Method of improving interface bonding performance of carbon fiber enhanced epoxy resin-based composite material based on curing agent modified sizing agent

A technology of epoxy resin and composite materials, applied in the direction of carbon fiber, fiber processing, textiles and papermaking, etc., can solve the problems of unsuitable industrial production, complex technological process, toxic human body and environment, etc., and achieve good economic benefits and industrial Application prospect, universal adaptability, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

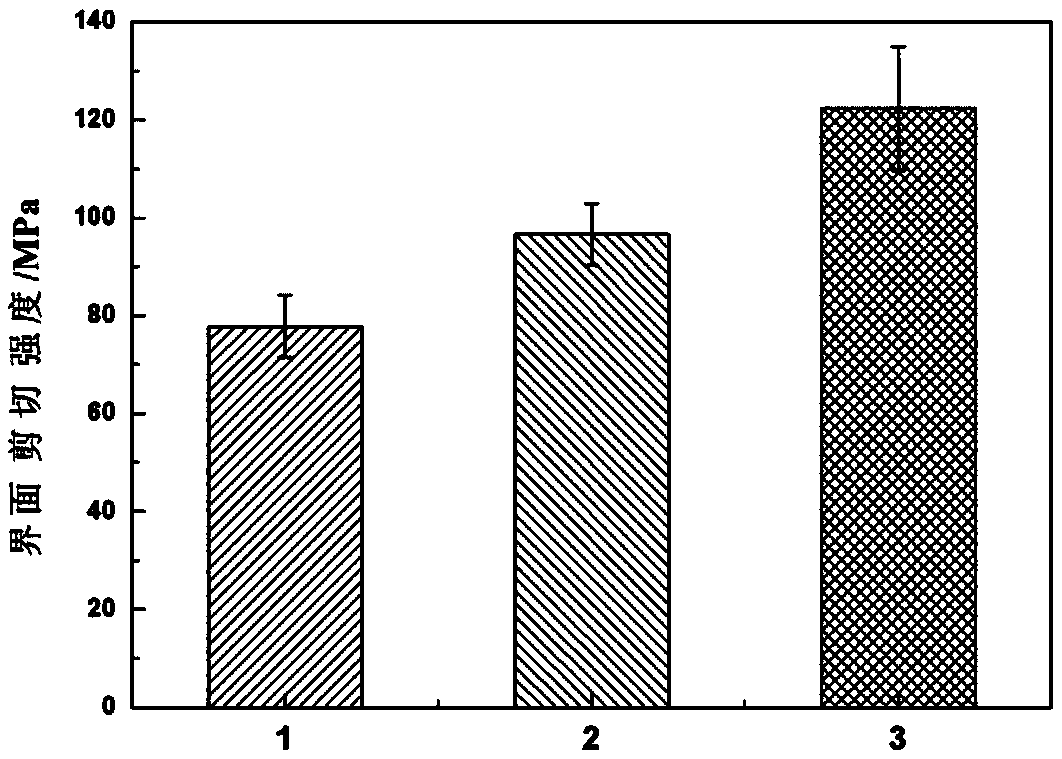

Embodiment 1

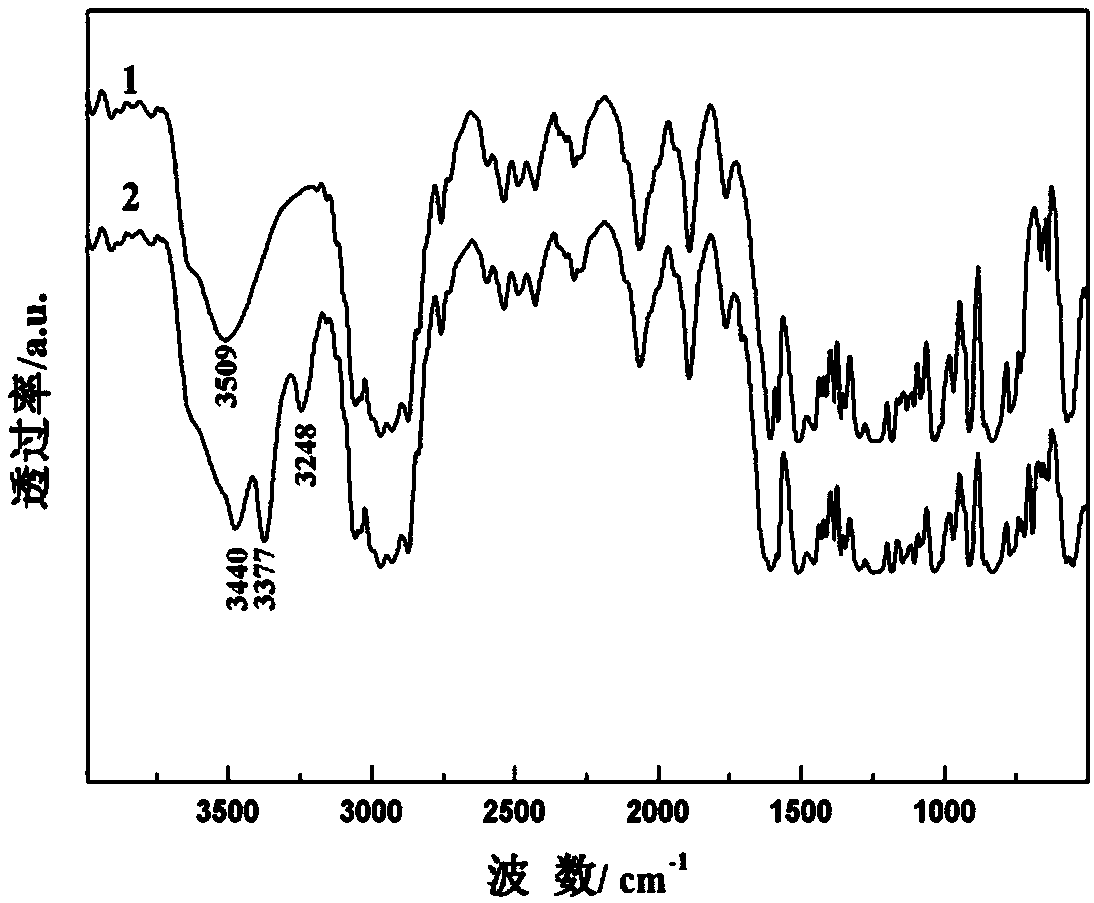

[0043] 1) Preparation of curing agent modified sizing agent

[0044] Get 1% thermosetting epoxy resin and 99% organic solvent acetone magnetically stirred by mass percentage for 10min to obtain epoxy sizing agent solution;

[0045] Then add an amine curing agent to the epoxy sizing agent solution by 15% of the stoichiometric ratio of the epoxy resin and stir magnetically for 20 minutes to obtain a sizing agent solution modified by the curing agent;

[0046] 2) Carbon fiber surface remover

[0047] Using acetone as a solvent, the carbon fiber was condensed and refluxed at 80°C for 24h by Soxhlet extraction, and then dried at 60°C for 3h;

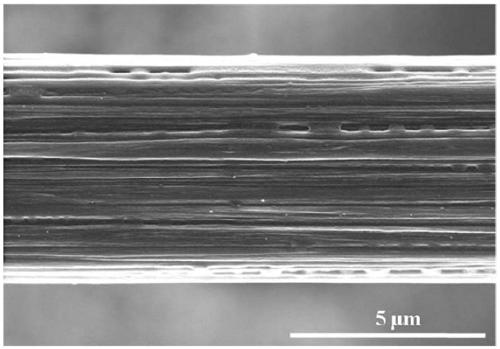

[0048] 3) carbon fiber surface sizing treatment

[0049] Using the impregnation method, step 2) the carbon fiber after the agent is removed is immersed in a slurry tank equipped with a sizing agent solution for 20 seconds, and then dried at 60 ° C for 3 hours, that is, the surface sizing treatment of the carbon fiber used in the carbon fibe...

Embodiment 2

[0057] 1) Preparation of curing agent modified sizing agent

[0058] Get 1% thermosetting epoxy resin and 99% organic solvent acetone magnetically stirred by mass percentage for 10min to obtain epoxy sizing agent solution;

[0059] Then add an amine curing agent to the epoxy sizing agent solution by 15% of the stoichiometric ratio of the epoxy resin and stir magnetically for 20 minutes to obtain a sizing agent solution modified by the curing agent;

[0060] 2) Carbon fiber surface remover

[0061] Using acetone as a solvent, the carbon fiber was condensed and refluxed at 80°C for 24h by Soxhlet extraction, and then dried at 60°C for 3h;

[0062] 3) carbon fiber surface sizing treatment

[0063] Using the impregnation method, step 2) the carbon fiber after the agent is removed is immersed in a slurry tank equipped with a sizing agent solution for 20 seconds, and then dried at 60 ° C for 3 hours, that is, the surface sizing treatment of the carbon fiber used in the carbon fibe...

Embodiment 3

[0070] 1) Preparation of curing agent modified sizing agent

[0071] Get 0.5% thermosetting epoxy resin and 99.5% organic solvent tetrahydrofuran by mass percentage and mechanically stir for 8 minutes to obtain epoxy sizing agent solution;

[0072] Then add an acid anhydride curing agent to the epoxy sizing agent solution by 30% of the stoichiometric ratio of the epoxy resin and mechanically stir for 10 minutes to obtain a sizing agent solution modified by the curing agent;

[0073] 2) Carbon fiber surface remover

[0074] Using acetone as solvent, the carbon fiber was condensed and refluxed at 70°C for 48h by Soxhlet extraction, and then dried at 80°C for 2h;

[0075] 3) carbon fiber surface sizing treatment

[0076] Using the impregnation method to dip the carbon fiber after step 2) in a slurry tank equipped with a sizing agent solution for 30 seconds and then dry it at 70° C. for 3 hours to complete the surface sizing treatment of the carbon fiber used in the carbon fiber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com