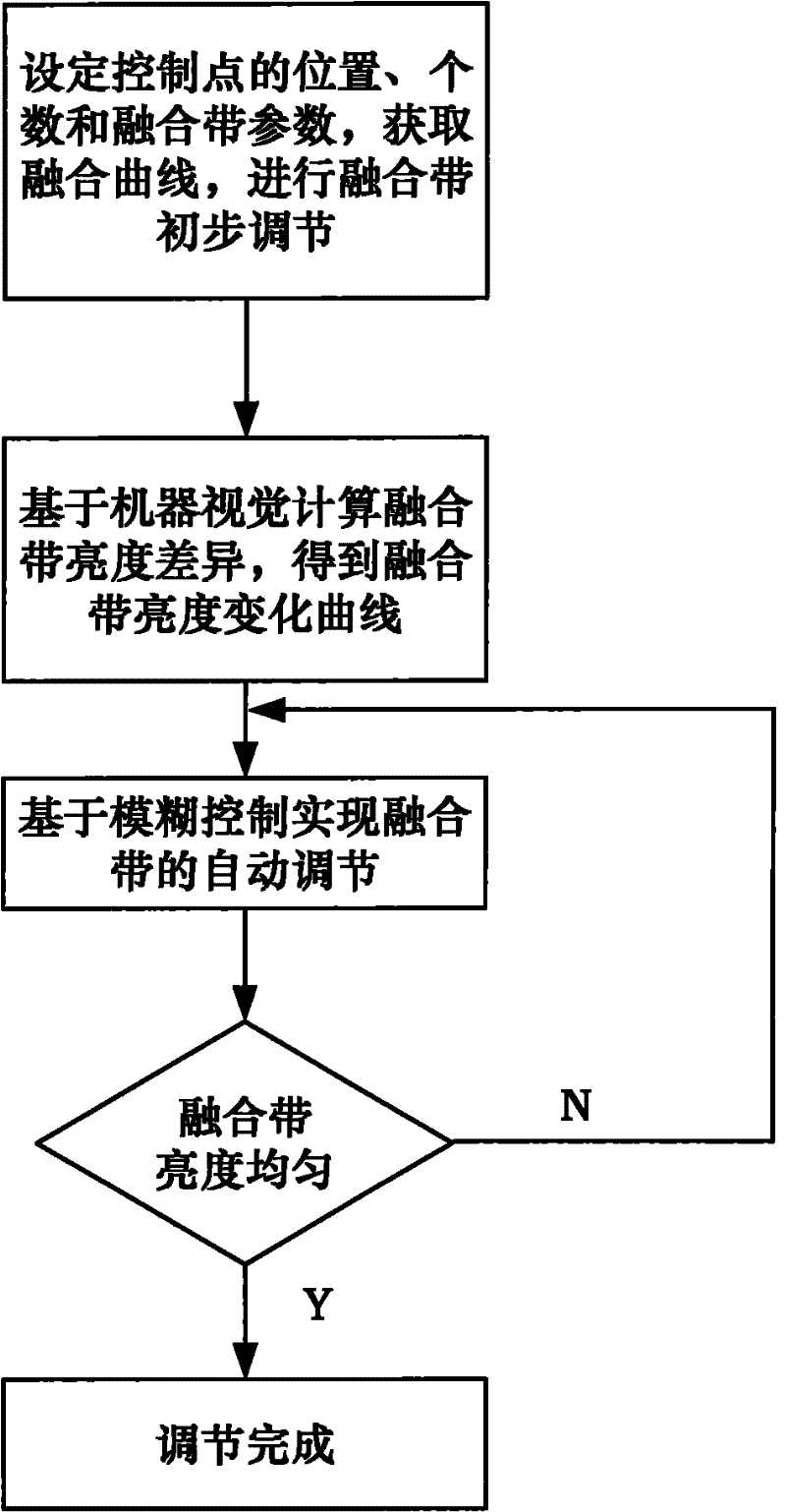

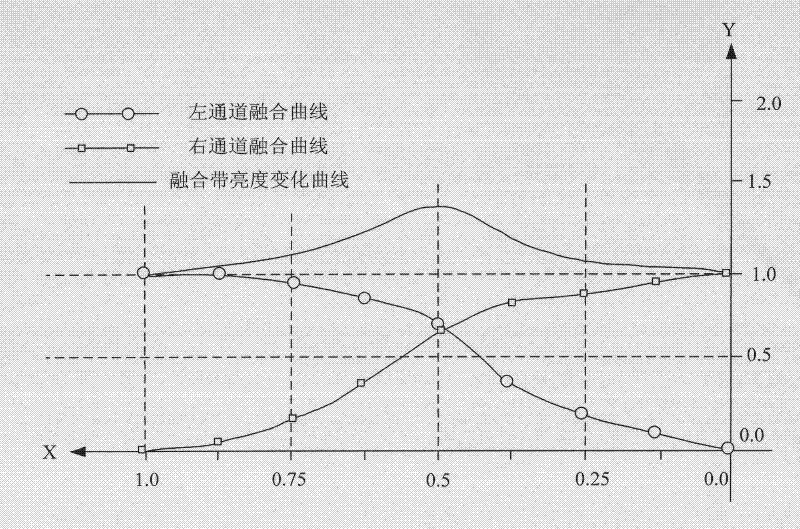

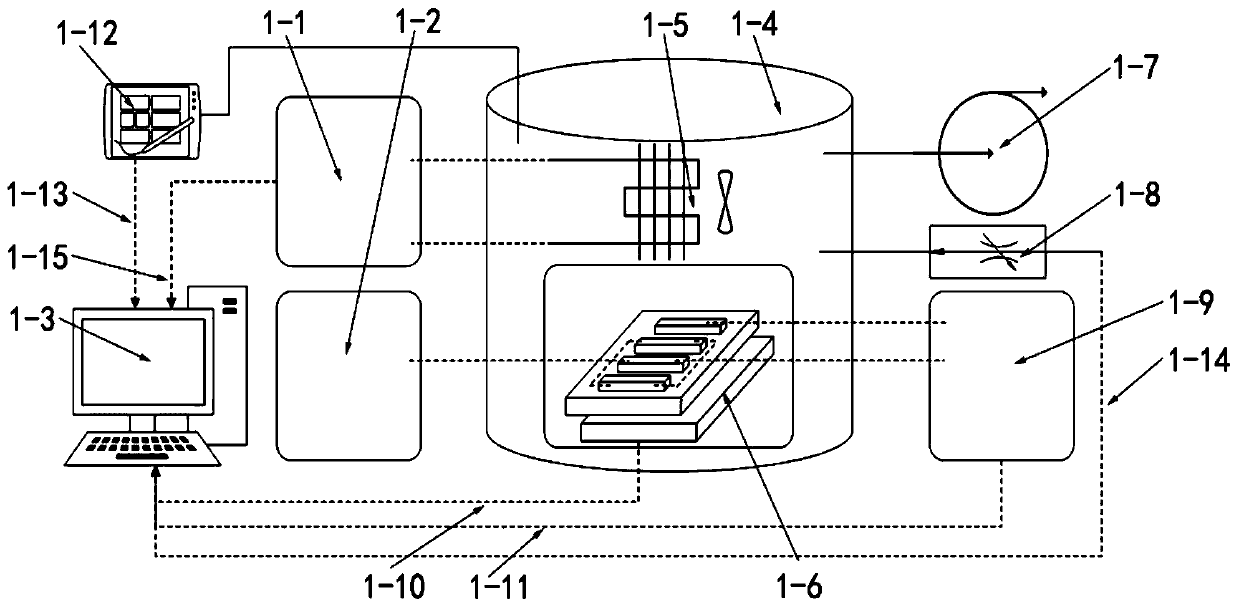

Multi-projecting apparatus image splicing automatic edge blending method based on fuzzy control

InactiveCN101866096AUniversally adaptableGood effectImage enhancementProjectorsMachine visionFuzzy control system

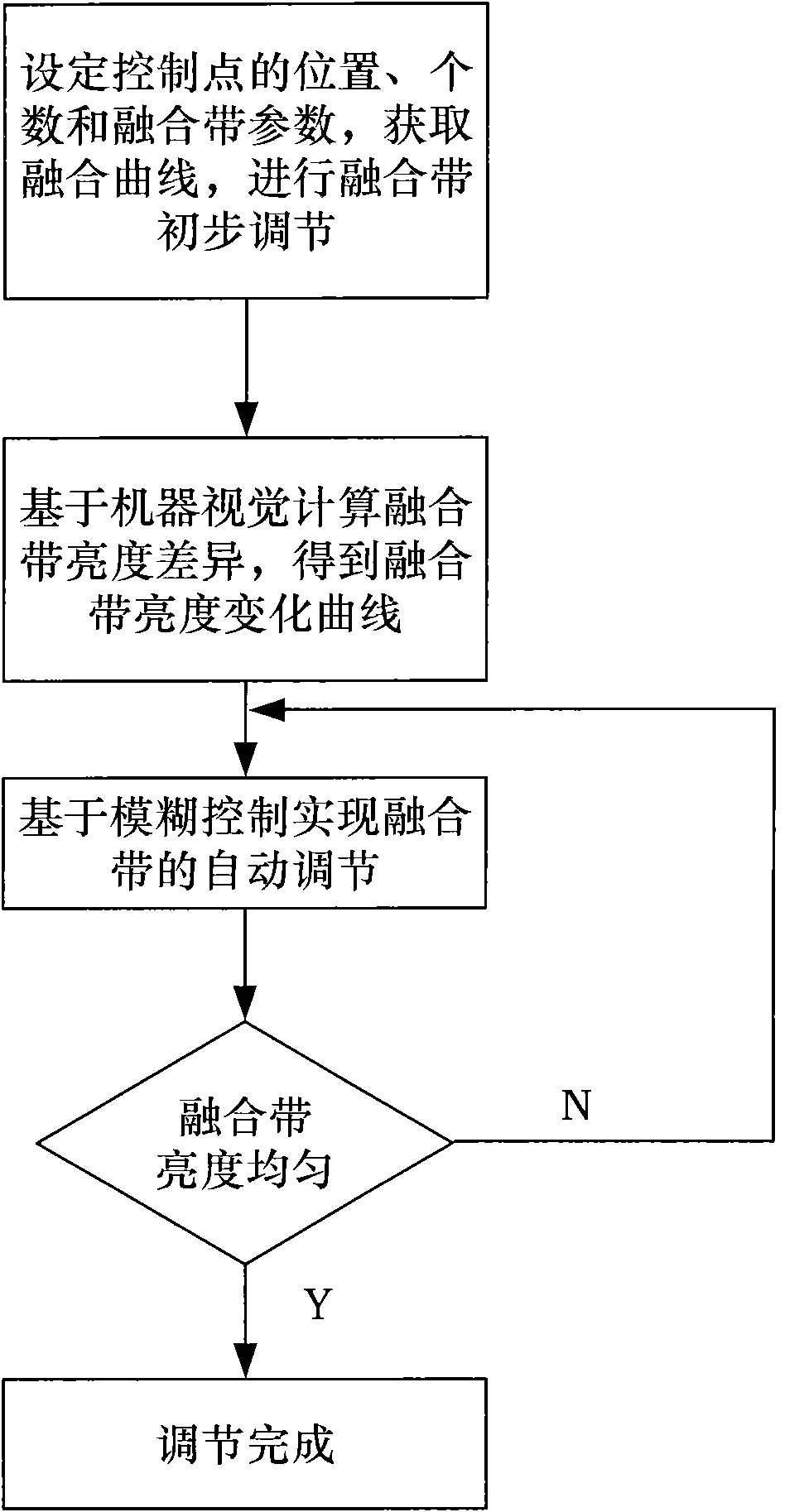

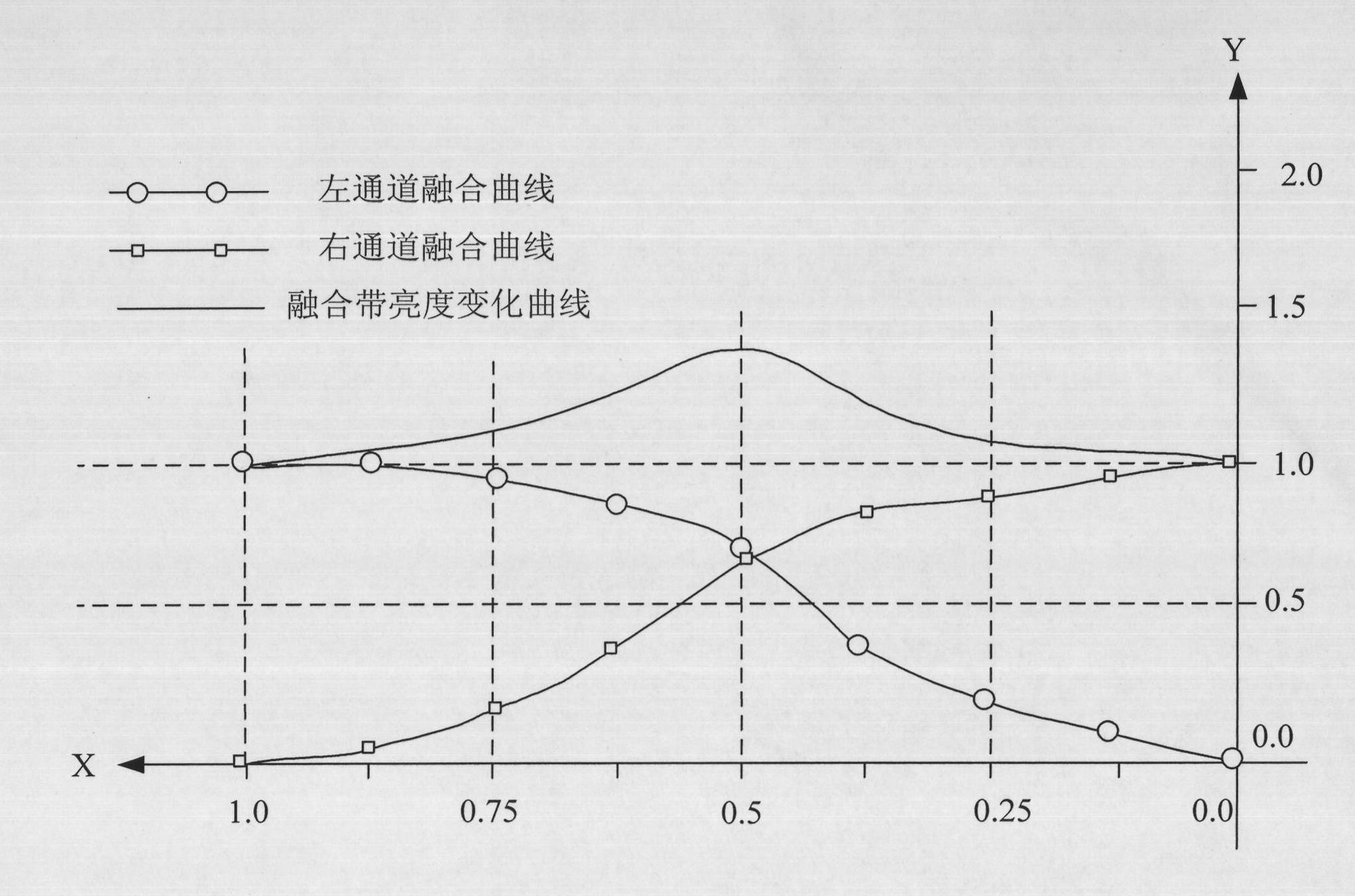

The invention discloses a multi-projecting apparatus image splicing automatic edge blending method based on fuzzy control, which comprises the following steps: step 1: setting the position, number and blending zone parameter of a control point, and carrying out blending zone primary adjustment; step 2, calculating blending zone brightness difference based on machine vision to obtain a blending zone brightness variation curve; and step 3, realizing automatic adjustment of blending zone based on the fuzzy control. The invention adopts a sectional spline function, timely generates the blending curve by the mode of online fitting, has universal adaptability, and can obtain good effect even if the projecting apparatus has bigger difference. The method is easy and convenient to implement, greatly simplifies the complexity of adjustment of the edge blending, and realizes the automatic adjustment of the multi-projecting apparatus image splicing automatic edge blending on the basis of the machine visual feedback and an artificial intelligence algorithm.

Owner:BEIHANG UNIV

Safe application program installing method and safe application program installing device

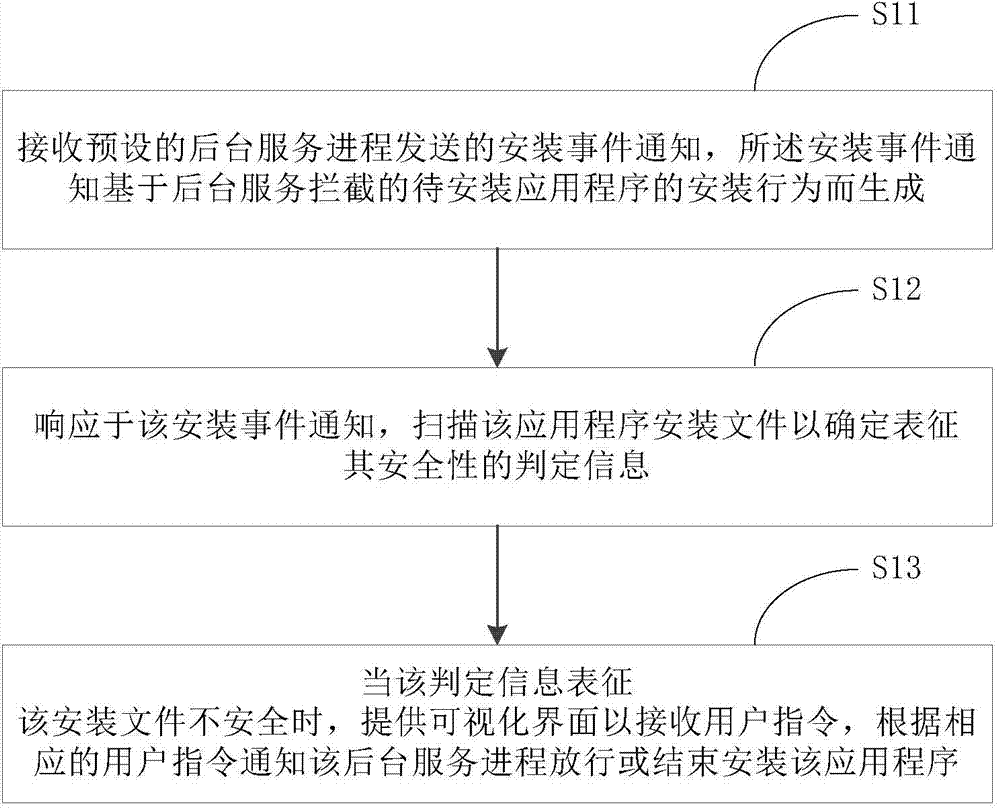

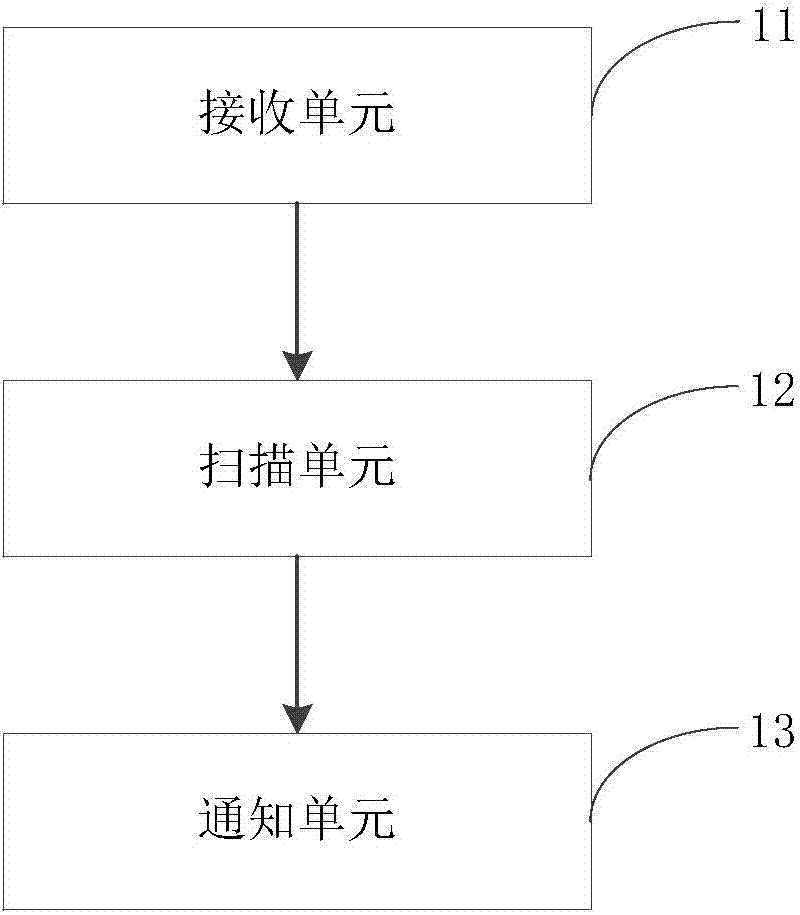

InactiveCN104850779AAvoid harmAvoid laggy performance of scansComputer security arrangementsApplication softwareOperating system

The invention provides a safe application program installing method. The safety application program installing method comprises the following specific steps of receiving a preset installing event inform which is transmitted from a background server and is generated on the basis of an installing behavior of a to-be-installed application program intercepted by the background server; responding the installing event inform; scanning an application program mounting file so as to determine judgment information which shows the safety of the application program installing file; providing a visual interface so as to receive a user command when the judgment information shows that the installing file is not safe; and informing the background server of releasing the installing file or finishing installation of the application program according to the corresponding user command. Moreover, the invention also provides a safe application program installing device. By the safe application program installing method, virus scanning can be finished before installation of the application program, and the application program can be installed safely.

Owner:BEIJING QIHOO TECH CO LTD +1

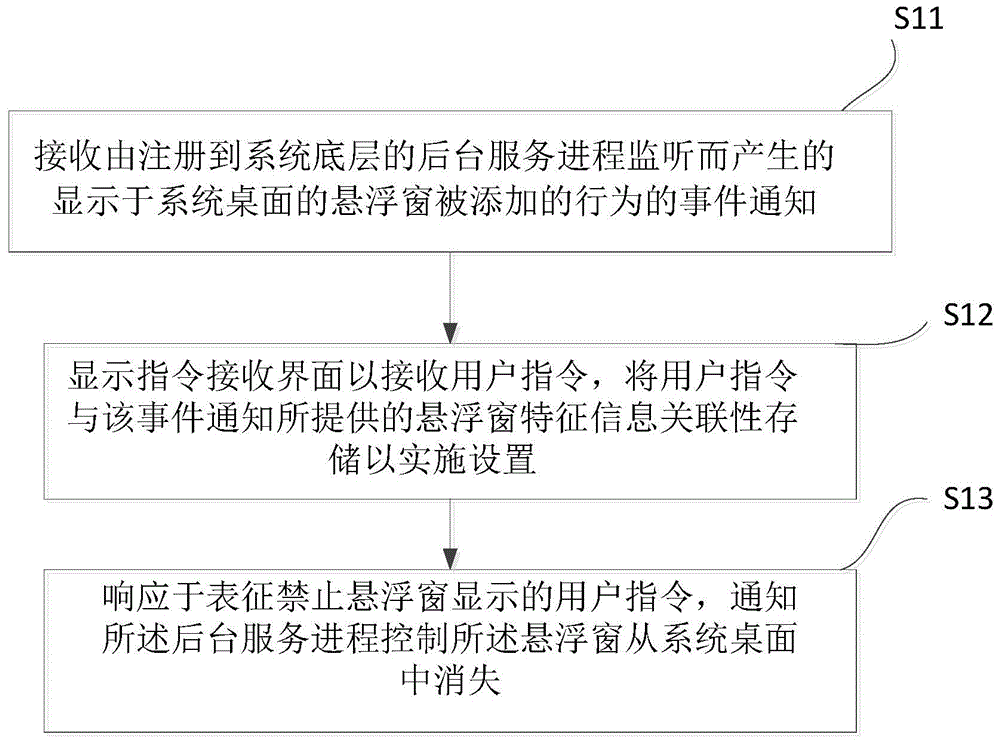

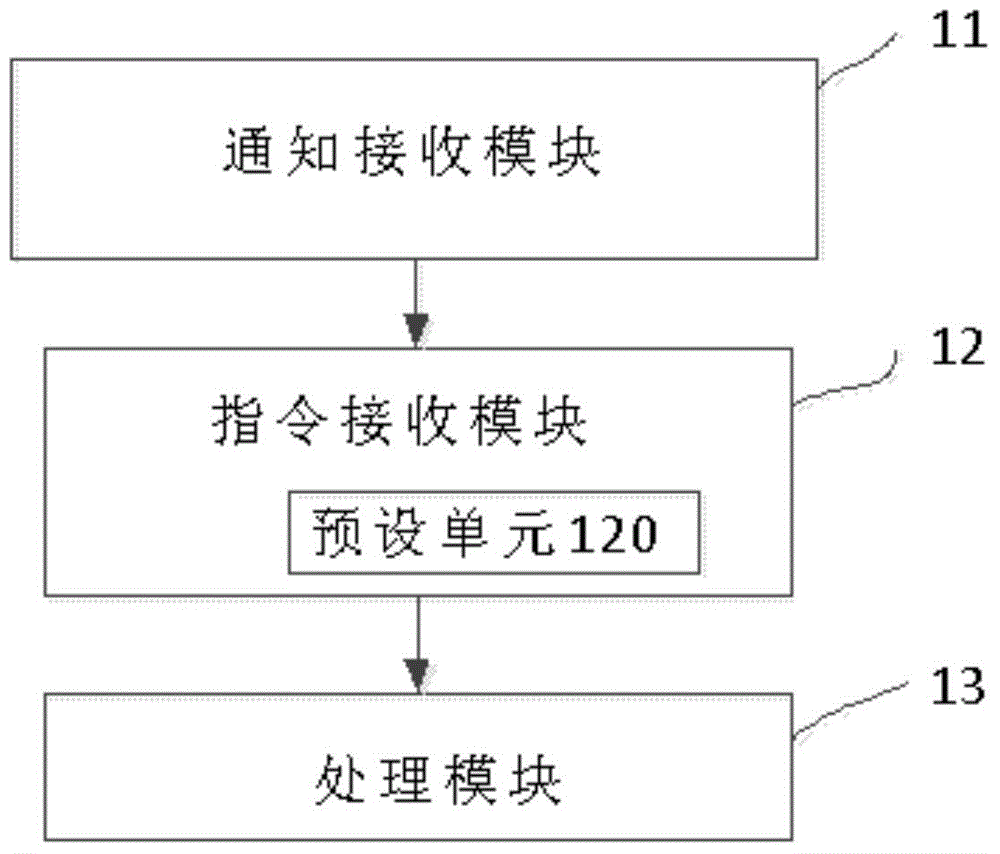

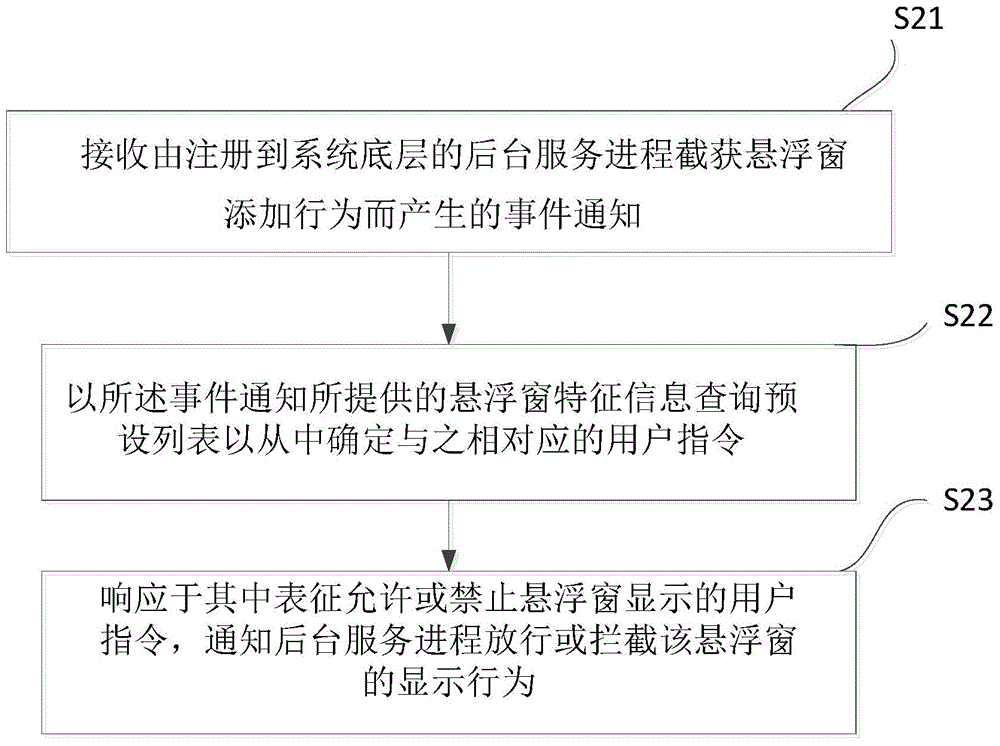

Floating window display setup, control method and device

InactiveCN104881601AImprove interception efficiencyImprove experiencePlatform integrity maintainanceOperating systemService process

The invention relates to an advertisement interception technique, and relates to a floating window display setup method and a device. The floating window display setup method comprises the following steps: receiving an event notice of behavior added by a floating window which is generated by the monitoring of a background service process registered to a system bottom layer and is displayed on a system desktop; displaying an instruction receiving interface to receive a user instruction, and relatively storing the feature information of the floating window provided by the user instruction and the event notice to implement setup; informing the background service progress of controlling the floating window to disappear in the system desktop by responding to a user instruction which represents the prohibition of the floating window display. Therefore, the technical problem that the display of the floating window cannot be effectively blocked can be solved in the prior art, the interception efficiency of the floating window can be improved by a way of looking for a preset list, and the experience that a user operates an IT (Intelligent Terminal) can be improved.

Owner:BEIJING QIHOO TECH CO LTD +1

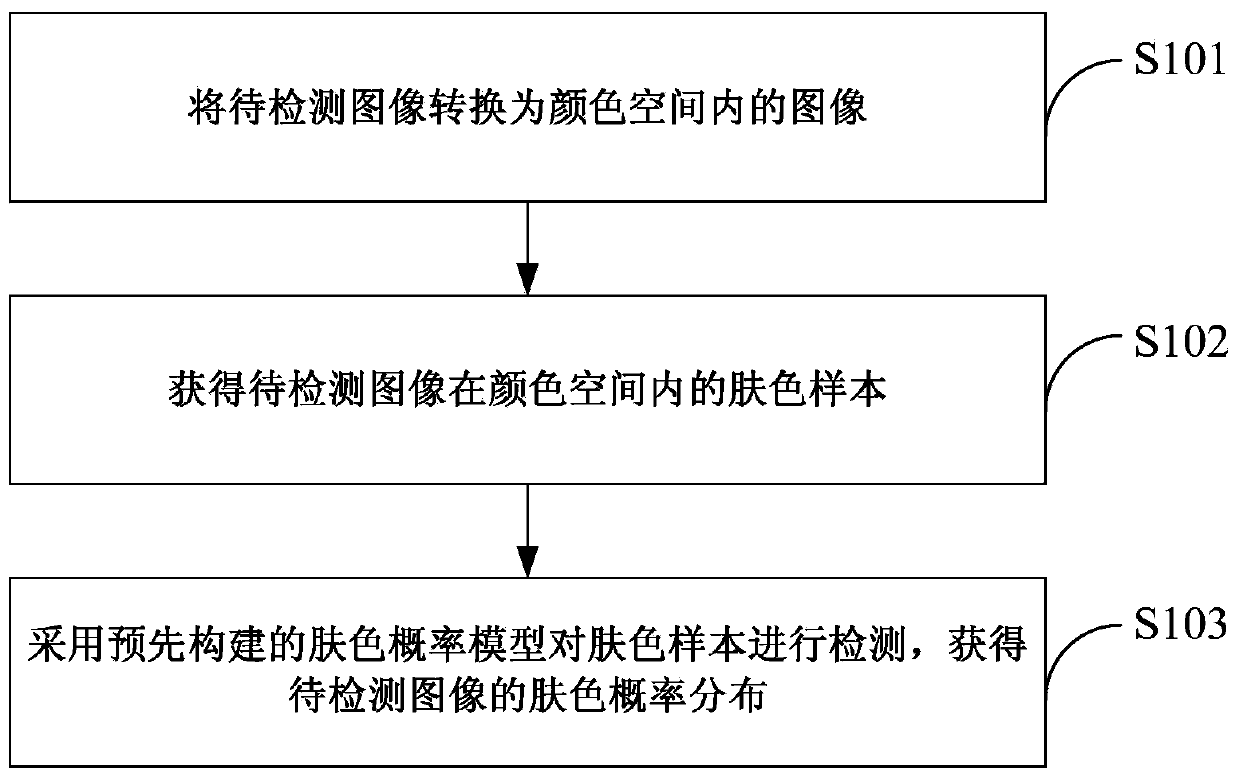

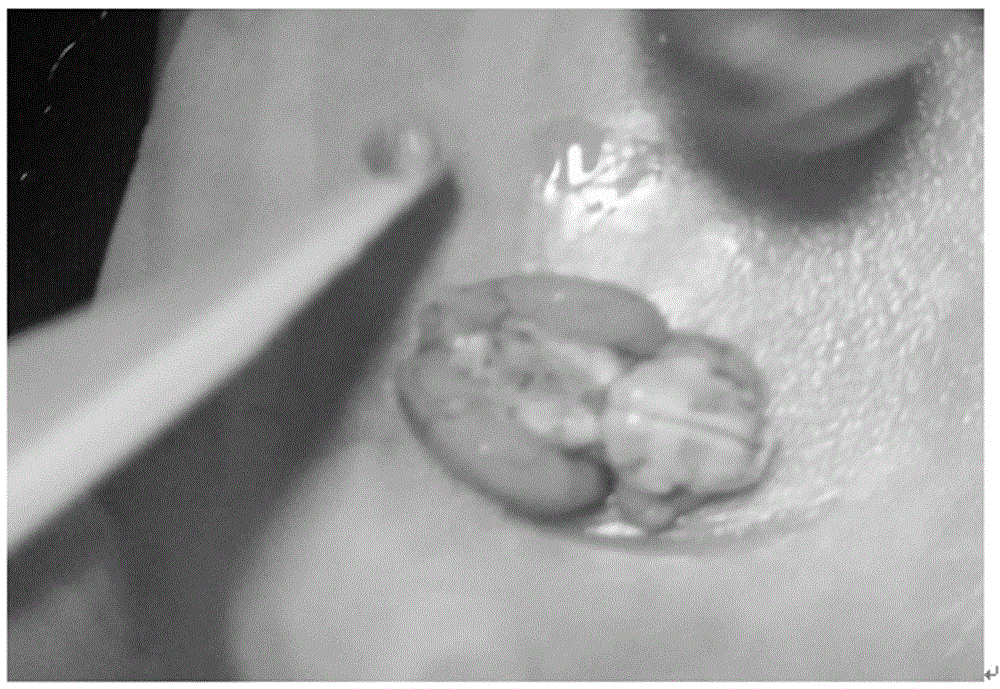

Skin color detection method and skin color detection device

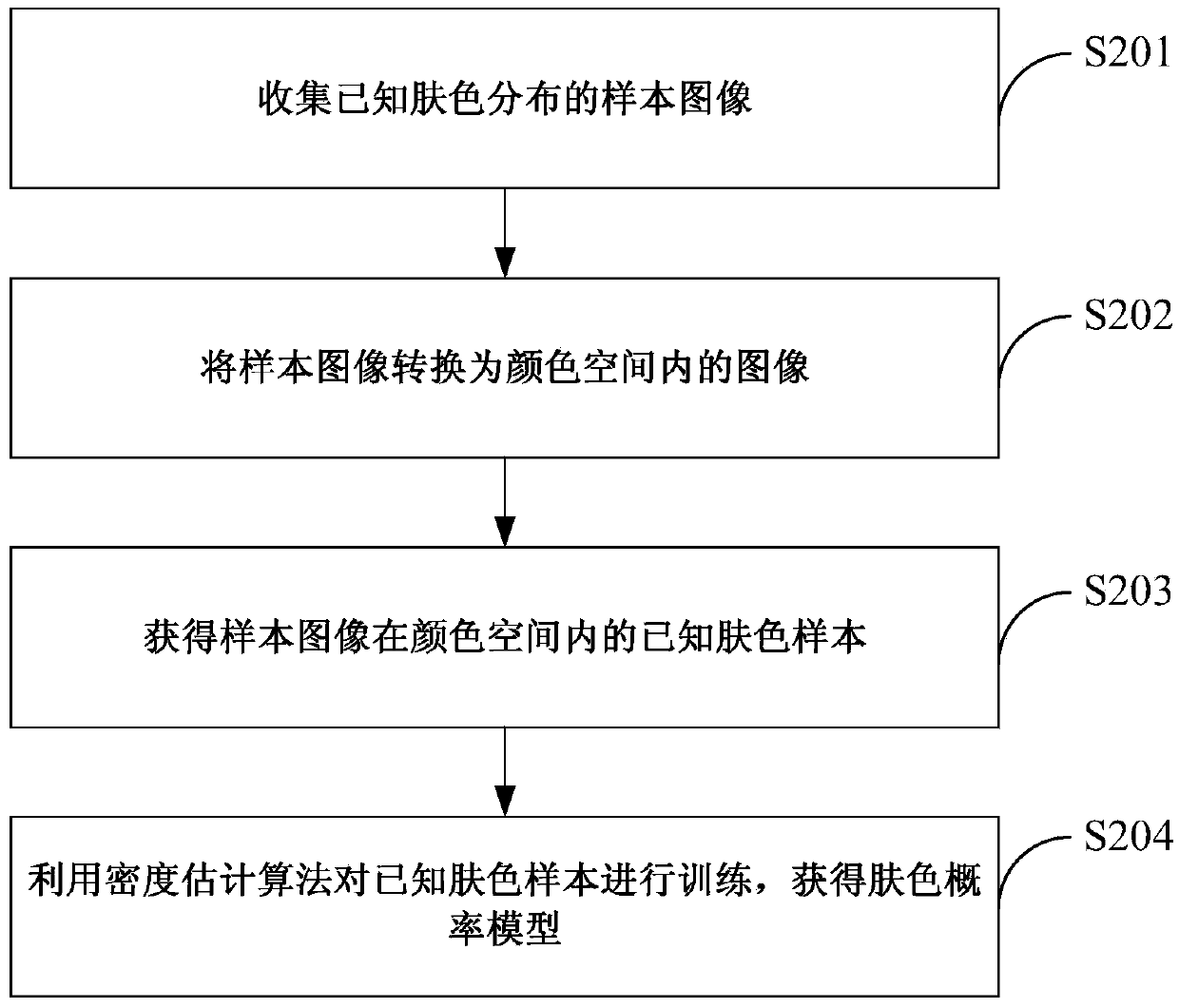

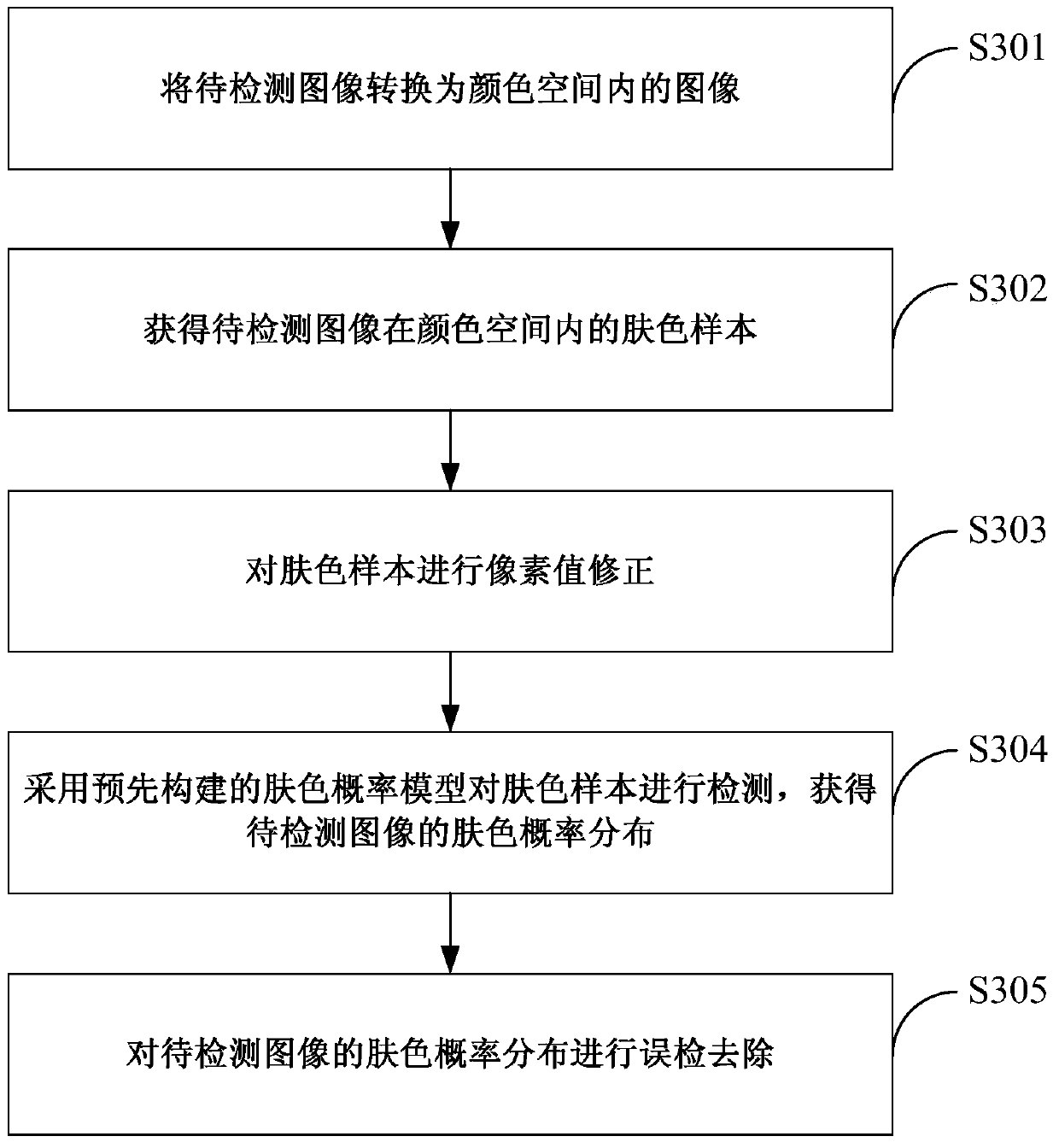

ActiveCN103745193AUniversally adaptableReduce false positivesCharacter and pattern recognitionPattern recognitionSkin color

The invention relates to a skin color detection method and a skin color detection device. The skin color detection method comprises the following steps: converting a to-be-detected image into an image in a color space; acquiring the skin color sample of the to-be-detected image in the color space; and adopting a pre-constructed skin color probability model to detect the skin color sample so as to obtain the skin color probability distribution of the to-be-detected image, wherein the skin color probability model is a model which is obtained through training with the use of a known skin color sample and is used for determining the skin color probability. The method can be applied to non-rectangular complex skin color distribution.

Owner:XIAOMI INC

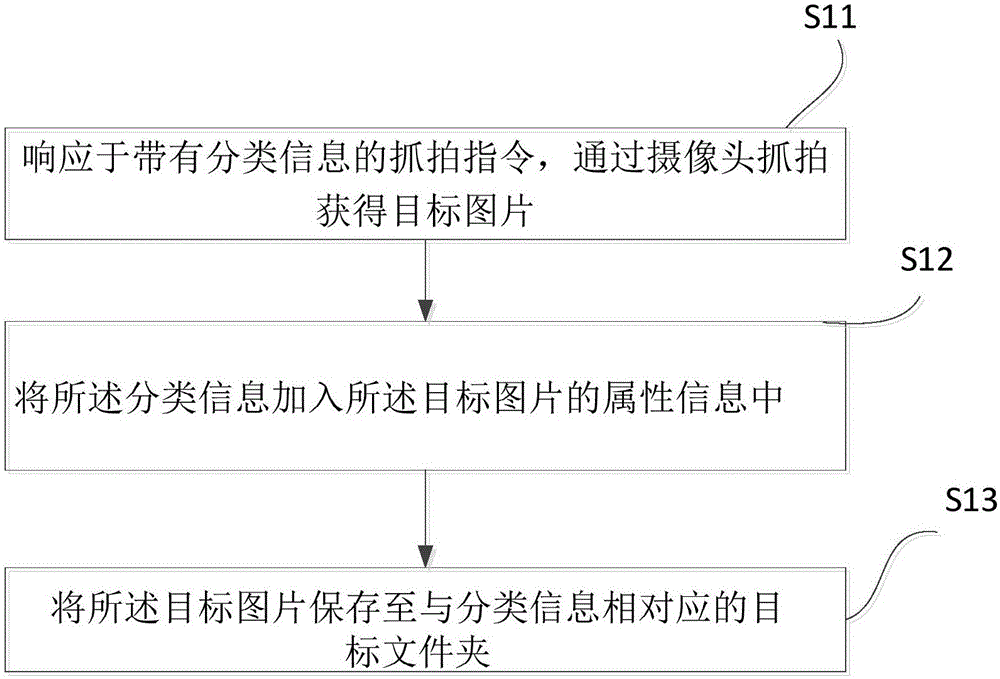

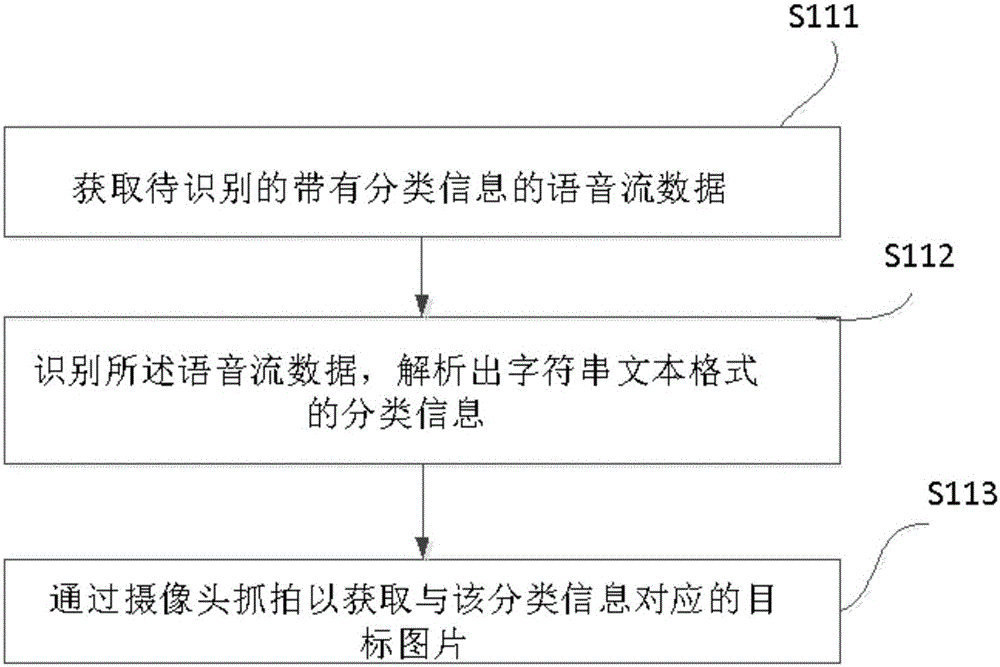

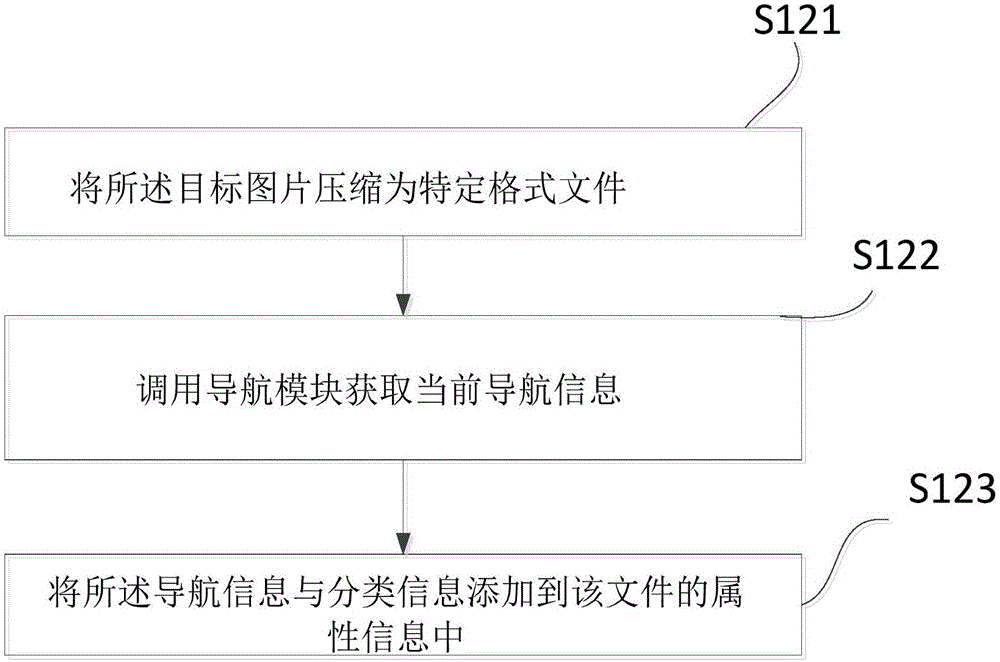

Sorted storage method for target picture and terminal employing sorted storage method

InactiveCN105138578AImprove user experience and securityThere will be no problem of being easily overwritten by video dataRelational databasesSpecial data processing applicationsControllabilityAlgorithm

The invention relates to the technical field of picture storage at intelligent terminals, in particular to a sorted storage method for a target picture and a corresponding terminal employing the sorted storage method, and discloses a sorted storage method of a target picture. The method comprises the following steps: responding to a capturing instruction with classified information and carrying out capturing to obtain a target picture through a camera; adding the classified information to attribute information of the target picture; and storing the target picture into a target folder corresponding to the classified information. The invention further provides a sorted storage terminal for a target employing the method. The terminal comprises a capturing module, an attribute setting module and a storage module. According to the method and the terminal disclosed by the invention, sorted storage of the target picture into the corresponding target folder on the basis of the classified information can be achieved; and a user only needs to directly access the corresponding target folder when searching the target picture, so that searching is facilitated; and the controllability of the user is improved.

Owner:BEIJING QIHOO TECH CO LTD +1

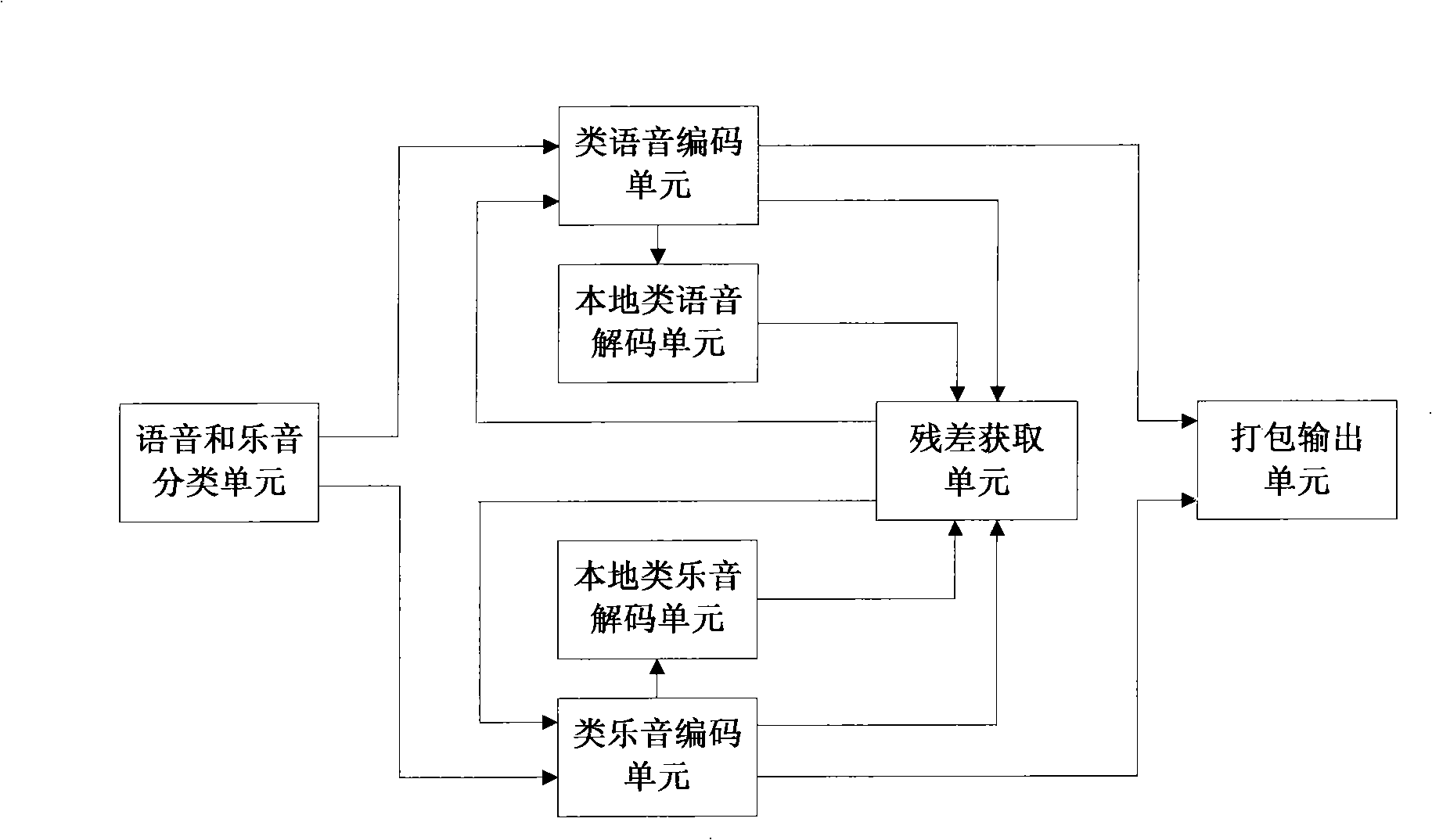

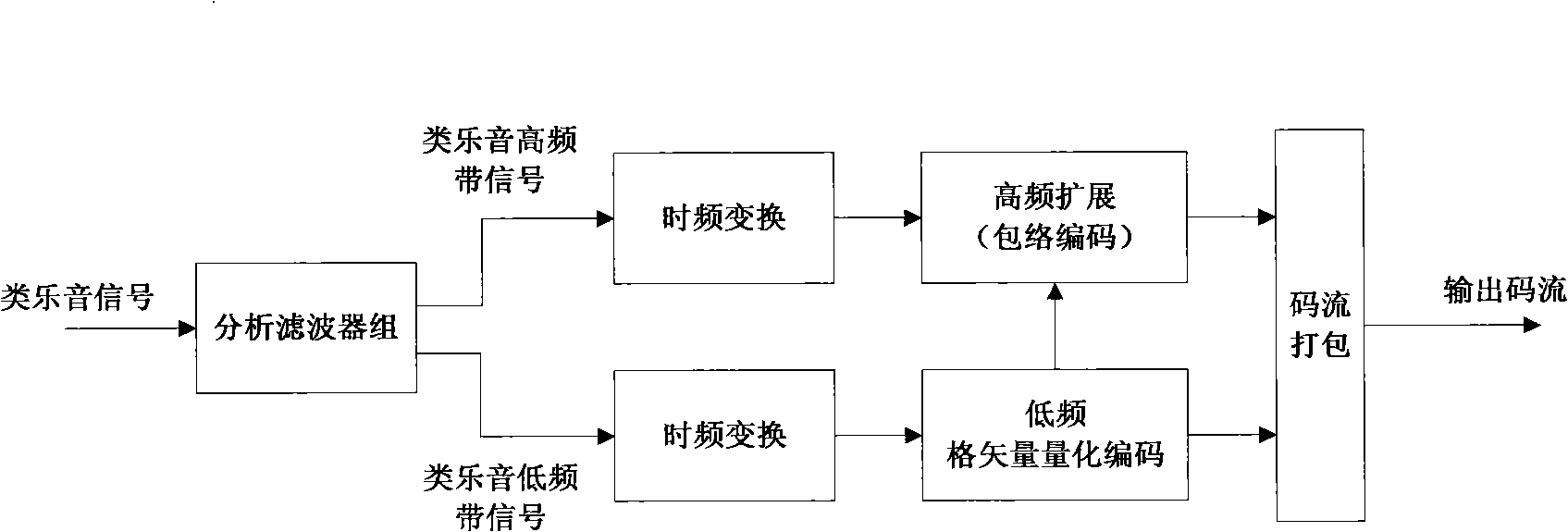

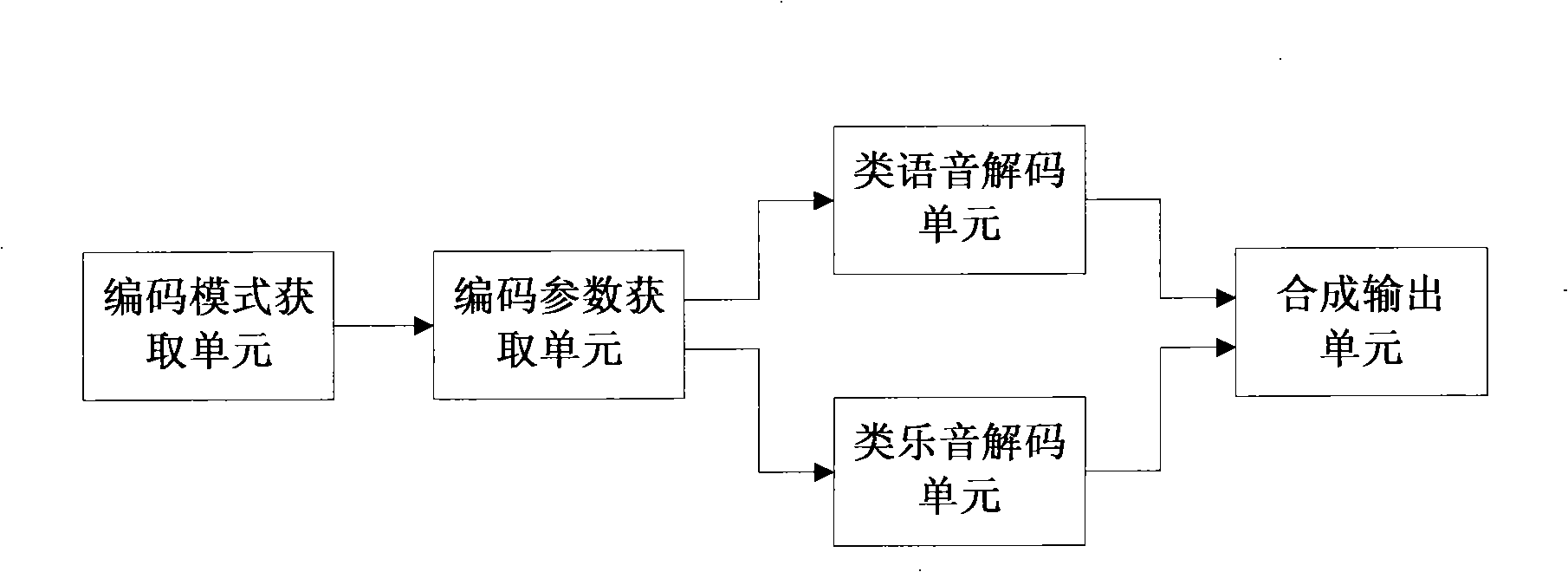

Apparatus for encoding and decoding hierarchical voice and musical sound together

A gradable combined voice and music CODEC device in the technical domain of digital audio encoding is provided. In the encoding unit in the present invention, a voice and music grading unit carries out gradation for audio signals, a graded voice encoding unit and a graded music residual encoding unit carry out encoding for graded voice signals, a graded music encoding unit and a graded voice residual encoding unit encoding unit carry out encoding for graded music signal, and provide output via a combined output module; the decoding unit comprises an encoding mode obtaining unit, an encoding parameter obtaining unit, a graded voice decoding unit, a graded music decoding unit, a combined output unit, and is designed to accomplish the process reverse to the process of the encoding unit. The CODEC device provided in the present invention is applicable to all voice and music signals, and can reduce data loss in the encoding process, improve encoding quality; especially, the CODEC device can maintain high acoustic quality at higher code rates.

Owner:SHANGHAI JIAO TONG UNIV

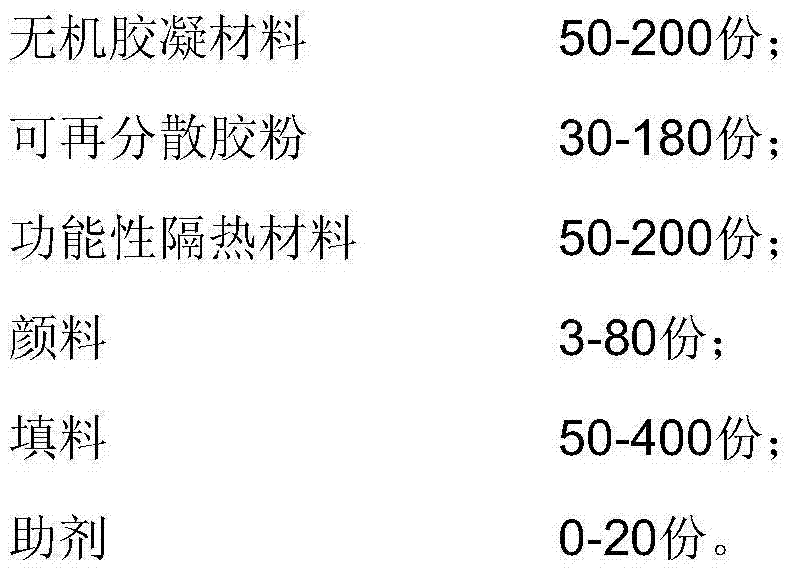

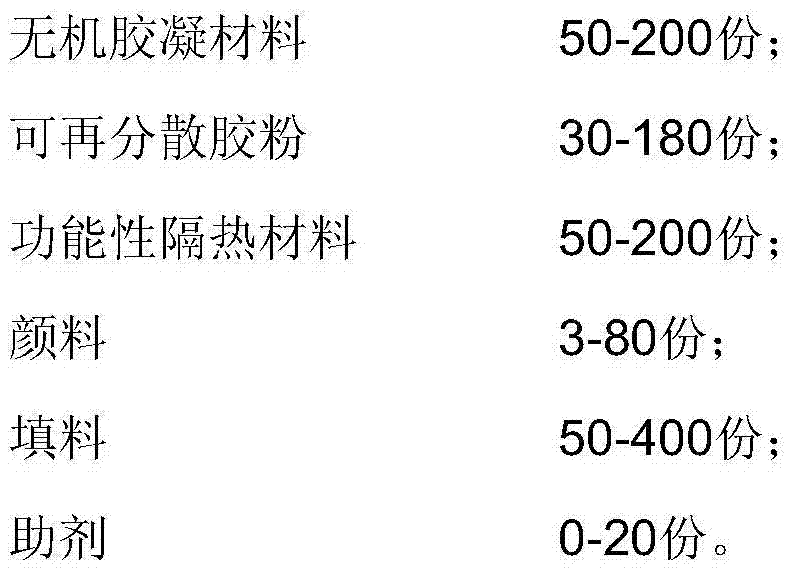

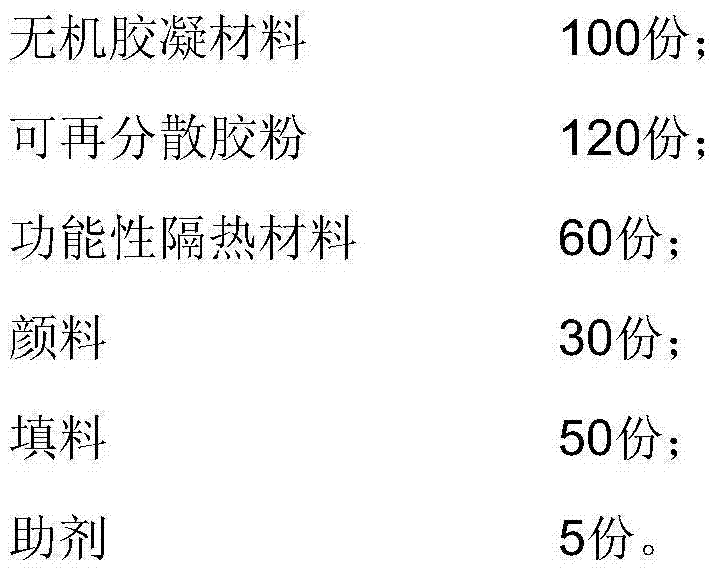

Inorganic dry powder reflective heat insulating coating

InactiveCN104496328AImprove insulation performanceStrong adhesionWeather resistanceHazardous substance

The invention provides an inorganic dry powder reflective heating insulating coating. The coating is in the form of dry powder and comprises the following components in parts by weight: 50-200 parts of an inorganic cementing material, 30-180 parts of re-dispersible rubber powder, 50-200 parts of a functional heat insulating material, 3-80 parts of a pigment, 50-400 parts of a filler and 0-20 parts of an auxiliary agent. The inorganic dry powder reflective heating insulating coating provided by the invention has excellent reflective illumination and light-heat isolation performances, and can meet related requirements in JC / T1040-2007 Heat Reflection Heat Insulating Coatings for Outer Surfaces of Building, and specifically the total reflectivity to sunlight heat rays is more than 85-90%; and besides, the coating also has good adhesive force, weathering resistance, storage stability and convenience in transportation, and meanwhile cannot generate harmful substances including VOC, benzene, formaldehyde, heavy metals and the like.

Owner:SHANGHAI GIANT ENERGY SAVING MATERIALS

Compound biological deodorizer as well as preparation method and application thereof

ActiveCN104548175AUniversally adaptableGood deodorizing effectFungiBacteriaBiotechnologyPichia pastoris

The invention relates to a compound biological deodorizer as well as a preparation method and application thereof. The compound biological deodorizer comprises a plant extract, pichia pastoris, pediococcus pentosaceus, pediococcus acidilactici, candida mycoderma and bacillus megatherium. Through the utilization of compound biological deodorizer to treat a waste transfer station, a livestock and poultry farm and a composting site, the NH3 removal rate can respectively reach 65.2-71.6%, 63.4-73.7% and 53.42-75.77%, and the H2S removal rate can reach 53.5-60.1%, 35.5-45.9% and 47.2-53.8%, so that the odor concentration is obviously reduced, the environment of the periphery of the waste transfer station, the livestock and poultry farm and the composting site is effectively improved, and the improvement of both economic benefits and environment-friendly benefits is facilitated.

Owner:北京沃土天地生物科技股份有限公司

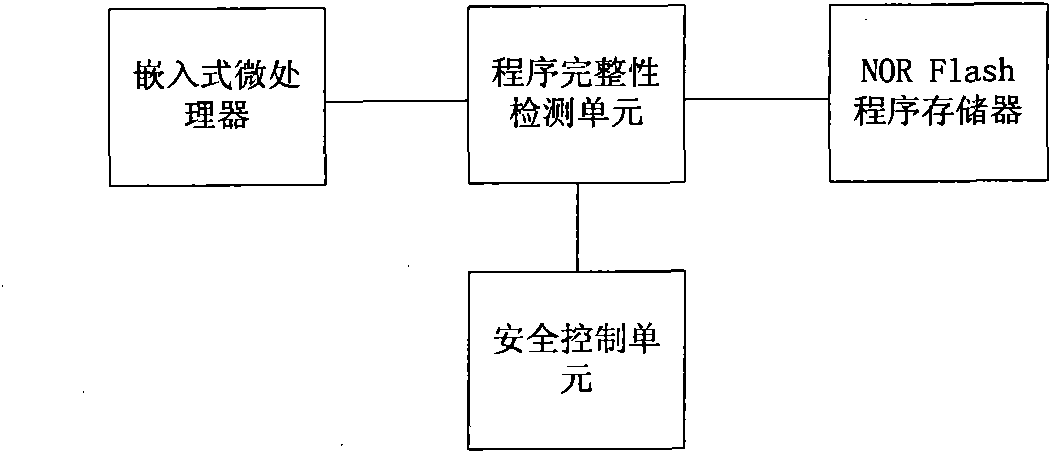

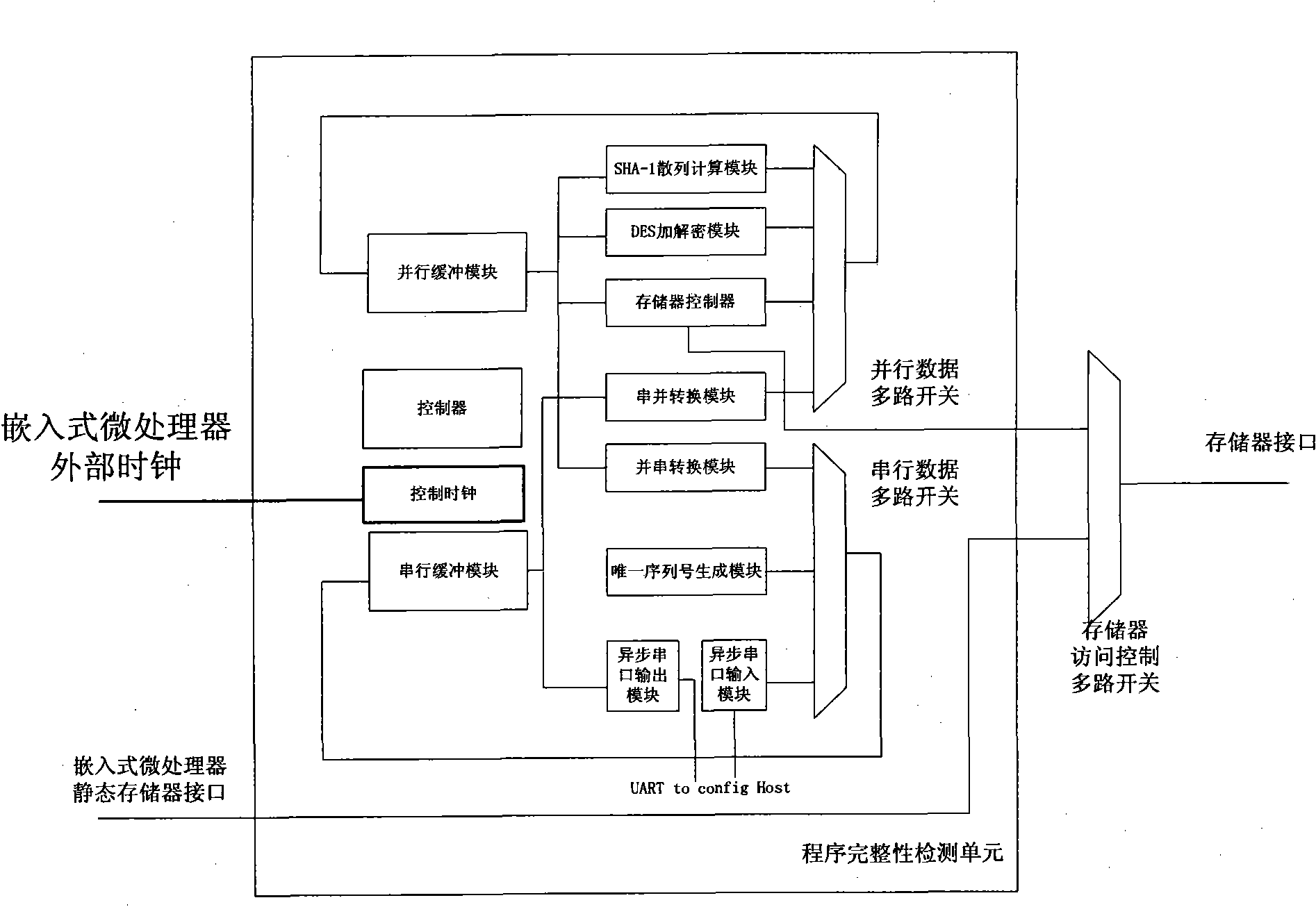

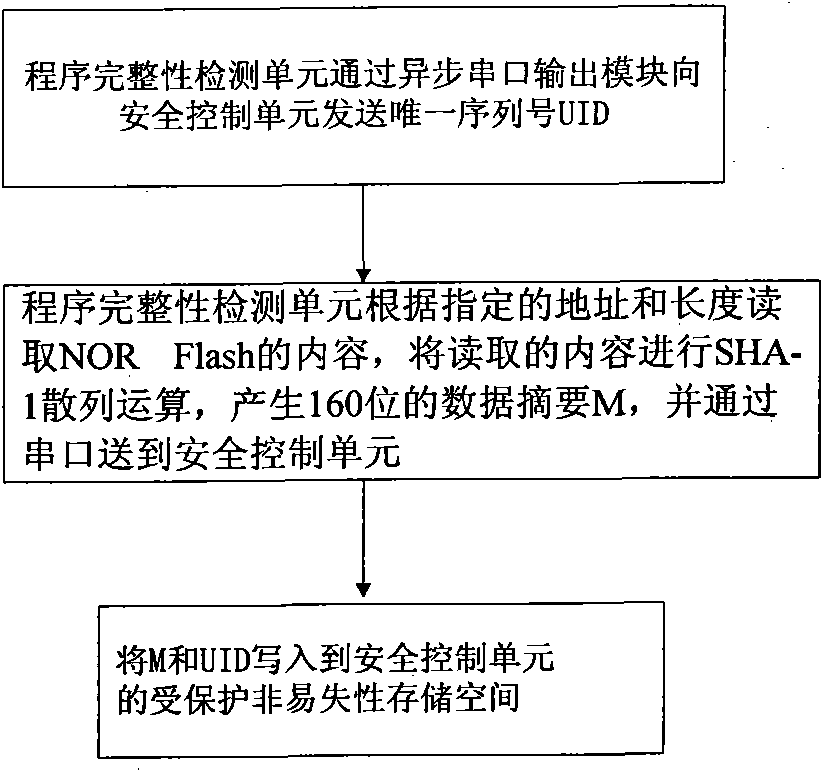

Embedded-type system for ensuring completeness of program and realization method thereof

InactiveCN101882189AEasy to tamper withEasy to implementDigital data protectionHash functionRunning time

The invention discloses an embedded-type system for ensuring the completeness of a program, which comprises an embedded-type microprocessor, a storage device, a program completeness detection unit and a safety control unit wherein: the program completeness detection unit is used for detecting content of an appointed area of the storage device before the running, utilizing a standard hash function to calculate the hashed value of the area in the appointed area, for encrypting the hashed value and for transmitting the hashed value to the safety control unit; and the safety control unit is used for storing a correct hashed value of the content in the appointed area of the storage device, for comparing the correct hashed value with a running time hashed value which is transmitted by the completeness detection unit, and for judging whether the appointed area is altered. The invention also discloses a realization method of the embedded-type system for ensuring the completeness of the program, which comprises a configuration process and a running time detection process. The embedded-type system solves the safety problem that the code in the conventional system is easy to be altered, has the advantages of universality, low cost, less running expenditure and the like, and is particularly suitable for ensuring the completeness of the most basic trusted root of the embedded-type system.

Owner:SOUTH CHINA UNIV OF TECH

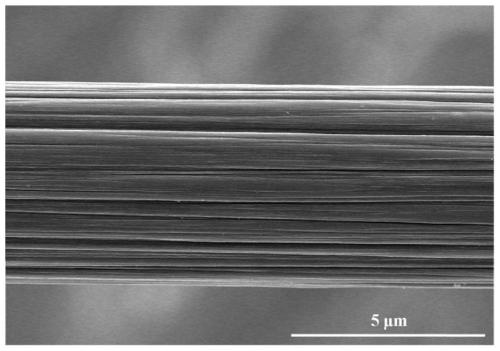

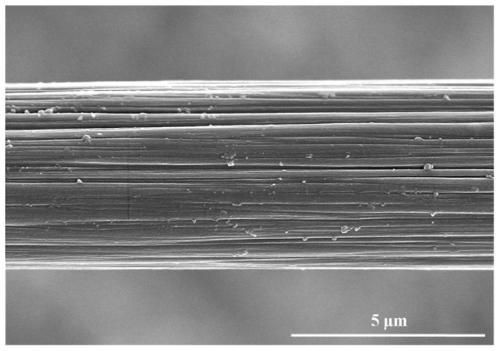

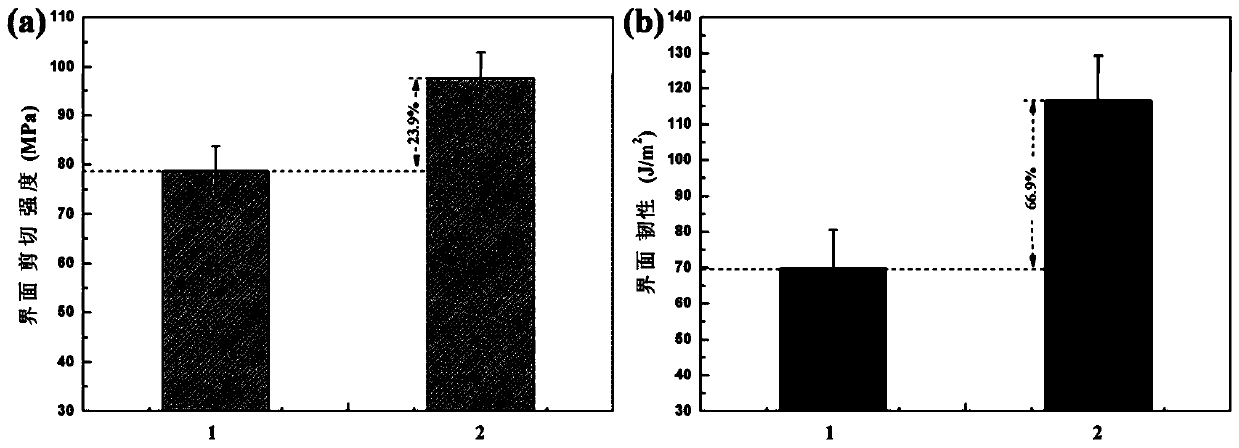

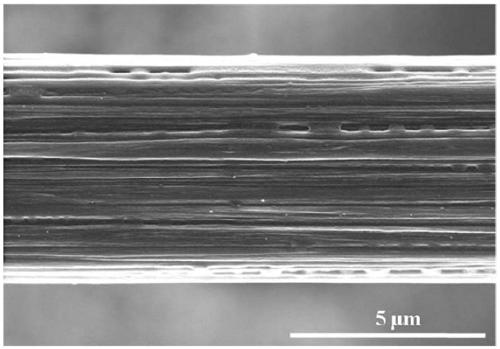

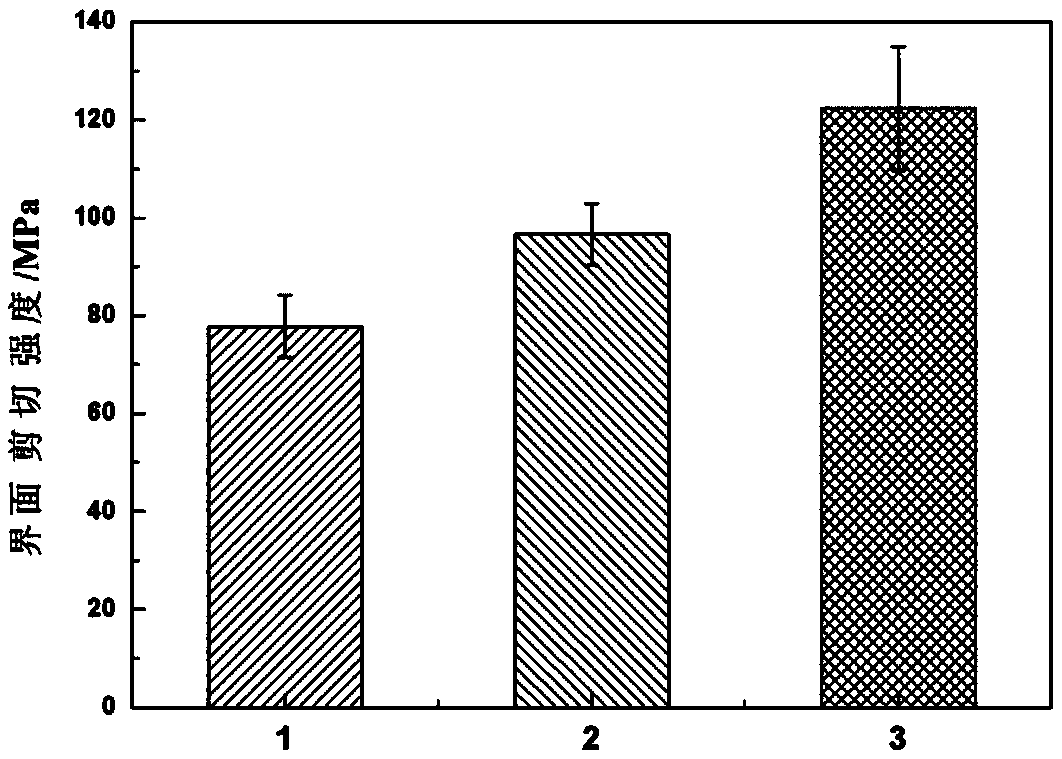

Dopamine/polyetheramine multilayer modified carbon fiber and preparation method thereof

ActiveCN109881485APromote stress redistributionFacilitates chemical bondingCarbon fibresChemistryStress redistribution

Provided are a dopamine / polyetheramine multilayer modified carbon fiber and a preparation method thereof. A polydopamine layer and a polyetheramine layer are sequentially applied on the surface of thecarbon fiber, the dopamine / polyetheramine multilayer modified carbon fiber is prepared by repeating the above operation 0-4 times, the polydopamine layer has a rigid molecular structure, the polyetheramine layer has a flexible long-chain molecular structure, and the dopamine / polyetheramine multilayer has a shell-like multilayer structure in which rigid and flexible chain segments are alternatelyarranged. Stress redistribution is promoted, chemical bonding is increased between the fiber and resin, the wettability of the fiber and resin is improved, and the interfacial bond strength of a composite material is improved. The rigid polydopamine layer has the ability to deflect cracks and induce microcracks, and the flexible polyetheramine layer promotes mutual slip between the polydopamine layers and enhances the shaping deformation, thereby improving the interfacial toughness of the composite material.

Owner:SHAANXI UNIV OF SCI & TECH

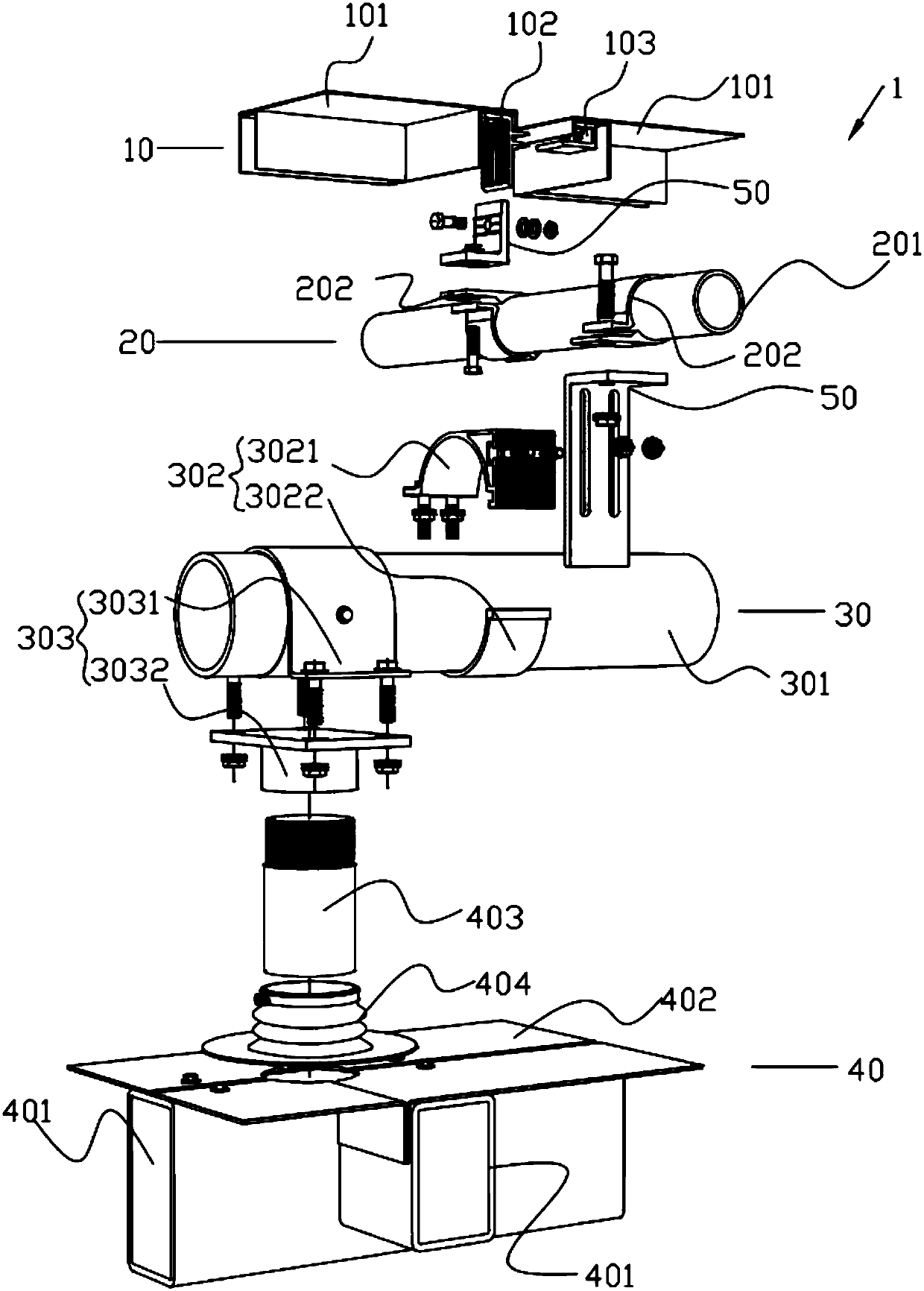

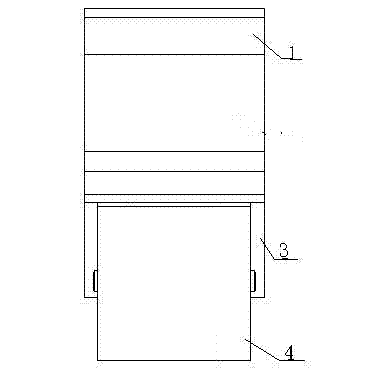

Universal adjusting mounting mechanism

ActiveCN107859219AUniversally adaptableAccurate control of shape and position differenceWallsBuilding insulationsKeelMechanical engineering

The invention provides a universal adjusting mounting mechanism. The universal adjusting mounting mechanism comprises a mounting layer assembly, a supporting layer assembly and a secondary adjusting piece; the mounting layer assembly comprises a mounting keel and a mounting connecting piece, the mounting keel is parallel to an X axis, and the mounting connecting piece is connected to the mountingkeel; the rotating position, relative to the mounting keel, of the mounting connecting piece and the moving position of the mounting connecting piece on the mounting keel can be adjusted; the supporting layer assembly comprises a supporting keel and a supporting connecting piece, the supporting keel is parallel to a Y axis, and the supporting connecting piece is connected to the supporting keel; the rotating position, relative to the supporting keel, of the supporting connecting piece and the moving position of the supporting connecting piece on the supporting keel can be adjusted; the mounting connecting piece and the supporting connecting piece are connected; and the secondary adjusting piece is connected with the mounting connecting piece and / or the supporting connecting piece, so thatthe mounting connecting piece and the supporting connecting piece has the degree of freedom to move and rotate along a Z axis. The universal adjusting mounting mechanism is a special-shaped curved surface curtain wall mounting system which can adjust the six degrees of freedom of a decoration panel and has universal adaptability.

Owner:深圳市大地幕墙科技有限公司

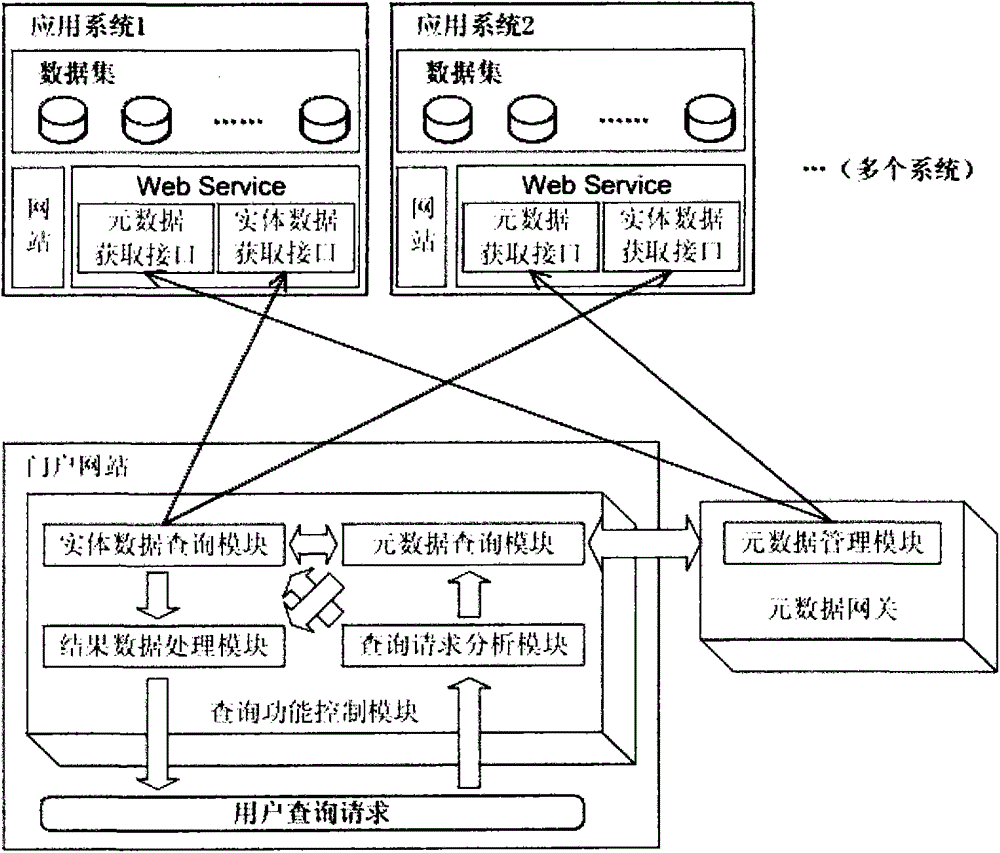

Unified management method for large-scale cross-platform heterogeneous data

InactiveCN104636329AAchieve accessAchieve sharingSpecial data processing applicationsData setData access

Provided is a unified management method for large-scale cross-platform heterogeneous data. Firstly, a metadata standard which accords with industry characteristics and has universal adaptability is made according to the conditions of existing data sets, and all the data sets in different application systems are described through metadata, wherein one piece of metadata corresponds to one data set; then, the application systems provide metadata access modes and entity data access modes for the outside; finally, a unified user entry is established to achieve data sharing and access functions based on the metadata.

Owner:CHINA CHANGFENG SCI TECH IND GROUPCORP

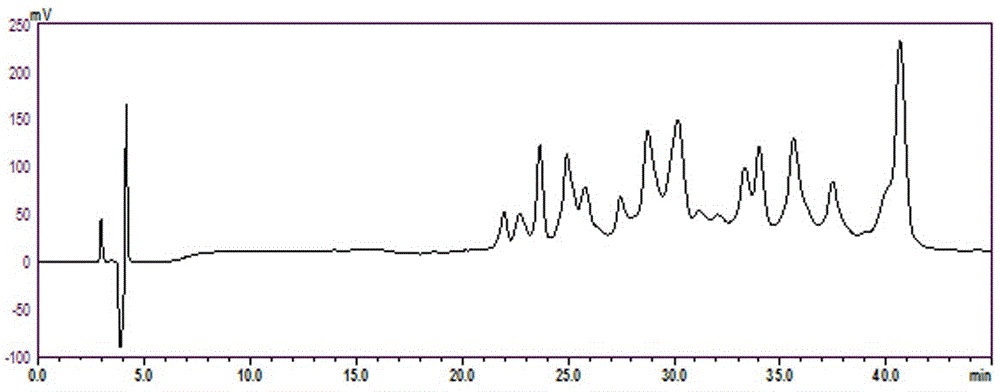

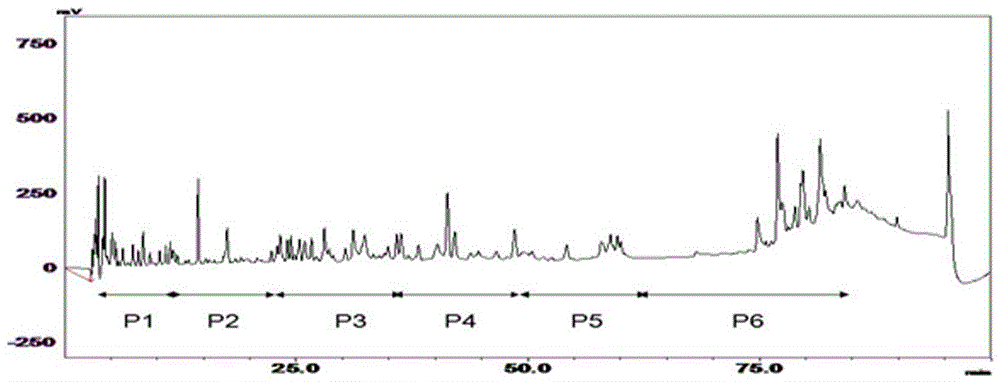

Method for screening crude delta sleep-inducing peptide extract from milk source in virtue of patch clamp technique

ActiveCN105548531AUniversally adaptableEasy to operatePreparing sample for investigationHydrolysateSteel columns

The invention provides a method for screening crude delta sleep-inducing peptide extract from a milk source in virtue of a patch clamp technique. The method comprises the following steps: adding water, trypsin and pepsin in cow's milk for enzymatic hydrolysis and carrying out spray drying after enzyme killing so as to obtain powdery casein hydrolysate; separating the casein hydrolysate through isoelectric precipitation; subjecting a purified product obtained after isoelectric precipitation to preparative liquid chromatography via a reversed-phase steel column so as to separate and purify samples again, dividing the samples into a plurality of sections according to different polarities of the samples and carrying out modeling to evaluate the activity of the crude delta sleep-inducing peptide extract; employing the whole cell patch clamp technique, giving an evoked action potential with a size of 30-60 Pa / 3000-4000 ms, delivering a drug with a dosage of 100 to 150 [mu]mol / L, recording an electrophysiological spectrum and screening out good active sleep-inducing fragments via discharging number and frequency. The method is simple to operate and has good separation effect; and the crude extract can shorten time for going to sleep and adjust sleep rhythm and provides better guarantee for health of patients with insomnia.

Owner:GREENCREAM BIOTECH

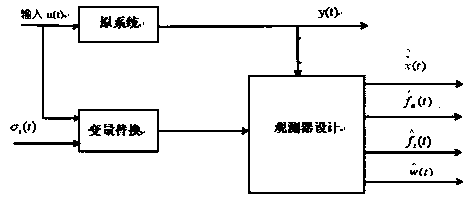

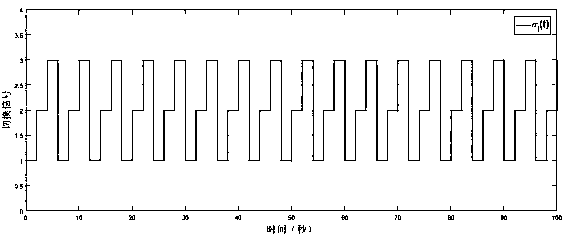

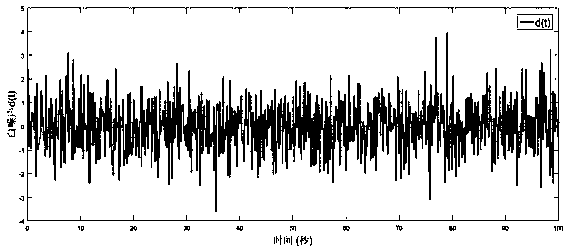

Actuator and sensor fault estimation design method for switching system

ActiveCN111090945AError system is stableExternal Disturbance EliminationDesign optimisation/simulationComplex mathematical operationsControl engineeringPerformance index

The invention discloses an actuator and sensor fault estimation design method for a switching system. The method comprises the steps: 1) building a continuous time switching system model, and completing the preparation work; 2) designing a fault estimation observer, and designing observer parameters to obtain a gain matrix of the fault estimation observer; and 3) accurately estimating a state actuator fault fa (t), a sensor fault fs (t) and measurement disturbance omega (t) of the system on line. Compared with the prior art, the self-adaptive observer serves as a fault diagnosis observer, therobustness of a fault diagnosis system to external disturbance is met, an error system is made to be stable, the H-infinity performance index is met, and accurate on-line estimation on actuator and sensor faults of the system is achieved.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

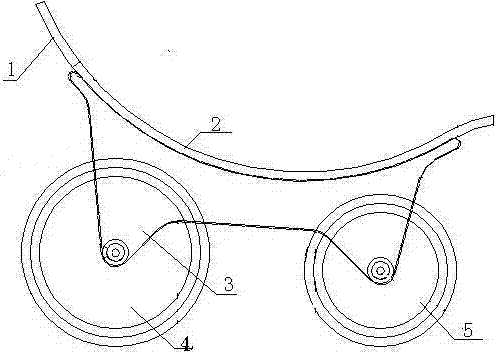

Trolley applicable to strawberry production and pickup

InactiveCN102951233ASafe walkingUniversally adaptablePassenger cyclesMechanical engineeringEngineering

The invention discloses a trolley applicable to strawberry production and pickup. The trolley comprises a body, a wheel carrier, a shaft table, a front wheel and a rear wheel. The shaft table is arranged at one end of the body, the wheel carrier is arranged below the body, the front wheel and the rear are both mounted on the wheel carrier, and the wheel face width of each of the front wheel and the rear wheel is L. Practicability and rest function of the strawberry pickup trolley are realized. The trolley applicable to strawberry production and pickup is provided with the shaft table and the body in proper shape, the function of providing a rest space besides pickup is added to the trolley, and accordingly applicability of the trolley is improved.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

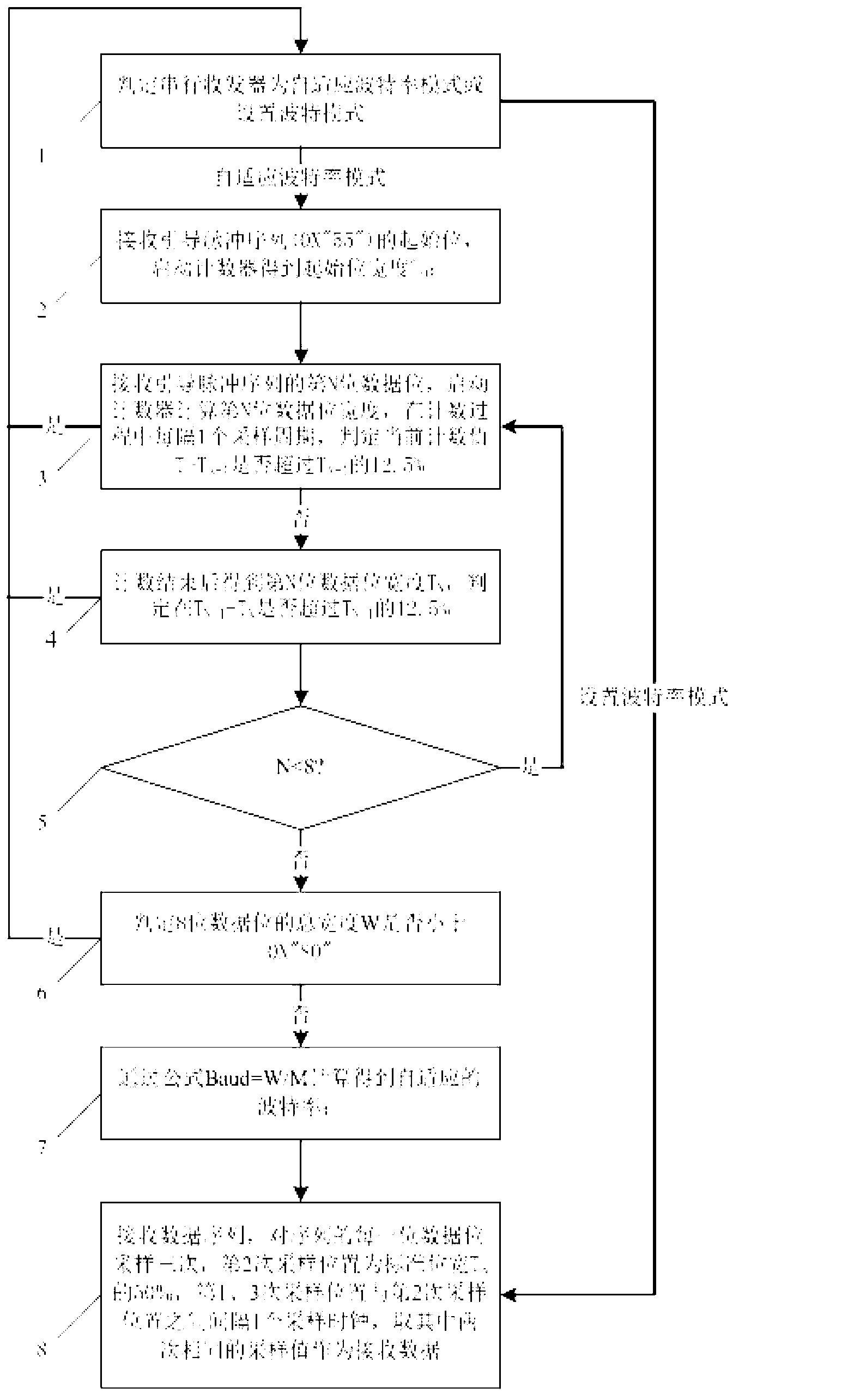

Method for realizing universal serial transceiver

ActiveCN102938744AImprove anti-interference abilityImprove reliabilityBaseband system detailsCommunication interfaceAsynchronous serial communication

The invention provides a method for realizing a universal serial transceiver. The baud rate of a sending end can be determined by receiving a pilot pulse sequence; the total width of the data bit of the pilot pulse sequence must be more than 16*M, the width difference of two adjacent bits (Nth bit and (Nth-1) bit, 1<=N<=M) of the pilot pulse sequence can not be more than x% (x value can be allocated) of the width of the (Nth-1) bit, if more than x%, the pilot pulse sequence needs to be received again for automatic matching connection; and the error of the accumulative bit width of a received data sequence can not be more than y% (y can be allocated) of a standard bit width. The method provided by the invention can not only enhance the anti-interference capacity of serial communications, but also have universality. In combined with a certain communication protocol controller, the universal serial transceiver can form a corresponding serial communication interface, such as a debugging interface and an asynchronous serial communication interface, achieves the effects of flexibility and high reliability and has wide application prospect.

Owner:NO 771 INST OF NO 9 RES INST CHINA AEROSPACE SCI & TECH

Preparation method of nano-hybrid composite membrane

ActiveCN112827369AHigh retention rateIncrease water fluxWater contaminantsWater/sewage treatment bu osmosis/dialysisNano hybridMetal particle

The invention relates to a preparation method of a nano-hybrid composite membrane. The preparation method comprises the following steps: when a water phase solution containing hybrid metal particles is prepared, adding water-soluble metal salt and a complexing agent into water so as to allow metal ions to be firstly combined with the complexing agent to form a stable complex which is uniformly distributed in the water phase; then adding a precipitant capable of reacting with the water-soluble metal salt to generate precipitates and a monomer for undergoing polymerizing to generate a composite membrane, and conducting stirring and mixing and / or performing ultrasonic treatment to obtain a water-phase solution containing uniform nanoparticles; and taking the water-phase solution as a reactant to participate in an interfacial polymerization reaction to generate a nano-particle hybridized composite membrane functional separation layer. According to the invention, the distribution uniformity of hybrid metal nanoparticles in the functional separation layer can be remarkably improved, the problem of membrane defects caused by uneven dispersion and even agglomeration of the nanoparticles is reduced, the water flux of the nano-hybrid composite membrane is improved while the high rejection rate of the nano-hybrid composite membrane is kept, the uniformity and stability of the permeability of the composite membrane are improved, and reproducibility is good.

Owner:蓝星(杭州)膜工业有限公司

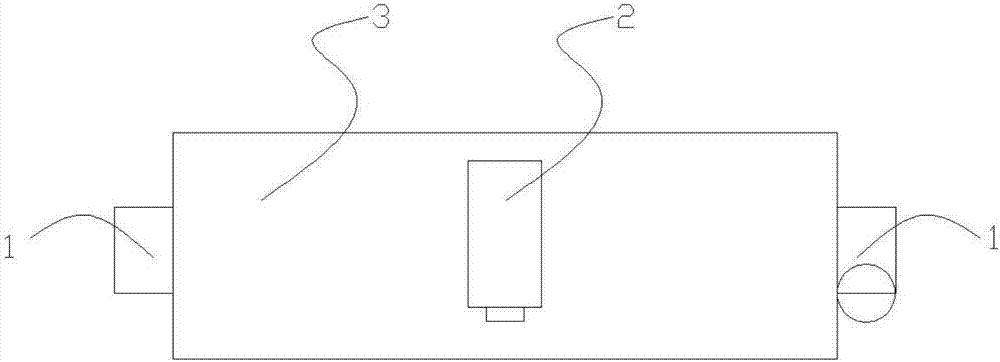

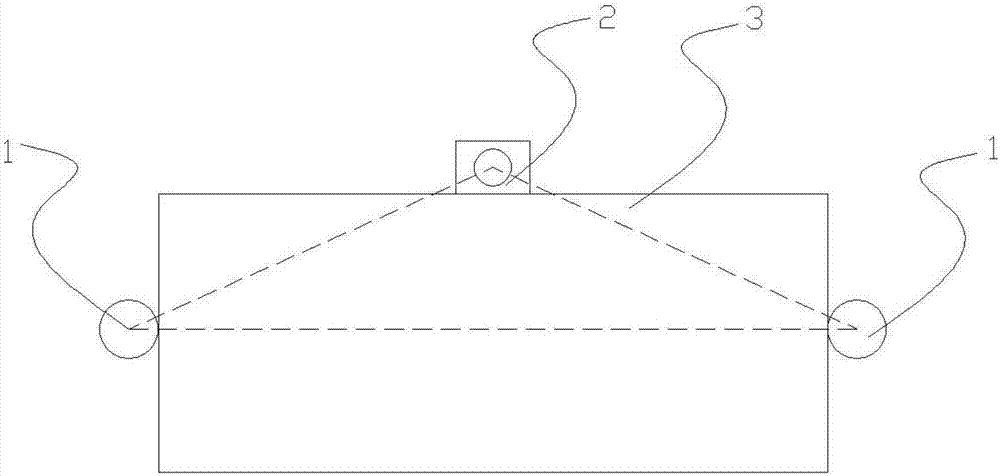

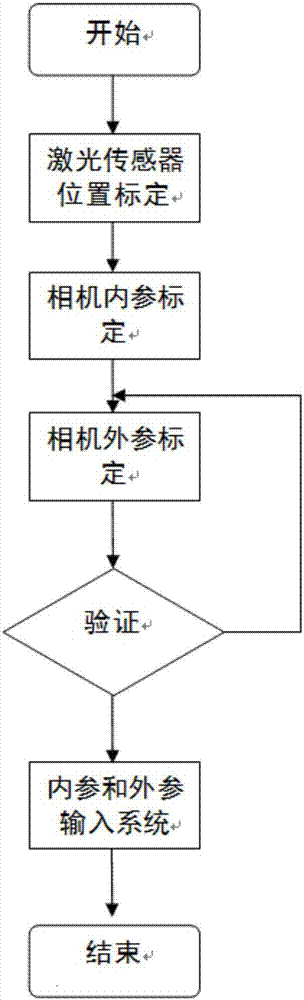

Electric car battery replacement visual system and calibration method thereof, and battery location method

ActiveCN107886545AUniversally adaptableCalibration method is simpleImage enhancementImage analysisElectricityElectrical battery

The present invention relates to an electric car battery replacement visual system and a calibration method thereof, and a battery location method. The system is provided with two laser sensors whichare installed at two sides of a battery replacement tool side by side, and a distance between the two laser sensors is G; and an industrial camera is installed on the battery replacement tool and is located between the two laser sensors; and connection lines of the industrial camera and the two laser sensors form an isoceles triangle. A concrete battery replacement flow is performed after positioncalibration of the laser sensors and calibration of internal and external parameters of the industrial camera are performed, and therefore, the electric car battery replacement visual system and thecalibration method thereof, and the battery location method are simple in implementation mode and high in applicability, can accurately obtain positions of batteries of different manufacturers, and can control the battery change tool to execute battery replacement motion.

Owner:XIAN AEROSPACE PRECISION ELECTROMECHANICAL INST

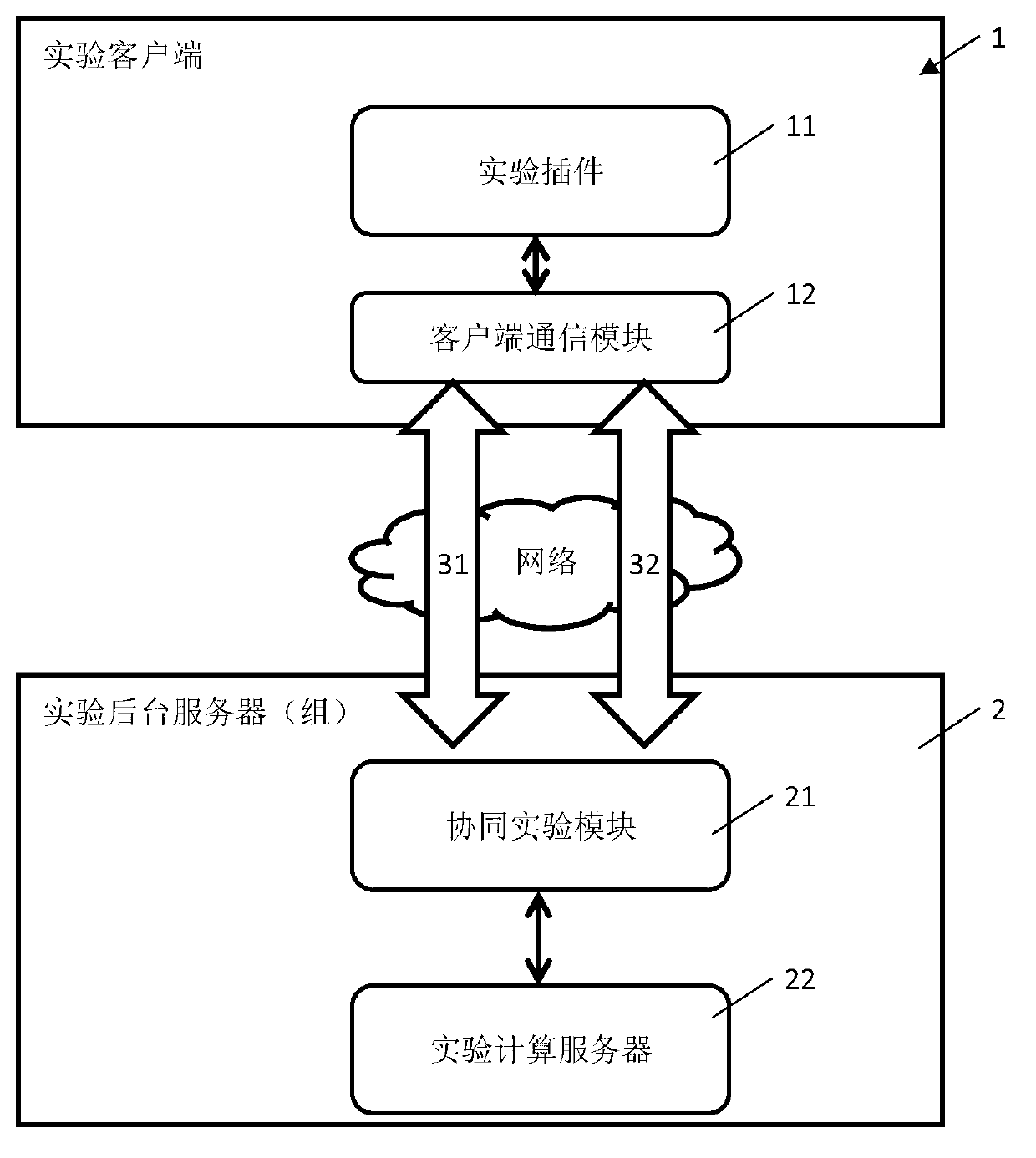

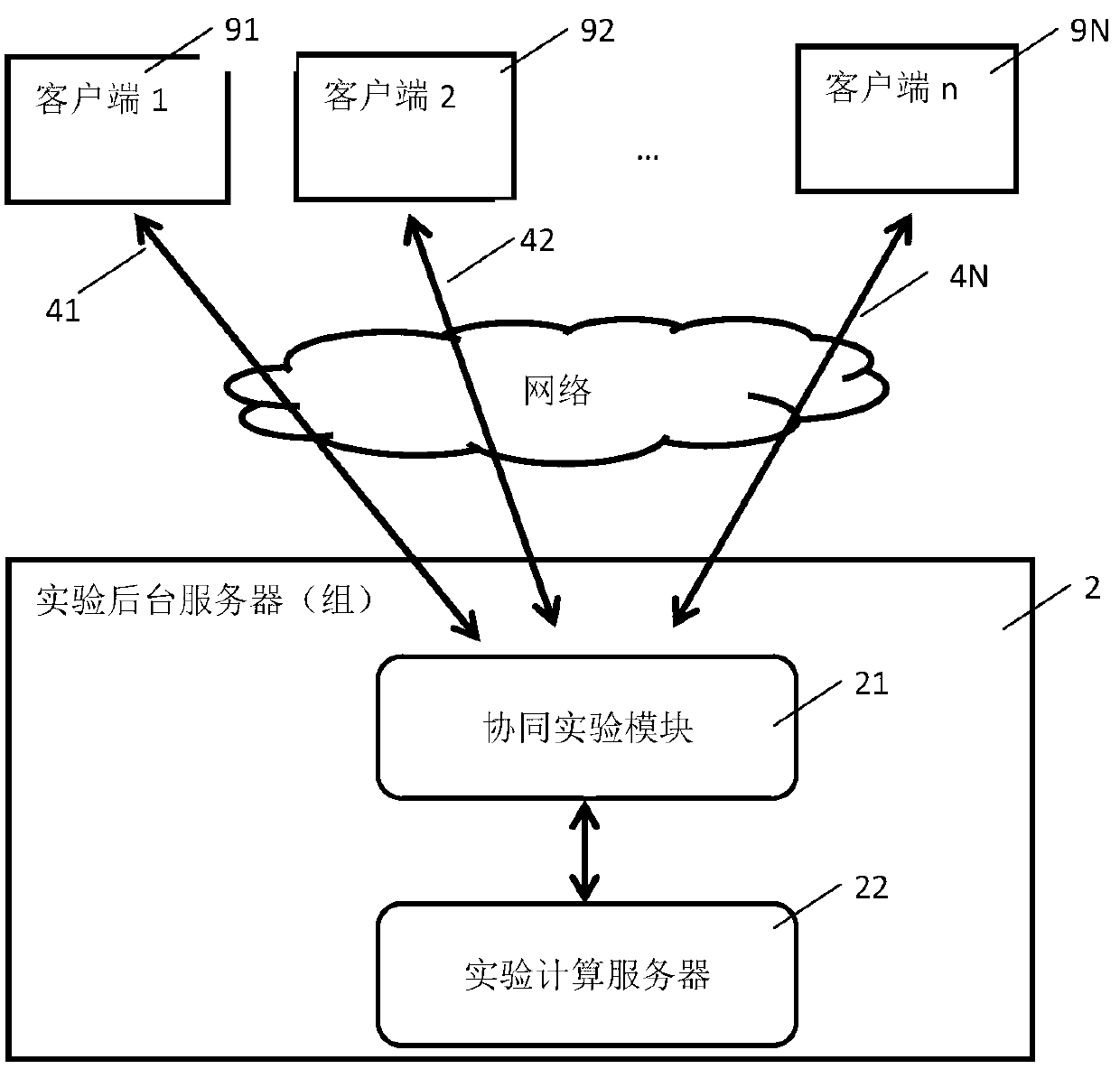

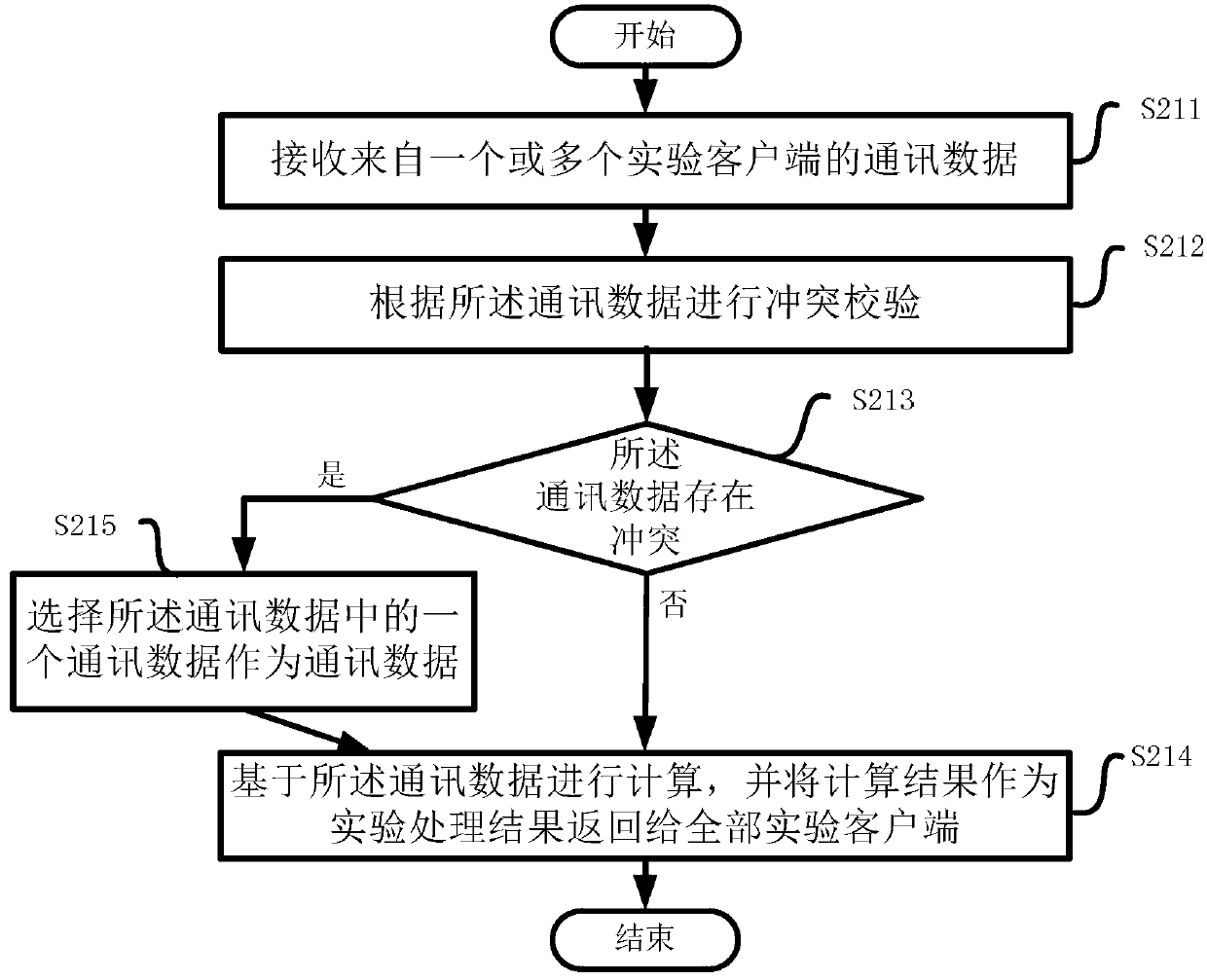

Control system and control method for networking cooperation virtual experiment

The invention provides a control system for a networking cooperation virtual experiment. The control system comprises one or more experiment client sides and one or more experiment backstage servers, wherein the experiment client side and the experiment backstage server are connected and are communicated through the internet. The experiment backstage server at least comprises a cooperation experiment module and an experiment calculating server, wherein the cooperation experiment module is used for synchronizing the data of the experiment client side and the data of the experiment backstage server, and the experiment calculating server is used for processing the data from the experiment client side and feeding the result of the processed data back to the experiment client side. Therefore, the cooperative work of the experiment client side is achieved. The invention further provides a control method for the networking cooperation virtual experiment. Unified virtual experiment standards and specifications are adopted, unified virtual experiment serving interfaces are provided, the existing network technology is utilized, and a virtual experiment cooperation platform which is strong in interaction, good in expandability, high in security and good in cooperation is developed.

Owner:TONGJI UNIV

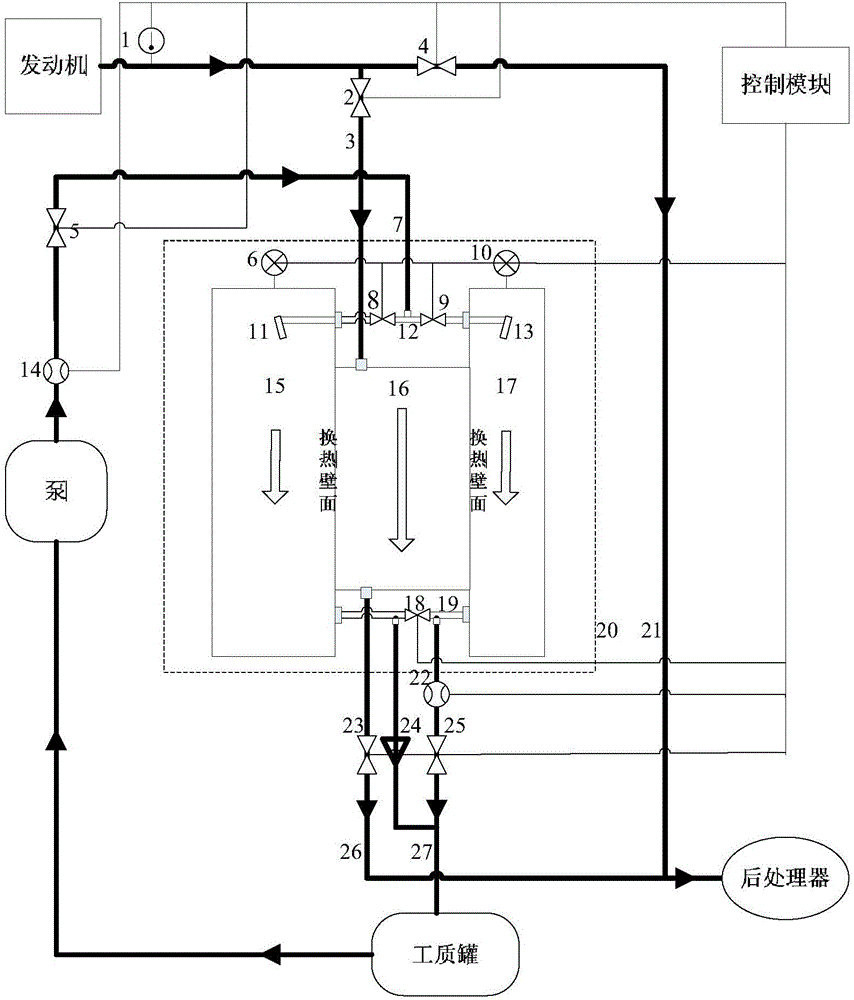

Internal combustion engine exhaust temperature control device capable of achieving sectional pressure and temperature adjustment

InactiveCN105822386ASolve the problem of real-time exhaust temperature mismatchAchieving the purpose of recycling surplus energyInternal combustion piston enginesExhaust apparatusTemperature controlEngineering

The invention relates to an internal combustion engine exhaust temperature control device capable of achieving sectional pressure and temperature adjustment. The internal combustion engine exhaust temperature control device is mainly composed of a temperature and pressure adjustor, a control unit and various electromagnetic valves. The temperature and pressure adjustor can be used for achieving sectional pressure and temperature adjustment so that a heat storage working medium can be basically kept near a preset target state, meanwhile, high temperature and high pressure are maintained in a state constant box, and the capability of heating low-temperature waste gas is achieved all the time. The heat storage working medium in the temperature and pressure adjustor can absorb and store heat of the high-temperature waste gas, after subsequent low-temperature waste gas passes through, heat can be transferred to the low-temperature waste gas again, and therefore control over the temperature of the waste gas is achieved. A control module controls a path of the waste gas according to a signal of a waste gas temperature sensor, when the temperature of the waste gas is in an efficient temperature window required by postprocessing, the waste gas directly flows into a postprocessor through a waste gas direct-through pipe, and when the temperature of the waste gas is not in the efficient temperature window required by postprocessing, the waste gas flows through the temperature and pressure adjustor to be subjected to temperature adjustment and then flows into the postprocessor.

Owner:JILIN UNIV

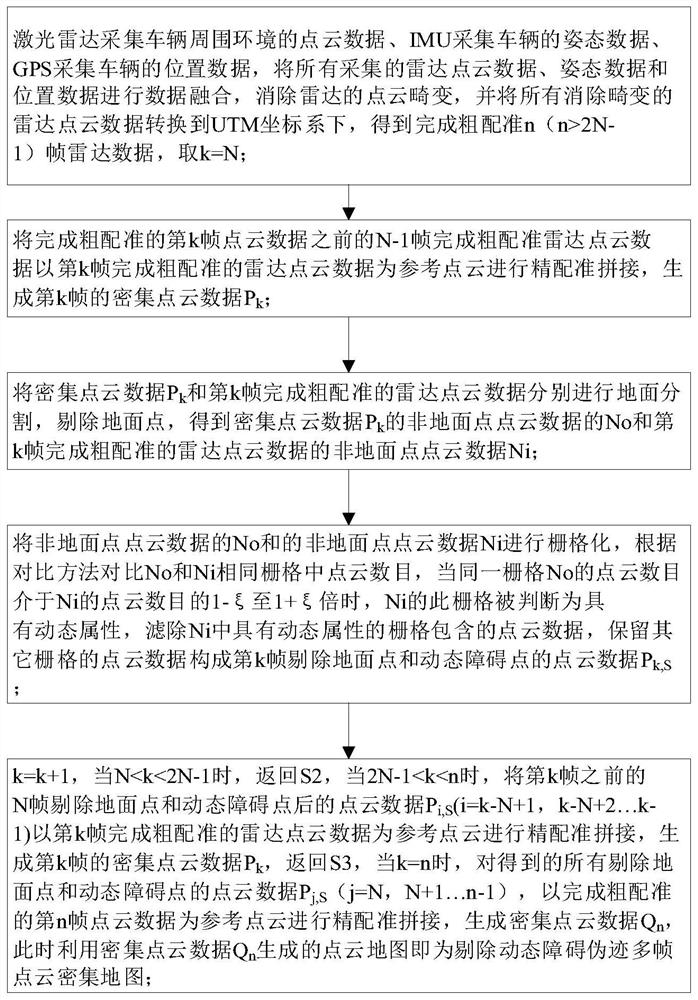

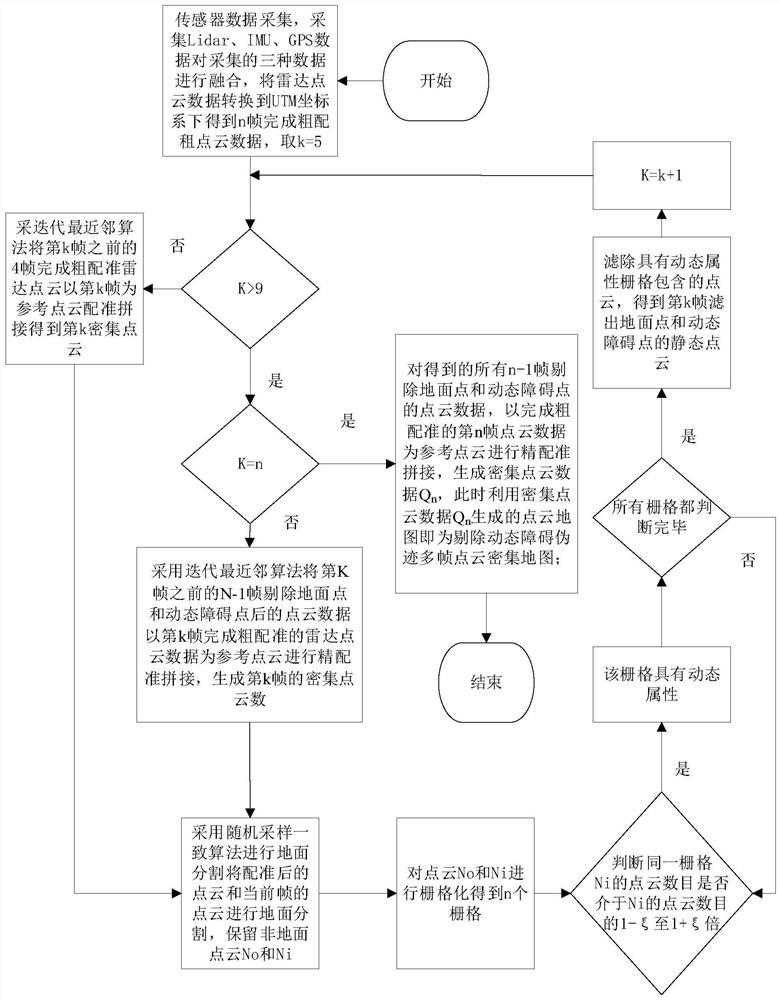

Method for eliminating dynamic obstacle artifacts in laser point cloud map

ActiveCN112162297AQuick cullingQuick buildImage analysisGeometric image transformationPoint cloudComputer graphics (images)

The invention discloses a method capable of quickly removing dynamic obstacle artifacts from a static background map in real time, and the method comprises the steps: collecting laser radar, IMU and GPS data, and converting n frames of radar point clouds into a UTM coordinate system, obtaining the kth frame of dense point cloud map by registering N-1 frames of point clouds before the kth frame tothe Nth frame, and for the frames of k being larger than 2N-2 frames, obtaining the kth frame of dense point cloud map by registering N-1 frames of static point clouds before the kth frame to the Nthframe; performing ground segmentation on the kth frame of dense point cloud map and the kth cloud, and reserving non-ground points No and Ni; rasterizing the point clouds No and Ni, and judging the dynamic and static attributes of each grid; and registering the static point clouds obtained by processing from the Nth frame to the (n-1) th frame to the nth frame of point clouds to generate a point cloud map which is the multi-frame point cloud dense map for eliminating the dynamic obstacle artifacts. The method greatly reduces the calculation amount while ensuring the precision, saves the calculation time, and achieves the purpose of quickly generating the dense point cloud map for eliminating the dynamic obstacle artifacts.

Owner:YANSHAN UNIV

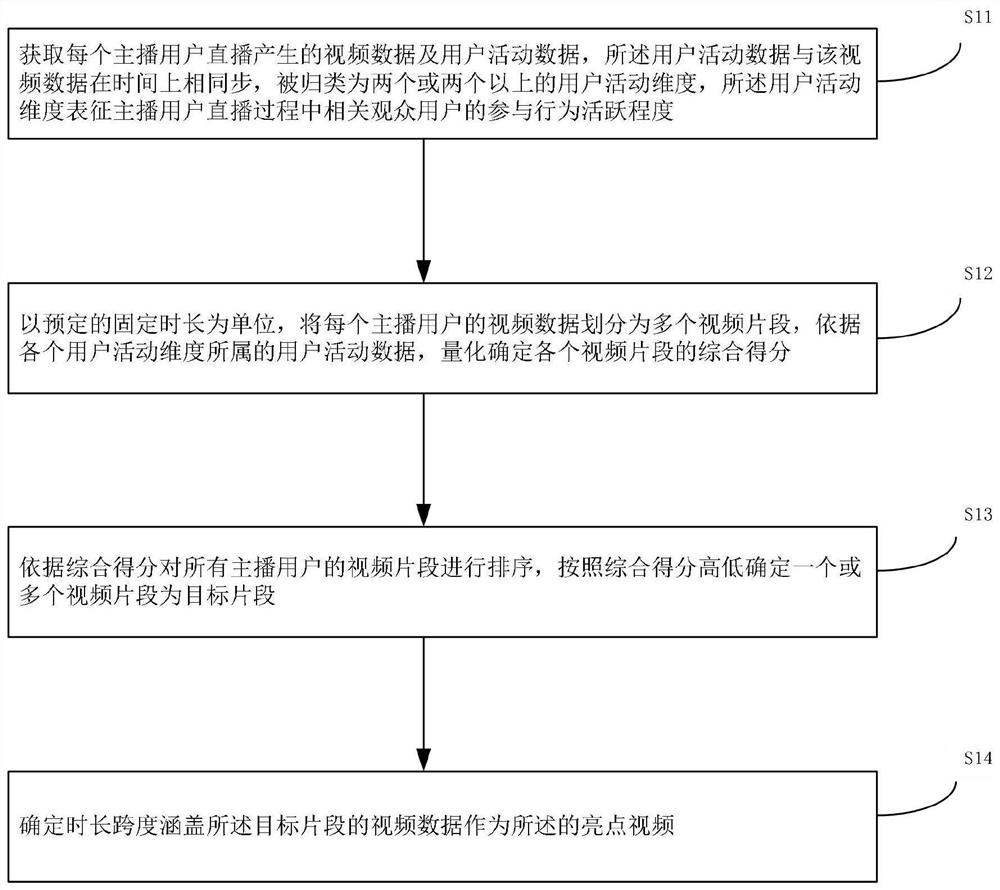

Live broadcast bright spot video editing method, device and equipment, and storage medium

ActiveCN111698575AImplement quality assessmentAccurate and effective determinationSelective content distributionEngineeringVideo editing

The invention discloses a live broadcast bright spot video editing method, device and equipment and a storage medium. The method comprises the steps of: obtaining video data and user activity data ofeach anchor user, wherein the user activity data and the video data are synchronous in time, and the user activity data comprises a plurality of user activity dimensions which represent participationbehavior activity degrees of related audience users in the live broadcast process of the anchor users; dividing the video data of each anchor user into a plurality of video clips by taking a preset fixed duration as a unit, and quantitatively determining a comprehensive score of each video clip according to the user activity data to which each user activity dimension belongs; sorting the video clips according to the comprehensive scores, and determining one or more video clips as target clips according to the comprehensive scores; and determining the video data of which the duration span covers the target segment as the bright spot video. According to the embodiment of the invention, related bright spot videos can be identified from historical video data generated by network live broadcastmore accurately and efficiently.

Owner:广州方硅信息技术有限公司

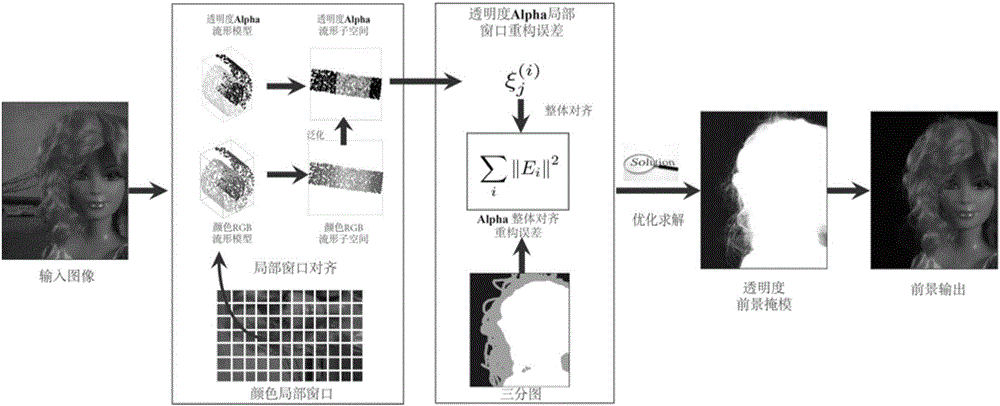

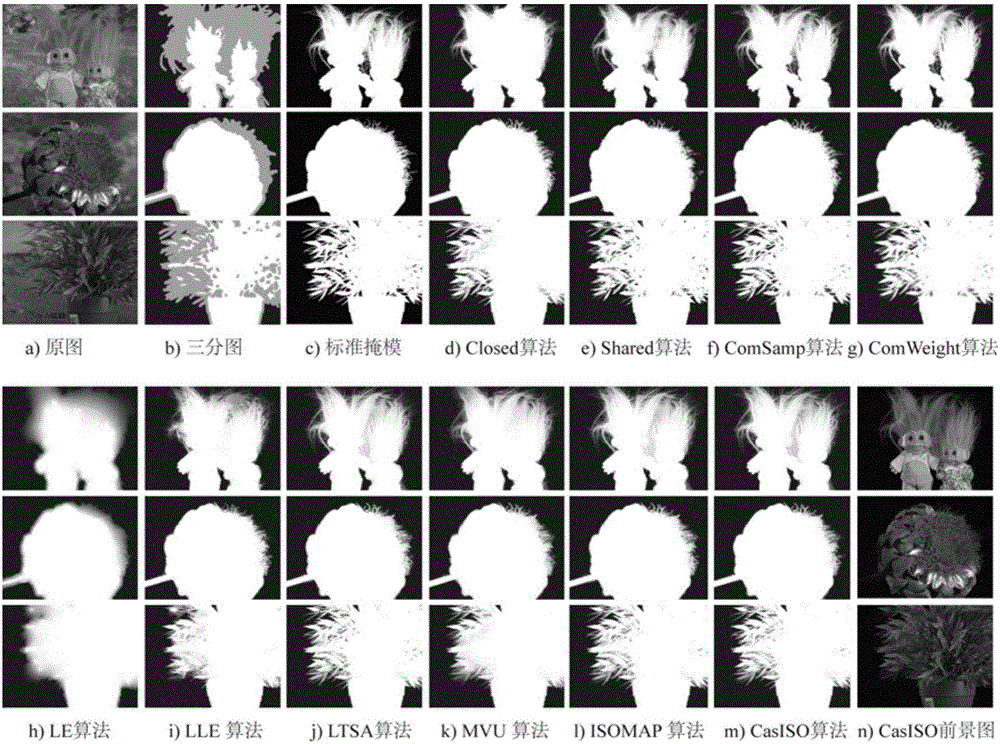

Manifold-learning-based sectional drawing method

InactiveCN106815844ASolve the problem of local data redundancyWith precisionImage enhancementImage analysisLearning basedComputer vision

The present invention relates to the field of computer vision and image processing, and more particularly to a manifold-learning-based sectional drawing method. According to the manifold-learning-based idea, a relationship between image color subspace and alpha subspace is dug deeply, so that a local data redundancy problem of sectional drawing can be solved. On the basis of qualitative and quantitative experiment comparison, the manifold-learning-based sectional drawing method has characteristics of high precision and universal adaptability and thus has the great practical application value.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Method of improving interface bonding performance of carbon fiber enhanced epoxy resin-based composite material based on curing agent modified sizing agent

The invention relates to a method of improving interface bonding performance of a carbon fiber enhanced epoxy resin-based composite material based on a curing agent modified sizing agent. The method comprises the following steps: mixing a curing agent, epoxy resin and an organic solvent uniformly to obtain the sizing agent; removing agents of carbon fibers; passing the carbon fibers to a slurry groove filled with the sizing agent by adopting an impregnating method and drying the carbon fibers; carrying out temperature treatment on the sized carbon fibers; and then compounding the carbon fiberswith an epoxy resin matrix to prepare the carbon fiber enhanced epoxy resin-based composite material. Under the premise of not losing the mechanical property of the carbon fibers, an interface area,the crosslinking density of which is changed gradiently is formed between the fibers and the resin, the interaction degree between the sizing agent and the active groups on the surfaces of the fibersis increased, the inner stress is uniformly transferred in the composite material, and the interface bonding performance of the composite material is improved. The method has the advantages of being simple and feasible, good in repeatability, low in cost, high in efficiency, suitable for industrial production and the like.

Owner:SHAANXI UNIV OF SCI & TECH

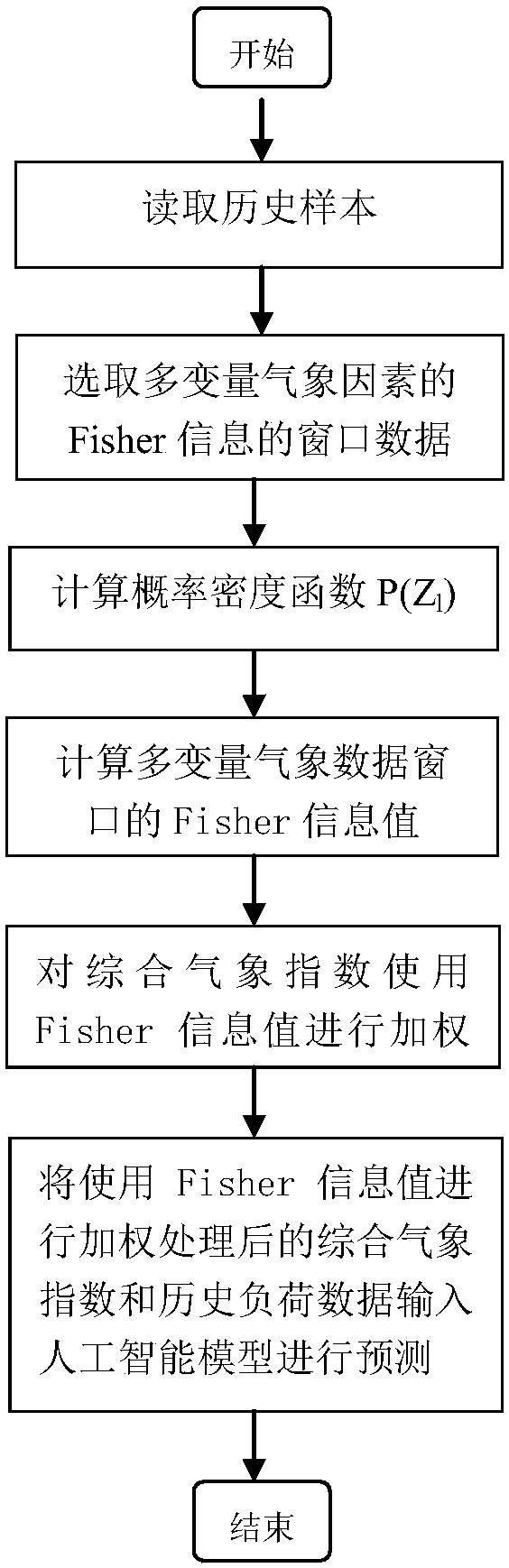

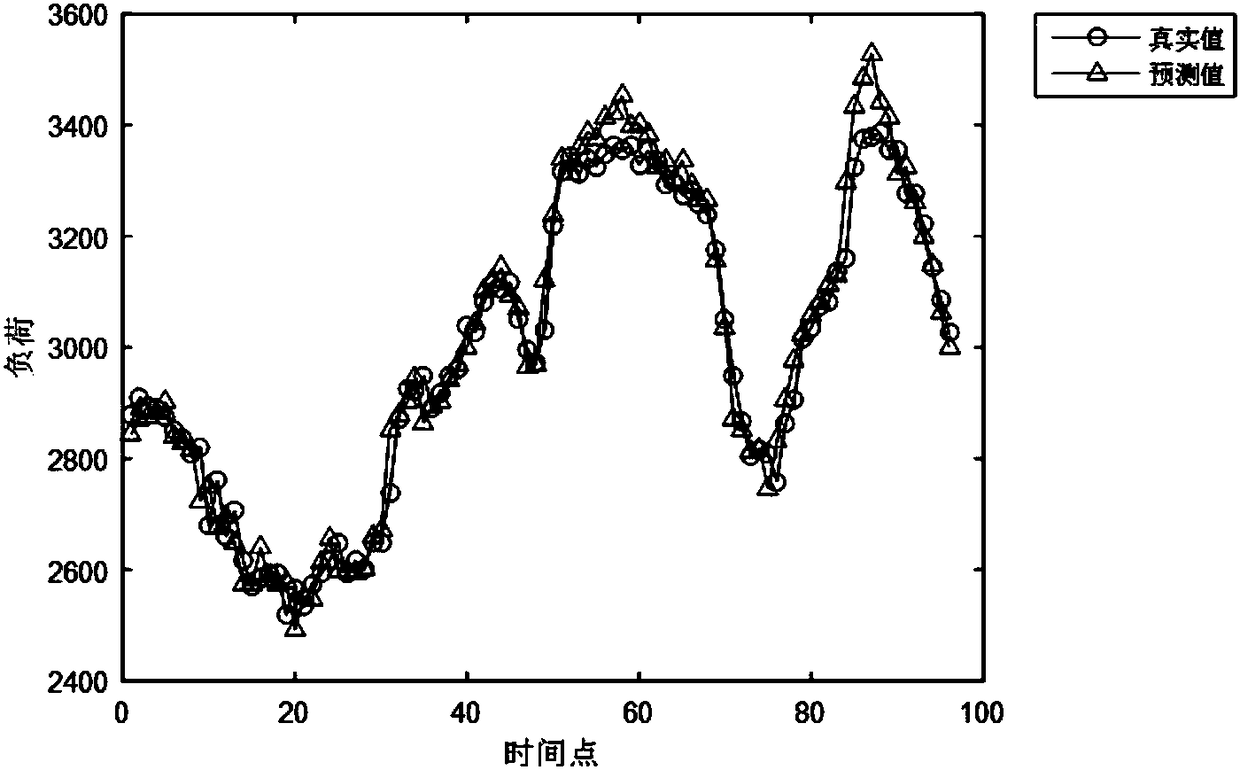

Short-term load processing method based on multidimensional meteorological factors of Fisher information processing

InactiveCN108171380ARealize the coupling effectAchieving a cumulative effectForecastingInformation processingShort terms

The invention relates to a short-term load processing method based on multidimensional meteorological factors of Fisher information processing, comprising the following steps: analyzing historical sample data to obtain multidimensional meteorological factor Fisher information window data of a corresponding load; calculating the Fisher information value of the multidimensional meteorological factorFisher information window data on the basis; weighting the Fisher information value to obtain input variables of Fisher information weighting; and inputting the input variables and historical load data to an artificial intelligence prediction model. The comprehensive index is weighted through calculation of multidimensional meteorological factor Fisher information, so as to realize the coupling effect and cumulative effect of multiple meteorological factors on a load and realize accurate prediction of a weather-sensitive load.

Owner:JIANGSU UNIV

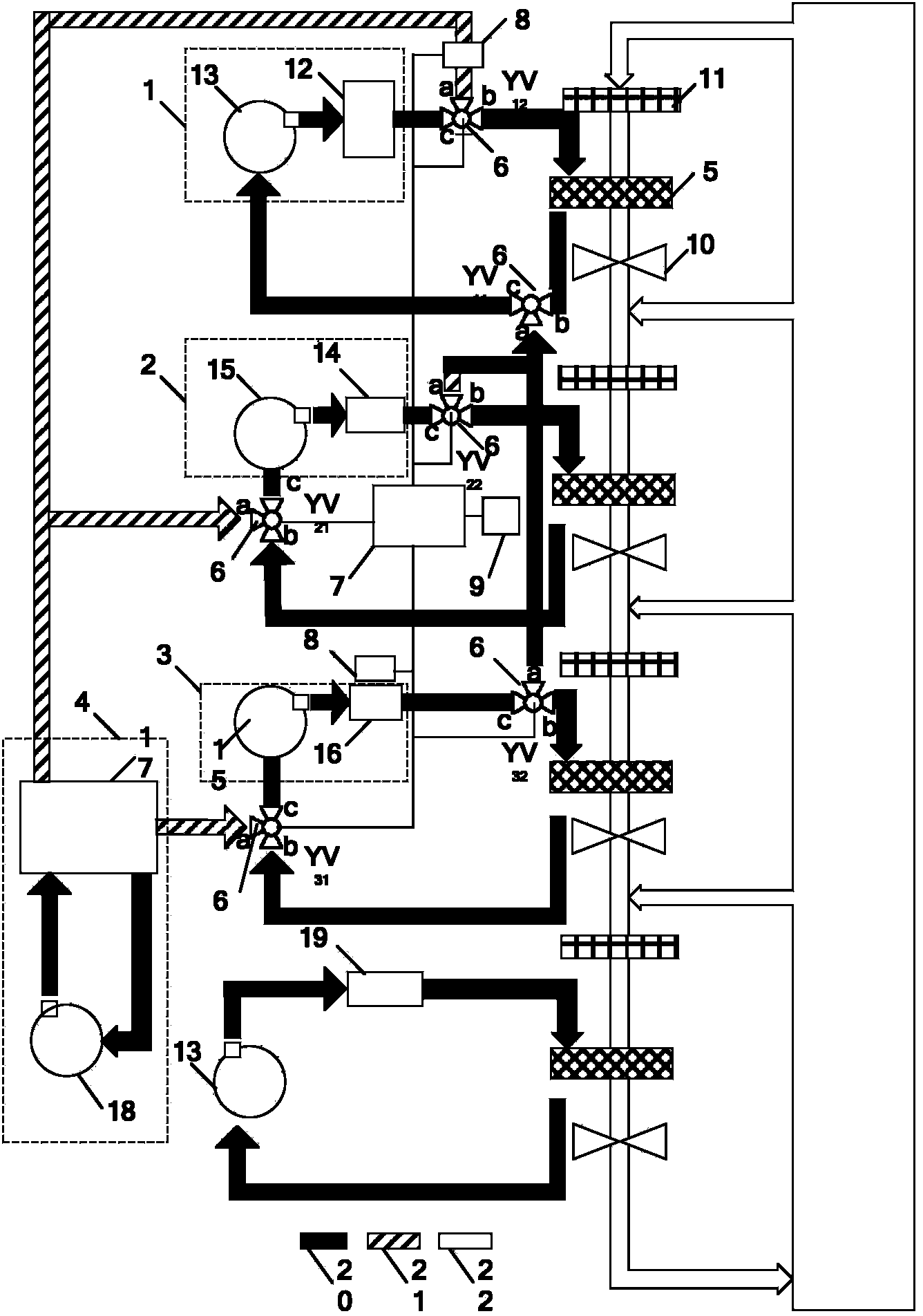

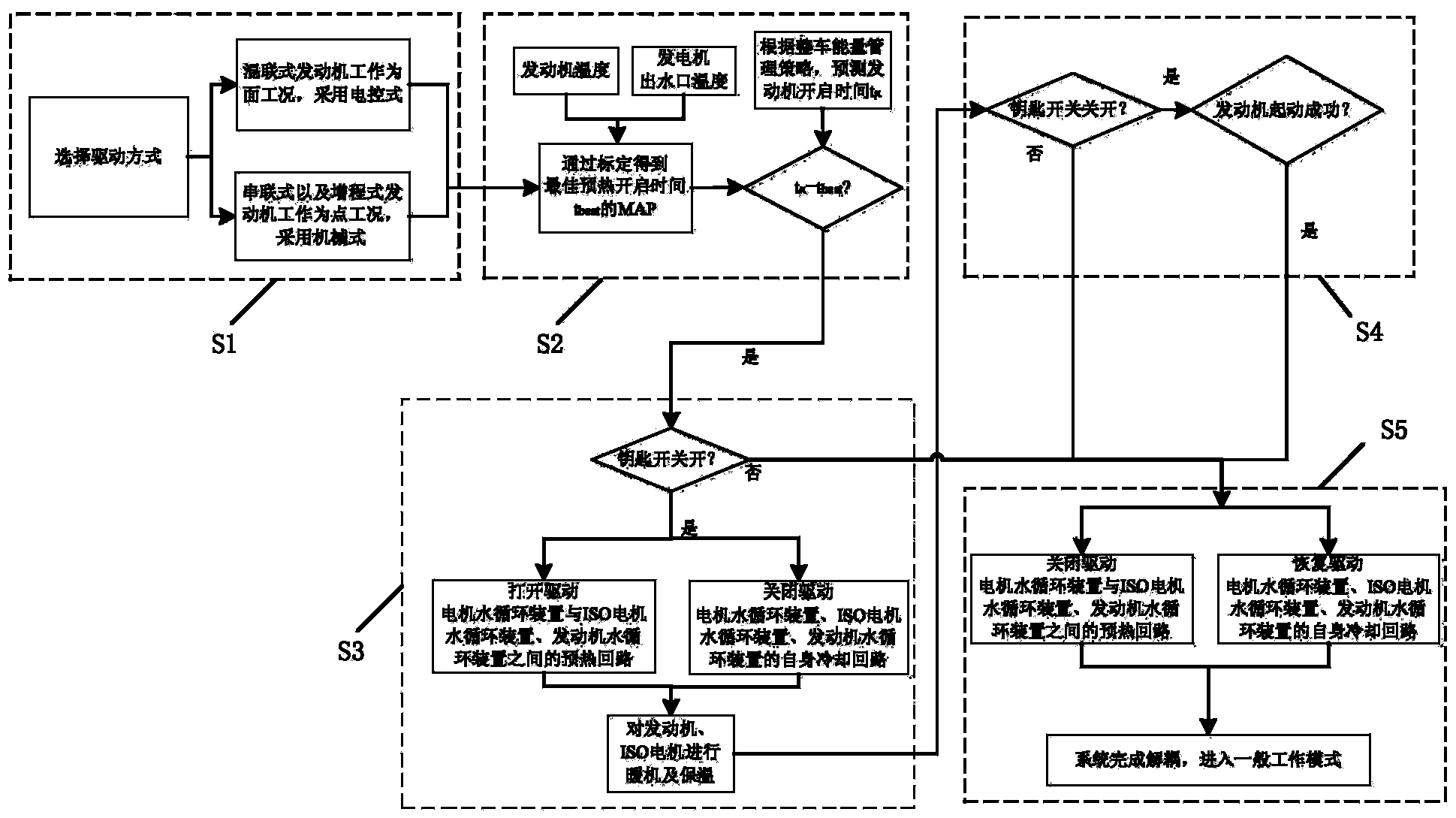

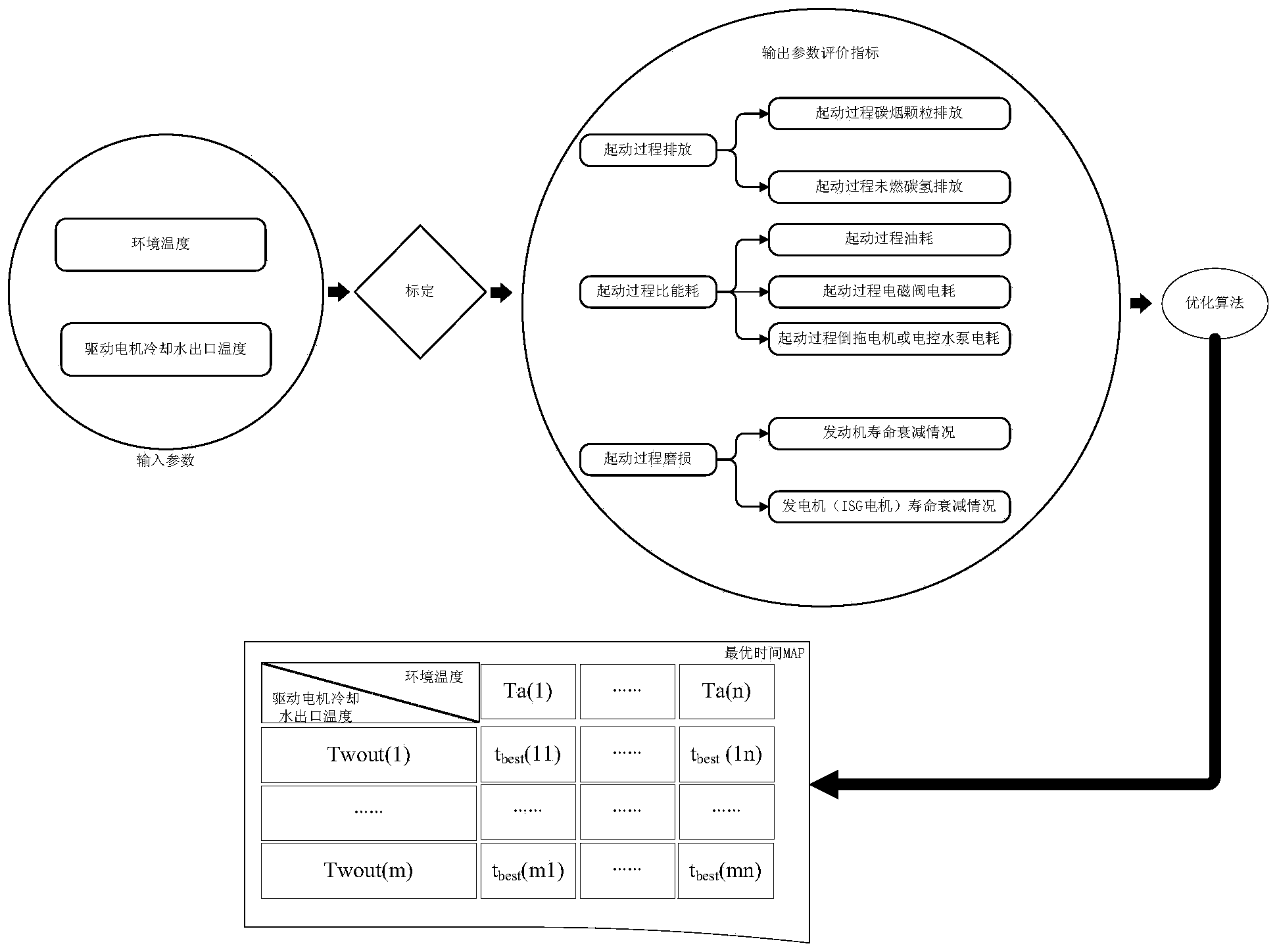

Pre-heating system and method for cold start of hybrid power vehicle

ActiveCN104110341AUniversally adaptableSimple structureMachines/enginesEngine startersWater circulationDrive motor

The invention relates to a pre-heating system and method for cold start of a hybrid power vehicle. The pre-heating system comprises a driving motor water circulation device, an ISG motor water circulation device, an engine water circulation device, an engine sump water circulation device and a radiator, wherein water inlets and water outlets of the driving motor water circulation device, the ISG motor water circulation device and the engine water circulation device are connected with the two ends of the radiator respectively. The pre-heating system further comprises six electric control three-way valves, an electric control unit, a key switch and two temperature sensors. The method for implementing the pre-heating system comprises the steps that the electric control unit controls coupling and decoupling of a cooling circuit, and cold water of a driving motor is utilized to heat an engine and an ISG motor. Compared with the prior art, the pre-heating system and method for cold start of the hybrid power vehicle have the advantages of being low in cost, simple in structure, capable of improving cold start performance and reducing emission of the engine of the hybrid power vehicle, and the like.

Owner:TONGJI UNIV

Multi-projecting apparatus image splicing automatic edge blending method based on fuzzy control

InactiveCN101866096BUniversally adaptableGood effectImage enhancementProjectorsMachine visionFuzzy control system

The invention discloses a multi-projecting apparatus image splicing automatic edge blending method based on fuzzy control, which comprises the following steps: step 1: setting the position, number and blending zone parameter of a control point, and carrying out blending zone primary adjustment; step 2, calculating blending zone brightness difference based on machine vision to obtain a blending zone brightness variation curve; and step 3, realizing automatic adjustment of blending zone based on the fuzzy control. The invention adopts a sectional spline function, timely generates the blending curve by the mode of online fitting, has universal adaptability, and can obtain good effect even if the projecting apparatus has bigger difference. The method is easy and convenient to implement, greatly simplifies the complexity of adjustment of the edge blending, and realizes the automatic adjustment of the multi-projecting apparatus image splicing automatic edge blending on the basis of the machine visual feedback and an artificial intelligence algorithm.

Owner:BEIHANG UNIV

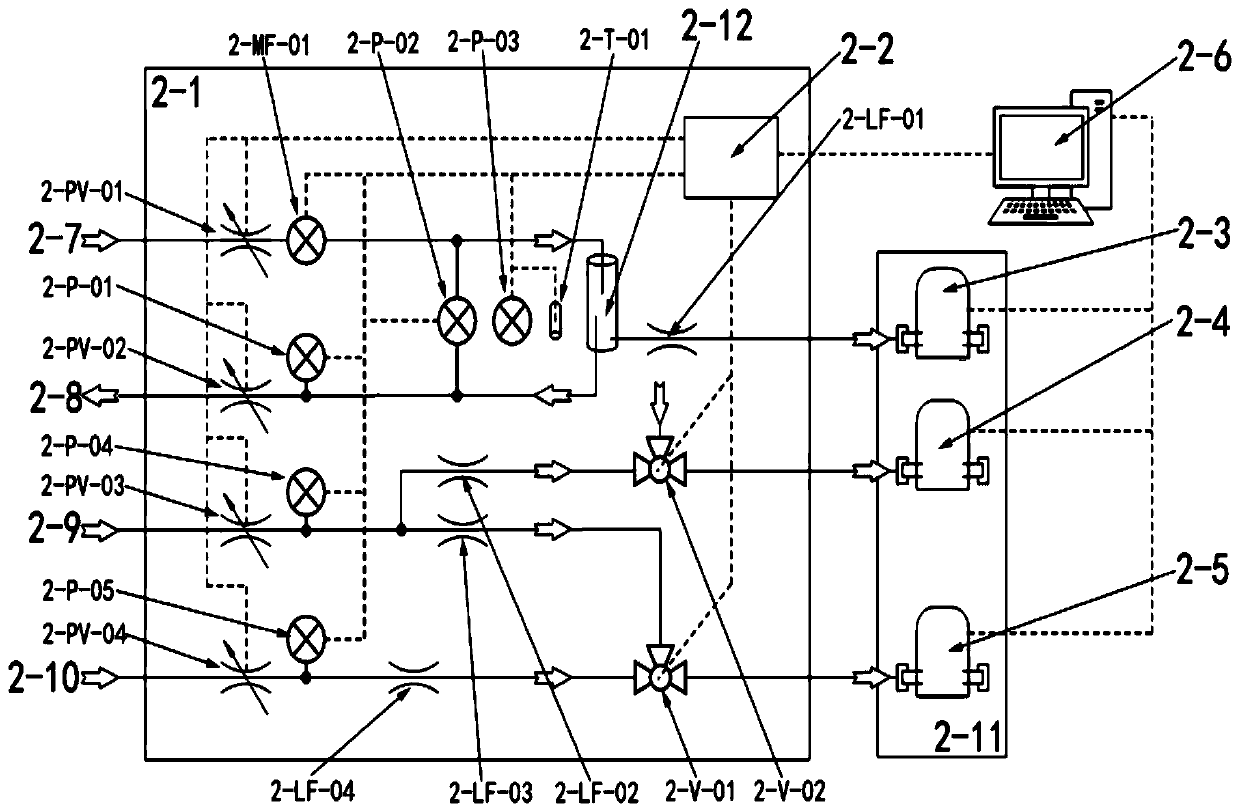

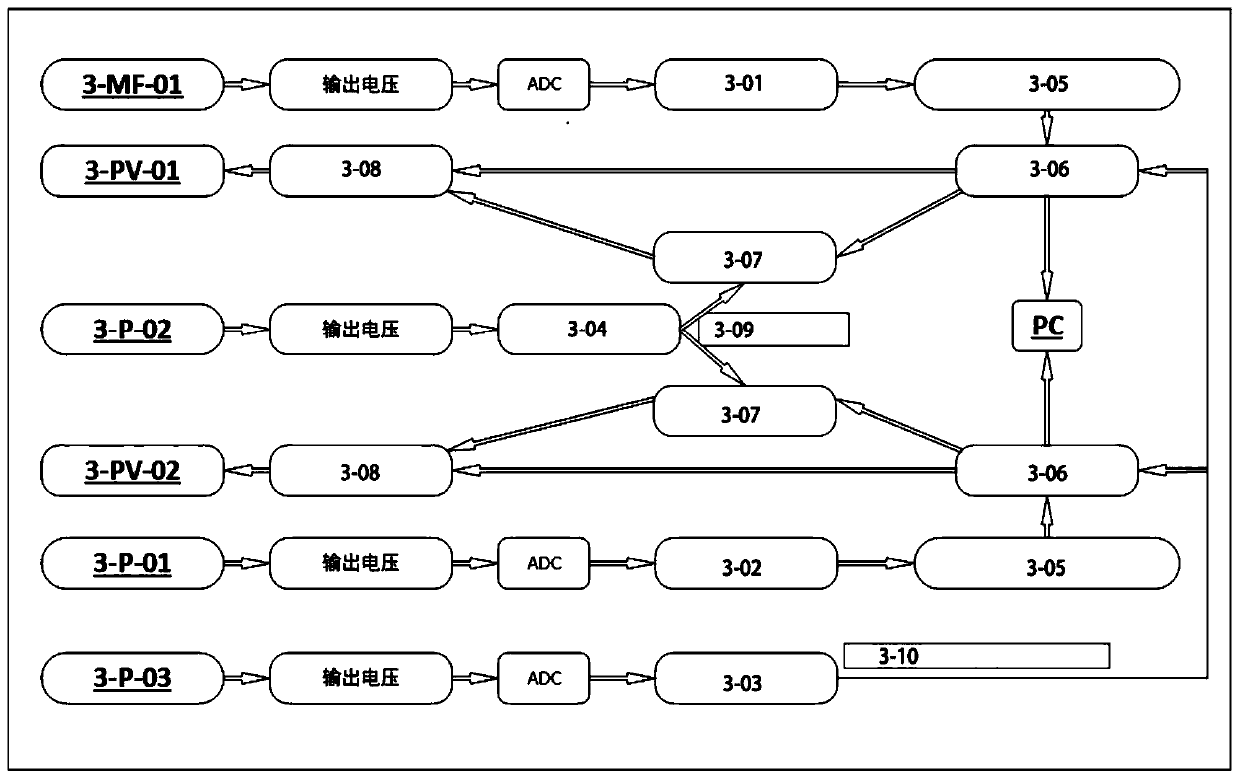

Multi-channel micro-flow control system

The invention discloses a multi-channel micro-flow control system and a calibration system thereof. The multi-channel micro-flow control system is applied to gas flow control and gas chromatography flow control and calibration. The multi-channel micro-flow control system comprises a flow control valve block and a data acquisition and analysis circuit; when multiple paths of different gases are used at the same time, different flows and different precisions of each path of gas are independently or uniformly controlled. An artificial intelligence algorithm is adopted in a calibration process, ahigh-dimensional calibration curve model and peripheral equipment suitable for the artificial intelligence algorithm are generated, and the problems of reference point pressure compensation and temperature compensation and valve switching-induced influences of internal pressure fluctuation on flow, influences of external environment changes on system internal flow and the like are solved at a time; high precision and low cost are achieved.

Owner:北京高斯匹克技术有限公司

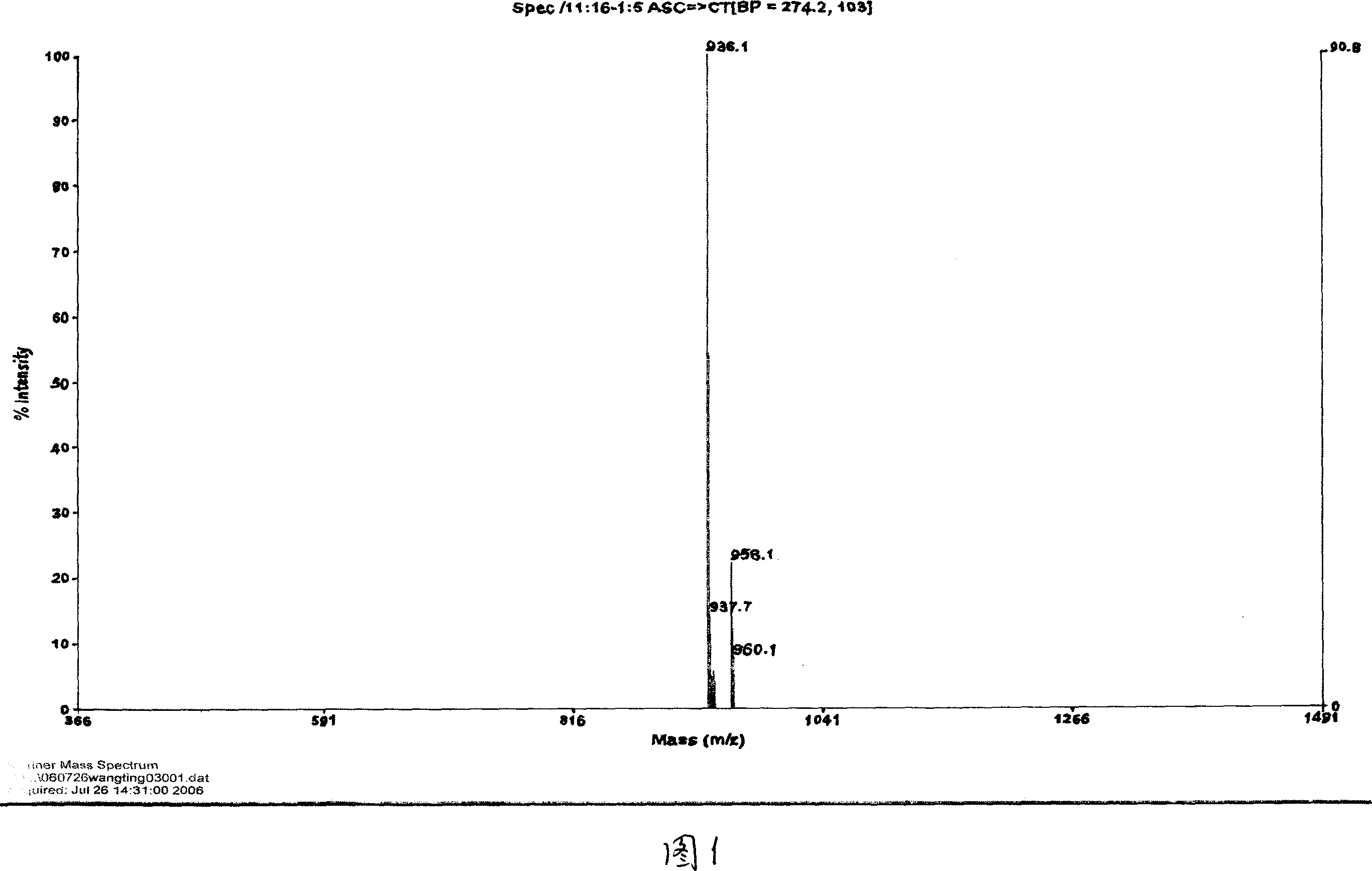

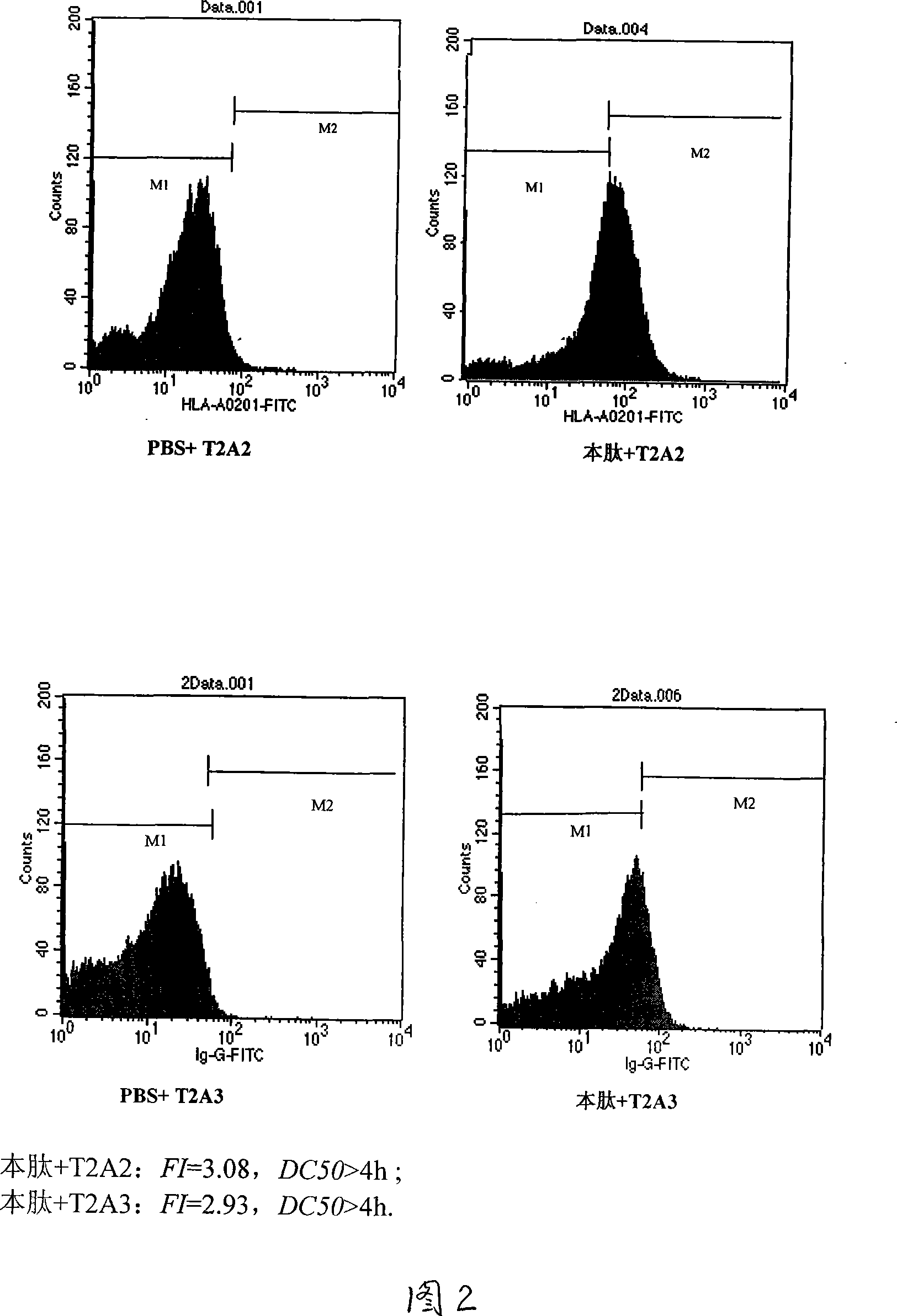

Antitumor CTL epitope peptide possessing population broad spectrum property

The present invention discloses one kind of antitumor CTL epitope peptide comprising nine natural amino acid residues in the sequence of Ala-Leu-Tyr-Gly-Asp-Ile-Asp-Ala-Val (ALYGDIDAV). The antitumor CTL epitope peptide has COX-2 as the target antigen, and amino acid sequence quoted from GENEBANK. The present invention has the advantages of no limitation of MHC polymorphism and capacity of being submitted simultaneously by HLA-A2 and HLA-A3, effectiveness on epithelium tumors, and effectiveness on other tumor expressing COX-2.

Owner:ZHENGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com