Ultrasonic surface modification treatment method for aramid fibers

An aramid fiber, surface modification technology, applied in fiber treatment, ultrasonic/sonic fiber treatment, fiber type, etc., can solve the problem that the surface state of aramid fiber cannot be improved, the bonding strength of resin and fiber cannot be enhanced, and ultrasonic treatment medium corrosion It can easily solve the problems of strong resistance and other problems, so as to achieve the effect of easy on-line continuous processing, shortening the modification time and improving the hand feeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

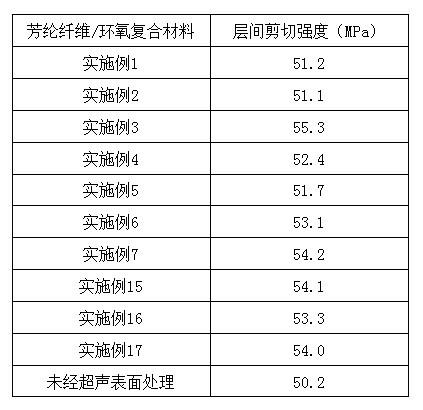

Examples

Embodiment 1

[0024] A method for ultrasonic surface modification treatment of aramid fiber, comprising ultrasonic treatment, cleaning and drying of aramid fiber tow to obtain modified aramid fiber (modification refers to improving surface roughness and interlayer shear strength ), characterized in that: in the ultrasonic treatment, the ultrasonic treatment medium used is one or several kinds of amides organic solvents in any proportion.

[0025] By using amide organic solvents as the medium of ultrasonic treatment, other processes adopt conventional techniques, which can significantly improve the performance of aramid fibers, such as interlayer shear strength.

Embodiment 2

[0027] A method for ultrasonic surface modification treatment of aramid fiber, comprising ultrasonic treatment, cleaning and drying of aramid fiber tow to obtain modified aramid fiber (modification refers to improving surface roughness and interlayer shear strength ), characterized in that: in the ultrasonic treatment, the ultrasonic treatment medium used is one or several kinds of amides organic solvents in any proportion.

[0028] Among them, N,N-dimethylformamide (DMF), N,N-dimethylacetamide (DMAC), N,N-dimethylpropionamide, N,N-diethyl One of propionamide, N,N-diethylacetamide, hexamethylphosphoric triamide (HMTA), N-methylpyrrolidone (NMP) or several in any proportion.

Embodiment 3

[0030] A method for ultrasonic surface modification treatment of aramid fiber, comprising ultrasonic treatment, cleaning and drying of aramid fiber tow to obtain modified aramid fiber (modification refers to improving surface roughness and interlayer shear strength ), characterized in that: in the ultrasonic treatment, the ultrasonic treatment medium used is one or several kinds of amides organic solvents in any proportion.

[0031] The ultrasonic treatment of the aramid fiber tow in the present invention is as follows: the aramid fiber tow is passed through the godet roller on-line and continuously through the ultrasonic cleaning tank filled with ultrasonic treatment medium, and the ultrasonic treatment is carried out, and the liquid surface is completely immersed in the aramid fiber. fiber tow.

[0032] The method of cleaning the aramid fiber tow in the present invention is as follows: the aramid fiber tow passing through the ultrasonic cleaning tank is continuously passed t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com